Use of X-ray Computed Tomography for Assessing Defects in Ti Grade 5 Parts Produced by Laser Melting Deposition

Abstract

1. Introduction

2. Materials and Methods

2.1. LMD Set-Up

2.2. Quantitative Analysis of High Resolution Computed Tomography Scans

3. Results

3.1. Micro-Scale Characterization of Ti6Al4V Metallic Powder

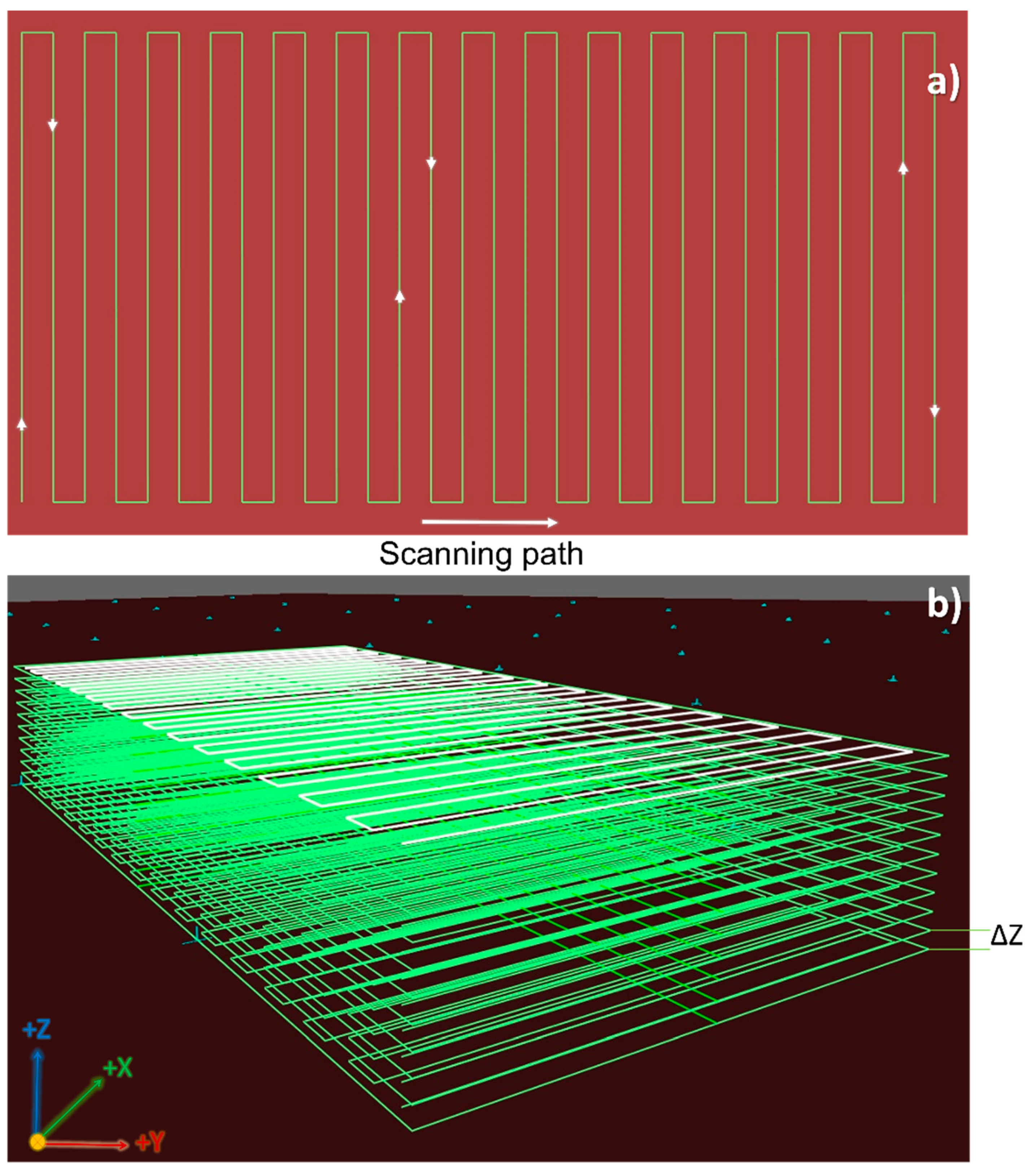

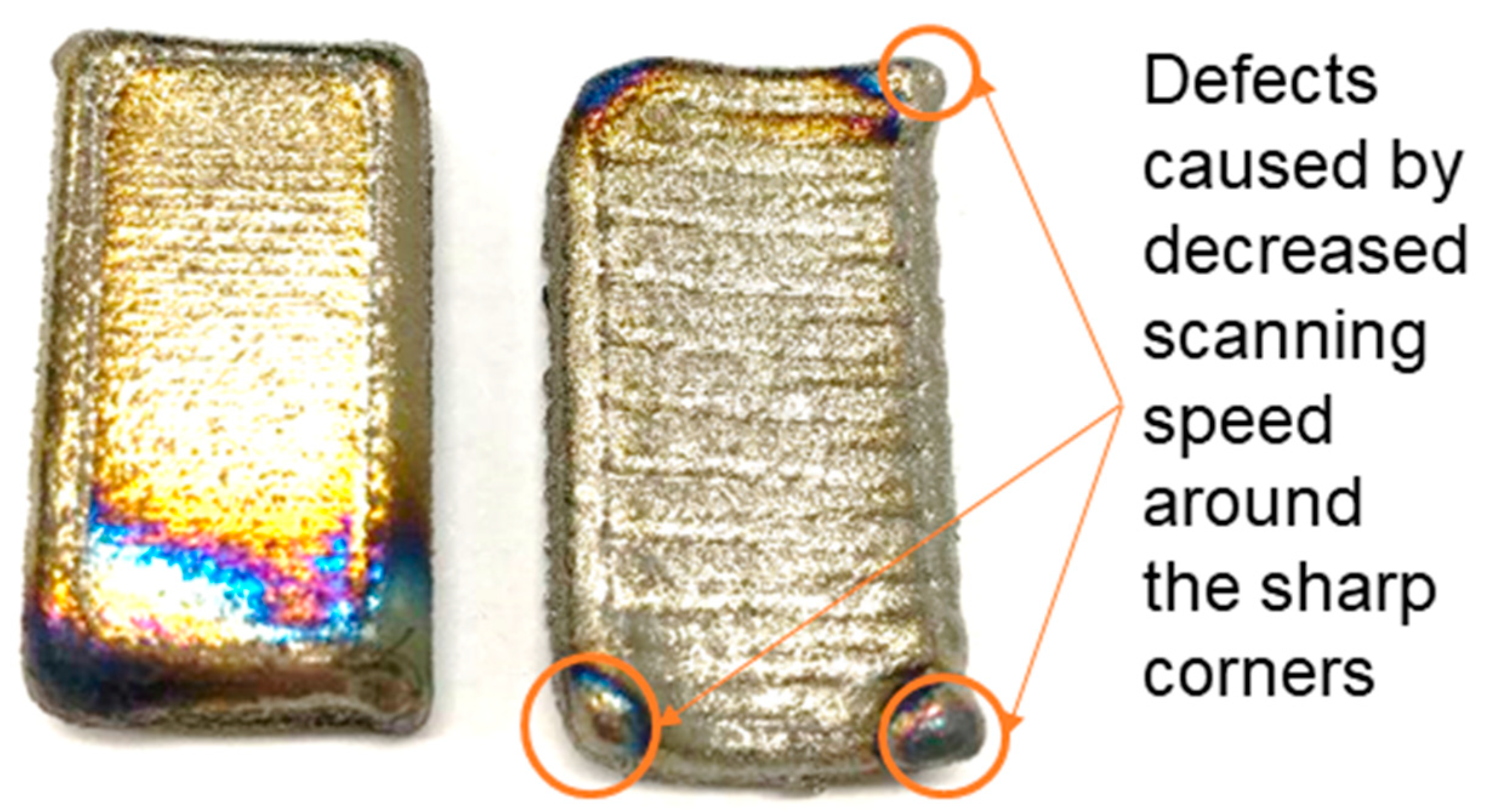

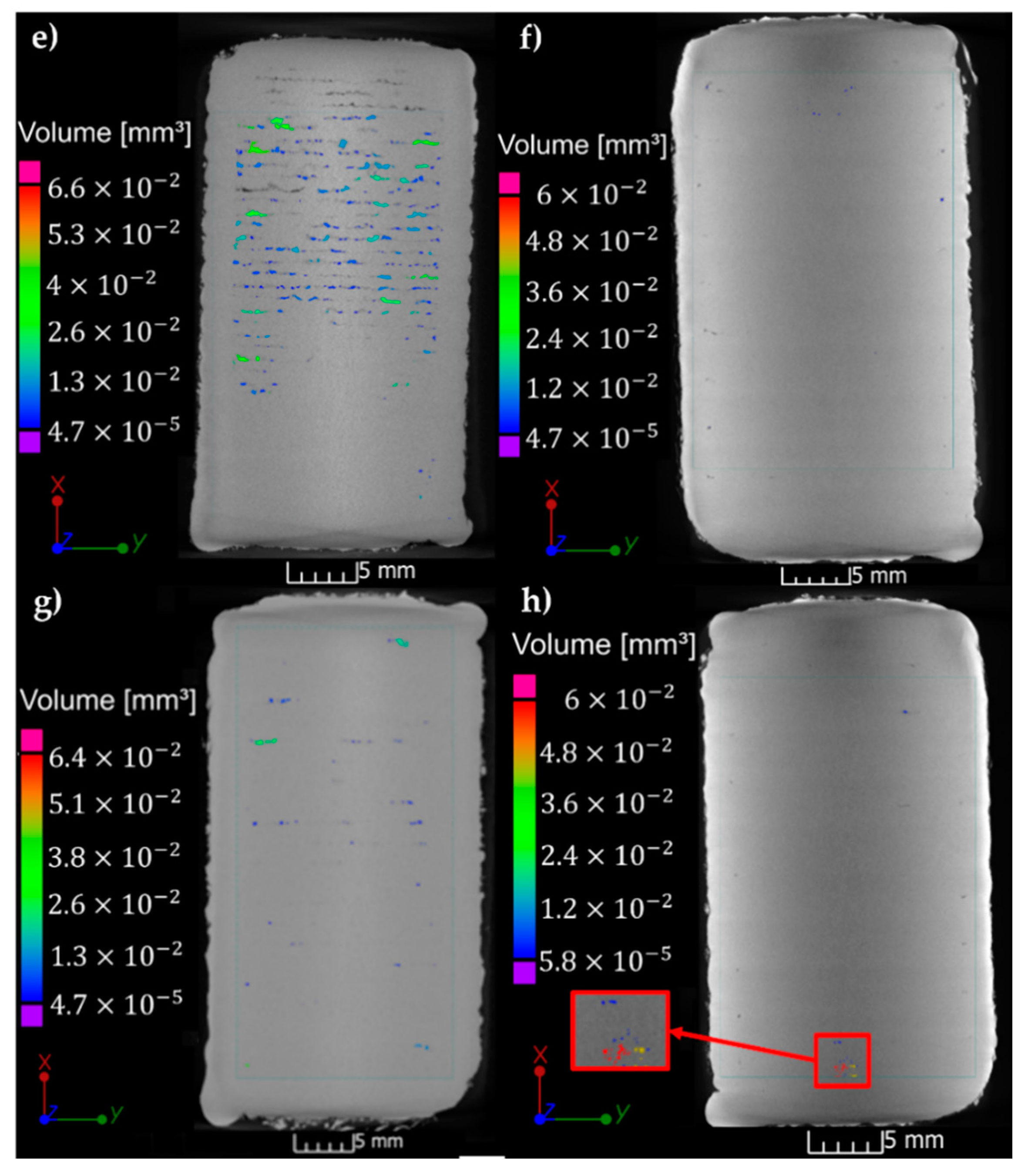

3.2. Scanning Strategy for Porosity Removal

3.3. XCT Examination of The Bulk Samples Manufactured by LMD

4. Discussion

- (a)

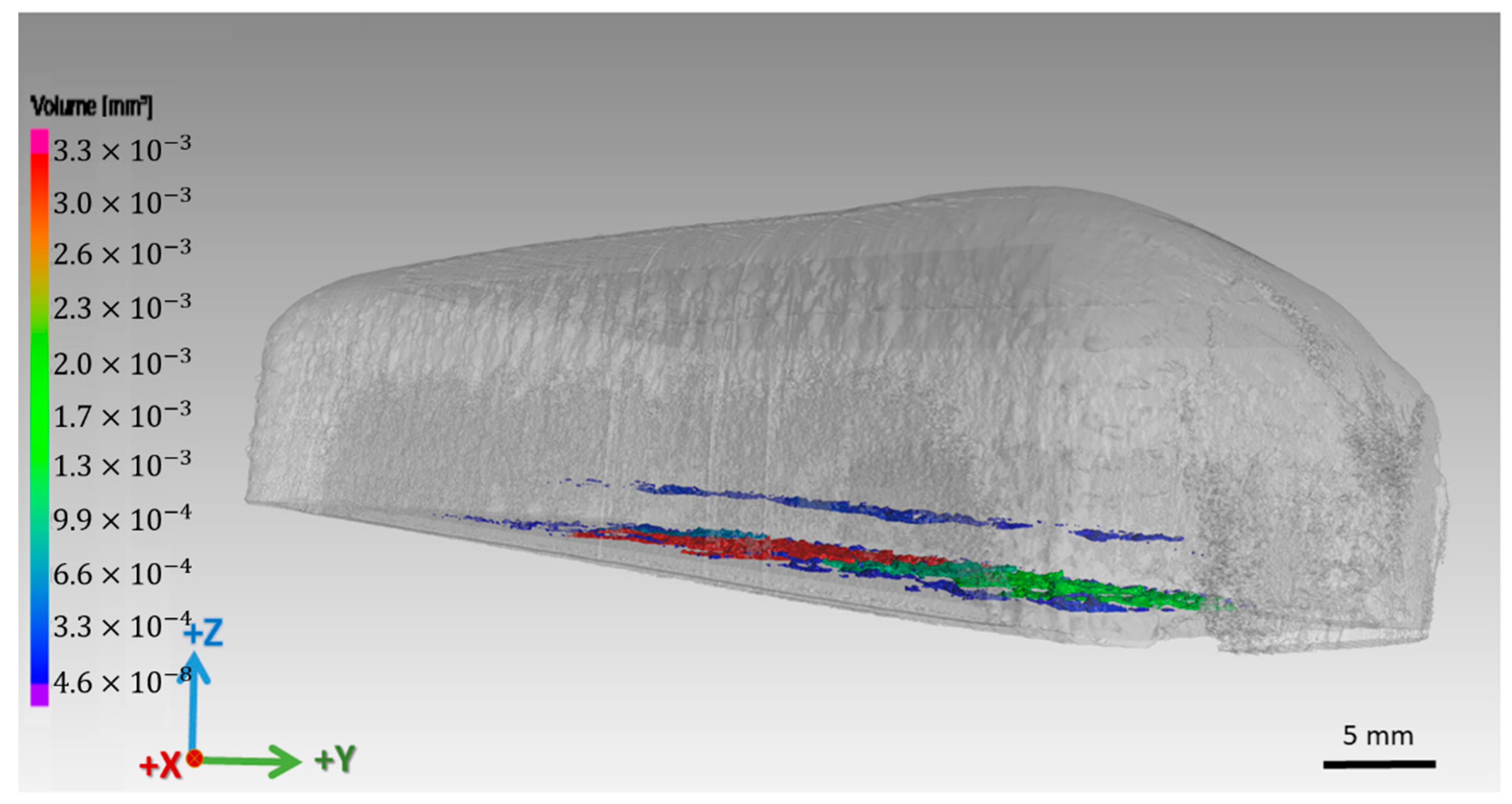

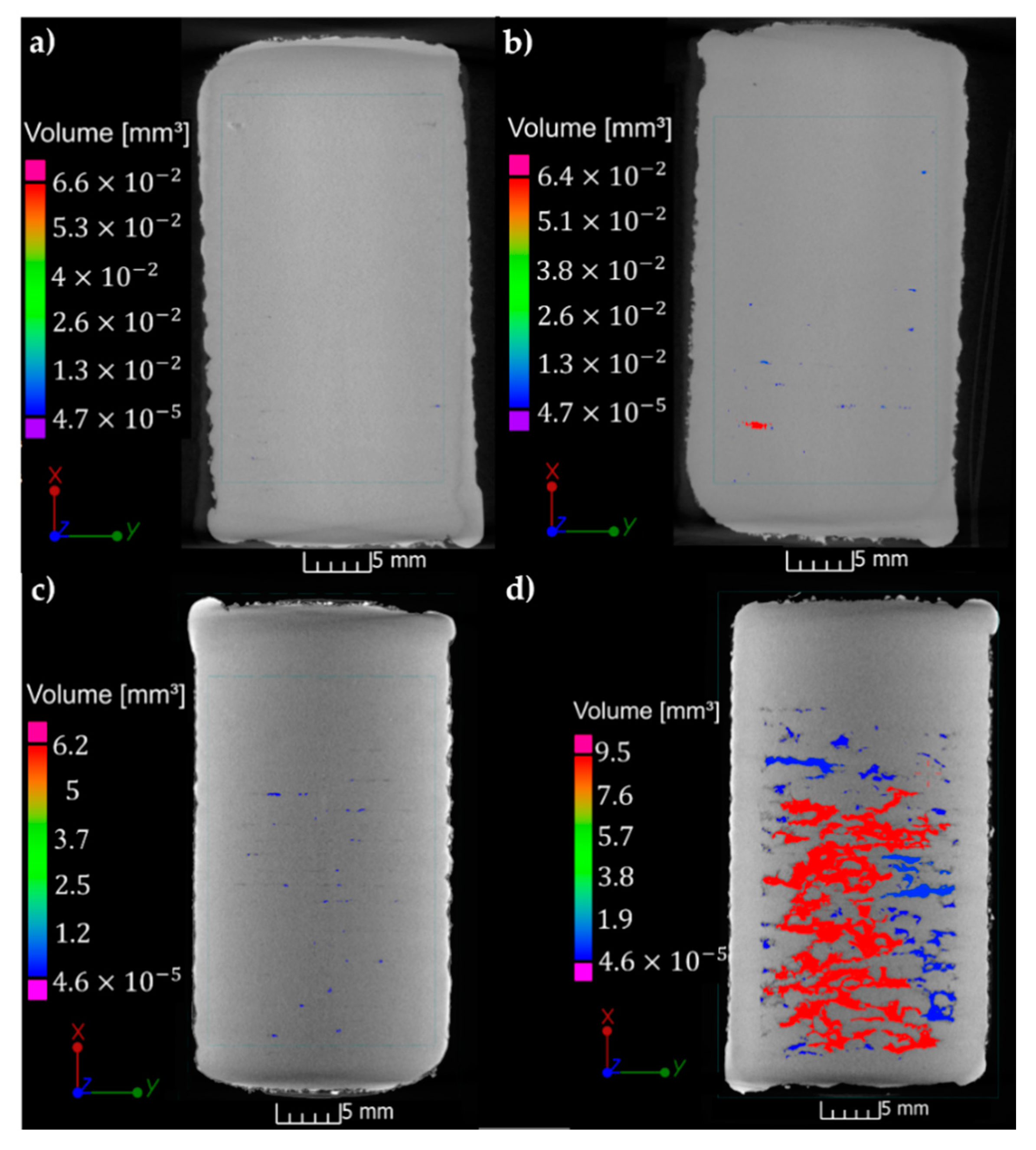

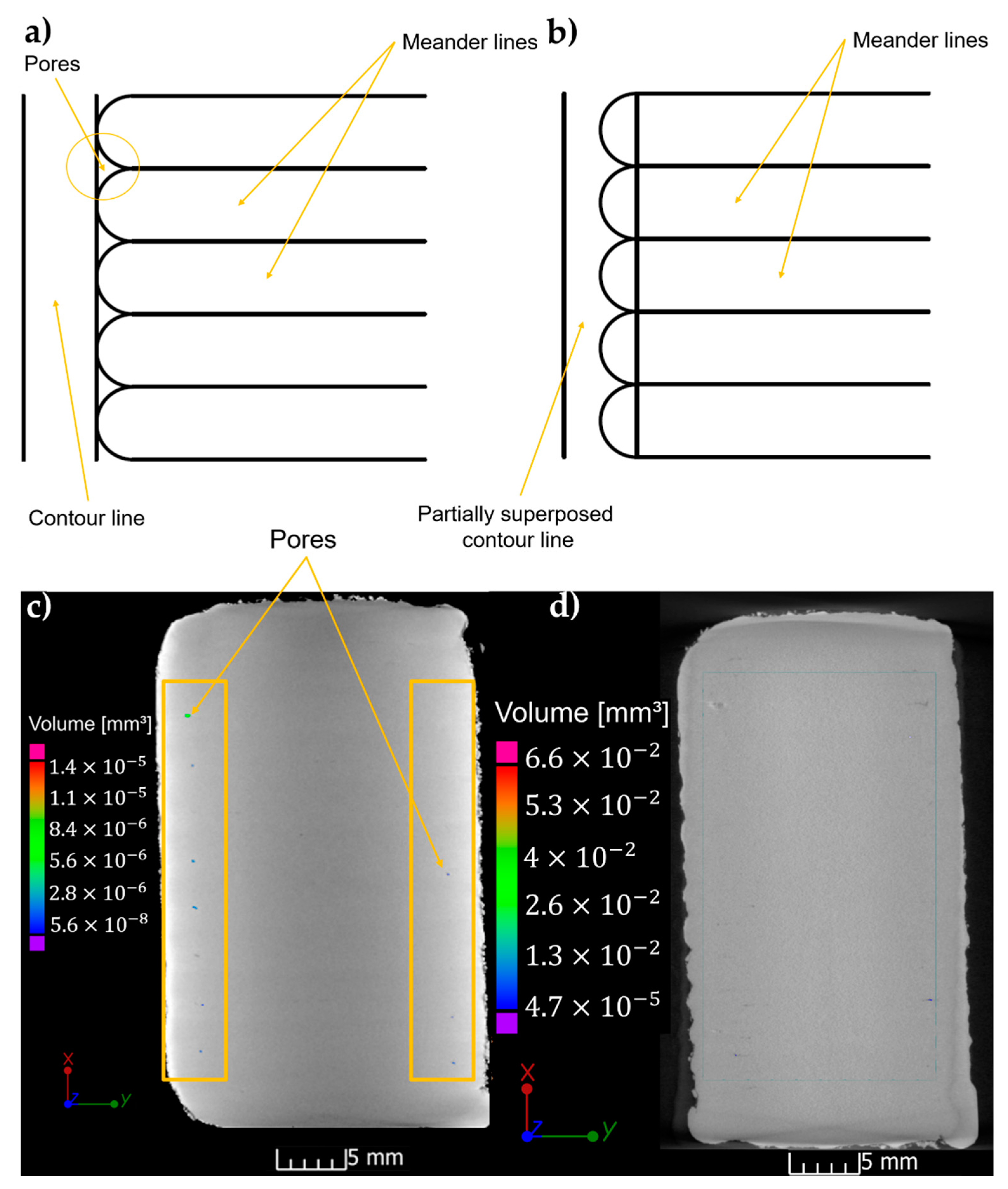

- The pores in the bulk of the material, which are due to the use of a high energy density and slow scanning speed that create local vaporization. During rapid solidification of the material, the gases are trapped into the bulk in form of circular pores. The reason for the pores to be oriented along the laser scanning direction is that the liquid tends to flow oppositely to the laser movement and the gases will be trapped along this direction when the liquid solidifies. The pores can be isolated or they can form a necklace of adjacent voids. In case of high overlaps, the necklace of pores can be remelted and the gases gather in large polyhedral voids. During LMD deposition with high overlaps, real interconnected networks of cavities can be created by successive melting and solidification of material. A relevant example is Figure 7d. Overlaps of 70% or more between the meander lines are therefore not suitable for depositing quality samples by LMD. Apparently, a hatching superposition of 60% or less influence only the built height, but not the quality of the deposition. In our case, overlaps less than 60% between the hatching lines produced samples with very low porosity (0.0002–0.005%). However, the possibility of pores with size less than 13.8 µm should not be ruled out as the XCT cannot identify them.

- (b)

- Pores caused by incomplete seam between the bulk layers and the contour layer. The fact that we use a meander trajectory to deposit our layers leaves at the borders some non-uniformities. The contour layer aims to fix them; however, if it is not superposed over the initial border, some voids can remain after contour solidification. The solution to remove them is to fill them with material by superposing part of the contour line with the border of the meander (Figure 8c).

5. Conclusions

- Two types of pores were identified by XCT: some spherical caused by gases produced by local evaporation and some polyhedral ones caused by lack of superposition between the lines that produced the samples and a supplemental contour line traced or correction of the sample borders.

- The circular pores were affected mainly by the hatch spacing, while the distance between planes had no major effect on the samples’ quality.

- The distance between planes affected the build height in corroboration with the hatch spacing. Distance between planes of 0.5 mm produced samples with height very close to the theoretical one, while increasing the offset between meander planes to 1 mm caused lower heights as compared to the theoretical ones.

- The circular pores were concentrated close to the interface with the substrate. They were aligned along scanning direction forming parallel rows of voids. The larger the hatch spacing the lower the number of pores. By increasing the hatch spacing to 1.5 mm the pores disappeared completely. For a hatch spacing of 0.5 mm we recorded the highest level of porosity of 0.0002%.

- For complete elimination of polyhedral pores from the borders of the samples, the contour line was superposed in various ratio of its thickness. XCT revealed that an overlap of 50% between the contour line and the meander was sufficient to eliminate the pores.

- XCT was an excellent assisting tool during the tuning of the scanning parameters, as it succeeded to provide valuable information on the pores’ arrangement, location, and size for every varied parameter. The alternative analysis would have been cutting of each sample in various locations, polishing and microscopic analysis that could slow the manufacturing process by days or even weeks. The alternative with non-destructive control with ultrasounds is also unreliable due to the lack of visual information.

Author Contributions

Funding

Conflicts of Interest

References

- Herzog, D.; Seyda, V.; Wycisk, E.; Emmelmann, C. Additive manufacturing of metals. Acta Mater. 2016, 117, 371–392. [Google Scholar] [CrossRef]

- Frazier, W.E. Metal additive manufacturing: A review. J. Mater. Eng. Perform. 2014, 23, 1917–1928. [Google Scholar] [CrossRef]

- Zhang, D.; Wang, W.; Guo, Y.; Hu, S.; Dong, D.; Poprawe, R.; Schleifenbaum, J.H.; Ziegler, S. Numerical simulation in the absorption behavior of Ti6Al4V powder materials to laser energy during SLM. J. Mater. Process. Technol. 2019, 268, 25–36. [Google Scholar] [CrossRef]

- Diegel, O.; Nordin, A.; Motte, D. Additive manufacturing technologies. In A Practical Guide to Design for Additive Manufacturing; Springer: Singapore, 2019. [Google Scholar] [CrossRef]

- Galarraga, H.; Warren, R.J.; Lados, D.A.; Dehoff, R.R.; Kirka, M.M.; Nandwana, P. Effects of heat treatments on microstructure and properties of Ti-6Al-4V ELI alloy fabricated by electron beam melting (EBM). Mater. Sci. Eng. A 2017, 685, 417–428. [Google Scholar] [CrossRef]

- Raju, R.; Duraiselvam, M.; Petley, V.; Verma, S.; Rajendran, R. Microstructural and mechanical characterization of Ti6Al4V refurbished parts obtained by laser metal deposition. Mater. Sci. Eng. A 2015, 643, 64–71. [Google Scholar] [CrossRef]

- Kozior, T.; Bochnia, J. The influence of printing orientation on surface texture parameters in powder bed fusion technology with 316L steel. Micromachines 2020, 11, 639. [Google Scholar] [CrossRef] [PubMed]

- Kozior, T.; Bochnia, J.; Zmarzły, P.; Gogolewski, D.; Mathia, T.G. Waviness of Freeform Surface Characterizations from Austenitic Stainless Steel (316L) Manufactured by 3D Printing-Selective Laser Melting (SLM) Technology. Materials 2020, 13, 4372. [Google Scholar] [CrossRef]

- Korsmik, R.S.; Rodionov, A.A.; Korshunov, V.A.; Ponomarev, D.A.; Prosychev, I.S.; Promakhov, V.V. Topological optimization and manufacturing of vessel propeller via LMD-method. Mater. Today Proc. 2020, 1–7. [Google Scholar] [CrossRef]

- Liu, S.; Shin, Y.C. The influences of melting degree of TiC reinforcements on microstructure and mechanical properties of laser direct deposited Ti6Al4V-TiC composites. Mater. Des. 2017, 136, 185–195. [Google Scholar] [CrossRef]

- Liu, S.; Shin, Y.C. Simulation and experimental studies on microstructure evolution of resolidified dendritic TiCx in laser direct deposited Ti-TiC composite. Mater. Des. 2018, 159, 212–223. [Google Scholar] [CrossRef]

- Wilson, J.M.; Shin, Y.C. Microstructure and wear properties of laser-deposited functionally graded Inconel 690 reinforced with TiC. Surf. Coat. Technol. 2012, 207, 517–522. [Google Scholar] [CrossRef]

- Wilson, J.M.; Piya, C.; Shin, Y.C.; Zhao, F.; Ramani, K. Remanufacturing of turbine blades by laser direct deposition with its energy and environmental impact analysis. J. Clean. Prod. 2014, 80, 170–178. [Google Scholar] [CrossRef]

- Thompson, S.M.; Bian, L.; Shamsaei, N.; Yadollahi, A. An overview of Direct Laser Deposition for additive manufacturing; Part I: Transport phenomena, modeling and diagnostics. Addit. Manuf. 2015, 8, 36–62. [Google Scholar] [CrossRef]

- Gasser, A.; Backes, G.; Kelbassa, I.; Weisheit, A.; Wissenbach, K. Laser Metal Deposition (LMD) and Selective Laser Melting (SLM) in Turbo-Engine Applications Laser Additive Manufacturing. Laser Tech. J. 2010, 7, 58–63. [Google Scholar] [CrossRef]

- Petrat, T.; Graf, B.; Gumenyuk, A.; Rethmeier, M. Laser metal deposition as repair technology for a gas turbine burner made of inconel 718. Phys. Procedia 2016, 18, 761–768. [Google Scholar] [CrossRef]

- Kumar, L.J.; Nair, C.G.K. Laser metal deposition repair applications for Inconel 718 alloy. Mater. Today Proc. 2017, 4, 11068–11077. [Google Scholar] [CrossRef]

- Culmone, C.; Smit, G.; Breedveld, P. Additive manufacturing of medical instruments: A state-of-the-art review. Addit. Manuf. 2019, 27, 461–473. [Google Scholar] [CrossRef]

- Everton, S.K.; Hirsch, M.; Stravroulakis, P.; Leach, R.K.; Clare, A.T. Review of in-situ process monitoring and in-situ metrology for metal additive manufacturing. Mater. Des. 2016, 95, 431–445. [Google Scholar] [CrossRef]

- Vaithilingam, J.; Goodridge, R.D.; Hague, R.J.; Christie, S.D.; Edmondson, S. The effect of laser remelting on the surface chemistry of Ti6al4V components fabricated by selective laser melting. J. Mater. Process. Technol. 2016, 232, 1–8. [Google Scholar] [CrossRef]

- Yasa, E.; Deckers, J.; Kruth, J.P. The investigation of the influence of laser re-melting on density, surface quality and microstructure of selective laser melting parts. Rapid Prototyp. J. 2011, 17, 312–327. [Google Scholar] [CrossRef]

- Wang, X.; Xu, S.; Zhou, S.; Xu, W.; Leary, M.; Choong, P.; Qian, M.; Brandt, M.; Xie, Y.M. Topological design and additive manufacturing of porous metals for bone scaffolds and orthopaedic implants: A review. Biomaterials 2016, 83, 127–141. [Google Scholar] [CrossRef] [PubMed]

- Hrabe, N.; Gnäupel-Herold, T.; Quinn, T. Fatigue properties of a titanium alloy (Ti–6Al–4V) fabricated via electron beam melting (EBM): Effects of internal defects and residual stress. Int. J. Fatigue 2017, 94, 202–210. [Google Scholar] [CrossRef]

- Majorell, A.; Srivatsa, S.; Picu, R.C. Mechanical behavior of Ti-6Al-4V at high and moderate temperatures-Part I: Experimental results. Mater. Sci. Eng. A 2002, 326, 297–305. [Google Scholar] [CrossRef]

- Picu, R.C.; Majorell, A. Mechanical behavior of Ti-6Al-4V at high and moderate temperatures-Part II: Constitutive modeling. Mater. Sci. Eng. A 2002, 326, 306–316. [Google Scholar] [CrossRef]

- Kasperovich, G.; Haubrich, J.; Gussone, J.; Requena, G. Correlation between porosity and processing parameters in TiAl6V4 produced by selective laser melting. Mater. Des. 2016, 105, 160–170. [Google Scholar] [CrossRef]

- Shunmugavel, M.; Polishetty, A.; Littlefair, G. Microstructure and Mechanical Properties of Wrought and Additive Manufactured Ti-6Al-4V Cylindrical Bars. Procedia Technol. 2015, 20, 231–236. [Google Scholar] [CrossRef]

- Moiduddin, K.; Mian, S.H.; Alkhalefah, H.; Umer, U. Digital design, analysis and 3D printing of prosthesis scaffolds for mandibular reconstruction. Metals 2019, 9, 569. [Google Scholar] [CrossRef]

- Weißmann, V.; Bader, R.; Hansmann, H.; Laufer, N. Influence of the structural orientation on the mechanical properties of selective laser melted Ti6Al4V open-porous scaffolds. Mater. Des. 2016, 95, 188–197. [Google Scholar] [CrossRef]

- Liu, Q.; Wang, Y.; Zheng, H.; Tang, K.; Ding, L.; Li, H.; Gong, S. Microstructure and mechanical properties of LMD-SLM hybrid forming Ti6Al4V alloy. Mater. Sci. Eng. A 2016, 660, 24–33. [Google Scholar] [CrossRef]

- Sterling, A.J.; Torries, B.; Shamsaei, N.; Thompson, S.M.; Seely, D.W. Fatigue behavior and failure mechanisms of direct laser deposited Ti-6Al-4V. Mater. Sci. Eng. A 2016, 655, 100–112. [Google Scholar] [CrossRef]

- Amsterdam, E.; Kool, G.A. High cycle fatigue of laser beam deposited Ti-6Al-4V and inconel 718. Bridging the gap between theory and operational practice. In Proceedings of the 25th Symposium of the International Committee on Aeronautical Fatigue, Rotterdam, The Netherlands, 27–29 May 2009; pp. 1261–1274. [Google Scholar]

- Keist, J.S.; Palmer, T.A. Role of geometry on properties of additively manufactured Ti-6Al-4V structures fabricated using laser based directed energy deposition. Mater. Des. 2016, 106, 482–494. [Google Scholar] [CrossRef]

- Carroll, B.E.; Palmer, T.A.; Beese, A.M. Anisotropic tensile behavior of Ti-6Al-4V components fabricated with directed energy deposition additive manufacturing. Acta Mater. 2015, 87, 309–320. [Google Scholar] [CrossRef]

- Cunningham, R.; Nicolas, A.; Madsen, J.; Fodran, E.; Anagnostou, E.; Sangid, M.D.; Rollett, A.D. Analyzing the effects of powder and post-processing on porosity and properties of electron beam melted Ti-6Al-4V. Mater. Res. Lett. 2017, 5, 516–525. [Google Scholar] [CrossRef]

- Ahsan, M.N.; Pinkerton, A.J.; Moat, R.J.; Shackleton, J. A comparative study of laser direct metal deposition characteristics using gas and plasma-atomized Ti-6Al-4V powders. Mater. Sci. Eng. A 2011, 528, 7648–7657. [Google Scholar] [CrossRef]

- Liou, F.W. Rapid prototyping processes. In Rapid Prototyping and Engineering Applications; CRC Press: Boka Raton, FL, USA, 2007; Chapter 6; p. 84. [Google Scholar] [CrossRef]

- Bian, L.; Thompson, S.M.; Shamsaei, N. Mechanical Properties and Microstructural Features of Direct Laser-Deposited Ti-6Al-4V. JOM 2015, 67, 629–638. [Google Scholar] [CrossRef]

- Reimers, P.; Goebbels, J. New Possibilities of Nondestructive Evaluation by X-ray Computed Tomography. Mater. Eval. 1983, 41, 732–737, ISSN 0025-5327. [Google Scholar]

- Krztońa, H.; Muchab, J.; Witkowskib, W. The application of laboratory X-ray micro-diffraction to study the effects of clinching process in steel sheets. Acta Phys. Pol. A 2016, 130, 985. [Google Scholar] [CrossRef]

- Gajjar, P.; Styliari, I.D.; Nguyen, T.T.H.; Carr, J.; Chen, X.; Elliott, J.A.; Hammond, R.B.; Burnett, T.L.; Roberts, K.; Withers, P.J.; et al. 3D characterization of dry powder inhaler formulations: Developing X-ray micro computed tomography approaches. Materials 2020, 151, 32–44. [Google Scholar] [CrossRef]

- De Chiffre, L.; Carmignato, S.; Kruth, J.P.; Schmitt, R.; Weckenmann, A. Industrial applications of computed tomography. CIRP Ann. Manuf. Technol. 2014, 63, 655–677. [Google Scholar] [CrossRef]

- Svintsitskiy, D.A.; Yu Kardash, T.; Lazareva, E.V.; Bondareva, V.M. X-ray-induced transformations on the surface of MoVNbTe mixed oxide catalyst: An XPS study. Appl. Surf. Sci. 2021, 535, 147676. [Google Scholar] [CrossRef]

- Chen, L.; Chang, J.; Ding, D.; Feng, H. Preparation, luminescent properties and X-ray imaging result of Lu2O3: Eu structured scintillation film on sapphire substrate by LCVD method. Mater. Lett. 2021, 282, 128689. [Google Scholar] [CrossRef]

- Romano, S.; Abel, A.; Gumpinger, J.; Brandão, A.D.; Beretta, S. Quality control of AlSi10Mg produced by SLM: Metallography versus CT scans for critical defect size assessment. Addit. Manuf. 2019, 28, 394–405. [Google Scholar] [CrossRef]

- Brandt, D.A.; Warner, J.C. Metallurgy Fundamentals: Ferrous and Nonferrous, 6th ed.; Goodheart-Willcox: Tinley Park, IL, USA, 2019; ISBN 10 1635638747. [Google Scholar]

- Chioibasu, D.; Achim, A.; Popescu, C.; Stan, G.E.; Pasuk, I.; Enculescu, M.; Iosub, S.; Duta, L.; Popescu, A. Prototype Orthopedic Bone Plates 3D Printed by Laser Melting Deposition. Materials 2019, 12, 906. [Google Scholar] [CrossRef] [PubMed]

- Tiseanu, I.; Zani, L.; Craciunescu, T.; Cotorobai, F.; Dobrea, C.; Sima, A. Characterization of superconducting wires and cables by X-ray micro-tomography. Fusion Eng. Des. 2013, 1613–1618. [Google Scholar] [CrossRef]

- Tiseanu, I.; Craciunescu, T.; Petrisor, T.; Corte A Della. 3D X-ray micro-tomography for modeling of NB3SN multifilamentary superconducting wires. Fusion Eng. Des. 2007, 82, 1447–1453. [Google Scholar] [CrossRef]

- Du Plessis, A.; Sperling, P.; Beerlink, A.; Tshabalala, L.; Hoosain, S.; Mathe, N.; Le Roux, S.G. Standard method for microCT-based additive manufacturing quality control 1: Porosity analysis. MethodsX 2018, 5, 1102–1110. [Google Scholar] [CrossRef]

- Thakkar, D.; Sahasrabudhe, H. Investigating microstructure and defects evolution in laser deposited single-walled Ti6Al4V structures with sharp and non-sharp features. J. Manuf. Process. 2020, 56, 928–940. [Google Scholar] [CrossRef]

- Li, P.H.; Guo, W.G.; Huang, W.D.; Su, Y.; Lin, X.; Yuan, K.B. Thermomechanical response of 3D laser-deposited Ti-6Al-4V alloy over a wide range of strain rates and temperatures. Mater. Sci. Eng. A 2015, 647, 34–42. [Google Scholar] [CrossRef]

- Zhang, K.; Wang, S.; Liu, W.; Long, R. Effects of substrate preheating on the thin-wall part built by laser metal deposition shaping. Appl. Surf. Sci. 2014, 317, 839–855. [Google Scholar] [CrossRef]

- Liu, S.; Shin, Y.C. Additive manufacturing of Ti6Al4V alloy: A review. Mater. Des. 2019, 164, 107552. [Google Scholar] [CrossRef]

- Kasperovich, G.; Hausmann, J. Improvement of fatigue resistance and ductility of TiAl6V4 processed by selective laser melting. J. Mater. Process. Technol. 2015, 220, 202–214. [Google Scholar] [CrossRef]

- Abdullah, M.F.; Anwar, S.; Al-Ahmari, A. Thermomechanical Simulations of Residual Stresses and Distortion in Electron Beam Melting with Experimental Validation for Ti-6Al-4V. Metals 2020, 10, 1151. [Google Scholar] [CrossRef]

| Process Parameter | Value |

|---|---|

| Laser power | 700 W |

| Scanning speed | 15 mm/s |

| Powder flow rate | 3 gr/min |

| Laser spot size | 800 µm |

| Layer thickness | 2.5 mm |

| Nozzle stand off | 16 mm |

| Ar shielding gas flow rate | 10 L/min |

| He shielding gas flow rate | 3 L/min |

| Sample | Offset between Meander Planes ΔZ [mm] | Hatch Spacing [mm] | Overlap [%] |

|---|---|---|---|

| S1 | 0.5 | 1 | 33 |

| S2 | 0.5 | 1.25 | 20 |

| S3 | 0.5 | 1.5 | 0 |

| S4 | 0.75 | 0.5 | 66 |

| S5 | 0.75 | 0.75 | 50 |

| S6 | 1 | 1 | 33 |

| S7 | 1 | 1.25 | 20 |

| S8 | 1 | 1.5 | 0 |

| Parameter | Powder | Bulk |

|---|---|---|

| Voltage [kV] | 90 | 110 |

| Current [µA] | 110 | 250 |

| Acquired projections | 2400 | 1800 |

| Rotation step [°] | 0.15 | 0.2 |

| Beam width [µm] | 1.5 | 13.8 |

| Magnification | 130 | 40 |

| Sample | Experimental Height [mm] | Theoretical Height [mm] | Error [%] |

|---|---|---|---|

| S1 | 8.69 ± 0.3 | 5 | 74 |

| S2 | 6.42 ± 0.1 | 5 | 28 |

| S3 | 5.96 ± 0.05 | 5 | 19 |

| S4 | 12.32 ± 0.15 | 7.5 | 64 |

| S5 | 11.39 ± 0.05 | 7.5 | 52 |

| S6 | 8.98 ± 0.01 | 10 | 10 |

| S7 | 5.89 ± 0.05 | 10 | 41 |

| S8 | 5.48 ± 0.02 | 10 | 45 |

| Sample No. | S1 | S2 | S3 | S4 | S5 | S6 | S7 | S8 |

|---|---|---|---|---|---|---|---|---|

| Volume analyzed [mm3] | 1500 | 1500 | 1400 | 2400 | 2200 | 1200 | 1800 | 1700 |

| Defect volume [mm3] | 0.0037 | 0.66 | 0.073 | 13 | 2.5 | 0.87 | 1.3 | 0.21 |

| Porosity percentage [%] | 0.00024 | 0.044 | 0.0052 | 0.54 | 0.12 | 0.0725 | 0.072 | 0.012 |

| Slice Position relative to substrate interface [mm] | 1.64 | 2.04 | 2.51 | 1.66 | 2.24 | 1.64 | 2.04 | 2.77 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chioibasu, D.; Mihai, S.; Mahmood, M.A.; Lungu, M.; Porosnicu, I.; Sima, A.; Dobrea, C.; Tiseanu, I.; Popescu, A.C. Use of X-ray Computed Tomography for Assessing Defects in Ti Grade 5 Parts Produced by Laser Melting Deposition. Metals 2020, 10, 1408. https://doi.org/10.3390/met10111408

Chioibasu D, Mihai S, Mahmood MA, Lungu M, Porosnicu I, Sima A, Dobrea C, Tiseanu I, Popescu AC. Use of X-ray Computed Tomography for Assessing Defects in Ti Grade 5 Parts Produced by Laser Melting Deposition. Metals. 2020; 10(11):1408. https://doi.org/10.3390/met10111408

Chicago/Turabian StyleChioibasu, Diana, Sabin Mihai, Muhammad Arif Mahmood, Mihail Lungu, Ioana Porosnicu, Adrian Sima, Cosmin Dobrea, Ion Tiseanu, and Andrei C. Popescu. 2020. "Use of X-ray Computed Tomography for Assessing Defects in Ti Grade 5 Parts Produced by Laser Melting Deposition" Metals 10, no. 11: 1408. https://doi.org/10.3390/met10111408

APA StyleChioibasu, D., Mihai, S., Mahmood, M. A., Lungu, M., Porosnicu, I., Sima, A., Dobrea, C., Tiseanu, I., & Popescu, A. C. (2020). Use of X-ray Computed Tomography for Assessing Defects in Ti Grade 5 Parts Produced by Laser Melting Deposition. Metals, 10(11), 1408. https://doi.org/10.3390/met10111408