Microstructure, Texture Evolution, and Mechanical Properties of MDFed GWZ Alloy Containing LPSO Phases on the Condition of High and Low Temperature Cycle Deformation

Abstract

1. Introduction

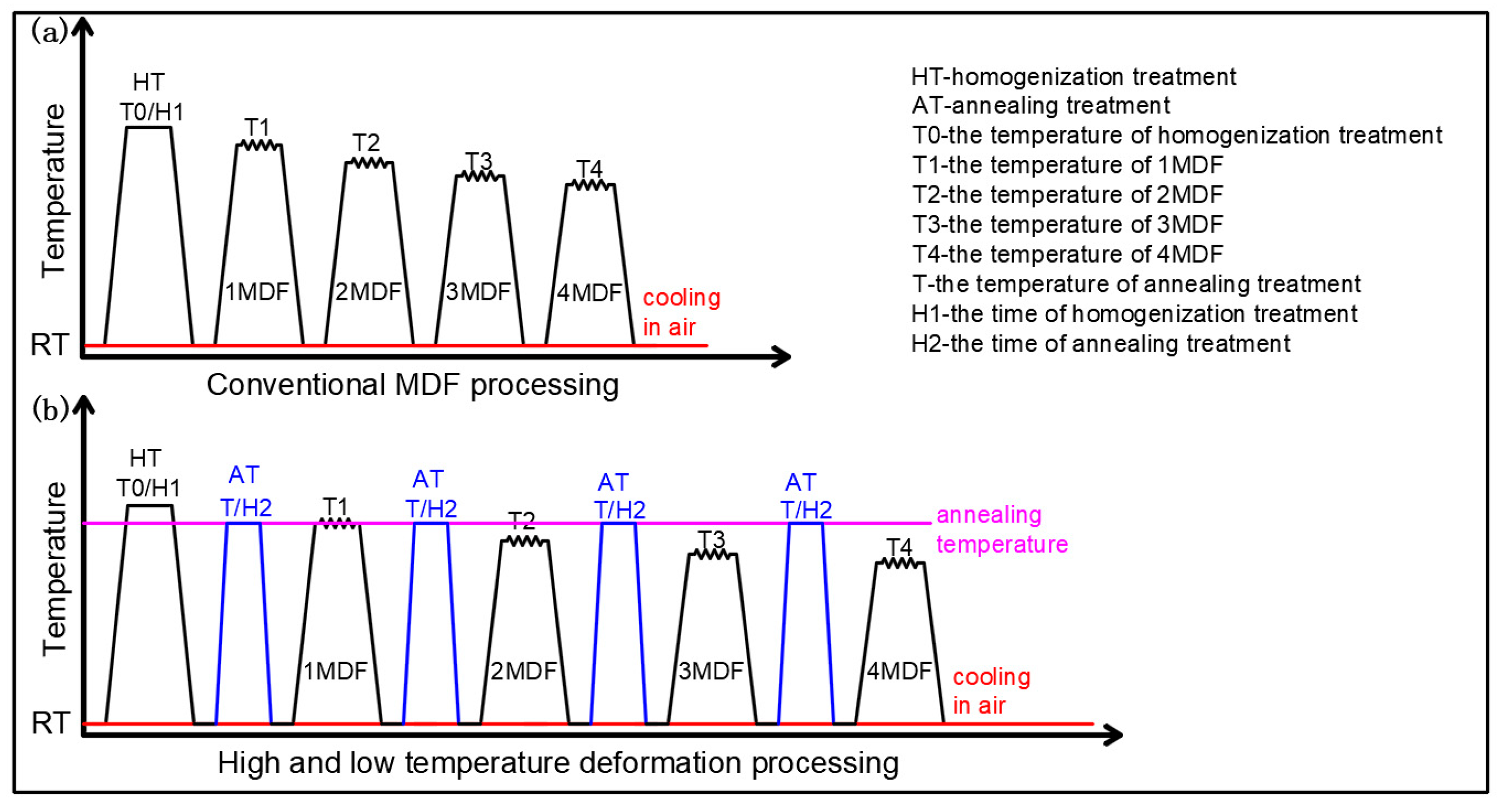

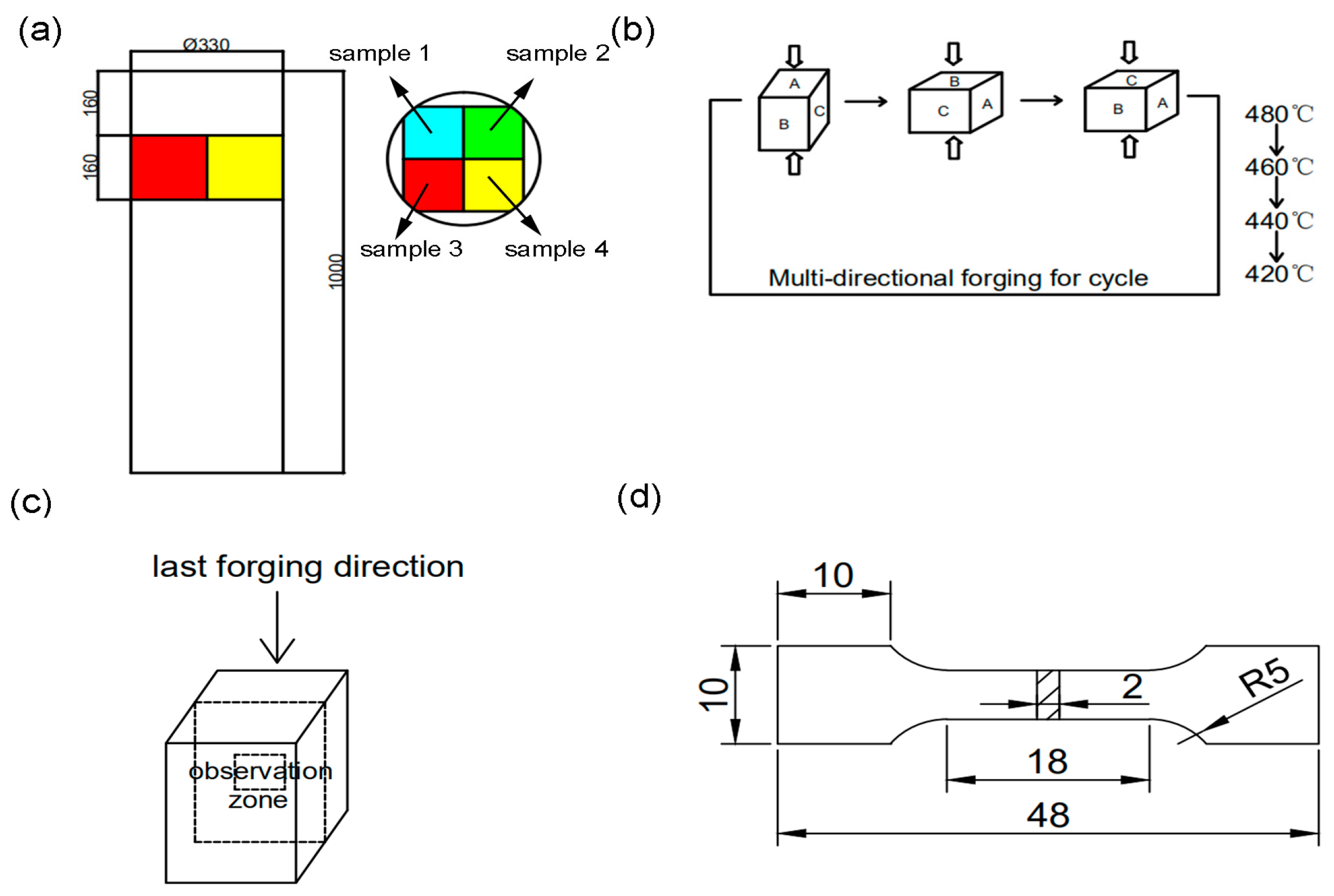

2. Materials and Methods

3. Results and Discussion

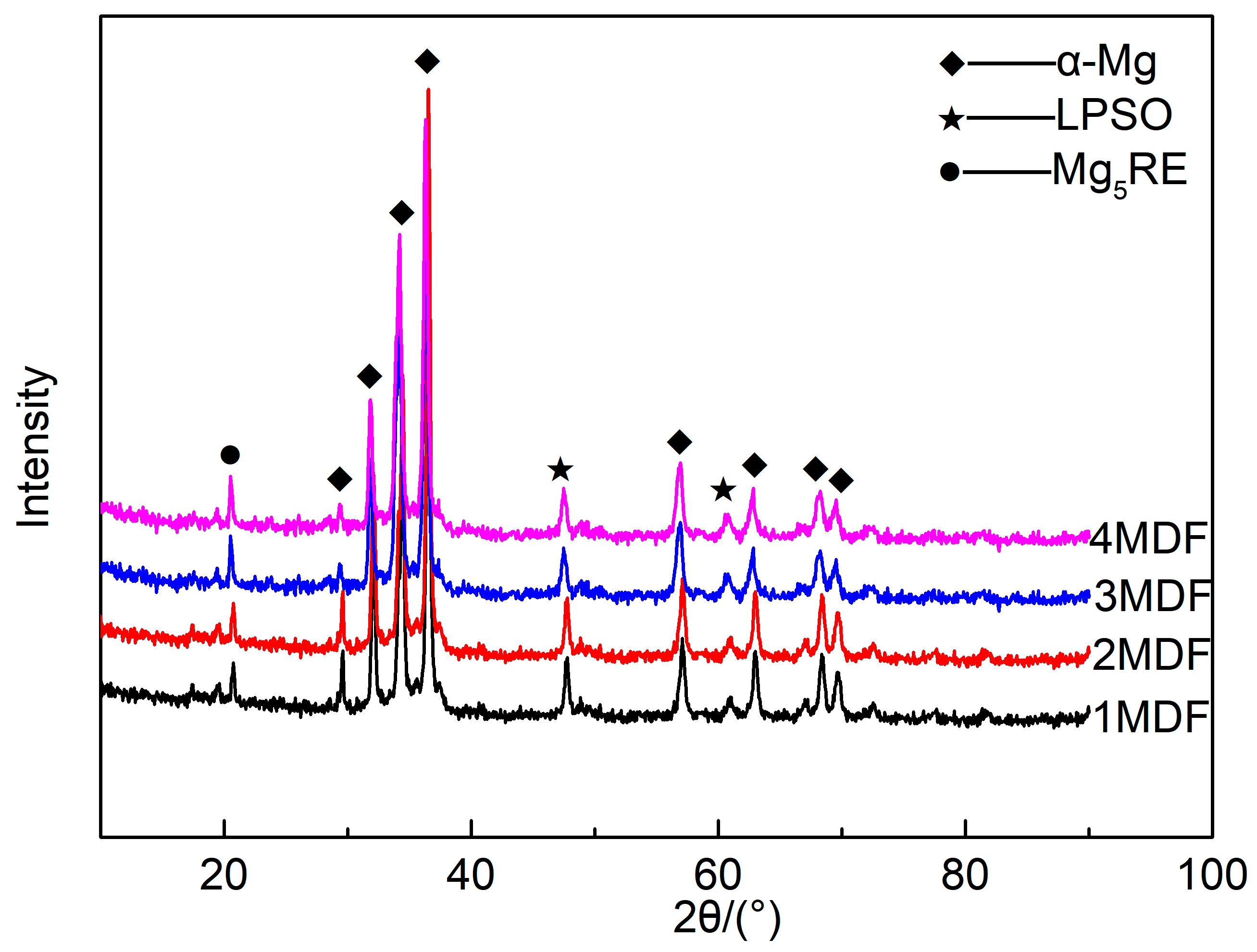

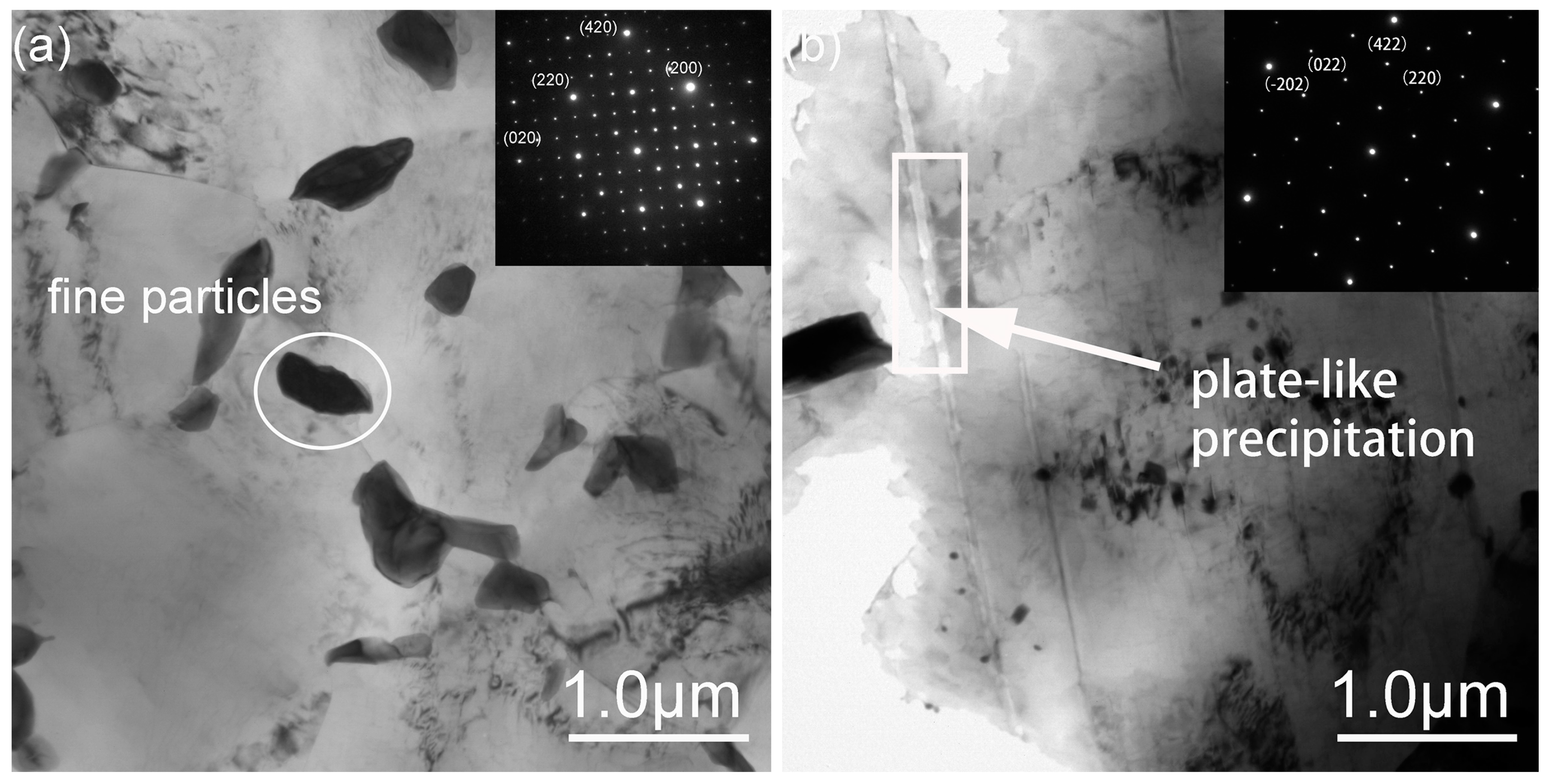

3.1. Microstructural Characterizations

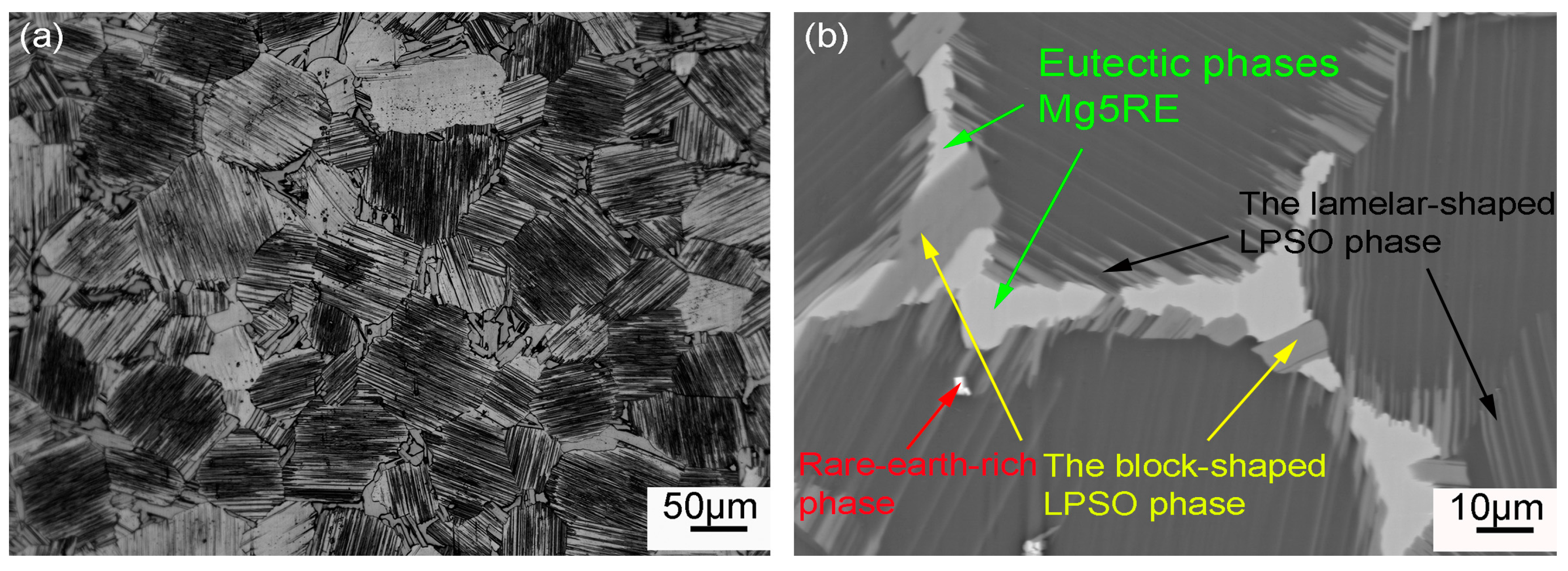

3.1.1. Microstructure after Homogenization Treatment

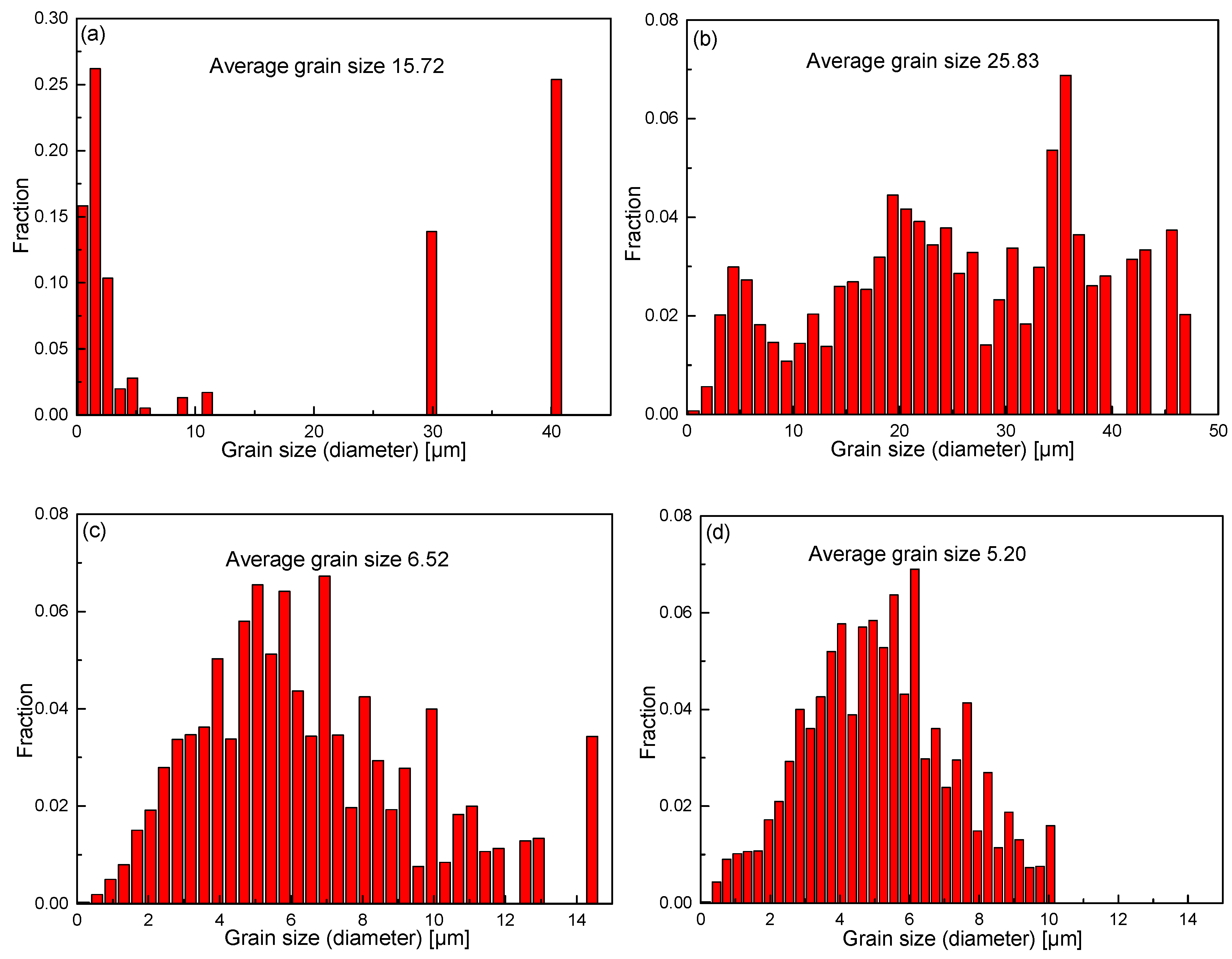

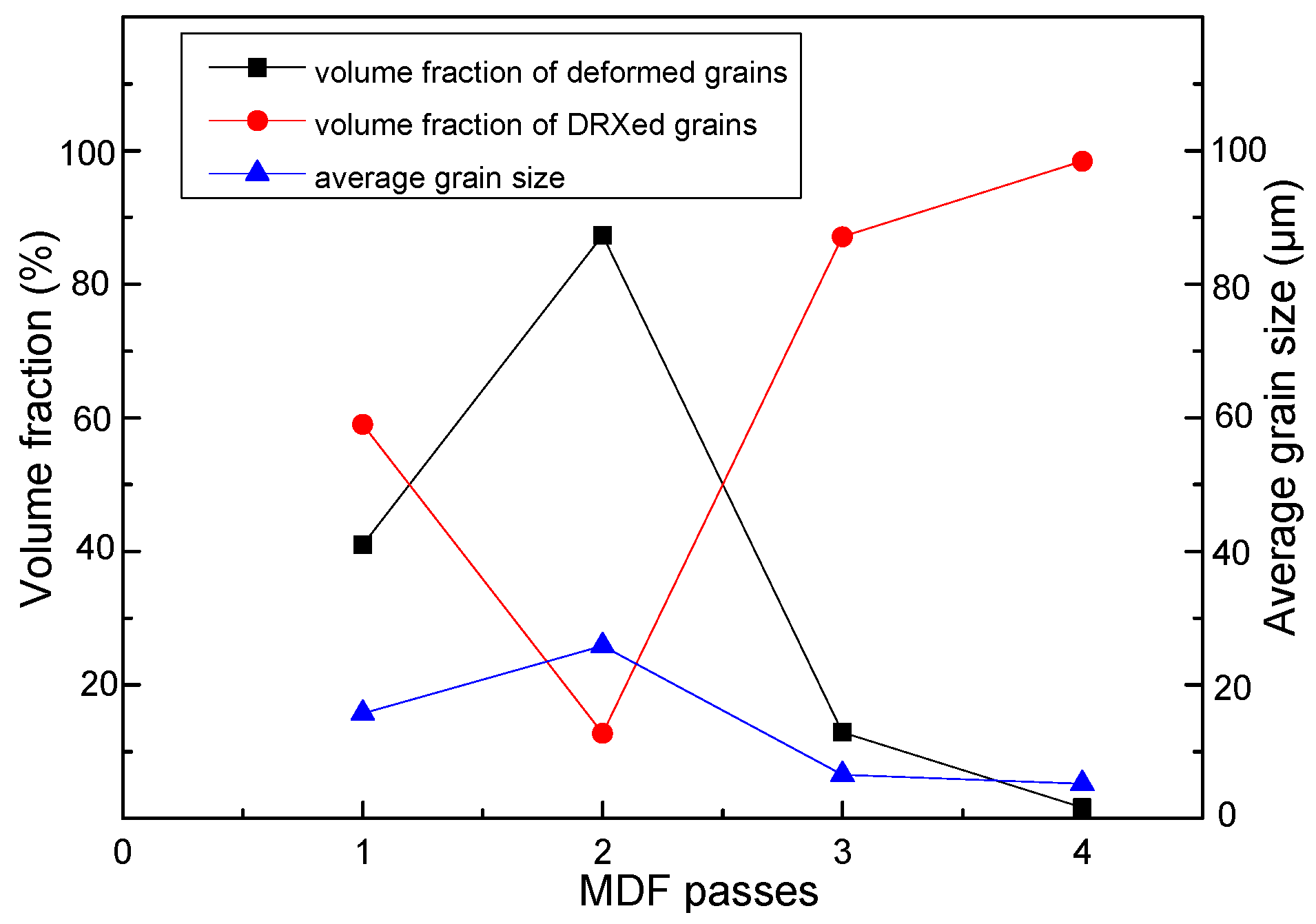

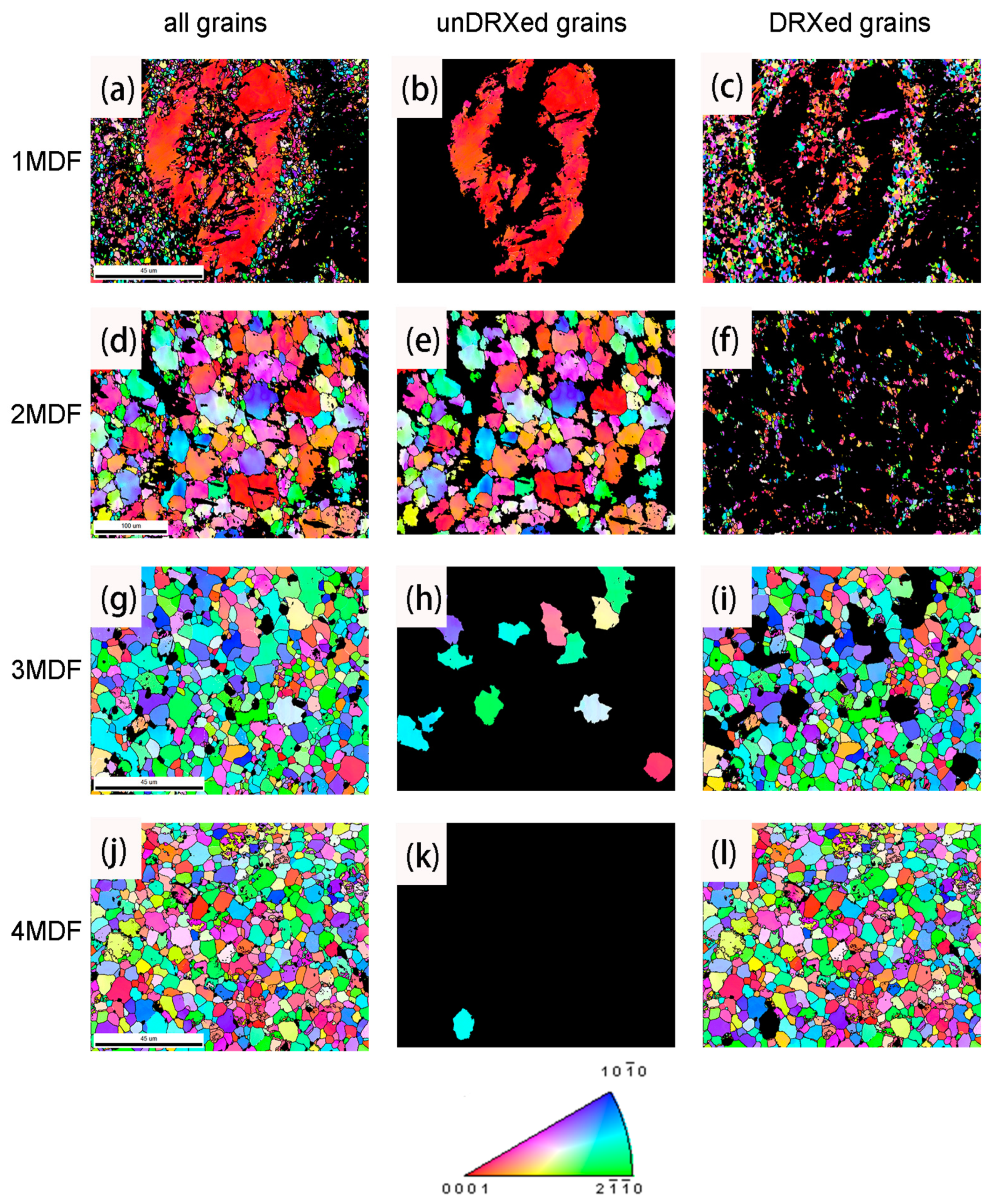

3.1.2. Microstructure after High and Low Temperature Cycle Deformation

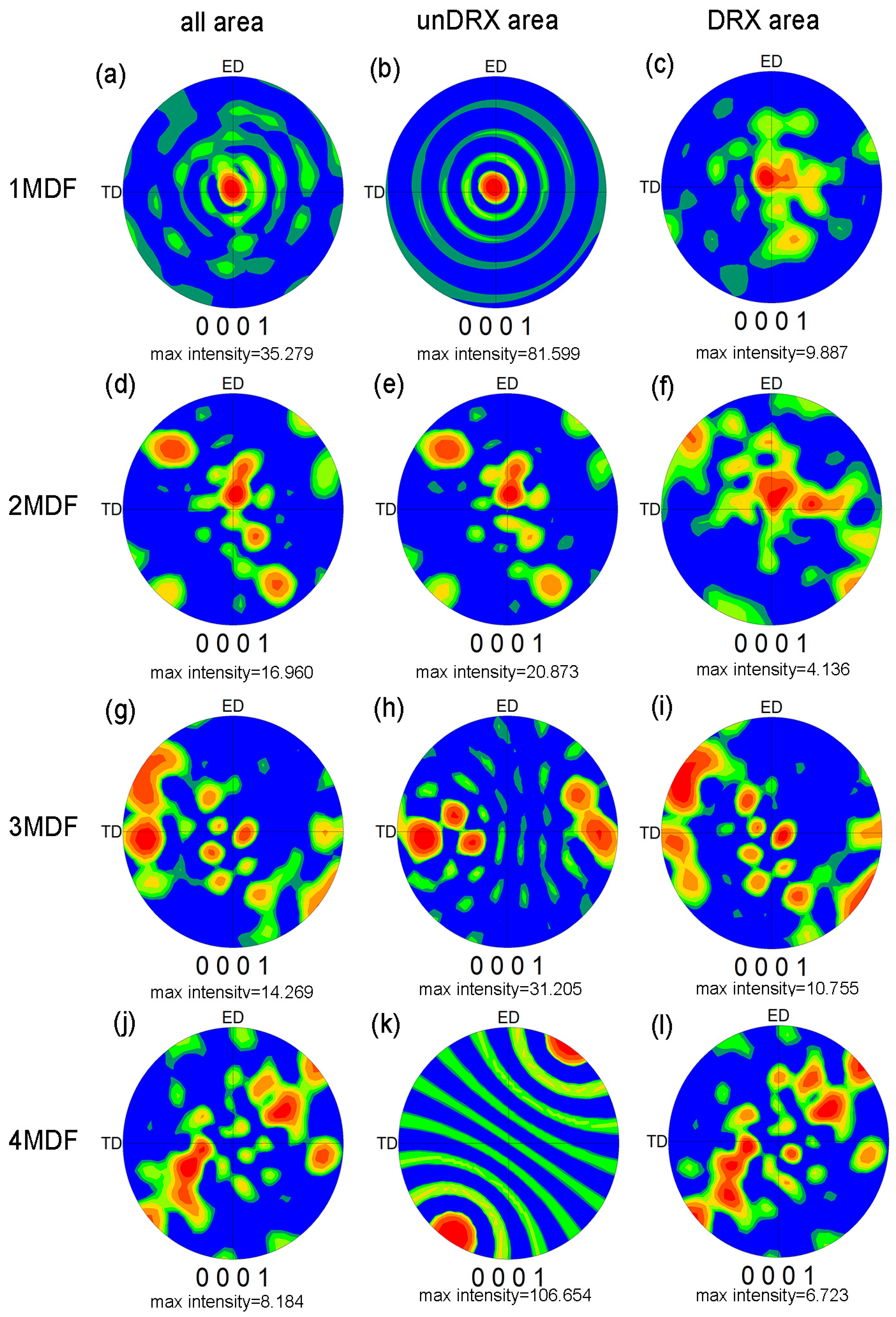

3.1.3. Texture Evolution during High and Low Temperature Cycle Deformation

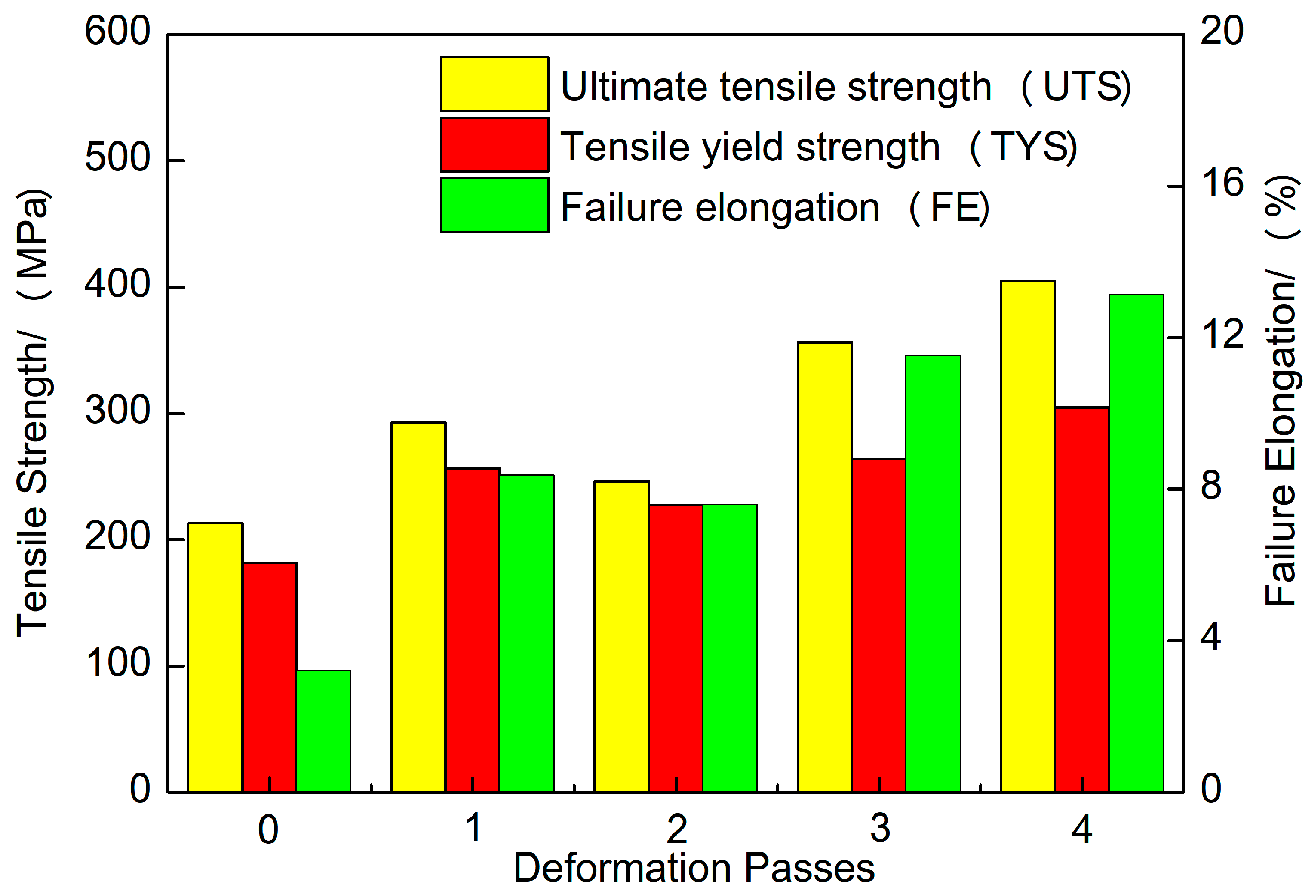

3.2. Mechanical Performance and Fracture Behaviour

4. Conclusions

- The MDF method can lead to a refined microstructure with the average grain size of 5.20 μm, and a fully DRX (~98.4%) also can be achieved after 4 passes through high and low temperature cycle deformation.

- With the increase of deformation passes, the microstructure gradually changed from a bimodal microstructure to a uniform fine-grained microstructure. Deformation texture is transformed from a basal texture to random texture, and the maximum texture intensity gradually decreases.

- It is shown that the MDF method significantly improved mechanical properties of the experimental alloy, the excellent tensile properties are UTS of 405 MPa, TYS of 305 MPa, and FE of 13.14% after 4 passes.

- The grain refining mechanism is attributed to the increase of grain boundaries by PSN and DRX mechanism. The uniform microstructure is obtained mainly due to the SRX mechanism caused by the annealing treatment between deformation passes.

- The high and low temperature cycle deformation, as a new deformation method, can guide us to obtain a uniform and fine microstructure. Meanwhile, it also can be applied in industrial production.

Author Contributions

Funding

Conflicts of Interest

References

- Mordike, B.L.; Ebert, T. Mg: Properties-applications-potential. Mater. Sci. Eng. A 2001, 302, 37–45. [Google Scholar] [CrossRef]

- Mohamed, W.; Gollapudi, S.; Charit, I.; Murty, K.L. Formability of a wrought Mg alloy evaluated by impression testing. Mater. Sci. Eng. A 2018, 712, 140–145. [Google Scholar] [CrossRef]

- Lu, J.W.; Yin, D.D.; Huang, G.H.; Quan, G.F.; Zeng, Y.; Zhou, H.; Wang, Q.D. Plastic anisotropy and deformation behavior of extruded Mg-Y sheets at elevated temperatures. Mater. Sci. Eng. A 2017, 700, 598–608. [Google Scholar] [CrossRef]

- Fang, C.; Liu, G.; Liu, X.; Hao, H.; Zhang, X. Significant texture weakening of Mg-8Gd-5Y-2Zn alloy by Al addition. Mater. Sci. Eng. A 2017, 701, 314–318. [Google Scholar] [CrossRef]

- Wu, Z.; Curtin, W.A. The origins of high hardening and low ductility in Mg. Nature 2015, 526, 62–67. [Google Scholar] [CrossRef]

- Stanford, N.; Atwell, D.; Beer, A.; Davies, C.; Barnett, M.R. Effect of microalloying with rare-earth elements on the texture of extruded Mg-based alloys. Scr. Mater. 2008, 59, 772–775. [Google Scholar] [CrossRef]

- Stanford, N. Micro-alloying Mg with Y, Ce, Gd and La for texture modification -a comparative study. Mater. Sci. Eng. A 2010, 527, 2669–2677. [Google Scholar] [CrossRef]

- Bohlen, J.; Nürnberg, M.R.; Senn, J.W.; Letzig, D.; Agnew, S.R. The texture and anisotropy of Mg-zinc-rare earth alloy sheets. Acta. Mater. 2007, 55, 2101–2112. [Google Scholar] [CrossRef]

- Mordike, B.L. Creep-resistant Mg alloys. Mater. Sci. Eng. A 2002, 324, 103–112. [Google Scholar] [CrossRef]

- Rokhlin, L.L. Mg Alloys Containing Rare Earth Metals: Structure and Properties; Taylor & Francis Ltd.: London, UK; New York, NY, USA, 2003; pp. 1–256. [Google Scholar]

- Homma, T.; Knito, N.; Kamado, S. Fabrication of extraordinary high-strength Mg alloy by hot extrusion. Scr. Mater. 2009, 61, 644–647. [Google Scholar] [CrossRef]

- He, S.M.; Zeng, X.Q.; Peng, L.M.; Gao, X.; Nie, J.F.; Ding, W.J. Microstructure and strengthening mechanism of high strength Mg-10Gd-2Y-0.5Zr alloy. JALLC 2007, 427, 316–323. [Google Scholar] [CrossRef]

- Yamasaki, M.; Anan, T.; Yoshimoto, S.; Kawamura, Y. Mechanical properties of warm-extruded Mg-Zn-Gd alloy with coherent 14H long periodic stacking ordered structure precipitate. Scr. Mater. 2005, 53, 799–803. [Google Scholar] [CrossRef]

- Yu, Z.J.; Xu, C.; Meng, J.; Zhang, X.H.; Kamado, S. Effects of pre-annealing on microstructure and mechanical properties of as-extruded Mg-Gd-Y-Zn-Zr alloy. J. Alloys Compd. 2017, 729, 627–637. [Google Scholar] [CrossRef]

- Peng, Q.M.; Hou, X.L.; Wang, L.D.; Wu, Y.M.; Cao, Z.Y.; Wang, L.M. Microstructure and mechanical properties of high performance Mg-Gd based alloys. Mater. Des. 2009, 30, 92–296. [Google Scholar] [CrossRef]

- Nie, K.B.; Deng, K.K.; Wang, X.J.; Xu, F.J.; Wu, K.; Zheng, M.Y. Multidirectional forging of AZ91 Mg alloy and its effects on microstructures and mechanical properties. Mater. Sci. Eng. A 2015, 624, 157–168. [Google Scholar] [CrossRef]

- Huang, H.; Zhang, J. Microstructure and mechanical properties of AZ31 Mg alloy processed by multi-directional forging at different temperatures. Mater. Sci. Eng. A 2016, 674, 52–58. [Google Scholar] [CrossRef]

- Saboori, A.; Dadkhah, M.; Pavese, M.; Manfredi, D.; Biamino, S.; Fino, P. Hot deformation behaviour of Zr-1%Nb alloy: Flow curve analysis and microstructure observations. Mater. Sci. Eng. A 2017, 696, 366–373. [Google Scholar] [CrossRef]

- Yu, Z.J.; Huang, Y.D.; Mendis, C.L.; Hort, N.; Meng, J. Microstructural evolution and mechanical properties of Mg-11Gd-4.5Y-1nD-1.5Zn-0.5Zr alloy prepared via pre-ageing and hot extrusion. Mater. Sci. Eng. A 2015, 624, 23–31. [Google Scholar] [CrossRef]

- Yu, Z.J.; Huang, Y.D.; Gan, W.M.; Zhong, Z.Y.; Hort, N.; Meng, J. Effects of extrusion ratio and annealing treatment on the mechanical properties and microstructure of a Mg-11Gd-4.5Y-1Nd-1.5Zn-0.5Zr (wt%) alloy. J. Mater. Sci. 2017, 52, 6670–6686. [Google Scholar] [CrossRef]

- Xia, X.; Chen, Q.; Zhao, Z.; Ma, M.; Li, X.; Zhang, K. Microstructure, texture and mechanical properties of coarse-grained Mg-Gd-Y-Nd-Zr alloy processed multidirectional forging. J. Alloys Compd. 2015, 638, 67–276. [Google Scholar] [CrossRef]

- Asqardoust, S.; Zarei-Hanzaki, A.; Abedi, H.R.; Krajnak, T.; Minarik, P. Enhancing the strength and ductility in accumulative back extruded WE43 Mg alloy through achieving bimodal grain size distribution and texture weakening. Mater. Sci. Eng. A 2017, 698, 218–229. [Google Scholar] [CrossRef]

- Xiao, H.; Tang, B.; Liu, C.; Gao, Y.; Yu, S.; Jiang, S. Dynamic precipitation in a Mg-Gd-Y-Zr alloy during hot compression. Mater. Sci. Eng. A 2015, 645, 241–247. [Google Scholar] [CrossRef]

- Ramezani, S.M.; Zarei-Hanzaki, A.; Abedi, H.R.; Salandari-Rabori, A.; Minarik, P. Achievement of fine-grained bimodal microstructures and superior mechanical properties in a multi-axially forged GWZ Mg alloy containing LPSO structures. J. Alloys Compd. 2019, 793, 134–145. [Google Scholar] [CrossRef]

- Salandari-Rabori, A.; Zarei-Hanzaki, A.; Fatemi, S.M.; Ghambari, M.; Moghaddam, M. Microstructure and superior mechanical properties of a multi-axially forged WE Mg alloy. J. Alloys Compd. 2017, 693, 406–413. [Google Scholar] [CrossRef]

- Asqardoust, S.; Zarei-Hanzaki, A.; Fatemi, S.M.; Moradjoy-Hamedani, M. High temperature deformation behaviour and microstructural evolutions of a high Zr containing WE Mg alloy. J. Alloys Compd. 2016, 669, 108–116. [Google Scholar] [CrossRef]

- Nie, K.B.; Wang, X.J.; Deng, K.K.; Xu, F.J.; Wu, K.; Zheng, M.Y. Microstructures and mechanical properties of AZ91 Mg alloy processed by multidirectional forging under decreasing temperature. J. Alloys Compd. 2014, 617, 979–987. [Google Scholar] [CrossRef]

- Li, Z.F.; Dong, J.; Zeng, X.Q.; Lu, C.; Ding, W.J. Influence of Mg17Al12 intermetallic compounds on the hot extruded microstructures and mechanical properties of Mg-9Al-1Zn alloy. Mater. Sci. Eng. A 2007, 466, 134–139. [Google Scholar] [CrossRef]

| Element | Gd | Y | Zn | Zr | Si | Cu | Mg |

|---|---|---|---|---|---|---|---|

| Wt% | 12.88 | 4.00 | 2.00 | 0.50 | <0.01 | <0.01 | Bal. |

| Designation History | |

|---|---|

| Sample 1 | 1st pass MDF at 480 °C (∑△ε = 3) |

| Sample 2 | 1st pass MDF at 480 °C + annealing treatment at 480 °C + 2nd pass MDF at 460 °C (∑△ε = 6) |

| Sample 3 | 1st pass MDF at 480 °C + annealing treatment at 480 °C + 2nd pass MDF at 460 °C + annealing treatment at 480 °C + 3rd pass MDF at 440 °C (∑△ε = 9) |

| Sample 4 | 1st pass MDF at 480 °C +annealing treatment at 480 °C + 2nd pass MDF at 460 °C + annealing treatment at 480 °C + 3rd pass MDF at 440 °C + annealing treatment at 480 °C + 4th pass MDF at 420 °C (∑△ε = 12) |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dong, B.; Zhang, Z.; Che, X.; Yu, J.; Meng, M.; Zhang, J. Microstructure, Texture Evolution, and Mechanical Properties of MDFed GWZ Alloy Containing LPSO Phases on the Condition of High and Low Temperature Cycle Deformation. Metals 2020, 10, 136. https://doi.org/10.3390/met10010136

Dong B, Zhang Z, Che X, Yu J, Meng M, Zhang J. Microstructure, Texture Evolution, and Mechanical Properties of MDFed GWZ Alloy Containing LPSO Phases on the Condition of High and Low Temperature Cycle Deformation. Metals. 2020; 10(1):136. https://doi.org/10.3390/met10010136

Chicago/Turabian StyleDong, Beibei, Zhimin Zhang, Xin Che, Jianmin Yu, Mu Meng, and Jinlu Zhang. 2020. "Microstructure, Texture Evolution, and Mechanical Properties of MDFed GWZ Alloy Containing LPSO Phases on the Condition of High and Low Temperature Cycle Deformation" Metals 10, no. 1: 136. https://doi.org/10.3390/met10010136

APA StyleDong, B., Zhang, Z., Che, X., Yu, J., Meng, M., & Zhang, J. (2020). Microstructure, Texture Evolution, and Mechanical Properties of MDFed GWZ Alloy Containing LPSO Phases on the Condition of High and Low Temperature Cycle Deformation. Metals, 10(1), 136. https://doi.org/10.3390/met10010136