A New Approach for Obtaining the Compression Behavior of Anisotropic Sheet Metals Applicable to a Wide Range of Test Conditions

Abstract

:1. Introduction

2. Materials and Methods

2.1. Development of the Experimental Methodology for Hot Compression Tests

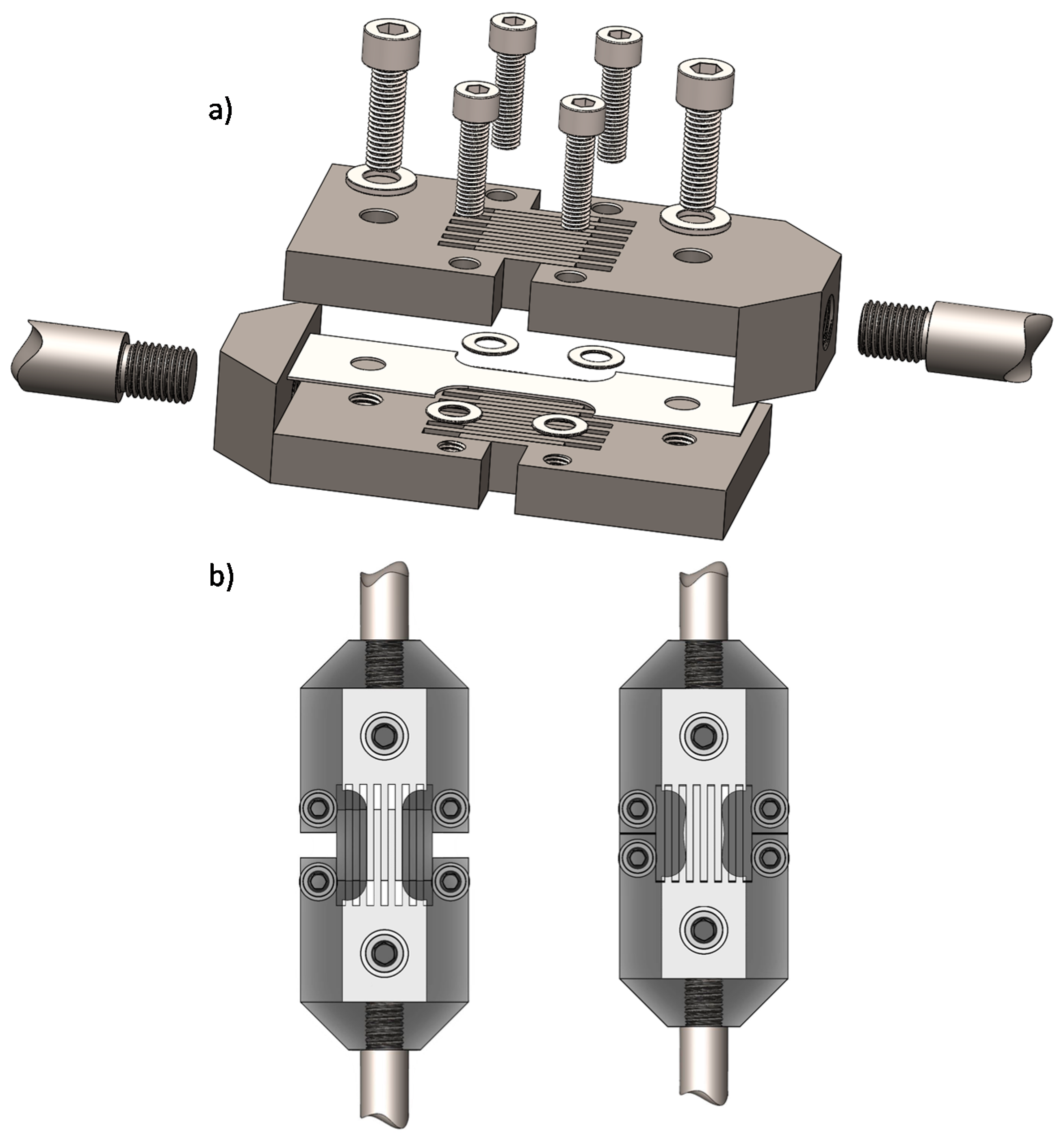

2.1.1. Description of Tools and Test System

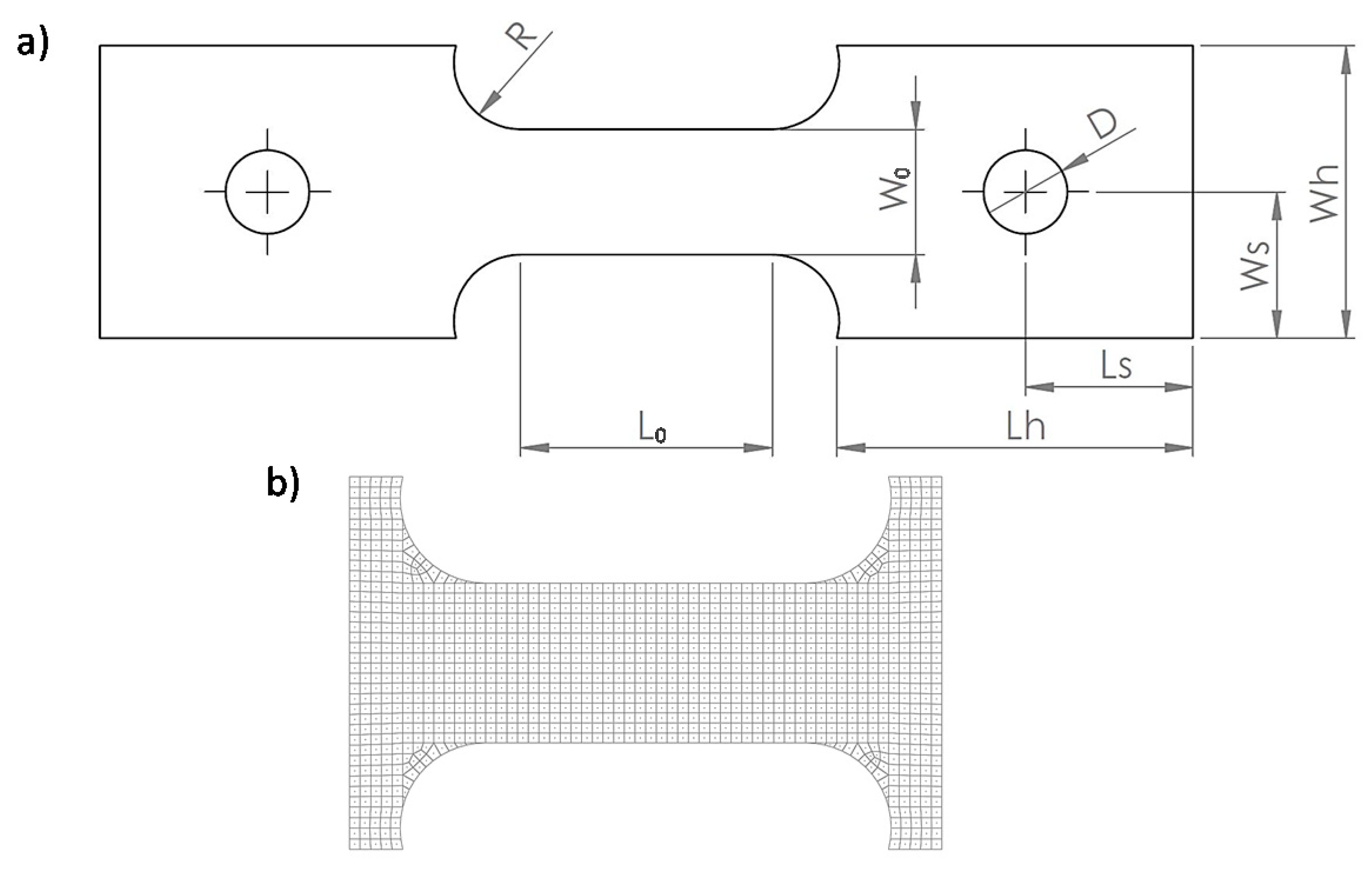

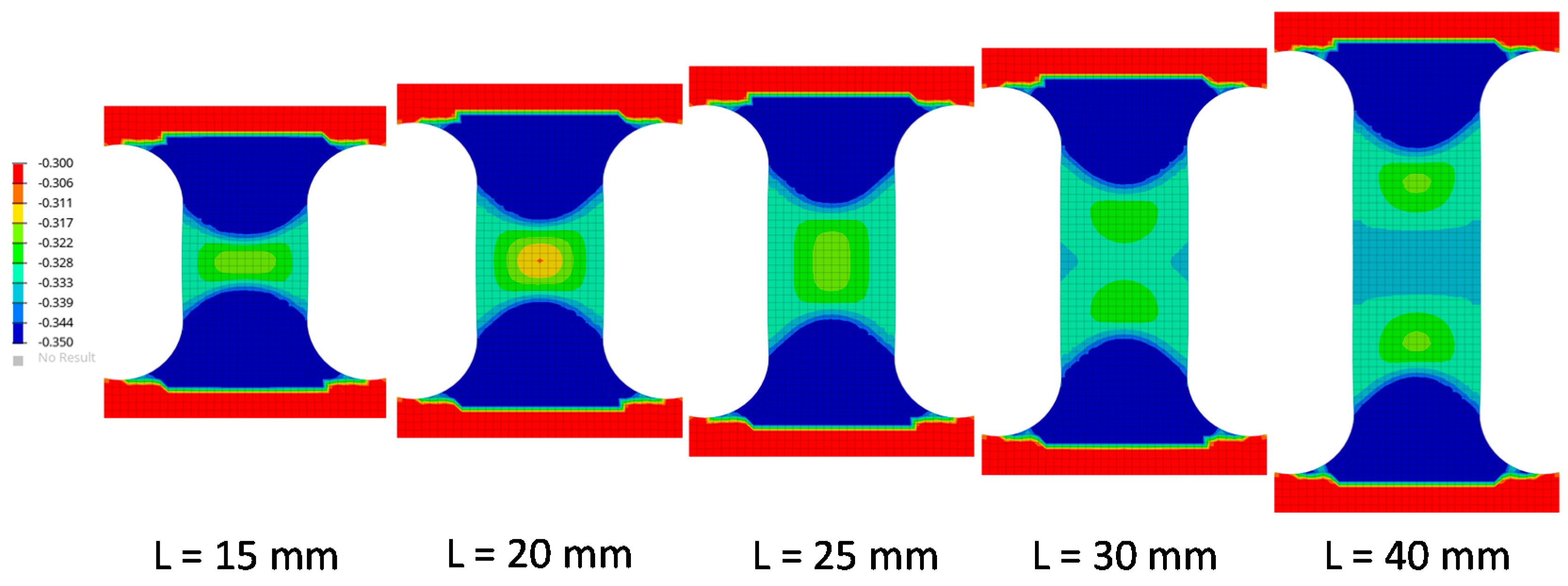

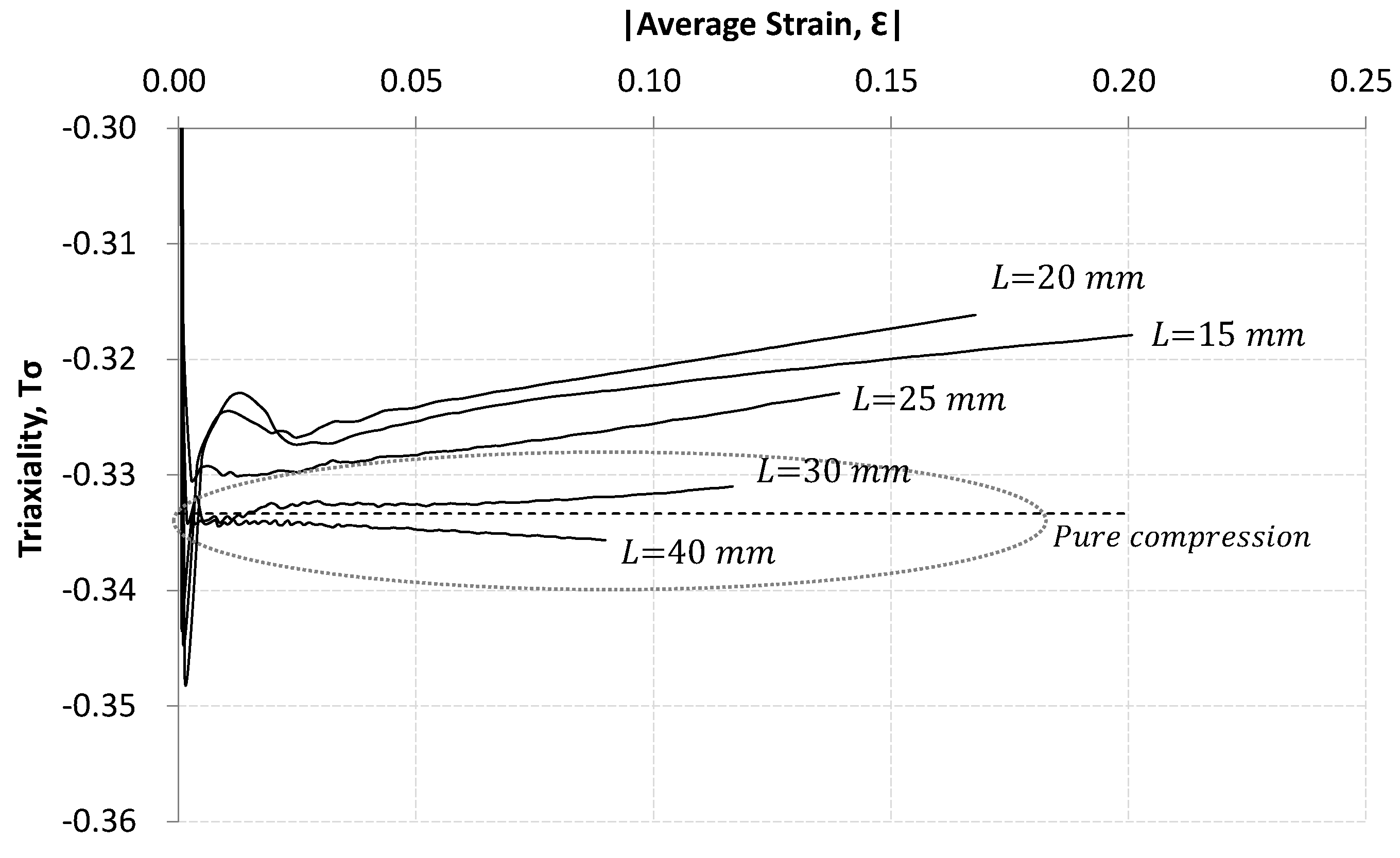

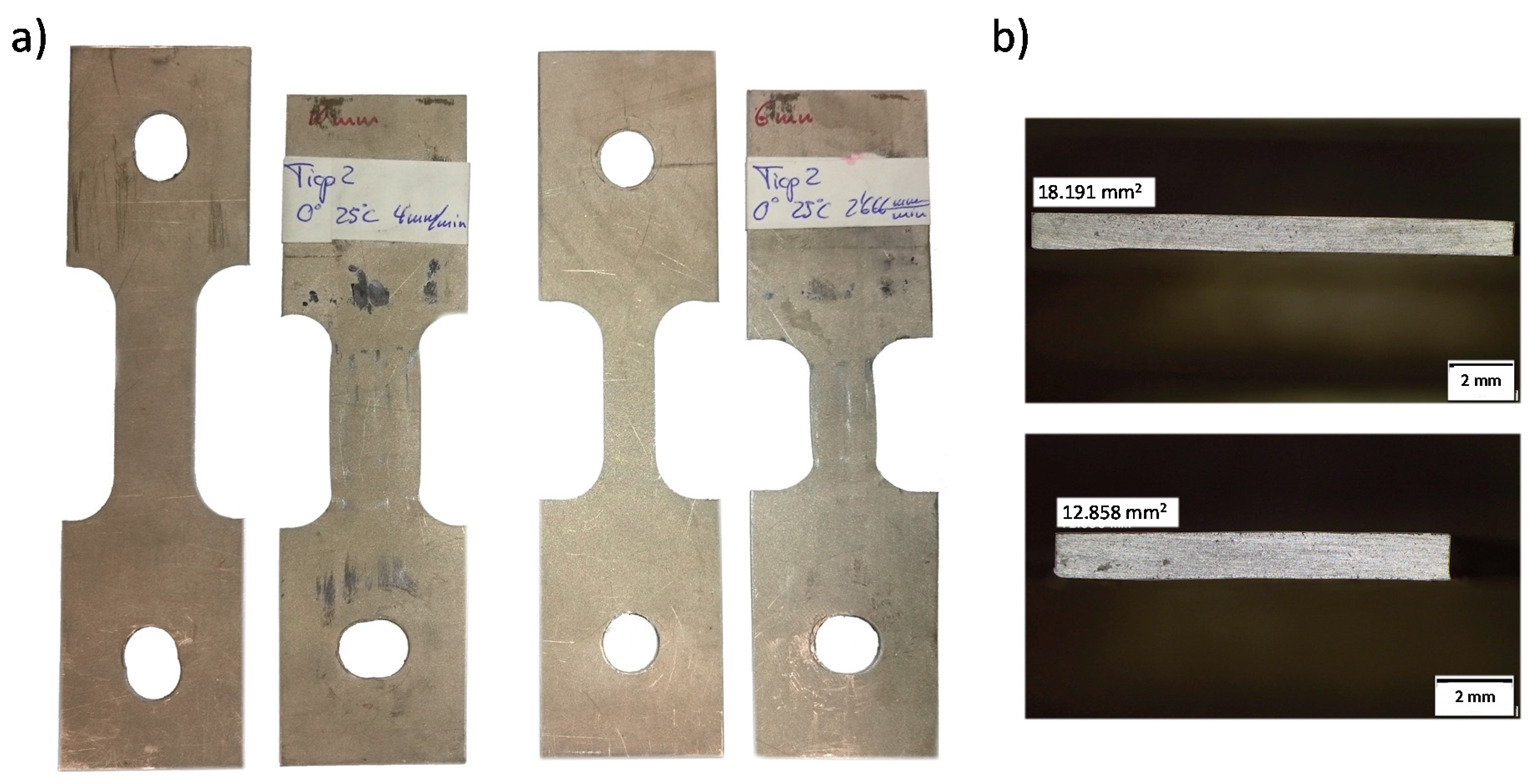

2.1.2. Design of the Compression Test Specimens

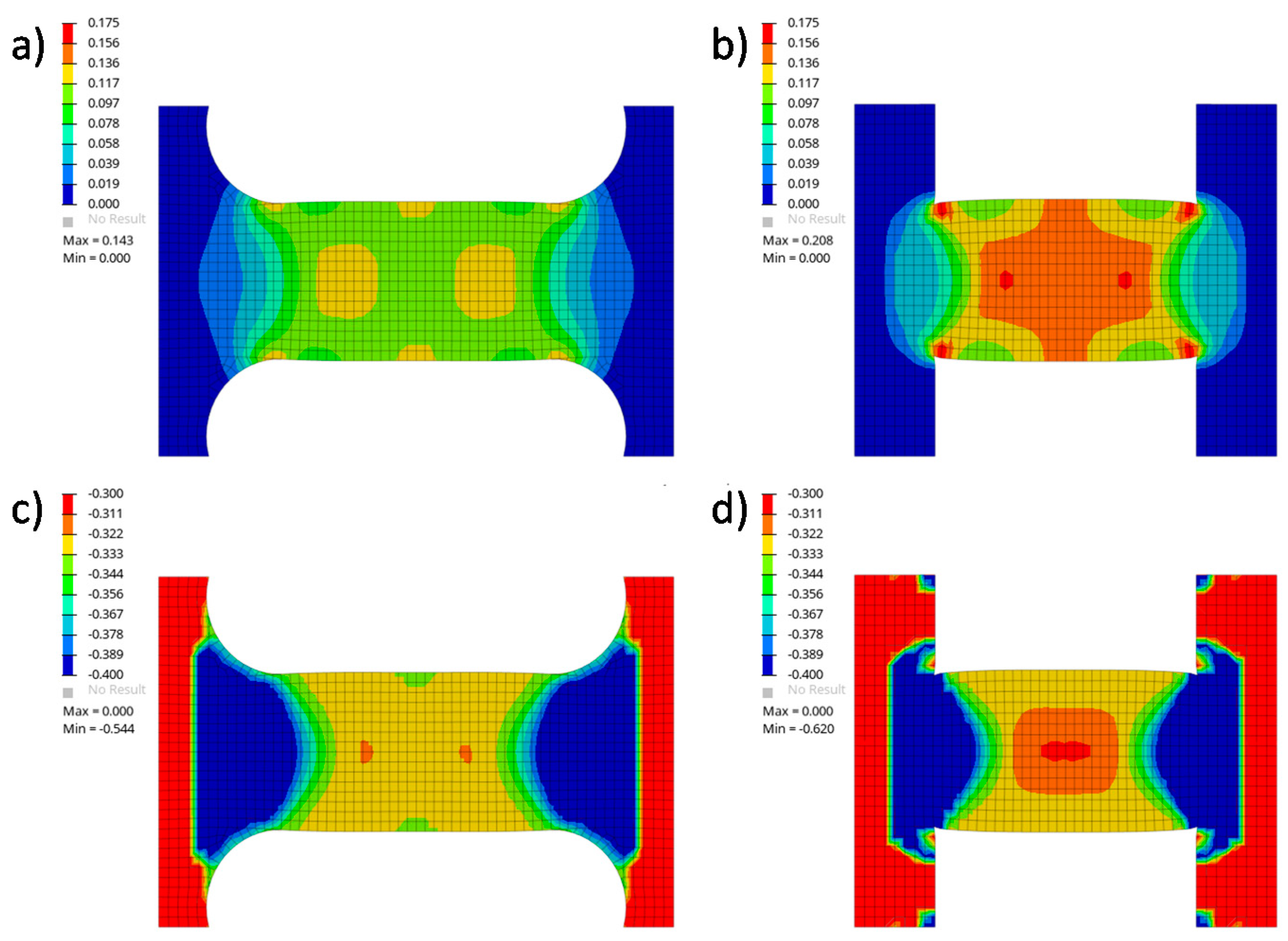

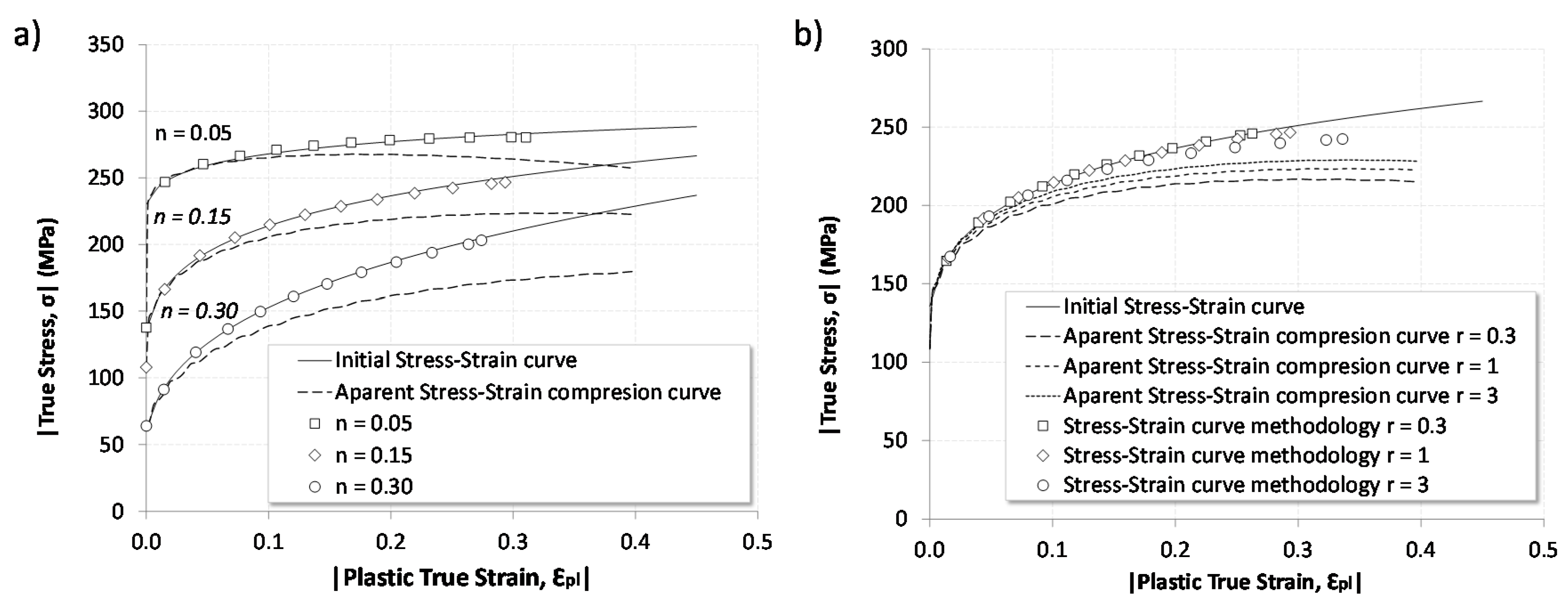

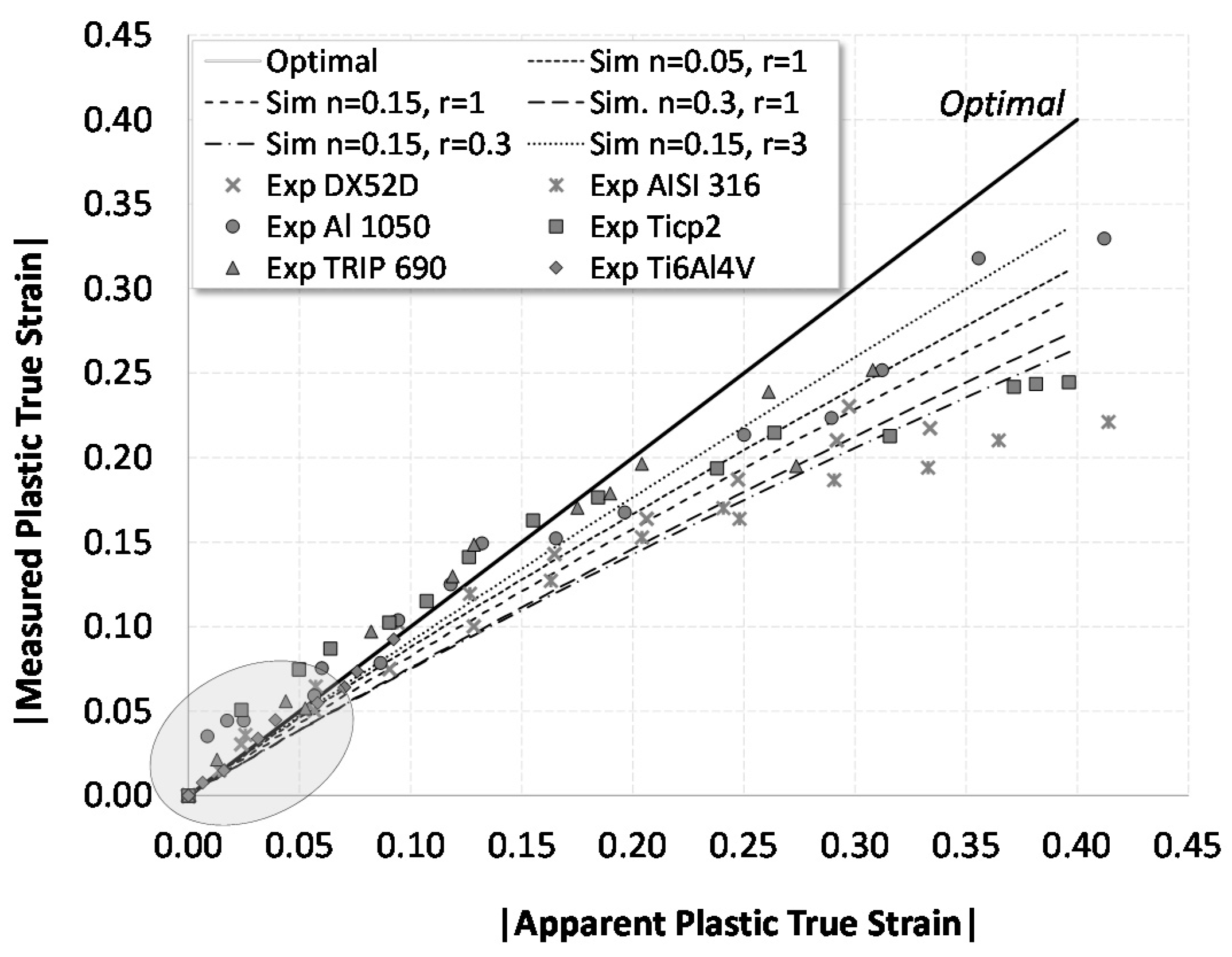

2.2. Approaches to Evaluate the Compression Behaviour of Sheet Metal

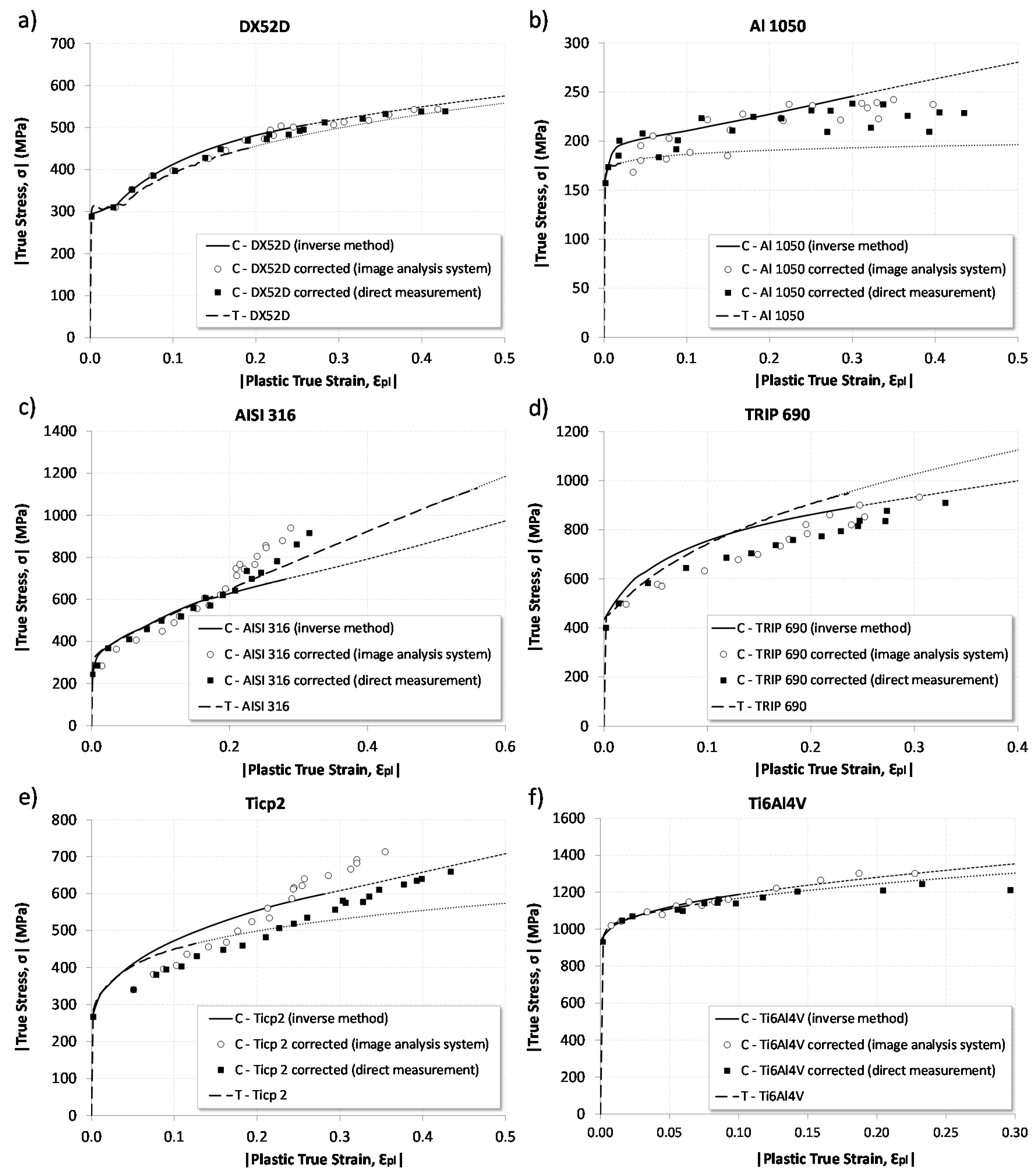

2.2.1. Procedure Based on the Central Cross-Section Measurement

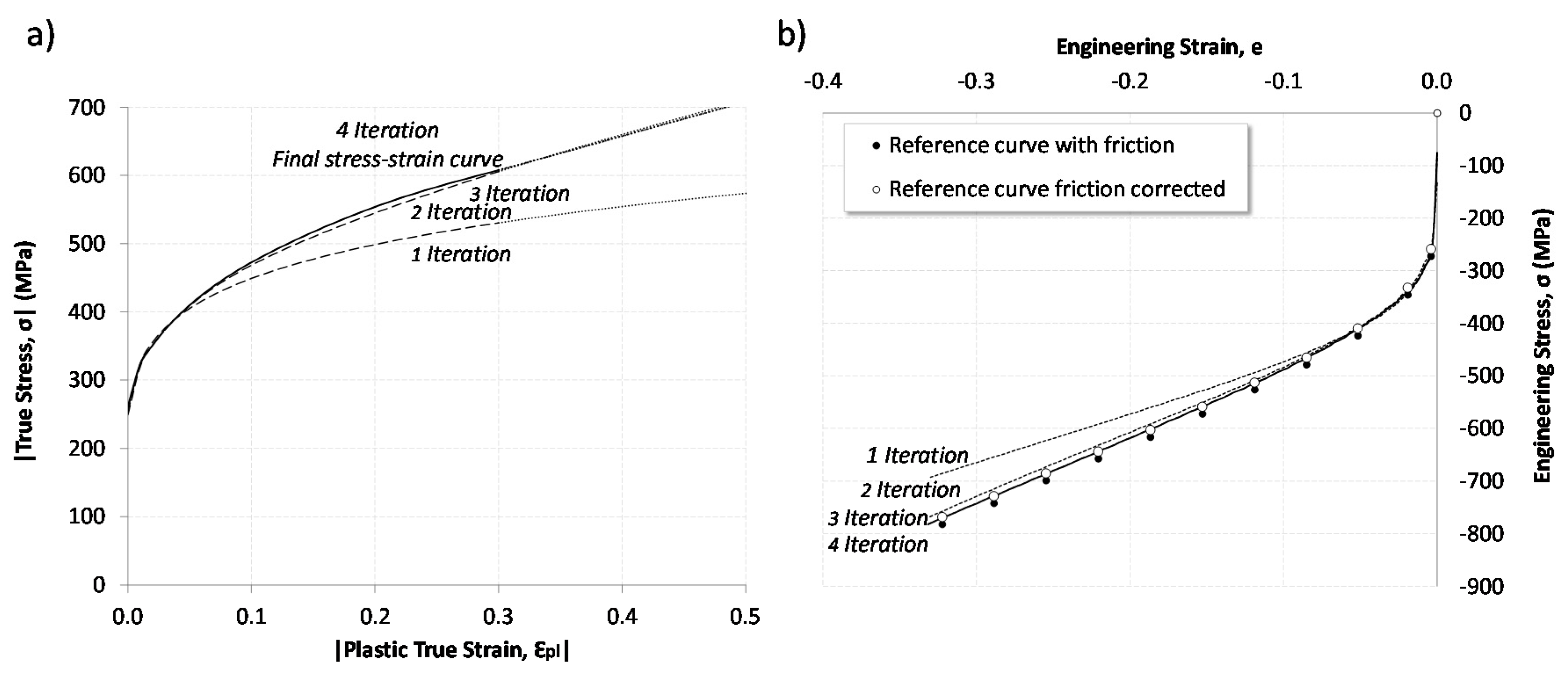

2.2.2. Procedure Based on the Inverse Modelling Method of the Compression True Stress-Strain Curve

2.3. Experimental Procedure

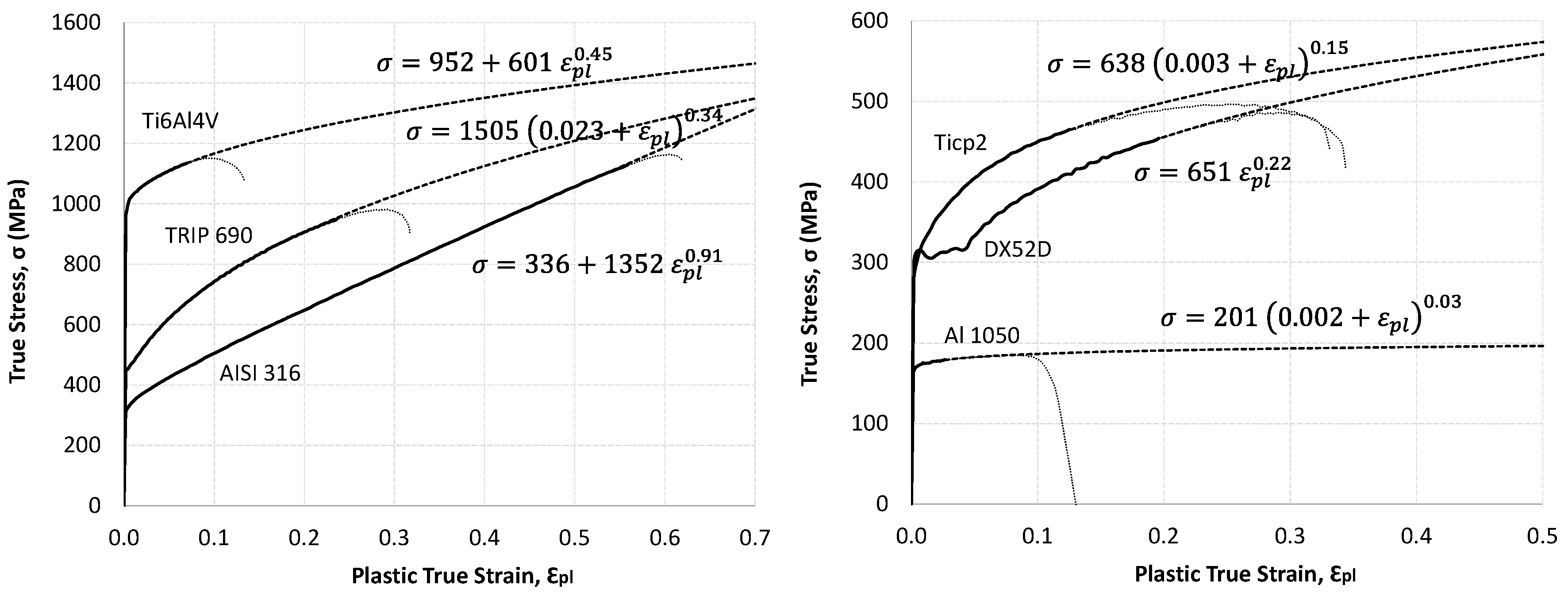

2.3.1. Test Materials

2.3.2. Compression Tests

2.3.3. Tensile Tests

2.3.4. Estimation of the Friction Force in the System and the Correction to be Considered in True Stress-Strain Curves

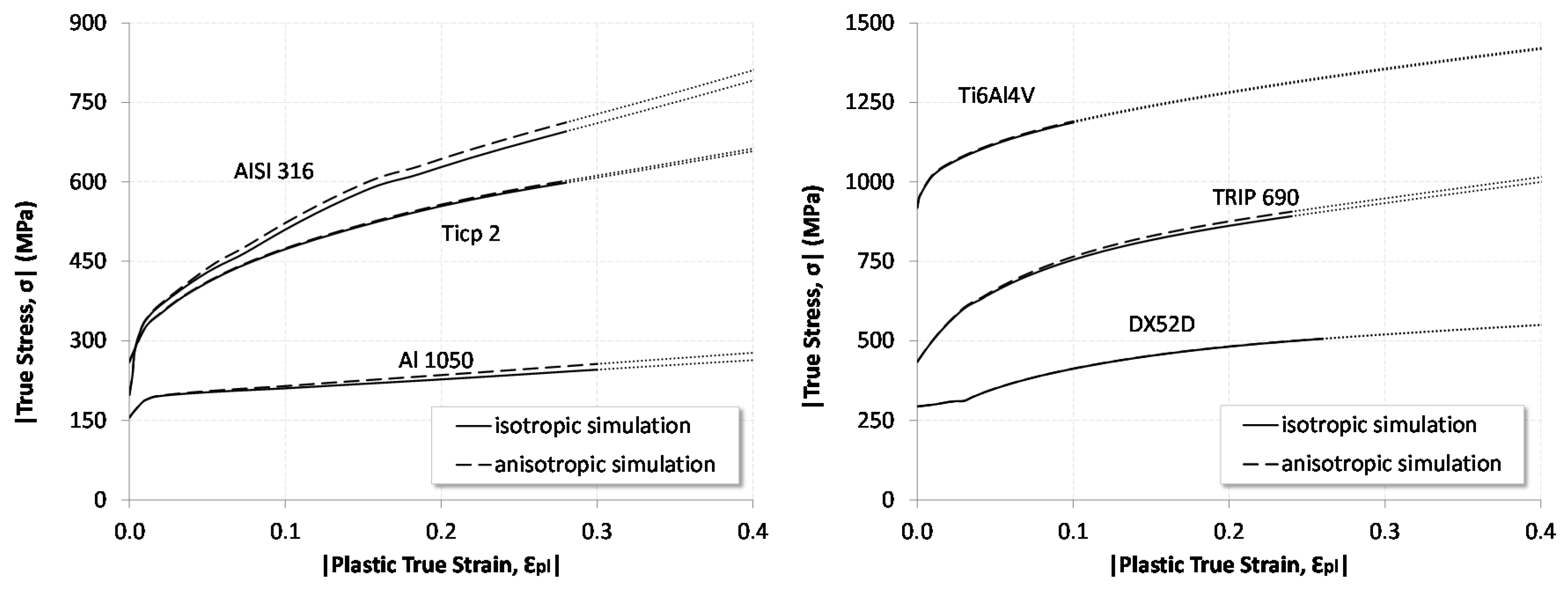

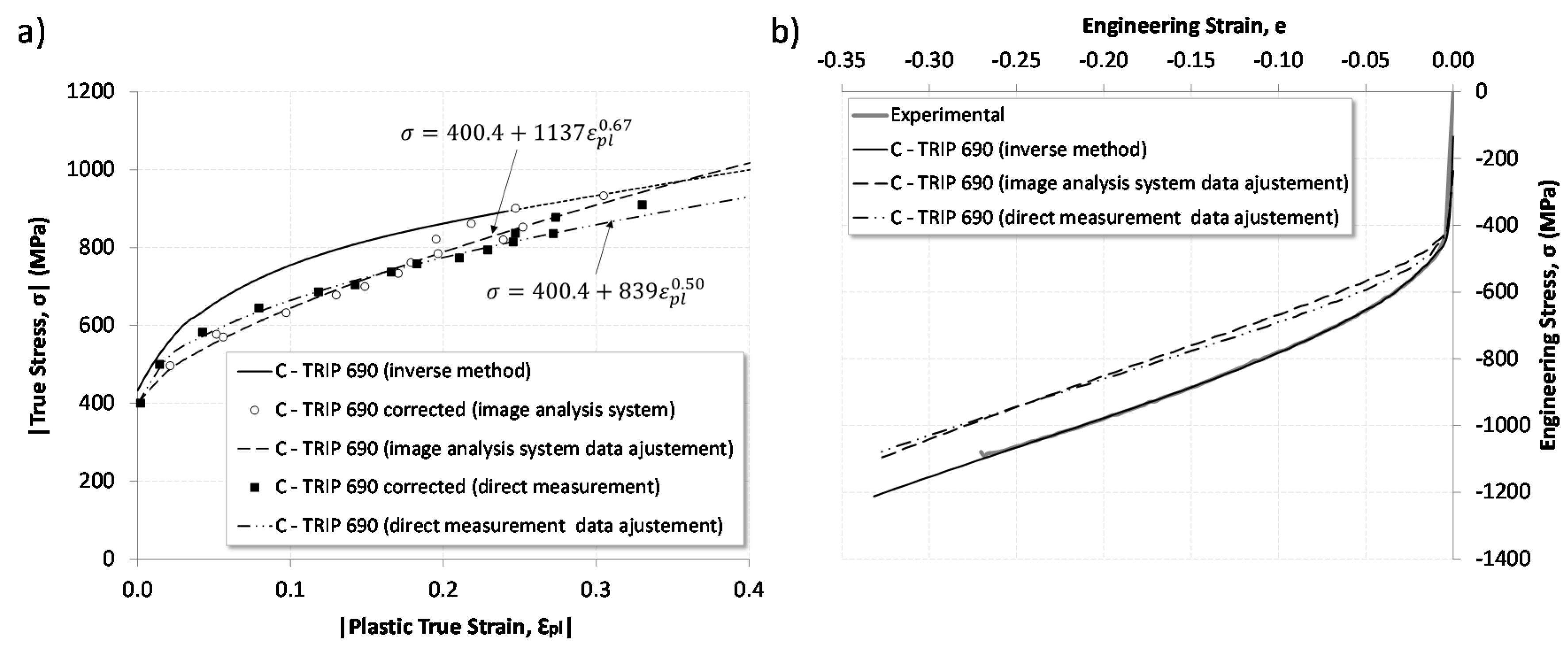

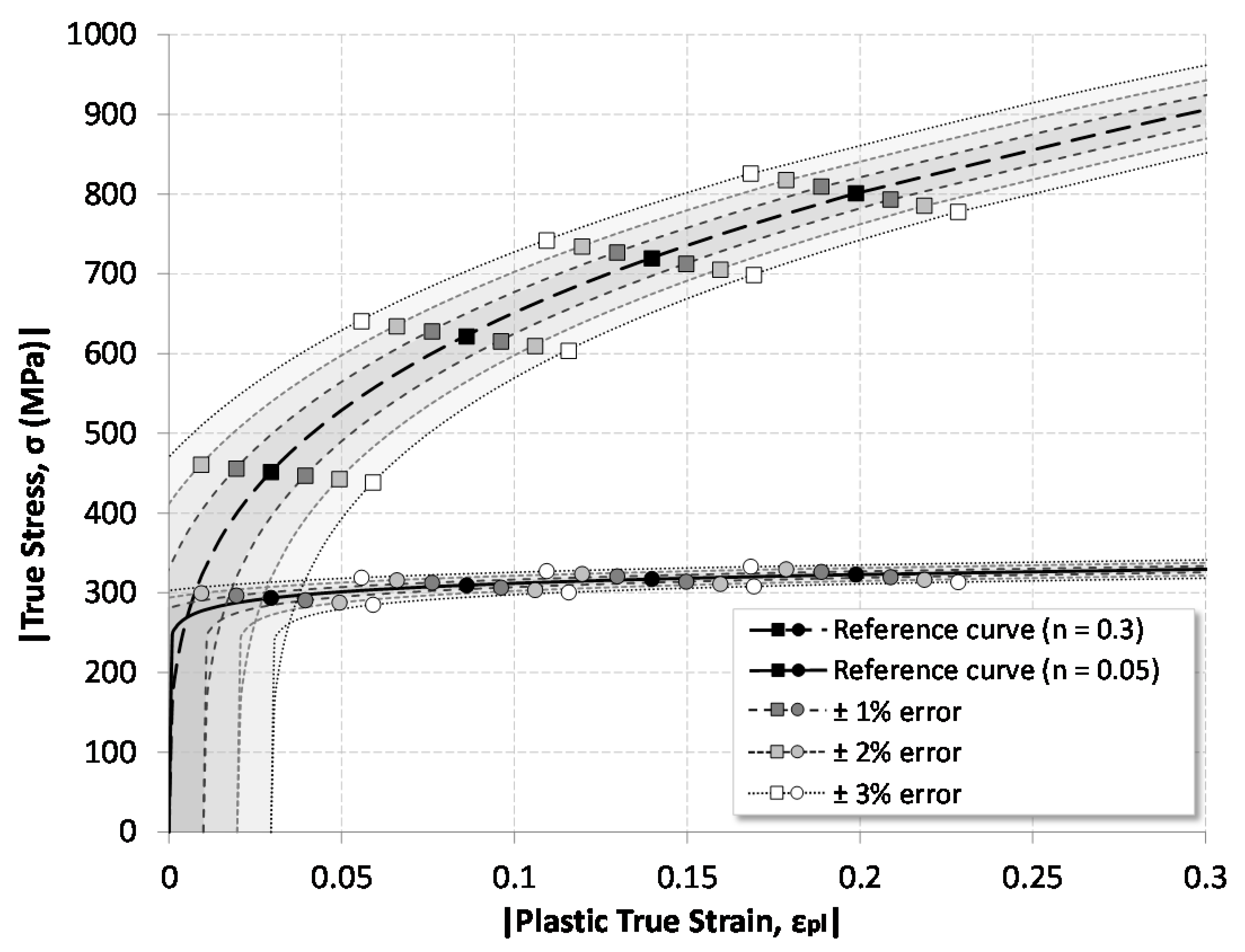

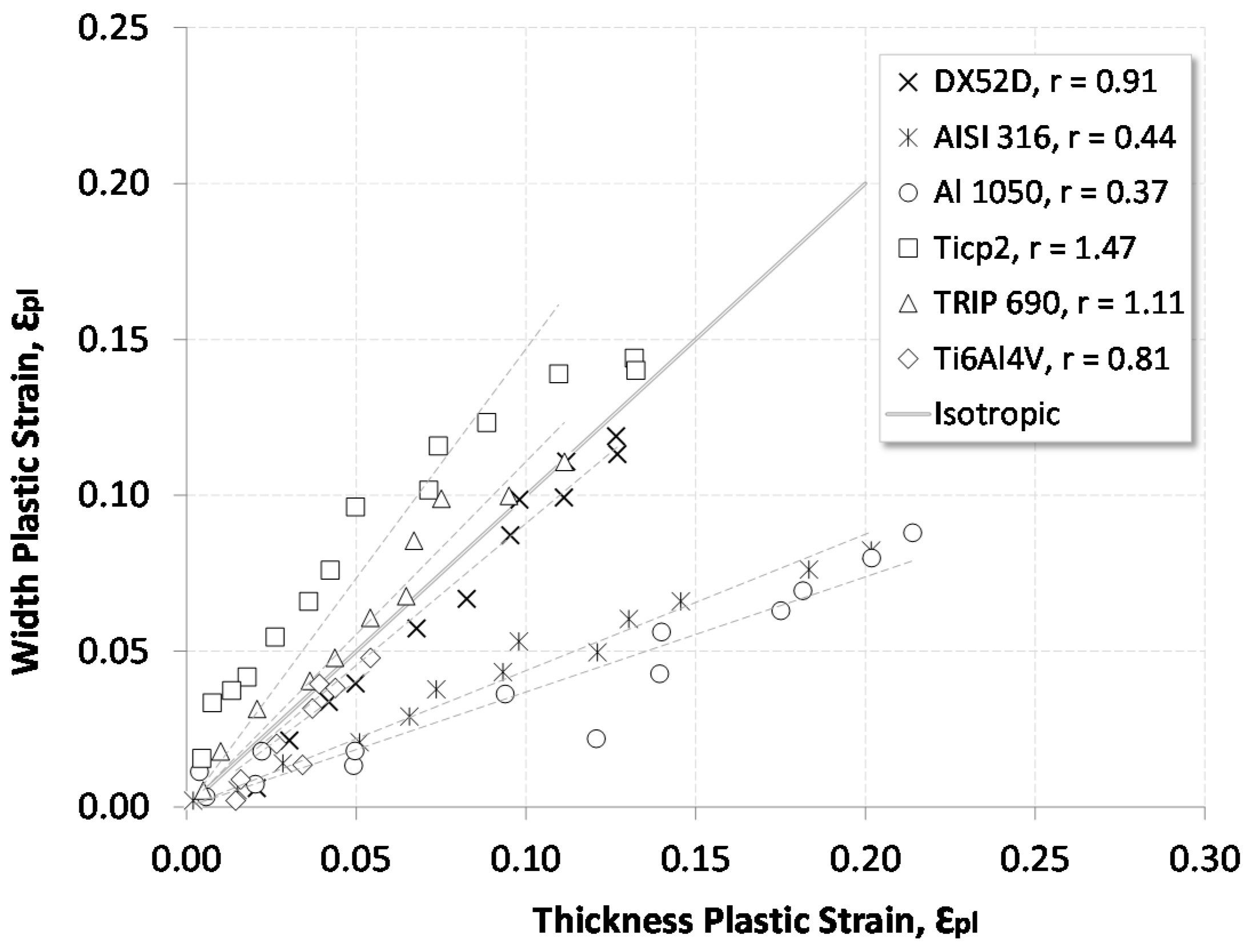

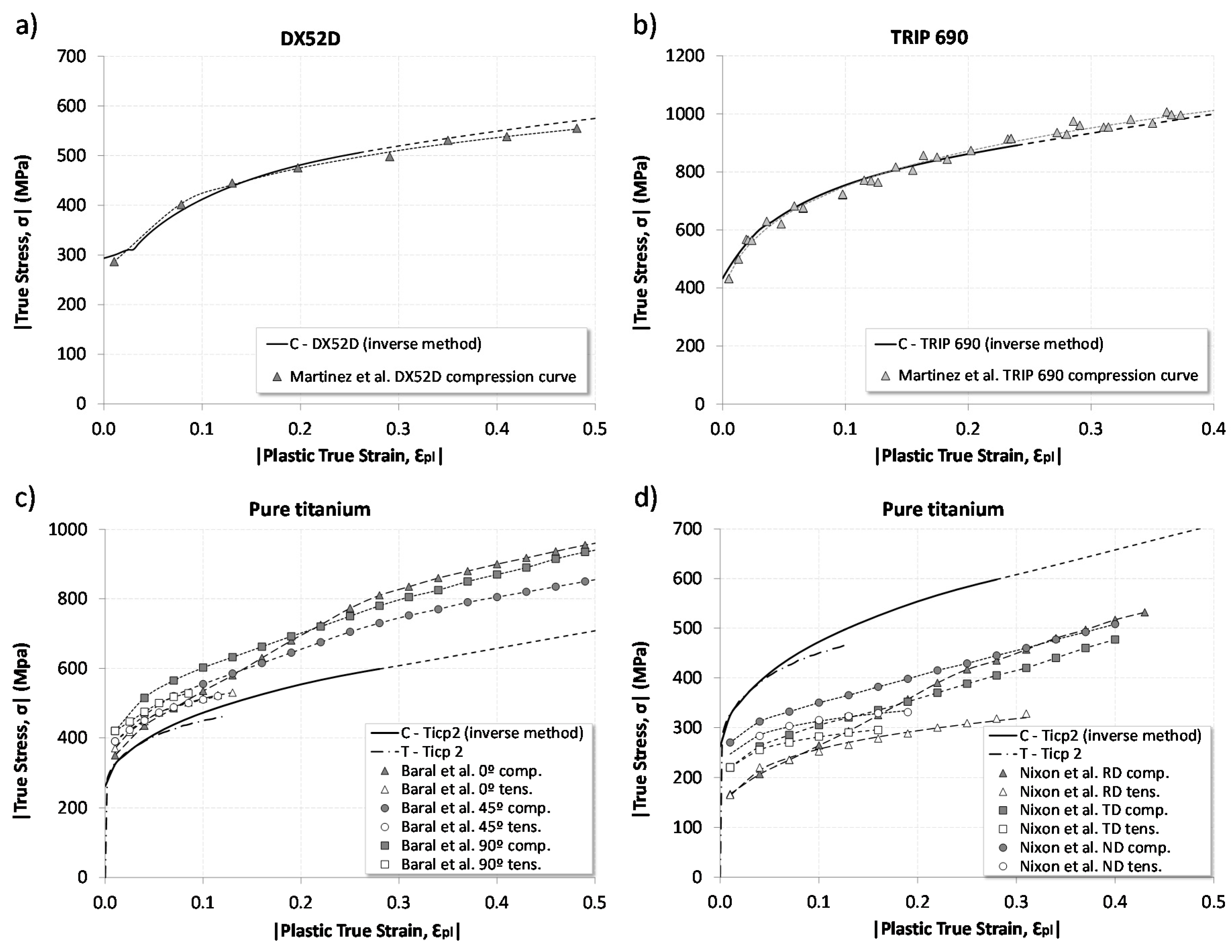

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

Notation

| true plastic strain | |

| prior strain | |

| average simulated plastic strain for a strain point i | |

| true stress | |

| hydrostatic stress | |

| equivalent stress | |

| estimated true stress for n+1 iteration for a strain point i | |

| estimated true stress in the current iteration for a strain point i | |

| engineering stress | |

| experimental reference stress for the inverse adjustment for a strain point i | |

| engineering stress obtained in the simulation for a strain point i | |

| D | diameter of the hole for the clamping screws |

| engineering strain | |

| engineering strain in ultimate tensile strength (UTS) | |

| average friction force | |

| effective compression force | |

| experimental measured compression force (with friction) | |

| tensile test force with anti-buckling support | |

| tensile test force | |

| K | strength coefficient |

| R | transition radius to the width of the test samples heads |

| L | length of the gauge area after deformation |

| gauge/initial length | |

| Lh | specimen head width |

| n | strain hardening index |

| r | normal anisotropy value or Lankford index |

| S | cross-section of the deformed sample |

| initial cross-section of the sample | |

| triaxiality parameter | |

| initial width | |

| Wh | specimen head length |

| Ls, Ws | position of the screw hole |

References

- Nixon, M.E.; Lebenshon, R.A.; Cazacu, O.; Liu, C. Experimental and finite-element analysis of the anisotropic response of high-purity x-titanium in bending. Acta Mater. 2010, 58, 5759–5767. [Google Scholar] [CrossRef]

- Noma, N.; Hashimoto, K.; Maeda, T.; Kuwabara, T. High accuracy springback simulation by using material model considering the SD effect. Iop Conf. Ser. J. Phys. Conf. Ser. 2018, 1063, 012096. [Google Scholar] [CrossRef]

- Martínez, A.; Miguel, V.; Coello, J.; Manjabacas, M.C. Determining stress distribution by tension and by compression applied to steel: Special analysis for TRIP steel sheets. Mater. Des. 2017, 125, 11–25. [Google Scholar] [CrossRef]

- Graf, M.; Henseler, T.; Ulmann, M.; Kawalla, R.; Prahl, U.; Awiszus, B. Study on determination of flow behavior of 6060-aluminium and AZ31-magnesium thin sheet by means of stacked compression test. Iop Conf. Ser. Mater. Sci. Ing. 2019, 480, 012023. [Google Scholar] [CrossRef]

- Merklein, M.; Kuppert, A. A method for the layer compression test considering the anisotropic material behavior. Int. J. Mater. 2009, 2, 483–486. [Google Scholar] [CrossRef]

- Steglich, D.; Tian, X.; Bohlen, J.; Kuwabara, T. Mechanical testing of thin sheet magnesium alloys in biaxial tension and uniaxial compression. Exp. Mech. 2014, 54, 1247–1258. [Google Scholar] [CrossRef]

- Kuwabara, T.; Kumano, Y.; Ziegelheim, J.; Kurosaki, I. Tension-compression asymmetry of phosphor bronze for electronic parts and its effect on bending behavior. Int. J. Plast. 2009, 25, 1759–1776. [Google Scholar] [CrossRef]

- Kuwabara, T.; Saito, R.; Hirano, T.; Oohashi, N. Difference in Tensile and Compressive Flow Stresses in Austenitic Stainless Steel Alloys and Its Effect on Springback Behavior. Int. J. Mater. 2009, 2, 499–502. [Google Scholar] [CrossRef]

- Gilles, G.; Hammami, W.; Libertiaux, V.; Cazacu, O.; Yoon, J.H.; Kuwabara, T.; Habraken, A.M.; Duchene, L. Experimental characterization and elasto-plastic modelling of the quasi-static mechanical response of TA-6V at room temperature. Int. J. Solids Struct. 2011, 48, 1277–1289. [Google Scholar] [CrossRef] [Green Version]

- Maeda, T.; Noma, N.; Kuwabara, T.; Barlat, F.; Korkolis, Y.P. Measurement of the strength differential effect of DP980 steel sheet and experimental validation using pure bending test. J. Mater. Process. Technol. 2018, 256, 247–253. [Google Scholar] [CrossRef]

- Hama, T.; Nagao, H.; Kobuki, A.; Fujimoto, H.; Takuda, H. Work-hardening and twinning behaviors in a commercially pure titanium sheet under various loading paths. Mater. Sci. Eng. 2015, 620, 390–398. [Google Scholar] [CrossRef] [Green Version]

- Boger, R.K.; Wagoner, R.H.; Barlat, F.; Lee, M.G.; Chung, K. Continuous, large strain, tension/compression testing of sheet material. Int. J. Plast. 2005, 21, 2319–2343. [Google Scholar] [CrossRef]

- Bae, G.H.; Hub, H. Tension/compression test of auto-body steel sheets with the variation of the pre-strain and the strain rate. Trans. Eng. Sci. 2011, 72, 213–225. [Google Scholar]

- Joo, G.; Huh, H.; Choi, M.K. Tension/compression hardening behaviors of auto-body steel sheets at intermediate strain rates. Int. J. Mech. Sci. 2016, 108–109, 174–187. [Google Scholar]

- Joo, G.; Huh, H. Rate-dependent isotropic-kinematic hardening model in tension-compression of TRIP and TWIP steel sheets. Int. J. Mech. Sci. 2018, 146–147, 432–444. [Google Scholar] [CrossRef]

- Hartel, M.; Illgen, C.; Bruder, E.; Frint, P.; Wagner, M.F.X. Microstructural evolution during uniaxial tension-compression in-plane deformation of an IF steel. Mat. Sci. Eng. 2019, 744, 652–660. [Google Scholar] [CrossRef]

- Cao, J.; Lee, W.; Cheng, H.S.; Seniw, M.; Wang, H.P.; Chung, K. Experimental and numerical investigation of combined isotropic-kinematic hardening behavior of sheet metals. Int. J. Plast. 2009, 25, 942–972. [Google Scholar] [CrossRef]

- Yoshida, F.; Uemori, T.; Fujiwara, K. Elastic-plastic behavior of steel sheets under in-plane cyclic tension-compression at large strain. Int. J. Plast. 2002, 18, 633–659. [Google Scholar] [CrossRef]

- Zhou, P.; Beeh, E.; Friedrich, H.E. Influence of tension-compression asymmetry on the mechanical behavior of AZ31B magnesium alloy sheets in bending. J. Mater. Eng. Perform. 2016, 25, 853–865. [Google Scholar] [CrossRef] [Green Version]

- Piao, K.; Lee, J.K.; Kim, J.H.; Kim, H.Y.; Chung, K.; Barlat, F.; Wagoner, R.H. A sheet tension/compression test for elevated temperature. Int. J. Plast. 2012, 38, 27–46. [Google Scholar] [CrossRef]

- Lee, M.G.; Kim, J.H.; Kim, D.; Seo, O.S.; Nguyen, N.T.; Kim, H.Y. Anisotropic hardening of sheet metal at elevated temperature: Tension-compressions test development and validation. Exp. Mech. 2013, 53, 1039–1055. [Google Scholar] [CrossRef]

- Odenberger, E.L.; Hertzman, J.; Thilderkvist, P.; Merklein, M.; Kuppert, A.; Stöhr, T.; Lechler, J.; Oldenburg, M. Thermo-mechanical sheet metal forming of aero engine components in Ti-6Al-4V-PART 1: Material characterisation. Int. J. Mater. 2013, 6, 391–402. [Google Scholar] [CrossRef]

- Noma, N.; Kuwabara, T. Specimen geometry optimization for in-plane reverse loading test of sheet metal and experimental validation. Steel Res. Int. 2012, 2012, 1283–1286. [Google Scholar]

- Zhao, K.; Wang, L.; Chang, Y.; Yan, J. Identification of post-necking stress-strain curve for sheet metals by inverse method. Mech. Mater. 2016, 92, 107–118. [Google Scholar] [CrossRef]

- Aydin, M.S.; Gerlach, J.; Kessler, L.; Tekkaya, A.E. Yield locus evolution and constitutive parameter identification using plane strain tension and tensile tests. J. Mat. Process. Technol. 2011, 211, 1957–1964. [Google Scholar] [CrossRef]

- Nixon, M.E.; Cazacu, O.; Lebensohn, R.A. Anisotropic response of high-purity x-titanium: Experimental characterization and constitutive modelling. Int. J. Plast. 2010, 26, 516–532. [Google Scholar] [CrossRef]

- Asgari, S.; El-Danaf, E.; Kalidindi, S.R.; Doherty, R.D. Strain hardening regimes and microstructural evolution during large strain compression of low stacking fault energy fcc alloys that form deformation twins. Met. Mat. Trans. A 1997, 28, 1781–1795. [Google Scholar] [CrossRef]

- Lee, M.G.; Kim, D.; Kim, C.; Wenner, M.L.; Wagoner, R.H.; Chung, K. Spring-back evaluation of automotive sheets based on isotropic-kinematic hardening laws and non-quadratic anisotropic yield functions. Part II: Characterization of material properties. Int. J. Plast. 2005, 21, 883–914. [Google Scholar]

- Tirry, W.; Nixon, M.; Cazacu, O.; Coghe, F.; Rabet, L. The importance of secondary and ternary twinning in compressed Ti. Scr. Mater. 2011, 64, 840–843. [Google Scholar] [CrossRef]

- Kuwabara, T.; Kuroda, M.; Hiwatashi, S.; Yoshida, H. Strength-differential effect in dual-phase and interstitial-free steel sheets. In Proceedings of the 9th International Symposium on Plasticity and Its Current Applications, Aruba, 2002; Khan, A.S., Ed.; Neat Press: Fulton, MD, USA, 2002; p. 325. [Google Scholar]

- Baral, M.; Hama, T.; Knudsen, E.; Korkolis, Y.P. Plastic deformation of commercially-pure titanium: Experiments and modelling. Int. J. Plast. 2018, 105, 164–194. [Google Scholar] [CrossRef]

- Lampman, S. Wrought titanium and titanium alloys. In ASM Handbook Volume 2, Properties and Selection: Nonferrous Alloys and Special-Purpose Materials, 10th ed.; ASM International: Cleveland, OH, USA, 1990; pp. 592–633. [Google Scholar]

- Yi, N.; Hama, T.; Kobuki, A.; Fujimoto, H.; Takuda, H. Anisotropic deformation behavior under various strain paths in commercially pure titanium Grade 1 and Grade 2 sheets. Mater. Sci. Eng. A 2016, 655, 70–85. [Google Scholar] [CrossRef] [Green Version]

- Knezevic, M.; Lebensohn, R.A.; Cazacu, O.; Revil-Baudard, B.; Proust, G.; Vogel, S.C.; Nixon, M.E. Modeling bending of x-titanium with embedded polycrystal plasticity in implicit finite elements. Mater. Sci. Eng. A 2013, 564, 116–126. [Google Scholar] [CrossRef]

- Salem, A.A.; Kalidindi, S.R.; Doherty, R.D.; Semiatin, S.L. Strain hardening due to deformation twinning in x-titanium: Mechanisms. Met. Mater. Tran. A 2006, 37A, 259–268. [Google Scholar] [CrossRef]

- Tuninetti, V.; Gilles, G.; Milis, O.; Pardoen, T.; Habraken, A.M. Anisotropy and tension-compression asymmetry modeling of the room temperature plastic response of Ti-6Al-4V. Int. J. Plast. 2015, 67, 53–68. [Google Scholar] [CrossRef]

- Khan, A.S.; Kazmi, R.; Farrokh, B. Multiaxial and non-proportinal loading responses, anisotropy and modeling of Ti-6Al-4V titanium alloy over wide ranges of strain rates and temperatures. Int. J. Plast. 2007, 23, 931–950. [Google Scholar] [CrossRef]

- Holmen, J.K.; Frodal, B.H.; Hopperstad, O.S.; Borvik, T. Strength differential effect in age hardened aluminum alloys. Int. J. Plast. 2017, 99, 144–161. [Google Scholar] [CrossRef]

| Dimension (mm) | L0 | W0 | R | D | Lh | Ls | Wh | Ws |

|---|---|---|---|---|---|---|---|---|

| Test specimen | 30 | 15 | 8 | 10 | 42.5 | 20 | 35 | 17.5 |

| Short test specimen | 20 | 10 | 8 | 10 | 47.5 | 20 | 35 | 17.5 |

| Material | Thickness (mm) | Crystallographic Structure | Rolling Direction | Anisotropy | Deformation Characteristics | |

|---|---|---|---|---|---|---|

| Ti6Al4V (Hot-rolled and annealed to 760 °C) | 0.8 | Hcp + Bcc | 1027 | 90° | 1.34 | Possible asymmetry t-c by hcp |

| Ticp2 (Cold-rolled) | 0.81 | Hcp | 282 | 0° | 4.27 | Asymmetry t-c by hcp. Highly anisotropic |

| AISI 316 (Annealed) | 0.8 | Fcc | 307 | 0° | 0.61 | Strain-induced martensitic transformation |

| Al 1050 | 0.975 | Fcc | 163 | 0° | 0.87 | − |

| TRIP 690 + EBT (Zinc-coated) | 1 | Bcc + Fcc | 446 | 0° | 0.89 | Strain-induced martensitic transformation |

| DX52C + Z (Hot did galvanised) | 0.8 | Bcc | 299 | 90° | 1.00 | Isotropic |

| Material | Screws for Tightening on Heads | Auxiliary Lateral Screws |

|---|---|---|

| Ti6Al4V | 40 Nm | 5 Nm |

| Ticp2 | 25 Nm | 5 Nm |

| AISI 316 | 20 Nm | 5 Nm |

| Al 1050 | 20 Nm | 5 Nm |

| TRIP 690 | 25 Nm | 5 Nm |

| DX52C | 20 Nm | 5 Nm |

| Material | FFriction (N) | Blank-Holding Pressure (MPa) | ||

|---|---|---|---|---|

| Ti6Al4V | 304 | 4.2–3.4 | 930 | 0.2–0.2 |

| Ticp2 | 166 | 2.3–1.8 | 267 | 0.4–0.3 |

| AISI 316 | 345 | 4.8–3.8 | 243 | 1.0–0.8 |

| Al 1050 | 282 | 3.9–3.1 | 157 | 1.2–1.0 |

| TRIP 690 | 436 | 6.1–4.8 | 400 | 0.7–0.6 |

| DX52C | 364 | 5.1–4.0 | 288 | 0.9–0.7 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ayllón, J.; Miguel, V.; Martínez-Martínez, A.; Coello, J.; Naranjo, J.A. A New Approach for Obtaining the Compression Behavior of Anisotropic Sheet Metals Applicable to a Wide Range of Test Conditions. Metals 2020, 10, 1374. https://doi.org/10.3390/met10101374

Ayllón J, Miguel V, Martínez-Martínez A, Coello J, Naranjo JA. A New Approach for Obtaining the Compression Behavior of Anisotropic Sheet Metals Applicable to a Wide Range of Test Conditions. Metals. 2020; 10(10):1374. https://doi.org/10.3390/met10101374

Chicago/Turabian StyleAyllón, Jorge, Valentín Miguel, Alberto Martínez-Martínez, Juana Coello, and Jesús Andrés Naranjo. 2020. "A New Approach for Obtaining the Compression Behavior of Anisotropic Sheet Metals Applicable to a Wide Range of Test Conditions" Metals 10, no. 10: 1374. https://doi.org/10.3390/met10101374

APA StyleAyllón, J., Miguel, V., Martínez-Martínez, A., Coello, J., & Naranjo, J. A. (2020). A New Approach for Obtaining the Compression Behavior of Anisotropic Sheet Metals Applicable to a Wide Range of Test Conditions. Metals, 10(10), 1374. https://doi.org/10.3390/met10101374