Nanoindentation Properties of 18CrNiMo7-6 Steel after Carburizing and Quenching Determined by Continuous Stiffness Measurement Method

Abstract

1. Introduction

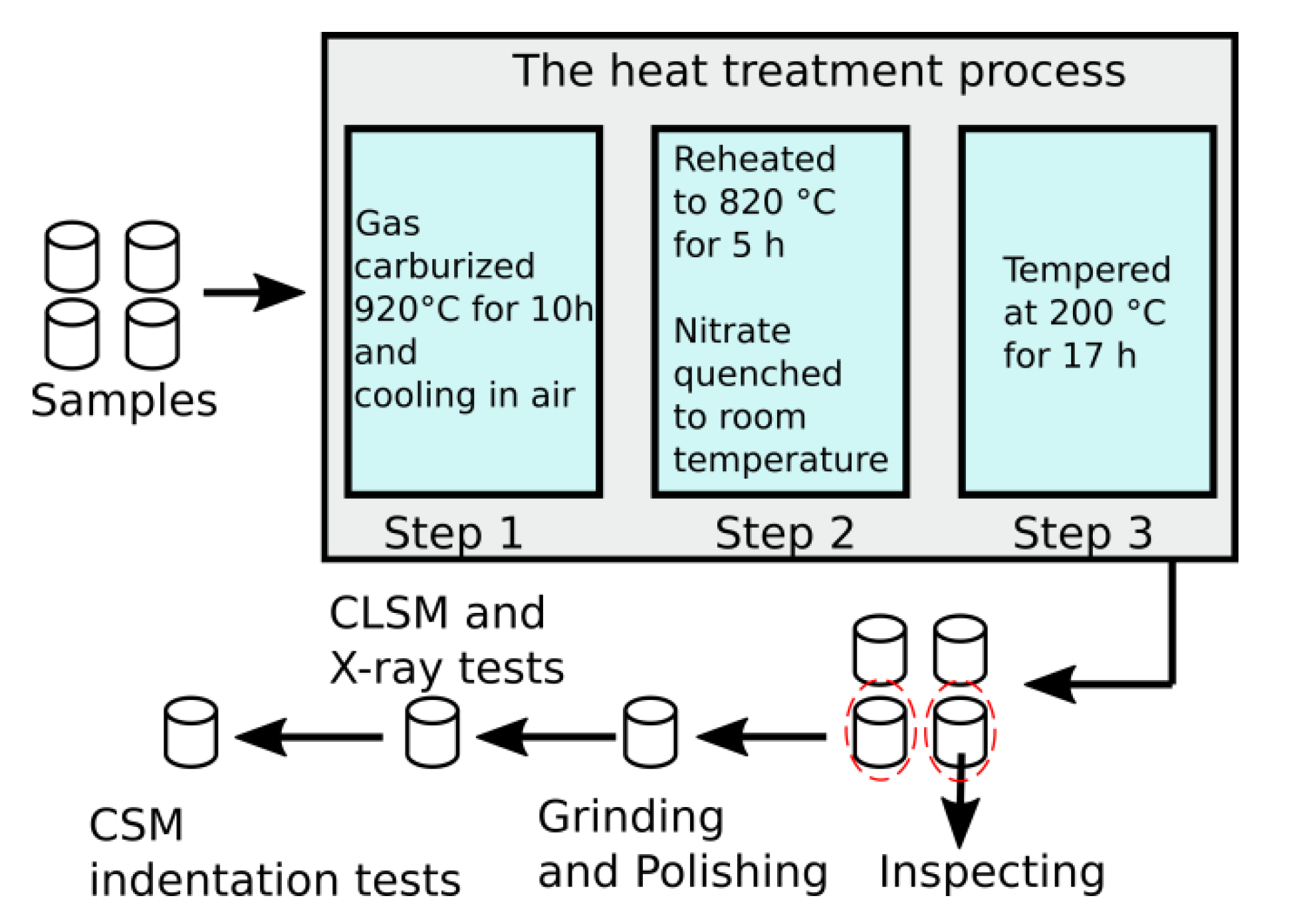

2. Materials and Methods

3. Results

3.1. The Load–Depth Curves

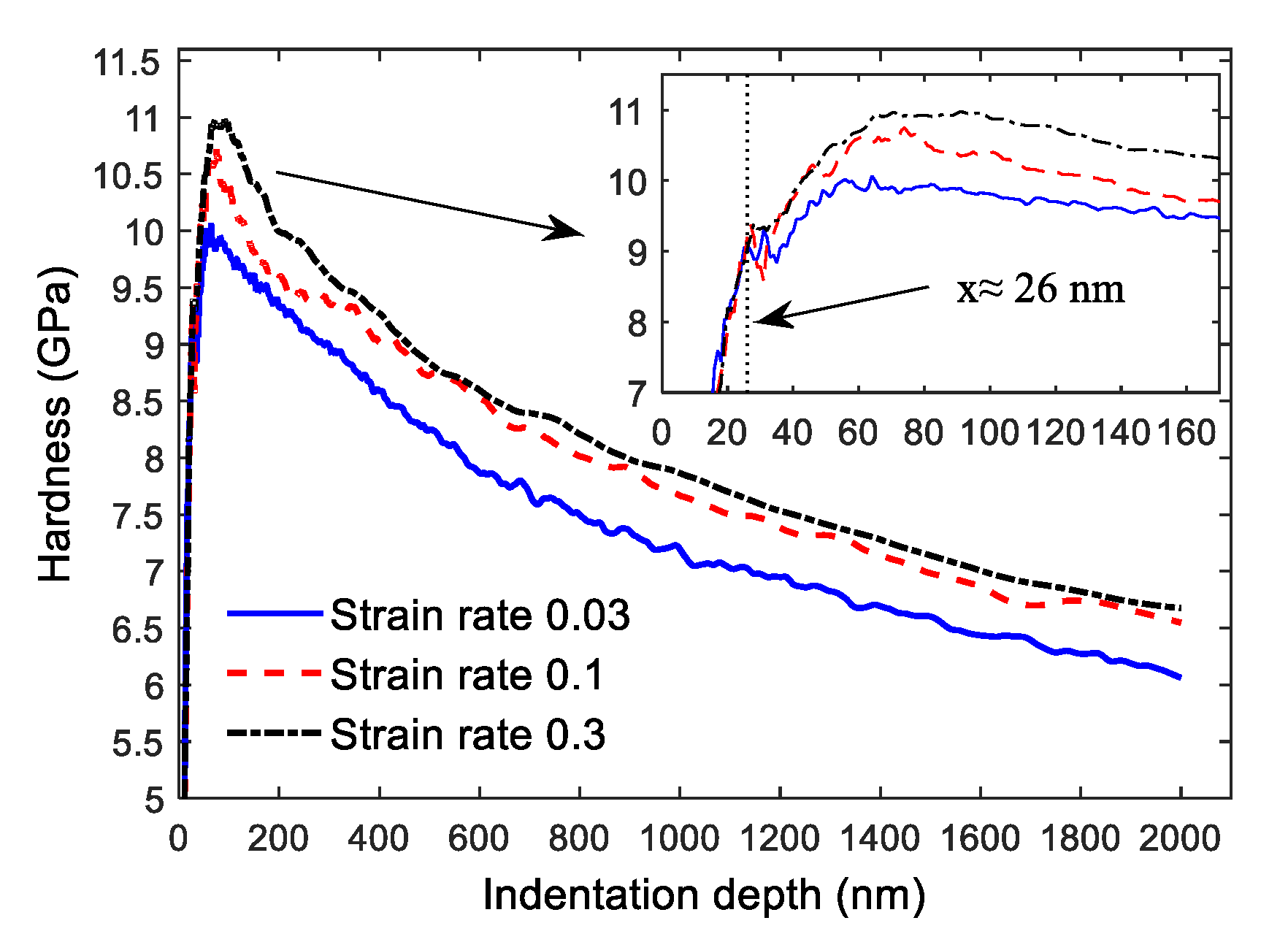

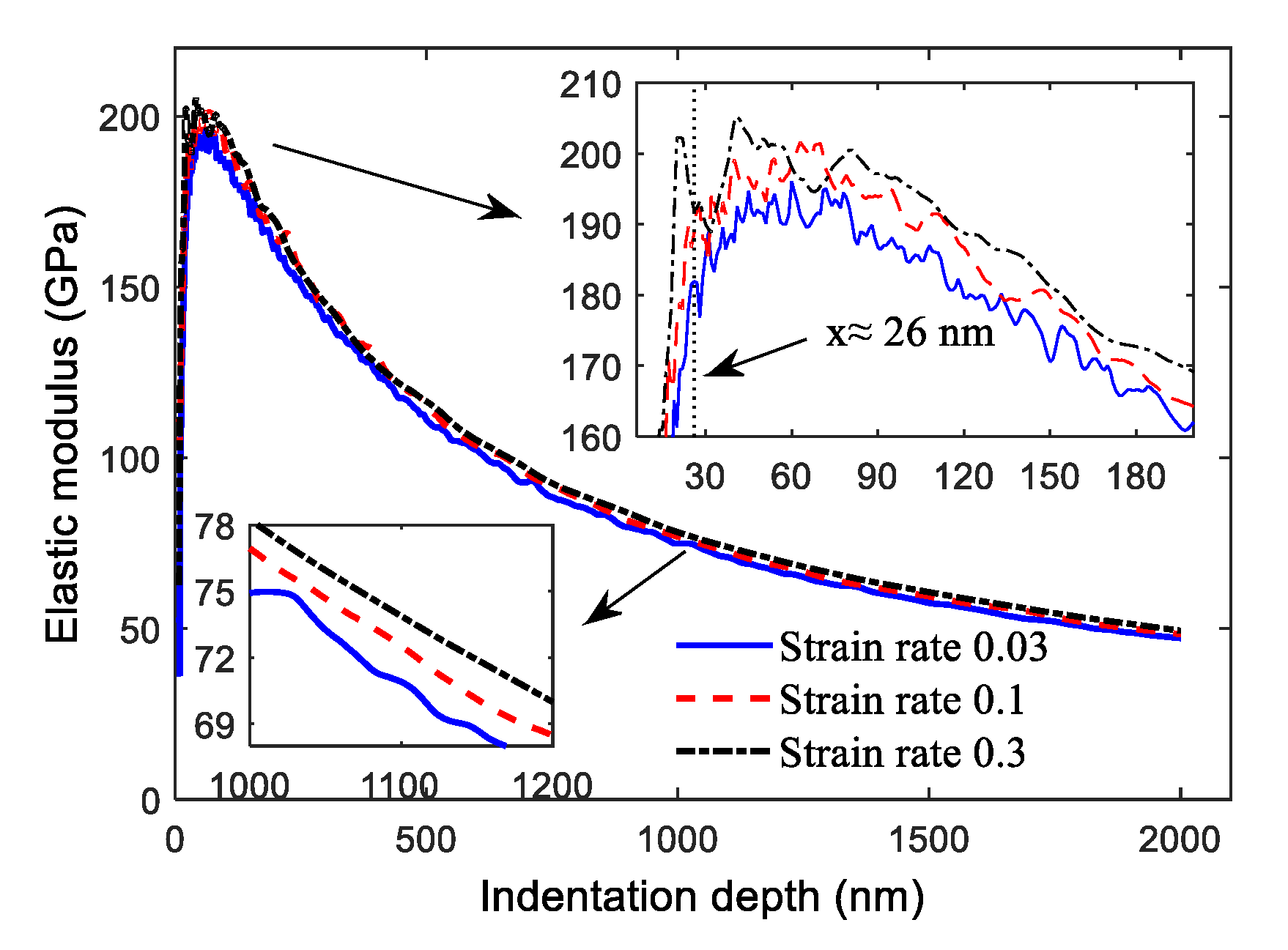

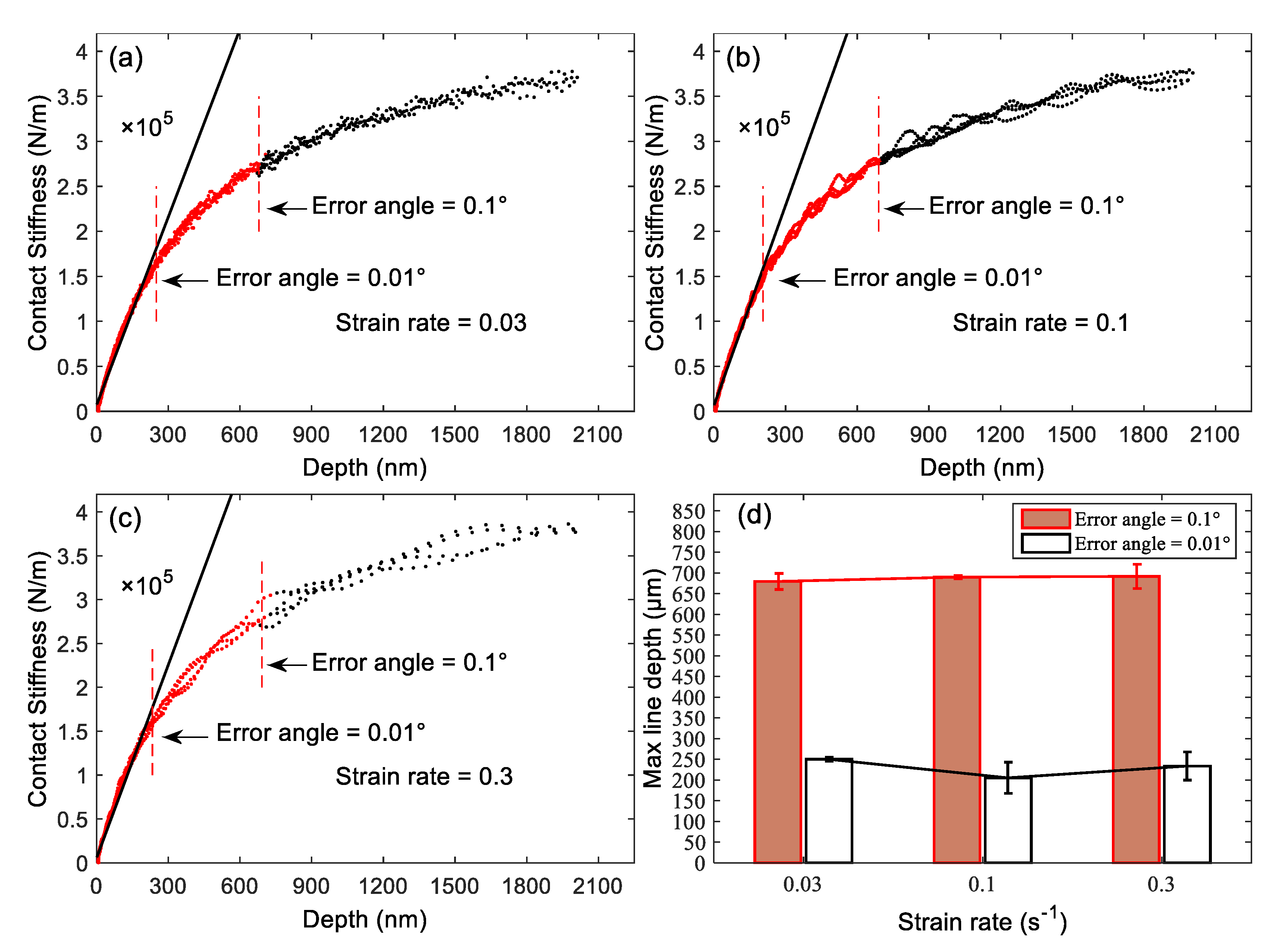

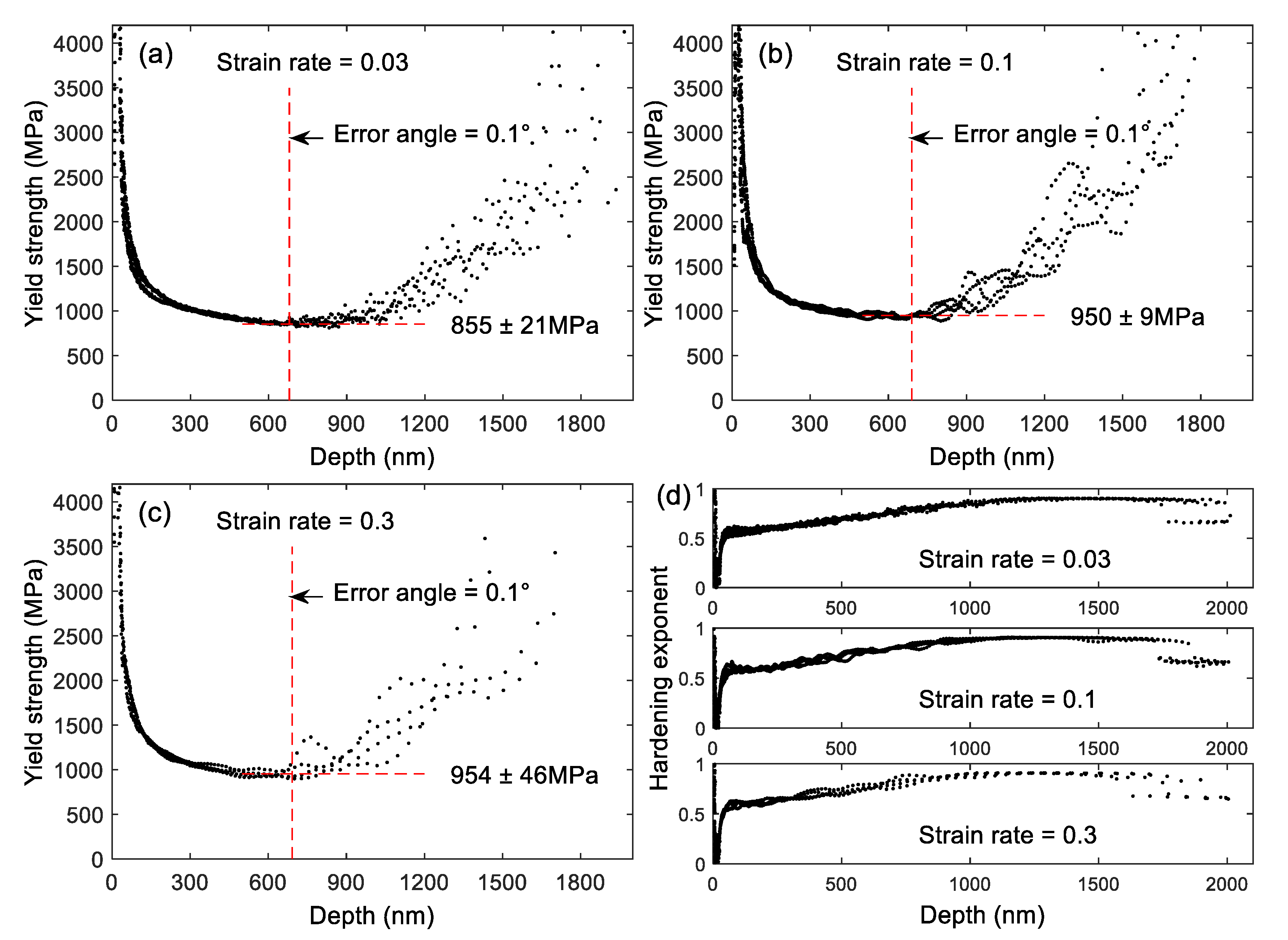

3.2. The Hardness and Elastic Modulus

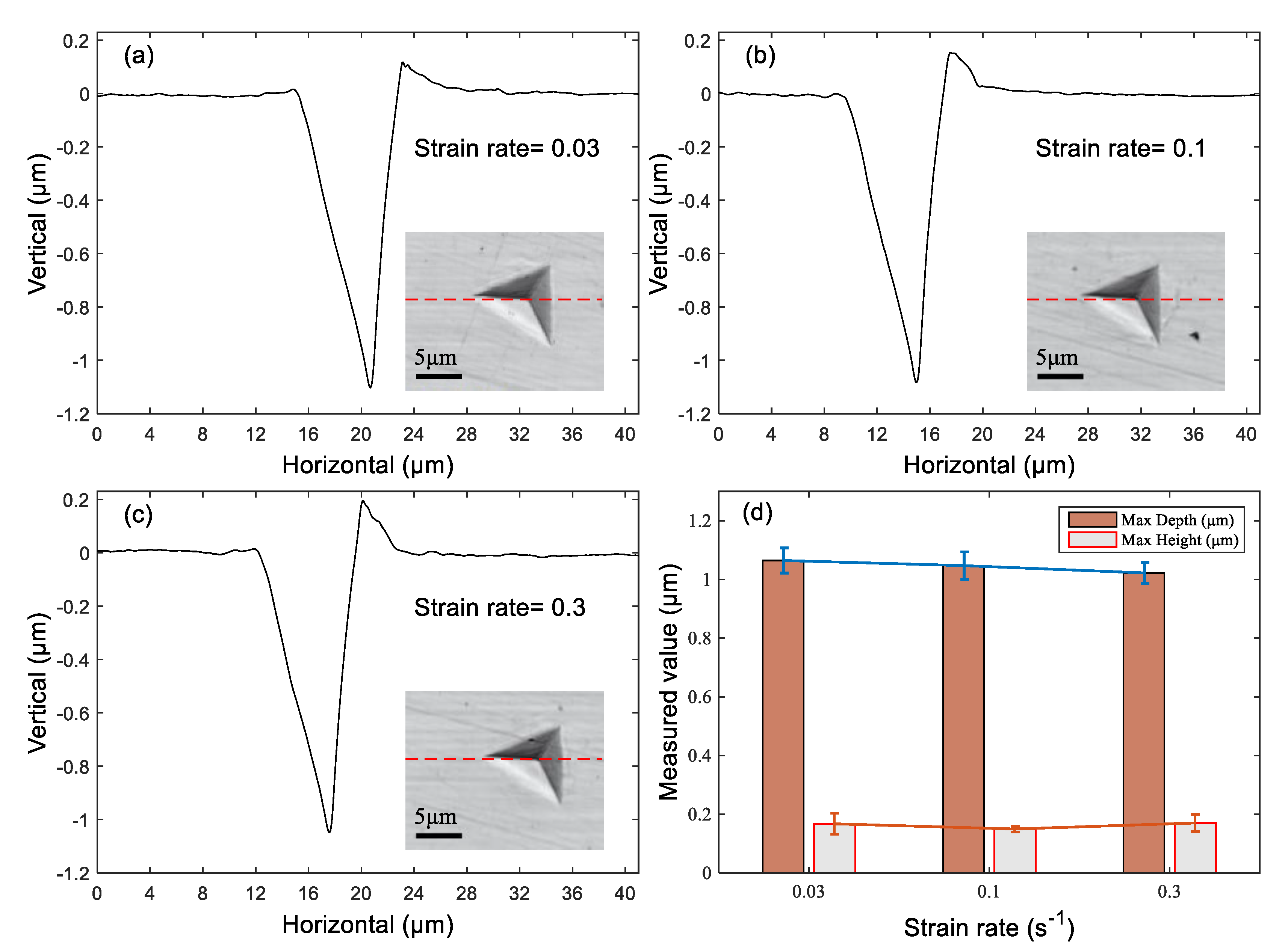

3.3. The Indentation Morphologies

4. Discussion

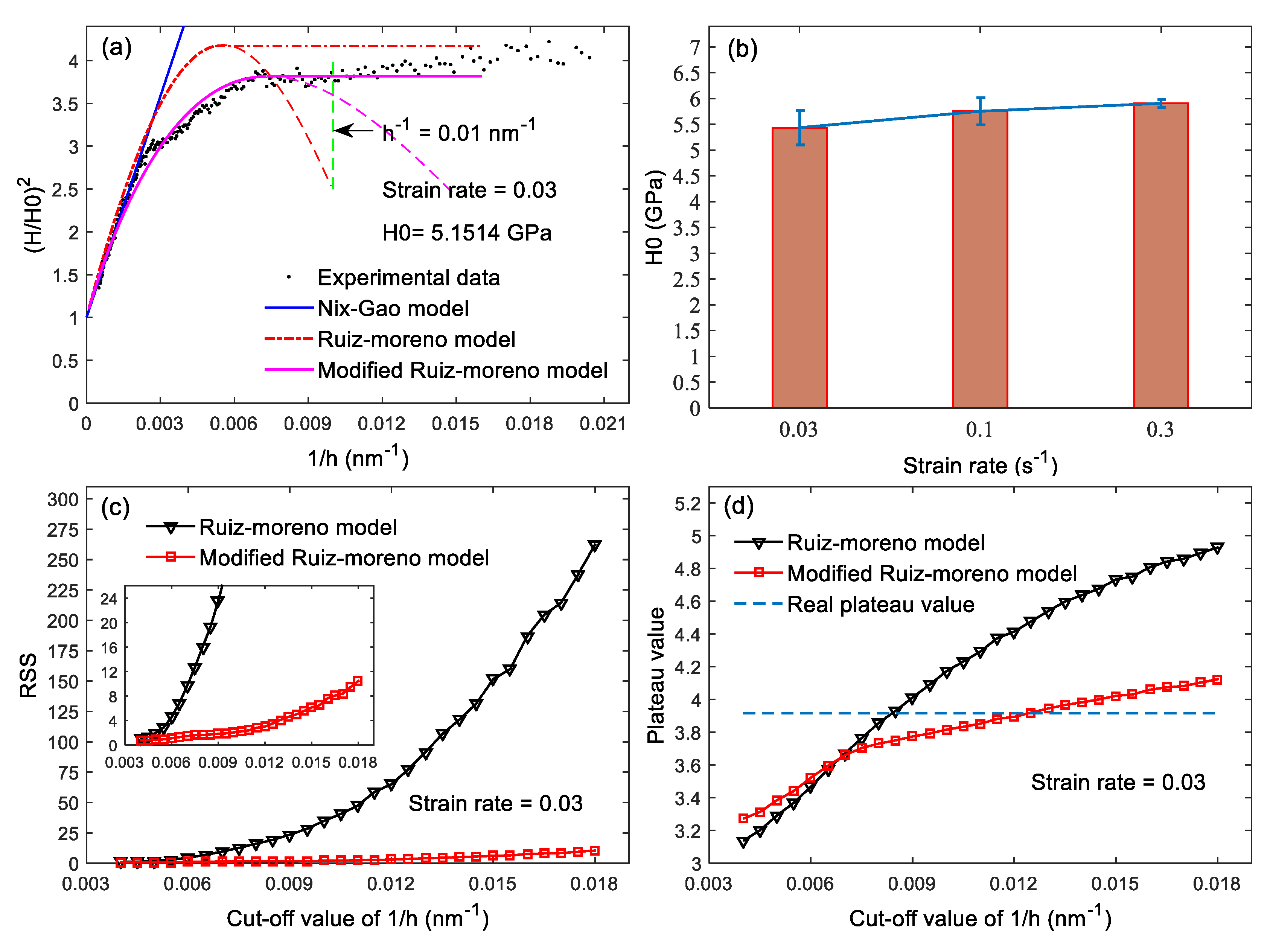

- (1)

- By changing the hardness that varies with depth into the form of with h−1 and extracting the straight line at the front section of the curve (h−1 is small), the fitting parameters k and b in can be obtained by fitting the data linearly. Thus, the following relation is obtained:

- (2)

- , compared with the Nix–Gao model (Equation (2)), we get, , . As H0 is the hardness value when , that means the depth is close to infinity, the ISE should no longer exist; and is equivalent to , so almost all ISE models satisfy , so the straight line always appears in region of smaller h-1. Therefore, the H0 and h* obtained by using the Nix–Gao model for straight-line segment are reliable.

- (3)

- The variation of the H2 with h−1 is transformed into the form of with h−1, and then the cut-off parameter r can be obtained by fitting with the Ruiz-Moreno model, Equation (3).

- (4)

- The two parameters, ρGND,max,0 and ψ of r(h) can be obtained via fitting with the modified Ruiz-Moreno model (Equation (4)).

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Nomenclature

| hardness measured by the CSM method | |

| true hardness calculated by the ISE models | |

| stiffness of the sample | |

| frame stiffness of the nanoindenter | |

| angular frequency | |

| phase angle of displacement lag load | |

| mass of moving parts in a nanoindenter | |

| amplitude of the excitation load | |

| displacement amplitude during the CSM tests | |

| stiffness of blade spring in the nanoindenter | |

| frequency during the CSM tests | |

| strain rate during the indentation process | |

| indentation rate during the indentation process | |

| indentation depth during the indentation process | |

| contact depth during the indentation process | |

| yield strength | |

| cut-off of the GND density | |

| hardening exponent | |

| elastic modulus | |

| cut-off parameter in the Ruiz-Moreno model | |

| cut-off parameter as a function of indentation depth in the modified Ruiz-Moreno model | |

| statistically stored dislocation density | |

| contact radius | |

| remaining distance that causes the singular behavior in the Ruiz-Moreno model | |

| characteristic length | |

| dimensionless inverse indentation depth | |

| first and second dimensionless function of the Ma model, respectively | |

| h0.1°, h0.01° | corresponding depth of the Hough transform error angles 0.1° and 0.01°, respectively |

References

- Carroll, J.; Koukoura, S.; McDonald, A.; Weiss, S.; McArthur, S. Wind turbine gearbox failure and remaining useful life prediction using machine learning techniques. Wind Energy 2019, 22, 360–375. [Google Scholar] [CrossRef]

- Bhardwaj, U.; Teixeira, A.P.; Soares, C.G. Reliability prediction of an offshore wind turbine gearbox. Renew. Energy 2019, 141, 693–706. [Google Scholar] [CrossRef]

- He, H.F.; Liu, H.J.; Zhu, C.C.; Tang, J.Y. Study on the gear fatigue behavior considering the effect of residual stress based on the continuum damage approach. Eng. Fail. Anal. 2019, 104, 531–544. [Google Scholar] [CrossRef]

- Oliver, W.C.; Pharr, G.M. An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments. J. Mater. Res. 1992, 7, 1564–1583. [Google Scholar] [CrossRef]

- Oliver, W.C.; Pharr, G.M. Measurement of hardness and elastic modulus by instrumented indentation: Advances in understanding and refinements to methodology. J. Mater. Res. 2004, 19, 3–20. [Google Scholar] [CrossRef]

- Pharr, G.M.; Strader, J.H.; Oliver, W.C. Critical issues in making small-depth mechanical property measurements by nanoindentation with continuous stiffness measurement. J. Mater. Res. 2009, 24, 653–666. [Google Scholar] [CrossRef]

- Rodríguez, R.; Gutierrez, I. Correlation between nanoindentation and tensile properties influence of the indentation size effect. Mater. Sci. Eng. A 2003, 361, 377–384. [Google Scholar] [CrossRef]

- Zhang, Y.F.; Zheng, J.; Yu, J.X.; He, H.T. Impact of strain rate on the hardness and elastic modulus of human tooth enamel. J. Mech. Behav. Biomed. Mater. 2018, 78, 491–495. [Google Scholar] [CrossRef]

- Nix, W.D.; Gao, H. Indentation size effects in crystalline materials: A law for strain gradient plasticity. J. Mech. Phys. Solids 1998, 46, 411–425. [Google Scholar] [CrossRef]

- Durst, K.; Backes, B.; Franke, O.; Göken, M. Indentation size effect in metallic materials: Modeling strength from pop-in to macroscopic hardness using geometrically necessary dislocations. Acta Mater. 2006, 54, 2547–2555. [Google Scholar] [CrossRef]

- Ruiz-Moreno, A.; Hähner, P. Indentation size effects of ferritic/martensitic steels: A comparative experimental and modelling study. Mater. Des. 2018, 145, 168–180. [Google Scholar] [CrossRef]

- Campbell, J.E.; Kalfhaus, T.; Vassen, R.; Thompson, R.P.; Dean, J.; Clyne, T.W. Mechanical properties of sprayed overlayers on superalloy substrates, obtained via indentation testing. Acta Mater. 2018, 154, 237–245. [Google Scholar] [CrossRef]

- Ma, Z.S.; Zhou, Y.C.; Long, S.G.; Lu, C.S. An inverse approach for extracting elastic-plastic properties of thin films from small scale sharp indentation. J. Mater. Sci. Technol. 2012, 28, 626–635. [Google Scholar] [CrossRef]

- Jamil, M.; Khan, A.M.; Hegab, H.; Sarfraz, S.; Sharma, N.; Mia, M.; Gupta, M.K.; Zhao, G.L.; Moustabchir, H.; Pruncu, C.I. Internal cracks and non-metallic inclusions as root causes of casting failure in sugar mill roller shafts. Materials 2019, 12, 2474. [Google Scholar] [CrossRef] [PubMed]

- Nguyen, N.V.; Kim, J.J.; Kim, S.E. Methodology to extract constitutive equation at a strain rate level from indentation curves. Int. J. Mech. Sci. 2019, 152, 363–377. [Google Scholar] [CrossRef]

- Jia, Y.F.; Cui, Y.Y.; Xuan, F.Z.; Yang, F. Comparison between single loading-unloading indentation and continuous stiffness indentation. RSC. Adv. 2017, 7, 35655–35665. [Google Scholar] [CrossRef]

- Bucaille, J.L.; Stauss, S.; Felder, E.; Michler, J. Determination of plastic properties of metals by instrumented indentation using different sharp indenters. Acta Mater. 2003, 51, 1663–1678. [Google Scholar] [CrossRef]

- Li, X.D.; Bhushan, B. A review of nanoindentation continuous stiffness measurement technique and its applications. Mater. Charact. 2002, 48, 11–36. [Google Scholar] [CrossRef]

- Wang, W.; Liu, H.J.; Zhu, C.C.; Wei, P.T.; Tang, J.Y. Effects of microstructure on rolling contact fatigue of a wind turbine gear based on crystal plasticity modeling. Int. J. Fatigue 2019, 120, 73–86. [Google Scholar] [CrossRef]

- Liu, H.J.; Wang, W.; Zhu, C.C.; Jiang, C.X.; Wu, W.; Parker, R.G. A microstructure sensitive contact fatigue model of a carburized gear. Wear 2019, 436, 203035. [Google Scholar] [CrossRef]

- Busby, J.T.; Hash, M.C.; Was, G.S. The relationship between hardness and yield stress in irradiated austenitic and ferritic steels. J. Nucl. Mater. 2005, 336, 267–278. [Google Scholar] [CrossRef]

- Tiryakioğlu, M. On the relationship between Vickers hardness and yield stress in Al-Zn-Mg-Cu Alloys. Mater. Sci. Eng. A 2015, 633, 17–19. [Google Scholar] [CrossRef]

| Element | C | Si | Mn | P | S | Cr | Ni | Mo | Al | Cu | Fe |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Chemical compositions | 0.188 | 0.204 | 0.510 | 0.007 | 0.002 | 1.658 | 1.675 | 0.299 | 0.014 | 0.149 | Bal. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, G.; Guo, J.; Zhao, J.; Tang, Q.; Hu, Z. Nanoindentation Properties of 18CrNiMo7-6 Steel after Carburizing and Quenching Determined by Continuous Stiffness Measurement Method. Metals 2020, 10, 125. https://doi.org/10.3390/met10010125

Zhou G, Guo J, Zhao J, Tang Q, Hu Z. Nanoindentation Properties of 18CrNiMo7-6 Steel after Carburizing and Quenching Determined by Continuous Stiffness Measurement Method. Metals. 2020; 10(1):125. https://doi.org/10.3390/met10010125

Chicago/Turabian StyleZhou, Guiyuan, Jian Guo, Junyu Zhao, Qian Tang, and Zhaonan Hu. 2020. "Nanoindentation Properties of 18CrNiMo7-6 Steel after Carburizing and Quenching Determined by Continuous Stiffness Measurement Method" Metals 10, no. 1: 125. https://doi.org/10.3390/met10010125

APA StyleZhou, G., Guo, J., Zhao, J., Tang, Q., & Hu, Z. (2020). Nanoindentation Properties of 18CrNiMo7-6 Steel after Carburizing and Quenching Determined by Continuous Stiffness Measurement Method. Metals, 10(1), 125. https://doi.org/10.3390/met10010125