Comparison of Finite Element Methods in Fusion Welding Processes—A Review

Abstract

1. Introduction

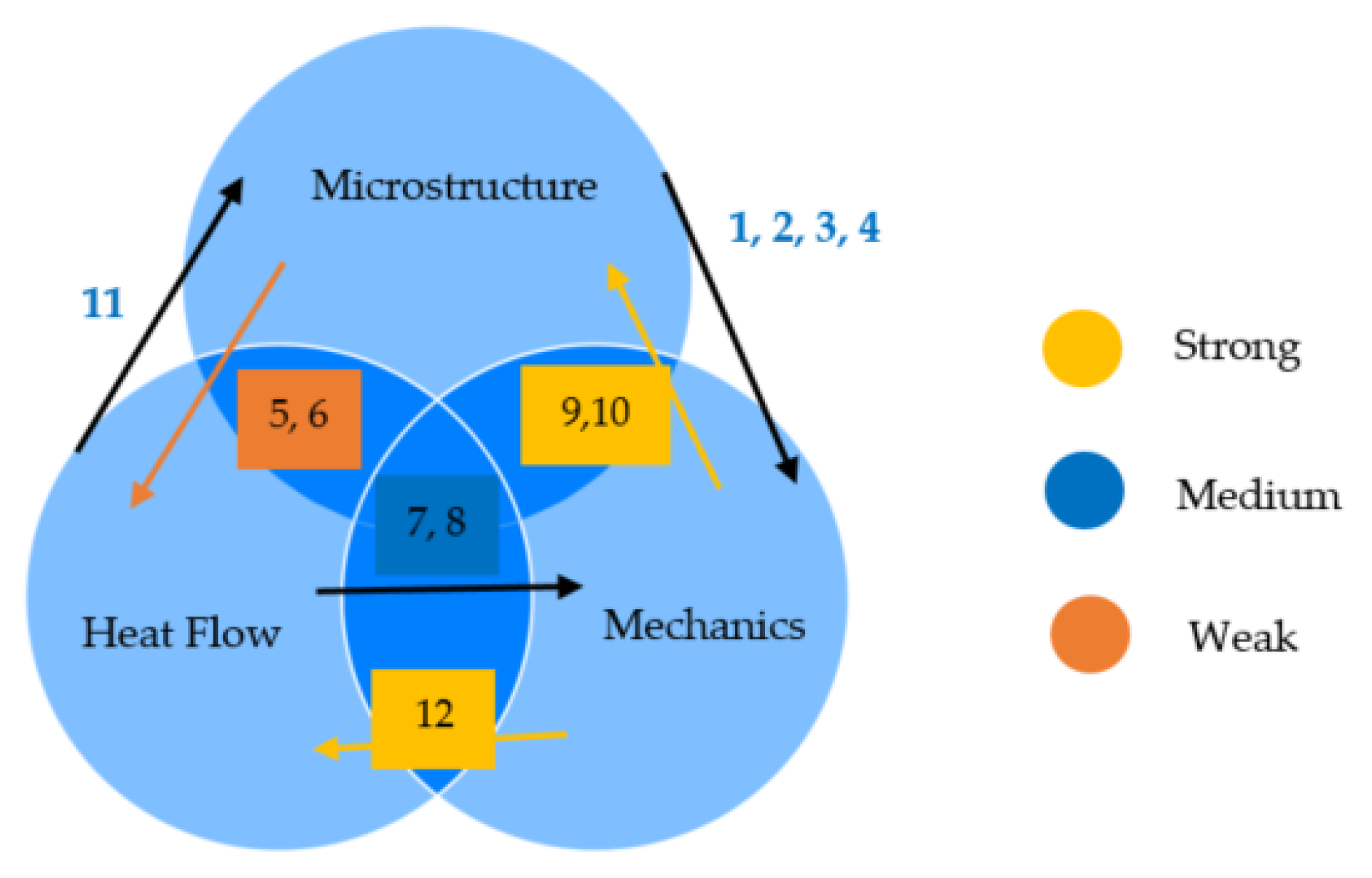

- Thermal stresses due to microstructural changes;

- Elastic/plastic behavior;

- Phase transformation origins volumetric changes;

- Microstructural changes are coupled with plastic stresses;

- Material’s microstructure can influence thermal properties;

- Phase transformation origins latent heat;

- Deformation evolution has influence on thermal boundary condition;

- Plastic and elastic stresses can influence heat generation;

- Deformations are from microstructural evolution;

- Phase transformations are influenced by stress;

- Thermal cycles have a direct link on thermal cycles;

- Deformations are caused by temperature changes.

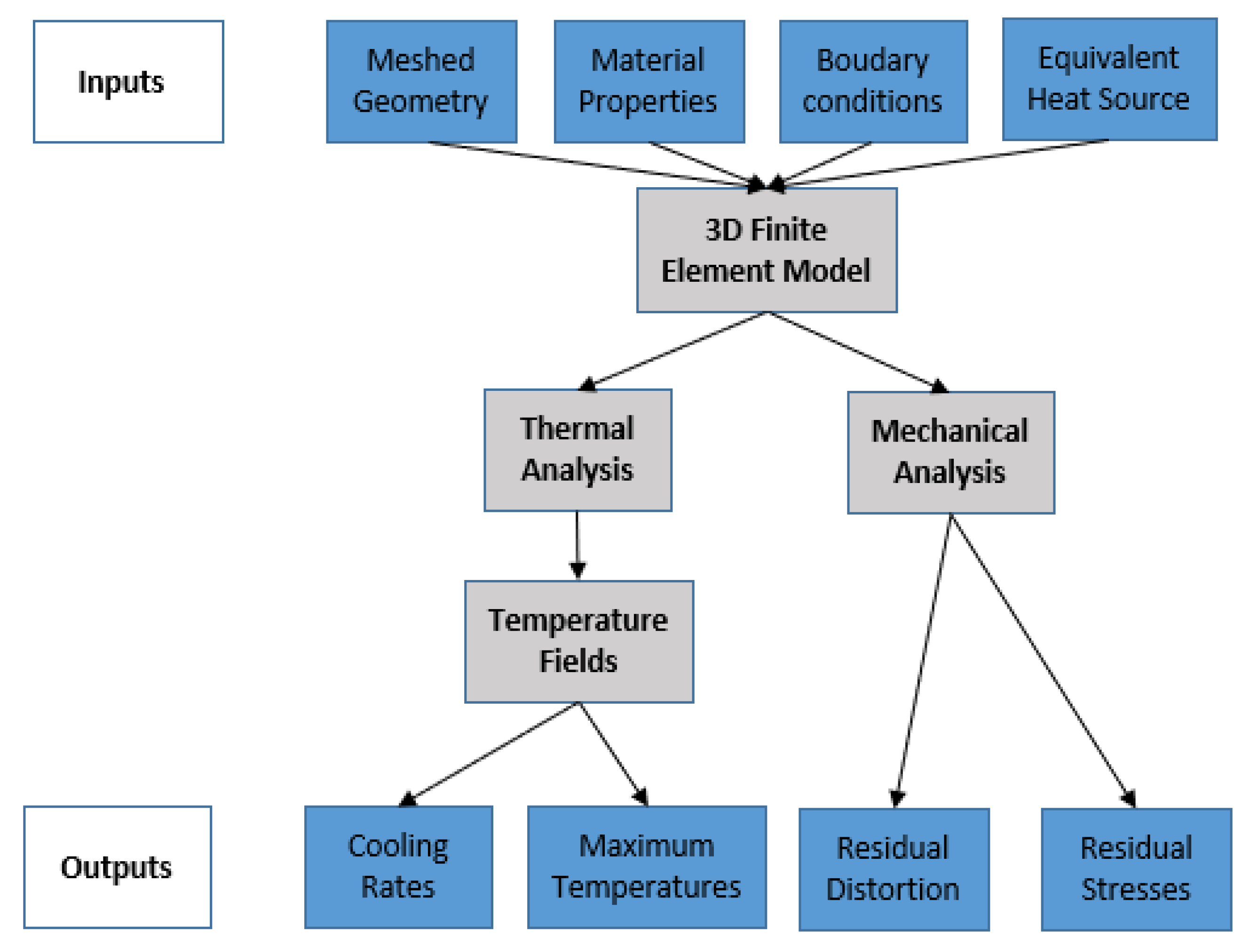

- A transient heat transfer simulation is done, determining the temperature data along time in the nodes. It is obtained from a non-linear thermal analysis;

- This temperature field is loaded into the simulation and then, a static mechanical analysis is performed. This transient temperature field is the initial input;

- The thermal expansion origins the deformation;

- When temperatures achieve their initial values, the residual stress field is obtained, as a result of all intermediary analysis steps.

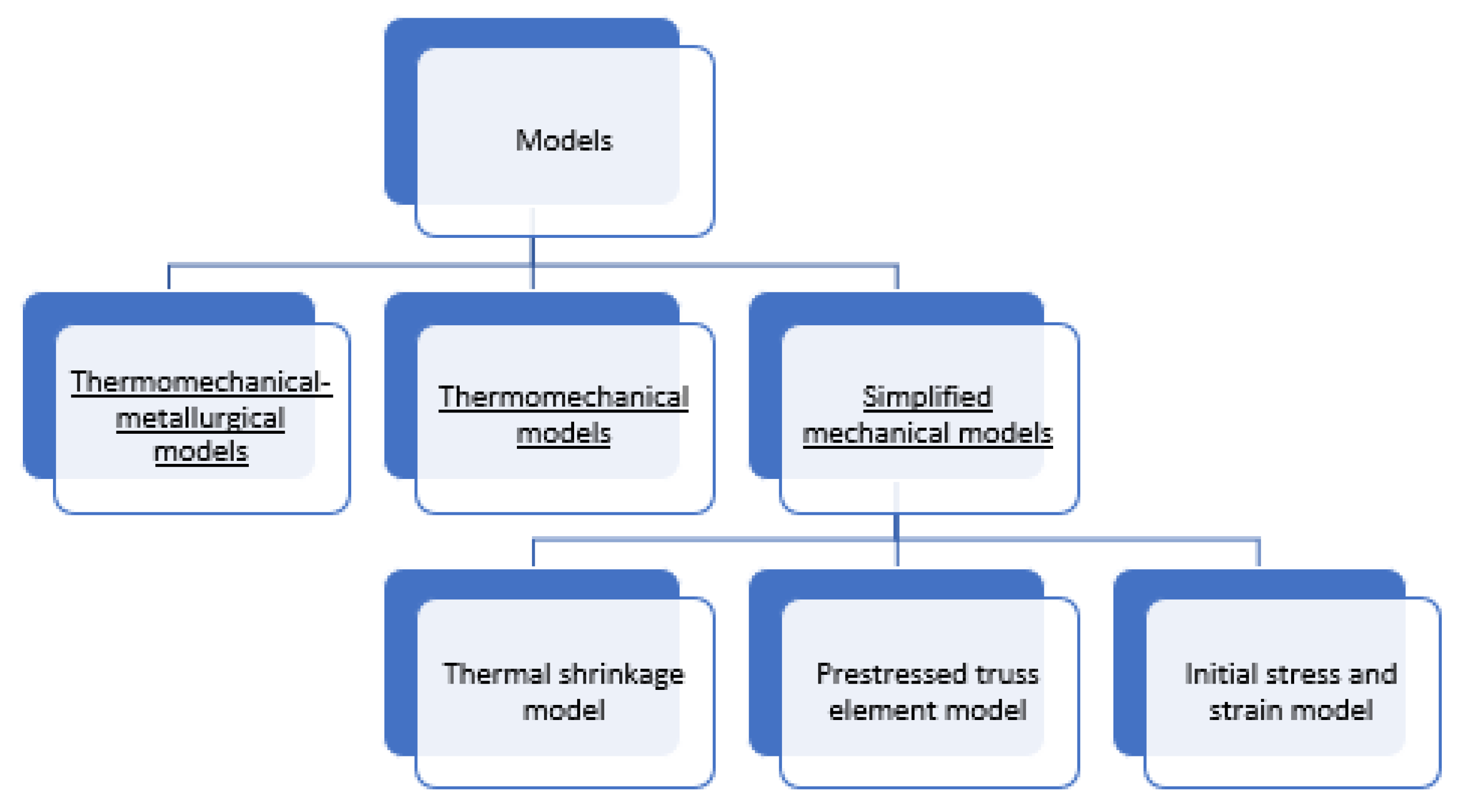

2. Models

2.1. Thermomechanical-Metallurgical Models

2.2. Thermomechanical Models

2.3. Simplified Mechanical Models

2.4. Thermal Shrinkage Model

2.5. Prestressed Truss Element Model

2.6. Initial Stress and Strain Model

3. Stages of FEM Analysis

3.1. Thermal and Heat Source Analysis

3.1.1. 2D Gaussian Surface Heat Source Model (2D Gauss)

3.1.2. Double-Ellipsoidal Heat Source Model (Goldak’s Model)

3.1.3. 3D-Gaussian Conical Heat Source Model

3.1.4. Uniform Surface Heat Flux

3.2. Thermal Material Model

3.3. Mechanical Boundary Conditions

3.4. Mechanical Material Properties

4. Inherent Deformation Theory

- The experimental weld pool width was 5.6 mm, while the one from the thermal simulation result was 5 mm, showing an 11% error rate;

- Empirical results showed a distortion of 5.85 mm, whereas the analysis from the inherent strains model showed a result of 5 mm (17% error rate);

- This method reduces analysis time by 70%.

5. FEM Software Comparison

6. FEM Simulation vs. Experimental Results

- The FE model underestimates the residual stress in the transverse and longitudinal direction to the welding seam by 7% and 2%, respectively.

- This study demonstrated the existence of high residual stress during the welding process of wide butt-welding seams (Table 6).

- While the pattern was similar across different welding widths, the strength of the residual stress increased when the width of the weld increased.

- The final temperature distribution using finite element model showed 4.5% error, compared to experimentally measured results;

- The numerically predicted distortion values using large distortion theory were 10–20 times larger than the small distortion theory (Table 7).

- Metallurgical phases and cooling rates were reflected in the hardness distributions;

- The concentration of martensite influenced the von Mises stress values;

- The values in the laser welding were higher 50 MPa, than the hybrid welding case;

- The maximum stress values were concentrated in the HAZ, for both welding processes;

- Areas subjected to strains were influenced by the thermal cycles.

- EB welding resulted in the largest HAZ;

- The level of butterfly distortion was highest for the GTAW joint 3.65°, followed by the SAW joint (1.87°), and the EB weld with the least value (0.08°);

- Since it was noted a much higher weld heat input during the filling passes for GTAW, when compared to SAW, there was a bigger distortion;

- Concerning maintaining weld quality, NG-GTAW was the most challenging.

- Displacement of discharge width caused by angular distortion;

- Displacement of cover height caused by shrinkage along the welding lines.

7. FEM Simulation with Post Heat Welding Treatment

- The RPEB weld created the largest region of tensile longitudinal residual stress;

- Transverse stresses in the RPEB weld were compressive near the top and bottom surfaces;

- Post-weld heat treatment was an effective method in reducing the levels of residual stress that were present in all weld samples.

8. Conclusions

- The selection of the model to be used depends on the users need to study. COMSOL has proved to be efficient in predicting heat transfer analyses, while SYSWELD, ABAQUS, and ANSYS have been often used to predict residual stresses, distortion, and fusion zone’s dimension in several welding processes, since the most conventional ones to advanced welding processes such as EBW and laser welding. Sometimes, the choice of software mainly depends on the preprocessing times and the parameters necessary for the simulation;

- Even presenting differences among the simplified mechanical models used, it is possible to observe a very good coherence between them. The main differences among them are the input parameters and the preprocessing time;

- Heat source models may be used depending on which welding process is being simulated. 2D Gaussian is advisable for MMAW, Goldak’s model for arc welding, and 3D-Gaussian or USHF for electron beam or laser welding;

- For larger structures simulation, inherent strains theory may be applied, since it is a simple model based on extrapolations, but it remains very accurate when compared to FEM analysis.

- For smaller structures simulation, FEM analysis is advisable;

- Software like ANSYS or ABAQUS can facilitate the processing of complex models such as thermomechanical models. The use of simplified models such as thermal shrinkage models or pre-stressed truss element models are less time-consuming and still accurate when compared to software results;

- The main difference between these software, is their code and the input data that are requested;

- FEM analysis is accurate in all software and when compared to experimental results. By comparing 37 papers presented in this work, it was possible to verify that some of them presented an error analysis (%) relatively to the experimental results. It can be seen in Table 9, that most of FEM analysis have an error % of 0% to 5%, which can be considered accurate when comparing simulations with experiments. It was also possible to obtain deviations from 11% to 20%, even though in a smaller number.

- This higher deviation can relate to some procedures that are performed during the FEM simulation. It was demonstrated that in these papers, the following methods were used:

- ⚬

- “Life and death” method;

- ⚬

- Mechanical boundary conditions conjugated with thermal boundary conditions;

- ⚬

- Changes in heat equivalent source types and parameters;

- Some problems while performing simulations were also found:

- ⚬

- Imprecise alignment of the arc welding;

- ⚬

- Use of small variations of thermomechanical material properties combined with differences of heat equivalent source;

- ⚬

- Use of an imperfect material model;

- With FEM analysis, it is possible to simulate PWHT, therefore verify which temperatures can be used to diminish residual stresses and distortion with this treatment;

- It is also possible to achieve very detailed information about the process parameters and results which changed over the processing time, and even the influence of phase transformations in these results;

- Through using numerical simulations, engineers can easily check what will happen when the welding processes parameters are changed.

Author Contributions

Funding

Conflicts of Interest

References

- Kik, T. Numerical analysis of MIG welding of butt joints in aluminium alloy. Biul. Inst. Spaw. 2014, 58, 37–43. [Google Scholar]

- Slováček, M.; Kik, T. Use of Welding process numerical analyses as Technical support in industry. part 1: Introduction to Welding process numerical simulations. Biul. Inst. Spaw. 2015, 59, 25–31. [Google Scholar] [CrossRef]

- Lindgren, L.-E. Finite Element Modeling and Simulation of Welding. Part 1: Increased Complexity. J. Therm. Stresses 2001, 24, 141–192. [Google Scholar] [CrossRef]

- Lindgren, L.-E. Finite Element Modeling and Simulation of Welding. Part 2: Improved Material Modeling. J. Therm. Stresses 2001, 24, 195–231. [Google Scholar] [CrossRef]

- Caprace, J.D.; Fu, G.; Carrara, J.F.; Remes, H.; Shin, S.B. A benchmark study of uncertainness in welding simulation. Mar. Struct. 2017, 56, 69–84. [Google Scholar] [CrossRef]

- Kose, K.; Rietman, B. Combining forming results via weld models to powerful numerical assemblies. In Proceedings of the 7th ESAFORM Conference on Material Forming, Trondheim, Norway, 28–30 April 2004. [Google Scholar]

- Rietman, B.; Kose, K.; Tikhomirov, D. Mechanische Schweißersatzmodelle für gekoppelte Simulationen. Fügetechnik LeichtbauHanser-Verl. In Proceedings of the 27th Annual International ACM SIGIR Conference, Sheffield, UK, 25–29 July 2004. [Google Scholar]

- SYSWELD 2003. Release Notes; ESI Group: Paris, France, 2003. [Google Scholar]

- Khurram, A.; Shehzad, K. Simulation of welding distortion and residual stresses in butt joint using inherent strain. Int. J. Appl. Phys. Maths 2012, 2, 405. [Google Scholar] [CrossRef][Green Version]

- Barsoum, Z.; Ghanadi, M.; Balawi, S. Managing welding induced distortion–comparison of different computational approaches. Procedia Eng. 2017, 114, 70–77. [Google Scholar] [CrossRef]

- Rietman, B.; Kose, K. The role of plasticity in the integrated approach of subsequent simulations of car structures. In Proceedings of the Esaform, Salerno, Italy, 28–30 April 2003. [Google Scholar]

- Schenk, T. Modelling Welding Distortion—Influence of Clamping and Sequencing. Ph.D. Thesis, Delft University of Technology, Delft, The Netherlands, 2011. [Google Scholar]

- Malik, M.; Qureshi, E.; Dar, U.; Khan, I. Analysis of circumferentially arc welded thin-walled cylinders to investigate the residual stress fields. Thin Walled Struct. 2008, 46, 1391–1401. [Google Scholar] [CrossRef]

- Aalami-Aleagha, M.E.; Foroutan, M.; Feli, S.; Nikabadi, S. Analysis preheat effect on thermal cycle and residual stress in a welded connection by FE simulation. Int. J. Press. Vessel. Pip. 2014, 114, 69–75. [Google Scholar] [CrossRef]

- Armentani, E.; Esposito, R.; Sepe, R. The influence of thermal properties and preheating on residual stresses in welding. Int. J. Comput. Mater. Sci. Surf. Eng. 2007, 1, 146–162. [Google Scholar] [CrossRef]

- Sepe, R.; Armentani, E.; Lamanna, G.; Caputo, F. Evaluation by FEM of the influence of the preheating and post-heating treatments on residual stresses in welding. Key Eng. Mater. 2015, 627, 93–96. [Google Scholar] [CrossRef]

- Anca, A.; Cardona, A.; Fachinotti, V. Finite element modelling of welded joints. Mecánica Comput. 2008, 27, 1445–1470. [Google Scholar]

- Kollár, D.; Kövesdi, B.; Néző, J. Numerical Simulation of Welding Process—Application in Buckling Analysis. Period. Polytech. Civ. Eng. 2017, 98–109. [Google Scholar] [CrossRef]

- Padmakumari, T.; Venkatasairam, S. Finite element analysis of EBW welded joint using SYSWELD. Int. J. Emerg. Technol. Adv. Eng. 2013, 3, 335–340. [Google Scholar]

- Lindgren, L.-E. Finite element modelling and simulation of welding, Part 3: Improved material modelling. J. Therm. Stresses 2001, 24, 305–334. [Google Scholar] [CrossRef]

- Francis, M.; Rahman, S. Probabilistic analysis of weld cracks in center cracked tension specimens. Comput. Struct. 2000, 76, 483–506. [Google Scholar] [CrossRef]

- Armentani, E.; Pozzi, A.; Sepe, R. Finite-element simulation of temperature fields and residual stresses in butt welded joints and comparison with experimental measurements, ASME. In Proceedings of the 2014 12th Biennial Conference on Engineering Systems Design and Analysis, ESDA, Copenhagen, Denmark, 25–27 July 2014; ASME: New York, NY, USA, 2014; p. 1. [Google Scholar] [CrossRef]

- Nowacki, J.; Sajek, A. Numerical Simulation of the Thermal Cycle of the PAW-MAG Hybrid Welding of Advanced High Strength Steels. Biul. Inst. Spaw. 2016, 60, 13–19. [Google Scholar] [CrossRef][Green Version]

- Sajek, A. Application of FEM simulation method in area of the dynamics of cooling AHSS steel with a complex hybrid welding process. Weld. World 2019, 63, 1065–1073. [Google Scholar] [CrossRef]

- Chang, P.; Teng, T. Numerical and experimental investigations on the residual stresses of the butt-welded joints. Comput. Mater. Sci. 2004, 29, 511–522. [Google Scholar] [CrossRef]

- Chen, J.; Lu, H.; Wang, J.; Chen, W.; Hao, D. Prediction of Welding Deformation of Underframe. J. Shanghai Jiao Tong Univ. (Science) 2004, 9, 10–14. [Google Scholar]

- Yukio, U.; Yuan, M.G. Prediction of Residual Stresses in Butt Welded Plates Using Inherent Strains. Eng. Mater. Technol. 1993, 115, 417–423. [Google Scholar] [CrossRef]

- Yukio, U.; Gang, Y. Predicting Method of Welding Residual stress Using source of Residual Stress (Report III): Prediction of Residual Stress in T-and I-joints Using Inherent Strains. Trans. JWRI 1993, 22, 157–168. [Google Scholar] [CrossRef][Green Version]

- Wang, R.; Zhang, J.; Serizawa, H.; Murakawa, H. Study of Welding Inherent Deformations in Thin Plates Based on Finite Element Analysis Using Interactive Substructure Method. Mater. Des. 2009, 3474–3481. [Google Scholar] [CrossRef]

- Cui, X.; Ma, J.; Zhao, W. Numerical Simulation Study of Welding Deformation in the Bogie Frame of the High-speed Locomotive. J. China Railw. Soc. 2004, 3, 31–35. [Google Scholar]

- Wang, J.; Rashed, S.; Murakawa, H.; Luo, Y. Numerical prediction and mitigation of out of plane welding distortion in ship panel structure by elastic FE analysis. Mar. Struct. 2013. [Google Scholar] [CrossRef]

- Deng, D.; Murakawa, H.; Liang, W. Numerical simulation of welding distortion in large structure. Comput. Methods Appl. Mech. Eng. 2007, 196, 4613–4627. [Google Scholar] [CrossRef]

- Rui, W.; Sherif, R.; Hisashi, S. Study on welding inherent deformation in welded structural material. Trans. JWRI 2008, 37, 9199. [Google Scholar]

- Lu, Y.; Wu, X.; Zeng, J.; Wu, P. Study on FEM Numerical Simulation Method for the Welding Distortion. Trans. Tech. Publ. 2012. [Google Scholar] [CrossRef]

- Farajpour, M.; Ranjbarnodeh, E. Finite Element Simulation of Welding Distortion in Dissimilar Joint by Inherent Deformation Method. Soldag. Inspeção 2008, 60–72. [Google Scholar] [CrossRef]

- Wei, L.; Dean, D.; Hidekazu, M. Measurement of Inherent Deformations in Typical Weld Joints Using Inverse Analysis (Part 2)—Prediction of Welding Distortion of Large Structures Transactions of JWRI; Joining and Welding Research Institute of Osaka University: Ibaraki, Osaka, Japan, 2005. [Google Scholar]

- Tikhomirova, D.; Rietmanb, B.; Kosec, K.; Makk, M. Computing Welding Distortion: Comparison of Different Industrially Applicable Methods. Adv. Mater. Res. 2005, 6, 195–202. [Google Scholar] [CrossRef]

- Stamenković, D.; Vasović, I. Finite Element Analysis of Residual Stress in Butt Welding of Two Similar Plates. Sci. Tech. Rev. 2009, 59, 57–60. [Google Scholar]

- Ding, Y.; Liu, Z.; Jia, B.; Zong, L. Experimental and Numerical Studies on Residual Stress in Wide Butt Welds. Adv. Mater. Sci. Eng. 2007. [Google Scholar] [CrossRef]

- Zubairuddin, M.; Albert, S.; Mahadevan, S.; Vasudevan, M.; Chaudhari, V.; Suri, V. Experimental and finite element analysis of residual stress and distortion in GTA welding of modified 9Cr-1Mo steel. J. Mech. Sci. Technol. 2014, 28, 5095–5105. [Google Scholar] [CrossRef]

- Kik, T.; Górka, J. Numerical Simulations of Laser and Hybrid S700MC T.-Joint. Weld. Mater. 2019, 12, 516. [Google Scholar] [CrossRef]

- Pavani, P.; Sivasankar, P.; Lokanadham, P.; Mhahesh, P.U. Finite element analysis of residual stress in butt welding of two similar plates. Int. Res. J. Eng. Technol. (IRJET) 2015, 2, 479–486. [Google Scholar]

- Dean, D.; Yu, L.; Hisashi, S.; Masakazu, S.; Hidekazu, M. Numerical Simulation of residual stress and Deformation considering Phase Transformation effect. Trans. JWRI 2003, 32, 325–333. [Google Scholar]

- Seleš, K.; Perićb, M.; Tonković, Z. Numerical simulation of a welding process using a prescribed temperature approach. J. Constr. Steel Res. 2018, 145, 49–57. [Google Scholar] [CrossRef]

- Zhao, L.; Liang, J.; Zhong, Q.; Yang, C.; Sun, B.; Du, J. Numerical simulation on the effect of welding parameters on welding residual stresses in T92/S30432 dissimilar welded pipe. Adv. Eng. Softw. 2014, 68, 70–79. [Google Scholar] [CrossRef]

- Dhinakaran, V.; Siva Shanmugam, N.; Sankaranarayanasamy, K. Experimental investigation and numerical simulation of weld bead geometry and temperature distribution during plasma arc welding of thin Ti-6Al-4V sheets. J. Strain Anal. Eng. Des. 2017, 52, 30–44. [Google Scholar] [CrossRef]

- Belitzki, A.; Stadter, C.; Zaeh, M. Distortion minimization of laser beam welded components by the use of finite element simulation and artificial intelligence. CIRP J. Manuf. Sci. Technol. 2019. [Google Scholar] [CrossRef]

- Chukkan, J.R.; Wu, G.; Fitzpatrick, M.E.; Jones, S.; Kelleher, J. An interative technique for the reconstruction of residual stress fields in a butt-welded plate from experimental measurement, and comparison with welding process simulation. Int. J. Mech. Sci. 2019, 160, 421–428. [Google Scholar] [CrossRef]

- Zhang, J.; Yu, L.; Liu, Y.; Li, H.; Liu, C.; Wub, J.; Ma, J.; Li, Z. Effect of welding sequences on the welding stress and distortion in the CFETR vacuum vessel assembly using finite element simulation. Int. J. Press. Vessel. Pip. 2019. [Google Scholar] [CrossRef]

- Liu, S.; Sun, J.; Zhou, H.; Wei, F.; Lu, M.; Lei, M. Experimental and numerical study on fatigue performance for TIG welding and EB welding of RAFM steel plate. Fusion Eng. Des. 2019, 146, 2663–2666. [Google Scholar] [CrossRef]

- Rathod, D.; Francis, J.; Vasileiou, A.; Roy, M.; English, P.; Balakrishnan, J.; Smith, M.; Irvine, N. Residual stresses in arc and electron-beam welds in 130mm thick SA508 steel: Part 1—Manufacture. Int. J. Press. Vessel. Pip. 2019, 172, 313–328. [Google Scholar] [CrossRef]

- Joshi, S.; Aloraier, A. Measurement of welding induced distortions in fabrication of a prototype dragline joint: A case study. IJRRAS 2011, 6, 310–317. [Google Scholar]

- Kobayashi, S.; Yamada, E.; Go, T.; Okano, S.; Mochizuki, M.; Kimura, K.; Ando, A. Numerical Simulation of Welding Deformation Produced in compressor Impeller, Ebara Engineering Review N 25. In Proceedings of the 5th International Conference on Advanced Design and Manufacturing Engineering, Bath, UK, 5–7 April 2014. [Google Scholar] [CrossRef]

- Bonnaud, E.; Gunnars, J. Three Dimensional Weld Residual Stresses Simulations of Star/Stop and Weld Repair Effects. Procedia Eng. 2015, 130, 531–543. [Google Scholar] [CrossRef]

- Pasternak, H.; Launert, B.; Kannengieβer, T.; Rhode, M. Advanced residual stress assessment of plate girders through welding simulation. Procedia Eng. 2017, 172, 23–30. [Google Scholar] [CrossRef]

- Ai, Y.; Jiang, P.; Shao, X.; Li, P.; Wang, C. A three dimensional numerical simulation model for weld characteristics analysis in fiber laser keyhole welding. Int. J. Heat Mass Transf. 2017, 108, 614–626. [Google Scholar] [CrossRef]

- Derakshshan, D.; Yazdian, N.; Craft, B.; Smith, S.; Kovacevic, R. Numerical simulation and experimental validation of residual stress and welding distortion induced by laser-based welding processes of thin structural steel plates in butt joint configuration. Opt. Laser Technol. 2018, 104, 170–182. [Google Scholar] [CrossRef]

- Balran, Y.; Babu, B.; Vardhan, T.; Ramana, G.; Chakradhar, G. Residual stress analysis of dissimilar tungsten inert gas weldments of AISI 304 and Monel 400 by numerical simulation and experimentation. Mater. Today Proc. 2019. [Google Scholar] [CrossRef]

- Lee, H.; Chung, H. Variation simulation and diagnosis considering in-plane/out-of-plane welding distortion. Int. J. Nav. Archit. Ocean. Eng. 2019, 11, 553–571. [Google Scholar] [CrossRef]

- Wenhang, L.; Yu, R.; Huang, D.; Wu, J.; Wang, Y.; Hu, T.; Wang, J. Numerical simulation of multi-layer rotating arc narrow gap MAG welding for medium steel plate. J. Manuf. Process. 2019, 45, 460–471. [Google Scholar] [CrossRef]

- D’Ostuni, S.; Leo, P.; Casalino, G. FEM Simulation of Dissimilar Aluminum Titanium Fiber Laser Welding Using 2D and 3D Gaussian Heat Sources. Metals 2017, 7, 307. [Google Scholar] [CrossRef]

- Casalino, G.; Mortello, M. Modeling and experimental analysis of fiber laser offset welding of Al-Ti butt joints. Int. J. Adv. Manuf. Technol. 2016, 83, 89–98. [Google Scholar] [CrossRef]

- Balakrishnan, J.; Vasileiou, A.; Francis, J.; Smith, M.; Roy, M.; Callaghan, M.; Irvine, N. Residual stress distributions in arc, laser and electron-beam welds in 30 mm thick SA508 steel: A cross-process comparison. Int. J. Press. Vessel. Pip. 2018, 162, 59–70. [Google Scholar] [CrossRef]

- Vasileiou, A.; Smith, C.; Francis, J.; Rathod, D.; Balakrishnan, J.; Irvine, N. Residual stresses in arc and electron-beam welds in 130mm thick SA508 steel: Part 2—Measurements. Int. J. Press. Vessel. Pip. 2019, 172, 379–390. [Google Scholar] [CrossRef]

- Yaghi, A.; Hyde, T.; Becker, A.; Sun, W. Finite element simulation of welding and residual stresses in a P91 steel pipe incorporating solid-state phase transformation and post-weld heat treatment. J. Strain Anal. Eng. Des. 2008, 43, 275–293. [Google Scholar] [CrossRef]

- Mouelle, L.; Praud, F.; Chatzigeorgiou, G.; Meraghni, F.; Serri, J.; Fleury, E. Thermally-activated hardening recovery of thermo-elasto-plastic metals during annealing: Constitutive modeling for the simulation of welding process. Mech. Mater. 2020, 140, 103218. [Google Scholar] [CrossRef]

- Zheng, J.; Ince, A.; Tang, L. Modeling and simulation of weld residual stresses and ultrasonic impact treatment of welded joints. Procedia Eng. 2018, 213, 36–47. [Google Scholar] [CrossRef]

| Model | Material Data | Computation Time | Applicability | Quality |

|---|---|---|---|---|

| Thermomechanical-metallurgical models | Temperature dependent material data, Young’s modulus, yield stress | Very high | Research | Certain—If the material data is available. Uncertain- if the material data is not available and is calculated by extrapolation. |

| Thermomechanical models | No need of temperature dependent material data. | High | Research and Industry | Efficient to predict the correct distortion. Only the average stress level can be evaluated. |

| Simplified mechanical models | No need of temperature dependent material data. | Low | Research and Industry | Efficient to predict the correct distortion. |

| Model | Material Data | Variables | Applicability |

|---|---|---|---|

| Thermal shrinkage model | Material shrinkage at the model nodes of the welded volume. | Welding sequence | Small computation effort; Low number of material parameters; Any general-purpose FE software can easily incorporate this kind of model. |

| Prestressed truss element model | 1D elements connecting the nodes of the weld line. | Longitudinal shrinkage mechanism | Mesh quality and element type is not important; Calculation is done in very short time; Low number of material parameters. |

| Initial stress and strain model | The stresses and strains in each element of the weld. | Distortion, plastic deformation and the existing stress state. | Can be applied for 3D or shell meshes; Requires low number of material and is very fast to run. The distortion can be minimized by changing the work conditions (e.g., welding sequence). |

| Distortion | Thermo–Elastic–Plastic FEM | Inherent Strains Method | %Error |

|---|---|---|---|

| Transverse deformation (mm) | 0.1410 | 0.0362 | 74.32 |

| Longitudinal deformation (mm) | 0.05 | 0.0705 | 29.07 |

| Angular deformation (mm) | 1.06 | 0.987 | 6.89 |

| Total deformation (mm) | 1.067 | 0.992 | 7.02 |

| Criteria | Thermal Shrinkage Model | Prestressed Truss Element Model | Initial Stress and Strain Model | SYSWELD |

|---|---|---|---|---|

| Number of material parameters | Small | Small | Small | Large |

| Preprocessing time required | Small | Small | Small | Large |

| Relative distortion with respect to the experiment (%) | 93 | 103 | 96 | 92 |

| Total computation time | 41 s | 26 s | 13 s | 38 h |

| Simulation | Software | Hardening Model | EHS Model |

|---|---|---|---|

| 1 | Ansys | Isotropic | USHF |

| 2 | Ansys | Kinematic | USHF |

| 3 | Sysweld | Isotropic | Goldak’s |

| 4 | Sysweld | Isotropic | Goldak’s |

| 5 | Virfac | Isotropic | Goldak’s |

| 6 | Abaqus | Isotropic | Goldak’s |

| Weld Width (mm) | Transverse Residual Stress of Location 1 | Longitudinal Residual Stress of Location 1 | ||||

|---|---|---|---|---|---|---|

| Test (MPa) | Prediction (MPa) | Test-to-Prediction Ratio | Test (MPa) | Prediction (MPa) | Test-to-Prediction Ratio | |

| 45 | 129.3 | 110.6 | 1.17 | 156.4 | 150.5 | 1.04 |

| 55 | 161.5 | 148.7 | 1.09 | 194.1 | 201.2 | 0.96 |

| 65 | 194.9 | 190.2 | 1.02 | 271.1 | 264.3 | 1.03 |

| 75 | 224.8 | 225.8 | 0.99 | 341.5 | 330.1 | 1.03 |

| Mean | - | - | 1.07 | - | - | 1.02 |

| Cov | - | - | 0.07 | - | - | 0.03 |

| Position | Experimental | Large Distortion Theory | Small Distortion Theory |

|---|---|---|---|

| Line 1 | 3.91 | 3.88 | 0.26 |

| Line 2 | 3.4 | 3.75 | 0.28 |

| Line 3 | 5.35 | 5.58 | 0.268 |

| Position | Groove Angle Decreased | Layer Number Increased and Less Heat Input |

|---|---|---|

| T92 side | Great reduction in the peak values of the hoop and axial stress | Little effect |

| S30432 side | Little effect | The peak value of the tensile residual stress was decreased |

| Error % | Papers % |

|---|---|

| 0–5% | 21.05% |

| 6–10% | 10.52% |

| 11–15% | 2.6% |

| 16–20% | 7.9% |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Marques, E.S.V.; Silva, F.J.G.; Pereira, A.B. Comparison of Finite Element Methods in Fusion Welding Processes—A Review. Metals 2020, 10, 75. https://doi.org/10.3390/met10010075

Marques ESV, Silva FJG, Pereira AB. Comparison of Finite Element Methods in Fusion Welding Processes—A Review. Metals. 2020; 10(1):75. https://doi.org/10.3390/met10010075

Chicago/Turabian StyleMarques, Eva S. V., Francisco J. G. Silva, and António B. Pereira. 2020. "Comparison of Finite Element Methods in Fusion Welding Processes—A Review" Metals 10, no. 1: 75. https://doi.org/10.3390/met10010075

APA StyleMarques, E. S. V., Silva, F. J. G., & Pereira, A. B. (2020). Comparison of Finite Element Methods in Fusion Welding Processes—A Review. Metals, 10(1), 75. https://doi.org/10.3390/met10010075