Influence of Severe Plastic Deformation on Static Recrystallization Microstructure of Pure Iron

Abstract

:1. Introduction

2. Materials and Methods

2.1. Experimental Method

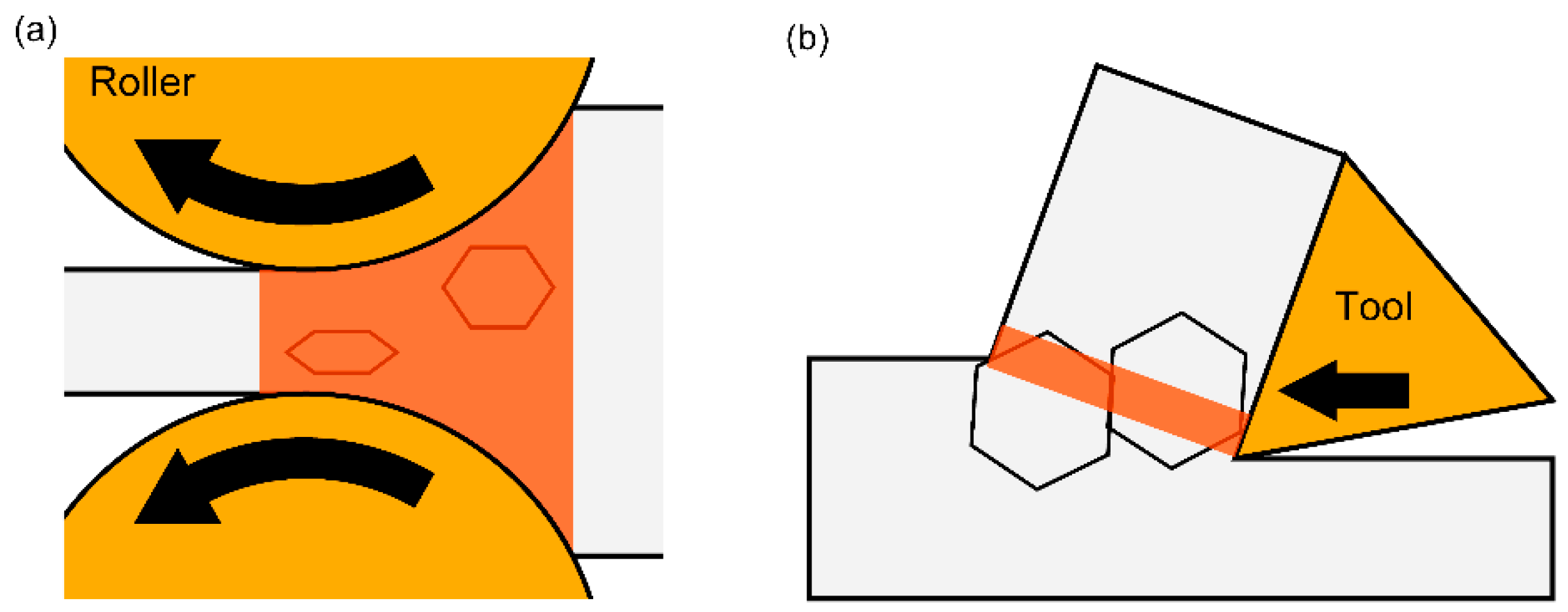

2.1.1. Orthogonal Cutting

2.1.2. Plate Rolling

2.1.3. Heat Treatment and Microstructure Analysis

2.2. Methods of Numerical Simulation of Static Recrystallization

3. Results and Discussion

3.1. Experimental Results and Discussion

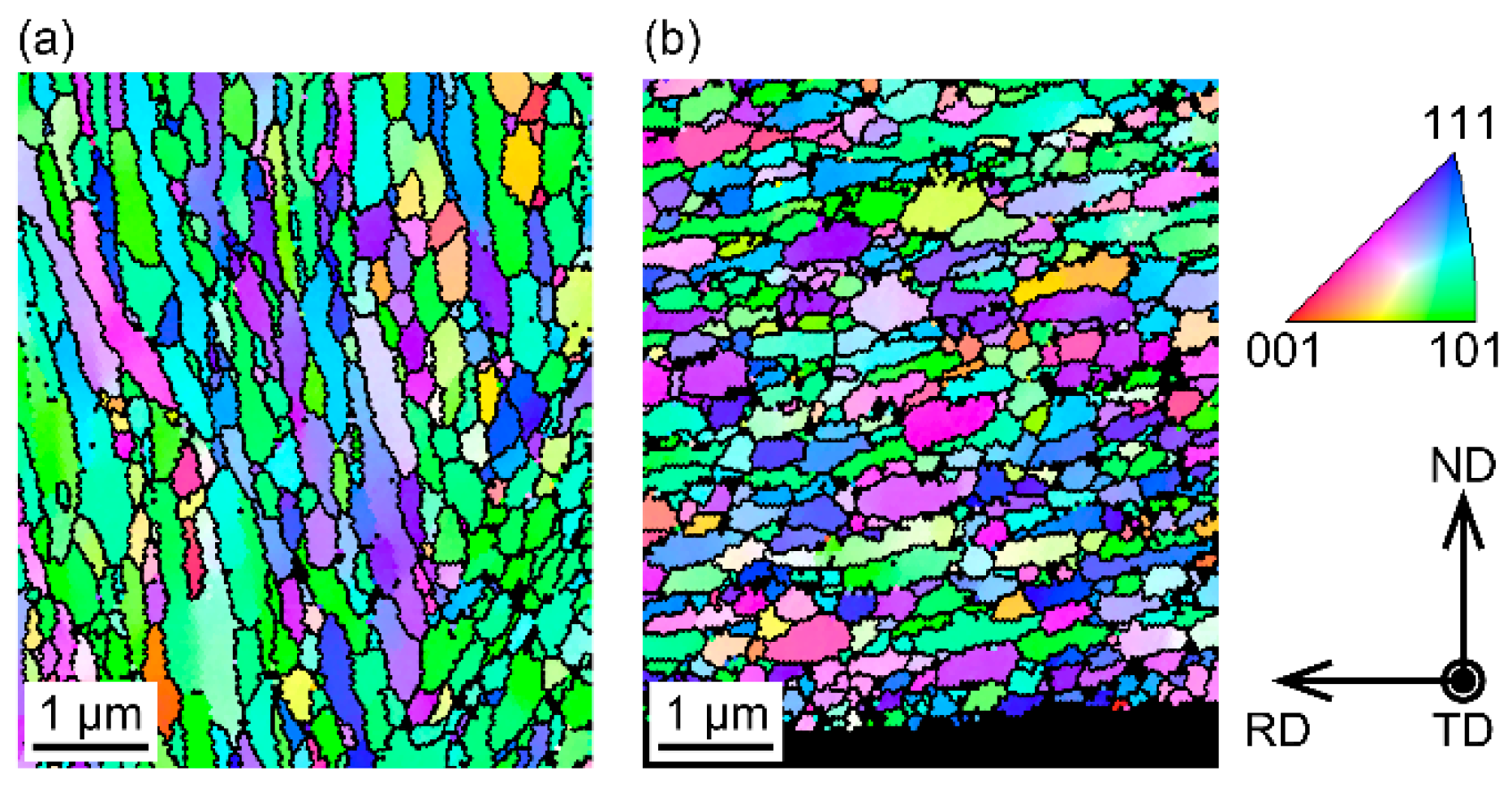

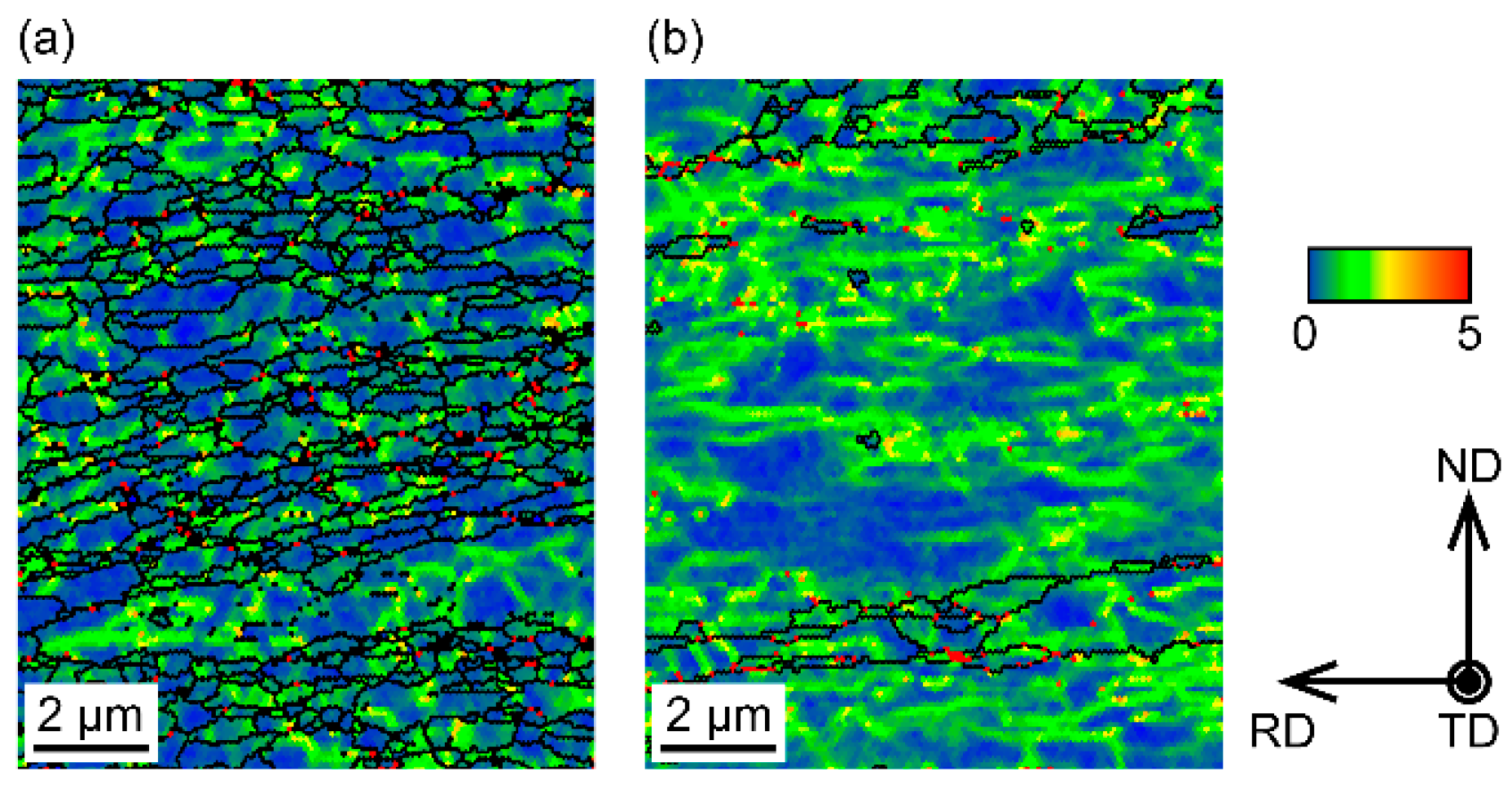

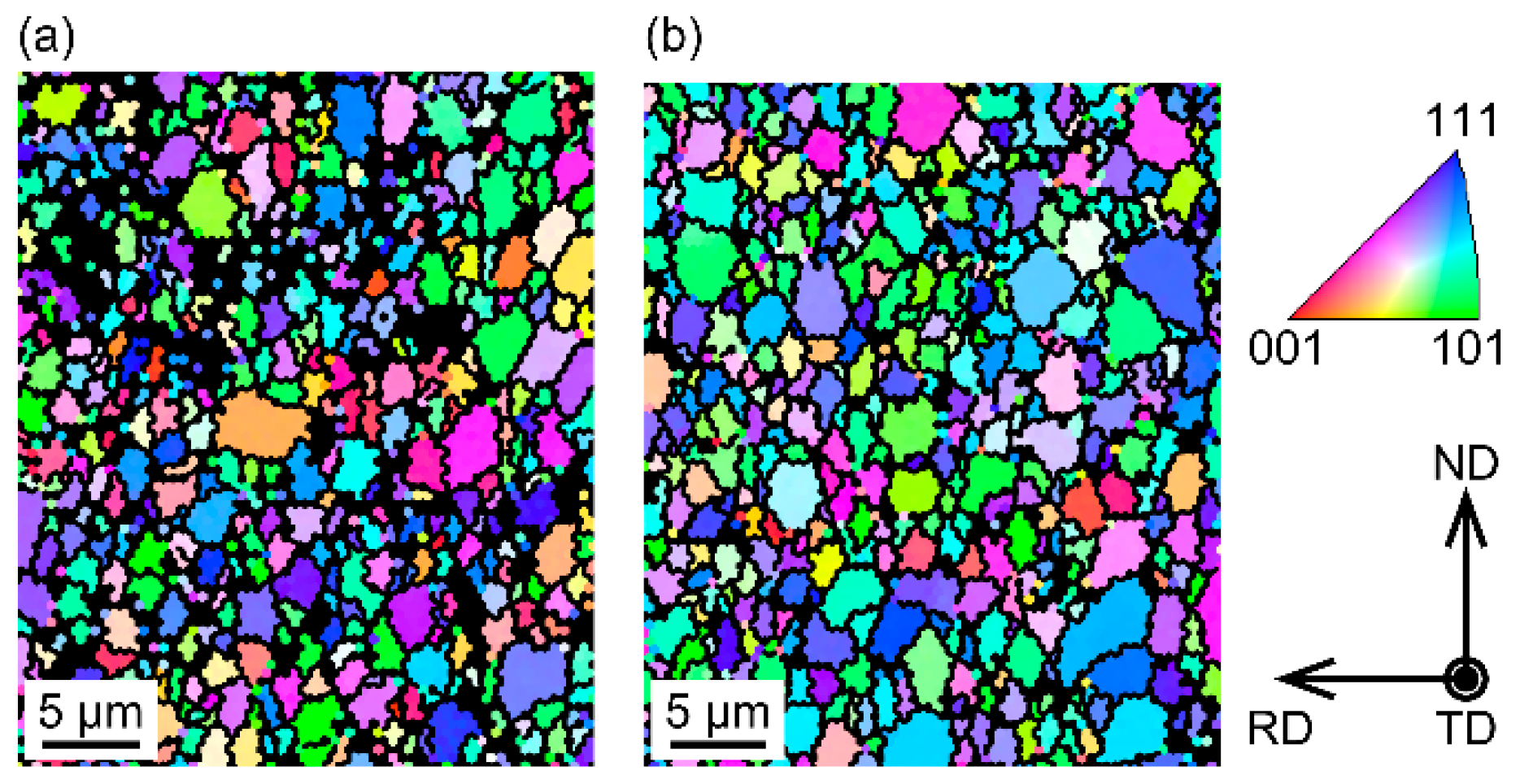

3.1.1. Deformed Microstructure

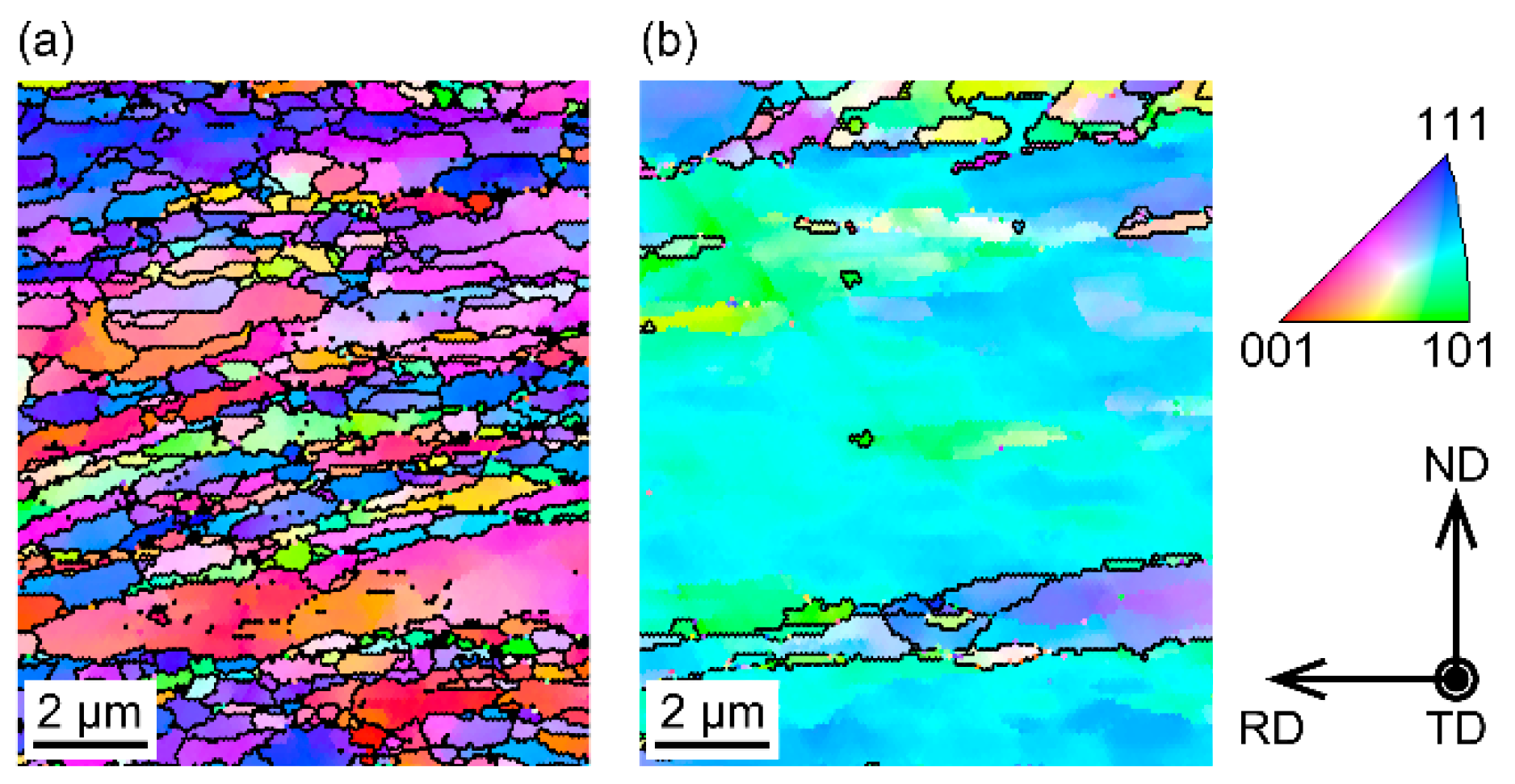

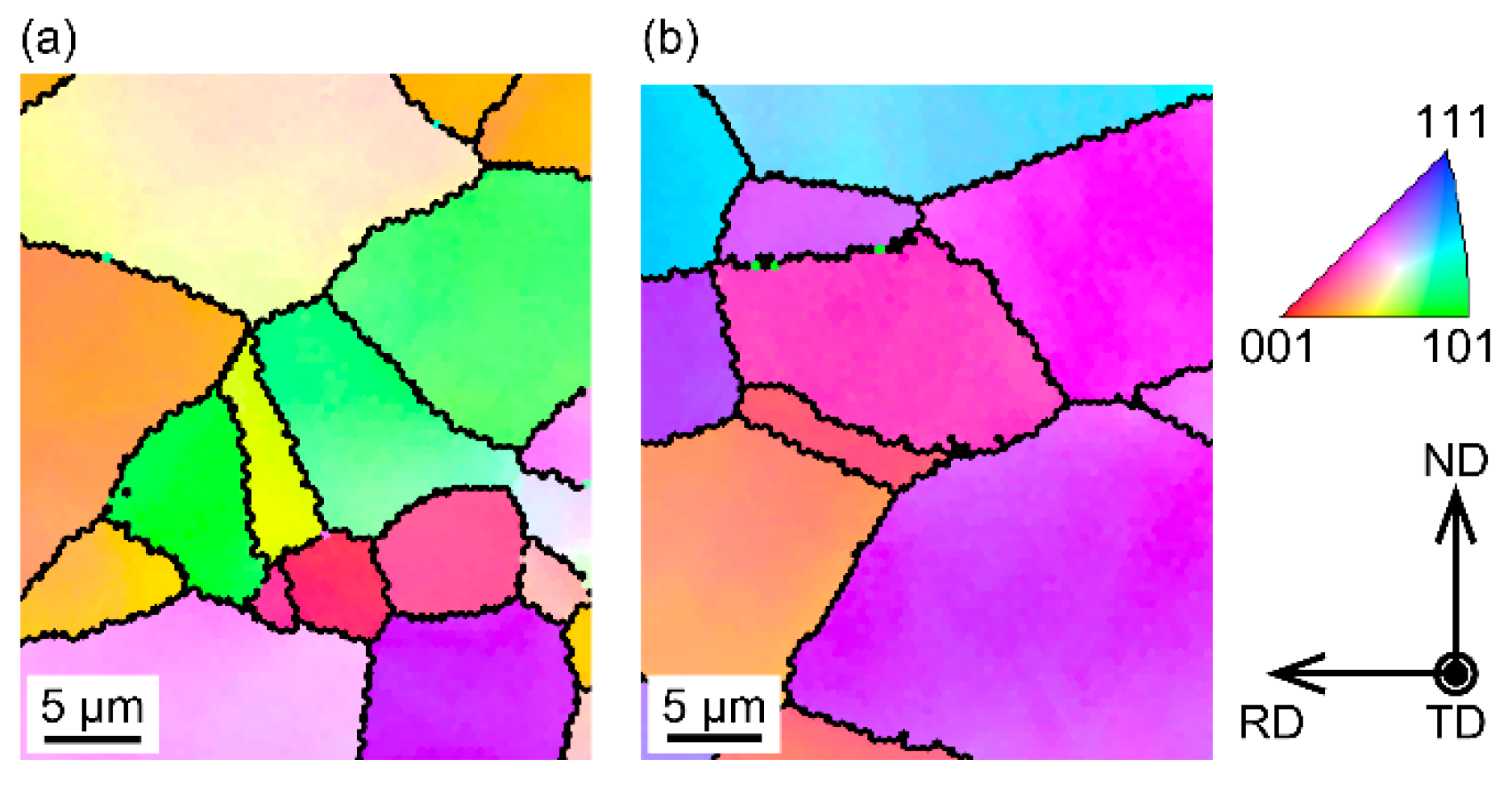

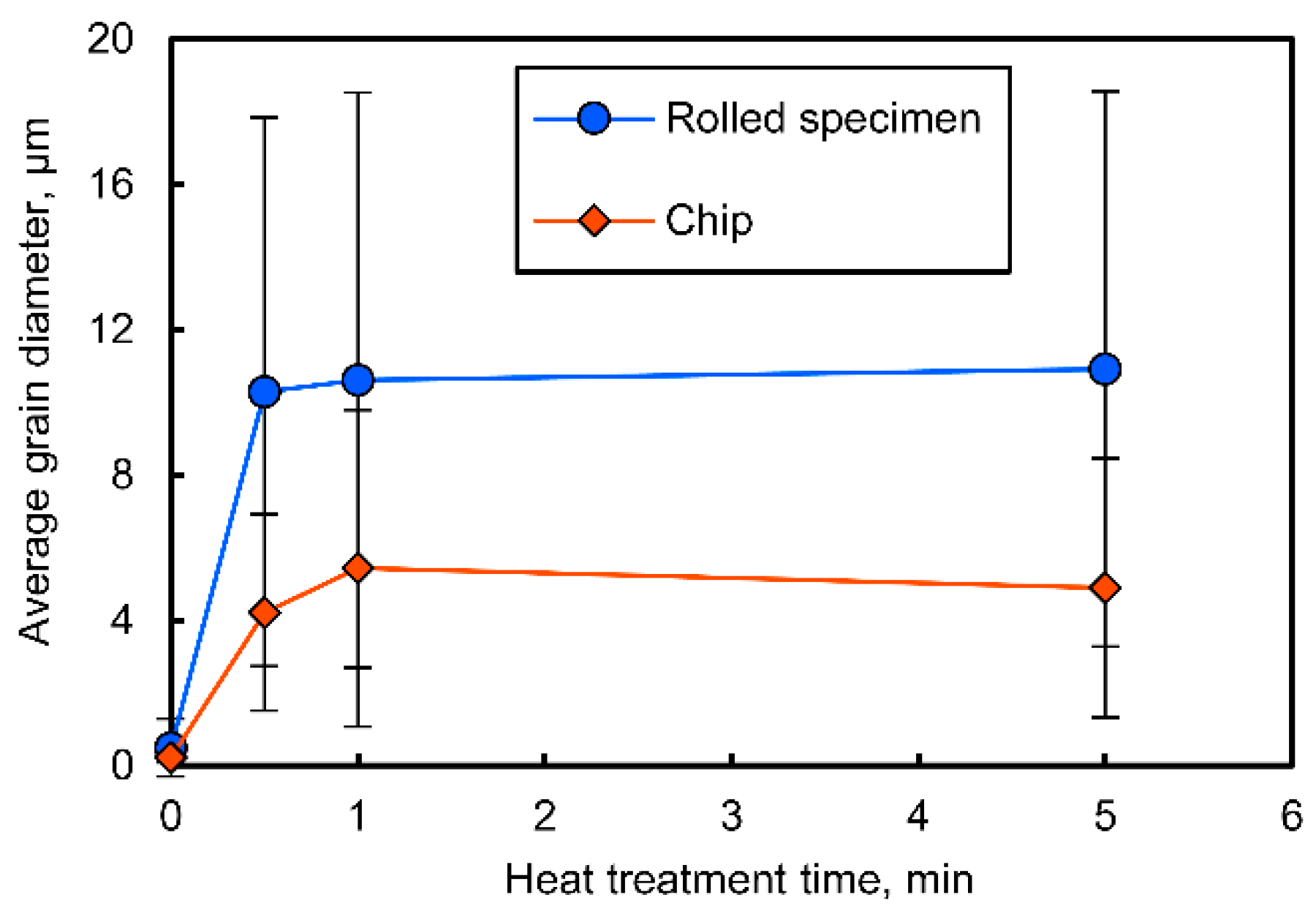

3.1.2. Recrystallized Microstructure

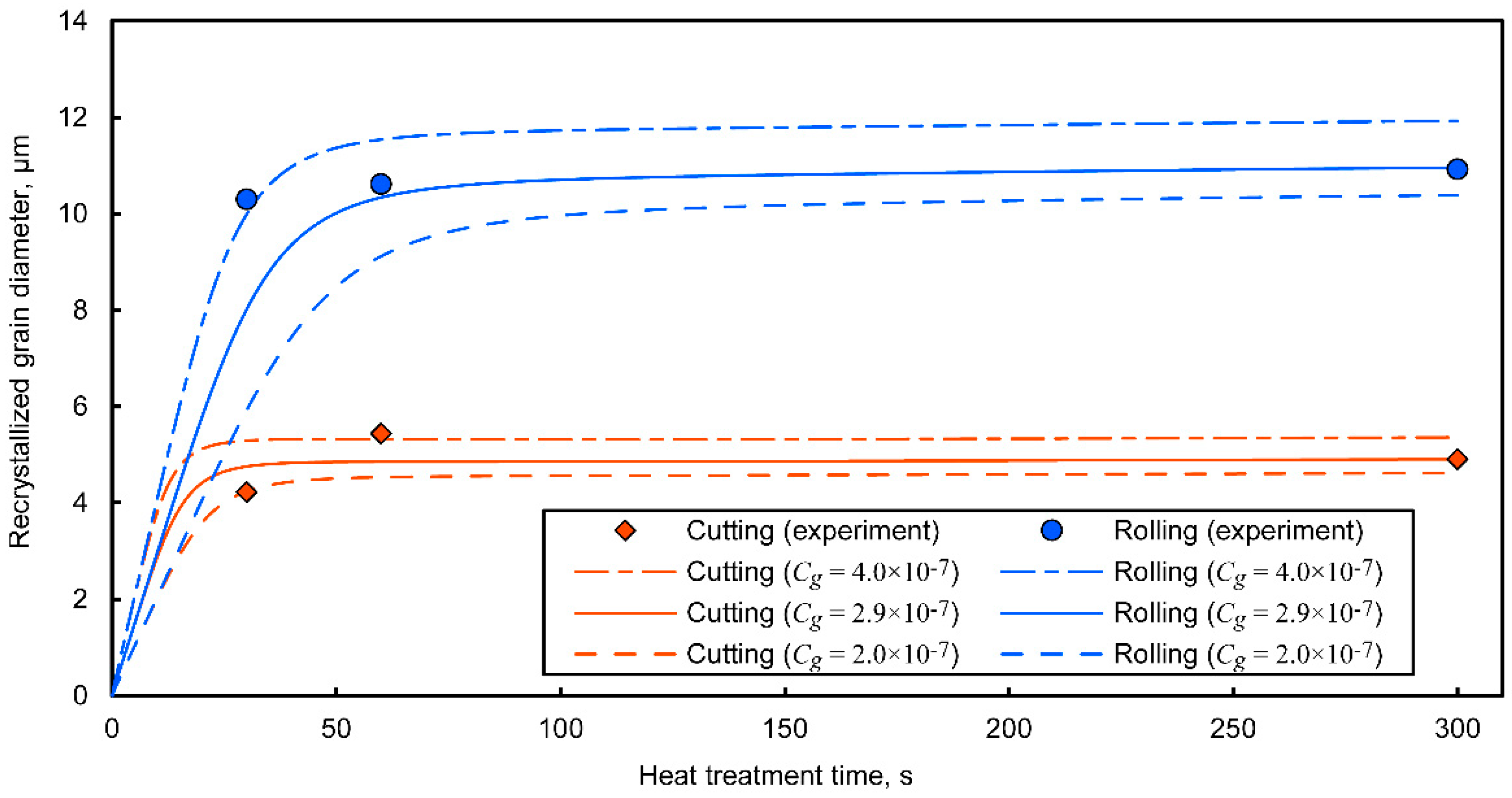

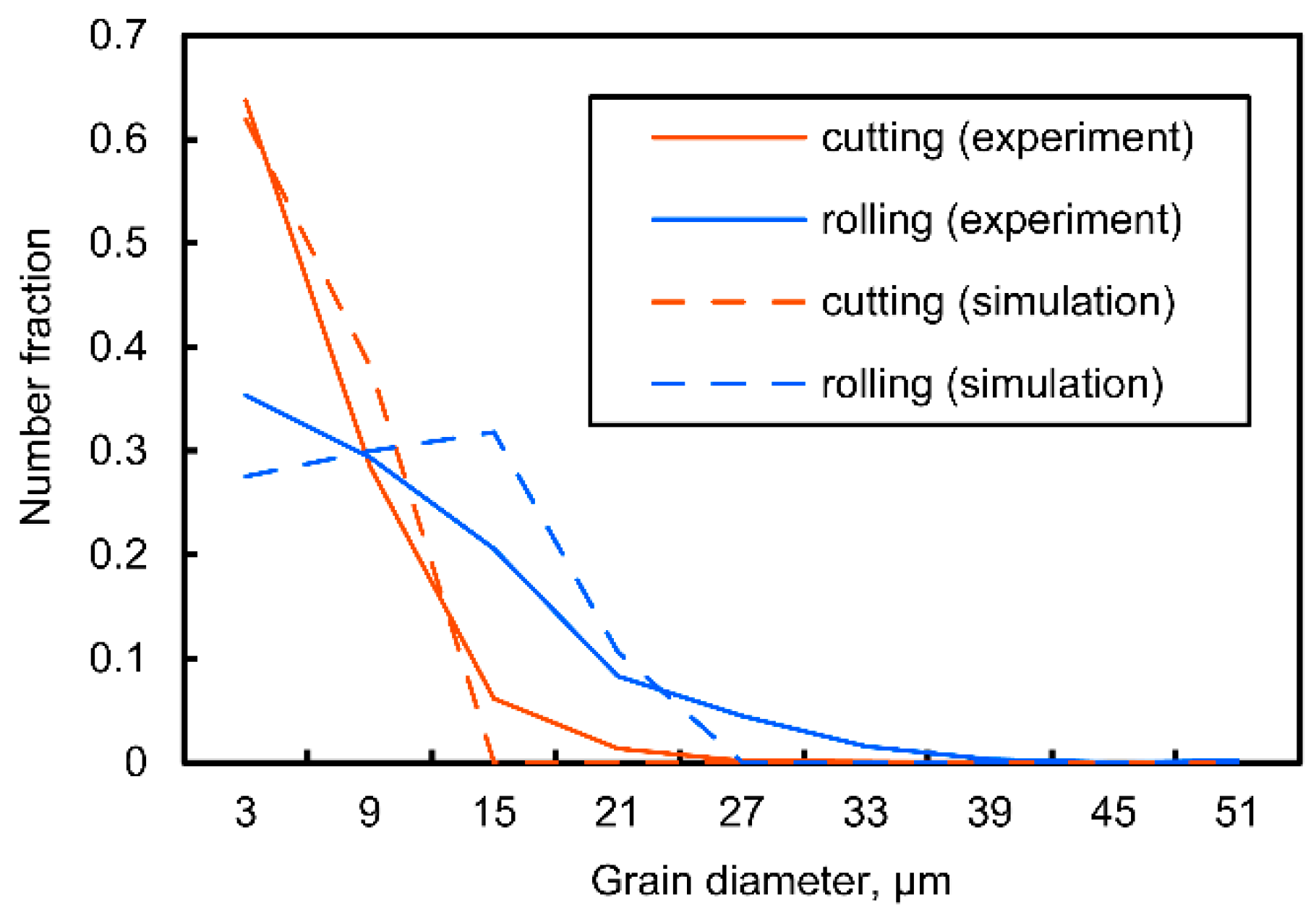

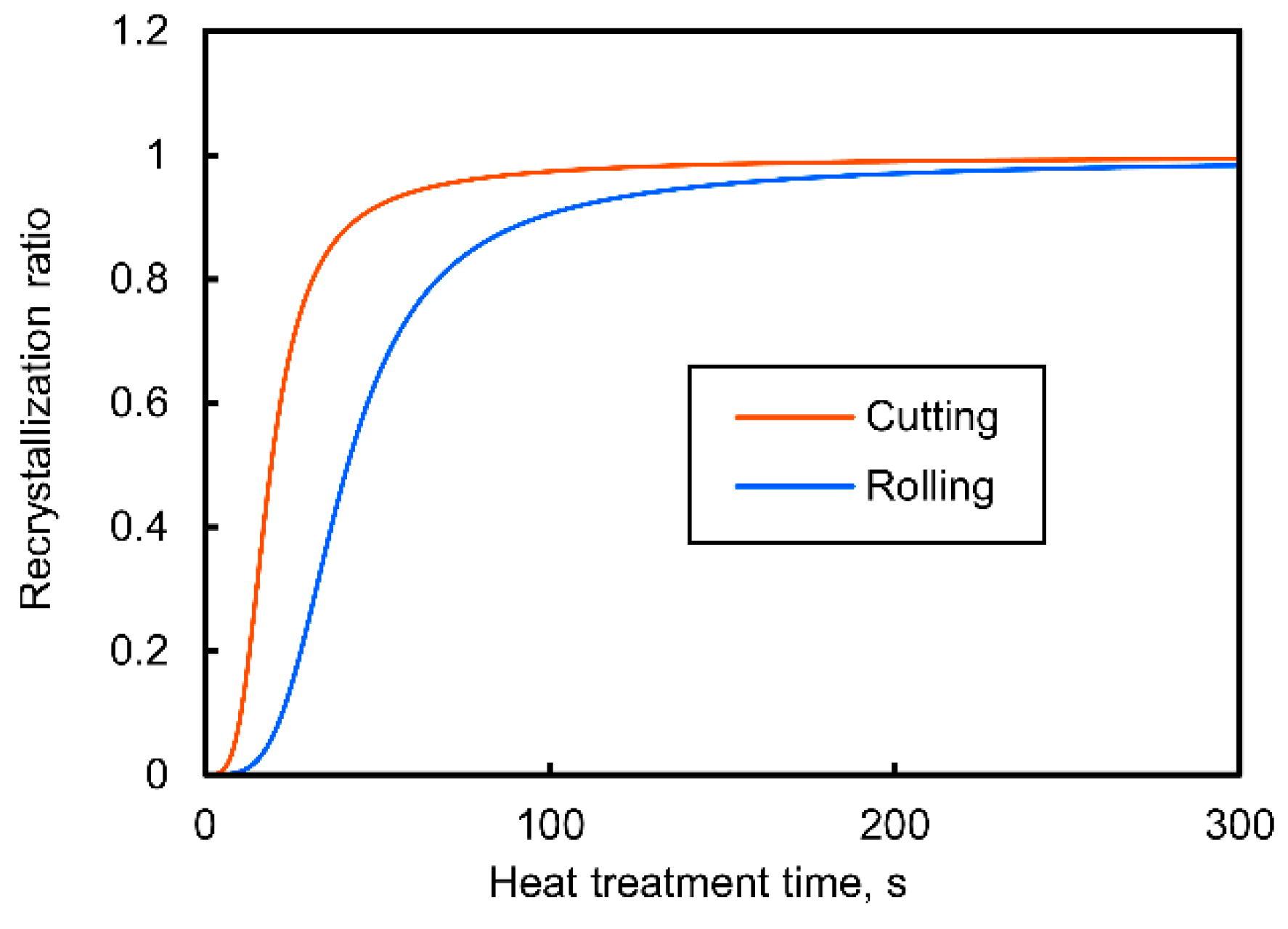

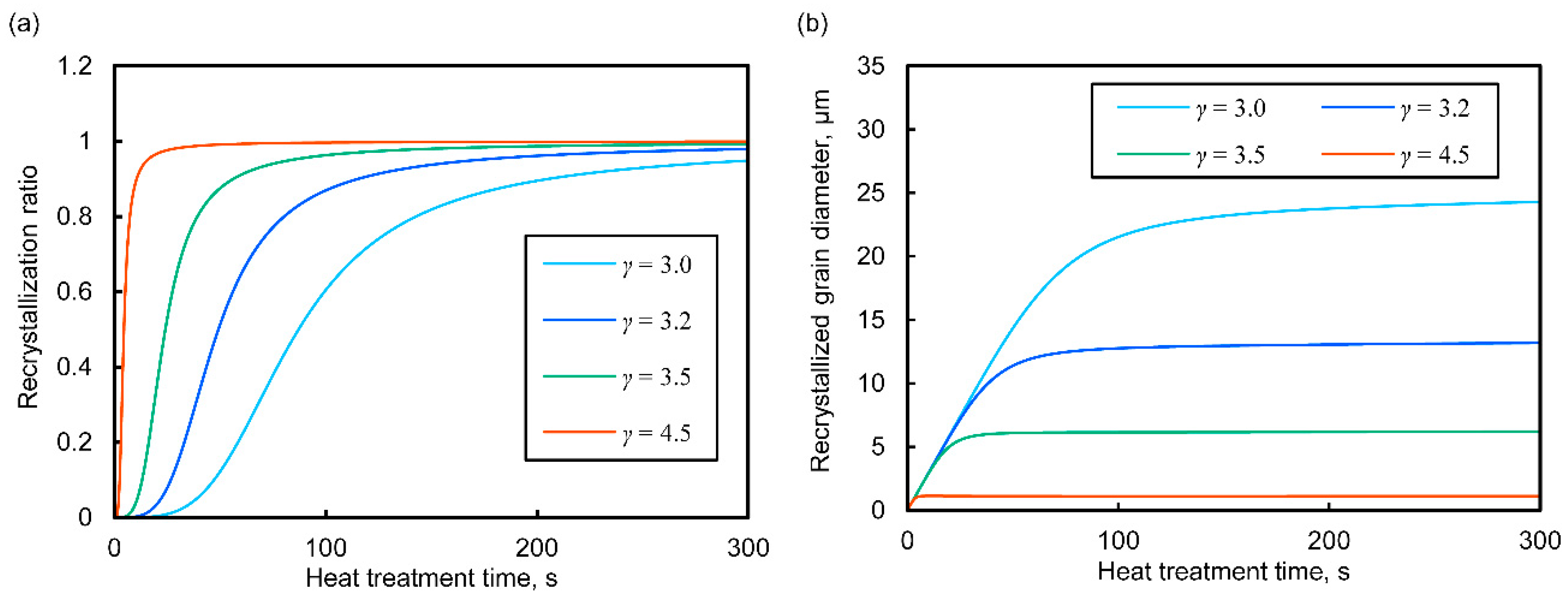

3.2. Simulation Results and Discussion

4. Conclusions

- In the cutting process, the grains of a chip specimen were uniformly subdivided into ultrafine grains by severe shear deformation with a high strain rate in the thin shear plane. Meanwhile, in the rolling process, the deformation of grains in a rolled specimen was significantly affected by crystal orientation, and the plastic deformation of grains was uneven in comparison with that in the chip specimen. Several grains were elongated along the rolling direction, but they were not subdivided, although a large strain was applied to the work material.

- A theoretical model was developed, and it was revealed that the number of recrystallized grains depended on the fraction of the large-misorientation area constructed with GNBs. Uniform plastic deformation of a chip specimen caused a high-misorientation-angle area, and more nucleation of static recrystallization occurred than in the rolled specimen.

- It was demonstrated that the cutting process was more advantageous than rolling in producing ultrafine recrystallized grains because cutting could apply severe plastic strain uniformly on a work material and effectively generate GNBs.

Author Contributions

Funding

Conflicts of Interest

References

- Buchmayr, B. Thermomechanical Treatment of Steels—A Real Disruptive Technology Since Decades. Steel Res. Int. 2017, 88, 14. [Google Scholar] [CrossRef]

- Maki, T.; Furuhara, T.; Tsuji, N.; Morito, S.; Miyamoto, G.; Shibata, A. Thermomechanical Processing of Steel—Past, Present and Future. Tetsu Hagane 2014, 100, 1062–1075. [Google Scholar] [CrossRef] [Green Version]

- Tsuji, N. Ultrafine Grained Steels. Tetsu Hagane 2002, 88, 359–369. [Google Scholar] [CrossRef] [Green Version]

- Xia, Z.S.; Kang, Y.L.; Wang, Q.L. Developments in the production of grain-oriented electrical steel. J. Magn. Magn. Mater. 2008, 320, 3229–3233. [Google Scholar] [CrossRef]

- Komatsu, T.; Matsumura, T.; Torizuka, S. Effect of Grain Size in Stainless Steel on Cutting Performance in Micro-Scale Cutting. Int. J. Autom. Technol. 2011, 5, 334–341. [Google Scholar] [CrossRef]

- Komatsu, T.; Kobayashi, H.; Torizuka, S.; Nagayama, S. Micro Hole Piercing for Ultra Fine Grained Steel. Int. J. Autom. Technol. 2012, 6, 802–808. [Google Scholar] [CrossRef]

- Komatsu, T. Effects of Grain Size on the Groove Depths in Microlaser Cutting of Austenitic Stainless Steel SUS304. Int. J. Autom. Technol. 2015, 9, 636–645. [Google Scholar] [CrossRef]

- Torizuka, S.; Muramatsu, E.; Komatsu, T.; Nagayama, S. Production processes for nanostructured wires, bars and strips. In Nanostructured Metals and Alloys: Processing, Microstructure, Mechanical Properties and Applications; Whang, S.H., Ed.; Woodhead Publ Ltd.: Cambridge, UK, 2011; pp. 715–746. [Google Scholar]

- Azushima, A.; Kopp, R.; Korhonen, A.; Yang, D.Y.; Micari, F.; Lahoti, G.D.; Groche, P.; Yanagimoto, J.; Tsuji, N.; Rosochowski, A.; et al. Severe plastic deformation (SPD) processes for metals. Cirp Ann. Manuf. Technol. 2008, 57, 716–735. [Google Scholar] [CrossRef]

- Segal, V.M. Materials processing by simple shear. Mater. Sci. Eng. A Struct. Mater. Prop. Microstruct. Process. 1995, 197, 157–164. [Google Scholar] [CrossRef]

- Segal, V.M.; Reznikov, V.I.; Drobyshevskiy, A.E.; Kopylov, V.I. Plastic working of metals by simple shear. Russ. Metall. 1981, 1, 99–105. [Google Scholar]

- Bridgman, P.W. Effects of High Shearing Stress Combined with High Hydrostatic Pressure. Phys. Rev. 1935, 48, 825–847. [Google Scholar] [CrossRef]

- Erbel, S. Mechanical properties and structure of extremely strainhardened copper. Met. Technol. 1979, 6, 482–486. [Google Scholar] [CrossRef]

- Saito, Y.; Tsuji, N.; Utsunomiya, H.; Sakai, T.; Hong, R.G. Ultra-fine grained bulk aluminum produced by accumulative roll-bonding (ARB) process. Scr. Mater. 1998, 39, 1221–1227. [Google Scholar] [CrossRef]

- Nagashima, F.; Yoshino, M.; Terano, M. Microstructure control of pure iron by utilizing metal cutting method. Procedia Manuf. 2018, 15, 1541–1548. [Google Scholar] [CrossRef]

- Nagashima, F.; Nakagawa, Y.; Yoshino, M. Study on effects of strong shear strain on recrystallized grain size of pure iron and microstructure control method. Procedia Manuf. 2020, 50, 248–252. [Google Scholar] [CrossRef]

- Baumeister, T. Standard Handbook for Mechanical Engineers, 7th ed.; McGraw-Hill: New York, NY, USA, 1967. [Google Scholar]

- Yoshida, S. Kaifukuto Saikessho. In Ten’iron: Sono Kinzokugakuheno Ouyo, Materials; The Japan Institute of Metals and Materials, Ed.; Maruzen Co., Ltd.: Tokyo, Japan, 1971; pp. 227–275. [Google Scholar]

- Read, W.T.; Shockley, W. Dislocation Models of Crystal Grain Boundaries. Phys. Rev. 1950, 78, 275–289. [Google Scholar] [CrossRef]

- Byrne, J.G. Recovery, Recrystallization, and Grain Growth; Macmillan: London, UK, 1965. [Google Scholar]

- Johnson, W.A.; Mehl, R.F. Reaction kinetics in processes of nucleation and growth. Trans. Am. Inst. Min. Metall. Eng. 1939, 135, 416–442. [Google Scholar]

- Avrami, M. Kinetics of phase change I—General theory. J. Chem. Phys. 1939, 7, 1103–1112. [Google Scholar] [CrossRef]

- Avrami, M. Kinetics of Phase Change. II Transformation-Time Relations for Random Distribution of Nuclei. J. Chem. Phys. 1940, 8, 212–224. [Google Scholar] [CrossRef]

- Avrami, M. Granulation, Phase Change, and Microstructure—Kinetics of Phase Change. III. J. Chem. Phys. 1941, 9, 177–184. [Google Scholar] [CrossRef]

- Turnbull, D. Theory of Grain Boundary Migration Rates. J. Met. 1951, 3, 661–665. [Google Scholar] [CrossRef]

- Lübbehusen, M.; Mehrer, H. Self-diffusion in α-iron: The influence of dislocations and the effect of the magnetic phase transition. Acta Metall. Mater. 1990, 38, 283–292. [Google Scholar] [CrossRef]

- Buffington, F.S.; Hirano, K.; Cohen, M. Self diffusion in iron. Acta Metall. 1961, 9, 434–439. [Google Scholar] [CrossRef]

- Umezaki, S.; Murata, Y.; Nomura, K.; Kubushiro, K. Quantitative Analysis of Dislocation Density in an Austenitic Steel after Plastic Deformation. J. Jpn. Inst. Met. Mater. 2014, 78, 218–224. [Google Scholar] [CrossRef] [Green Version]

- Hansen, N. New discoveries in deformed metals. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 2001, 32, 2917–2935. [Google Scholar] [CrossRef]

- Maki, T. Tekko No Soshikiseigyo -Sono Genri To Houho-; Uchida Rokakuho Publishing: Tokyo, Japan, 2015. [Google Scholar]

- Tomita, M.; Inaguma, T.; Sakamoto, H.; Ushioda, K. Development of Recrystallization Texture in Severely Cold-rolled Pure Iron. ISIJ Int. 2016, 56, 693–699. [Google Scholar] [CrossRef] [Green Version]

- Hook, R.E.; Hirth, J.P. The deformation behavior of isoaxial bicrystals of Fe-3%Si. Acta Metall. 1967, 15, 535–551. [Google Scholar] [CrossRef]

- Abe, M.; Kokabu, Y.; Hayashi, Y.; Hayami, S. Effects of Initial Grain Boundaries on the Cold-Rolling and Annealing Textures of Pure Iron. J. Jpn. Inst. Met. 1980, 44, 84–94. [Google Scholar] [CrossRef] [Green Version]

- Sugino, Y.; Ukai, S.; Leng, B.; Tang, Q.; Hayashi, S.; Kaito, T.; Ohtsuka, S. Grain Boundary Deformation at High Temperature Tensile Tests in ODS Ferritic Steel. ISIJ Int. 2011, 51, 982–986. [Google Scholar] [CrossRef] [Green Version]

- Kaibyshev, R.; Goloborodko, A.; Musin, F.; Nikulin, I.; Sakai, T. The Role of Grain Boundary Sliding in Microstructural Evolution during Superplastic Deformation of a 7055 Aluminum Alloy. Mater. Trans. 2002, 43, 2408–2414. [Google Scholar] [CrossRef] [Green Version]

- Usui, E. Sessaku/kensakukakogaku Jou -Sessakukako-; Kyoritsu Shuppan Co., Ltd.: Tokyo, Japan, 1971. [Google Scholar]

- Sims, R.B. The Calculation of Roll Force and Torque in Hot Rolling Mills. Proc. Inst. Mech. Eng. 1954, 168, 191–200. [Google Scholar] [CrossRef]

- Kawasaki, M.; Horita, Z.; Langdon, T.G. Microstructural evolution in high purity aluminum processed by ECAP. Mater. Sci. Eng. A 2009, 524, 143–150. [Google Scholar] [CrossRef]

| Cutting Conditions | |

|---|---|

| Tool material | Carbide, P10 |

| Rake angle | 10° |

| Cutting speed | 25 m/min |

| Depth of cut | 0.04 mm |

| Lubrication | Dry |

| Geometry of Chip | |

| Thickness of the chip | 0.15 mm |

| Shear angle | 15.8° |

| Shear strain of a chip | 3.6 |

| Equivalent strain of a chip | 2.1 |

| Rolling Conditions | |

|---|---|

| Roll diameter | 40 mm |

| Rolling speed | 10 rpm |

| Thickness reduction | 91% |

| Number of rolling passes | 1 pass |

| Lubrication | Dry |

| Geometry of Rolled Sheet | |

| Thickness before rolling | 2.96 mm |

| Thickness after rolling | 0.27 mm |

| Equivalent strain | 2.8 |

| Parameter | Value | Reference |

|---|---|---|

| 0.231 | [19] for Si-Fe | |

| 33.8 kcal/mol | [25] | |

| 3.025 eV | [26] | |

| 60 kcal | [27] |

| Parameter | Cutting | Rolling |

|---|---|---|

| Parameter | Cutting | Rolling |

|---|---|---|

| Large-misorientation area ratio | 0.28 | 0.038 |

| Calculated dislocation density at large-misorientation area [/m2] | ||

| Number of recrystallized grains [/mm3] | ||

| Grain growth rate when recrystallization ratio reaches 50% [µm/s] |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nagashima, F.; Nakagawa, Y.; Yoshino, M. Influence of Severe Plastic Deformation on Static Recrystallization Microstructure of Pure Iron. Metals 2020, 10, 1320. https://doi.org/10.3390/met10101320

Nagashima F, Nakagawa Y, Yoshino M. Influence of Severe Plastic Deformation on Static Recrystallization Microstructure of Pure Iron. Metals. 2020; 10(10):1320. https://doi.org/10.3390/met10101320

Chicago/Turabian StyleNagashima, Fumihisa, Yuki Nakagawa, and Masahiko Yoshino. 2020. "Influence of Severe Plastic Deformation on Static Recrystallization Microstructure of Pure Iron" Metals 10, no. 10: 1320. https://doi.org/10.3390/met10101320

APA StyleNagashima, F., Nakagawa, Y., & Yoshino, M. (2020). Influence of Severe Plastic Deformation on Static Recrystallization Microstructure of Pure Iron. Metals, 10(10), 1320. https://doi.org/10.3390/met10101320