Leaching Kinetics of Arsenic Sulfide-Containing Materials by Copper Sulfate Solution

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials and Reagents

2.2. Analysis

2.3. Experiments

3. Results and Discussion

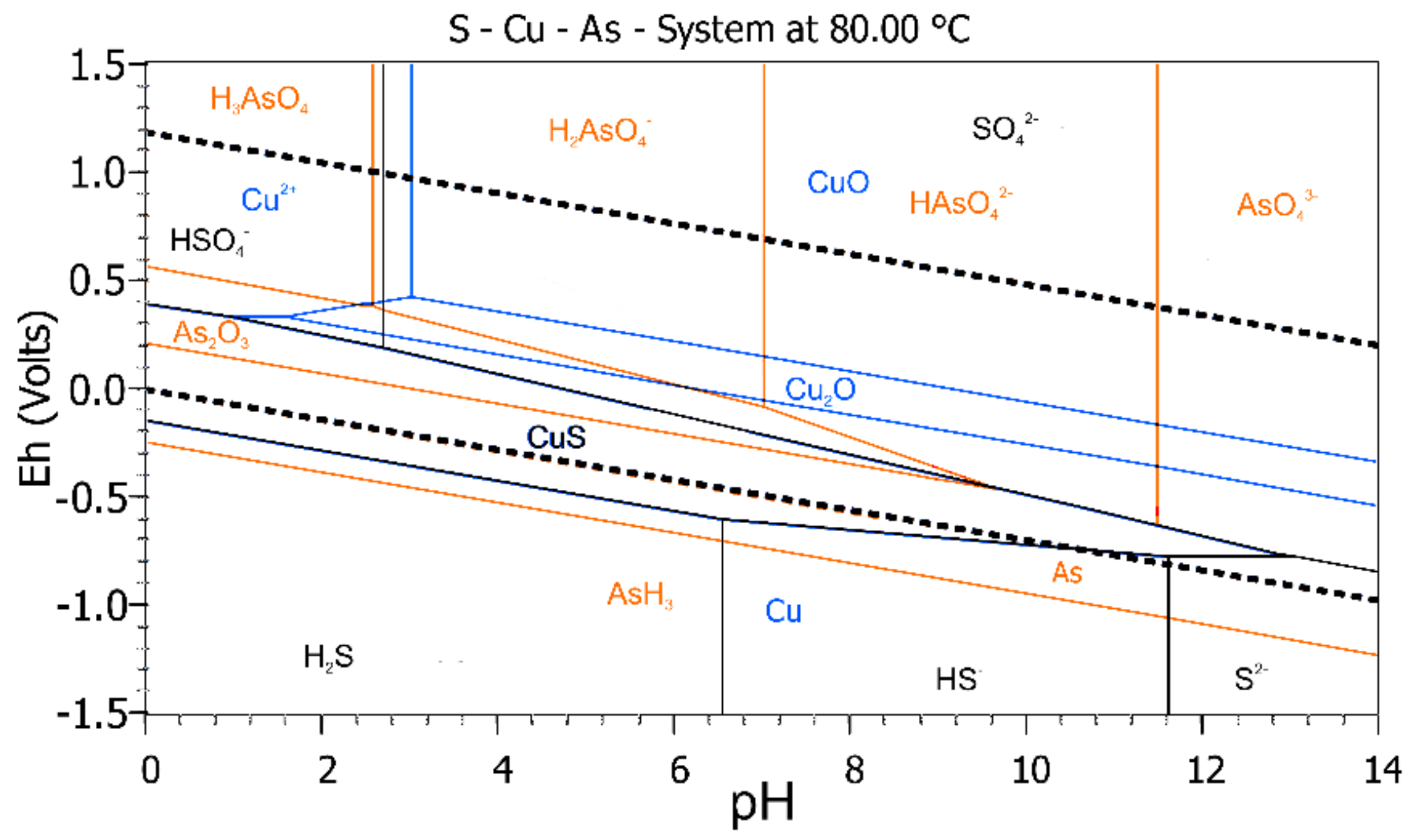

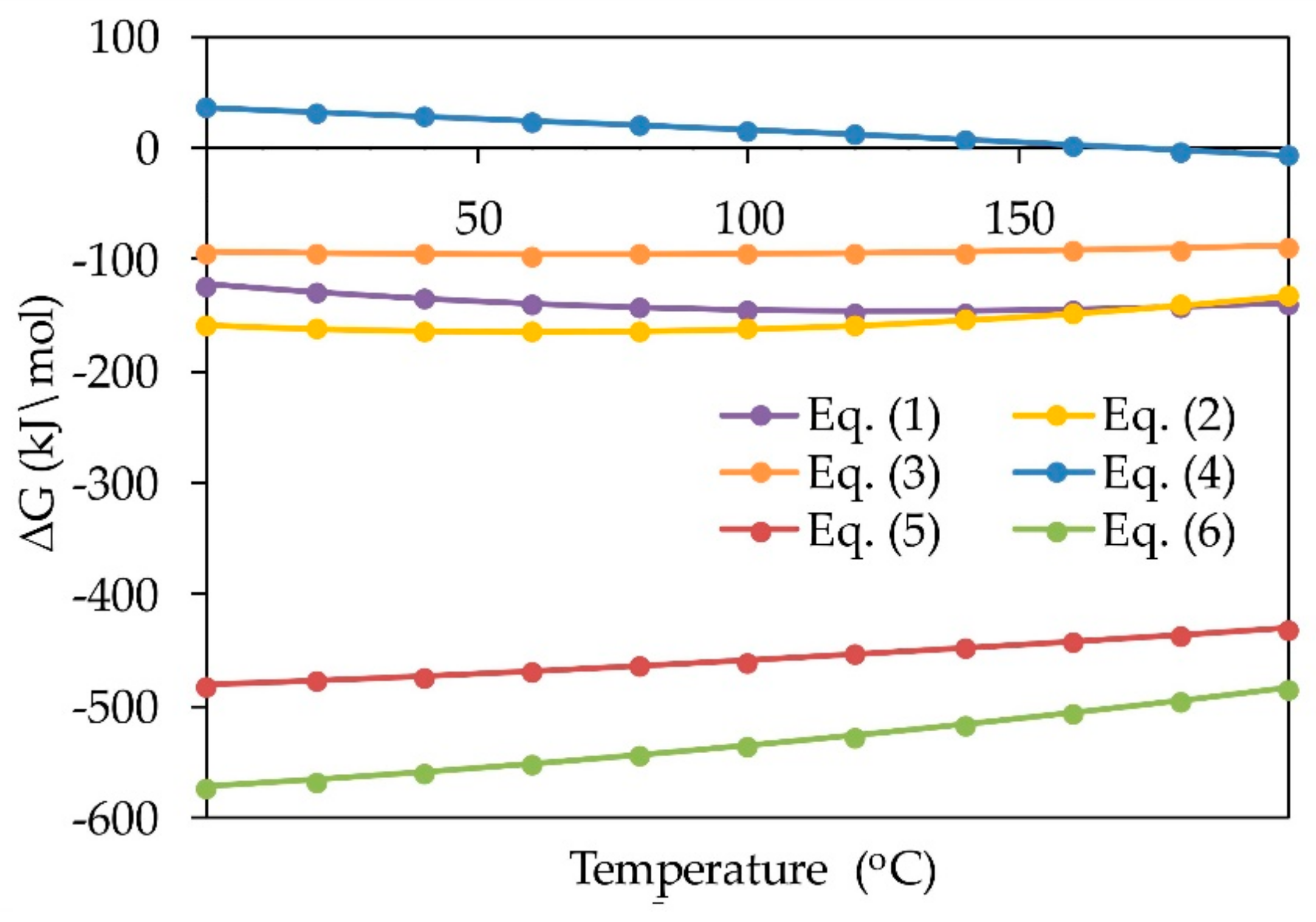

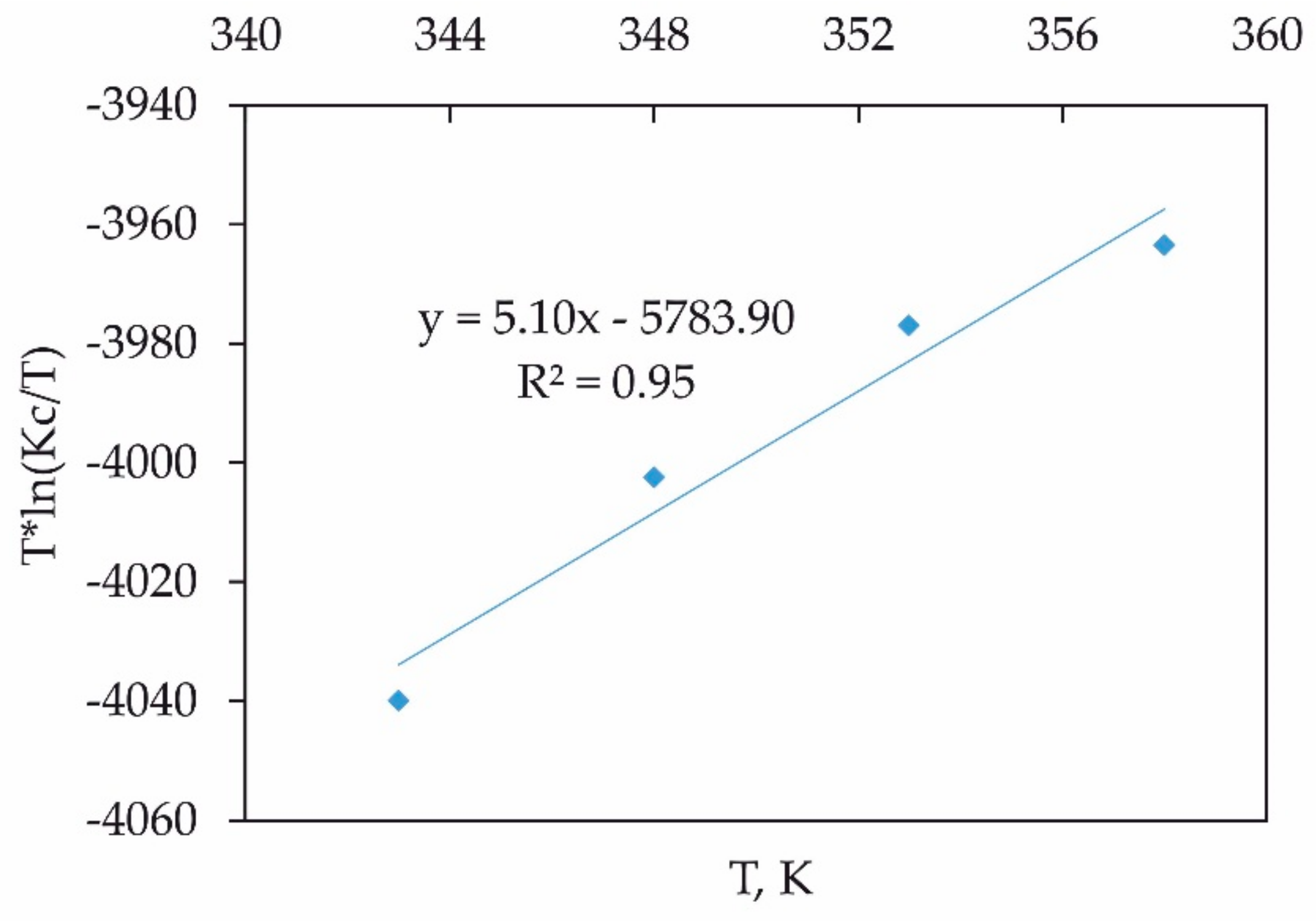

3.1. Thermodynamics of Leaching Arsenic Trisulfide with Copper-Containing Solution

3.2. Effect of Process Parameters on As Recovery from Trisulfide

3.2.1. Effect of Temperature

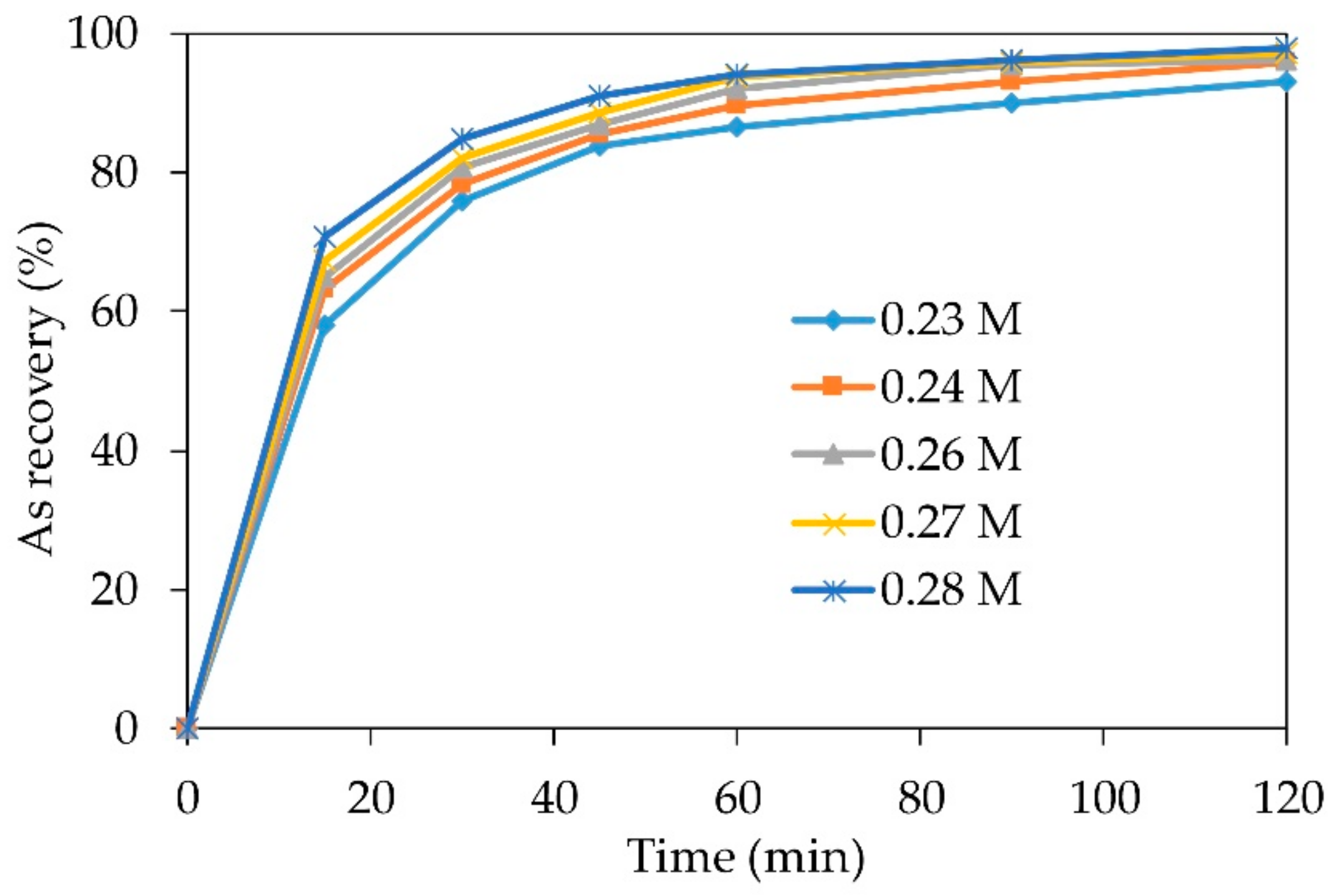

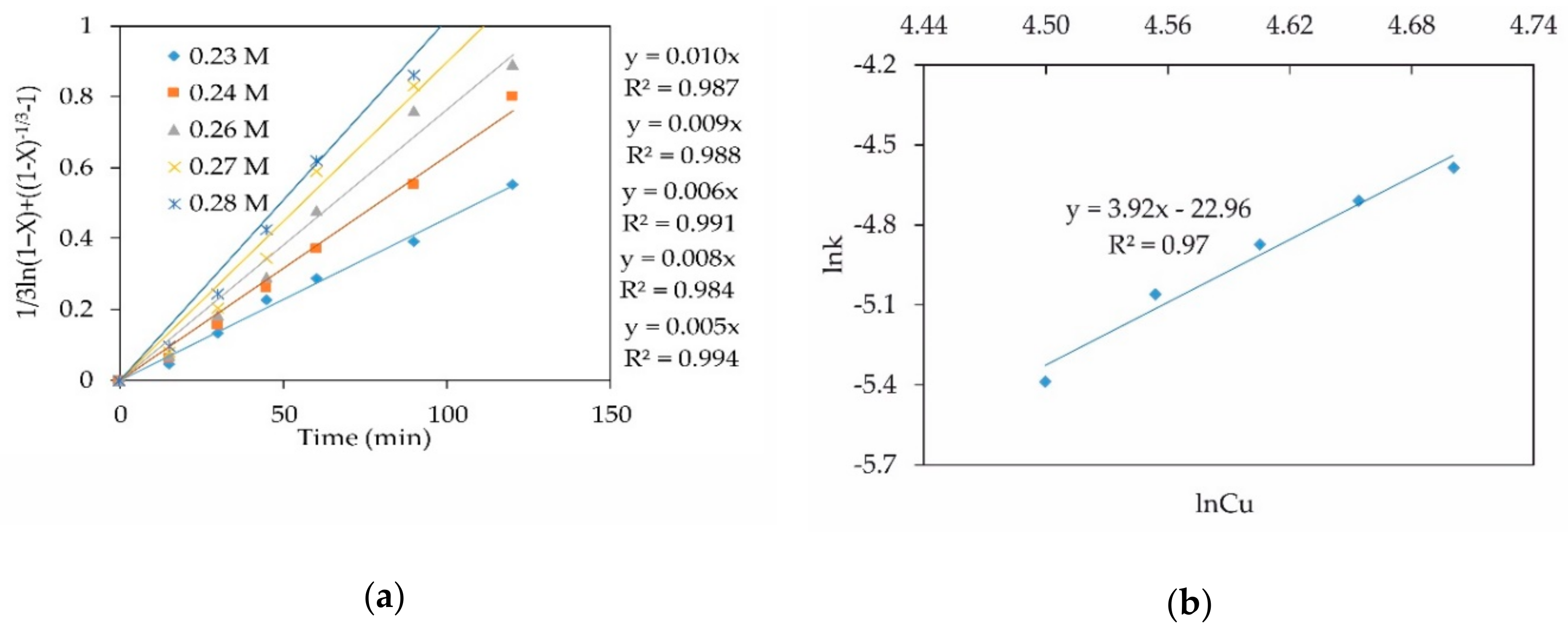

3.2.2. Effect of Copper Concentration

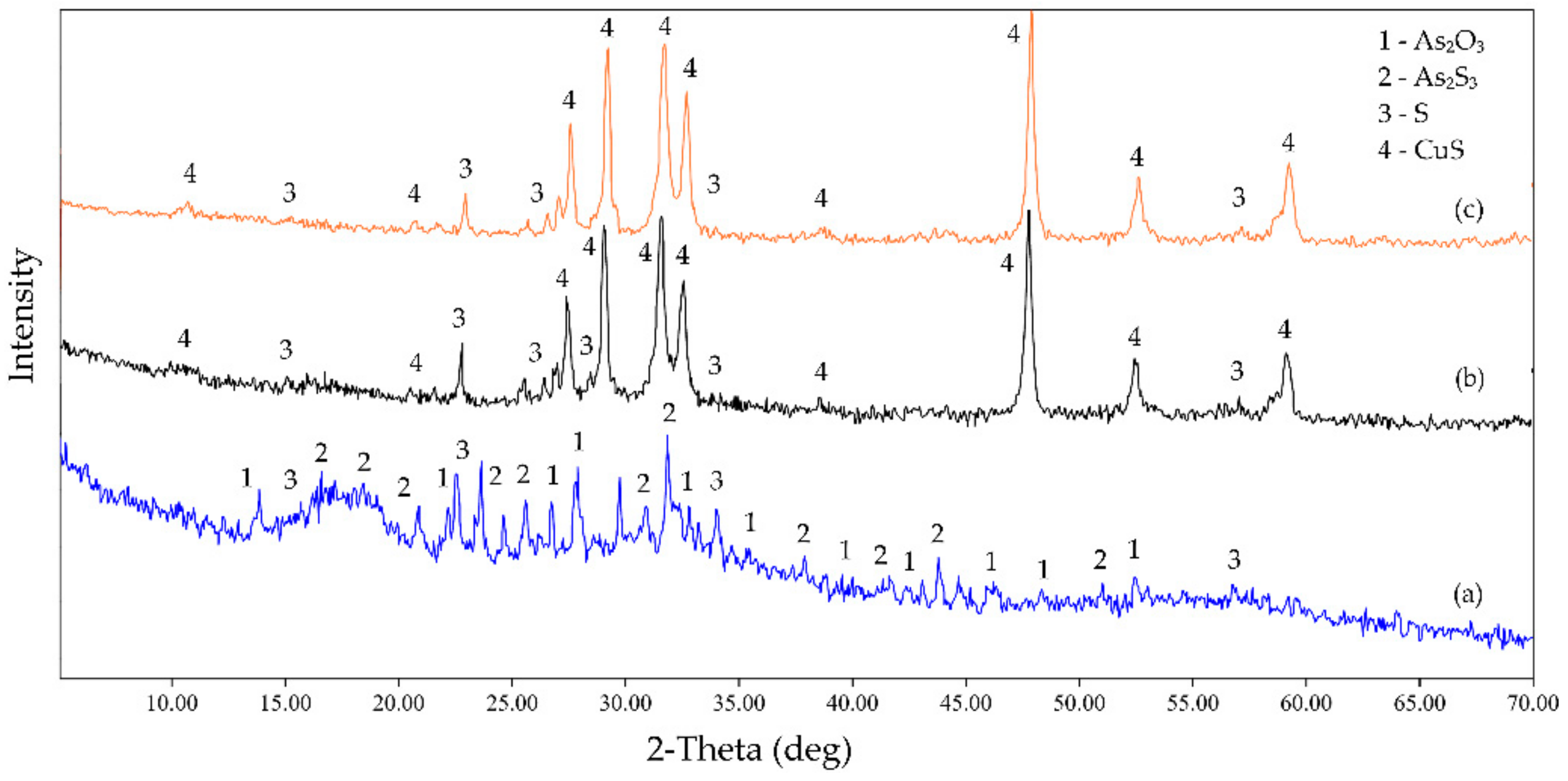

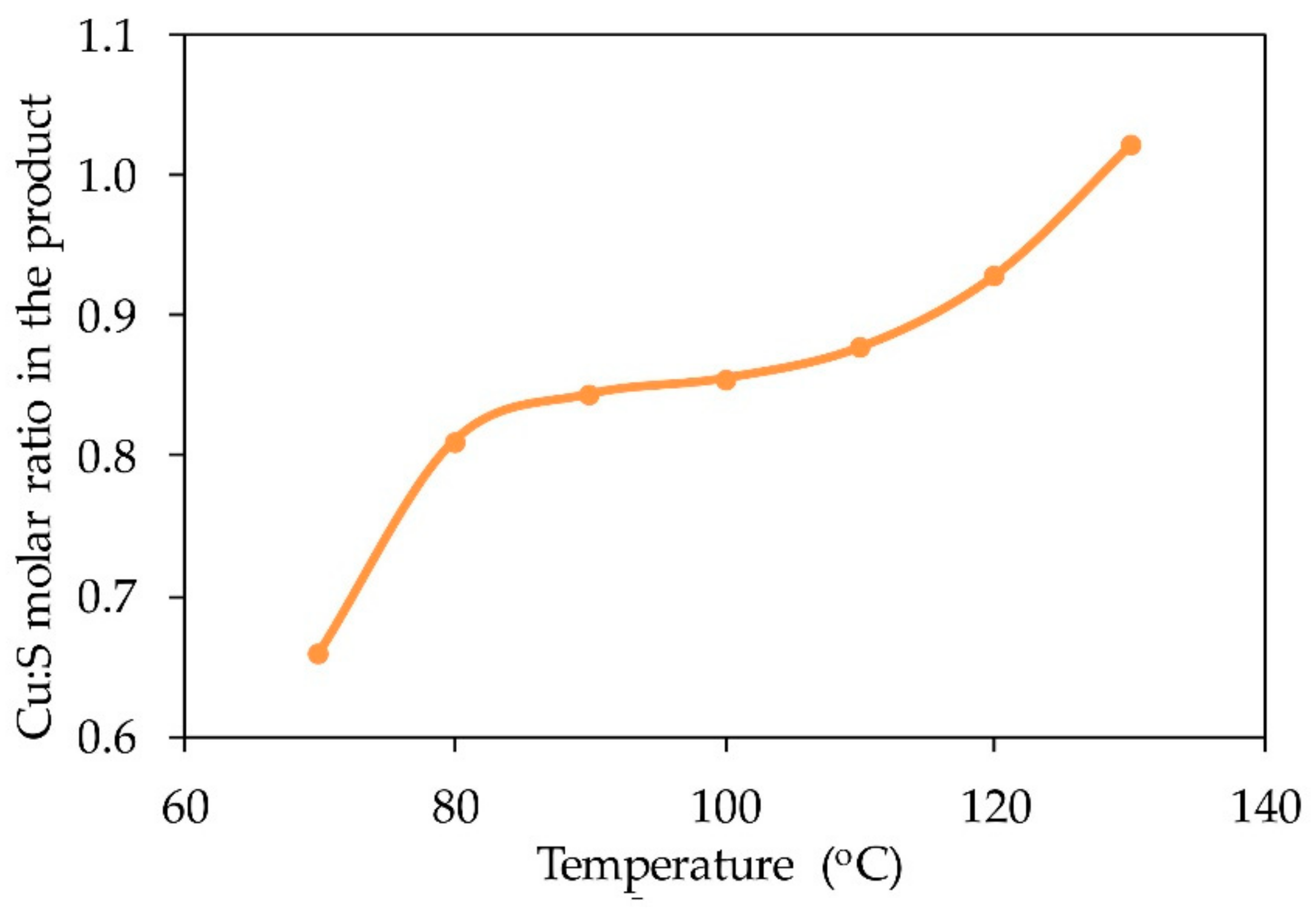

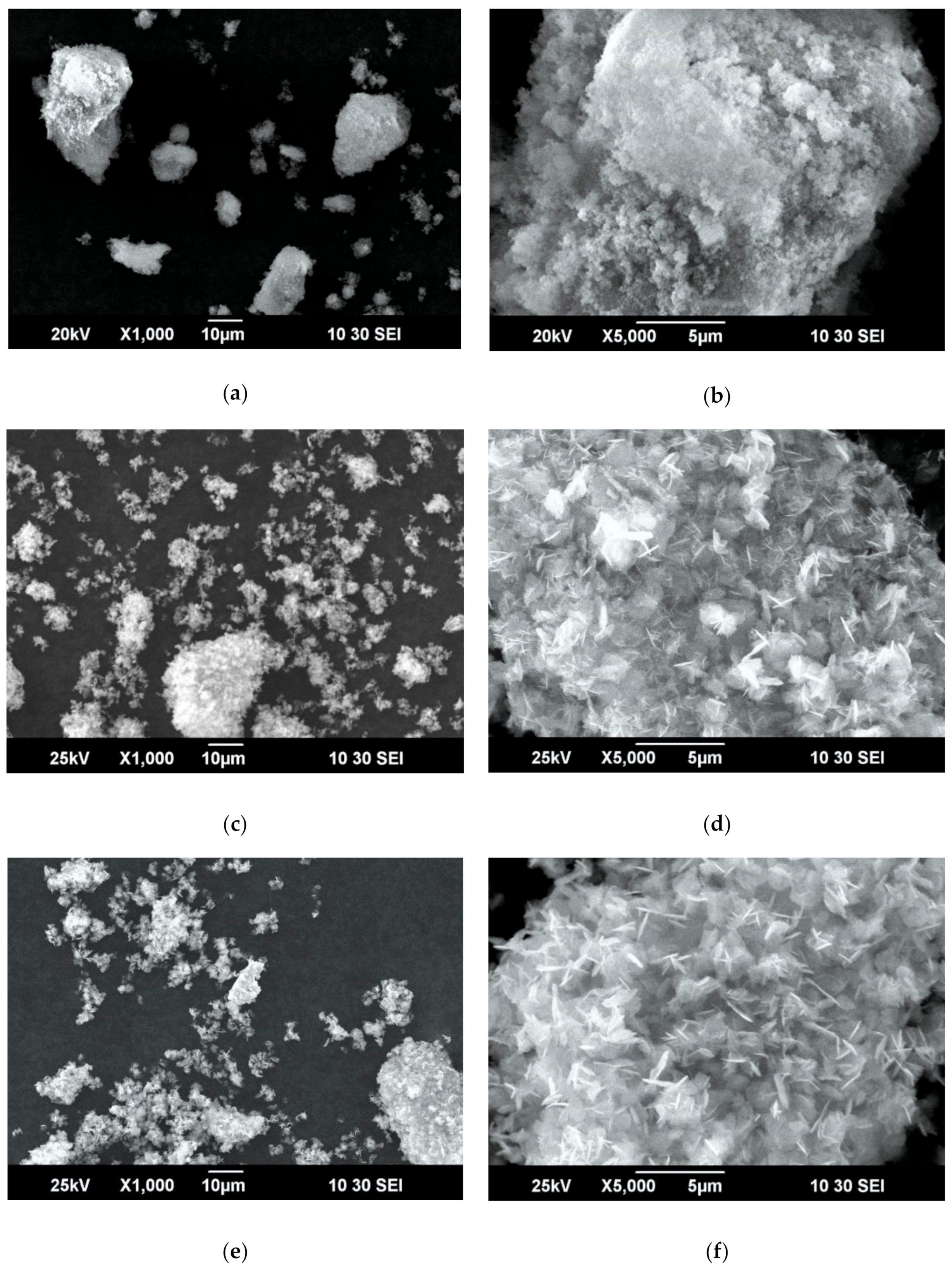

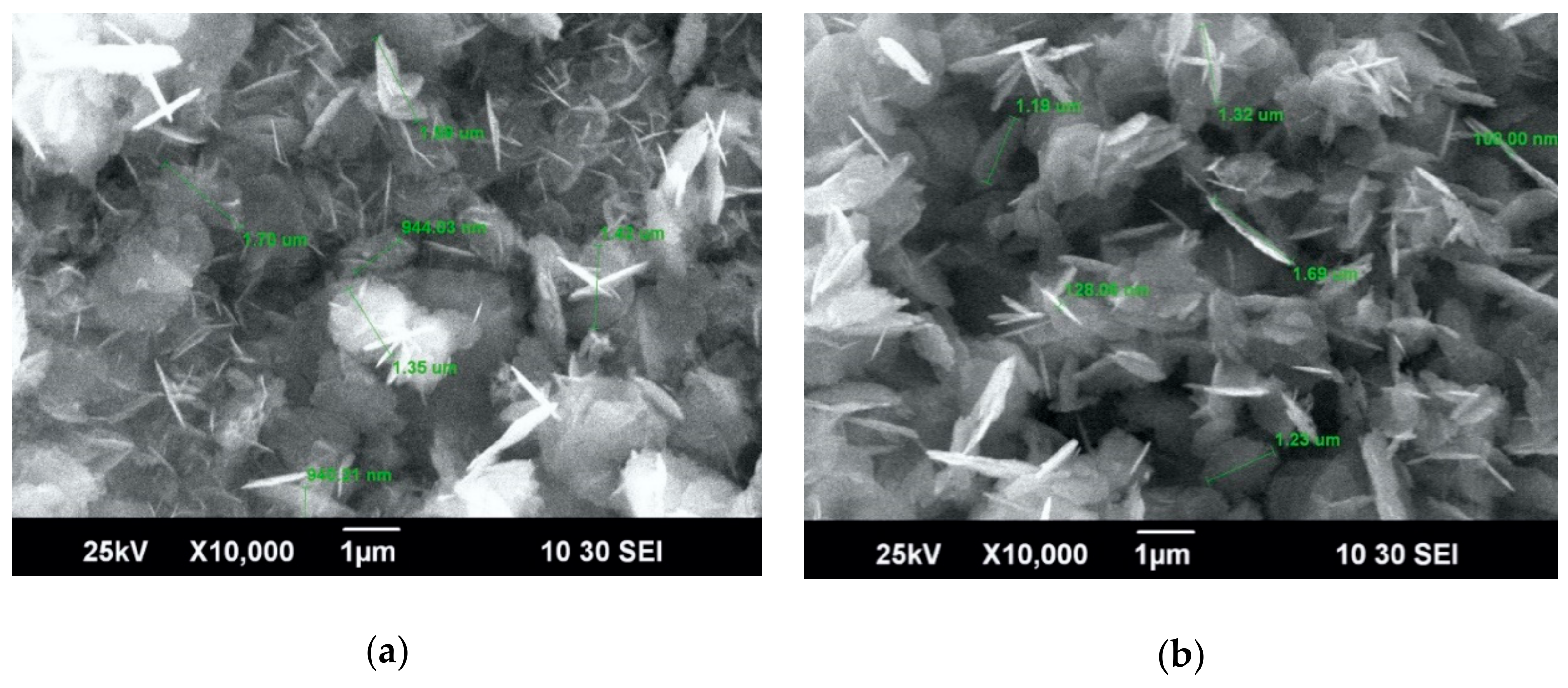

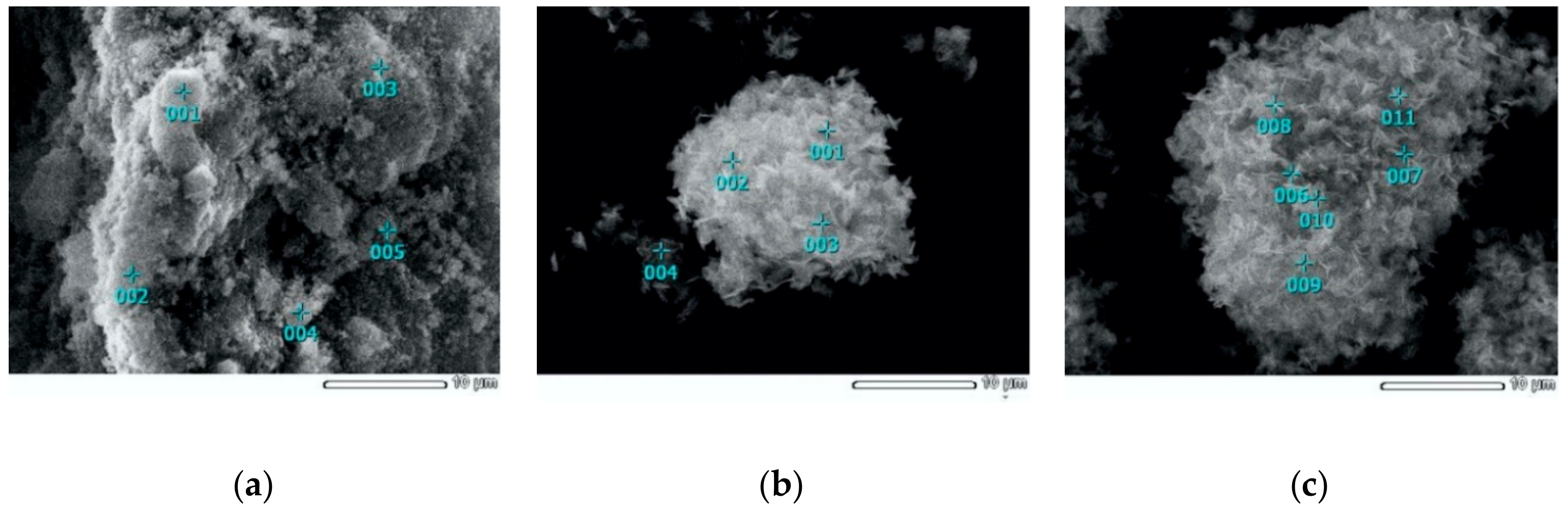

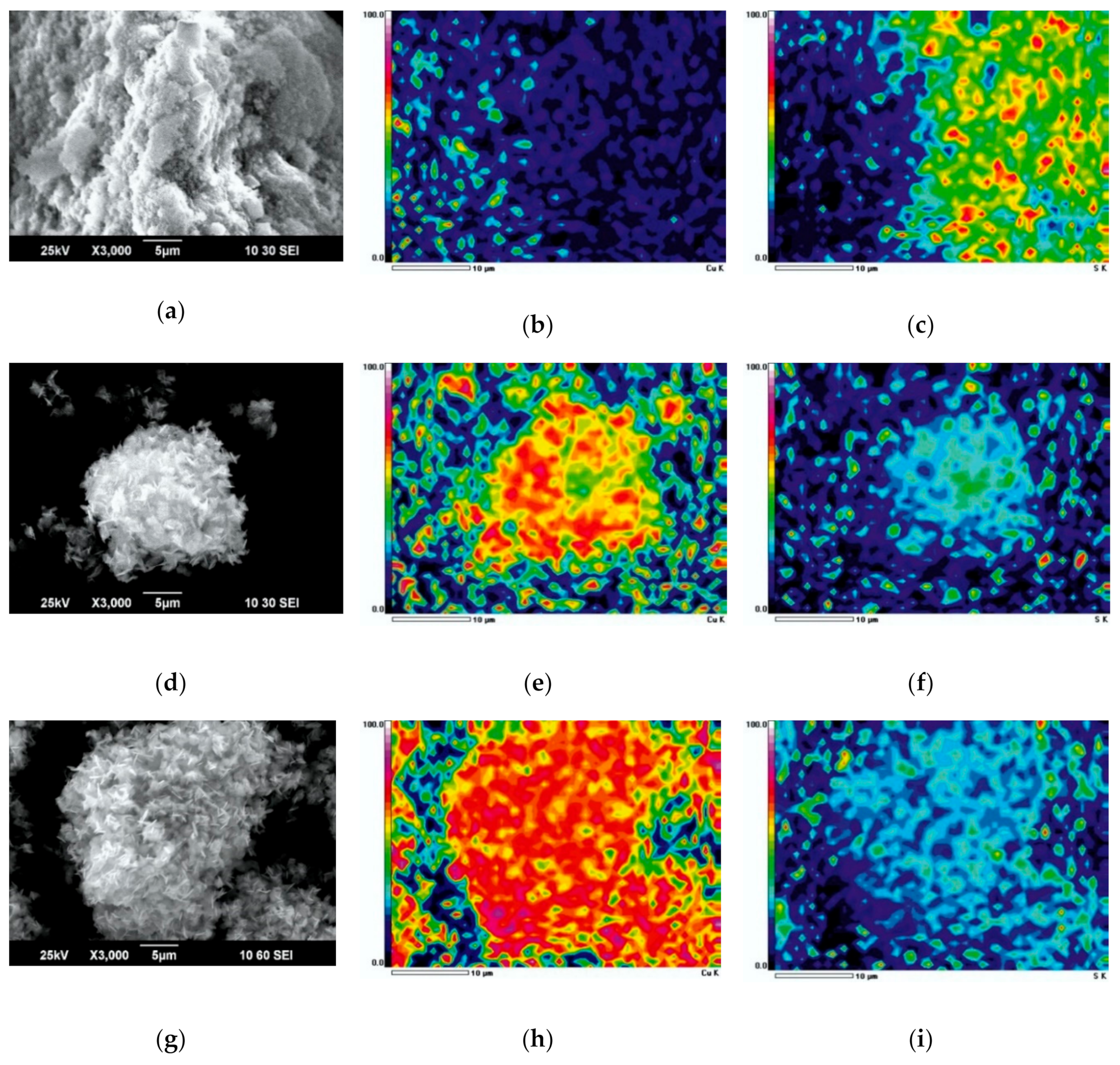

3.3. Characteristics of Residue

- Interaction occurs immediately on the surface of the raw material, between the solid sulfur–sulfides and copper ions in the solution.

- The process involves an intermediate stage of H2S production when sulfides contact with acidified solutions. The H2S then interacts with copper ions to form covellite.

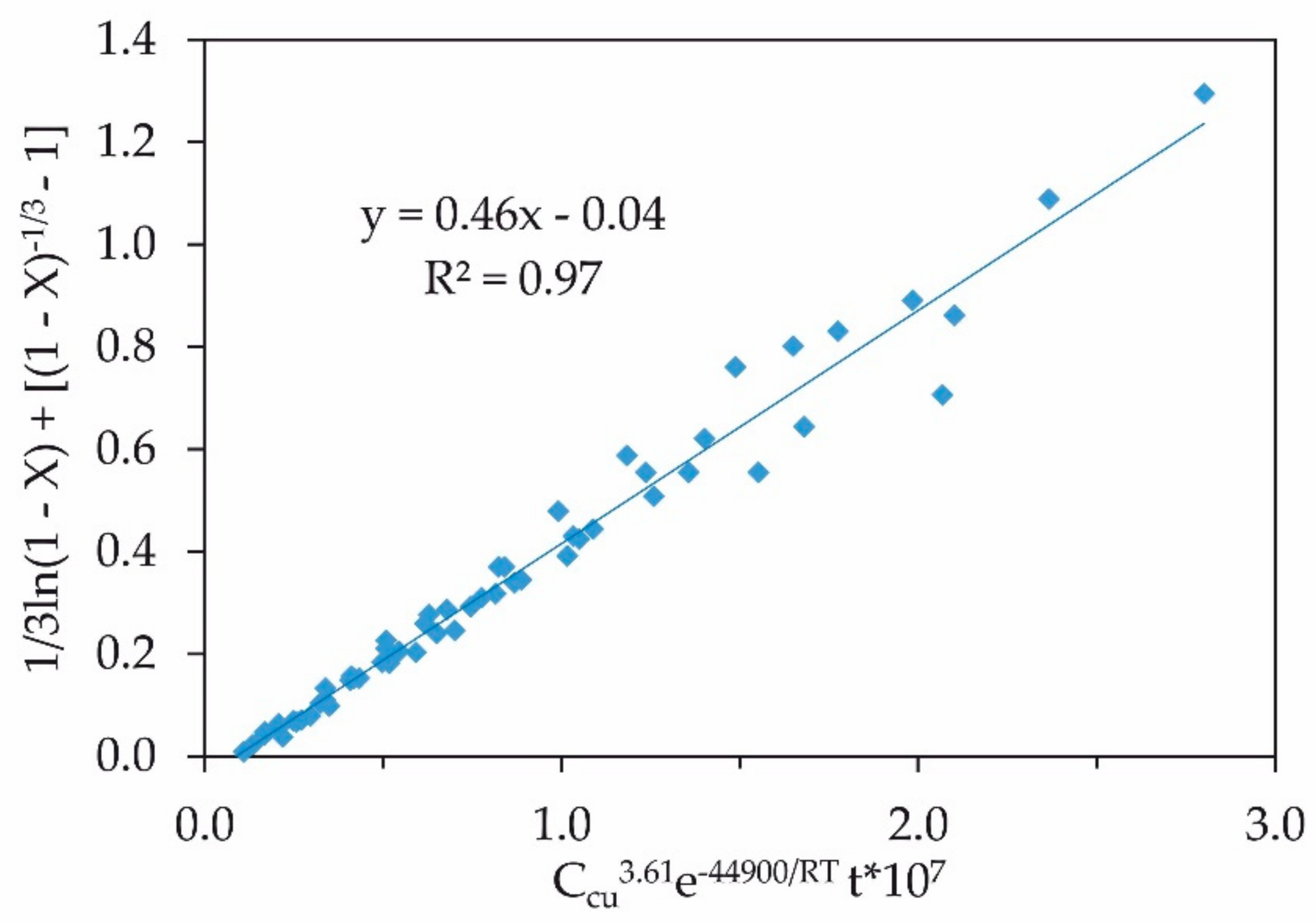

3.4. Kinetic Model

4. Conclusions

- The original arsenic sulfide material contains a substantial amorphous phase and, thermodynamically, an exchange reaction to form copper sulfide and various arsenic oxides should take place in the presence of copper sulfate in the entire studied temperature range. However, the leaching mechanisms may vary, since at the starting point arsenic sulfide is likely to be oxidized to form elemental sulfur or H2S, which only then go on to react with copper cations.

- Achieving the stoichiometric composition of copper sulfide in the final product is possible only with a large excess of copper cations and at increased temperature, which is due to the slow kinetics of the reaction of elemental sulfur with copper cations.

- SEM images, EDS, and EDS mapping demonstrate that solid sulfur–sulfides react with copper ions. H2S also could be generated and can react with the copper.

- At 90 °C, up to 80.7% of arsenic trisulfide is leached within 30 min. A decrease in temperature to 70 °C leads to a decrease in the degree of arsenic recovery to solution to 54.0% in a similar time. Up to 88.6% of arsenic dissolves at 70 °C, and 94.9% at 90 °C within 120 min. This shows a significant effect of temperature on the As recovery. An increase in copper concentration from 0.23 to 0.28 M effects an increase in As transfer into solution from 75.8% to 84.7% for 30 min of leaching, and from 93.2 to 97.8% for 120 min.

- The process temperature has the greatest effect on the kinetics. However, the shrinking core model that best fits the data suggests the process occurs by the intra-diffusion mode with the average activation energy of 44.9 kJ/mol.

- Using the time-to-a-given-fraction kinetics analysis, it was determined that the leaching mechanism does not change during the reaction. The value of activation energy during the reaction increases from 47.1 kJ/mol at 15% arsenic recovery to 55.9 kJ/mol at 75%. This may be due to the slow kinetics of elemental sulfur reacting with copper cations.

- Based on the findings, a semi-empirical equation was obtained, which allows us to describe the kinetics of the leaching of arsenic-containing cake by copper cations with a great accuracy: 1/3ln(1 − X) + [(1 − X)−1/3 − 1] = 4560000Cu3.61e−44900/RT t.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Celep, O.; Alp, İ.; Deveci, H. Improved gold and silver extraction from a refractory antimony ore by pretreatment with alkaline sulphide leach. Hydrometallurgy 2011, 105, 234–239. [Google Scholar] [CrossRef]

- Bissen, M.; Frimmel, F.H. Arsenic–A review. Part I: Occurrence, Toxicity, Speciation, Mobility. Acta Hydroch. Hydrob. 2003, 31, 9–18. [Google Scholar] [CrossRef]

- Shibayama, A.; Takasaki, Y.; William, T.; Yamatodani, A.; Higuchi, Y.; Sunagawa, S.; Ono, E. Treatment of smelting residue for arsenic removal and recovery of copper using pyro–hydrometallurgical process. J. Hazard. Mater. 2010, 181, 1016–1023. [Google Scholar] [CrossRef] [PubMed]

- Long, G.; Peng, Y.; Bradshaw, D. A review of copper–arsenic mineral removal from copper concentrates. Miner. Eng. 2012, 36–38, 179–186. [Google Scholar] [CrossRef]

- Dalewski, F. Removing Arsenic from Copper Smelter Gases. JOM 1999, 51, 24–26. [Google Scholar] [CrossRef]

- Vircikova, E.; Havlik, M. Removing As from Converter Dust by a Hydrometallurgical Method. JOM 1999, 51, 20–23. [Google Scholar] [CrossRef]

- Piret, N.L. The Removal and Safe Disposal of Arsenic in Copper Processing. JOM 1999, 51, 16–17. [Google Scholar] [CrossRef]

- Cheng, R.; Ni, H.; Zhang, H.; Zhang, X.; Bai, S. Mechanism research on arsenic removal from arsenopyrite ore during a sintering process. Int. J. Min. Met. Mater. 2017, 24, 353–359. [Google Scholar] [CrossRef]

- Safarzadeh, M.S.; Miller, J.D. Reaction of Enargite (Cu3AsS4) in Hot Concentrated Sulfuric Acid under an Inert Atmosphere. Part II: High-quality Enargite. Int. J. Miner. Process. 2014, 128, 79–85. [Google Scholar] [CrossRef]

- Liu, J.; Chi, R.; Xu, Z.; Zeng, Z.; Liang, J. Selective arsenic-fixing roast of refractory gold concentrate. Metall. Mater. Trans. B 2000, 31, 1163–1168. [Google Scholar] [CrossRef]

- Safarzadeh, M.S.; Miller, J.D. Reaction of Enargite (Cu3AsS4) in Hot Concentrated Sulfuric Acid under an Inert Atmosphere. Part I: Enargite Concentrate. JOM 2014, 128, 68–78. [Google Scholar] [CrossRef]

- Ritcey, G.M. Tailings management in gold plants. Hydrometallurgy 2005, 78, 3–20. [Google Scholar] [CrossRef]

- Riveros, P.A.; Dutrizac, J.E.; Spencer, P. Arsenic disposal practices in the metallurgical industry. Can. Metall. Q. 2001, 40, 395–420. [Google Scholar] [CrossRef]

- Smedley, P.L.; Kinniburgh, D.G. A review of the source, behaviour and distribution of arsenic in natural waters. Appl. Geochem. 2002, 17, 517–568. [Google Scholar] [CrossRef]

- Yao, L.; Min, X.; Xu, H.; Ke, Y.; Liang, Y.; Yang, K. Hydrothermal Treatment of Arsenic Sulfide Residues from Arsenic-Bearing Acid Waste Water. J. Environ. Res. Public Health 2018, 15, 1863. [Google Scholar] [CrossRef]

- Smith, A.H.; Smith, M.M.H. Arsenic drinking water regulations in developing countries with extensive exposure. Toxicology 2004, 198, 39–44. [Google Scholar] [CrossRef]

- Shoppert, A.; Loginova, I.; Rogozhnikov, D.; Karimov, K.; Chaikin, L. Increased As Adsorption on Maghemite-Containing Red Mud Prepared by the Alkali Fusion-Leaching Method. Minerals 2019, 9, 60. [Google Scholar] [CrossRef]

- Nazari, A.M.; Radzinski, R.; Ghahreman, A. Review of arsenic metallurgy: Treatment of arsenical minerals and the immobilization of arsenic. Hydrometallurgy 2017, 174, 258–281. [Google Scholar] [CrossRef]

- Ruiz, M.C.; Vera, M.V.; Padilla, R. Mechanism of enargite pressure leaching in the presence of pyrite. Hydrometallurgy 2011, 105, 290–295. [Google Scholar] [CrossRef]

- Anderson, C.G.; Twidwell, L.G. Hydrometallurgical processing of gold-bearing copper enargite concentrates. Can. Metall. Q. 2008, 47, 337–346. [Google Scholar] [CrossRef]

- Jiang, G.M.; Bing, P.E.N.G.; Chai, L.Y.; Wang, Q.W.; Shi, M.Q.; Wang, Y.Y.; Hui, L.I.U. Cascade sulfidation and separation of copper and arsenic from acidic wastewater via gas−liquid reaction. Trans. Nonferrous Met. Soc. China 2017, 27, 925–931. [Google Scholar] [CrossRef]

- Jiang, J.Q. Research progress in the use of ferrate(VI) for the environmental remediation. J. Hazard. Mater. 2007, 146, 617–623. [Google Scholar] [CrossRef] [PubMed]

- Prucek, R.; Tuček, J.; Kolařík, J.; Filip, J.; Marušák, Z.; Sharma, K.; Zbořil, R. Ferrate(VI)-induced arsenite and arsenate removal by in situ structural incorporation into magnetic iron(III) oxide nanoparticles. Environ. Sci. Technol. 2013, 47, 3283–3292. [Google Scholar] [CrossRef] [PubMed]

- Lee, Y.; Um, I.H.; Yoon, J. Arsenic(III) oxidation by iron(VI) (ferrate) and subsequent removal of arsenic(V) by iron(III) coagulation. Environ. Sci. Technol. 2003, 37, 5750–5756. [Google Scholar] [CrossRef]

- Gomez, M.A.; Becze, L.; Blyth, R.I.R.; Cutler, J.N.; Demopoulos, G.P. Molecular and structural investigation of yukonite (synthetic & natural) and its relation to arseniosiderite. Geochim. Cosmochim. Acta 2010, 74, 5835–5851. [Google Scholar] [CrossRef]

- Guo, L.; Du, Y.; Yi, Q.; Li, D.; Cao, L.; Du, D. Efficient removal of arsenic from “dirty acid” wastewater by using a novel immersed multi-start distributor for sulphide feeding. Sep. Purif. Technol. 2015, 142, 209–214. [Google Scholar] [CrossRef]

- Moon, D.H.; Dermatas, D.; Menounou, N. Arsenic immobilization by calcium–arsenic precipitates in lime treated soils. Sci. Total Environ. 2004, 330, 171–185. [Google Scholar] [CrossRef]

- Zhu, Y.N.; Zhang, X.H.; Xie, Q.L.; Wang, D.Q.; Cheng, G.W. Solubility and stability of calcium arsenates at 25 °C. Water Air Soil Pollut. 2006, 169, 221–238. [Google Scholar] [CrossRef]

- Gomez, M.A. The effect of copper on the precipitation of scorodite (FeAsO4·2H2O) under hydrothermal conditions: Evidence for a hydrated copper containing ferric arsenate sulfate-short lived intermediate Original Research Article. J. Colloid Interface Sci. 2011, 360, 508–518. [Google Scholar] [CrossRef]

- Fujita, T.; Taguchi, R.; Abumiya, M.; Matsumoto, M.; Shibata, E.; Nakamura, T. Effects of zinc, copper and sodium ions on ferric arsenate precipitation in a novel atmospheric scorodite process. Hydrometallurgy 2008, 93, 30–38. [Google Scholar] [CrossRef]

- Yang, B.; Zhang, G.L.; Deng, W.; Ma, J. Review of arsenic pollution and treatment progress in nonferrous metallurgy industry. Adv. Mater. Res. 2013, 634–638, 3239–3243. [Google Scholar] [CrossRef]

- Caetano, M.L.; Ciminelli, S.; Rocha, S.D.; Spitale, M.C.; Caldeira, C.L. Batch and continuous precipitation of scorodite from dilute industrial solutions. Hydrometallurgy 2009, 95, 44–52. [Google Scholar] [CrossRef]

- Monhemius, A.J.; Swash, P.M. Removing and stabilizing as from copper refining circuits by hydrothermal processing. JOM 1999, 51, 30–33. [Google Scholar] [CrossRef]

- Morales, A.; Cruells, M.; Roca, A.; Bergó, R. Treatment of copper flash smelter flue dusts for copper and zinc extraction and arsenic stabilization. Hydrometallurgy 2010, 105, 148–154. [Google Scholar] [CrossRef]

- Ke, Y.; Shen, C.; Min, X.B.; Shi, M.Q.; Chai, L.Y. Separation of Cu and As in Cu-As-containing filter cakes by Cu2+-assisted acid leaching. Hydrometallurgy 2017, 172, 45–50. [Google Scholar] [CrossRef]

- Lundström, M.; Liipo, J.; Taskinen, P.; Aromaa, J. Copper precipitation during leaching of various copper sulfide concentrates with cupric chloride in acidic solutions. Hydrometallurgy 2016, 166, 136–142. [Google Scholar] [CrossRef]

- Crundwell, F.K.; Moats, M.; Ramachandran, V. Hydrometallurgical Production of High-Purity Nickel and Cobalt, Extractive Metallurgy of Nickel, Cobalt and Platinum Group Metals; Elsevier: Oxford, UK, 2011; pp. 281–299. [Google Scholar] [CrossRef]

- Toshimasa, I.; Yoshio, M. Method for Separating and Recovering Arsenious Acid from Substance Containing Arsenic Sulfide. J.P. Patent S59107923, 22 June 1984. [Google Scholar]

- Tadashi, N.; Yoshio, M.; Naoki, K. Recovery of Arsenious Acid from Substance Containing Arsenic Sulfide. J.P. Patent S5869723, 26 April 1983. [Google Scholar]

- Gong, D.; Gong, H.; Li, C.H. Method for Recovering Simple Substance Arsenic from Arsenic Sulfide Slag. C.N. Patent 101386915, 18 March 2009. [Google Scholar]

- Karimov, K.A.; Naboichenko, S.S. Sulfuric Acid Leaching of High-Arsenic Dust from Copper Smelting. Metallurgist 2016, 60, 456–459. [Google Scholar] [CrossRef]

- Karimov, K.A.; Naboichenko, S.S.; Kritskii, A.V.; Tret’yak, M.A.; Kovyazin, A.A. Oxidation Sulfuric Acid Autoclave Leaching of Copper Smelting Production Fine Dust. Metallurgist 2019, 62, 1244–1249. [Google Scholar] [CrossRef]

- Mamyachenkov, S.V.; Anisimova, O.S.; Kostina, D.A. Improving the precipitation of arsenic trisulfide from washing waters of sulfuric-acid production of copper smelteries. Russ. J. Non Ferr. Met. 2017, 58, 212–217. [Google Scholar] [CrossRef]

- Nabojčenko, S.S. (Ed.) Avtoklavnaja Gidrometallurgija Cvetnych Metallov; GOU UGTU-UPI: Ekaterinburg, Russia, 2002; ISBN 978-5-321-00065-6. (In Russia) [Google Scholar]

- Levenspiel, O. Chemical Reaction Engineering, 3rd ed.; Wiley: New York, NY, USA, 1999; ISBN 978-0-471-25424-9. [Google Scholar]

- Rogozhnikov, D.A.; Shoppert, A.A.; Dizer, O.A.; Karimov, K.A.; Rusalev, R.E. Leaching Kinetics of Sulfides from Refractory Gold Concentrates by Nitric Acid. Metals 2019, 9, 465. [Google Scholar] [CrossRef]

- Dickinson, C.F.; Heal, G.R. Solid-liquid diffusion controlled rate equations. Thermochim. Acta 1999, 340, 89. [Google Scholar] [CrossRef]

- Gok, O.; Anderson, C.G.; Cicekli, G.; Cocen, E.I. Leaching kinetics of copper from chalcopyrite concentrate in nitrous-sulfuric acid. Physicochem. Probl. Mi. 2014, 50, 399–413. [Google Scholar] [CrossRef]

- Hidalgo, T.; Kuhar, L.; Beinlich, A.; Putnis, A. Kinetic study of chalcopyrite dissolution with iron(III) chloride in methanesulfonic acid. Miner. Eng. 2018, 125, 66–74. [Google Scholar] [CrossRef]

- Lente, G.; Fábián, I.; Poë, A.J. A common misconception about the Eyring equation. New J. Chem. 2005, 29, 759. [Google Scholar] [CrossRef]

- Hidalgo, T.; Kuhar, L.; Beinlich, A.; Putnis, A. Kinetics and mineralogical analysis of copper dissolution from a bornite/chalcopyrite composite sample in ferric-chloride and methanesulfonic-acid solutions. Hydrometallurgy 2019, 188, 140–156. [Google Scholar] [CrossRef]

| Cu | As | S | Zn | Fe | Pb |

|---|---|---|---|---|---|

| 0.14 | 40.20 | 44.86 | 0.42 | 0.23 | 1.24 |

| Element | S | Fe | Cu | Zn | As | Total |

|---|---|---|---|---|---|---|

| Figure 9a. Point 001 | 52.8 | 0.4 | 2.8 | 2.8 | 41.2 | 100.0 |

| Figure 9a. Point 002 | 39.6 | 0.4 | 4.7 | 3.9 | 51.4 | 100.0 |

| Figure 9a. Point 003 | 61.4 | 0.3 | 2.9 | 2.6 | 32.7 | 100.0 |

| Figure 9a. Point 004 | 51.2 | 0.2 | 3.1 | 3.2 | 42.3 | 100.0 |

| Figure 9a. Point 005 | 64.6 | 0.3 | 2.7 | 2.2 | 30.2 | 100.0 |

| Figure 9b. Point 001 | 44.4 | 0.1 | 51.4 | 0.5 | 3.6 | 100.0 |

| Figure 9b. Point 002 | 40.7 | 0.2 | 56.0 | 0.4 | 2.7 | 100.0 |

| Figure 9b. Point 003 | 45.2 | 0.1 | 48.5 | 1.1 | 5.1 | 100.0 |

| Figure 9b. Point 004 | 39.4 | 0.0 | 54.3 | 1.0 | 5.3 | 100.0 |

| Figure 9c. Point 006 | 39.8 | 0.0 | 60.2 | 0.0 | 0.0 | 100.0 |

| Figure 9c. Point 007 | 41.6 | 0.1 | 57.4 | 0.3 | 0.6 | 100.0 |

| Figure 9c. Point 008 | 41.1 | 0.0 | 58.2 | 0.3 | 0.4 | 100.0 |

| Figure 9c. Point 009 | 35.6 | 0.0 | 64.4 | 0.0 | 0.0 | 100.0 |

| Figure 9c. Point 010 | 41.5 | 0.1 | 58.0 | 0.2 | 0.1 | 100.0 |

| Figure 9c. Point 011 | 42.7 | 0.1 | 56.9 | 0.0 | 0.3 | 100.0 |

| # | Limiting Step | Equation | R2 | ||||

|---|---|---|---|---|---|---|---|

| 70 °C | 75 °C | 80 °C | 85 °C | 90 °C | |||

| 1 | Diffusion through the product layer (sp) | 1 − 3(1 − X)2/3 + 2(1 − X) | 0.955 | 0.937 | 0.873 | 0.810 | 0.774 |

| 2 | Diffusion through the product layer (pp) | X2 | 0.899 | 0.815 | 0.696 | 0.606 | 0.557 |

| 3 | Diffusion through the product layer (cp) | X + (1 − X)ln(1 − X) | 0.948 | 0.905 | 0.823 | 0.749 | 0.708 |

| 4 | Diffusion through the liquid film (sp) | X | 0.691 | 0.539 | 0.414 | 0.341 | 0.305 |

| 5 | Surface chemical reactions (cp) | 1 − (1 − X)1/2 | 0.828 | 0.727 | 0.625 | 0.558 | 0.523 |

| 6 | Surface chemical reactions (sp) | 1 − (1 − X)1/3 | 0.869 | 0.789 | 0.699 | 0.639 | 0.607 |

| 7 | New shrinking core model | 1/3ln(1 − X) + [(1 − X)−1/3 − 1] | 0.968 | 0.985 | 0.993 | 0.991 | 0.987 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Karimov, K.A.; Rogozhnikov, D.A.; Kuzas, E.A.; Shoppert, A.A. Leaching Kinetics of Arsenic Sulfide-Containing Materials by Copper Sulfate Solution. Metals 2020, 10, 7. https://doi.org/10.3390/met10010007

Karimov KA, Rogozhnikov DA, Kuzas EA, Shoppert AA. Leaching Kinetics of Arsenic Sulfide-Containing Materials by Copper Sulfate Solution. Metals. 2020; 10(1):7. https://doi.org/10.3390/met10010007

Chicago/Turabian StyleKarimov, Kirill A., Denis A. Rogozhnikov, Evgeniy A. Kuzas, and Andrei A. Shoppert. 2020. "Leaching Kinetics of Arsenic Sulfide-Containing Materials by Copper Sulfate Solution" Metals 10, no. 1: 7. https://doi.org/10.3390/met10010007

APA StyleKarimov, K. A., Rogozhnikov, D. A., Kuzas, E. A., & Shoppert, A. A. (2020). Leaching Kinetics of Arsenic Sulfide-Containing Materials by Copper Sulfate Solution. Metals, 10(1), 7. https://doi.org/10.3390/met10010007