Finite Element Analysis and Experimental Evaluation of Residual Stress of Zr-4 alloys Processed through Swaging

Abstract

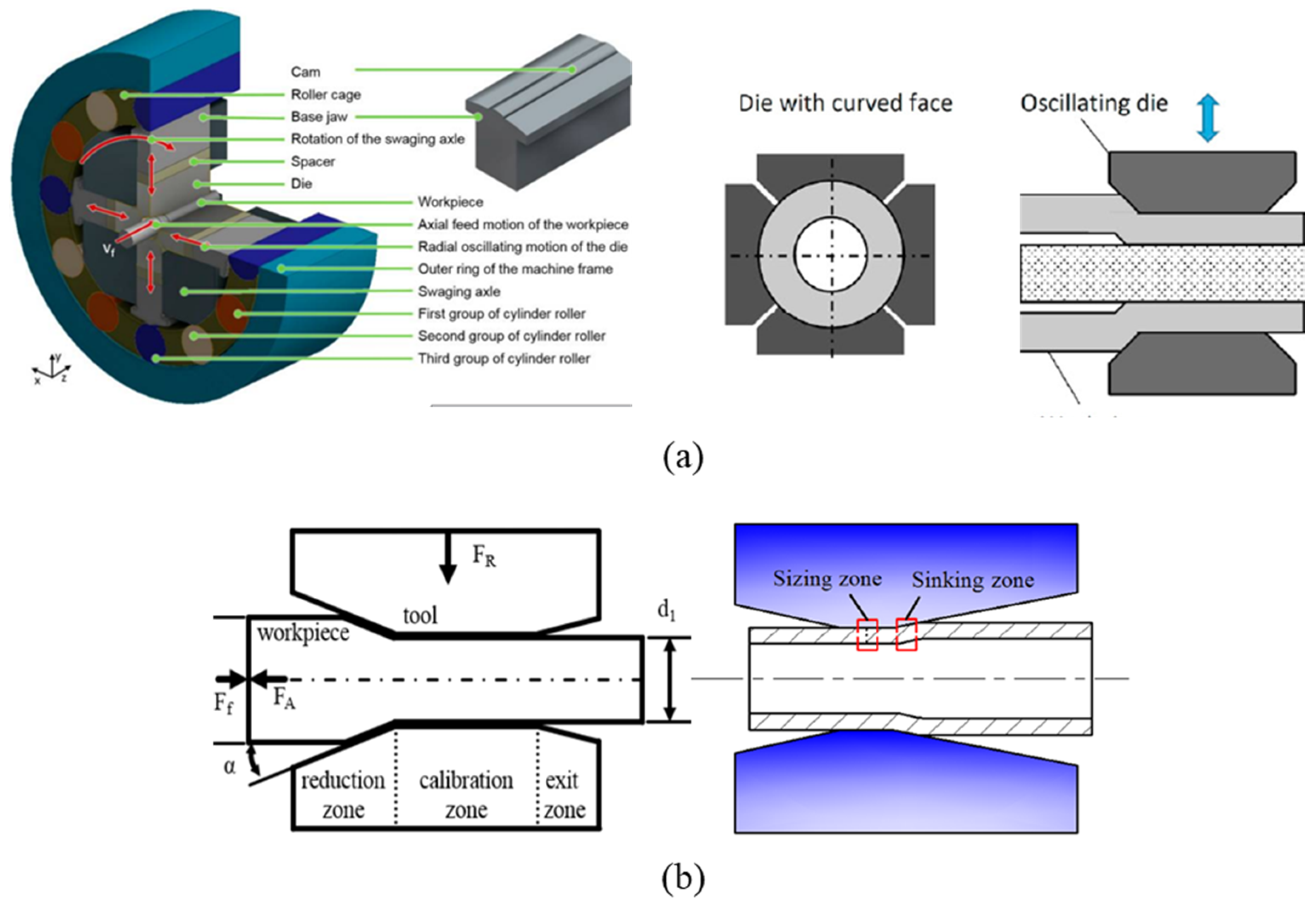

:1. Introduction

2. Finite Element Analysis

2.1. Modelling

2.2. Material

2.3. Mesh

2.4. Boundary Condition

2.5. Residual Stress Analysis Using FEM

3. Experimental-Residual Stress Measurement

- A through reference hole is drilled at the measured location using gun drilling.

- The measurement of the reference hole diameter is made at pre-decided angles for each increment in the depth direction.

- A core of material containing the reference hole is trepanned free of the rest of the material using an electric discharge machine (EDM) (Makino, Mason, Ohio, United States).

- The reference hole diameter is again measured to calculate the magnitude of residual stress fields from the amount of deformation observed in the inner core column of trepanning process.

4. Results and Discussion

4.1. FEM Results

4.2. Deep Hole Drilling

4.3. Experimental vs. Numerical

5. Conclusions

- Numerical and experimental results both show a similar trend of residual stresses from the surface to center on the 25% swaged rod at different feed rates (0.7 m/min, 1.25 m/min and 2 m/min). Almost the same magnitude of residual stress on the surface as well as center of the 25% swaged rod are observed.

- Deep hole drilling results show an increase in magnitude of residual stress on increasing the percentage of cold work. This is due to increase in the amount of deformation, which leads to an increase in yield strength at higher cold work on zirconium alloys.

- The inhomogeneous deformation observed from the surface to the center (in the radial direction) on the 25% swaged rod (0.7 m/min, 1.25 m/min and 2 m/min) as observed in residual stress magnitude for both experimental and numerical methods.

- It can be concluded from the load curve that at the same time all four dies exert an equal amount of load over the work piece, it results in a uniform homogeneous deformation in the axial direction of the swaged Zr-4 rod.

- The axial (X) and radial (Z) residual stresses on the surface are compressive and thus, can help in preventing crack propagation and can enhance product life. On the other hand, the stresses towards the center of the rod are tensile and thus, may assist the propagation of possible cracks. Hence, there is a need to undergo heat treatment before use.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Zhang, Q.; Jin, K.; Mu, D.; Zhang, Y.; Li, Y. Energy-controlled rotary swaging process for tube workpiece. Int. J. Adv. Manuf. Technol. 2015, 80, 2015–2026. [Google Scholar] [CrossRef]

- Ishkina, S.; Charni, D.; Herrmann, M.; Liu, Y.; Epp, J.; Schenck, C.; Kuhfuss, B.; Zoch, H.W. Influence of Process Fluctuations on Residual Stress Evolution in Rotary Swaging of Steel Tubes. Materials 2019, 12, 855. [Google Scholar] [CrossRef] [Green Version]

- Zhang, Q.; Jin, K.; Mu, D.M.; Ma, P.; Tian, J. Rotary Swaging Forming Process of Tube Workpieces. Procedia Eng. 2014, 81, 2336–2341. [Google Scholar] [CrossRef] [Green Version]

- Ameli, A.; Movahhedy, M.R. A parametric study on residual stresses and forging load in cold radial forging process. Int. J. Adv. Manuf. Technol. 2007, 33, 7–17. [Google Scholar] [CrossRef]

- Brenneis, M.; Groche, P. Smart Components through Rotary Swaging. Key Eng. Mater. 2012, 504–506, 723–728. [Google Scholar] [CrossRef]

- Domblesky, J.P.; Shivpuri, R. Development and validation of a finite-element model for multiple-pass radial forging. J. Mater. Process. Technol. 1995, 55, 432–441. [Google Scholar] [CrossRef]

- Yuan, L.; Wang, W.; Li, Y.; Yang, M.; Zhang, H.; Zhang, W. Effect of annealing temperature on texture and residual stress of Ti-6Al-4V alloy seamless tubing processed by cold rotary swaging. Vacuum 2020, 177, 109399. [Google Scholar] [CrossRef]

- Ishkina, S.; Schenck, C.; Herrmann, M.; Kuhfuss, B. Visualization of Axial Material Flow by Eccentric Thread Swaging. Procedia Manuf. 2020, 47, 1339–1344. [Google Scholar] [CrossRef]

- Grosman, F.; Piela, A. Metal flow in the deformation gap at primary swaging. J. Mater. Process. Technol. 1996, 56, 404–411. [Google Scholar] [CrossRef]

- Piela, A. Analysis of the metal flow in swaging—numerical modelling and experimental verification. Int. J. Mech. Sci. 1997, 39, 221–231. [Google Scholar] [CrossRef]

- Rong, L.; Nie, Z.-R.; Zuo, T.-Y. FEA modeling of effect of axial feeding velocity on strain field of rotary swaging process of pure magnesium. Trans. Nonferr. Met. Soc. China 2006, 16, 1015–1020. [Google Scholar] [CrossRef]

- Macháčková, A.; Krátká, L.; Petrmichl, R.; Kunčická, L.; Kocich, R. Affecting Structure Characteristics of Rotary Swaged Tungsten Heavy Alloy Via Variable Deformation Temperature. Materials 2019, 12, 4200. [Google Scholar] [CrossRef] [Green Version]

- Kocich, R.; Kunčická, L.; Dohnalík, D.; Macháčková, A.; Šofer, M. Cold rotary swaging of a tungsten heavy alloy: Numerical and experimental investigations. Int. J. Refract. Met. Hard Mater. 2016, 61, 264–272. [Google Scholar] [CrossRef]

- Han, C.; Wen, S.; Ye, F.; Wu, W.; Xue, S.; Liang, Y.; Liu, B.; Lin, J. Deformation twinning in equiaxed-grained Fe-6.5 wt.%Si alloy after rotary swaging. J. Mater. Sci. Technol. 2020, 49, 25–34. [Google Scholar] [CrossRef]

- Kocich, R.; Kunčická, L.; Davis, C.F.; Lowe, T.C.; Szurman, I.; Macháčková, A. Deformation behavior of multilayered Al-Cu clad composite during cold-swaging. Mater. Des. 2016, 90, 379–388. [Google Scholar] [CrossRef]

- Rong, L.; Nie, Z.; Zuo, T. 3D finite element modeling of cogging-down rotary swaging of pure magnesium square billet-Revealing the effect of high-frequency pulse stroking. Mater. Sci. Eng. A 2007, 464, 28–37. [Google Scholar] [CrossRef]

- Herrmann, M.M. Graded Structured Tools for Dry Rotary Swaging. Dry Met. Form. Open Access J. 2018, 4, 018–024. [Google Scholar]

- Zhang, Q.; Mu, D.; Jin, K.; Liu, Y. Recess swaging method for manufacturing the internal helical splines. J. Mater. Process. Technol. 2014, 214, 2971–2984. [Google Scholar] [CrossRef]

- Moumi, E.; Ishkina, S.; Kuhfuss, B.; Hochrainer, T.; Struss, A.; Hunkel, M. 2D-simulation of Material Flow During Infeed Rotary Swaging Using Finite Element Method. Procedia Eng. 2014, 81, 2342–2347. [Google Scholar] [CrossRef] [Green Version]

- Ripoll, M.R.; Weygand, S.M.; Riedel, H. Reduction of tensile residual stresses during the drawing process of tungsten wires. Mater. Sci. Eng. A 2010, 527, 3064–3072. [Google Scholar] [CrossRef]

- Kortabarria, A.; Arrazola, P.J.; Ostolaza, K. Multi Revolution Finite Element Model to Predict Machining Induced Residual Stresses in Inconel 718. Procedia CIRP 2013, 8, 111–116. [Google Scholar] [CrossRef] [Green Version]

- Király, M.; Antók, D.M.; Horváth, L.; Hózer, Z. Evaluation of axial and tangential ultimate tensile strength of zirconium cladding tubes. Nucl. Eng. Technol. 2018, 50, 425–431. [Google Scholar] [CrossRef]

- Singh, G.; Tiwari, A.; Agarwal, V.; Jayaganthan, R.; Vishnu Narayanan, K.I.; Arora, U.K.; Srivastava, D. Tensile and Fracture Behaviour of Zr-4 Alloy Processed Through Swaging. Trans. Indian Inst. Met. 2020, 73, 955–965. [Google Scholar] [CrossRef]

- Singh, G.; Jayaganthan, R.; Arora, U.K.; Vishnu Narayanan, K.I.; Srivastava, D. Texture Analysis and Fracture Behavior of Zircaloy-4 Processed Through Swaging. Metallogr. Microstruct. Anal. 2020, 9, 273–284. [Google Scholar] [CrossRef]

- Ferrando, W.A. PROCESSING AND USE OF ZIRCONIUM BASED MATERIALS. Adv. Mater. Manuf. Process. 1988, 3, 195–231. [Google Scholar] [CrossRef]

- Yoon, J.; Kim, J.; Kim, H.; Won, C.; Song, Y.; Park, S.H. Calibration of hoop stress in ring tensile test with Zircaloy-4 tube. J. Mech. Sci. Technol. 2017, 31, 4183–4188. [Google Scholar] [CrossRef]

- Kim, J.-S.; Kim, M.-W.; Yang, J.-S. Investigation on effect of thermal aging embrittlement on residual stresses of austenitic stainless steel repair welds in nuclear components subject to seismic loads. J. Mech. Sci. Technol. 2020, 34, 2821–2831. [Google Scholar] [CrossRef]

- Yan, M.; Wang, C.; Luo, T.; Li, Y.; Feng, X.; Huang, Q.; Yang, Y. Effect of Pulsed Magnetic Field on the Residual Stress of Rolled Magnium Alloy AZ31 Sheet. Acta Metall. Sin. (Engl. Lett.) 2020. [Google Scholar] [CrossRef]

- Sastry, C.C.; Abeens, M.; Pradeep, N.; Manickam, M.A.M. Microstructural analysis, radiography, tool wear characterization, induced residual stress and corrosion behavior of conventional and cryogenic trepanning of DSS 2507. J. Mech. Sci. Technol. 2020, 34, 2535–2547. [Google Scholar] [CrossRef]

- Yoon, S.C.; Horita, Z.; Kim, H.S. Finite element analysis of plastic deformation behavior during high pressure torsion processing. J. Mater. Process. Technol. 2008, 201, 32–36. [Google Scholar] [CrossRef]

- Taraphdar, P.K.; Thakare, J.G.; Pandey, C.; Mahapatra, M.M. Novel residual stress measurement technique to evaluate through thickness residual stress fields. Mater. Lett. 2020, 277, 128347. [Google Scholar] [CrossRef]

- Liu, Z.G.; Wong, T.I.; Huang, W.; Sridhar, N.; Wang, S.J. Effect of Surface Polishing Treatment on the Fatigue Performance of Shot-Peened Ti-6Al-4V Alloy. Acta Metall. Sin. (Engl. Lett.) 2017, 30, 630–640. [Google Scholar] [CrossRef]

- Kunčická, L.; Macháčková, A.; Lavery, N.P.; Kocich, R.; Cullen, J.C.T.; Hlaváč, L.M. Effect of thermomechanical processing via rotary swaging on properties and residual stress within tungsten heavy alloy. Int. J. Refract. Met. Hard Mater. 2020, 87, 105120. [Google Scholar] [CrossRef]

- Gloaguen, D.; Berchi, T.; Girard, E.; Guillén, R. Examination of residual stresses and texture in zirconium alloy cladding tubes after a large plastic deformation: Experimental and numerical study. J. Nucl. Mater. 2008, 374, 138–146. [Google Scholar] [CrossRef] [Green Version]

- Henriksen, E.K. Residual Stresses in Machined Surfaces; ASME: New York, NY, USA, 1948. [Google Scholar]

- Stenberg, N.; Proudian, J. Numerical Modelling of Turning to Find Residual Stresses. Procedia CIRP 2013, 8, 258–264. [Google Scholar] [CrossRef] [Green Version]

- Koric, S.; Thomas, B.G. Efficient thermo-mechanical model for solidification processes. Int. J. Numer. Methods Eng. 2006, 66, 1955–1989. [Google Scholar] [CrossRef]

- Harewood, F.J.; McHugh, P.E. Comparison of the implicit and explicit finite element methods using crystal plasticity. Comput. Mater. Sci. 2007, 39, 481–494. [Google Scholar] [CrossRef]

- Koric, S.; Gupta, A. Sparse matrix factorization in the implicit finite element method on petascale architecture. Comput. Methods Appl. Mech. Eng. 2016, 302, 281–292. [Google Scholar] [CrossRef] [Green Version]

- Taraphdar, P.K.; Mahapatra, M.M.; Pradhan, A.K.; Singh, P.K.; Sharma, K.; Kumar, S. Evaluation of through-thickness residual stresses in narrow gap dissimilar weld joint of ferritic to austenitic stainless steel. In Proceedings of the 64th Congress of Indian Society of Theoretical and Applied Mechanics (ISTAM 2019), Bhubaneswar, India, 9–12 December 2019. [Google Scholar]

| Parameters for FEA | Before Simulation | After Simulation |

|---|---|---|

| Diameter (mm) | 21 | 20–19–18.2–17.4–16.2 |

| Temperature (°C) | 20 | 20 |

| Swaging stroke (mm) | 10 | 10 |

| Number of bites | (L/f + 1) = 51 | |

| Length of work piece(L) | 500 mm | 580 mm |

| Axial feed per bite (f) | Varies (10 mm) | |

| Rotation per bite | 45, 90 degree | |

| Die movement velocity | 30 mm/sec | |

| Number of pass | 1 to 5 | |

| Rotation per pass | 180 degree (For multiple pass) | |

| Pass schedule for round bar | 21 to 20 mm, 20 to 19 mm, 19 to 18.2 mm, 18.2 to 17.4 mm, 17.4 to 16.2 mm | |

| Swaging through feed rate for bars | 0.7 m/min, 1.25 m/min, 2 m/min |

| Alloying Element | Sn% | Fe% | Cr% | O% | H ppm | Zr% |

|---|---|---|---|---|---|---|

| Composition (Wt.%) | 1.46 | 0.11 | 0.22 | 0.13 | 21 | Bal. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Singh, G.; Kalita, B.; Vishnu Narayanan, K.I.; Arora, U.K.; Mahapatra, M.M.; Jayaganthan, R. Finite Element Analysis and Experimental Evaluation of Residual Stress of Zr-4 alloys Processed through Swaging. Metals 2020, 10, 1281. https://doi.org/10.3390/met10101281

Singh G, Kalita B, Vishnu Narayanan KI, Arora UK, Mahapatra MM, Jayaganthan R. Finite Element Analysis and Experimental Evaluation of Residual Stress of Zr-4 alloys Processed through Swaging. Metals. 2020; 10(10):1281. https://doi.org/10.3390/met10101281

Chicago/Turabian StyleSingh, Gaurav, Bijit Kalita, K. I. Vishnu Narayanan, Umesh Kumar Arora, Manas M. Mahapatra, and Rengaswamy Jayaganthan. 2020. "Finite Element Analysis and Experimental Evaluation of Residual Stress of Zr-4 alloys Processed through Swaging" Metals 10, no. 10: 1281. https://doi.org/10.3390/met10101281

APA StyleSingh, G., Kalita, B., Vishnu Narayanan, K. I., Arora, U. K., Mahapatra, M. M., & Jayaganthan, R. (2020). Finite Element Analysis and Experimental Evaluation of Residual Stress of Zr-4 alloys Processed through Swaging. Metals, 10(10), 1281. https://doi.org/10.3390/met10101281