Minimising Defect Formation in Sand Casting of Sheet Lead: A DoE Approach

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

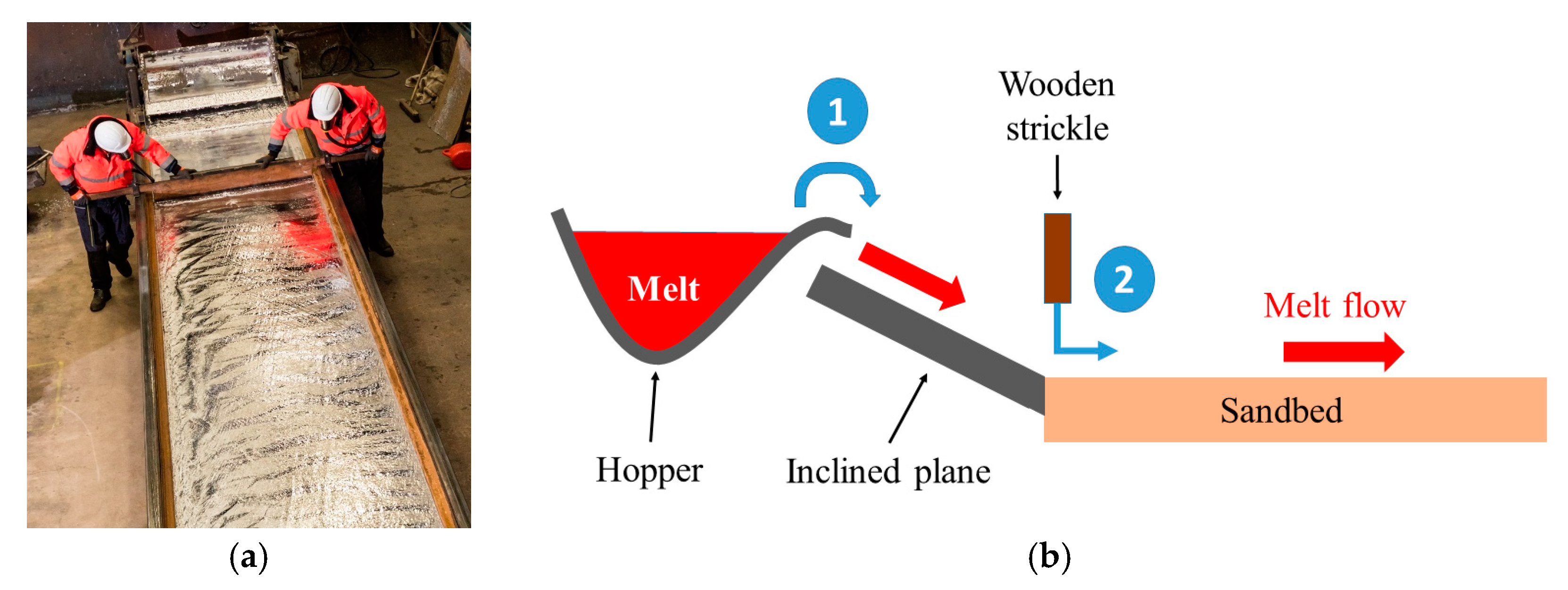

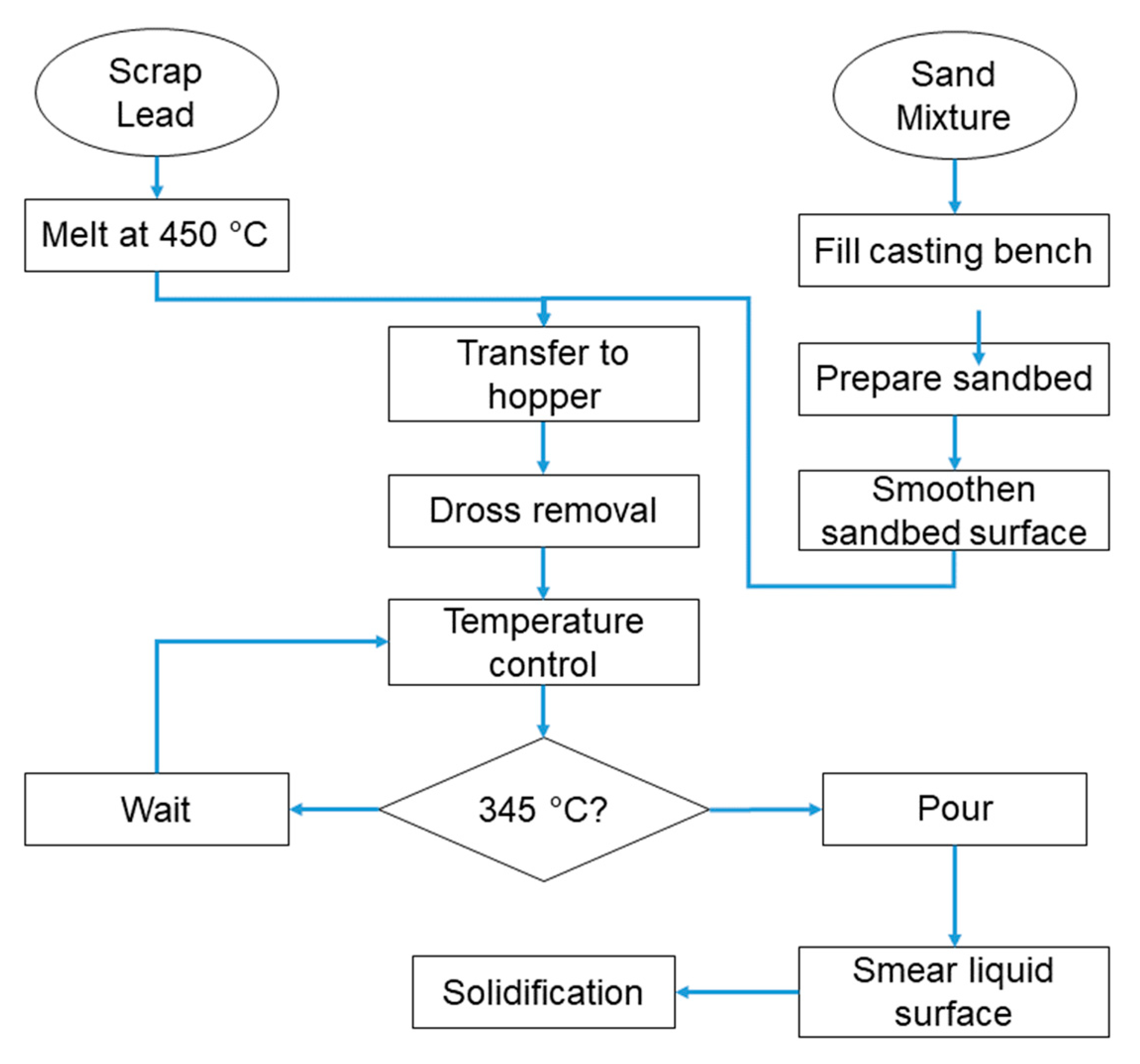

2.2. Process

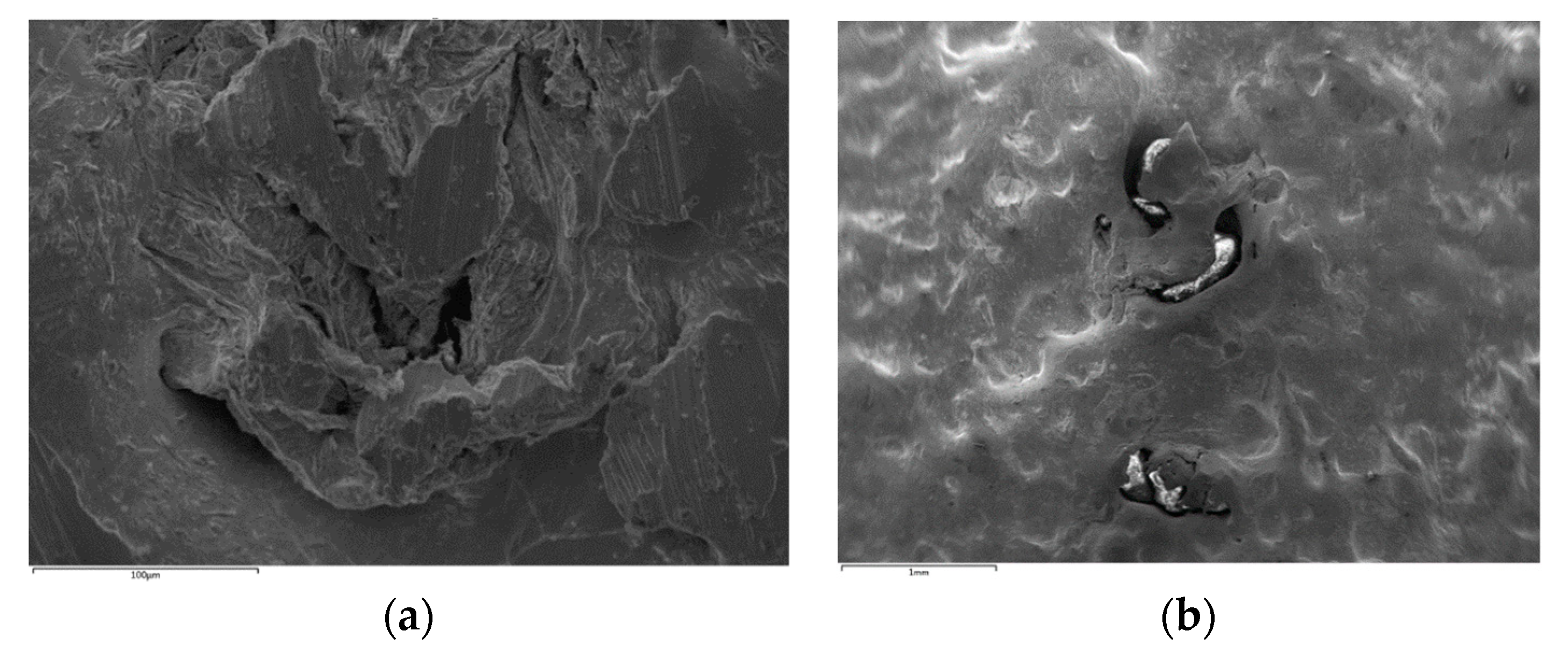

2.3. Defect Analysis

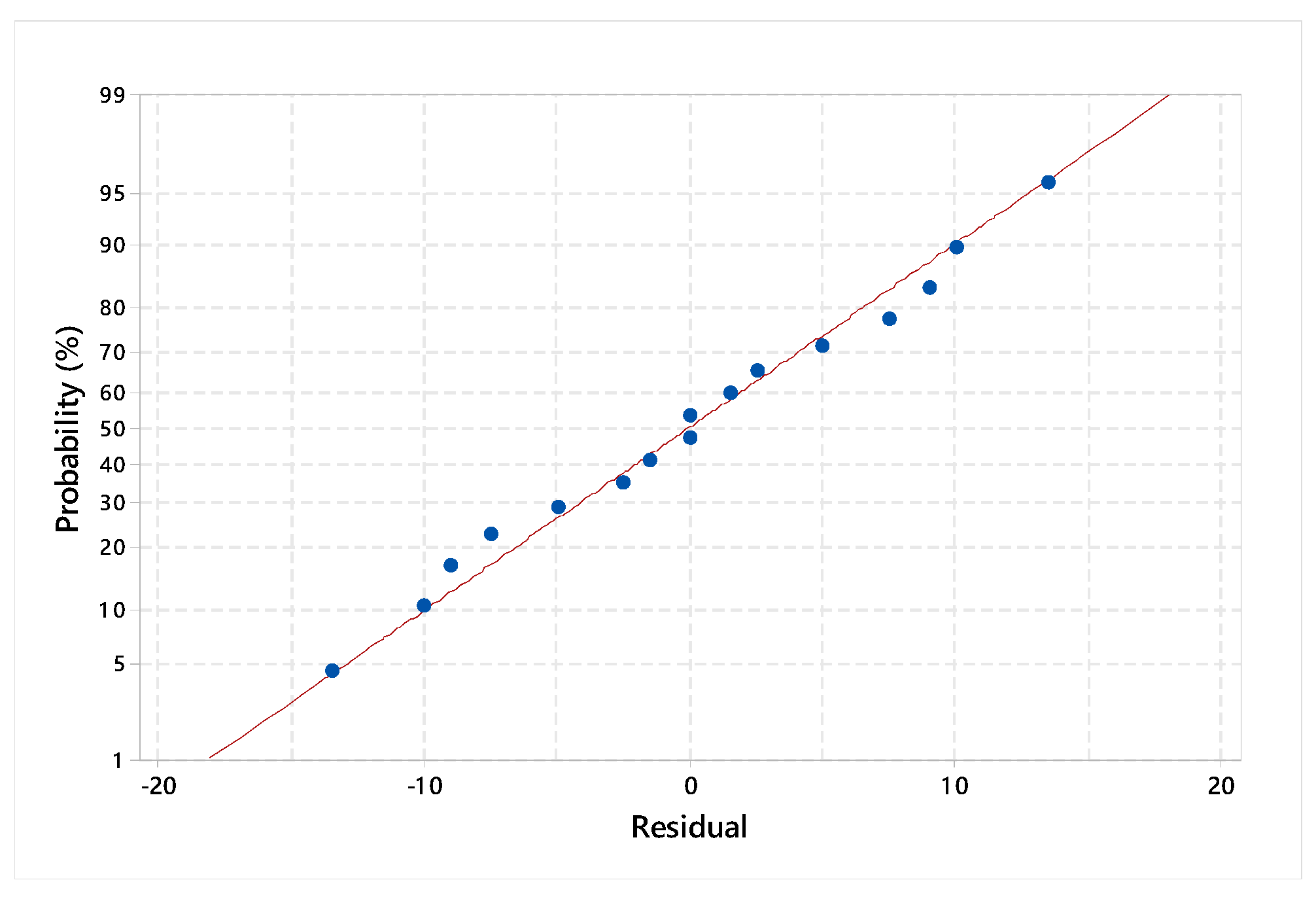

2.4. Design of Experiments

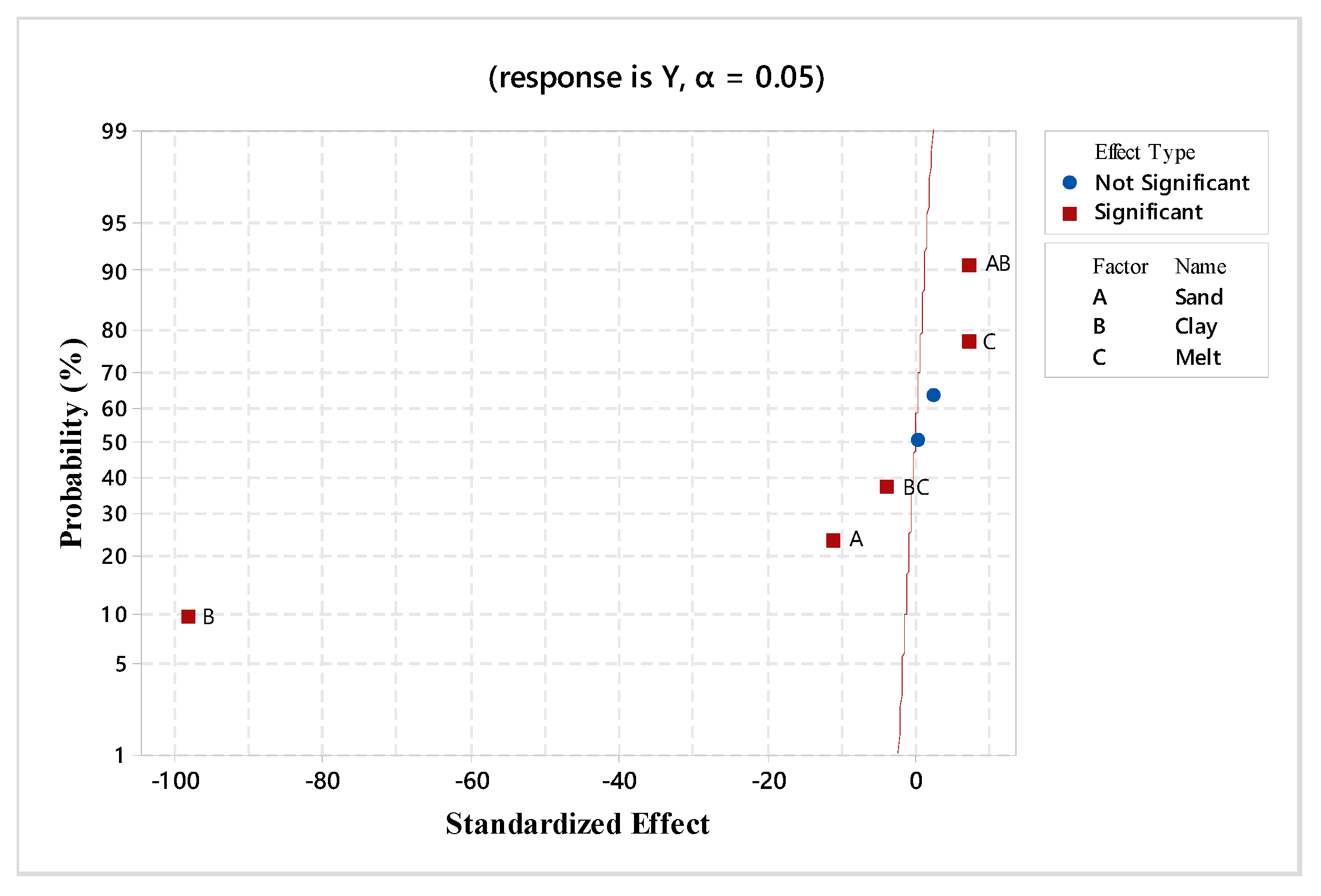

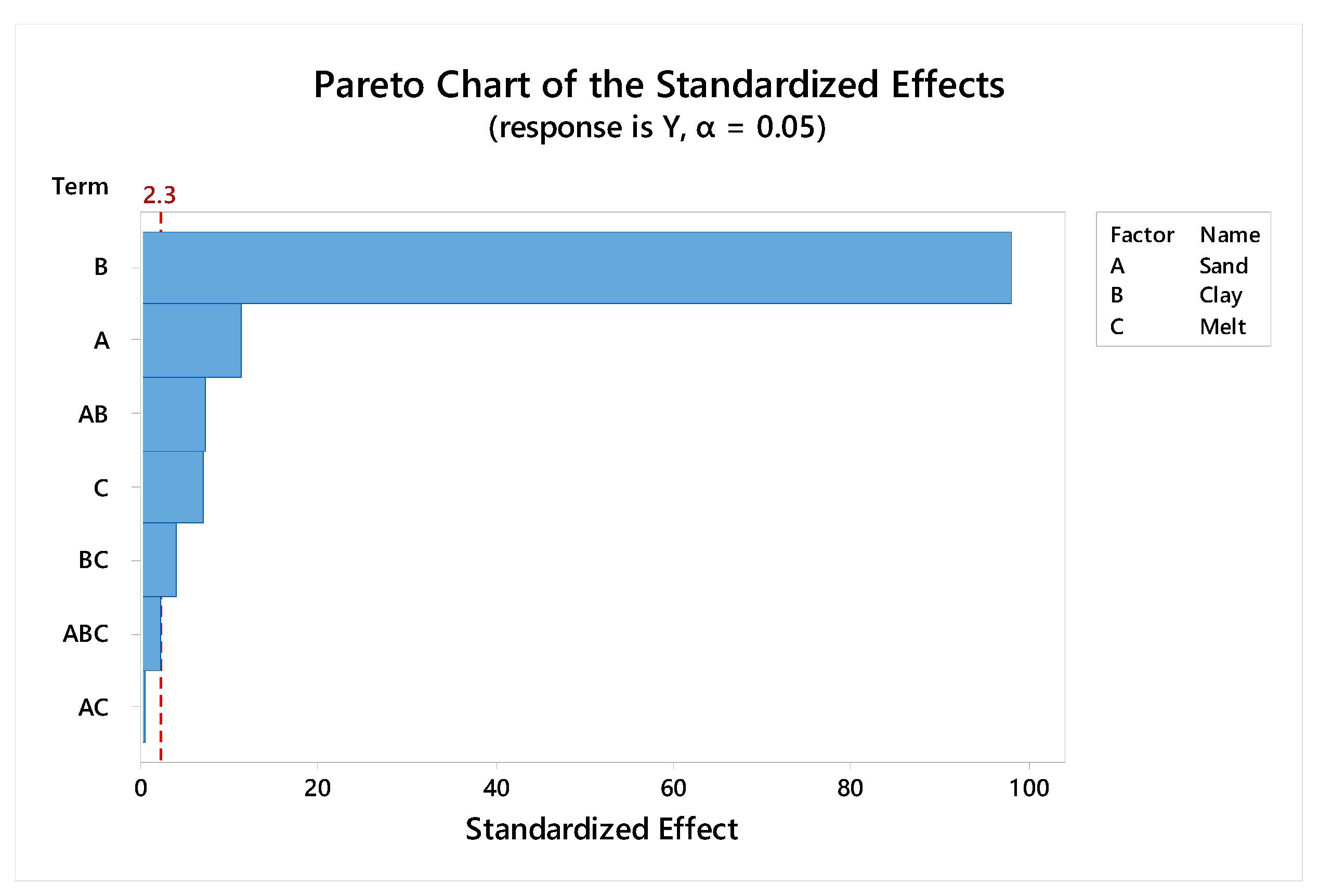

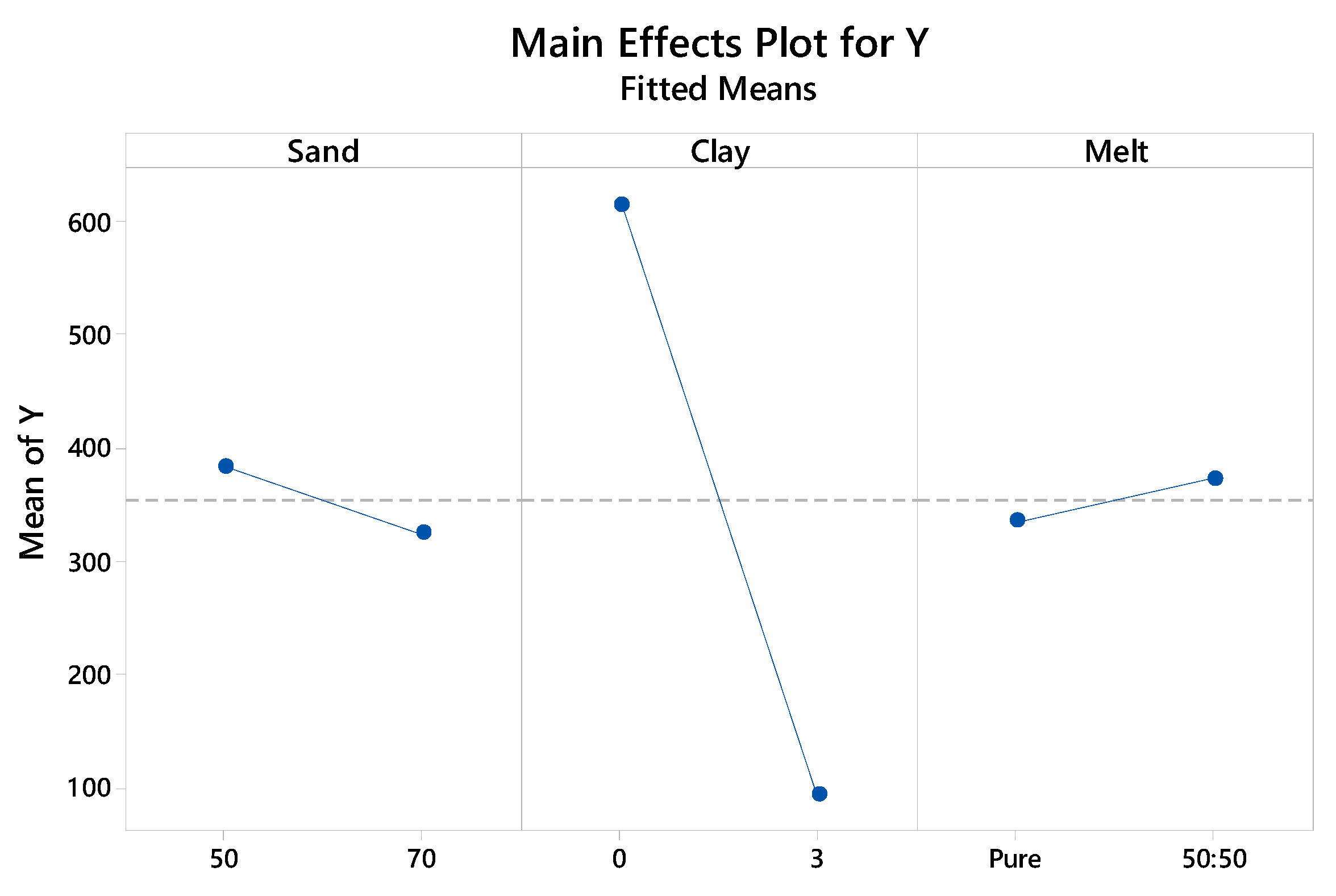

3. Results and Discussion

4. Conclusions

- (1)

- The majority of the defects produced in lead sheet casting industry can be attributed to mould properties and moulding materials. This paper substantiates the fact that green sand casting provides better surface quality and finish as compared to traditional sand mixtures used in sand casting of lead sheet.

- (2)

- The trials conducted with the green sand mixture showed an improved surface finish and substantial reduction in the grooves produced on the sand side. Addition of bentonite in the sand mixture results in a substantial reduction of groove defects in sand cast lead sheet.

- (3)

- Grooves are reduced for higher AFS grain fineness numbers. Fine grained sand contributes to superior surface finish due to the decreased lead penetration into the sand.

- (4)

- The quality of the melt also affects the formation of the grooves. Pure lead should be favoured over a mix of refined and scrap lead.

- (5)

- Groove defects in sand cast lead sheet can be minimised by 90% for a combination of 70 AFS sand, 3% bentonite and pure melt.

Author Contributions

Funding

Conflicts of Interest

References

- Hofmann, W. Lead and lead alloys. In Lead and Lead Alloys; Springer: Berlin/Heidelberg, Germany, 1970; pp. 25–320. [Google Scholar]

- Ben-Yosef, E.; Vassal, Y.; Van Den Brink, E.C.M.; Beeri, R. A new Ghassulian metallurgical assemblage from Bet Shemesh (Israel) and the earliest leaded copper in the Levant. J. Archaeol. Sci. Rep. 2016, 9, 493–504. [Google Scholar]

- Rocca, E.; Mirambet, F.; Steinmetz, J. Study of ancient lead materials: A gallo-roman sarcophagus—Contribution of the electrolytic treatment to its restoration. J. Mater. Sci. 2004, 3, 2767–2774. [Google Scholar] [CrossRef]

- Prabhakar, A.; Mielnicka, J.; Jolly, M.; Salonitis, K. Improving energy efficiency in direct method for continuous casting of lead sheets. In Proceedings of the TMS Annual Meeting & Exhibition, Phoenix, AZ, USA, 11–15 March 2018; Springer: Berlin, Germany; pp. 121–132. [Google Scholar]

- Haynes, W. CRC Handbook of Chemistry and Physics; CRC Press: Boca Raton, FL, USA, 2015. [Google Scholar]

- Hubbell, J.H.; Seltzer, S.M. Tables of X-ray Mass Attenuation Coefficients and Mass Energy-Absorption Coefficients 1 keV to 20 MeV for Elements Z= 1 to 92 and 48 Additional Substances of Dosimetric Interest; NISTIR-5632; National Inst. of Standards and Technology-PL: Gaithersburg, MD, USA, May 1995.

- Whillock, S.; Charles, J.A.; Smith, G.C. Microstructures and mechanical properties of milled and continuously cast lead sheet Part 1 Microstructures. Mater. Sci. Technol. 1989, 5, 1074–1083. [Google Scholar] [CrossRef]

- Prabhakar, A.; Salonitis, K.; Jolly, M.; Manufacturing, S.; Centre, S.; Kingdom, U. Characterization of Lead Sheet Manufactured Using Traditional Sand-Casting Technique; Springer: Berlin, Germany, 2019; pp. 283–292. [Google Scholar]

- Campbell, J. Complete Casting Handbook: Metal Casting Processes, Techniques and Design; Butterworth-Heinemann: Oxford, UK, 2015; ISBN 978-0-444-63509-9. [Google Scholar]

- Campbell, J. An overview of the effects of bifilms on the structure and properties of cast alloys. Metall. Mater. Trans. B Process. Metall. Mater. Process. Sci. 2006, 37, 857–863. [Google Scholar] [CrossRef]

- Tian, C.; Law, J.; Van der Touw, J.; Murray, M.; Yao, J.Y.; Graham, D.; John, D. Effect of melt cleanliness on the formation of porosity defects in automotive aluminium high pressure die castings. J. Mater. Process. Technol. 2002, 122, 82–93. [Google Scholar] [CrossRef]

- Saikaew, C.; Wiengwiset, S. Optimization of molding sand composition for quality improvement of iron castings. Appl. Clay Sci. 2012, 67–68, 26–31. [Google Scholar] [CrossRef]

- Mane, V.V.; Sata, A.; Khire, M.Y. New Approach to Casting Defects Classification and Analysis Supported by Simulation. In Proceedings of the 59th Indian Foundry Congress, Chandigarh, India, 11–13 February 2010; pp. 87–104. [Google Scholar]

- Dabade, U.A.; Bhedasgaonkar, R.C. Casting defect analysis using design of experiments (DoE) and computer aided casting simulation technique. Procedia CIRP 2013, 7, 616–621. [Google Scholar] [CrossRef] [Green Version]

- Guharaja, S.; Noorul Haq, A.; Karuppannan, K.M. Optimization of green sand casting process parameters by using Taguchi’s method. Int. J. Adv. Manuf. Technol. 2006, 30, 1040–1048. [Google Scholar] [CrossRef]

- Kumar, S.; Gupta, A.K.; Chandna, P. Optimization of process parameters of pressure die casting using taguchi methodology. Int. J. Mech. Aerosp. Ind. Mechatron. Manuf. Eng. 2012, 6, 1484–1488. [Google Scholar]

- Perzyk, M.; Kochański, A. Detection of causes of casting defects assisted by artificial neural networks. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2003, 217, 1279–1284. [Google Scholar] [CrossRef]

- Chopra, O.; Niessen, P. Solidification of lead and lead alloys in continuous drum sheet casting. Z. Met. Res. Adv. Tech. 1975, 66, 10–16. [Google Scholar]

- Whillock, S.; Charles, J.A.; Smith, G.C. Microstructures and mechanical properties of milled and continuously cast lead sheet. Mater. Sci. Technol. 1991, 7, 1116–1127. [Google Scholar] [CrossRef]

- Prabhakar, A.; Papanikolaou, M.; Salonitis, K.; Jolly, M. Sand casting of sheet lead: Numerical simulation of metal flow and solidification. Int. J. Adv. Manuf. Technol. 2019, 106, 1–13. [Google Scholar] [CrossRef]

- SPECTROMAXx Metal Analyzer|SPECTRO Analytical. Available online: https://www.spectro.com/products/optical-emission-spectroscopy/spectromaxx-metal-analyzer (accessed on 6 February 2020).

- Kumaravadivel, A.; Natarajan, U.; Ilamparithi, C. Determining the optimum green sand casting process parameters using Taguchi’s method. J. Chin. Inst. Ind. Eng. 2012, 29, 148–162. [Google Scholar] [CrossRef]

- Thiel, J.; Ziegler, M.; Dziekonski, P.; Joyce, S. Investigation into the technical limitations of silica sand due to thermal expansion. Trans. Am. Foundry Soc. 2007, 115, 383–400. [Google Scholar]

- Hakimi, S.; Zahraee, S.M.; Mohd Rohani, J. Application of Six-Sigma DMAIC methodology in plain yogurt production process. Int. J. Lean Six Sigma 2018, 9, 562–578. [Google Scholar] [CrossRef]

- Wulff, S.S. A First Course in Design and Analysis of Experiments; University of Minnesota: Minneapolis, MN, USA, 2003; Volume 57, ISBN 0716735105. [Google Scholar]

- Hossain, M.S.; Rahim, N.A.; Aman, M.M.; Selvaraj, J. Application of ANOVA method to study solar energy for hydrogen production. Int. J. Hydrogen Energy 2019, 44, 14571–14579. [Google Scholar] [CrossRef]

- Minitab 18 Statistical Software 2017; [Computer software]; Minitab, Inc.: State College, PA, USA, 2017.

- Scarpa, F.; Vieira, L.M.G.; Freire, R.T.S.; Panzera, T.H.; Oliveira, L.Á.; Santos, J.C. Evaluation of hybrid-short-coir-fibre-reinforced composites via full factorial design. Compos. Struct. 2018, 202, 313–323. [Google Scholar]

- Montgomery, D.C. Design and Analysis of Experiments; John Wiley & Sons: Hoboken, NJ, USA, 2017. [Google Scholar]

- Jolly, M. Comprehensive Structural Integrity; Elsevier: Amsterdam, The Netherlands, 2003. [Google Scholar]

- Brown, J.R. Foseco Foundryman’s Handbook; Butterworth-Heinemann: Oxford, UK, 1994. [Google Scholar]

| Elements (wt%) | Cu | Zn | Sn | Sb | Bi | Ag |

|---|---|---|---|---|---|---|

| Mean | 0.0283 | 0.0029 | 0.086 | 0.0315 | 0.0179 | 0.0041 |

| SD | 0.0255 | 0.0101 | 0.0011 | 0.079 | 0.0030 | 0.0184 |

| No. | Process Parameters | Classification as per 5 M |

|---|---|---|

| 1 | Temperature of Melt | Material |

| 2 | Melt Composition | Material |

| 3 | Sand | Machine |

| 4 | Water content | Machine |

| 5 | Velocity of screed | Method |

| 6 | Angle of inclination of sand bed | Machine |

| 7 | Use of screed | Method |

| 8 | Ambient temperature | Environment |

| 9 | Bed preparation | Man |

| Source | DF | SS | MS | F |

|---|---|---|---|---|

| Treatments | g-1 | SSTrt | SSTrt/(g-1) | MSTrt/MSE |

| Error | N-g | SSE | SSE/(N-g) |

| Factors | Type | Low Level | High Level |

|---|---|---|---|

| A: Sand AFS (Dimensionless) | Numeric | 50 | 70 |

| B: Clay (wt%) | Numeric | 0 | 3 |

| C: Melt | Categoric | Pure | 50:50 Mix of refined and scrap lead |

| Standard Order | Run Order | A: Sand AFS (Dimensionless) | B: Bentonite (wt%) | C: Melt (Composition) | Response: Y (1/mm) |

|---|---|---|---|---|---|

| 1 | 1 | 50 | 0 | Pure | 620 |

| 15 | 2 | 50 | 3 | 50:50 | 105 |

| 2 | 3 | 70 | 0 | Pure | 538 |

| 16 | 4 | 70 | 3 | 50:50 | 99 |

| 3 | 5 | 50 | 3 | Pure | 110 |

| 12 | 6 | 70 | 3 | Pure | 70 |

| 9 | 7 | 50 | 0 | Pure | 640 |

| 8 | 8 | 70 | 3 | 50:50 | 96 |

| 4 | 9 | 70 | 3 | Pure | 65 |

| 6 | 10 | 70 | 0 | 50:50 | 582 |

| 13 | 11 | 50 | 0 | 50:50 | 712 |

| 14 | 12 | 70 | 0 | 50:50 | 600 |

| 7 | 13 | 50 | 3 | 50:50 | 105 |

| 11 | 14 | 50 | 3 | Pure | 95 |

| 10 | 15 | 70 | 0 | Pure | 548 |

| 5 | 16 | 50 | 0 | 50:50 | 685 |

| Source | DF | Adj SS | Adj MS | F-Value | P-Value |

|---|---|---|---|---|---|

| Model | 7 | 1,119,746 | 159,964 | 1412.48 | 0.000 |

| Linear | 3 | 1,111,617 | 370,539 | 3271.87 | 0.000 |

| Sand | 1 | 14,042 | 14,042 | 123.99 | 0.000 |

| Clay | 1 | 1,092,025 | 1,092,025 | 9642.60 | 0.000 |

| Melt | 1 | 5550 | 5550 | 49.01 | 0.000 |

| 2-Way Interactions | 3 | 7552 | 2517 | 22.23 | 0.000 |

| Sand-Clay | 1 | 5776 | 5776 | 51.00 | 0.000 |

| Sand-Melt | 1 | 12 | 12 | 0.11 | 0.751 |

| Clay-Melt | 1 | 1764 | 1764 | 15.58 | 0.004 |

| 3-Way Interactions | 1 | 576 | 576 | 5.09 | 0.054 |

| Sand-Clay-Melt | 1 | 576 | 576 | 5.09 | 0.054 |

| Error | 8 | 906 | 113 | - | - |

| Total | 15 | 1,120,652 | - | - | - |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Prabhakar, A.; Papanikolaou, M.; Salonitis, K.; Jolly, M. Minimising Defect Formation in Sand Casting of Sheet Lead: A DoE Approach. Metals 2020, 10, 252. https://doi.org/10.3390/met10020252

Prabhakar A, Papanikolaou M, Salonitis K, Jolly M. Minimising Defect Formation in Sand Casting of Sheet Lead: A DoE Approach. Metals. 2020; 10(2):252. https://doi.org/10.3390/met10020252

Chicago/Turabian StylePrabhakar, Arun, Michail Papanikolaou, Konstantinos Salonitis, and Mark Jolly. 2020. "Minimising Defect Formation in Sand Casting of Sheet Lead: A DoE Approach" Metals 10, no. 2: 252. https://doi.org/10.3390/met10020252

APA StylePrabhakar, A., Papanikolaou, M., Salonitis, K., & Jolly, M. (2020). Minimising Defect Formation in Sand Casting of Sheet Lead: A DoE Approach. Metals, 10(2), 252. https://doi.org/10.3390/met10020252