The Microstructure and Mechanical Properties of Cu-20Ni-20Mn Alloy Fabricated by a Compact Preparation Process

Abstract

1. Introduction

2. Experimental

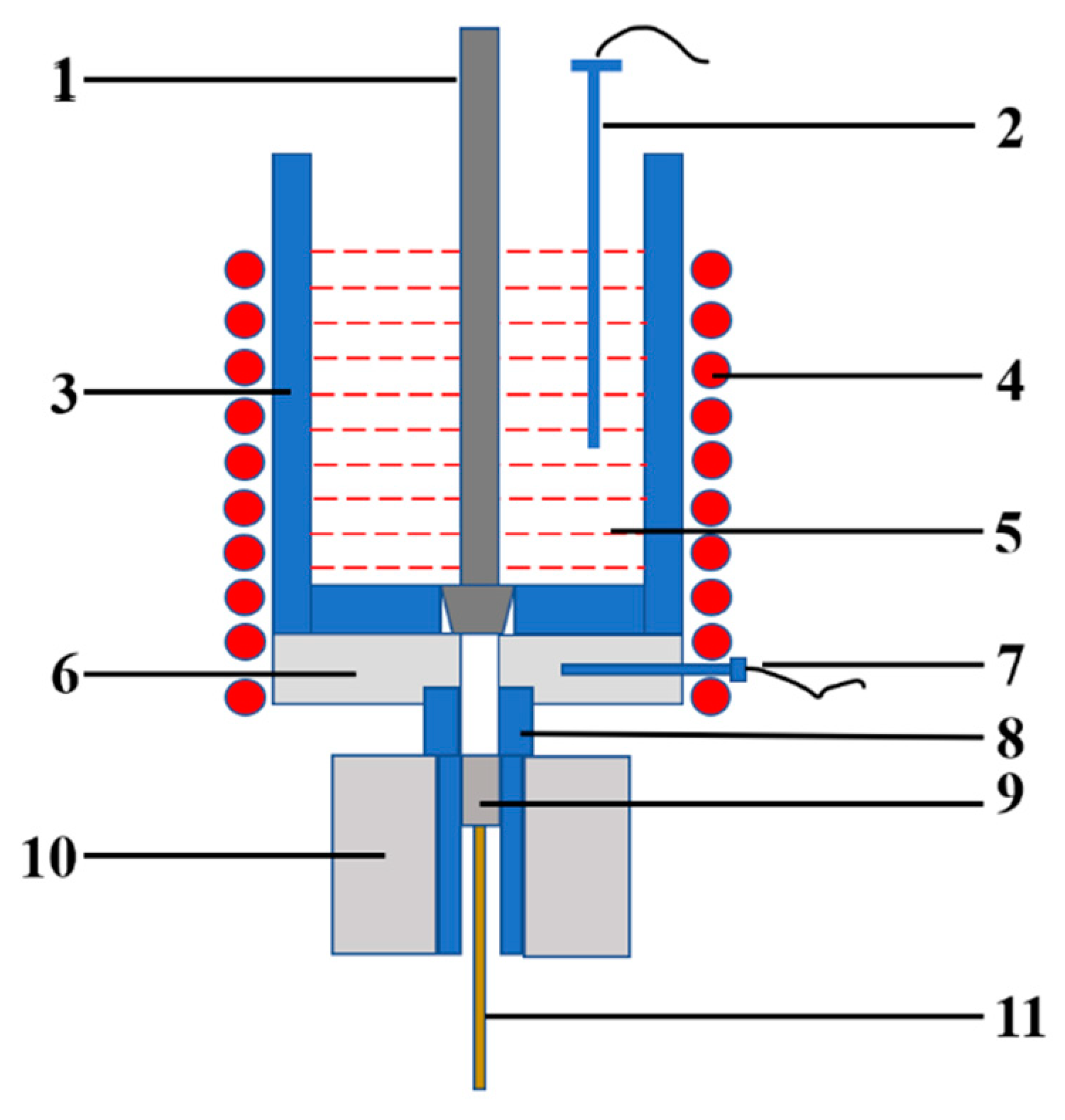

2.1. Material Preparation

2.2. Mechanical Properties

2.3. Microstructure Observations and Analysis

3. Results

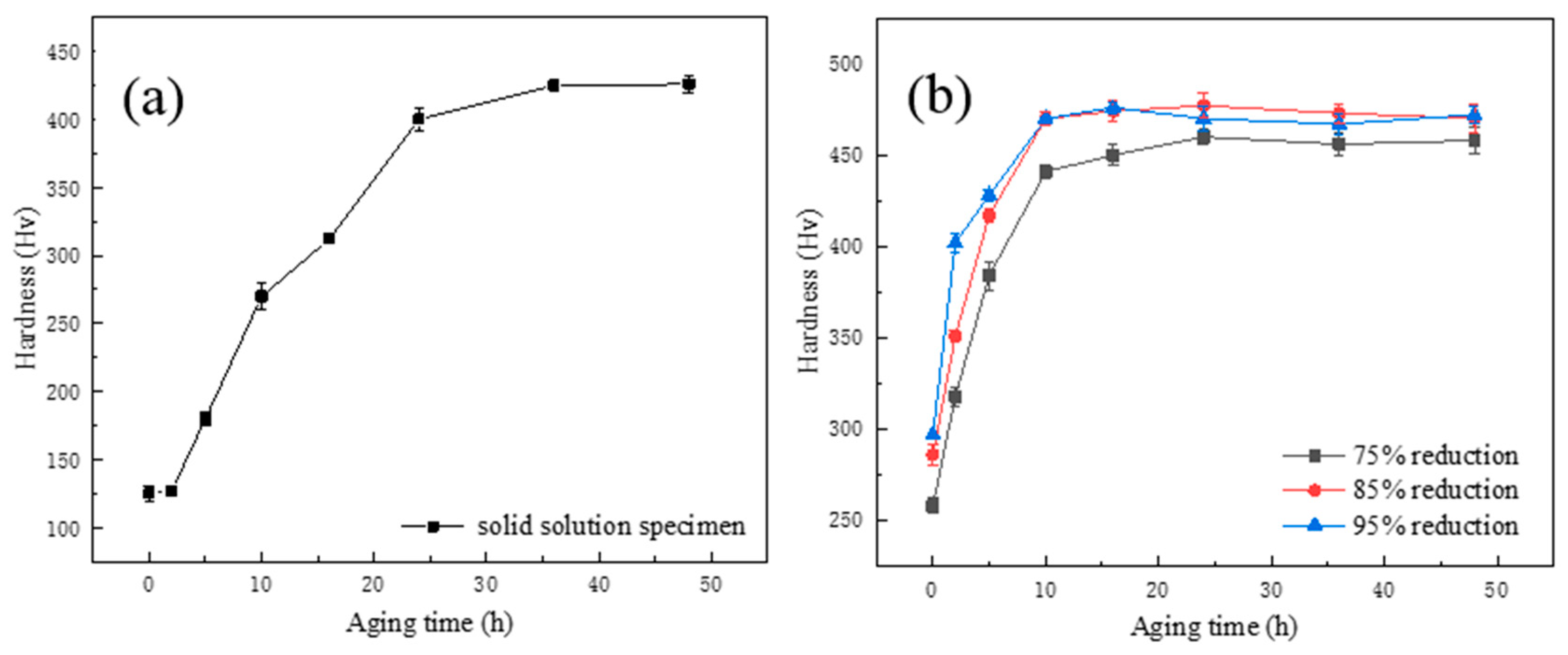

3.1. Variation of the Hardness of the Samples Treated with Different Process

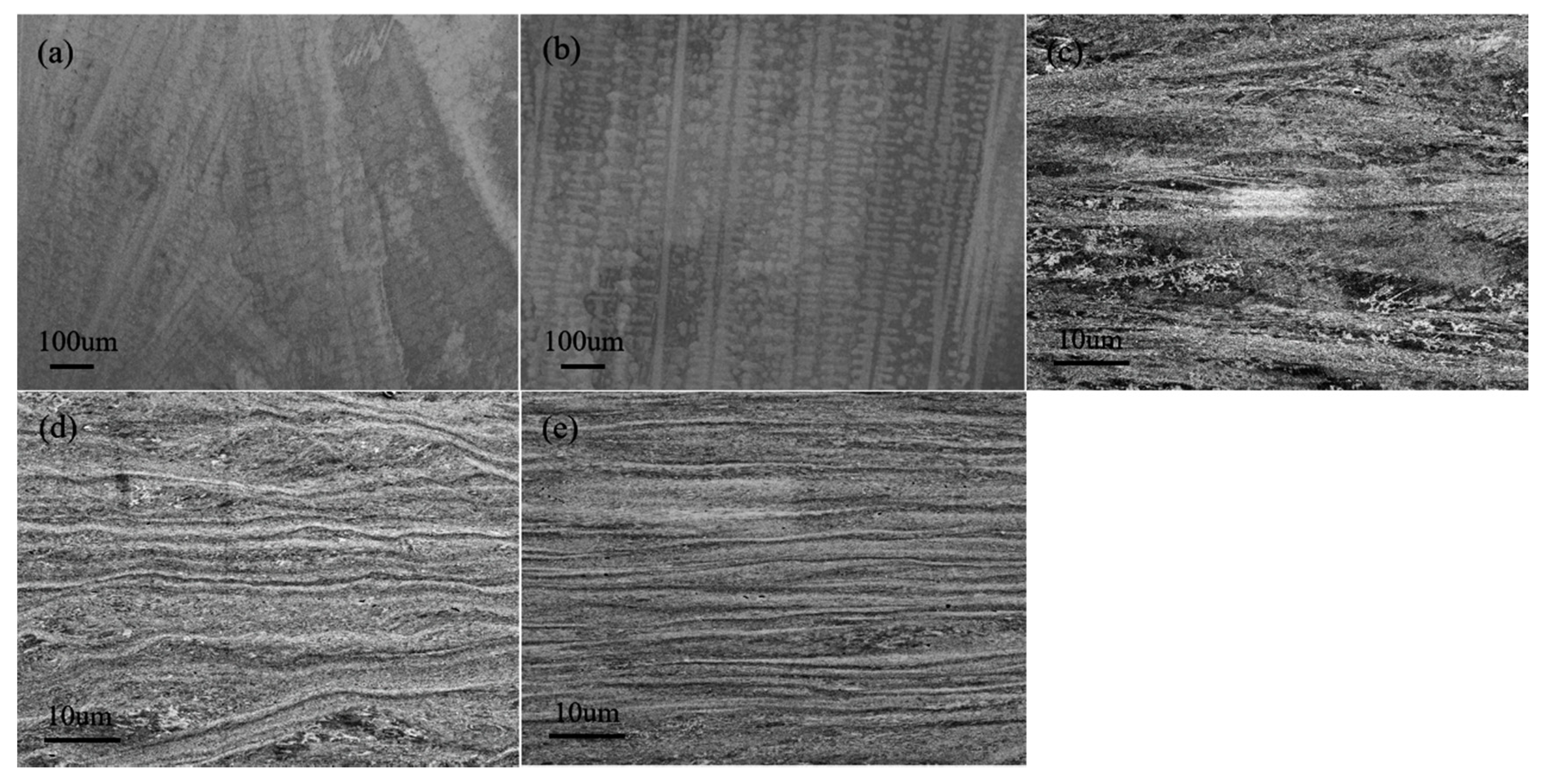

3.2. Microstructure of the Sample Treated with Different Rolling Process

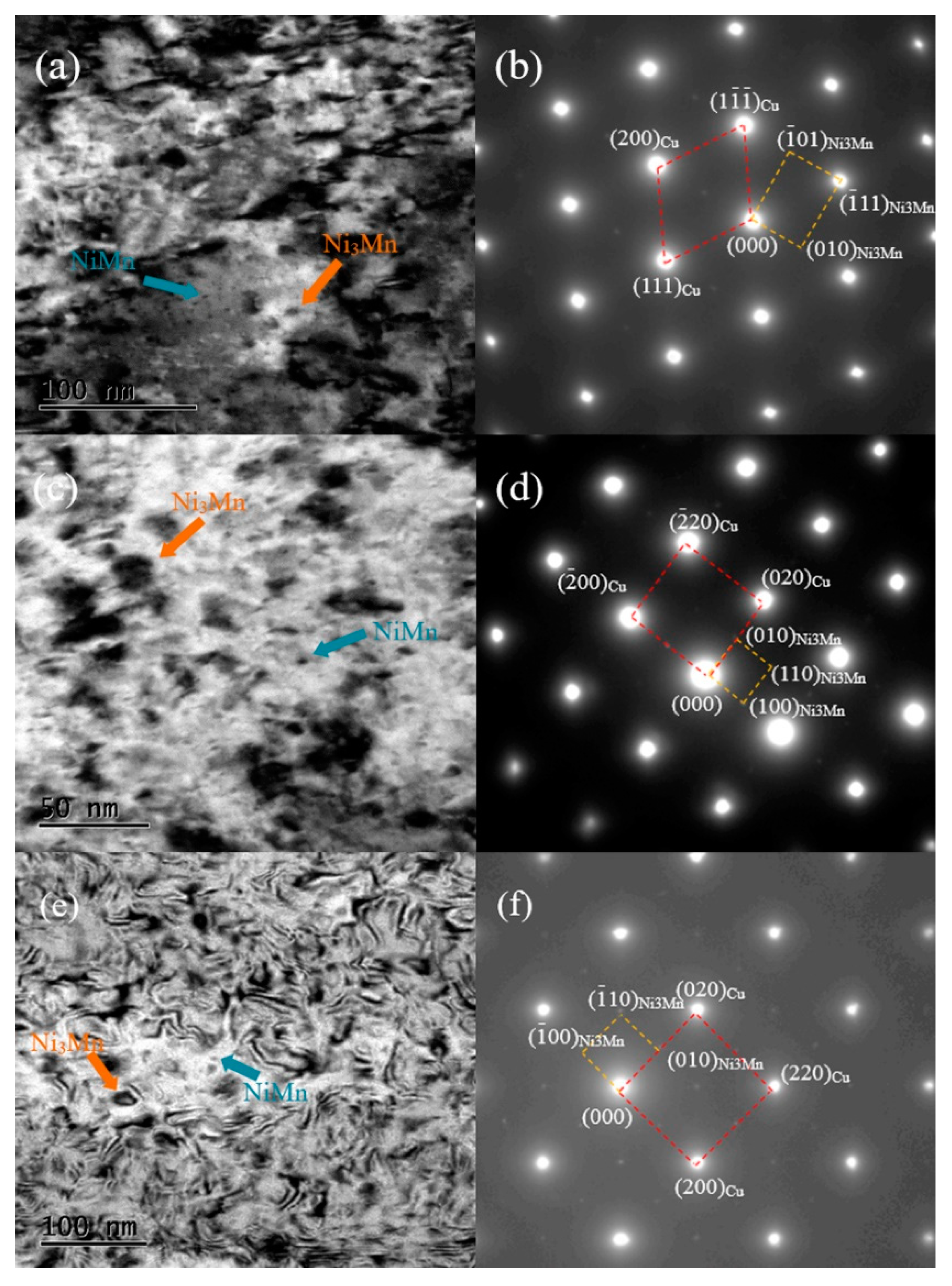

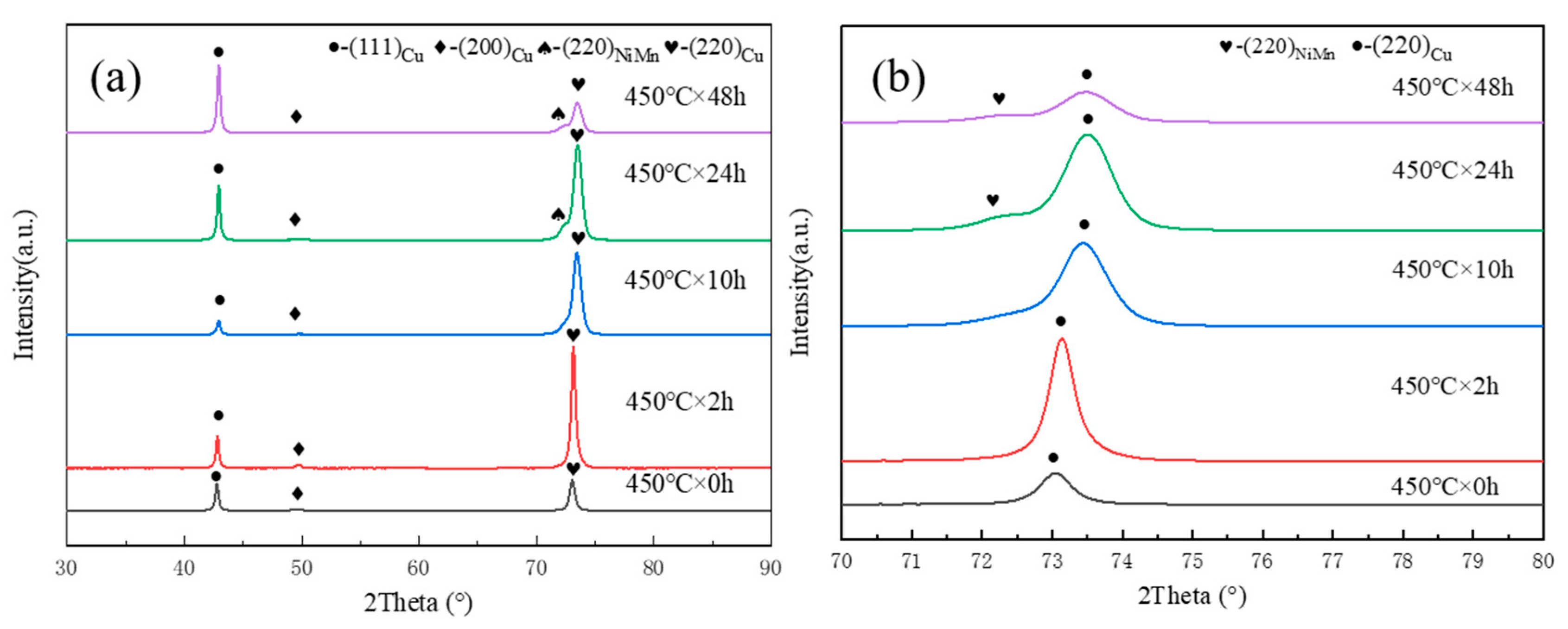

3.3. Microstructure Evolution of the Rolled Sample during Aging Process

4. Discussion

4.1. Strengthening Mechanism of the Alloy during the Ageing Process

4.2. Effect of Rolling Process on Microstructure and Properties of Cu-20Ni-20Mn Alloys

5. Conclusions

- (1)

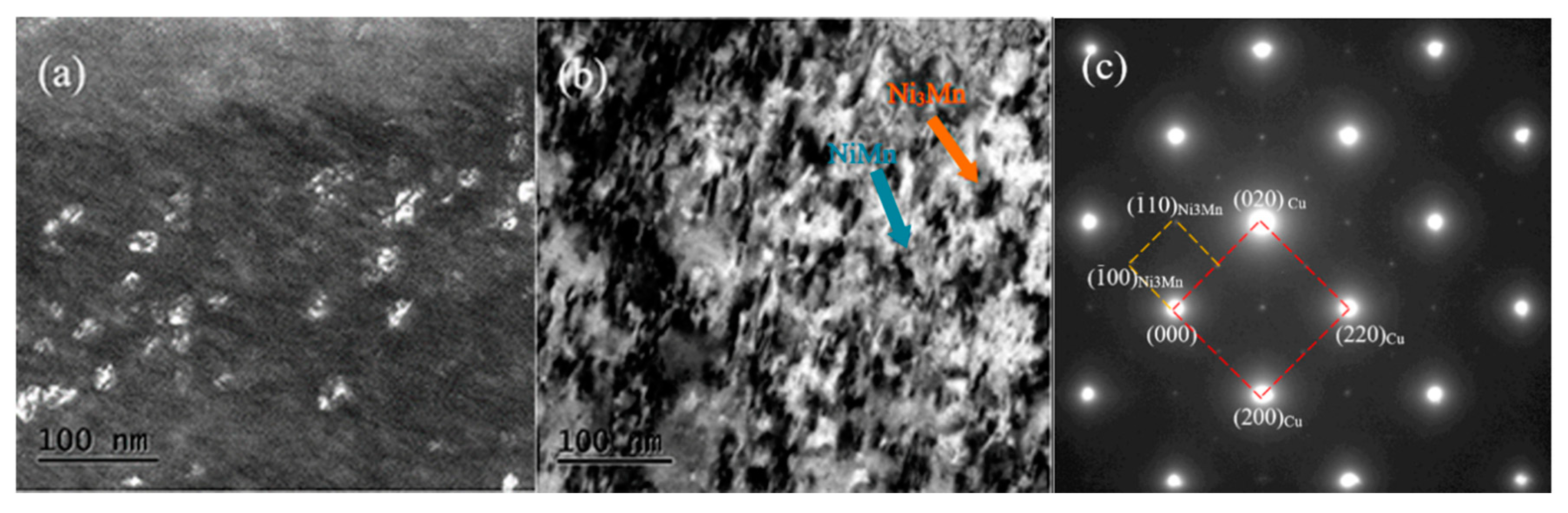

- Two types of precipitates, i.e., NiMn and Ni3Mn, could be observed in the aged sample. The structure of the Ni3Mn phase is face-centred cubic (L structure), with the orientation relationship between the copper matrix and ordered Ni3Mn phase (L phase) is (200)Cu//(010)Ni3Mn and [011]Cu//[011]Ni3Mn.

- (2)

- Precipitation strengthening is the main strengthening mechanism of the ageing process. The cutting mechanism is the main strengthening mechanism of the small NiMn precipitates. The Ni3Mn phase is larger in size, suggesting that the sample will be strengthened by the Ni3Mn precipitates in the form of dislocation bypassing.

- (3)

- The ageing precipitation process and mechanical properties of the alloys are affected by the rolling process. The precipitation rate of the rolled sample is greatly increased during the ageing process. The time required to reach the peak ageing during the ageing process of rolled samples is greatly reduced compared with solid solution samples. The incubation period is not found during the ageing process of the rolled sample, which could be found during the ageing process of the solid solution sample. In addition, more precipitates could be obtained during the ageing process of the rolled sample, which led to the hardness of the rolled sample in the peak ageing state being higher than that of the solid solution state.

Author Contributions

Funding

Conflicts of Interest

References

- Yuan, S.J.; Pehkonen, S.O. Surface characterization and corrosion behavior of 70/30 Cu−Ni alloy in pristine and sulfide-containing simulated seawater. Corros. Sci. 2007, 49, 1276–1304. [Google Scholar] [CrossRef]

- Wu, Y.; Li, Y.; Lu, J.; Tan, S.; Jiang, F.; Sun, J. Correlations between microstructures and properties of Cu-Ni-Si-Cr alloy. Mater. Sci. Eng. A 2018, 731, 403–412. [Google Scholar] [CrossRef]

- Shen, L.; Li, Z.; Zhang, Z.; Dong, Q.; Xiao, Z.; Lei, Q.; Qiu, W. Effects of silicon and thermomechanical process on microstructure and properties of Cu−10Ni−3Al−0.8Si alloy. Mater. Des. 2014, 62, 265–270. [Google Scholar] [CrossRef]

- Liu, J.Z.; Chen, J.H.; Hu, T. The crystallographic and morphological evolution of the strengthening precipitates in Cu-Ni-Si alloys. Acta Mater. 2013, 61, 1210–1219. [Google Scholar]

- Zhang, H.; Jiang, Y.; Xie, J.; Li, Y.; Yue, L. Precipitation behavior, microstructure and properties of aged Cu-1.7 wt% Be alloy. J. Alloy Compd. 2019, 733, 1121–1130. [Google Scholar] [CrossRef]

- Xie, G.; Wang, Q.; Mi, X.; Xiong, B.; Peng, L. The precipitation behavior and strengthening of a Cu-2.0wt% Be alloy. Mater. Sci. Eng. A 2012, 558, 326–330. [Google Scholar]

- Zhou, Y.J.; Song, K.X.; Xing, J.D.; Zhang, Y.M. Precipitation behavior and properties of aged Cu-0.23Be-0.84Co alloy. J. Alloy Compd. 2016, 658, 920–930. [Google Scholar] [CrossRef]

- Xie, W.B.; Wang, Q.S.; Mi, X.J.; Xie, G.L.; Liu, D.M.; Gao, X.C.; Yang, L.I. Microstructure evolution and properties of Cu-20Ni-20Mn alloy during aging process. Trans. Nonferrous Met. Soc. China 2015, 25, 3247–3251. [Google Scholar] [CrossRef]

- Pan, Q.H. The Cu-20Ni-20Mn alloy with high elasticity. Chin. J. Nonferrous Met. 1996, 6, 91–95. [Google Scholar]

- Cai, W.; Wu, Y.; Yin, J.Z.; Wang, G.; Yang, S.L.; Wang, C.X. Effect of Ti on the Structure and Properties of Cu-15Ni-10Mn Alloy As-Cast Smelted at Atmosphere. In Advanced Materials Research; Trans Tech Publications Ltd.: Stafa-Zurich, Switzerland, 2014; Volume 887, pp. 362–365. [Google Scholar]

- Shao, L.; Xie, G.; Liu, X.; Wu, Y.; Yu, J.; Wang, Y. Combustion behaviour and mechanism of a Cu-Ni-Mn alloy in an oxygen enriched atmosphere. Corros. Sci. 2020, 163, 108253. [Google Scholar] [CrossRef]

- Xu, S.Y.; Li, Y.L.; Cai, Z.H.; Ding, H. The current situation and prospect for high−strength and high−elasticity copper alloy. J. Mater. Metall. 2018, 17, 64–69. [Google Scholar]

- Wang, J.; Lei, Y.; Liu, X.H.; Xie, G.L.; Jiang, Y.Q.; Zhang, S. Microstructure and properties of Cu–Al-laminated composites fabricated via formation of a horizontal continuous casting composite. Chin. J. Eng. 2020, 42, 216–224. [Google Scholar]

- Pan, Q.H. Heat treatment process of Cu–Ni–Mn alloy. Heat Treat. Met. 1985, 3, 43–48. [Google Scholar]

- Wang, D.M.; Pan, Q.H. Study on Aging Phase Transformation of Cu-Ni-Mn Alloy. Rare Met. Mater. Eng. 1986, 06, 44–48. [Google Scholar]

- Starink, M.J.; Wang, S.C. A model for the yield strength of overaged Al-Zn-Mg-Cu alloys. Acta Mater. 2003, 51, 5131–5150. [Google Scholar] [CrossRef]

- Zhang, X.; Godfrey, A.; Huang, X.; Hansen, N.; Liu, Q. Microstructure and strengthening mechanisms in cold-drawn pearlitic steel wire. Acta Mater. 2011, 59, 3422–3430. [Google Scholar] [CrossRef]

- Chihiro, W.; Satoshi, T.; Ryoichi, M. Effects of Small Addition of Ti on Strength and Microstructure of a Cu-Ni-Si Alloy. Metall. Mater. Trans. A 2015, 46, 2469–2475. [Google Scholar]

- Labusch, R. A Statistical Theory of Solid Solution Hardening. Phys. Status Solidi 1970, 41, 659–669. [Google Scholar] [CrossRef]

- Balogh, L.; Ungár, T.; Zhao, Y.; Zhu, Y.T.; Horita, Z.; Xu, C.; Langdon, T.G. Influence of stacking-fault energy on microstructural characteristics of ultrafine-grain copper and copper–zinc alloys. Acta Mater. 2008, 46, 471–473. [Google Scholar] [CrossRef]

- Mabuchi, M.; Higashi, K. Strengthening mechanisms of Mg–Si alloys. Acta Mater. 1996, 44, 4611–4618. [Google Scholar] [CrossRef]

- Lee, J.; Jung, J.Y.; Lee, E.S.; Park, W.J.; Ahn, S.; Kim, N.J. Microstructure and properties of titanium boride dispersed Cu alloys fabricated by spray forming. Mater. Sci. Eng. 2000, 277, 274–283. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, R.; Fu, Y.; Xie, G.; Hao, Z.; Zhang, S.; Liu, X. The Microstructure and Mechanical Properties of Cu-20Ni-20Mn Alloy Fabricated by a Compact Preparation Process. Metals 2020, 10, 1528. https://doi.org/10.3390/met10111528

Wang R, Fu Y, Xie G, Hao Z, Zhang S, Liu X. The Microstructure and Mechanical Properties of Cu-20Ni-20Mn Alloy Fabricated by a Compact Preparation Process. Metals. 2020; 10(11):1528. https://doi.org/10.3390/met10111528

Chicago/Turabian StyleWang, Rui, Yilei Fu, Guoliang Xie, Zifan Hao, Shuai Zhang, and Xinhua Liu. 2020. "The Microstructure and Mechanical Properties of Cu-20Ni-20Mn Alloy Fabricated by a Compact Preparation Process" Metals 10, no. 11: 1528. https://doi.org/10.3390/met10111528

APA StyleWang, R., Fu, Y., Xie, G., Hao, Z., Zhang, S., & Liu, X. (2020). The Microstructure and Mechanical Properties of Cu-20Ni-20Mn Alloy Fabricated by a Compact Preparation Process. Metals, 10(11), 1528. https://doi.org/10.3390/met10111528