Sustainability Assessment, Investigations, and Modelling of Slot Milling Characteristics in Eco-Benign Machining of Hardened Steel

Abstract

1. Introduction

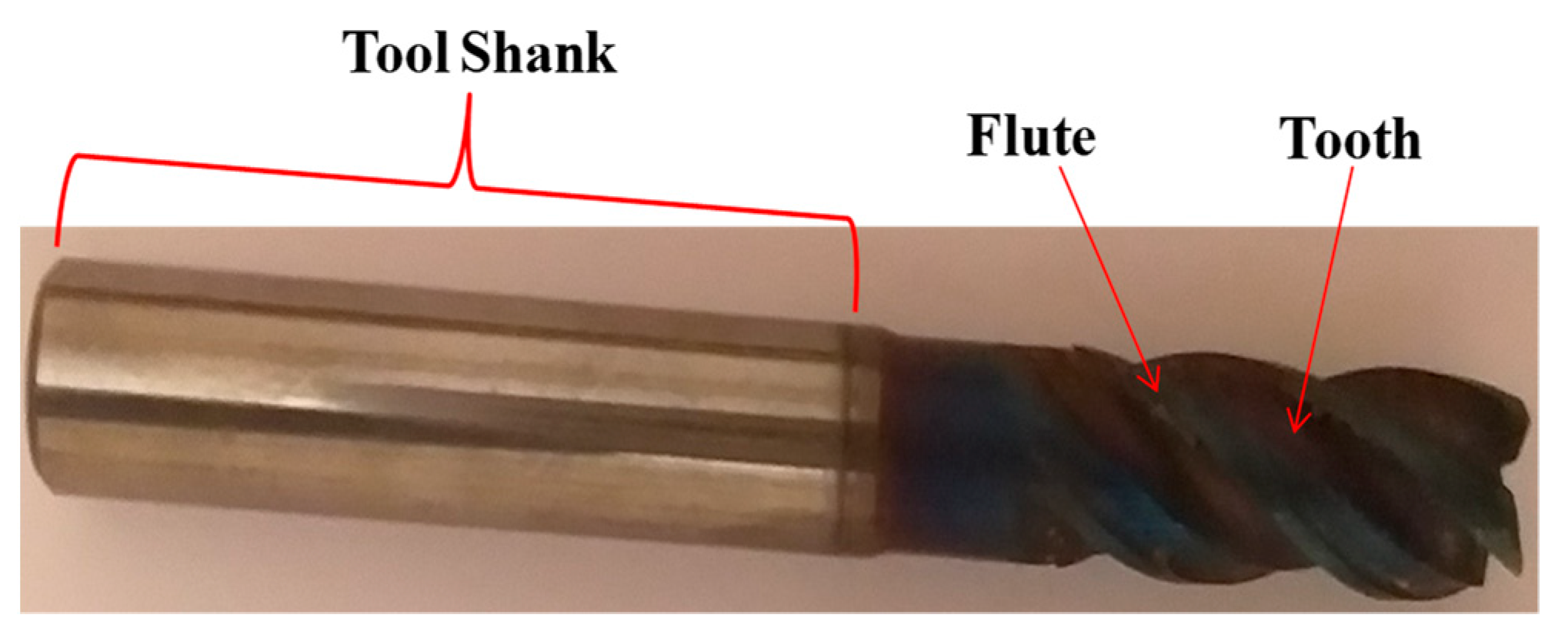

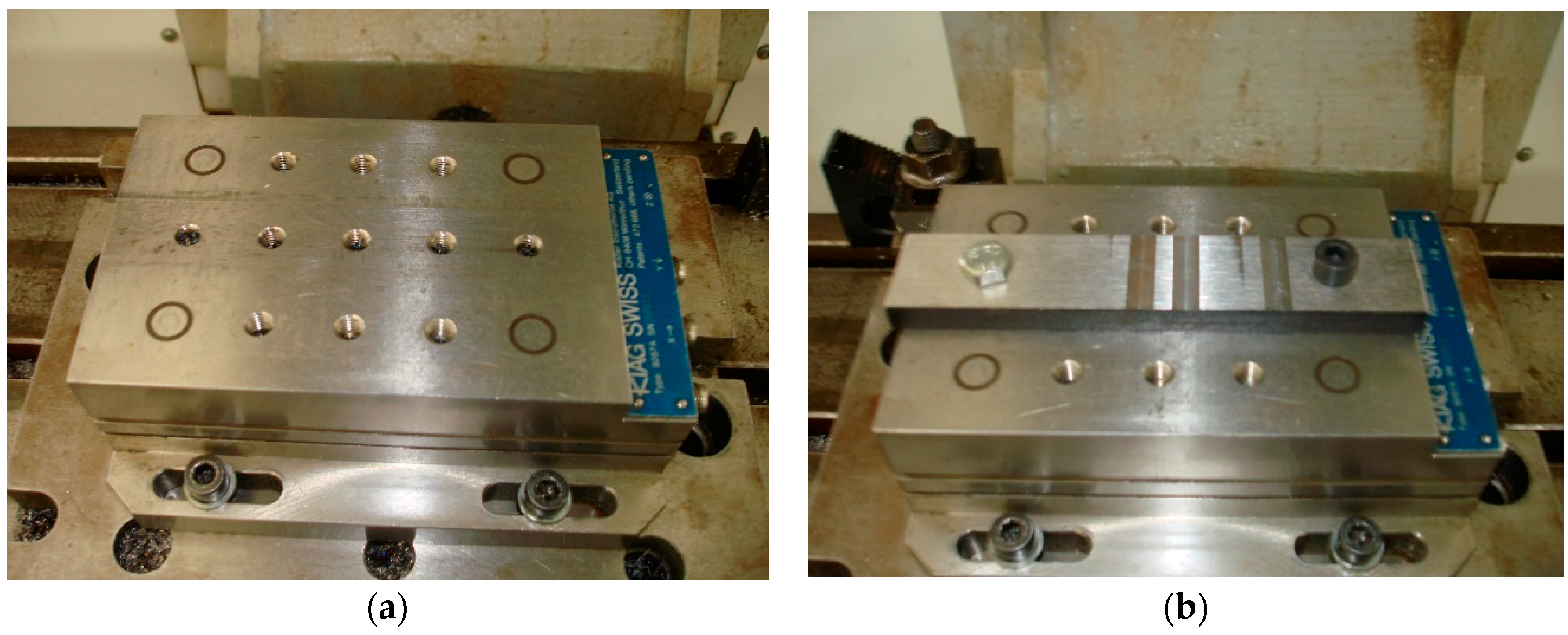

2. Materials and Methods

2.1. Experimental

2.1.1. Cutting Power

2.1.2. Machining Cost

- T’ represents machining time in face milling, T’ = (l + d)/vf, where l is the machining length in mm, d the cutter diameter in mm, and vf the feed rate in mm/min;

- CMh represents the cost of machining hour (SR 400) CMh = $2;

- CToolmin represents the tool cost per minute and is calculated as: [(CIn·z)/(T·k’)] + (CToolh/LTToolh);

- CToolh represents the cost of tool holder (CToolh = $50);

- LTToolh represents the tool holder life (LTToolh = 5 Year in min = 2,628,000 min);

- CIn represents the cost of Insert (CIn = $15). As the tool is a milling cutter, this cost represents the actual cost of the milling cutter rather than the cost of an insert;

- k’ represents the setup insert (k’ = 1);

- z represents the number of cutting inserts (z = 1) z = 1 was selected as the cutting tool contains no removable cutting inserts;

- T represents tool life (T = 60 min);

- Cw represents the unit cost of the workpiece (Cw = $3.2).

2.1.3. Sustainability Assessment

- 1

- Combining the effects of both machining characteristics and the sustainability metrics and indicators (normalisation stage);

- 2

- Assigning weighting factors for the normalised factors;

- 3

- Determining the overall index (total weighted index).

2.2. Optimisation Using the Desirability Function Approach

- ‘‘Higher is better”,where yi* is the minimum adequate value of yi, yi′ is the maximum value of yi and t describes the shape function for desirability.

- “Smaller is better”,where yi″ is the minimum value of yi, yi* is the highest adequate value of yi and r describes the shape function.

- “Nominal is better”,where Ci is the mainly adequate or objective value and s and t describe the exponential parameters, which verify the shape of the desirability function.

3. Results and Discussions

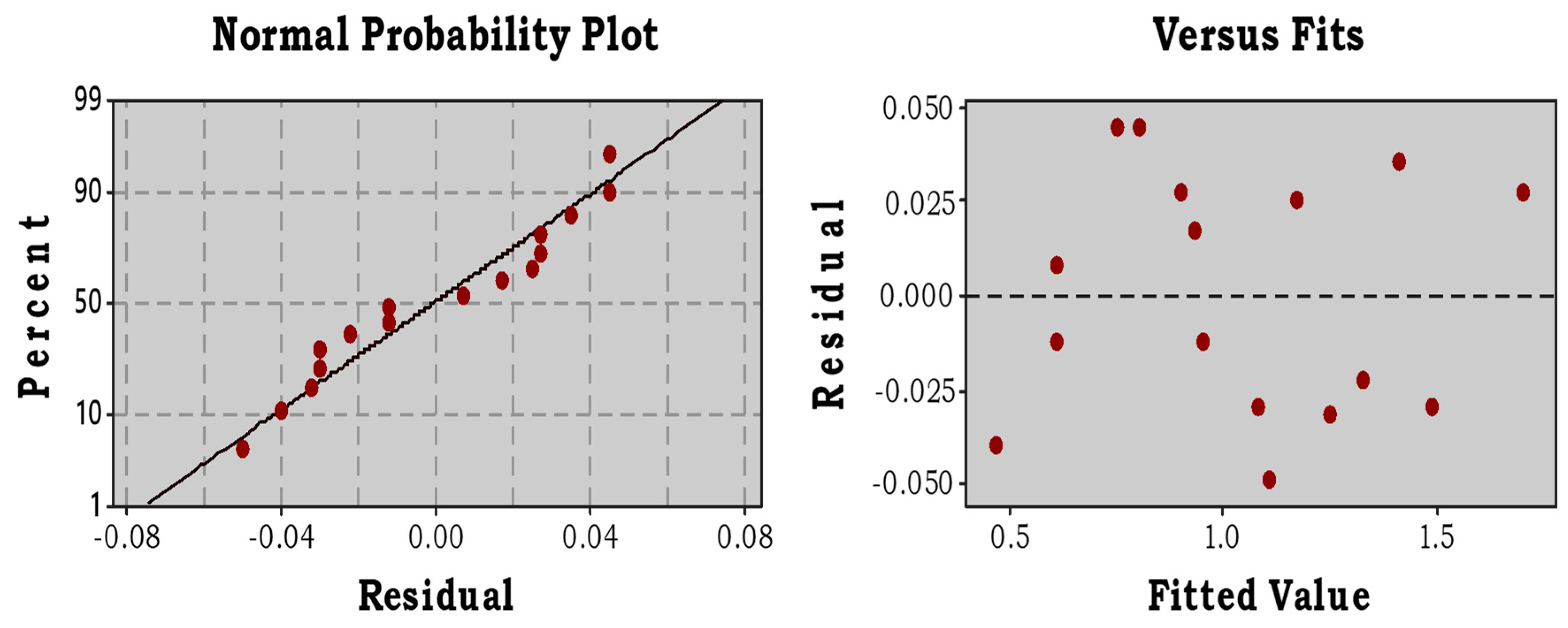

3.1. Modelling of Process Parameters

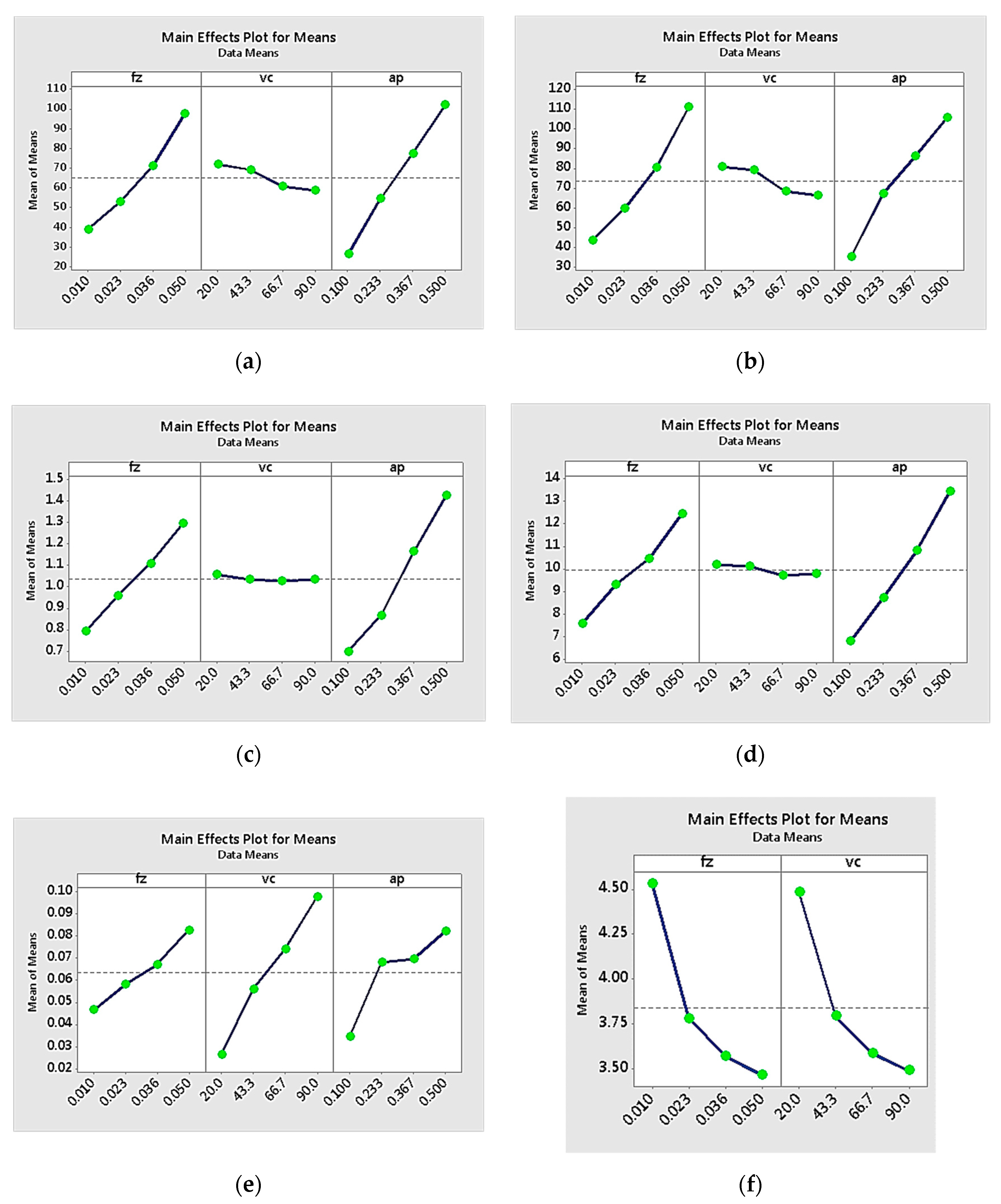

3.2. Effect of Process Parameters on Process Responses (Surface Roughness, Cutting Forces, Power, and Cost)

3.3. Optimisation

4. Conclusions

- For resource efficiency, the optimum parameters for eco-benign machining of the AISI O1 steel alloy should be set at 0.01 mm/tooth, 20 m/min, and 0.1 mm for feed rate, cutting speed, and depth of cut respectively. This selection of parameters would reduce the trial and error process involved in determining optimum parameters for machining that machinists undergo.

- The power consumption model and the machining cost model could be adopted as generic for slot milling and milling operations for difficult to cut materials.

- Both linear and non-linear laws were revealed by regression analysis of the influence of feed (fz), cutting speed (vc), cutting of depth (ap) on surface roughness (Ra, Rt), cutting force (Fx, Fy), cutting power (Pc), machining cost (Ci), and carbon dioxide (Ene), which can be easily integrated into CNC machines. Each of the developed regression equations was consistent with the characteristics of the slot milling process. Cutting forces increased with increasing feed per tooth and depth of cut and decrease with increasing cutting speed. Likewise, the depth of cut and feed will result in higher surface roughness. Increasing feed per tooth, depth of cut, and cutting speed increases power consumption. Increasing feed per tooth and cutting speed results in lower machining costs.

- The sustainability assessment model adopted produced the optimal and stable levels of design variables when machining AISI O1 tool steel with the P1 values set to “1” at a cutting speed of 20 m/min or 43.3 m/min and “2” at a cutting speed of 66.7 m/min or 90 m/min.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Nomenclature

| Ra | Arithmetic average value of surface roughness |

| Ene | Carbon dioxide |

| Fx, Fy | Components of cutting forces in the direction of the x, y axes |

| d | Cutter diameter |

| Pc | Cutting power (Power consumption) |

| vc | Cutting speeds |

| ap | Depth of cut |

| fz | Feed per tooth |

| vf | Feed speed |

| Ci | Machining cost |

| l | Machining length |

| T’ | Machining time in face milling |

| k’ | Represents the setup insert |

| CIn | The cost of Insert |

| CMh | The cost of machining hour |

| CToolh | The cost of Tool holder |

| z | The number of cutting inserts |

| CToolmin | The tool cost per minute |

| LTToolh | The tool holder life |

| Cw | The unit cost of workpiece |

| T | Tool life |

| Rt | Total height of the roughness profile |

References

- Vatavuk, J.; Totten, G.E.; Nucci, J.E.; Albano, L.L.M.; Canale, L.D.C.F. Comparative impact behavior of high-C steel after conventional quenching, tempering, and austempering. Mater. Perform. Charact. 2016, 5, 227–238. [Google Scholar] [CrossRef]

- Brar, M.S.; Simha, C.H.M. High strain rate compression and tension response of high hard tool steel. J. Phys. IV France 2000, 10, 611–615. [Google Scholar] [CrossRef]

- Rosales, I.; Martinez, H.; Guardian, R. Mechanical performance of thermally post-treated ion-nitrided steels. Appl. Surf. Sci. 2016, 371, 576–582. [Google Scholar] [CrossRef]

- Bourithis, L.; Papadimitriou, G.D.; Sideris, J. Comparison of wear properties of tool steels AISI D2 and O1 with the same hardness. Tribol. Int. 2006, 39, 479–489. [Google Scholar] [CrossRef]

- Kataria, R.; Kumar, J. A comparison of the different multiple response optimization techniques for turning operation of AISI O1 tool steel. J. Eng. Res. 2014, 2, 161–184. [Google Scholar] [CrossRef]

- Tamilarasan, A.; Marimuthu, K.; Renugambal, A. Investigations and optimization for hard milling process parameters using hybrid method of RSM and NSGA-II. Rev. Tec. De La Fac. De Ing. Univ. Del Zulia 2016, 39, 41–54. [Google Scholar]

- Navas, V.G.; García-Rosales, C.; Sevillano, J.G.; Ferreres, I.; Marañón, J.A. Hard turning plus grinding-a combination to obtain good surface integrity in AISI O1 tool steel machined parts. Mach. Sci. Technol. 2008, 12, 15–32. [Google Scholar] [CrossRef]

- Pereira, R.B.D.; Leite, R.R.; Alvim, A.C.; Paiva, A.P.D.; Ferreira, J.R.; Davim, J.P. Multi-objective robust optimization of the sustainable helical milling process of the aluminum alloy Al 7075 using the augmented-enhanced normalized normal constraint method. J. Clean. Prod. 2017, 152, 474–496. [Google Scholar] [CrossRef]

- Liu, Z.Y.; Li, C.; Fang, X.Y.; Guo, Y.B. Cumulative energy demand and environmental impact in sustainable machining of inconel superalloy. J. Clean. Prod. 2018, 181, 329–336. [Google Scholar] [CrossRef]

- Pervaiz, S.; Kannan, S.; Kishawy, H.A. An extensive review of the water consumption and cutting fluid based sustainability concerns in the metal cutting sector. J. Clean. Prod. 2018, 197, 134–153. [Google Scholar] [CrossRef]

- Yan, J.; Li, L. Multi-objective optimization of milling parameters-the trade-offs between energy, production rate and cutting quality. J. Clean. Prod. 2013, 52, 462–471. [Google Scholar] [CrossRef]

- Singh, A.; Philip, D.; Ramkumar, J.; Das, M. A simulation based approach to realize green factory from unit green manufacturing processes. J. Clean. Prod. 2018, 182, 67–81. [Google Scholar] [CrossRef]

- Cao, H.; Li, H.; Cheng, H.; Luo, Y.; Yin, R.; Chen, Y. A carbon efficiency approach for life-cycle carbon emission characteristics of machine tools. J. Clean. Prod. 2012, 37, 19–28. [Google Scholar] [CrossRef]

- Lu, Q.; Zhou, G.; Zhao, F.; Ren, Y.; Li, L.; Luan, X. Sutherland JW. Topology optimization of oilstone components considering carbon emissions associated with honing processes. J. Clean. Prod. 2019, 225, 181–195. [Google Scholar] [CrossRef]

- Camposeco-Negrete, C.; de Dios Calderón-Nájera, J. Optimization of energy consumption and surface roughness in slot milling of AISI 6061 T6 using the response surface method. Int. J. Adv. Manuf. Technol. 2019, 103, 4063–4069. [Google Scholar] [CrossRef]

- Zhou, G.; Lu, Q.; Xiao, Z.; Zhou, C.; Tian, C. Cutting parameter optimization for machining operations considering carbon emissions. J. Clean. Prod. 2019, 208, 937–950. [Google Scholar] [CrossRef]

- Sihag, N.; Sangwan, K.S. Development of a Multi-criteria Optimization Model for Minimizing Carbon Emissions and Processing Time during Machining. Procedia CIRP 2018, 69, 300–305. [Google Scholar] [CrossRef]

- Wang, M.-Y.; Chang, H.-Y. Experimental study of surface roughness in slot end milling AL2014-T6. Int. J. Mach. Tools Manuf. 2004, 44, 51–57. [Google Scholar] [CrossRef]

- Niknam, S.A.; Songmene, V. Simultaneous optimization of burrs size and surface finish when milling 6061-T6 aluminium alloy. Int. J. Precis. Eng. Manuf. 2013, 14, 1311–1320. [Google Scholar] [CrossRef]

- Pimenov, D.Y. Experimental research of face mill wear effect to flat surface roughness. J. Frict. Wear 2014, 35, 250–254. [Google Scholar] [CrossRef]

- Duboust, N.; Ghadbeigi, H.; Pinna, C.; Ayvar-Soberanis, S.; Collis, A.; Scaife, R.; Kerrigan, K. An optical method for measuring surface roughness of machined carbon fibre-reinforced plastic composites. J. Compos. Mater. 2016, 51, 289–302. [Google Scholar] [CrossRef]

- Niknam, S.A.; Balazinski, M.; Songmene, V. To characterize and optimize the surface quality attributes in slot milling operation. Int. J. Adv. Manuf. Technol. 2017, 93, 727–746. [Google Scholar] [CrossRef]

- Wang, C.; Wen, L.; Ming, W.; An, Q.; Chen, M. Experimental study on effects of fiber cutting angle in milling of high-strength unidirectional carbon fiber–reinforced polymer laminates. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2018, 232, 1813–1824. [Google Scholar] [CrossRef]

- Pimenov, D.Y.; Hassui, A.; Wojciechowski, S.; Mia, M.; Magri, A.; Suyama, D.I.; Bustillo, A.; Krolczyk, G.; Gupta, M.K. Effect of the Relative Position of the Face Milling Tool towards the Workpiece on Machined Surface Roughness and Milling Dynamics. Appl. Sci. 2019, 9, 842. [Google Scholar] [CrossRef]

- Jebaraj, M.; Pradeep Kumar, M. Effect of cryogenic CO 2 and LN 2 coolants in milling of aluminum alloy. Mater. Manuf. Process. 2019, 34, 511–520. [Google Scholar] [CrossRef]

- Yeganefar, A.; Niknam, S.A.; Asadi, R. The use of support vector machine, neural network, and regression analysis to predict and optimize surface roughness and cutting forces in milling. Int. J. Adv. Manuf. Technol. 2019, 105, 951–965. [Google Scholar] [CrossRef]

- Pimenov, D.Y.; Abbas, A.T.; Gupta, M.K.; Erdakov, I.N.; Soliman, M.S.; El Rayes, M.M. Investigations of surface quality and energy consumption associated with costs and material removal rate during face milling of AISI 1045 steel. Int. J. Adv. Manuf. Technol. 2020, 107, 3511–3525. [Google Scholar] [CrossRef]

- Balogun, V.A.; Edem, I.F.; Bonney, J.; Ezeugwu, E.; Mativenga, P.T. Effect of Cutting Parameters on Surface Finish when Turning Nitronic 33 Steel alloy. Int. J. Sci. Eng. Res. 2015, 6, 1–9. [Google Scholar]

- Osman, K.A.; Yılmaz, V.; Ünver, H.Ö.; Şeker, U.; Kılıç, S.E. Slot milling of titanium alloy with hexagonal boron nitride and minimum quantity lubrication and multi-objective process optimization for energy efficiency. J. Clean. Prod. 2020, 258, 120739. [Google Scholar] [CrossRef]

- Muñoz-Escalona, P.; Shokrani, A.; Dhokia, V.; Imani-Asrai, R.; Newman, S.T. A surface roughness and power consumption analysis when slot milling austenitic stainless steel in a dry cutting environment. Lect. Notes Mech. Eng. 2013, 7, 637–649. [Google Scholar] [CrossRef]

- Liu, N.; Zhang, Y.F.; Lu, W.F. A hybrid approach to energy consumption modelling based on cutting power: A milling case. J. Clean. Prod. 2015, 104, 264–272. [Google Scholar] [CrossRef]

- Liu, N.; Wang, S.B.; Zhang, Y.F.; Lu, W.F. A novel approach to predicting surface roughness based on specific cutting energy consumption when slot milling Al-7075. Int. J. Mech. Sci. 2016, 118, 13–20. [Google Scholar] [CrossRef]

- Edem, I.F.; Balogun, V.A. Sustainability analyses of cutting edge radius on specific cutting energy and surface finish in side milling processes. Int. J. Adv. Manuf. Technol. 2018, 95, 3381–3391. [Google Scholar] [CrossRef]

- Pimenov, D.Y.; Bustillo, A.; Mikolajczyk, T. Artificial intelligence for automatic prediction of required surface roughness by monitoring wear on face mill teeth. J. Intell. Manuf. 2018, 29, 1045–1061. [Google Scholar] [CrossRef]

- Abbas, A.T.; Pimenov, D.Y.; Erdakov, I.N.; Mikolajczyk, T.; Soliman, M.S.; El Rayes, M.M. Optimization of cutting conditions using artificial neural networks and the Edgeworth-Pareto method for CNC face-milling operations on high-strength grade-H steel. Int. J. Adv. Manuf. Technol. 2019, 105, 2151–2165. [Google Scholar] [CrossRef]

- Abbas, A.T.; Pimenov, D.Y.; Erdakov, I.N.; Taha, M.A.; El Rayes, M.M.; Soliman, M.S. Artificial intelligence monitoring of hardening methods and cutting conditions and their effects on surface roughness, performance, and finish turning costs of solid-state recycled aluminum alloy 6061 chips. Metals 2018, 8, 394. [Google Scholar] [CrossRef]

- Abbas, A.T.; Pimenov, D.Y.; Erdakov, I.N.; Taha, M.A.; Soliman, M.S.; El Rayes, M.M. ANN Surface Roughness Optimization of AZ61 Magnesium Alloy Finish Turning: Minimum Machining Times at Prime Machining Costs. Materials 2018, 11, 808. [Google Scholar] [CrossRef]

- Pusavec, F.; Krajnik, P.; Kopac, J. Transitioning to sustainable production—Part I: Application on machining technologies. J. Clean. Prod. 2010, 18, 174–184. [Google Scholar] [CrossRef]

- Krolczyk, G.M.; Maruda, R.W.; Krolczyk, J.B.; Wojciechowski, S.; Mia, M.; Nieslony, P.; Budzik, G. Ecological trends in machining as a key factor in sustainable production—A review. J. Clean. Prod. 2019, 218, 601–615. [Google Scholar] [CrossRef]

- Krolczyk, G.M.; Nieslony, P.; Maruda, R.W.; Wojciechowski, S. Dry cutting effect in turning of a duplex stainless steel as a key factor in clean production. J. Clean. Prod. 2017, 142, 3343–3354. [Google Scholar] [CrossRef]

- Hegab, H.A.; Darras, B.; Kishawy, H.A. Towards sustainability assessment of machining processes. J. Clean. Prod. 2018, 170, 694–703. [Google Scholar] [CrossRef]

- Narita, H.; Desmira, N.; Fujimoto, H. Environmental burden analysis for machining operation using LCA method. Manuf. Syst. Technol. New Front. 2008, 65–68. [Google Scholar] [CrossRef]

- Khanna, N.; Shah, P.; Agrawal, C.; Pusavec, F.; Hegab, H. Inconel 718 machining performance evaluation using indigenously developed hybrid machining facilities: Experimental investigation and sustainability assessment. Int. J. Adv. Manuf. Technol. 2020, 106, 4987–4999. [Google Scholar] [CrossRef]

- Khanna, N.; Shah, P.; Maruda, R.W.; Krolczyk, G.M.; Hegab, H. Experimental investigation and sustainability assessment to evaluate environmentally clean machining of 15-5 PH stainless steel. J. Manuf. Process. 2020, 56, 1027–1038. [Google Scholar] [CrossRef]

- Xu, C.; Dou, J.; Chai, Y.; Li, H.; Shi, Z.; Xu, J. The relationships between cutting parameters, tool wear, cutting force and vibration. Adv. Mech. Eng. 2018, 10, 1–14. [Google Scholar] [CrossRef]

- Korkut, I.; Donertas, M.A. The influence of feed rate and cutting speed on the cutting forces, surface roughness and tool-chip contact length during face milling. Mater. Des. 2007, 28, 308–312. [Google Scholar] [CrossRef]

- Shi, K.; Dinghua, Z.; Junxue, R.; Changfeng, Y.; Xinchun, H. Effect of cutting parameters on machinability characteristics in milling of magnesium alloy with carbide tool. Adv. Mech. Eng. 2016, 8, 1–9. [Google Scholar] [CrossRef]

- Kaya, E.; Akyuz, B. Effects of cutting parameters on machinability characteristics of Ni-based superalloys: A review. Open Eng. 2017, 7, 330–342. [Google Scholar] [CrossRef]

- Subramanian, M.; Sakthivel, M.; Sooryprakash, K.; Sudharakan, R. Optimization of cutting parameters for cutting force in shoulder milling of Al7075-T6 using response surface methodology and genetic algorithm. Procedia Eng. 2013, 64, 690–700. [Google Scholar] [CrossRef]

- Begić-Hajdarević, Đ.; Čekić, A.; Kulenović, M. Effect of the cutting parameters on cutting forces in high speed face milling| [Utjecaj parametara obrade na sile rezanja pri visokobrzinskom Čeonom glodanju]. Teh. Vjesn. 2013, 20, 775–780. [Google Scholar]

- Ghoreishi, R.; Roohi, A.H.; Ghadikolaei, A.D. Analysis of the influence of cutting parameters on surface roughness and cutting forces in high speed face milling of Al/SiCMMC. Mater. Res. Express 2018, 5, 086521. [Google Scholar] [CrossRef]

- Subramanian, A.V.M.; Nachimuthu, M.D.G.; Cinnasamy, V. Assessment of cutting force and surface roughness in LM6/SiCp using response surface methodology. J. Appl. Res. Technol. 2017, 15, 283–296. [Google Scholar] [CrossRef]

- Balogun, V.A.; Edem, I.F.; Adekunle, A.A.; Mativenga, P.T. Specific energy based evaluation of machining efficiency. J. Clean. Prod. 2016, 116, 187–197. [Google Scholar] [CrossRef]

- Hayajneh, M.T.; Tahar, M.S.; Bluhm, J. A study of the effects of machining parameters on the surface roughness in end-milling process. Jordan J. Mech. Ind. Eng. 2007, 1, 1–5. [Google Scholar]

- Felhő, C.; Karpuschewski, B.; Kundrák, J. Surface roughness modelling in face milling. Procedia CIRP 2015, 31, 136–141. [Google Scholar] [CrossRef]

- Kundrák, J.; Felhő, C. Topography of the machined surface in high performance face milling. Procedia CIRP 2018, 77, 340–343. [Google Scholar] [CrossRef]

- Hernández-González, L.W.; Pérez-Rodríguez, R.; Quesada-Estrada, A.M.; Dumitrescu, L. Effects of cutting parameters on surface roughness and hardness in milling of AISI 304 steel. DYNA 2018, 85, 57–63. [Google Scholar] [CrossRef]

- Shnfir, M.; Olufayo, O.A.; Jomaa, W.; Songmene, V. Machinability study of hardened 1045 steel when milling with ceramic cutting inserts. Materials 2019, 12, 3974. [Google Scholar] [CrossRef]

| C (%) | Si (%) | Mn (%) | P (%) | S (%) | Cr (%) | W (%) | V (%) | Fe (%) |

|---|---|---|---|---|---|---|---|---|

| 0.96 | 0.22 | 1.08 | 0.008 | 0.004 | 0.45 | 0.41 | 0.09 | Balance |

| Cutting Parameter | Level 1 | Level 2 | Level 3 | Level 4 |

|---|---|---|---|---|

| Depth of cut (mm) | 0.1 | 0.233 | 0.367 | 0.5 |

| Cutting speed (m/min) | 20 | 43.3 | 66.7 | 90 |

| Feed rate (mm/tooth) | 0.01 | 0.023 | 0.036 | 0.05 |

| No. of Experiment | Feed per Tooth, fz (mm/tooth) | Cutting Speed, vc (m/min) | Cutting of Depth, ap (mm) | Roughness, Ra (µm) | Roughness, Rt (µm) | Force, Fx (N) | Force, Fy (N) | Cutting Power, Pc (kW) | Machining Cost, Ci ($) | Carbon Dioxide, Ene | High-Speed Surface Exposure, P1 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 0.01 | 20 | 0.1 | 0.43 | 4.93 | 20 | 25 | 0.008 | 5.89 | 0.00305 | 1 |

| 2 | 0.01 | 43.3 | 0.233 | 0.6 | 6.8 | 23 | 32 | 0.023 | 4.44 | 0.00876 | 1 |

| 3 | 0.01 | 66.7 | 0.367 | 0.93 | 7.87 | 43 | 45 | 0.049 | 4.01 | 0.01867 | 2 |

| 4 | 0.01 | 90 | 0.5 | 1.2 | 10.7 | 70 | 72 | 0.106 | 3.80 | 0.04039 | 2 |

| 5 | 0.023 | 20 | 0.233 | 0.85 | 8.2 | 40 | 52 | 0.017 | 4.37 | 0.00648 | 1 |

| 6 | 0.023 | 43.3 | 0.1 | 0.62 | 5.87 | 24 | 33 | 0.023 | 3.74 | 0.00876 | 1 |

| 7 | 0.023 | 66.7 | 0.5 | 1.31 | 12.93 | 83 | 85 | 0.092 | 3.55 | 0.03505 | 2 |

| 8 | 0.023 | 90 | 0.367 | 1.05 | 10.2 | 65 | 68 | 0.100 | 3.46 | 0.0381 | 2 |

| 9 | 0.036 | 20 | 0.367 | 1.22 | 11.43 | 82 | 92 | 0.030 | 3.95 | 0.01143 | 1 |

| 10 | 0.036 | 43.3 | 0.5 | 1.46 | 14.06 | 110 | 112 | 0.079 | 3.54 | 0.0301 | 1 |

| 11 | 0.036 | 66.7 | 0.1 | 0.8 | 7.2 | 27 | 38 | 0.041 | 3.42 | 0.01562 | 2 |

| 12 | 0.036 | 90 | 0.233 | 0.95 | 9.1 | 65 | 80 | 0.118 | 3.37 | 0.04496 | 2 |

| 13 | 0.05 | 20 | 0.5 | 1.73 | 16.17 | 145 | 155 | 0.051 | 3.73 | 0.01943 | 1 |

| 14 | 0.05 | 43.3 | 0.367 | 1.45 | 13.77 | 120 | 140 | 0.099 | 3.45 | 0.03772 | 1 |

| 15 | 0.05 | 66.7 | 0.233 | 1.06 | 10.83 | 90 | 105 | 0.114 | 3.36 | 0.04343 | 2 |

| 16 | 0.05 | 90 | 0.1 | 0.94 | 9.1 | 35 | 45 | 0.066 | 3.32 | 0.02515 | 2 |

| No. of Experiment | Force, Fx (N)-1st Replication | Force, Fy (N)-1st Replication | Force, Fx (N)-2nd Replication | Force, Fy (N)-2nd Replication | Force, Fx (N)-3rd Replication | Force, Fy (N)-3rd Replication | Average Force, Fx (N) | Average Force, Fy (N) | CVFx (%) | CVFy (%) |

|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 20.6 | 25.6 | 19.6 | 24.8 | 19.8 | 24.6 | 20 | 25 | 2.65 | 2.12 |

| 5 | 39.3 | 50.2 | 40.2 | 54.3 | 40.5 | 51.5 | 40 | 52 | 1.56 | 4.03 |

| 8 | 63.7 | 64.2 | 66.1 | 71.5 | 65.2 | 68.3 | 65 | 68 | 1.87 | 5.38 |

| 13 | 146.3 | 150.6 | 150.2 | 155.1 | 138.5 | 159.3 | 145 | 155 | 4.11 | 2.81 |

| No. of Experiment | Ra (μm)-1st Replication | Rt (μm)-1st Replication | Ra (μm)-2nd Replication | Rt (μm)-2nd Replication | Ra (μm)-3rd Replication | Rt (μm)-3rd Replication | Average Ra (μm) | Average Rt (μm) | CVRa (%) | CVRt (%) |

|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 0.43 | 4.82 | 0.45 | 5.07 | 0.41 | 4.9 | 0.43 | 4.93 | 4.65 | 2.59 |

| 5 | 0.84 | 7.7 | 0.9 | 8.6 | 0.81 | 8.3 | 0.85 | 8.2 | 5.39 | 5.59 |

| 8 | 1.04 | 10.3 | 1.01 | 9.6 | 1.1 | 10.7 | 1.05 | 10.2 | 4.36 | 5.46 |

| 13 | 1.75 | 15.7 | 1.79 | 16.12 | 1.65 | 16.7 | 1.73 | 16.17 | 4.17 | 3.10 |

| No. of Experiment | Feed per Tooth, f (mm/tooth) | Cutting Speed, vc (m/min) | Cutting of Depth, ap (mm) | Roughness, Ra (µm) | Roughness, Rt (µm) | Force, Fx (N) | Force, Fy (N) | Cutting Power, Pc (kW) | Machining Cost, Ci ($) | Carbon Dioxide, Ene | Desirability Value |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 0.01 | 22 | 0.2 | 0.42 | 4.85 | 22 | 22 | 0.010 | 5.94 | 0.00317 | 0.999 |

| 2 | 0.01 | 25 | 0.233 | 0.45 | 4.95 | 23 | 24 | 0.015 | 5.98 | 0.00325 | 0.9842 |

| 3 | 0.01 | 22 | 0.235 | 0.46 | 5.01 | 25 | 26 | 0.013 | 5.8 | 0.00330 | 0.8425 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Markopoulos, A.P.; Karkalos, N.E.; Mia, M.; Pimenov, D.Y.; Gupta, M.K.; Hegab, H.; Khanna, N.; Aizebeoje Balogun, V.; Sharma, S. Sustainability Assessment, Investigations, and Modelling of Slot Milling Characteristics in Eco-Benign Machining of Hardened Steel. Metals 2020, 10, 1650. https://doi.org/10.3390/met10121650

Markopoulos AP, Karkalos NE, Mia M, Pimenov DY, Gupta MK, Hegab H, Khanna N, Aizebeoje Balogun V, Sharma S. Sustainability Assessment, Investigations, and Modelling of Slot Milling Characteristics in Eco-Benign Machining of Hardened Steel. Metals. 2020; 10(12):1650. https://doi.org/10.3390/met10121650

Chicago/Turabian StyleMarkopoulos, Angelos P., Nikolaos E. Karkalos, Mozammel Mia, Danil Yurievich Pimenov, Munish Kumar Gupta, Hussein Hegab, Navneet Khanna, Vincent Aizebeoje Balogun, and Shubham Sharma. 2020. "Sustainability Assessment, Investigations, and Modelling of Slot Milling Characteristics in Eco-Benign Machining of Hardened Steel" Metals 10, no. 12: 1650. https://doi.org/10.3390/met10121650

APA StyleMarkopoulos, A. P., Karkalos, N. E., Mia, M., Pimenov, D. Y., Gupta, M. K., Hegab, H., Khanna, N., Aizebeoje Balogun, V., & Sharma, S. (2020). Sustainability Assessment, Investigations, and Modelling of Slot Milling Characteristics in Eco-Benign Machining of Hardened Steel. Metals, 10(12), 1650. https://doi.org/10.3390/met10121650