Effect of Heterogeneous Microstructure on Refining Austenite Grain Size in Low Alloy Heavy-Gage Plate

Abstract

1. Introduction

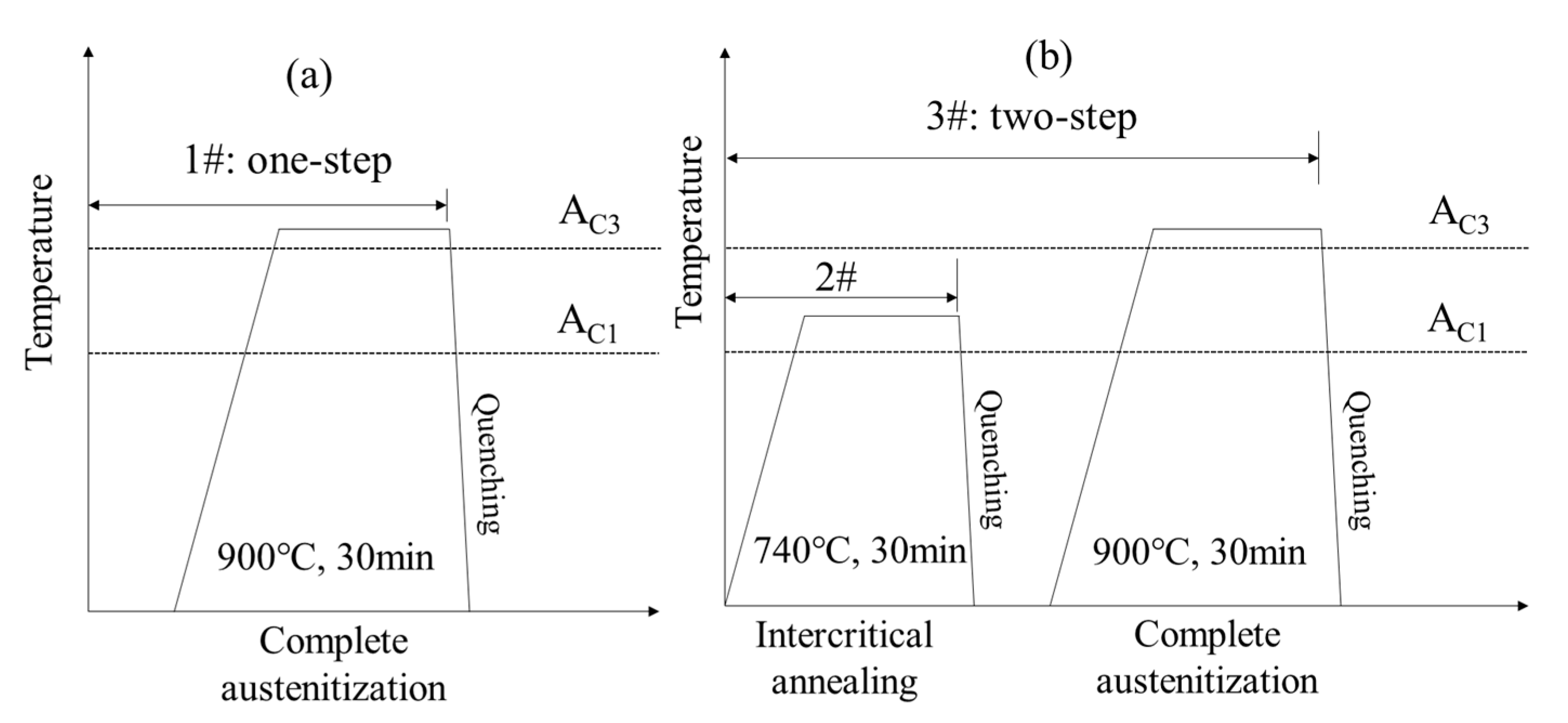

2. Experimental Material and Procedure

3. Results and Discussion

3.1. Refining Prior Austenite Grain

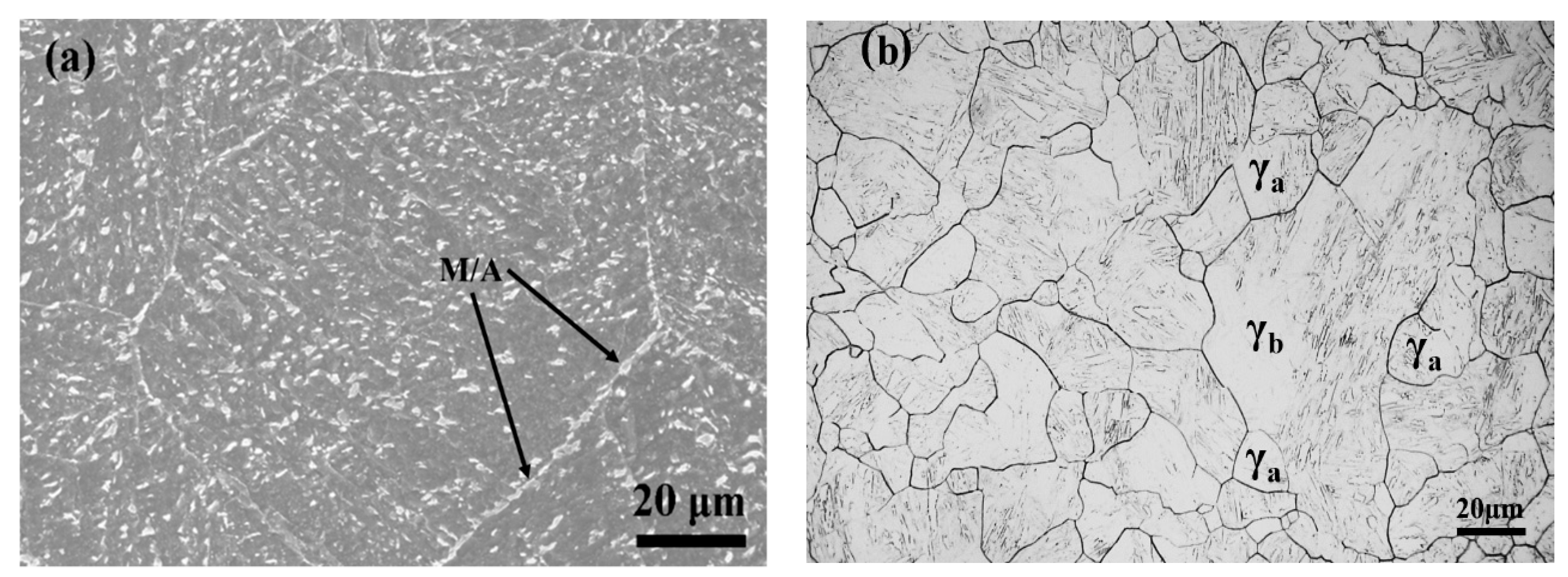

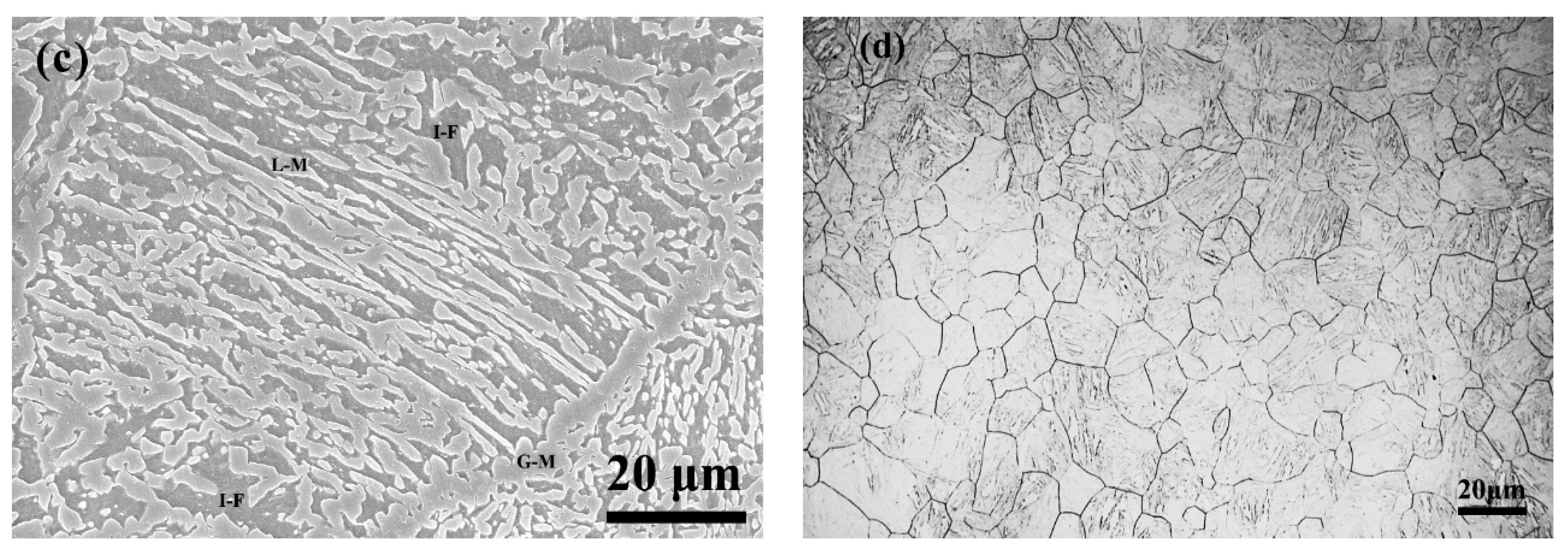

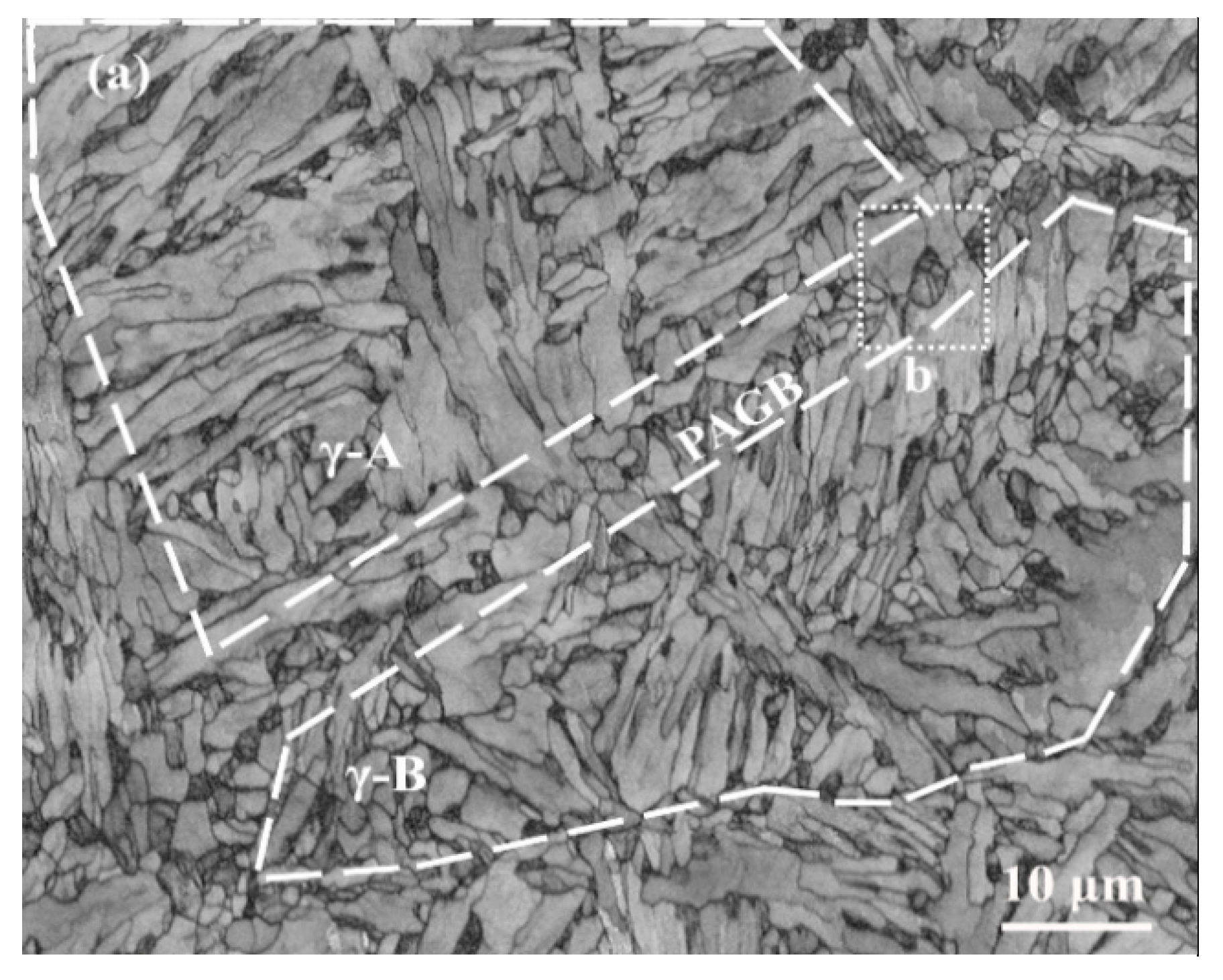

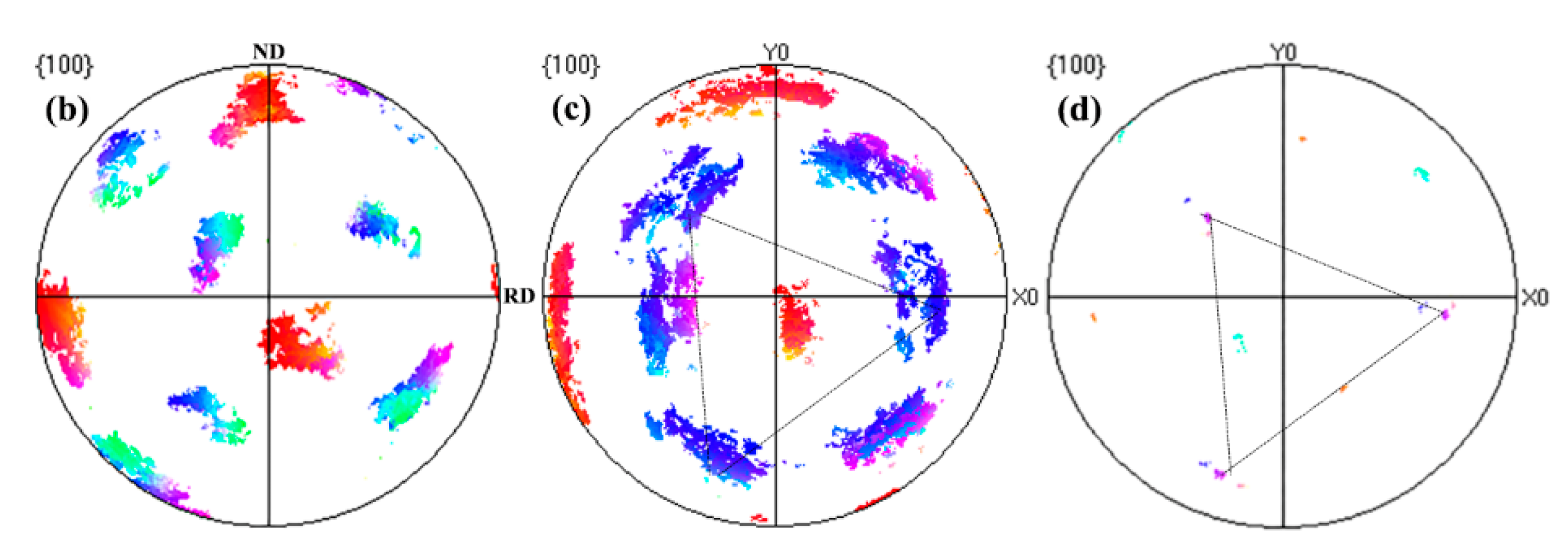

3.2. Crystallographic Characteristics of Pre-Annealed Microstructure

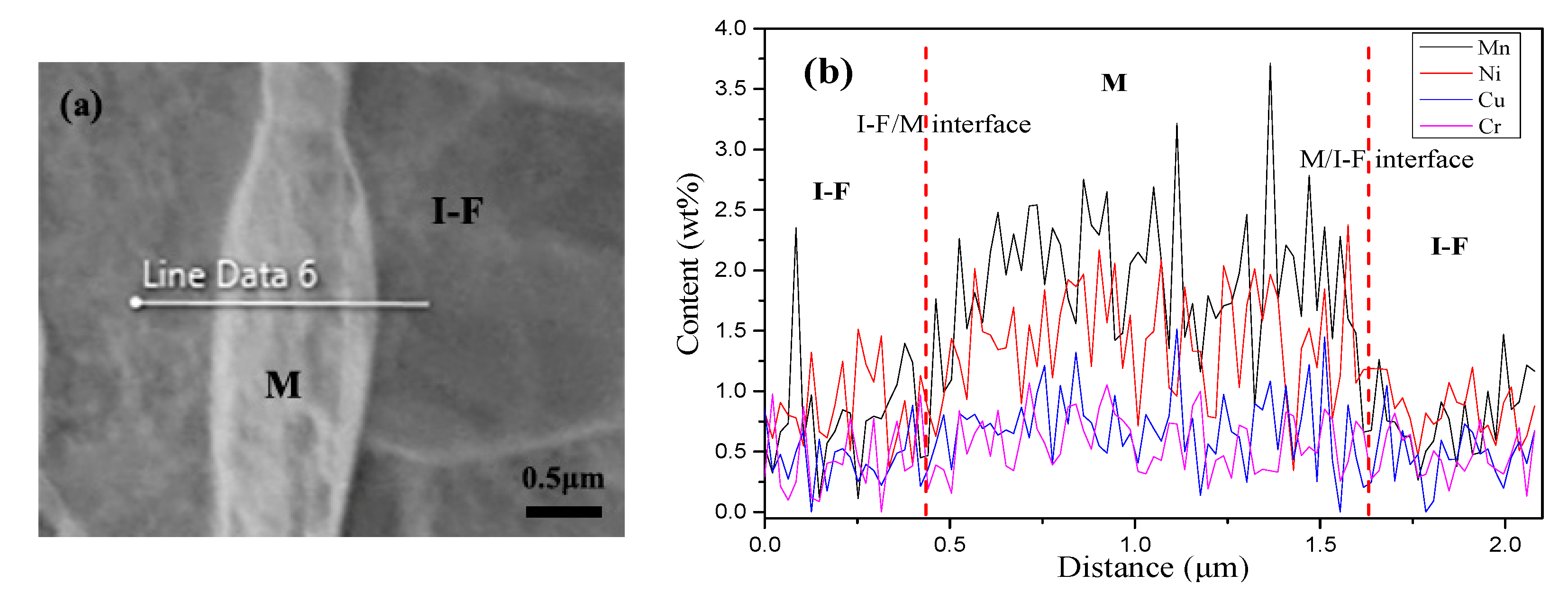

3.3. Enrichment of Alloying Elements

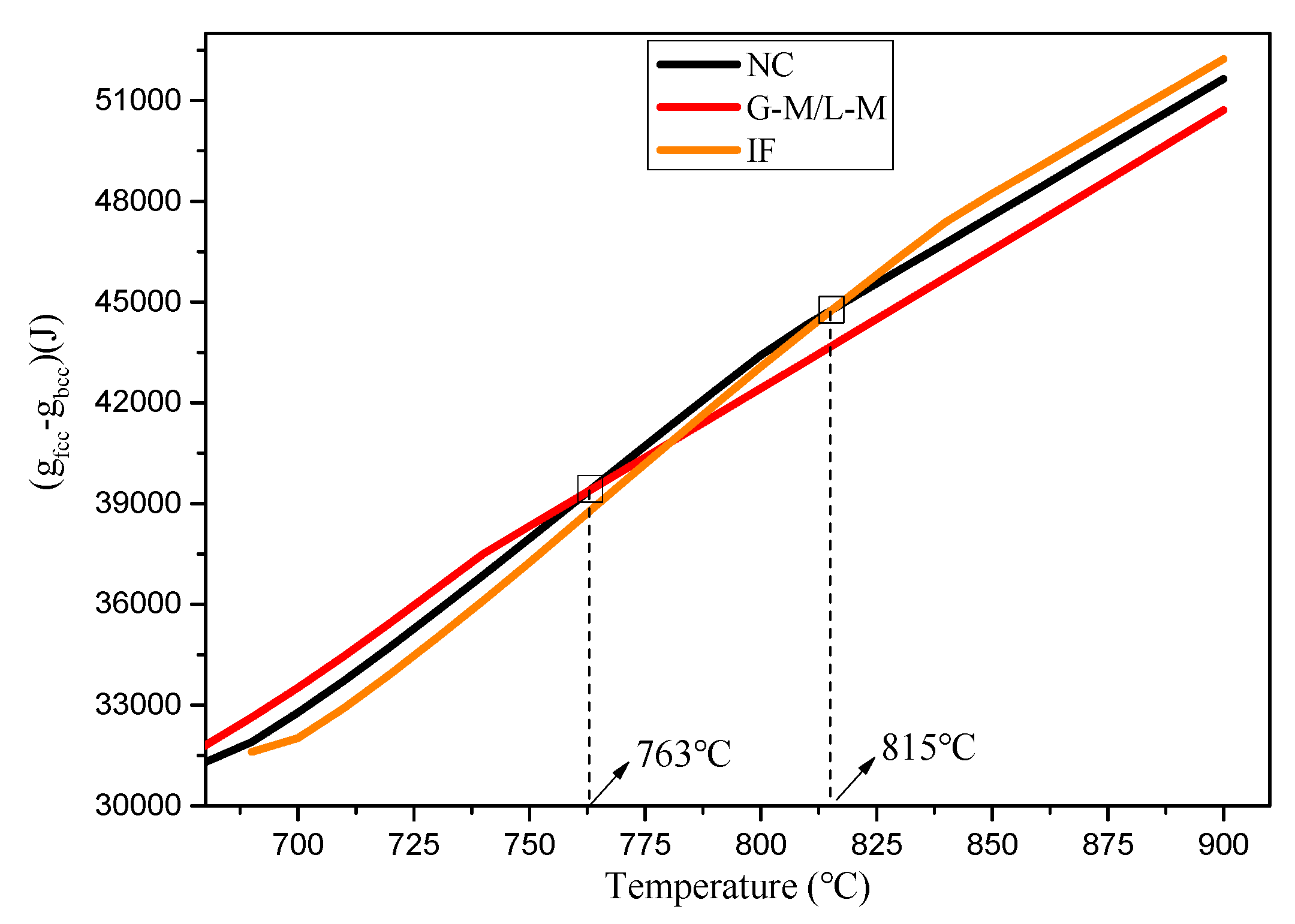

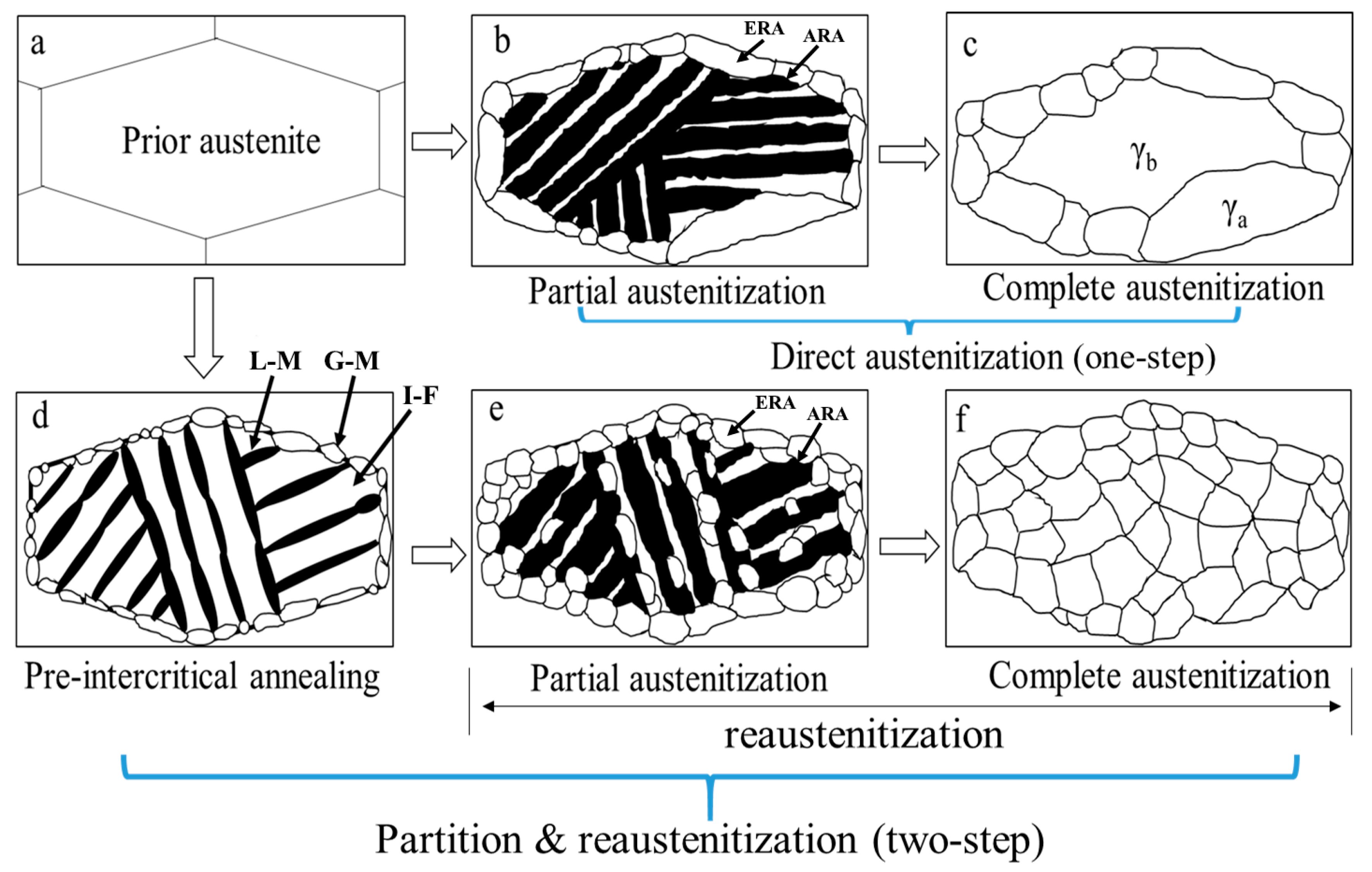

3.4. Role of Heterogeneous Microstructure

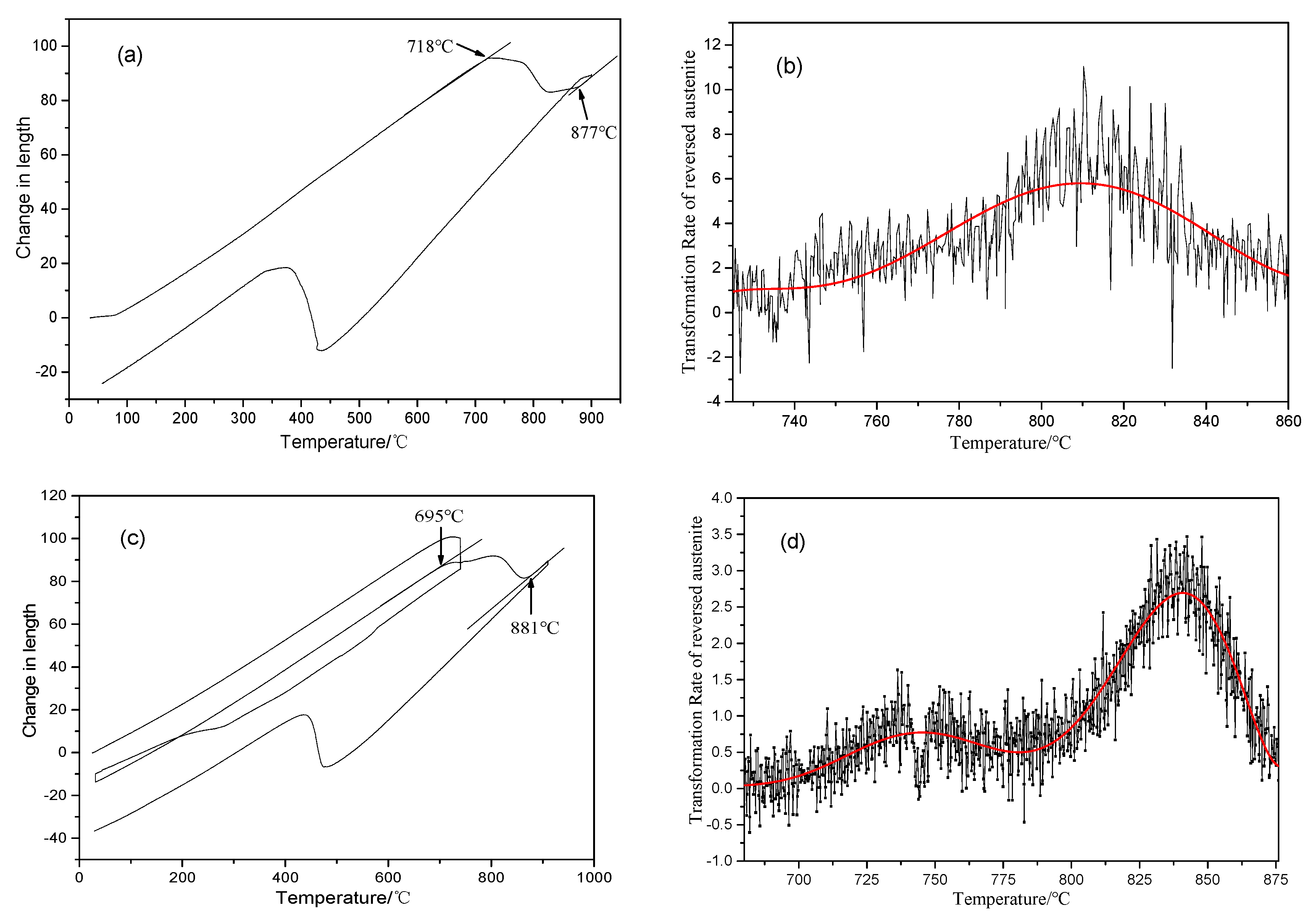

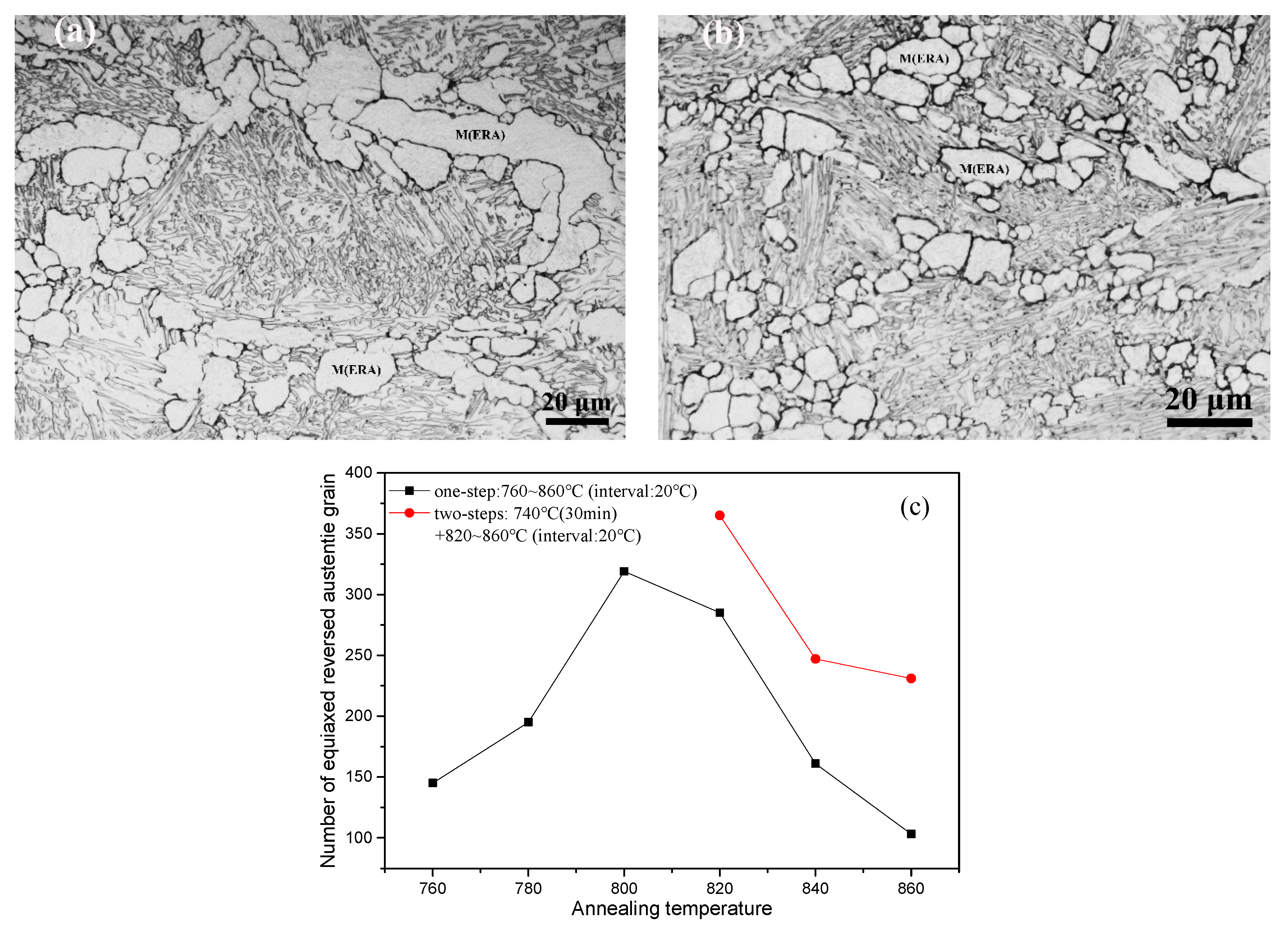

3.5. Nucleation Rate of Reversed Austenite

4. Conclusions

- The heterogeneous microstructures of alloying elements-enriched fresh martensite and -depleted intercritical ferrite were obtained after intercritical annealing. The fresh martensite was distributed at prior austenite grain boundary (G-M) and inter-lath (L-M). G-M was transformed by equiaxed reversed austenite and the L-M was formed by acicular reversed austenite, when the reversed austenite obtained during intercritical annealing was quenched to room temperature.

- The heterogeneous microstructure increased the intrinsic energy difference of fcc phase and bcc phase below 763 °C or above 815 °C, and the interface energy decreased because of alloying element enrichment at the interface, which reduces the nucleation energy barrier according to the nucleation theory under ideal state. Therefore, the nucleation driving energy of equiaxed reversed austenite is less. The heterogeneous microstructure can enhance the equiaxed reversed austenite nucleation at intragranular and prior austenite grain boundary during reheating, which effectively refined the coarse prior austenite grains in the core of hot rolled heavy plate processed by TMCP.

- The prior austenite grains in the core of heavy plate processed by TMCP was very large (~105 μm). The austenite grains were inhomogeneous when the hot rolled specimen was reheated by one-step heat treatment process. However, for the two-step heat treatment process, fine and uniform austenite grain size (~12 μm) was obtained, which was two times finer compared to the one-step heat treatment. An effective way of improving strength, ductility and low temperature toughness in alloy steel is to refine the prior austenite grain size. This study provides a possible way of effectively refining prior austenite grain size.

Author Contributions

Funding

Conflicts of Interest

References

- Liu, D.S.; Cheng, B.G.; Chen, Y.Y. Strengthening and toughening of a heavy plate steel for shipbuilding with yield strength of approximately 690 MPa. Metal. Mater. Trans. A 2013, 44A, 440. [Google Scholar] [CrossRef]

- Hua, J.; Du, L.X.; Xie, H.; Gao, X.H.; Misra, R.D.K. Microstructure and mechanical properties of TMCP heavy plate microalloyed steel. Mater. Sci. Eng. A 2014, 607, 122–131. [Google Scholar] [CrossRef]

- Wu, T.; Wu, R.; Liu, B.; Liang, W.; Ke, D.Q. Enhancing the mechanical properties of a hot rolled high-strength steel produced by ultra-fast cooling and Q&P process. Metals 2019, 9, 958. [Google Scholar]

- Hu, J.; Du, L.X.; Liu, H.; Sun, G.S.; Xie, H.; Yi, H.L.; Misra, R.D.K. Structure—mechanical property relationship in a low-C medium-Mn ultrahigh strength heavy plate steel with austenite-martensite submicro-laminate structure. Mater. Sci. Eng. A 2015, 647, 144–151. [Google Scholar] [CrossRef]

- Kaijalainen, A.J.; Suikkanen, P.P.; Limnell, T.J.; Karjalainen, L.P.; Kömi, J.I.; Porter, D.A. Effect of austenite grain structure on the strength and toughness of direct-quenched martensite. J. Alloys Compd. 2013, 577, S642–S648. [Google Scholar] [CrossRef]

- Kamada, A.; Koshizuka, N.; Funakoshi, T. Effect of austenite grain size and C content on the substructure and toughness of tempered martensite and bainite. Trans. Iron Steel Inst. Jpn. 1976, 16, 407–416. [Google Scholar] [CrossRef]

- Morrito, S.; Saito, H.; Ogawa, T.; Furuhara, T.; Maki, T. Effect of austenite grain size on the morphology and crystallography of lath martensite in low carbon steels. ISIJ Int. 2005, 45, 91–94. [Google Scholar] [CrossRef]

- Morris, J.W.; Guo, Z.; Krenn, C.R.; Kim, Y.-H. The limits of strength and toughness in steel. ISIJ Int. 2001, 41, 599–611. [Google Scholar] [CrossRef]

- Miller, R.L. Ultrafine-grained microstructures and mechanical properties of alloy steels. Metall. Mater. Trans. 1972, 3, 905–912. [Google Scholar] [CrossRef]

- Grange, R.A. Strengthening steel by austenite grain refinement. ASM Trans. Quart 1966, 59, 26. [Google Scholar]

- Sanij, H.K.; Banadkouki, S.S.G.; Mashreghi, A.R.; Moshrefifar, M. The effect of single and double quenching and tempering heat treatments on the microstructure and mechanical properties of AISI 4140 steel. Mater. Des. 2012, 42, 339–346. [Google Scholar] [CrossRef]

- Hara, T.; Maruyama, N.; Shinohara, Y.; Asahi, H.; Shigesato, G.; Sugiyama, M.; Koseki, T. Abnormal a to g transformation behavior of steels with a martensite and bainite microstructure at a slow reheating rate. ISIJ Int. 2009, 49, 1792–1800. [Google Scholar] [CrossRef]

- Zhang, X.G.; Miyamoto, G.; Toji, Y.; Nambu, S.; Koseki, T.; Furuhara, T. Orientation of austenite reverted from martensite in Fe-2Mn-1.5 Si-0.3 C alloy. Acta Mater. 2018, 144, 601–612. [Google Scholar] [CrossRef]

- Nakada, N.; Tsuchiyama, T.; Takaki, S.; Hashizume, S. Variant selection of reversed austenite in lath martensite. ISIJ Int. 2007, 47, 1527–1532. [Google Scholar] [CrossRef]

- Kimmins, S.T.; Gooch, D.J. Austenite memory effect in 1 Cr–1 Mo–0·75V (Ti, B) steel. Met. Sci. 1983, 17, 519–532. [Google Scholar]

- Shirazi, H.; Miyamoto, G.; Nedjad, S.H.; Chiba, T.; Ahmadabadi, M.N.; Furuhara, T. Microstructure evolution during austenite reversion in Fe-Ni martensitic alloys. Acta Mater. 2018, 144, 269–280. [Google Scholar] [CrossRef]

- Liu, Z.Q.; Miyamoto, G.; Yang, Z.G.; Zhang, C.; Furuhara, T. Effects of pretempering on intercritical annealing in Fe-2Mn-0.3 C alloy. Metall. Mater. Trans. A 2014, 45, 5290–5294. [Google Scholar] [CrossRef]

- Ding, R.; Tang, D.; Zhao, A.M. A novel design to enhance the amount of retained austenite and mechanical properties in low-alloyed steel. Scr. Mater. 2014, 88, 21. [Google Scholar] [CrossRef]

- Li, Z.D.; Miyamoto, G.; Yang, Z.G.; Furuhara, T. Nucleation of austenite from pearlitic structure in an Fe–0.6 C–1Cr alloy. Scr. Mater. 2009, 60, 485–488. [Google Scholar] [CrossRef]

- Matsuda, S.; Okamura, Y. Reverse transformation of low-carbon low alloy steels. Tetsu-to-Hagane 1974, 60, 226–238. [Google Scholar] [CrossRef]

- Plichata, M.R.; Aaronson, H.I. Influence of alloying elements upon the morphology of austenite formed from martensite in Fe-C-X alloys. Metall. Trans. 1974, 5, 2611–2613. [Google Scholar] [CrossRef]

- Watanabe, S.; Kunitake, T. On the formation of austenite grains from prior martensitic structure. Tetsu-to-Hagané 1975, 61, 96–106. [Google Scholar] [CrossRef]

- Nakada, N.; Tsuchiyama, T.; Takaki, S.; Miyano, N. Temperature dependence of austenite nucleation behavior from lath martensite. ISIJ Int. 2011, 51, 299–304. [Google Scholar] [CrossRef]

- Nakada, N.; Mizutani, K.; Tsuchiyama, T.; Takaki, S. Difference in transformation behavior between ferrite and austenite formations in medium manganese steel. Acta Mater. 2014, 65, 251–258. [Google Scholar] [CrossRef]

- Shtansky, D.V.; Nakai, K.; Ohmori, Y. Pearlite to austenite transformation in an Fe–2.6Cr–1C alloy. Acta Mater. 1999, 47, 2619–2632. [Google Scholar] [CrossRef]

- Zhou, D.S.; Shiflet, G.J. Interfacial steps and growth mechanism in ferrous pearlites. Metal. Trans. A 1991, 22A, 1349–1365. [Google Scholar] [CrossRef]

- Shtansky, D.V.; Inden, G. Phase transformation in Fe-Mo-C and Fe-WC steels—II. eutectoid reaction of M23C6 carbide decomposition during austenitization. Acta Mater. 1997, 45, 2879. [Google Scholar] [CrossRef]

- Spanos, G.; Aaronson, H.I. The interfacial structure and habit plane of proeutectoid cementite plates. Acta Metal. Mater. 1990, 38, 2721–2732. [Google Scholar] [CrossRef]

- Sadovskii, V.D.; Sokolov, B.K. Problems of Physical Metallurgy and Heat Treatment; Mashgiz: Moscow, Russia, 1956; p. 31. [Google Scholar]

- Haasen, P. Physical Metallurgy; Section 4.1; Cambridge University Press: Cambridge, UK, 1978. [Google Scholar]

| Position | Mn | Ni | Cu | Cr |

|---|---|---|---|---|

| 1# | 1.89 | 1.59 | 0.68 | 0.51 |

| 2# | 2.08 | 1.67 | 0.85 | 0.68 |

| 3# | 1.81 | 1.56 | 0.72 | 0.56 |

| 4# | 1.95 | 1.57 | 0.79 | 0.59 |

| 5# | 2.09 | 1.74 | 0.82 | 0.65 |

| Mean | 1.96 | 1.63 | 0.77 | 0.60 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yuan, S.; Xie, Z.; Wang, J.; Zhu, L.; Yan, L.; Shang, C.; Misra, R.D.K. Effect of Heterogeneous Microstructure on Refining Austenite Grain Size in Low Alloy Heavy-Gage Plate. Metals 2020, 10, 132. https://doi.org/10.3390/met10010132

Yuan S, Xie Z, Wang J, Zhu L, Yan L, Shang C, Misra RDK. Effect of Heterogeneous Microstructure on Refining Austenite Grain Size in Low Alloy Heavy-Gage Plate. Metals. 2020; 10(1):132. https://doi.org/10.3390/met10010132

Chicago/Turabian StyleYuan, Shengfu, Zhenjia Xie, Jingliang Wang, Longhao Zhu, Ling Yan, Chengjia Shang, and R. D. K. Misra. 2020. "Effect of Heterogeneous Microstructure on Refining Austenite Grain Size in Low Alloy Heavy-Gage Plate" Metals 10, no. 1: 132. https://doi.org/10.3390/met10010132

APA StyleYuan, S., Xie, Z., Wang, J., Zhu, L., Yan, L., Shang, C., & Misra, R. D. K. (2020). Effect of Heterogeneous Microstructure on Refining Austenite Grain Size in Low Alloy Heavy-Gage Plate. Metals, 10(1), 132. https://doi.org/10.3390/met10010132