Effects of Extreme Thermal Shock on Microstructure and Mechanical Properties of Au-12Ge/Au/Ni/Cu Solder Joint

Abstract

1. Introduction

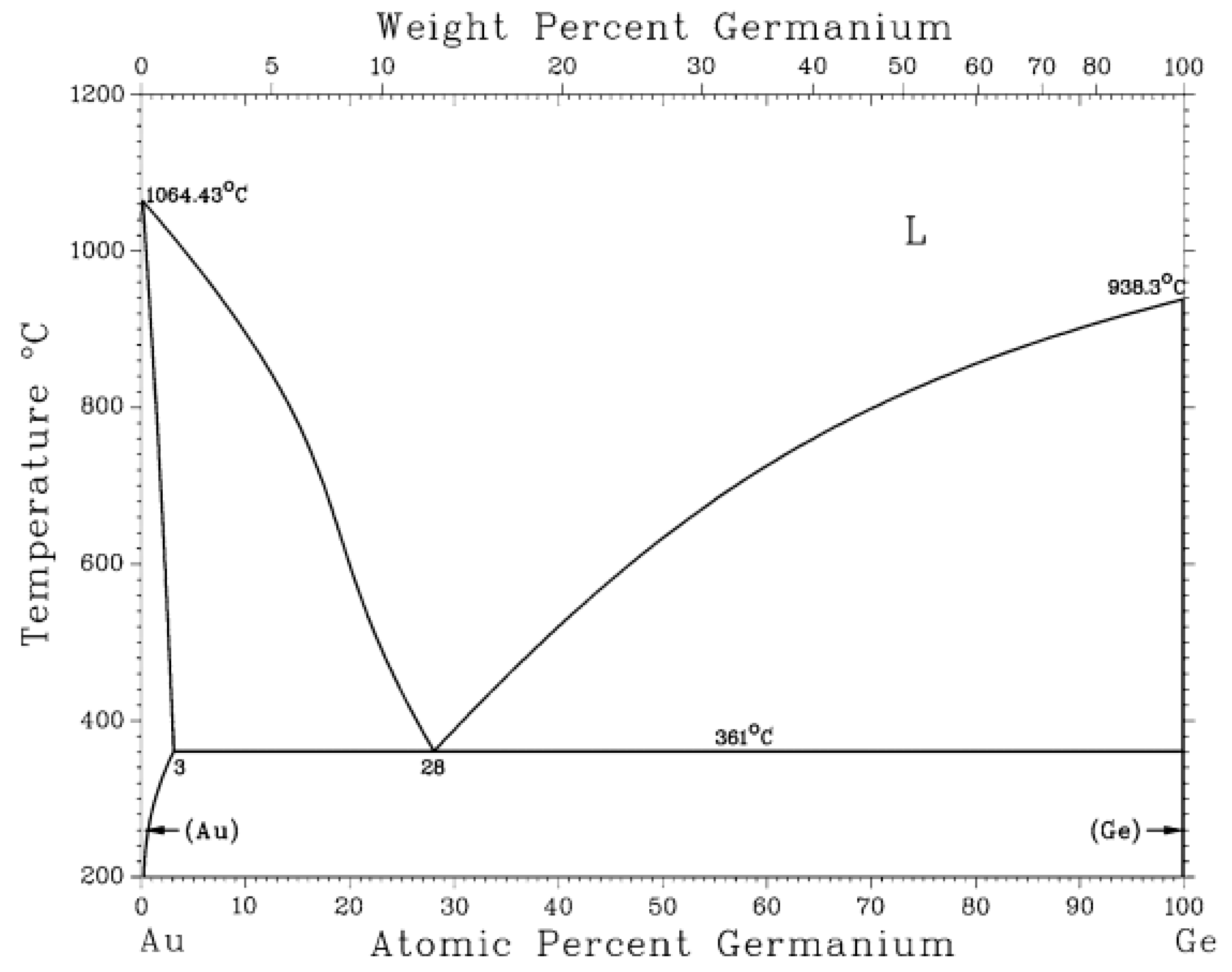

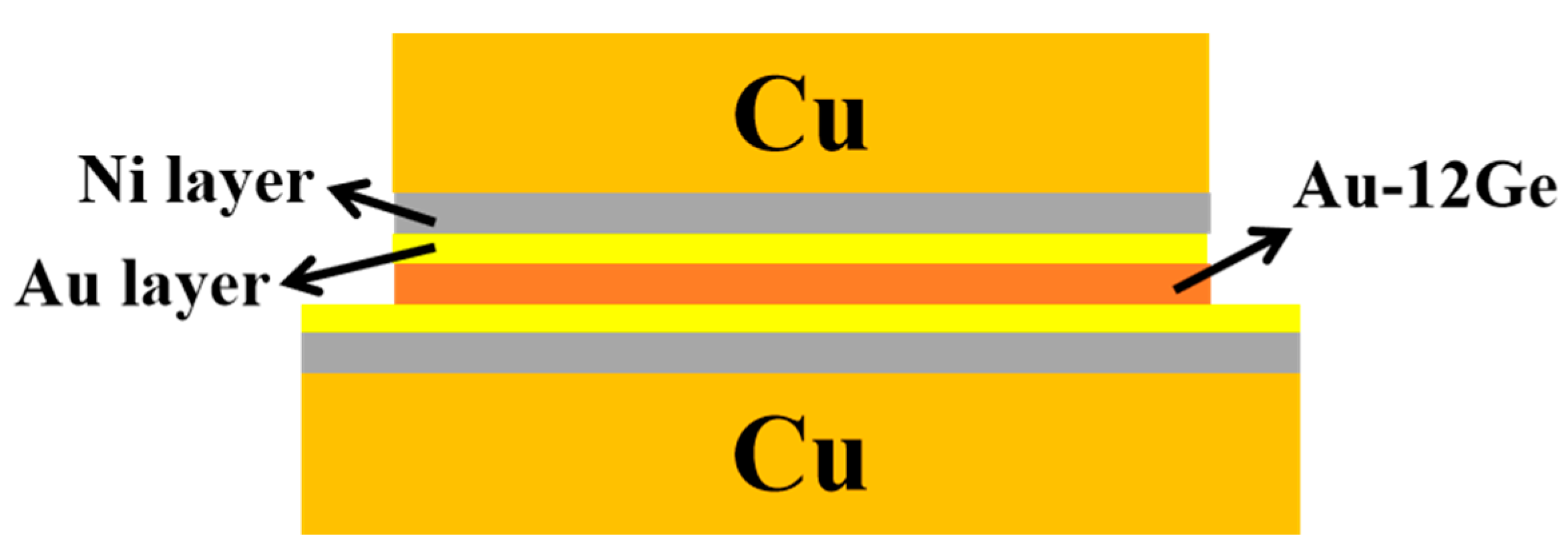

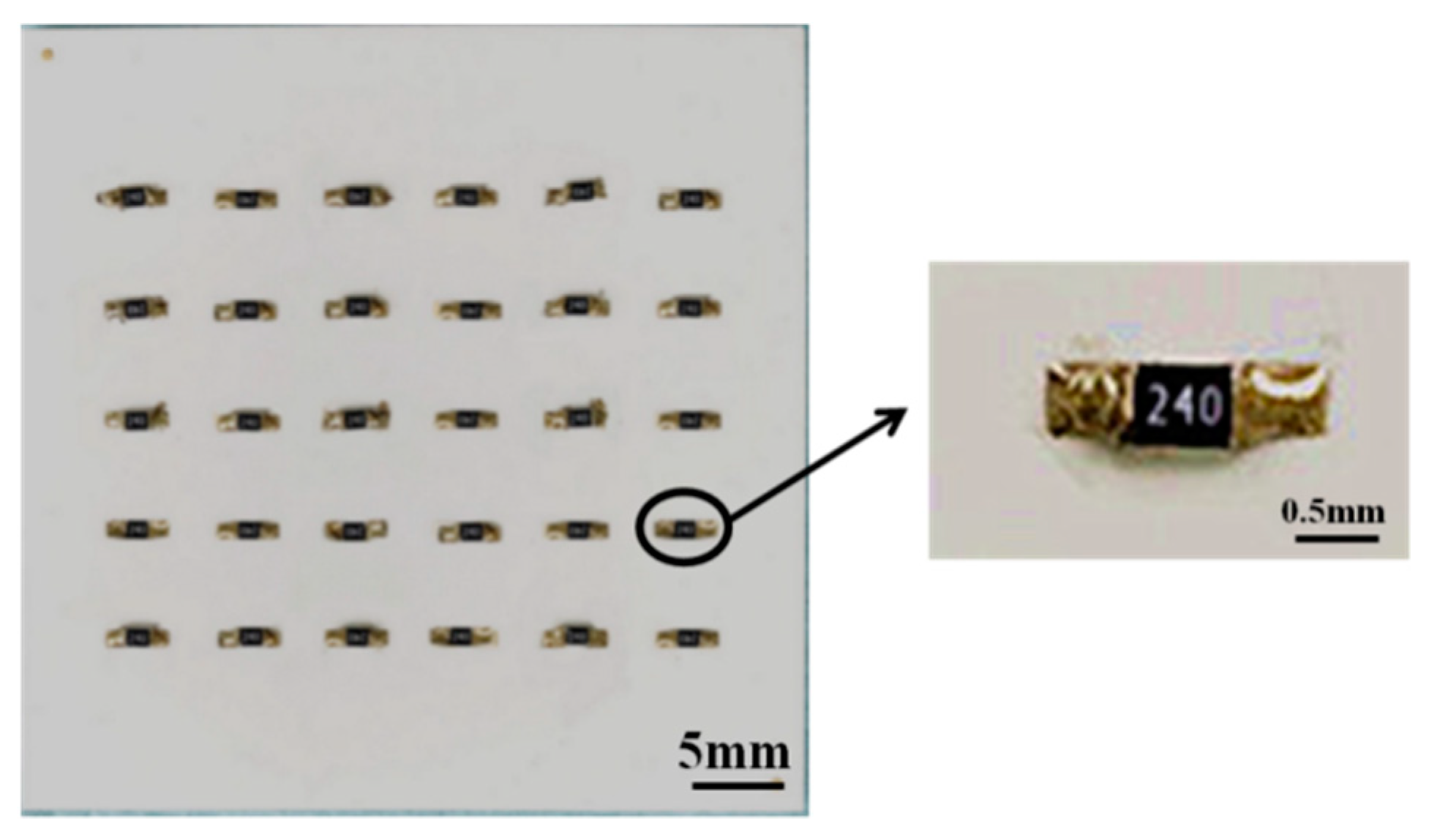

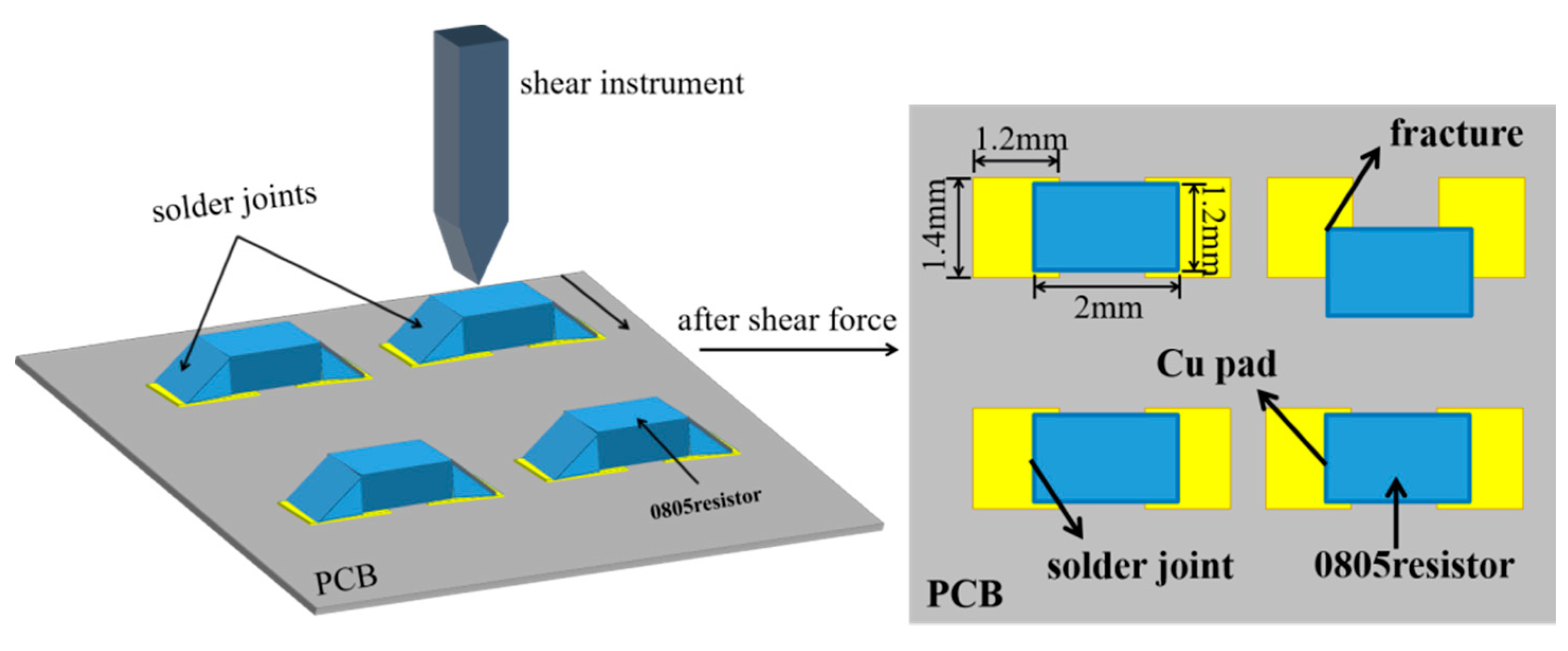

2. Materials and Methods

3. Results

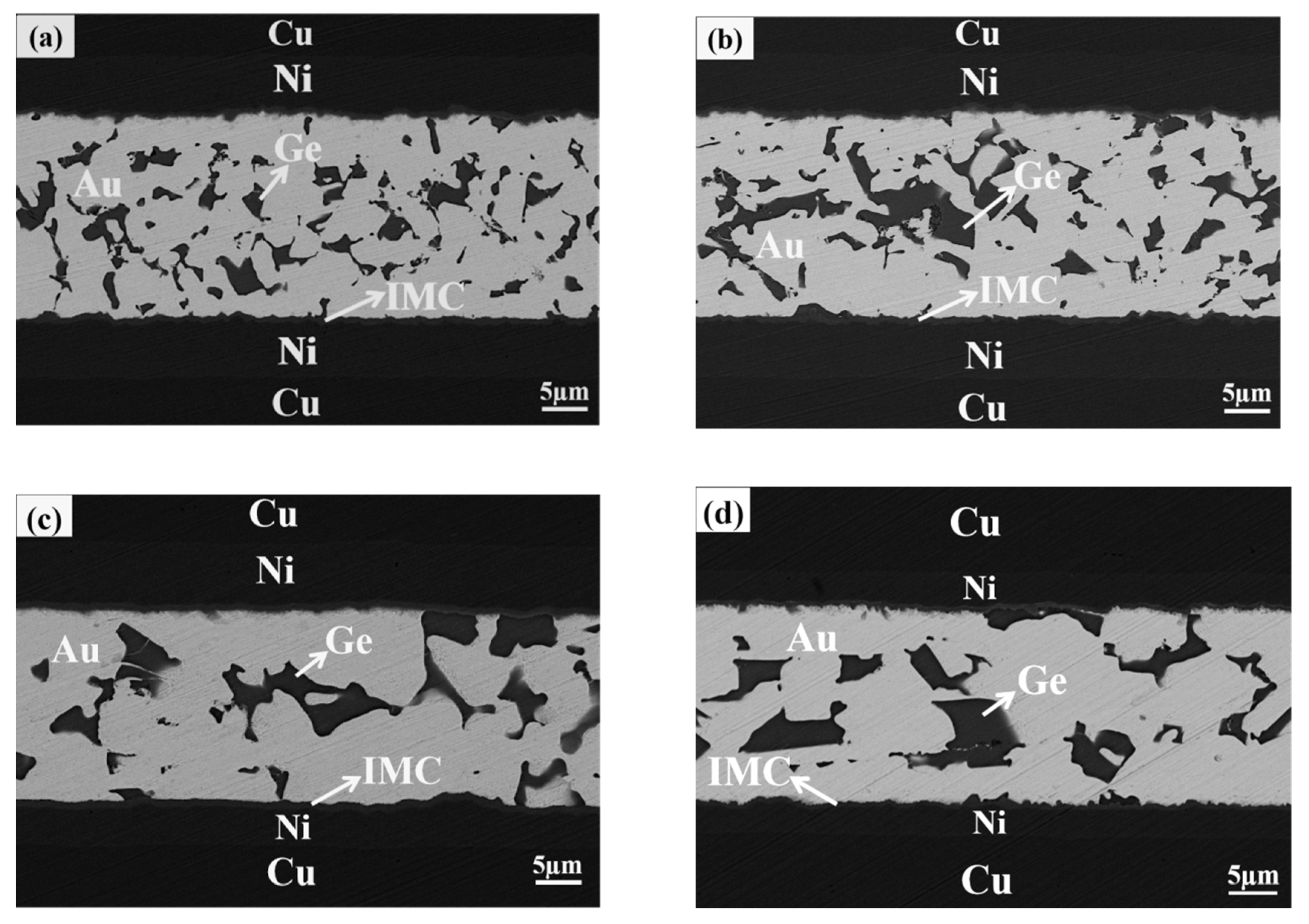

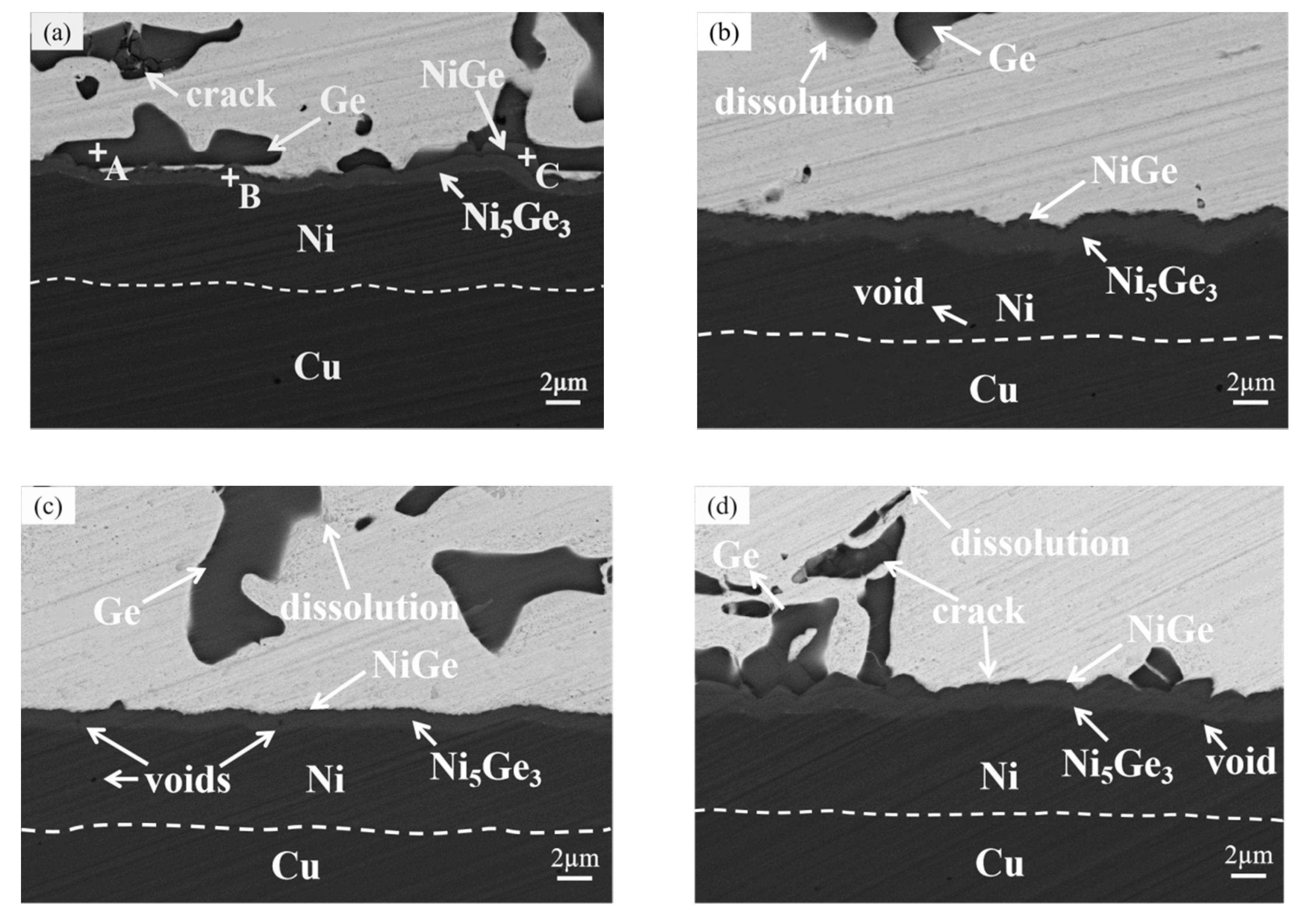

3.1. The Microstructure Evolution of Au-12Ge Solder Joint during Extreme Thermal Shock

3.2. Mechanical Properties of Au-12Ge Joints after Thermal Shock Test

4. Conclusions

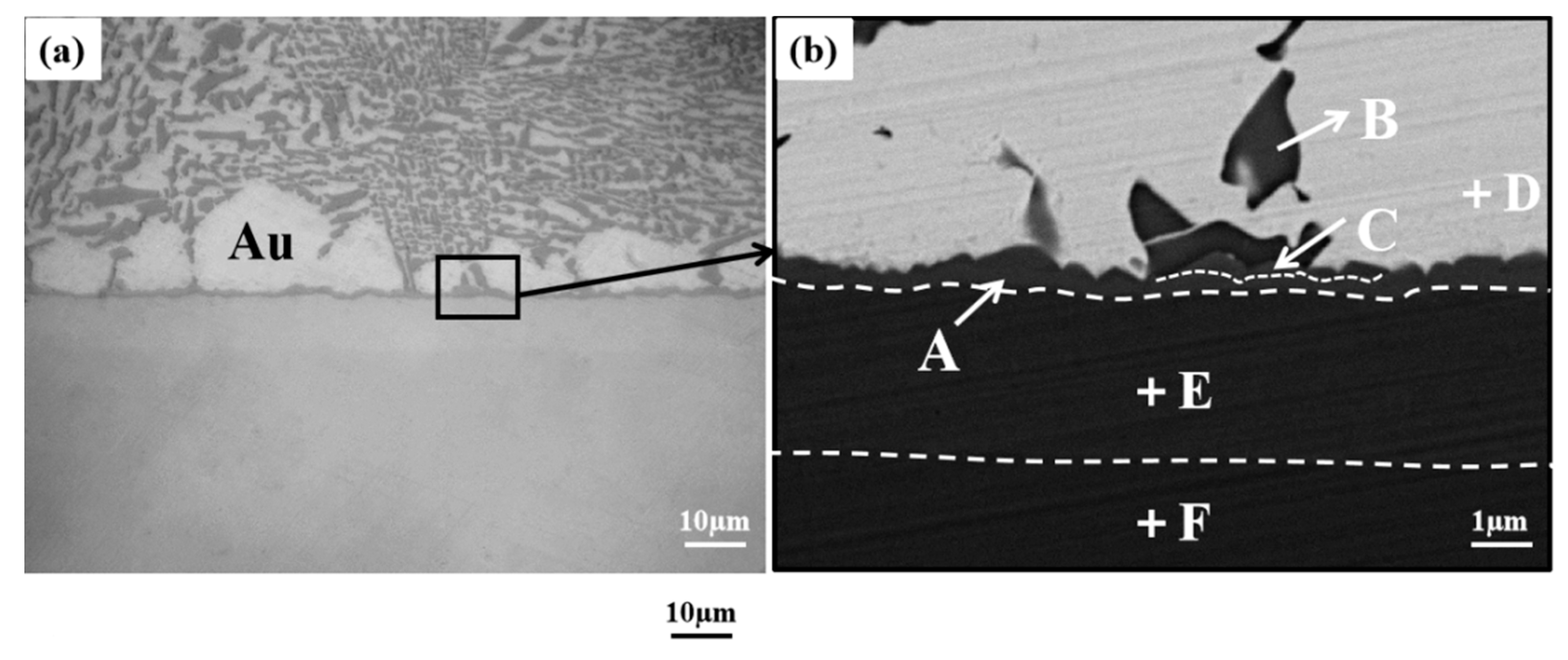

- After soldering at 410 °C and dwelling for 2 min, the Cu/Ni/Au/Au-12Ge/Au/Ni/Cu joint was dense and faultless. The interface layer was uniform, thin and continuous. The IMCs from the Au-12Ge solder to the Cu basal plate were NiGe and Ni5Ge3, respectively.

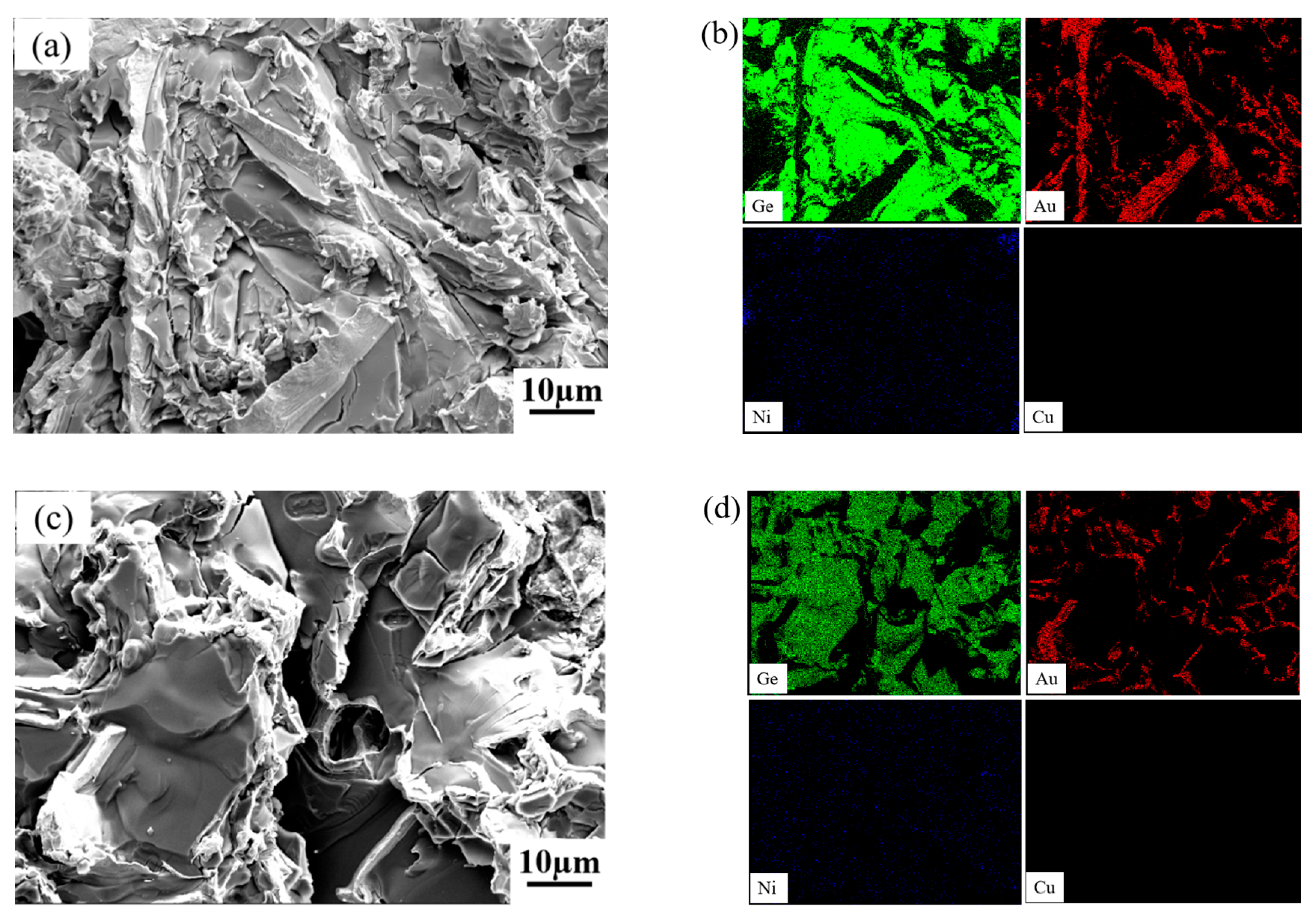

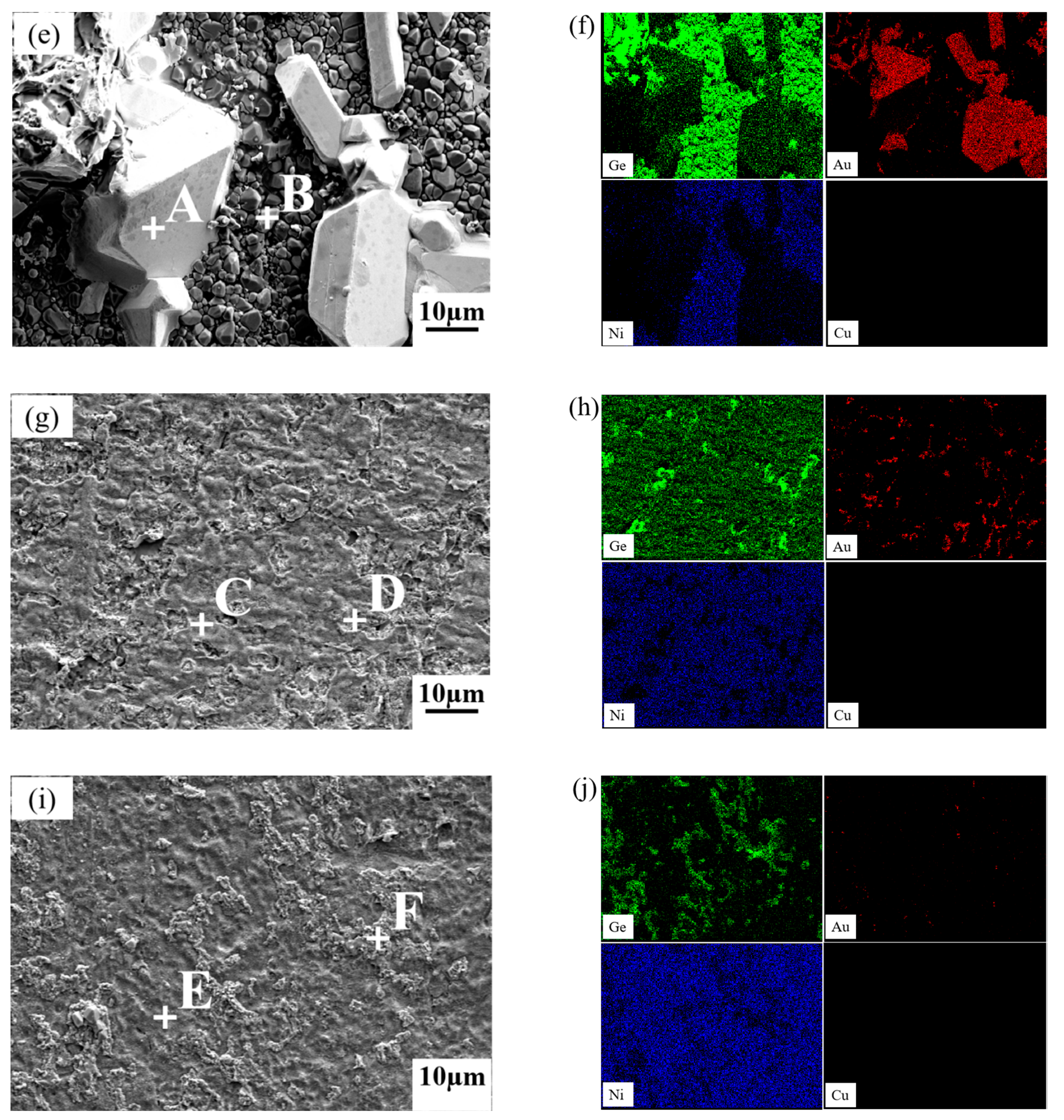

- The extreme thermal shock had slight effects on the interfacial layer thickness of the joints. Even after 400 cycles, the IMC layer was quite thin. As the experiment went on, partial NiGe IMC layer converted into Ni5Ge3 IMC layer, resulting in a planar NiGe layer. After 100 cycles, cracks were formed at the Ge phase due to the fragile nature and higher hardness of Ge. Cracks were detected at Ni5Ge3, NiGe layer and Ge phase after 400 cycles. The stress concentration caused by the superior temperature variation and the mismatch CTE of solder, interface layer and substrate led to formation and propagation of cracks.

- The solder joint after soldering was 50.9 MPa. The shear strength of solder joints subjected to thermal shock was in a minor degradation due to the generation of defects. The strengths were 47.8 MPa after 100 cycles, 40.2 MPa after 200 cycles, 35.1 MPa after 300 cycles, 29.5 MPa after 400 cycles, respectively. The fracture shifted from solder to the solder/NiGe interface and then to the IMC layer with the increasing number of cycles. The fracture mode transformed from ductile-brittle type to the brittle type.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Jiang, N.; Zhang, L.; Liu, Z.Q.; Sun, L.; Long, W.M.; He, P.; Xiong, M.Y.; Zhao, M. Reliability issues of lead-free solder joints in electronic devices. Sci. Technol. Adv. Mater. 2019, 20, 876–901. [Google Scholar] [CrossRef] [PubMed]

- Tan, S.H.; Han, J.; Guo, F. Recrystallization Behavior in Mixed Solder Joints of BGA Components during Thermal Shock. J. Electron. Mater. 2018, 47, 4156–4164. [Google Scholar] [CrossRef]

- Wang, J.H.; Xue, S.B.; Lv, Z.P.; Wen, L.; Liu, S.Y. Study on the Reliability of Sn50Pb49Sb1/Cu Solder Joints Subjected to γ-ray Irradiation. Appl. Sci. 2018, 8, 1706. [Google Scholar] [CrossRef]

- Abtew, M.; Selvaduray, G. Lead-free Solders in Microelectronics. Mater. Sci. Eng. R-Rep. 2000, 27, 95–141. [Google Scholar] [CrossRef]

- Wu, J.; Xue, S.B.; Wang, J.W.; Xue, P. Effect of Thermal Cycling on Interfacial Microstructure and Mechanical Properties of Sn-0.3Ag-0.7Cu-(α-Al2O3) Nanoparticles/Cu Low-Ag Solder Joints. J. Electron. Mater. 2019, 48, 4562–4572. [Google Scholar] [CrossRef]

- Liu, S.F.; Zhang, D.X.; Xiong, J.R.; Chen, C.; Song, T.J.; Liu, L.; Huang, S.Y. Microstructure evolution and properties of rapidly solidified Au-20Sn eutectic solder prepared by single-roll technology. J. Alloys Compd. 2019, 4781, 873–882. [Google Scholar] [CrossRef]

- Chidambaram, V.; Hald, J.; Hattel, J. Development of Au-Ge based candidate alloys as an alternative to high-lead content solders. J. Alloys Compd. 2010, 490, 170–179. [Google Scholar] [CrossRef]

- Huang, Y.F.; Chen, X.; Xue, F.; Wu, T.; Liu, W.H.; Ma, Y.Z.; Tang, S.W. Effects of isothermal aging on interfacial microstructure evolution and shear behavior of Au-12Ge/Ni(P)/Cu Solder Joints. Intermetallics 2020, 124, 106865. [Google Scholar] [CrossRef]

- Wen, L.; Xue, S.B.; Wang, L.J.; Liu, H.; Wu, J. Microstructural evolution and shear performance of AuSn20 solder joint under gamma-ray irradiation and thermal cycling. J. Mater. Sci. Mater. Electron. 2020, 31, 7200–7210. [Google Scholar] [CrossRef]

- Li, J.Z.; Acoff, V.L.; Gong, X.B. Characterization of the brittle mechanism in a Au-Ge microalloy. Gold Bull. 2015, 48, 47–56. [Google Scholar] [CrossRef][Green Version]

- Zeng, G.; Mcdonald, S.; Nogita, K. Development of high-temperature solders: Review. Microelectron. Reliab. 2012, 52, 1306–1322. [Google Scholar] [CrossRef]

- Chidambaram, V.; Yeung, H.B.; Shan, G. Reliability of Au-Ge and Au-Si Eutectic Solder Alloys for High-Temperature Electronics. J. Electron. Mater. 2012, 41, 2107–2117. [Google Scholar] [CrossRef]

- Lau, F.L.; Made, R.I.; Putra, W.N.; Lim, J.Z.; Nachiappan, V.C.; Aw, J.L.; Gan, C.L. Electrical behavior of Au-Ge eutectic solder under aging for solder bump application in high temperature Electronics. Microelectron. Reliab. 2013, 53, 1582–1586. [Google Scholar] [CrossRef]

- Zhang, Y.M.; Zhu, H.L.; Fujiwara, M.; Xu, J.Q.; Dao, M. Low-temperature creep of SnPb and SnAgCu solder alloys and reliability prediction in electronic packaging modules. Scr. Mater. 2013, 68, 607–610. [Google Scholar] [CrossRef]

- Wang, J.H.; Xue, S.B.; Lv, Z.P.; Wen, L.; Liu, S.Y. Microstructure and performance evolution of SnPbSb solder joint under γ-ray irradiation and thermal cycling. J. Mater. Sci. Mater. Electron. 2019, 30, 1–10. [Google Scholar] [CrossRef]

- Wang, J.; Leinenbach, C.; Roth, M. Thermodynamic modeling of the Au–Ge–Sn ternary system. J. Alloys Compd. 2009, 481, 830–836. [Google Scholar] [CrossRef]

- Zhao, L.Y.; Tian, Y.H.; Tian, R.Y.; Wang, C.X. Mechanical properties and fracture mechanisms of Sn-3.0Ag-0.5Cu solder alloys and joints at cryogenic temperatures. Mater. Sci. Eng. A 2017, 684, 697–705. [Google Scholar]

- Tian, R.Y.; Hang, C.J.; Tian, Y.H.; Zhao, L.Y. Growth behavior of intermetallic compounds and early formation of cracks in Sn-3Ag-0.5Cu solder joints under extreme temperature thermal shock. Mater. Sci. Eng. A 2017, 709, 125–133. [Google Scholar] [CrossRef]

- Drevin-Bazin, A.; Badawi, F.; Lacroix, F.; Barbot, J.F. Investigation of Die Attach for SiC Power Device for 300 °C Applications. Mater. Sci. Forum 2013, 742, 1032–1035. [Google Scholar] [CrossRef]

- Jin, S.; Valenza, F.; Novakovic, R.; Leinenbach, C. Wetting Behavior of Ternary Au-Ge-X (X=Sb, Sn) Alloys on Cu and Ni. J. Electron. Mater. 2013, 42, 1024–1032. [Google Scholar] [CrossRef][Green Version]

- Ma, Y.Z.; Wu, T.; Liu, W.S.; Huang, Y.F.; Tang, S.W.; Wang, Y.K. Interfacial microstructure evolution and shear behavior of Au-12Ge/Ni solder joints during isothermal aging. J. Mater. Sci.-Mater. Electron. 2017, 28, 3685–3694. [Google Scholar] [CrossRef]

- Dong, H.Q.; Vuorinen, V.; Liu, X.W.; Laurila, T.; Krockel, M.P. Microstructural Evolution and Mechanical Properties of Au-20wt.%Sn/Ni Interconnection. J. Electron. Mater. 2015, 45, 566–575. [Google Scholar] [CrossRef]

- Leinenbach, C.; Valenza, F.; Giuranno, D.; Elsener, H.R.; Novakovic, S.J.R. Wetting and Soldering Behavior of Eutectic Au-Ge Alloy on Cu and Ni Substrates. J. Electron. Mater. 2011, 40, 1533–1541. [Google Scholar] [CrossRef]

- Lang, F.Q.; Yamaguchi, H.; Nakagawa, H.; Sato, H. Solid-State Interfacial Reaction between Eutectic Au−Ge Solder and Cu/Ni(P)/Au Metalized Ceramic Substrate and Its Suppression. J. Mater. Sci. Technol. 2015, 31, 445–452. [Google Scholar] [CrossRef]

- Weyrich, N.; Jin, S.; Duarte, L.I.; Leinenbach, C. Joining of Cu, Ni, and Ti Using Au-Ge-Based High-Temperature Solder Alloys. J. Mater. Eng. Perform. 2014, 23, 1585–1592. [Google Scholar] [CrossRef]

- Lin, S.K.; Tsai, M.Y.; Tsai, P.C.; Hsu, B.H. Formation of alternating interfacial layers in Au-12Ge/Ni joints. Sci. Rep. 2015, 4, 4557. [Google Scholar] [CrossRef]

- Jin, S.; Leinenbach, C.; Wang, J.; Duarte, L.I.; Delsante, S.; Borzone, B.; Scott, A.; Watson, A. Thermodynamic study and reassessment of the Ge-Ni system. Calphad 2012, 38, 23–34. [Google Scholar] [CrossRef]

- Weyrich, N.; Leinenbach, C. Characterization of the isothermal solidification process in the Ni/Au-Ge layer system. J. Mater. Sci. 2015, 50, 3835–3844. [Google Scholar] [CrossRef]

- Weyrich, N.P. Joining of Metals and Ceramics Using Au-(Ge, Si)-Based Solder Alloys. Ph.D. Thesis, ETH Zürich, Zürich, Switzerland, 2015. [Google Scholar]

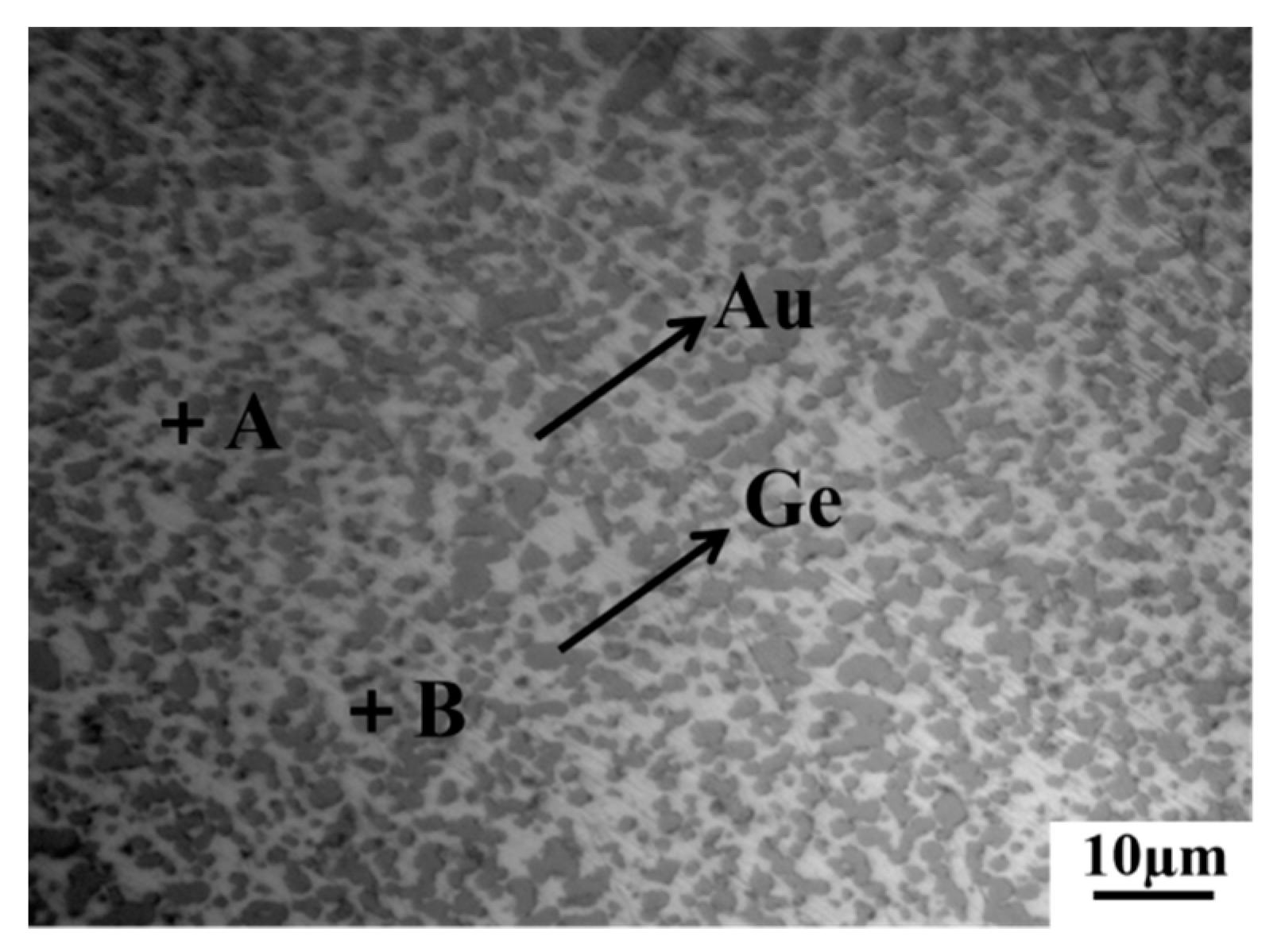

| Points | Composition, at.% | Phase | |

|---|---|---|---|

| Au | Ge | ||

| A | 98.32 | 1.68 | Au |

| B | 0 | 100.00 | Ge |

| Points | Composition, at.% | Phase | |||

|---|---|---|---|---|---|

| Au | Ge | Ni | Cu | ||

| A | - | 38.72 | 61.28 | - | Ni5Ge3 |

| B | - | 100.00 | - | - | Ge |

| C | - | 49.31 | 50.69 | - | NiGe |

| D | 100.00 | - | - | - | Au |

| E | - | - | 100.00 | - | Ni |

| F | - | - | - | 100.00 | Cu |

| Points | Composition, at.% | Phase | ||

|---|---|---|---|---|

| Au | Ge | Ni | ||

| A | - | 100.00 | - | Ge |

| B | - | 38.33 | 61.67 | Ni5Ge3 |

| C | 0.30 | 50.63 | 49.07 | NiGe |

| Points | Composition, at.% | Phase | ||

|---|---|---|---|---|

| Au | Ge | Ni | ||

| A | 88.58 | 7.96 | 3.46 | Au |

| B | 0.60 | 51.53 | 47.87 | NiGe |

| C | - | 38.63 | 61.37 | Ni5Ge3 |

| D | 1.83 | 47.51 | 50.67 | NiGe |

| E | - | - | 100.00 | Ni |

| F | - | 39.12 | 62.88 | Ni5Ge3 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Z.; Xue, S.; Long, W.; Wang, B.; Wang, J.; Zhang, P. Effects of Extreme Thermal Shock on Microstructure and Mechanical Properties of Au-12Ge/Au/Ni/Cu Solder Joint. Metals 2020, 10, 1373. https://doi.org/10.3390/met10101373

Wang Z, Xue S, Long W, Wang B, Wang J, Zhang P. Effects of Extreme Thermal Shock on Microstructure and Mechanical Properties of Au-12Ge/Au/Ni/Cu Solder Joint. Metals. 2020; 10(10):1373. https://doi.org/10.3390/met10101373

Chicago/Turabian StyleWang, Ziyi, Songbai Xue, Weimin Long, Bo Wang, Jianhao Wang, and Peng Zhang. 2020. "Effects of Extreme Thermal Shock on Microstructure and Mechanical Properties of Au-12Ge/Au/Ni/Cu Solder Joint" Metals 10, no. 10: 1373. https://doi.org/10.3390/met10101373

APA StyleWang, Z., Xue, S., Long, W., Wang, B., Wang, J., & Zhang, P. (2020). Effects of Extreme Thermal Shock on Microstructure and Mechanical Properties of Au-12Ge/Au/Ni/Cu Solder Joint. Metals, 10(10), 1373. https://doi.org/10.3390/met10101373