Change of Microstructure and Hardness of Duo-Casted Al3003/Al4004 Clad Material during Extrusion Process

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

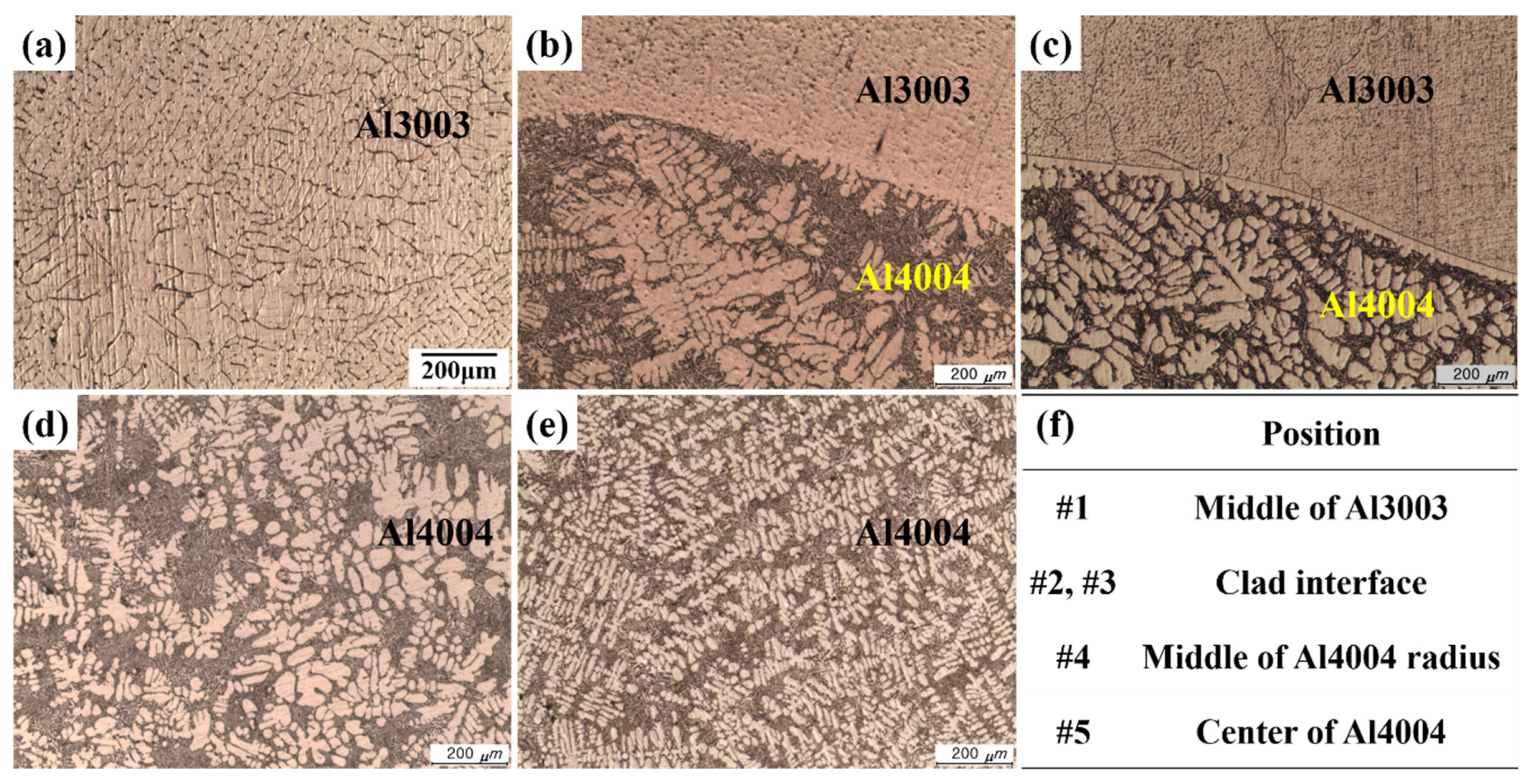

3.1. Microsturucture of Cross Section

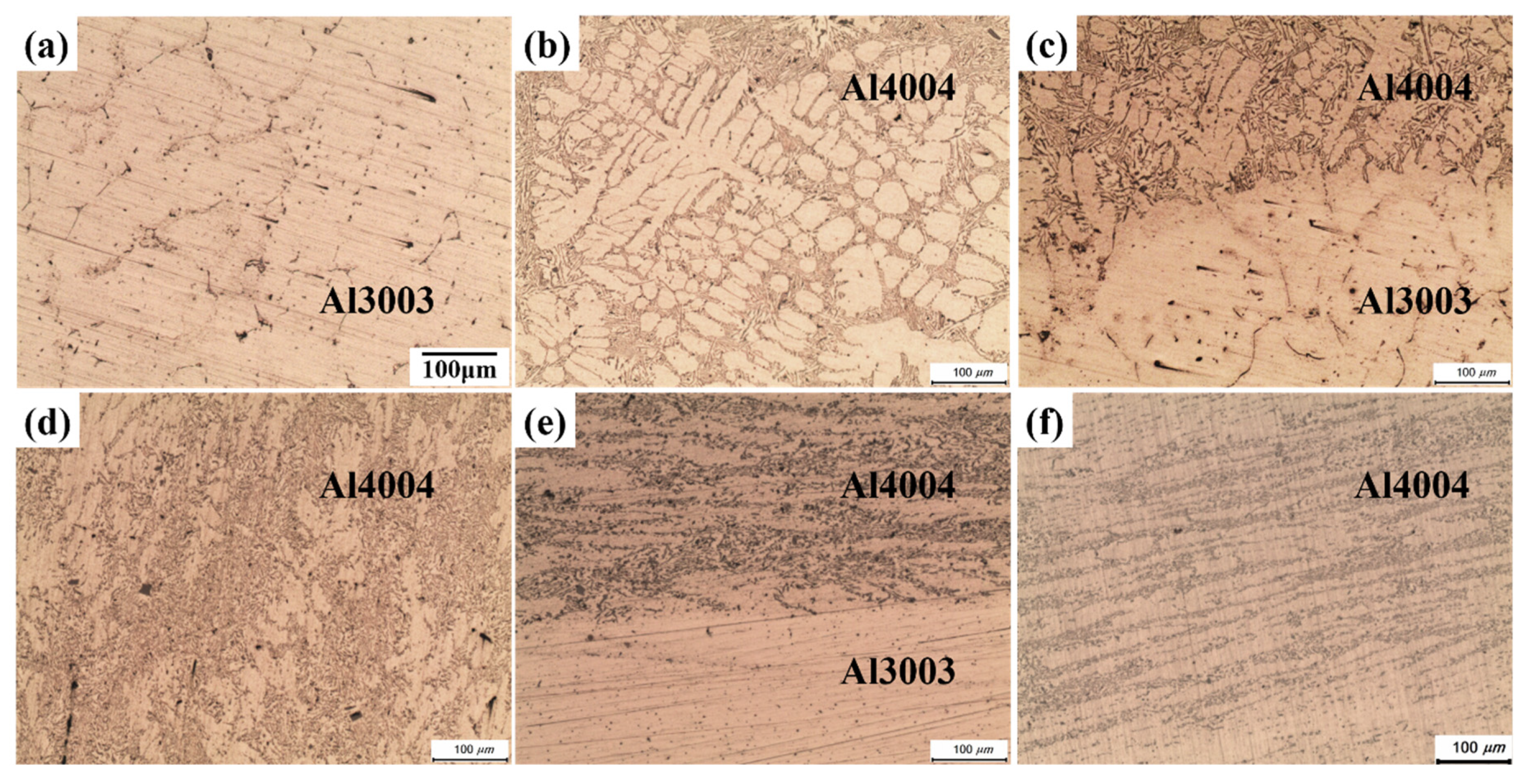

3.2. Structure Change and Hardness Change before and after Extrusion

4. Conclusions

- At the surface of the casting material, a proeutectic α phase with a grain size of about 63 μm was observed; in all other parts, a proeutectic α phase and dendrites were observed.

- Al3003 exhibits equiaxed crystals and Al4004 has a casted structure with dendrites before extrusion; this shows that there was slight deformation during extrusion. Then, finally, the material exhibited completely deformed structures after extrusion.

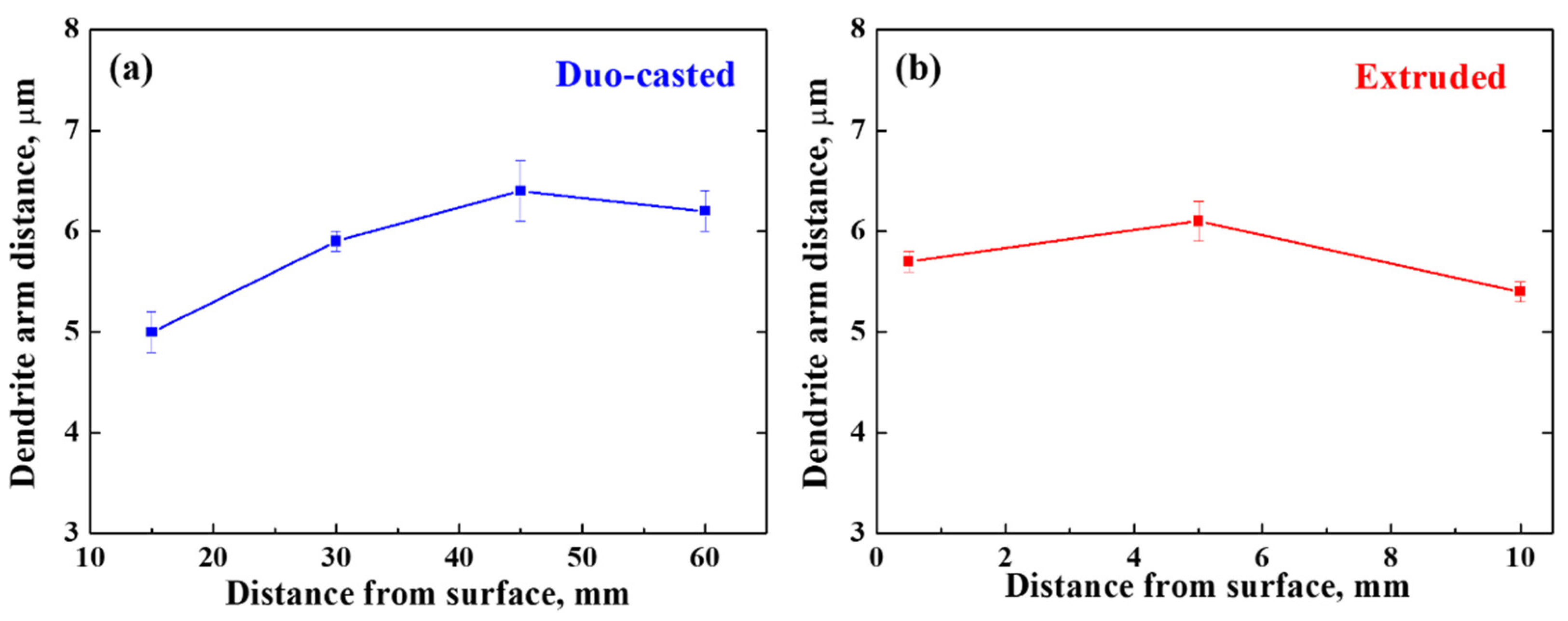

- The distance between the dendrite arms of the casting material increased from the surface to the inside; however, in the case of the extruded material, the distance between dendrite arms did not change from the surface to the center. The aspect ratio of dendrites for the cast material tended to decrease from the surface to the center; however, throughout the extruded material, the aspect ratio did not change significantly.

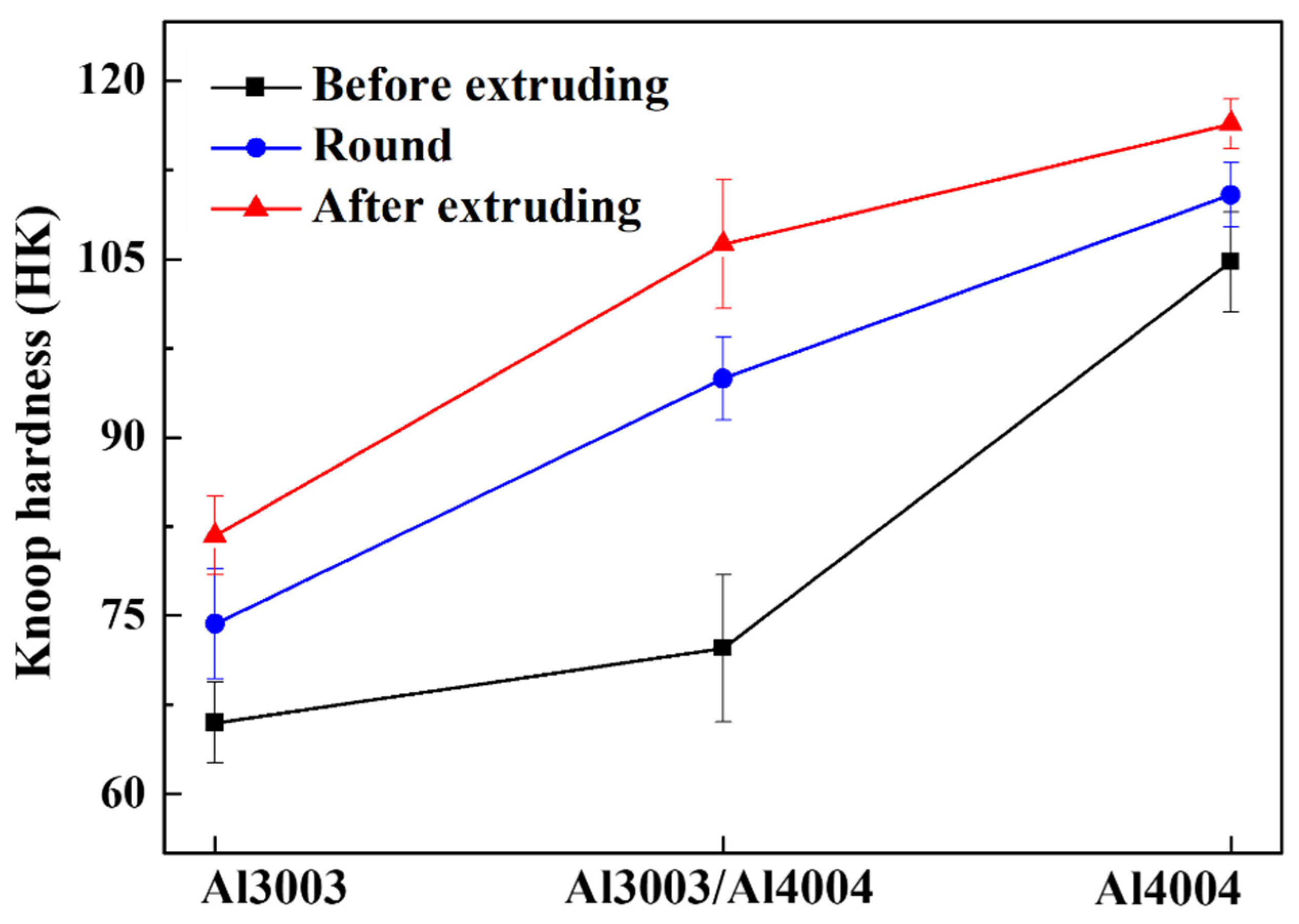

- As extrusion progressed, the Knoop hardness values of Al3003, the Al3003/Al4004 interface, and Al4004 increased due to work hardening. Hardness values at the boundary of Al3003/Al4004 increased approximately 2.2 and 2.9 times compared with those of the Al3003 and Al4004 matrixes, respectively. The hardness value of Al 3003 was the lowest, and that of Al4004 was the highest.

- After the extrusion process, the Knoop hardness of the Al3003/Al4004 clad interface increased; the existence of oxides at the interface could deteriorate the mechanical properties of the extruded parts.

- The aspect ratio and the dendrite arm distance from extrusion show constant values; it can be seen that overall, reduction has been achieved in the clad material compared to the cast material. The hardness has increased due to work hardening.

Author Contributions

Funding

Conflicts of Interest

References

- Park, H.; Na, K.; Cho, N.; Lee, Y.; Kim, S.-W. A study of the hydrostatic extrusion of copper-clad aluminium tube. J. Mater. Process. Technol. 1997, 67, 24–28. [Google Scholar] [CrossRef]

- Kim, N.H.; Kang, C.G.; Kwon, H.C. Extrusion process analysis of Al/Cu clad composite materials by finite element method. J. Korean Soc. Compos. Mater. 1999, 43, 1507–1520. [Google Scholar]

- Wu, C.; Hsu, R. Extrusion of three-layer composite hexagonal clad rods. J. Mater. Process. Technol. 2002, 123, 47–53. [Google Scholar] [CrossRef]

- Kang, C.-G.; Kwon, H. Finite element analysis considering fracture strain of sheath material and die lubricant in extrusion process of Al/Cu clad composites and its experimental investigation. Int. J. Mech. Sci. 2002, 44, 247–267. [Google Scholar] [CrossRef]

- Lee, J.; Son, H.; Oh, I.; Kang, C.; Yun, C.; Lim, S.; Kwon, H. Fabrication and characterization of Ti-Cu clad materials by indirect extrusion. J. Mater. Process. Technol. 2007, 187–188, 653–656. [Google Scholar] [CrossRef]

- Sun, X.J.; Tao, J.; Guo, X.Z. Bonding properities of interface in Fe/Al clad tube prepared by explosive welding. Trans. Nonferrous Met. Soc. 2011, 21, 2175–2180. [Google Scholar] [CrossRef]

- Bae, D.-S.; Kim, S.-M.; We, S.-N.; Bae, D.-H.; Lee, G.-A.; Lee, J.; Kim, Y.-B.; Lee, S. Effect of post heat treatment temperature on interface diffusion layer and bonding force in roll cladded Ti/mild steel/Ti material. Korean J. Met. Mater. 2012, 50, 316–323. [Google Scholar] [CrossRef]

- Lee, S.; Lee, M.-G.; Lee, S.-P.; Lee, G.-A.; Kim, Y.-B.; Lee, J.; Bae, D. Effect of bonding interface on delamination behavior of drawn Cu/Al bar clad material. Trans. Nonferrous Met. Soc. China 2012, 22, s645–s649. [Google Scholar] [CrossRef]

- Fu, Y.; Jie, J.-C.; Zhang, Y.; Zhong, D.-S.; Li, J.-Z.; Li, T. Microstructure evolution of 3003/4004 clad ingots under diverse physical fields. Trans. Nonferrous Met. Soc. China 2013, 23, 2496–2501. [Google Scholar] [CrossRef]

- Son, I.-S.; Lee, S.-P.; Lee, J.-K.; Kim, W.-C.; Moon, J.-S.; Lee, S.; Lee, J.; Kim, Y.-B.; Lee, G.-A.; Bae, D.-S. Effect of hydro co-extrusion on microstructure of duo-cast Al 3003/Al 4004 clad materials. Trans. Nonferrous Met. Soc. China 2014, 24, s75–s80. [Google Scholar] [CrossRef]

- Yan, G.; Mao, F.; Jie, J.; Cao, Z.; Li, T.; Wang, T. Effect of Sr addition on the characteristics of as-cast and rolled 3003/4004 clad aluminum. J. Alloys Compd. 2016, 678, 201–211. [Google Scholar] [CrossRef]

- Lee, K.S.; Kim, Y.-B.; Lee, S.; Lee, J.-S.; Lee, G.-A.; Lee, S.-P.; Bae, D. Evaluation of intermediate phases formed on the bonding interface of hot pressed Cu/Al clad materials. Met. Mater. Int. 2016, 22, 849–855. [Google Scholar] [CrossRef]

- Jaradeh, M.M.; Carlberg, T. Solidification studies of 3003 aluminium alloys with Cu and Zr additions. J. Mater. Sci. Technol. 2011, 27, 615–627. [Google Scholar] [CrossRef]

- Chen, X.; Tian, W.; Li, S.; Yu, M.; Liu, J. Effect of temperature on corrosion behavior of 3003 aluminum alloy in ethylene glycol—Water solution. Chin. J. Aeronaut. 2016, 29, 1142–1150. [Google Scholar] [CrossRef]

- Flood, S.C.; Hunt, J.D. Modification of Al-Si eutectic alloys with Na. Met. Sci. 1981, 15, 287–294. [Google Scholar] [CrossRef]

- Shi, W.X.; Gao, B.; Tu, G.F.; Li, S.W. Microstructure and fracture morphology of hypereutectic Al-17.5%Si alloy modified with Nd. Trans. Nonferrous Met. Soc. 2011, 21, 719–726. [Google Scholar]

- Hegde, S.; Prabhu, K.S. Modification of eutectic silicon in Al-Si alloys. J. Mater. Sci. 2008, 43, 3009–3027. [Google Scholar] [CrossRef]

- Jung, K.; Heo, H.; Park, Y.-C.; Kang, C.-Y.; Lee, J.H. Enhanced corrosion resistance of hypo-eutectic Al-1Mg-xSi alloys against molten sodium attack in high temperature sodium sulfur batteries. Corros. Sci. 2015, 98, 748–757. [Google Scholar] [CrossRef]

- Fu, Y.; Jie, J.; Wu, L.; Park, J.; Sun, J.; Kim, J.; Li, T. Microstructure and mechanical properties of Al-1Mn and Al-10Si alloy circular clad ingot prepared by direct chill casting. Mater. Sci. Eng. A 2013, 561, 239–244. [Google Scholar] [CrossRef]

- Liu, N.; Jie, J.; Lu, Y.; Wu, L.; Fu, Y.; Li, T. Characteristics of clad aluminum hollow billet prepared by horizontal continuous casting. J. Mater. Process. Technol. 2014, 214, 60–66. [Google Scholar] [CrossRef]

| Conditions | Extrusion Temp. [K] | Initial Billet Diameter [mm] | Extrusion Die Diameter [mm] | Extrusion Ratio | Half Die Angle [deg.] |

|---|---|---|---|---|---|

| Values | 423 | 100 | 40 | 6.25 | 45 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, J.-K.; Lee, S.-P.; Lee, J.-S.; Lee, S.; Jo, I.; Bae, D.-S. Change of Microstructure and Hardness of Duo-Casted Al3003/Al4004 Clad Material during Extrusion Process. Metals 2020, 10, 1648. https://doi.org/10.3390/met10121648

Lee J-K, Lee S-P, Lee J-S, Lee S, Jo I, Bae D-S. Change of Microstructure and Hardness of Duo-Casted Al3003/Al4004 Clad Material during Extrusion Process. Metals. 2020; 10(12):1648. https://doi.org/10.3390/met10121648

Chicago/Turabian StyleLee, Jin-Kyung, Sang-Pill Lee, Jong-Sup Lee, Sangmok Lee, Ilguk Jo, and Dong-Su Bae. 2020. "Change of Microstructure and Hardness of Duo-Casted Al3003/Al4004 Clad Material during Extrusion Process" Metals 10, no. 12: 1648. https://doi.org/10.3390/met10121648

APA StyleLee, J.-K., Lee, S.-P., Lee, J.-S., Lee, S., Jo, I., & Bae, D.-S. (2020). Change of Microstructure and Hardness of Duo-Casted Al3003/Al4004 Clad Material during Extrusion Process. Metals, 10(12), 1648. https://doi.org/10.3390/met10121648