Effect of Cr Addition on Microstructure and Properties of AuGa Solder

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

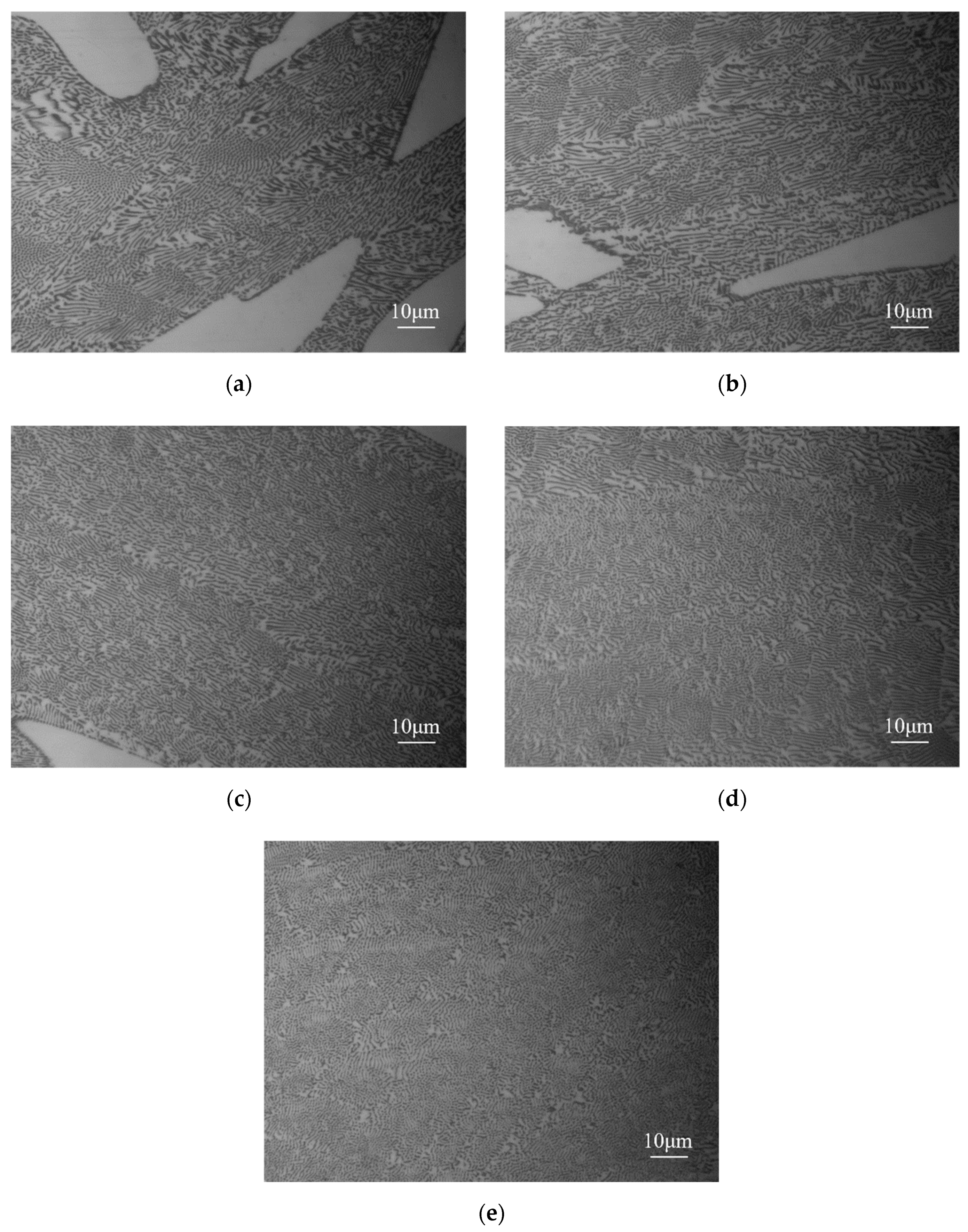

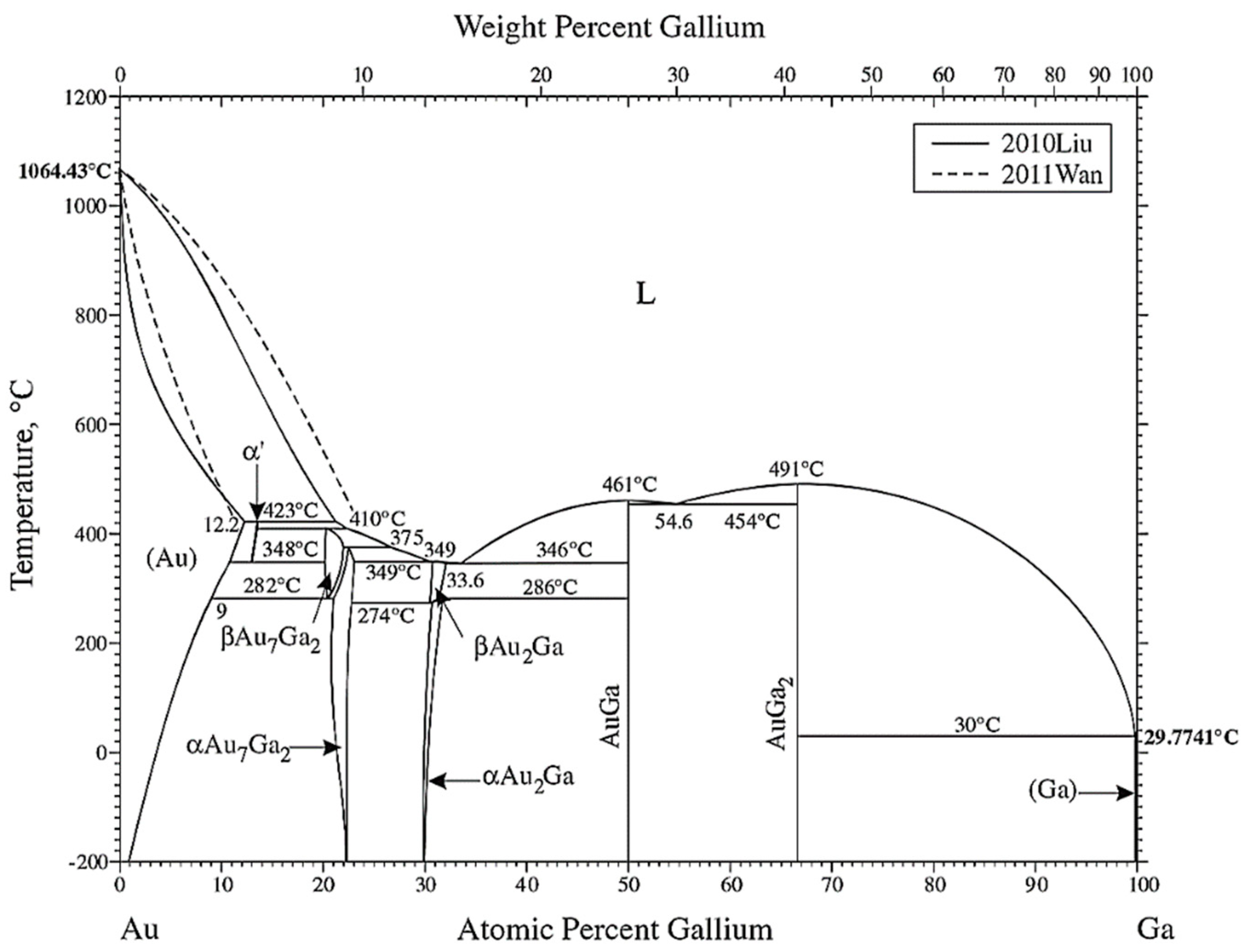

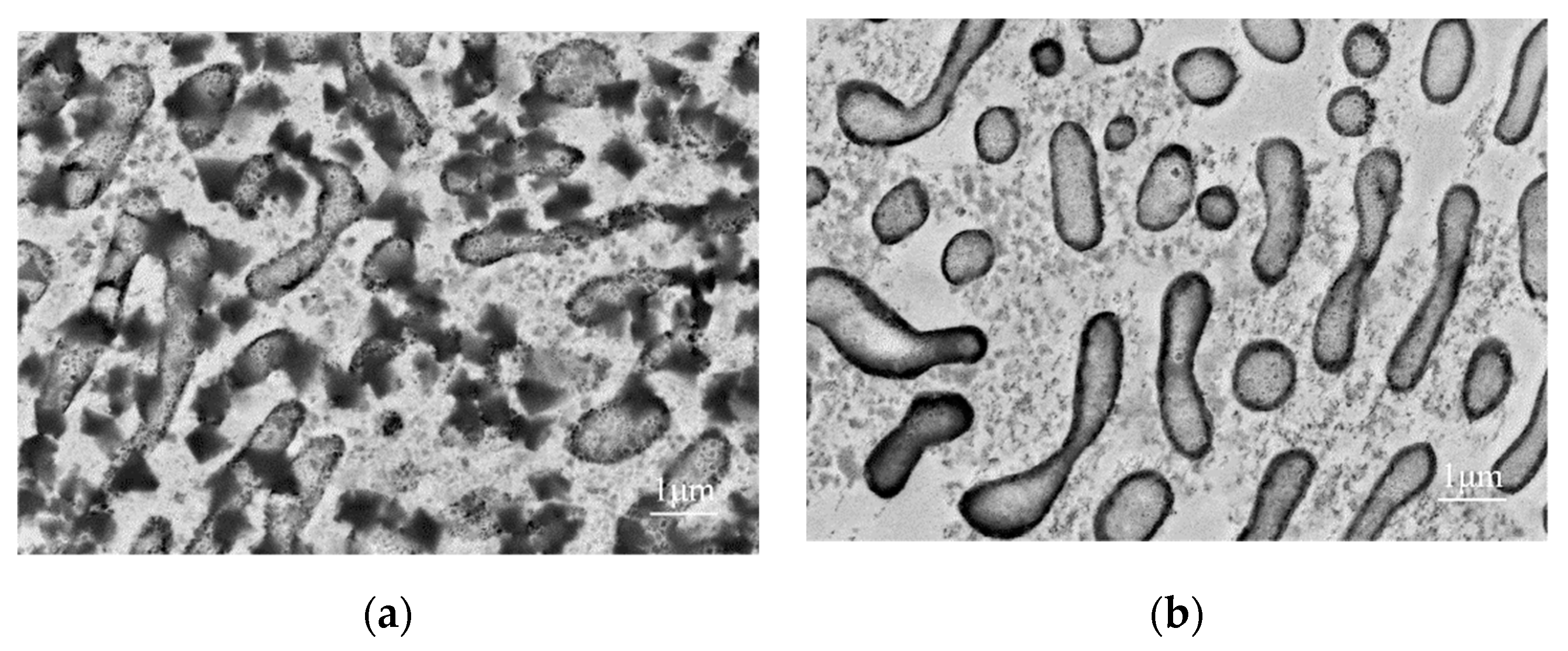

3.1. Effect of Cr on the Matrix Structure of As-Cast Solder

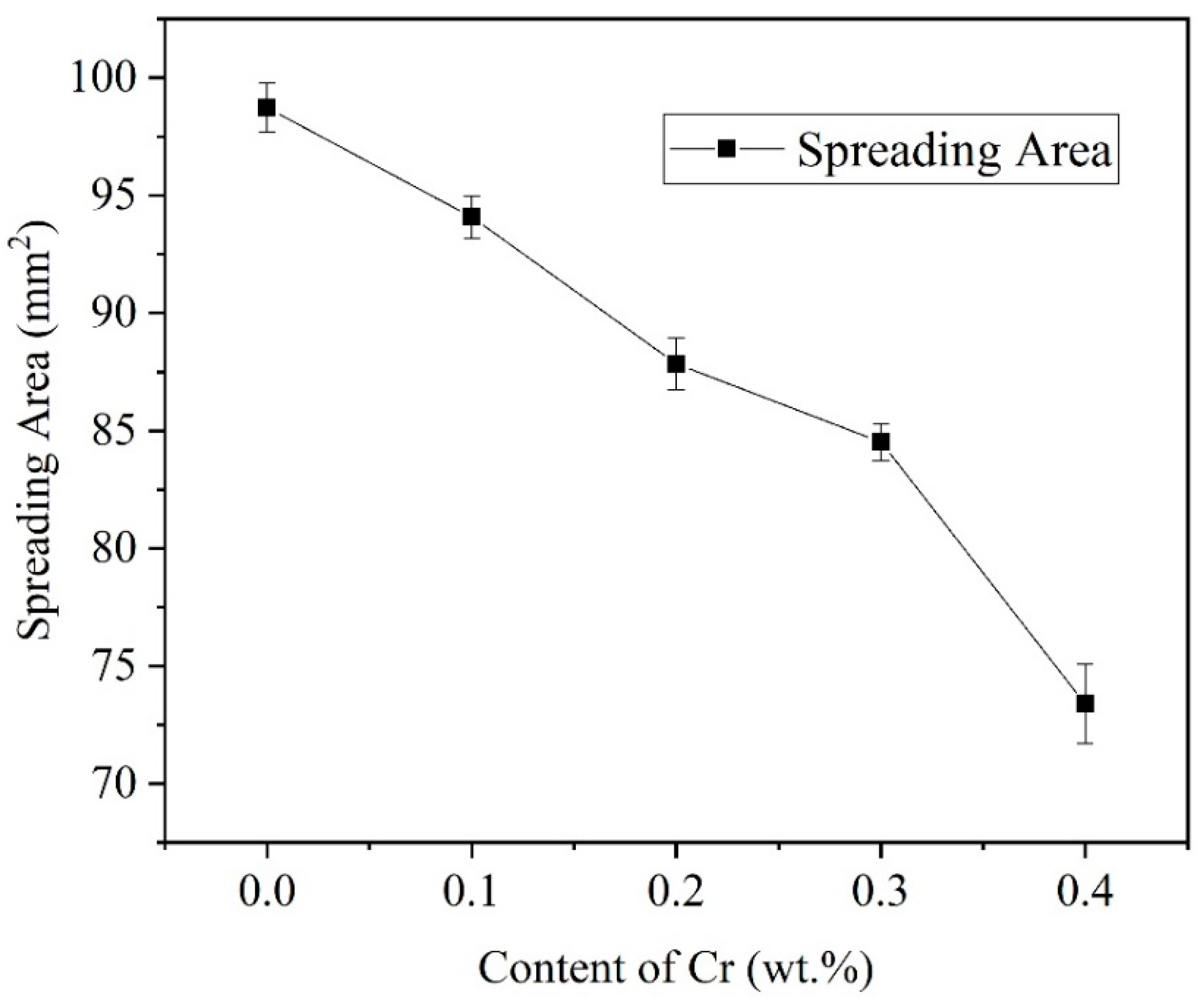

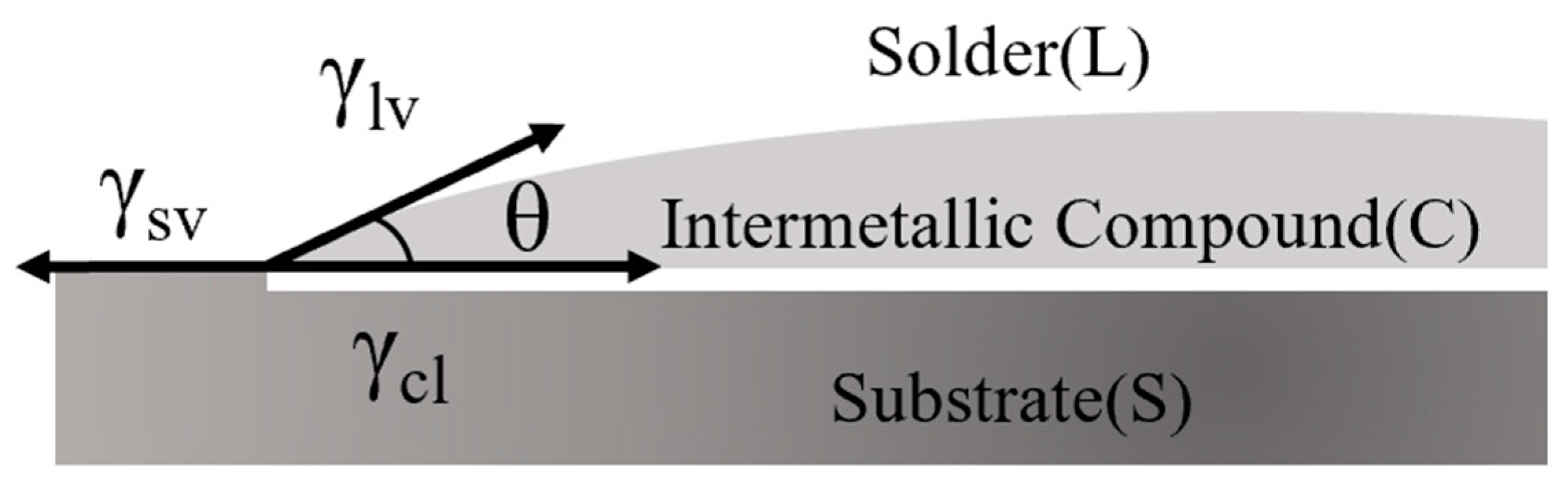

3.2. Effect of Cr Element on Wetting Spreading Performance and Oxidation Resistance of Solder

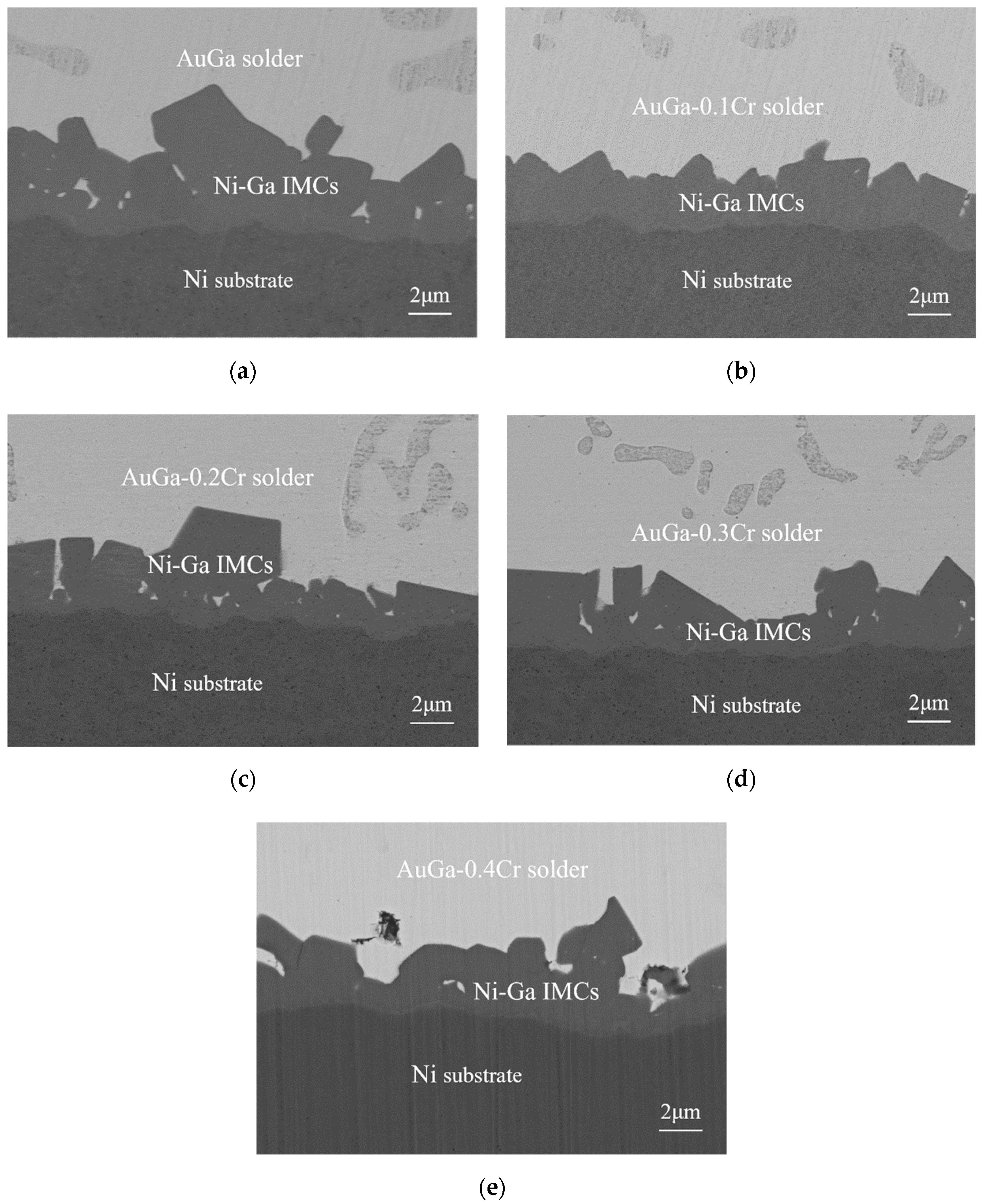

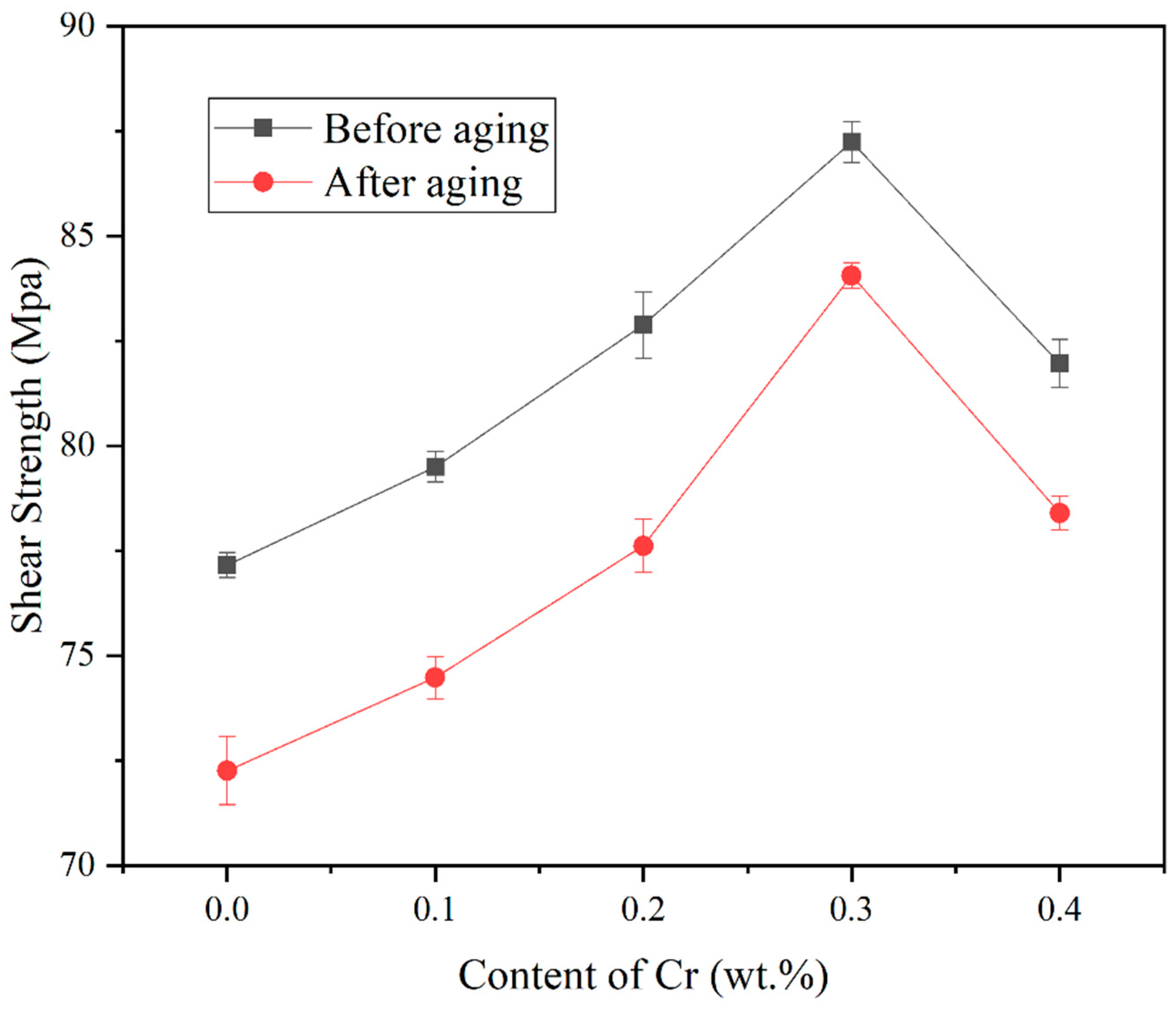

3.3. Effect of Cr Element on Microstructure and Mechanical Properties of Joint Interface

4. Conclusions

- (1)

- The addition of 0.3 wt.% Cr reduced the loss of Ga element in the process of smelting and casting, and effectively improved the uneven composition of the as-cast microstructure of the solder matrix.

- (2)

- Although the spreading area of the solder decreased slightly after adding a trace amount of Cr, it still met the requirements for application and prevented the excessive overflow of solder. Cr was enriched on the surface of the solder and oxidized to form a dense and stable protective film, which enhanced the oxidation resistance of the solder.

- (3)

- The addition of 0.3 wt.% Cr optimized the interface morphology and improved the mechanical properties of the solder joint. The shear strength of the solder joint reached 87.2 MPa, which was 13.1% higher than that of the solder joint without Cr element. After aging at 300 °C for 240 h, the shear strength of the AuGa-0.3Cr joint was still the peak value at 84.1 MPa, which was 16.3% higher than that of the AuGa joint.

Author Contributions

Funding

Conflicts of Interest

References

- Ramli, M.I.I.; Saud, N.; Salleh, M.A.A.M.; Derman, M.N.; Said, R.M. Effect of TiO2 additions on Sn-0.7Cu-0.05Ni lead-free composite solder. Microelectron. Reliab. 2016, 65, 255–264. [Google Scholar] [CrossRef]

- Liu, H.; Xue, S.; Tao, Y.; Long, W.; Zhong, S. Design and solderability characterization of novel Au–30Ga solder for high-temperature packaging. J. Mater. Sci. Mater. Electron. 2020, 31, 2514–2522. [Google Scholar] [CrossRef]

- Chidambaram, V.; Yeung, H.B.; Shan, G. High reliability gold based solder alloys for micro-electronics packaging for high temperature applications. In Proceedings of the 19th IEEE International Symposium on the Physical and Failure Analysis of Integrated Circuits, Singapore, 2–6 July 2012. [Google Scholar]

- Zhao, H.; Liu, J.; Li, Z.; Song, X.; Zhao, Y.; Niu, H.; Tian, H.; Dong, H.; Feng, J. A Comparative Study on the Microstructure and Mechanical Properties of Cu6Sn5 and Cu3Sn Joints Formed by TLP Soldering With/Without the Assistance of Ultrasonic Waves. Metall. Mater. Trans. A 2018, 49, 2739–2749. [Google Scholar] [CrossRef]

- Chin, H.S.; Cheong, K.Y.; Ismail, A.B. A review on die attach materials for SiC-based high-temperature power devices. Metall. Mater. Trans. B 2010, 41, 824–832. [Google Scholar] [CrossRef]

- Xiong, M.; Zhang, L.; Sun, L.; He, P.; Long, W. Effect of CuZnAl particles addition on microstructure of Cu/Sn58Bi/Cu TLP bonding solder joints. Vacuum 2019, 167, 301–306. [Google Scholar] [CrossRef]

- Zhu, W.; Zhang, W.; Zhou, W.; Wu, P. Improved microstructure and mechanical properties for SnBi solder alloy by addition of Cr powders. J. Alloys Compd. 2019, 789, 805–813. [Google Scholar] [CrossRef]

- Bi, J.; Hu, A.; Hu, J.; Luo, T.; Li, M.; Mao, D. Effect of Cr additions on interfacial reaction between the Sn–Zn–Bi solder and Cu/electroplated Ni substrates. Microelectron. Reliab. 2011, 51, 636–641. [Google Scholar] [CrossRef]

- Chen, X.; Hu, A.; Li, M.; Mao, D. Effect of a trace of Cr on intermetallic compound layer for tin–zinc lead-free solder joint during aging. J. Alloys Compd. 2009, 470, 429–433. [Google Scholar] [CrossRef]

- Chen, X.; Li, M.; Ren, X.; Hu, A.; Mao, D. Effect of small additions of alloying elements on the properties of Sn-Zn eutectic alloy. J. Electron. Mater. 2006, 35, 1734–1739. [Google Scholar] [CrossRef]

- Chen, X.; Hu, A.; Li, M.; Mao, D. Study on the properties of Sn–9Zn–xCr lead-free solder. J. Alloys Compd. 2008, 460, 478–484. [Google Scholar] [CrossRef]

- Liu, M.; Yang, W.; Ma, Y.; Tang, C.; Tang, H.; Zhan, Y. The electrochemical corrosion behavior of Pb–free Sn–8.5Zn–xCr solders in 3.5 wt.% NaCl solution. Mater. Chem. Phys. 2015, 168, 27–34. [Google Scholar] [CrossRef]

- Okamoto, H. Au-Ga (Gold-Gallium). J. Phase Equilib. Diffus. 2013, 34, 174–175. [Google Scholar] [CrossRef]

- Gan, G.; Du, C.; Luo, Y.; Chen, F.; Yang, B. Effect of Trace Ni, Al and Cr on the Surface Film Structure of Sn-Pb Liquid Alloys. Adv. Mat. Res. 2011, 217–218, 969–975. [Google Scholar]

- Zhang, S.; Zhu, B.; Zhou, X.; Wang, X.; Lin, T.; He, P.; Paik, K.W. Wettability and interfacial morphology of Sn–3.0 Ag–0.5 Cu solder on electroless nickel plated ZnS transparent ceramic. J. Mater. Sci. Mater. Electron. 2019, 30, 17972–17985. [Google Scholar] [CrossRef]

- Zhang, L.; Xue, S.; Gao, L.; Sheng, Z.; Ye, H.; Xiao, Z.; Zeng, G.; Chen, Y.; Yu, S. Development of Sn–Zn lead-free solders bearing alloying elements. J. Mater. Sci. Mater. Electron. 2010, 21, 1–15. [Google Scholar] [CrossRef]

- Luo, T.; Hu, A.; Hu, J.; Li, M.; Mao, D. Microstructure and mechanical properties of Sn–Zn–Bi–Cr lead-free solder. Microelectron. Reliab. 2012, 52, 585–588. [Google Scholar] [CrossRef]

- Tu, K.N.; Liu, Y. Recent advances on kinetic analysis of solder joint reactions in 3D IC packaging technology. Mater. Sci. Eng. 2019, 136, 1–12. [Google Scholar] [CrossRef]

- Annuar, S.; Mahmoodian, R.; Hamdi, M.; Tu, K.N. Intermetallic compounds in 3D integrated circuits technology: A brief review. Sci. Technol. Adv. Mater. 2017, 18, 693–703. [Google Scholar] [CrossRef] [PubMed]

- Lee, C.; Hsieh, C.; Guo, Y.; Lin, Y.; Zhan, C.; Chang, T. Reliability enhancement of ultra-thin chip assembly module in 3D-ICs integrations by the assistance of molding compounds. In Proceedings of the Microsystems, Packaging, Assembly & Circuits Technology Conference, Taiwan, China, 22–24 October 2014. [Google Scholar]

- Liu, H.; Xue, S.; Tao, Y.; Long, W.; Zhong, S.; Wang, B. Wetting behavior and vacuum soldering of novel Au-30Ga solder on Ni and Cu substrate. Vacuum 2020, 179, 109478. [Google Scholar] [CrossRef]

- Zhang, P.; Xue, S.; Wang, J.; Xue, P.; Long, W. Effect of Nanoparticles Addition on the Microstructure and Properties of Lead-Free Solders: A Review. Appl. Sci. 2019, 9, 2044. [Google Scholar] [CrossRef]

| No. | Au | Ga | Cr |

|---|---|---|---|

| 1 | Bal. | 30 | 0 |

| 2 | Bal. | 30 | 0.1 |

| 3 | Bal. | 30 | 0.2 |

| 4 | Bal. | 30 | 0.3 |

| 5 | Bal. | 30 | 0.4 |

| Phase | Au (at.%) | Ga (at.%) |

|---|---|---|

| the white phase | 54.75 | 45.25 |

| the dark phase | 34.30 | 65.70 |

| Elements | wt.% | at.% |

|---|---|---|

| Ga | 43.95 | 33.38 |

| O | 16.06 | 53.15 |

| Au | 35.70 | 9.06 |

| Ni | 4.29 | 3.87 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tao, Y.; Xue, S.; Liu, H.; Long, W.; Wang, B. Effect of Cr Addition on Microstructure and Properties of AuGa Solder. Metals 2020, 10, 1449. https://doi.org/10.3390/met10111449

Tao Y, Xue S, Liu H, Long W, Wang B. Effect of Cr Addition on Microstructure and Properties of AuGa Solder. Metals. 2020; 10(11):1449. https://doi.org/10.3390/met10111449

Chicago/Turabian StyleTao, Yu, Songbai Xue, Han Liu, Weimin Long, and Bo Wang. 2020. "Effect of Cr Addition on Microstructure and Properties of AuGa Solder" Metals 10, no. 11: 1449. https://doi.org/10.3390/met10111449

APA StyleTao, Y., Xue, S., Liu, H., Long, W., & Wang, B. (2020). Effect of Cr Addition on Microstructure and Properties of AuGa Solder. Metals, 10(11), 1449. https://doi.org/10.3390/met10111449