Abstract

In this study, tribological properties of custom formulated and stabilized nano lubricant are investigated. Spherical CuO nanoparticles are suspended in 20W-50 mineral base lubricant using Oleic Acid (OA) as a surfactant. Three different nano lubricant concentrations with 0.2, 0.5, and 1 wt.% were analyzed through ASTM G-99 pin-on-disc tribometer standardized test under boundary/mixed lubrication regimes. The generated friction and wear analyses confirm a consolidation of tribological properties with a reduction in friction coefficient in the range of 14.59–42.92%, compared with the base lubricant. Analysis of worn surfaces (SEM/EDX) as well as (AFM) was conducted. Combined hypotheses were proposed from the analysis of worn surfaces; these hypotheses suggested that CuO nanoparticles exhibit an integrated effect of two phenomenal lubrication mechanisms. Additionally, dispersion stability evaluation of the suspended nanoparticles was performed through Zeta potential, (FTIR), and sedimentation analyses. Stability results showed that steric stabilization is the dominating effect of the repulsive forces between nanoparticles, surpassing the electrostatic repulsive forces.

1. Introduction

In different lubricated frameworks, mechanical friction through internal constituent accounts for a significant portion of power losses. Controlling tribological performance for these lubricants has a major role in limiting those losses. This development can be achieved by diminishing the boundary friction coefficient, which is considered a crucial factor for efficiency improvement [1]. Moreover, the Growing of global fuel energy consumption with the necessity of a green environment to be in existence is the present decade challenge. Studies conducted by the USA Department of Energy [1,2] concluded that 22% of global energy consumption savings could be achieved by reducing frictional losses emerging from many areas, such as power generation, transportation, and industrial sectors. Researchers have discovered that ordinary lubricants nowadays and various surface enhancements may not afford enough protection to meet durability, functioning, and oil utilization [3,4]. Over the last few years, attention to the employment of nanoparticles as an environmentally friendly lubricant additive had steadily expanded. This is due to the apparent moderation in wear properties of nano lubricants [5]. There are many reasons for the motivation of using nanoparticles as a lubricant additive. An essential advantage is the teeny sizes of nanoparticles that empower them to enter the contact area’s micro crevices. This gives rise to a positive lubrication mechanism.

Tribo-chemical film formation is often encountered, and even nanoscale ball bearing mechanisms have been proposed in many recent studies as well [6,7]. Spikes [8] has pointed out numerous benefits during his study of nanoparticles as lubricant additives. The study revealed many benefits, such as low interaction with other lubricant additives, high probability of protective film formation on contact surfaces, high durability compared with traditional lubricant additives, high ability to withstand extreme operating temperature, and good solubility in non-polar lubricants. The influence and performance of nano additives depend on many factors, such aas their concentration, their size, morphology, and their compatibility with base lubricants [9].

A recent study was conducted with CuO and ZnO with a concentration of 0.5 wt.% compared with the commonly used anti-wear additive ZDDP [10]. Both of the nanoparticles showed a considerable tribological enhancement regarding friction reduction and anti-wear behavior.

Robert Jackson [11] studied the effect of adding CuO nanoparticles to a base lubricant. Results showed a reduction in friction coefficient by 14 and 23% for two different nanoparticle concentrations of 1.0 and 2.0 wt.%, respectively. Manu Varghese [12] studied the enhancement of CuO’s tribological properties with coconut oil, a concentration of 0.34 wt.% led to a reduction of 8% in the coefficient of friction. Oleic Acid (OA) had been used in many studies as a surfactant for nano lubricants. This leads to enhancing the dispersion stability of the colloidal nanoparticles. Oleic Acid is believed to have a weak effect on changing the chemistry of both base lubricants and fully formulated ones when using the effective concentration [13,14,15,16,17,18,19].

ZnO and MoS2 nanoparticles were assessed as additives on diesel lubricants; this was conducted under different concentrations of 0.1, 0.4, and 0.7 wt.% using a pin on disc tribo-tester [20]. The overall results revealed that MoS2 could lessen the mass loss and coefficient of friction of moving pairs up to 93% and 12.29%, respectively when using 0.7 wt.%. As for ZnO, it was suitable for enhancing the thermophysical properties of the lubricant. The flashpoint of nano lubricant expanded by 5.88% and 5.04% for ZnO and MoS2, respectively, when applying 0.7 wt.%. The pour point of the lubricant decreased for both nanoparticles under a concentration of 0.4 wt.%. The viscosity index increased by 7.88% and 7.04% for ZnO and MoS2, respectively, with a concentration of 0.7 wt.%. At all tested temperatures, ZnO nano lubricant showed a higher viscosity value than MoS2. The highest viscosity increase was at 100 °C by 9.58% and 10.14% for MoS2 and ZnO, respectively, for 0.7 wt.% in nanoparticle content.

Hybrid nano-diamond/nano-graphite was tested at a concentration of 1% v/v [21]. The test was carried out under no external loading. The average fuel consumption was reduced by 21% when compared to the base lubricant, and the viscosity index was reduced by 6%.

Copper and hybrid copper/graphene nanoparticles were evaluated as automobile engine nano lubricants with different concentrations (0.03, 0.4, 0.6 wt.%) using ring and liner tribo-tester [22]. Oleic Acid was used as a surfactant with 2 wt.% from the base oil weight. Results showed that hybrid Cu/Gr nano lubricants have a promising function for increasing the lifespan of frictional components and fuel economy in engines. The friction coefficient decreased by 17.3–23.6% and 26.5–32.6% for the Cu and Cu/Gr nano lubricants, respectively. Simultaneously, the wear rate decreased by 13–20% and 25–30% for Cu and Cu/Gr nano lubricants, respectively. The morphology results of AFM and SEM/EDX recognized the formation of the tribo-film on the frictional surfaces. The evaluated surfaces presented smooth worn areas that promoted a low surface roughness, which can increase the lifespan of the internal components in engines, especially the ring and liner. This improvement can reduce gas leakage from the combustion chamber area, leading to more convenient pressure inside the cylinder, thus enhancing the fuel consumption and reducing exhaust emissions.

Hybrid Al2O3/TiO2 nanoparticles were examined under different working conditions with an engine lubricant concentration of 0.1 wt.% [18]. Results showed a reduction in both friction coefficient and wear rate by 39–53% and 25–33%, respectively. The reinforcement in this nano lubricant’s tribological behavior had been justified due to the combined effect of the tribo-film formation and nano ball bearing.

In many studies, nanodiamond particles have been found to provide a significant reduction in friction and wear when used as a nonadditive for engine oils [23]. Nanodiamonds can significantly improve engine oil performance due to their ability for the polishing mechanism throughout the surface asperities and enhancing the strength of the formed tribo-films.

The nano lubricants of base elements as Fe, C, Gr, Cu, Co, and other base candidates showed a promising improvement in both tribological and thermal properties [24,25]. However, oxides, as CuO, ZnO, and GrO, manifest themselves to have a long-lasting stable time [26]. This is due to the plenty of hydroxyl or carboxyl groups on their surface, which help their interaction with surfactants to improve their dispersion stability in non-polar mediums [27]. In addition to their substantial dispersion stability, oxides have extraordinary tribological as well as thermal properties. CuO nano lubricant has been studied to enhance the durability of piston linear contact in engines [28]. The study showed an improvement in COF by 80%.

The fundamental concept of all mentioned nanomaterials in different lubricant studies aims to reduce the irreversible losses through friction and wear arising from many sorts of machines and instruments. This is to balance the incrementalism demands of efficient energy production and minimize its drawbacks on the environment [29]. To bridge this gap, designing machinery with low friction losses is the primary requirement for a potential reduction in energy loss of 40% over the upcoming 15 years [2].

Over the last decade, nano lubricants, as new technology, have been used as one of the most pivotal solutions to curtail systematic machinery losses [30]. Studies on nano lubricants based on nano CuO focused only on their tribological properties or thermal stability with paying no attention to dispersion stability. This would have a considerable effect on these nano’s final behavior.

The present study offers extensive experimental work toexplore the tribological properties of custom formulated and stabilized nano lubricant. This nano lubricant holds spherical CuO nanoparticles suspended in 20W-50 mineral-based lubricant. The CuO nano lubricant is tribologically tested using a test rig with a pin-on-disc system (ASTM G-99). This system offers a good compromise between actual and laboratory tests. Samples of pins were selected for surface analysis through Scanning Electron Microscopy/Energy-Dispersive X-ray spectroscopy (SEM/EDX), as well as Atomic Force Microscopy (AFM). Moreover, stabilization analyses were conducted for the nano lubricant through sedimentation, (FTIR), and Zeta analyses.

2. Experimental Setup and Procedure

2.1. Nanoparticles and Base Lubricant

A mineral lubricant of 20 W-50 was selected to be the base fluid. The main properties of nanoparticles (CuO) and base lubricants used in the experiments are listed in Table 1. Copper oxide nanoparticles were dispersed into the base lubricant at three different wt.% concentrations 0.2%, 0.5%, and 1%. These concentrations were selected based on the effective concentration in many studies [13,31,32].

Table 1.

Material properties of nanoparticles and base lubricant.

2.2. Preparation and Surface Modification of CuO Nano Lubricant

Nano lubricant was prepared using the two-step method [33,34], which is the most widely accepted approach for preparing nanofluids. Oleic Acid (OA) was added as a surfactant to nano lubricant to enhance nanoparticle stabilization by minimizing the aggregation and sedimentation [3,13,31,35]. OA’s active ratio ranges from 1 wt.% to 11 wt.% of nanoparticles [33]. The preparation steps of CuO nano lubricant were conducted, as follows (based on the two-step method):

- Oleic Acid was added by 8 wt.% (nanoparticles basis) to a 500-mL preparation beaker with 50 mL ethanol under the magnetic steering process to enhance the pervasion and spreading of oleic acid.

- While the solution is mixed under magnetic steering, a specific CuO nanopowder concentration is added to the Becker.

- The solution was then heated under magnetic stirring until all Ethanol was entirely volatile.

- The resulted solution is CuO nanoparticles capped by OA as a surfactant.

- The base lubricant was then added slowly to the resulted solution until a homogenous solution of nano lubricant was obtained.

- Finally, the solution was placed into an ultrasonic probe for 30 min. for further dispersion and nano lubricant homogenization.

Therefore, the formulation of nano lubricant compromised CuO wt.%, OA wt.%, and base lubricant wt.%, as shown in Table 2.

Table 2.

The formulation of CuO Nano lubricant.

2.3. Characterization of Nanoparticles and Dispersion Stability

Copper oxide nanoparticles were analyzed using X-ray Diffraction (XRD) to characterize the crystalline structure, which indicates the current phase and the purity of Copper Oxide. Transmission electron microscopy (TEM) was used to analyze the surface morphology of nanoparticles.

2.4. Dispersion Stability Analysis for Prepared CuO Nano Lubricants

In this study, two significant dispersion methods of sedimentation and zeta potential analyses were conducted to analyze CuO’s dispersion stability capped with OA. Oleic acid’s primary function is to form a barrier between colloidal particles within nanofluid by the meaning of steric and electrostatic stabilization. OA is an ionic surfactant that consists of two parts. Hydrophilic head of the carboxyl group (-COOH-) and a hydrophobic tail of hydrocarbon group [15,36]. The hydrophilic head is adsorbed to the hydrophilic CuO nanoparticles. This is because CuO has been proved to have a high affinity to carboxyl groups [37], whereas the hydrophobic tail is extended to the solution of hydrocarbon lubricant. The result is a continuous endeavor, in which OA’s hydrophilic head is trying to bind with CuO. The hydrocarbon tail group binds with the mineral lubricant forming micelles of CuO capped by OA [38,39]. Eventually, these micelles would provide a barrier against aggregation. The sedimentation test is conducted by taking many photography shoots during a specified period. The Zeta analysis is conducted through the Malvern Zetasizer nano series Z-S. The equipment could measure both the size of CuO nanoparticles suspended in the lubricant as well as the zeta potential.

The general criteria of Zeta potential value that determine the system’s stability are approaching +25 mV or −25 mV [34,40]. This is to say that this suspension system is considered to be stable. Moreover, OA-treated CuO nanoparticles were analyzed using Fourier transform infrared spectrometry (FTIR-BRUKER-A225/Q, Multiple Crystals CRY). This is to present the functional group in OA/CuO treatment and to justify the results of XRD for the purity of CuO nanopowder.

2.5. Setup of Tribological Testing

Tribological properties of CuO nano lubricant were conducted through the Computer Control Vertical Universal Friction and Wear Testing Machine Model MMW-1A. An ASTM standard Pin-on-disc test (ASTM G-99) was conducted. This test simulates most of the critical machinery and the tribological behavior of engine components as pins, shafts, piston skirts, piston rings, valve train, and cylinder liners under mixed/boundary lubrication regimes [41,42,43]. The test is done under an average working temperature at 60 degrees Celsius. This test simulates the wear process under different loads and sliding speeds with friction coefficient versus sliding distance as output data. A total of six runs were performed for each of nano lubricant concentrations under different levels of testing parameters of the load and sliding speed according to the literature [44]. The accuracy of test variation and repeatability of data were considered by varying loads, speeds, and concentrations of nanoparticles, as well as calibrating the load cell before starting all of the tests. The same technique was considered in many studies, as in [45]. The nominal chemical composition of disc and pin alloys, as well as testing configuration, are outlined in Table 3 and Table 4, respectively. The coefficient of friction was recorded by pin-on-disc test rig instantaneously. Mean values have been calculated for all runs under different testing configurations of load and sliding speed. Moreover, the average mass loss and specific wear rate for pins were calculated for all runs using the following formula:

where K is the specific wear rate (sometimes called the wear coefficient [46]), V is the worn volume of the pin , is the normal load (N), and d is the sliding distance (m). The worn volume of the pin is calculated from mass loss and density (ρ = ∆w/V). Specific wear rate is considered an accurate indication of the wear properties of lubricants under extreme sliding conditions [18]. For rheological behavior as viscosity, adding CuO with OA has a weak effect, as mentioned in [11].

Table 3.

Materials of Tribo-pair.

Table 4.

Testing configuration for each concentration of Nano lubricant.

2.6. Analyses of Surface Topography and Surface Morphology

To reveal the character of worn surfaces, selected samples of the pin on disc tests were examined under different microscopic examinations. Scanning electron microscopy/Energy-dispersive X-ray spectroscopy (SEM/EDX), and Atomic force microscopy (AFM) were conducted to analyze the surface damage features, as well as the surface enhancement that was adopted by nano lubricant. SEM analysis has been used mainly to reveal the severity of wear mode inherited by tested friction pairs, whereas EDX was used to provide elemental identification of the tested surfaces. This is to investigate tribo-sintering and mending lubrication mechanisms. AFM is used to provide three-dimensional topographic features of the tested surfaces to examine out polishing lubrication mechanism assorted by nanoparticles (Topographical analysis) [11].

3. Results and Discussion

3.1. Structure of Nanoparticles

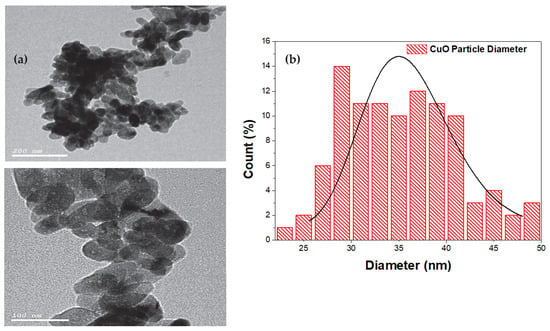

The particles of TEM analysis appear elongated and not spherical because of the nature of the agglomeration of the powder nanoparticles, Figure 1a. The Copper oxide nanoparticles are dark brown with a surface morphology nearly spherical with an average size of 35 ± 5 nm, Figure 1b.

Figure 1.

(a) (TEM) micrographs of CuO nanoparticles, (b) Size distribution of CuO nanoparticles.

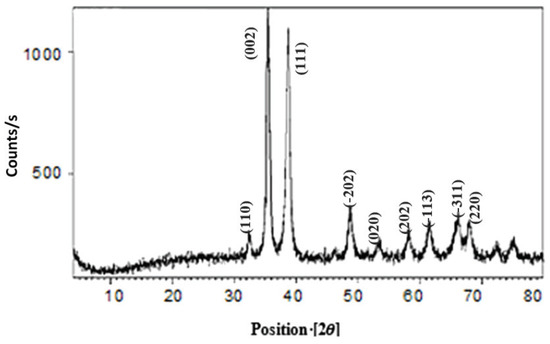

Figure 2 shows the XRD pattern of the Copper oxide nanoparticles. In this pattern, most of the diffraction peaks are indexed to the cupric oxide (CuO). This indicates that nanoparticles are CuO only without any additives. Mainly, Copper Oxide could be found in two phases as (Cuprous Oxide) and CuO (Cupric oxide), depending on the valence state of the copper [47]. The peak resulted from the XRD pattern has an angulation 2θ ranges from 35.7 to 38.5, represented by (002) and (111) crystallographic planes, respectively. This is the same as reported in the literature for CuO (Cupric oxide) nanoparticles with no existence of any impurities or other peaks corresponding to or phases [32,48,49,50]. The peaks of 32.6, 49, 53.6, 61.7, 66.2, and 68.4 are represented by crystallographic planes of (110), (−202), (020), (−113), (−311), (220) respectively. These results are consistent with the standardized copper oxide nanopowder peaks, as mentioned in [51]. These resulted diffraction sharp peaks indicate a pure monoclinic CuO copper oxide nanopowder.

Figure 2.

Analysis of (XRD) pattern for copper oxide nanoparticles.

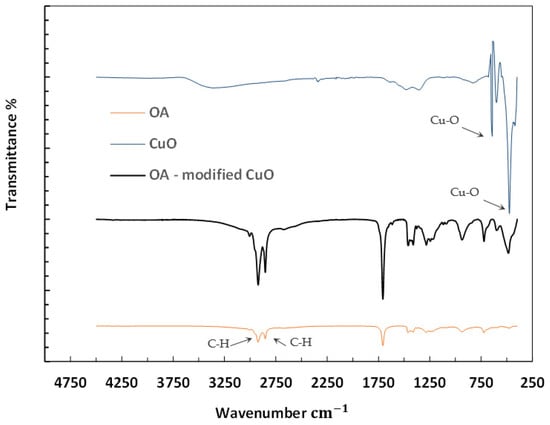

Figure 3 shows FTIR spectra results for CuO nanopowder, Oleic acid, and oleic acid-modified CuO nanoparticles. For CuO nanoparticles, the resulted spectra display an absorbed band of approximately 406 and 640 , which show the characteristic monoclinic band of pure copper oxide, as mentioned in an earlier study [50]. For OA, the C–H stretching vibration peaks of both -- and -- are showed approximately at 2927 and 2852 , respectively, as mentioned by Zhang [15]. Moreover, the characteristic peak of the carboxylate groups of the OA head appears at approximately 1710 [15]. Interestingly, this characteristic peak is not shown at the spectra of OA-modified CuO nanoparticles. This is because of the OA and CuO nanoparticles chemical reaction to attain OA’s grafted layer on to CuO’s surface. This is to afford OA modified CuO nanoparticles that can be stable in non-polar systems.

Figure 3.

Analysis of (FTIR) spectra for functionalized OA-CuO nanoparticles.

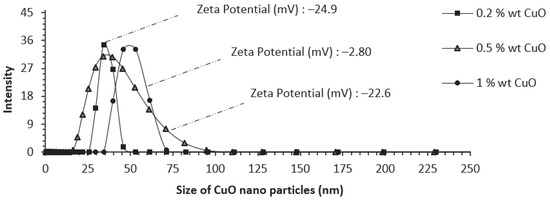

3.2. Dispersion Stability

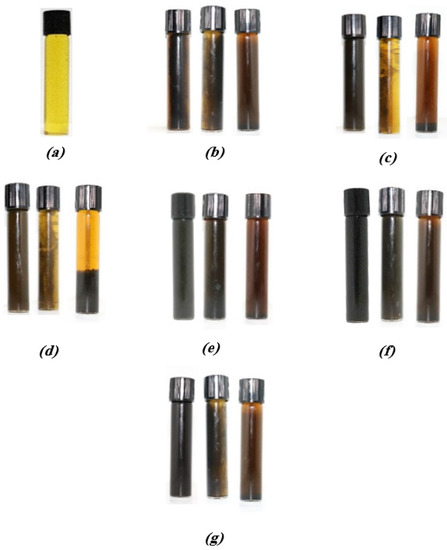

Stabilization analysis of CuO nanoparticles dispersed with OA was conducted through two methods, Zeta and sedimentation analyses. Figure 4 and Figure 5 show the zeta and sedimentation analyses correspondingly for the three different nano lubricant concentrations used over the current study. The zeta analysis shows weak repulsive forces between particles handled through the electrostatic stabilization for all concentrations. This is because the minimum acceptable Zeta potential value is recommended by literature to be 25 mV (negative or positive). However, the most effective value is shown to be for 0.2% and 0.5 wt.% CuO with −24.9 and −22.6 mV, respectively. Whereas, for 1 wt.% CuO, a low value of −2.8 mV, is recognized. This could be explained through the size of dispersed CuO nanoparticles with the base lubricant (Figure 4). The peaks of size for dispersed 0.2 and 0.5 wt.% CuO are shown to be within the size range of the CuO nanoparticles as obtained (35 ± 5) with 34.2 and 39.4 nm, respectively. Whereas, for 1 wt.% CuO, an extraordinary size of 53.1 nm is recognized. This could clarify the hypothesis triggered through this study by the surface analysis for the weak tribological performance of 1 wt.% CuO, which accounted for nanoparticles’ agglomeration at this concertation. Zeta’s results recommend that the dominant repulsive forces between CuO nanoparticles are a steric repulsion instead of electrostatic repulsion.

Figure 4.

Zeta sizer and Zeta potential analyses for different concentrations of CuO Nano lubricant dispersed with oleic acid.

Figure 5.

Photographs of sedimentation analysis of CuO nano lubricant. (a) Base lubricant, (b) 0.2 wt.% CuO, (c) 0.5 wt.% CuO, (d) 1 wt.% CuO, (e) 0.2 wt.% CuO + OA, (f) 0.5 wt.% CuO + OA, and (g) 1 wt.% CuO + OA.

The steric stabilization could be slightly discerned through the sedimentation analysis (Figure 5). Sedimentation analysis was carried out through two months of test duration. Three photographs were taken, respectively, for each case. One after the first day, and second and third photographs after the first and second months. The test was conducted with transparent vials to observe any sedimentation that shall happen during the test duration. OA’s addition as a surfactant had increased the turbidity of CuO nanoparticles through the base lubricant, as shown in Figure 5, compared to the bare CuO nano lubricant without OA as shown in Figure 5b–d.

The zeta potential in non-polar mediums is known to be weak (in the range of 20 mV or lower) compared to the steric potential. The steric potential is considered the dominant repulsive force due to OA’s grafted layer. This is considered a critical point that had been rarely discussed in most studies related to nano additives in non-polar mediums. Most of the published studies just concentrated their works on nano lubricant tribological effects without mentioning the colloidal system’s stability factor. This stabilization of nano lubricant ensures that the dispersed nanoparticles will effectively enhance the tribological properties of base lubricant during the flow of fluid in the long term.

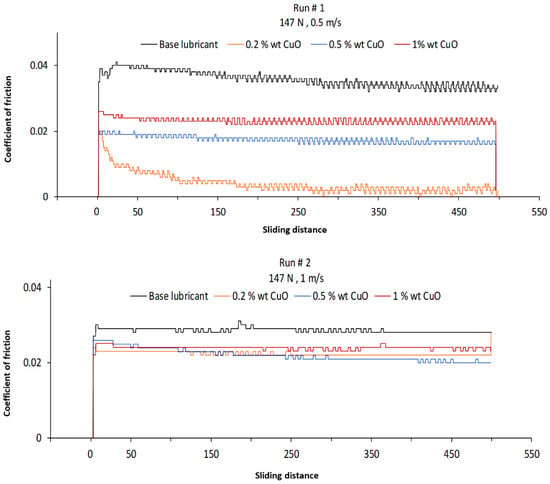

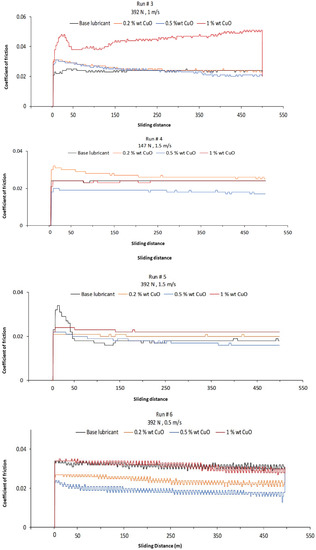

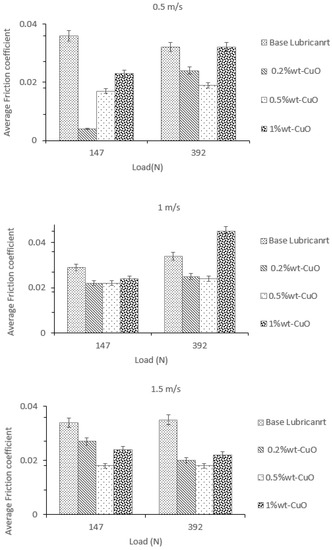

3.3. Friction Studies

Figure 6 and Figure 7 show the coefficient of friction (COF) as well as the average COF under different working conditions of the contact loads (147 N, 392 N) and sliding speeds (0.5, 1, 1.5 m/s). From the first glance of friction results, the highest COF value would be observed at the onset of each test. This comes back to the static friction (static COF) that must be overcome at the beginning of the sliding motion between any two surfaces. Other fluctuations in COF along the rest of the sliding distance are according to the dynamic COF, which accounted for the energy required to shear the adhered peaks of surface asperities during the relative motion of surfaces. All CuO nano lubricant concentrations show a considerable COF reduction under most testing conditions concerning the base lubricant. At run # 1, with a contact load of 147 N and a sliding speed of 0.5 m/s (206 rpm), there is a clear trend of reduction in COF for all CuO concentrations concerning the reference lubricant. However, some CuO concentrations failed to enhance the lubrication process and, on the contrary, increase the COF as in runs 3, 4, and 5 for 0.2 and 1 wt.% CuO. It can be figured out that raising load and sliding speed simultaneously increases the COF for the base lubricant. This verifies that the test is undergoing boundary and mixed lubrication regimes. This is considered a regular phenomenon at these lubrication regimes where the high normal load would squeeze the lubricant. The film thickness of lubricant will be smaller than the average surface roughness of sliding surfaces, and then higher contact at the micro peaks of asperities is expected. This would also increase the shear strength and plastic deformation of asperity peaks at the surface of contact, raising the coefficient of friction.

Figure 6.

Experimental runs of the pin on disc test show the variation of friction coefficient vs. sliding distance under different CuO nano lubricant conditions.

Figure 7.

The average friction coefficient for experimental runs of the pin on disc test.

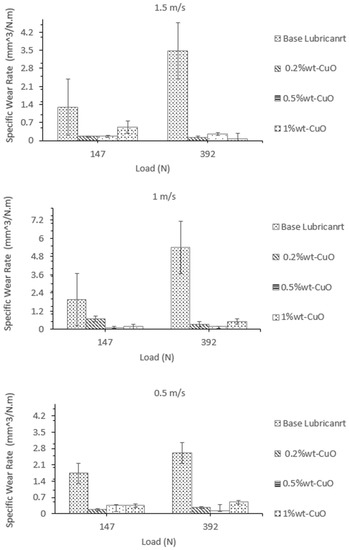

Moreover, the lubricating oil would be unable to separate the asperities of contacts effectively. Hence, the wear rate of frictional surfaces starts to grow. This is remarkable at the specific wear rate (Figure 8). The specific wear rate is increasing with load and sliding speed simultaneously in the case of base lubricant. The reason is also related to the high normal load with a sliding speed, which prevents the production of a sufficient thick lubricant film from separating the peaks of asperities at the contact area. Hence, a higher rate of asperities deformation is attainted. For CuO nano lubricant, lower COF and specific wear rate are observed at the same conditions (higher load and sliding speed). This means that the nano lubricants system works correctly at these lubrication regimes to boost the tribological properties of base lubricants. This is correlated to less time for contact at asperities, which leads to minimal time for asperities distortion. Thus, the entire contact area at frictional surfaces decreases, causing a decline in the COF and wear rate. It is observed that, at the lowest normal load and sliding speed of 0.5 m/s−147 N, nano lubricant with 0.2 wt.% achieved the lowest COF and wear rate. This is because, at this condition, the film thickness is sufficient to separate the two frictional surfaces slightly; consequently, a low rate of asperities contact is obtained. For 0.5 wt.% nano lubricant, a convenient, low COF, and wear rate are discerned under most of the testing conditions of load and sliding speed in contrast with the base lubricant.

Figure 8.

Specific wear rate for experimental runs of the pin on disc test.

Meanwhile, for 1 wt.% nano lubricant, the scenario got worsened. At this high concentration of nano lubricant, COF and wear rate had risen. These observations are then requireing more verifications through both surface and stabilization analyses. These results are consistent with the reported studies for nanoparticles conducted with boundary lubrication and mixed lubrication regimes. The reported studies recommended that there is usually optimum concertation of the added nanoparticles to boost the lubricant tribological properties for different working conditions [28]. Many hypotheses had been reported in the literature for CuO nanoparticles engaged in the lubrication of sliding surfaces. It is believed that CuO nanoparticles can manifest a combination of two kinds of lubrication mechanisms at boundary/mixed lubrication regimes. These two mechanisms are named Tribosintering and Third body (nano-ball bearings) [9,11,52]. In the Tribosintering mechanism, the small size of nanoparticles allows them to penetrate the contact surfaces and filling the micro-grooves of asperities (valleys). A very thin layer, named tribo-film, is formed. During the sliding motion at boundary/mixed lubrication, nanoparticles that fill the micro valleys of asperities will be trapped under the effect of heat generated by friction and high contact pressure.

Nanoparticles will exfoliate and flattened on the frictional surfaces. The real contact area of asperities will grow. This will cause the contact pressure to be diminished. Moreover, the presence of this tribo-film would reduce direct contact and deformation/collision between asperities. Hence, lowering the shear stresses at contact as well as the specific wear rate. The formation of tribo-film is mainly affected by two critical parameters, the hardness, and size of nanoparticles. The hardness of nanoparticles shall be lower than the hardness of frictional pairs. When nanoparticles are harder than frictional pairs, they will be prone to scratch and indent the frictional surfaces. This will lead to high plastic deformation of surfaces and, thus, prominent wear rate and COF.

On the contrary, the low hardness shall give a high probability for nanoparticles to be mechanically exfoliated and deformed on the surface, forming the protective tribo-film. For the size parameter, when the radius of the nanoparticles (r) is considerably more significant than the average roughness (h) of frictional surfaces, nanoparticles would easily escape from the contact area. Upon loading and shearing of asperities, nanoparticles will be squeezed out of the contact zone, reducing the probability of forming the protective tribo-film [53]. Therefore, the frictional surfaces will not acquire any tribological benefit from nanoparticles, leading to a low lubrication mechanism at boundary/mixed regimes. On the contrary, when the radius of the nanoparticles is much smaller than the average roughness, the valleys of asperities would be filled effectively, allowing the formation of the tribo-film upon the loading of frictional surfaces.

Hence, Nanoparticles can enhance and smooth out the frictional surfaces and significantly improve tribological properties. In this study, CuO nanoparticles have a low bulk hardness of 3.5 Mohs (20 HRC), which is lower than the hardness of frictional pairs of pin and disc (40–63 HRC). The size of spherical CuO nanoparticles is about 35 nm, which is very small compared to the average surface roughness of pairs (also mentioned in this study’s proceedings).

In the third body mechanism, spherical nanoparticles as CuO would act as an artificial ball bearing (nano ball bearings). Spherical nanoparticles could roll among the frictional surfaces in asperities, providing a transformation from a sliding friction of asperities to rolling friction. At rolling friction, less energy is required for the deformation/collision of asperities. This will result in a minimal wear rate and coefficient of friction. At all events, an essential parameter that could affect lubrication mechanisms that are inherited by the nano lubricant is the melting temperature of nanoparticles. This parameter should be considered during nanoparticle-based lubricant design to guarantee that nanoparticles will not melt through the lubrication fluid due to their working temperature.

Regarding this study, CuO nanoparticles have a melting point of 1326 , whereas the base lubricant (20 W-50) has a maximum operating temperature of 240 . This ensures that the nanoparticle will not undergo the liquid phase under the lubricant’s different operating conditions, thus enhancing of tribological properties of the lubricant.

3.4. Surface Analysis Studies

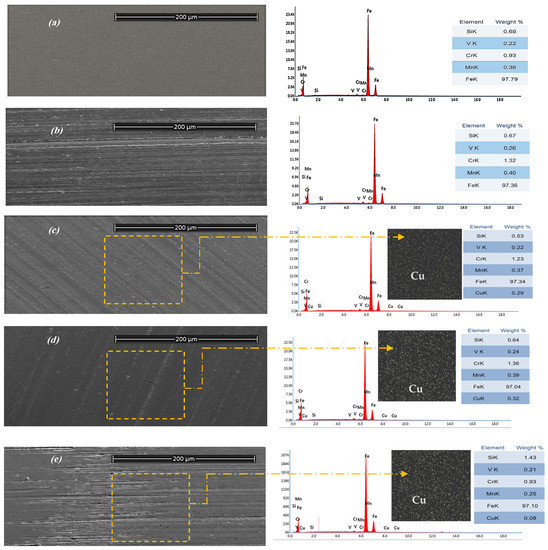

In this section, the morphological examination is conducted of selected, tested pin samples. In this way, a better insight into lubrication mechanisms inherited by nano lubricant could be attained. All of the surfaces were cleaned by Ethanol before any test of surface analysis. This is to remove any transient lubricant and debris deposited during the friction test. Scanning electron microscopy (SEM) and electron dispersive X-ray spectroscopy (EDX) were used to get to the bottom of the Tribo-sintering mechanism and the consistency of tribo-film.

On top of that, Atomic force microscopy (AFM) was used to investigate the consolidation of average surface roughness of the tested samples. Surface analyses were conducted before and after friction tests. Figure 9 and Figure 10 illustrate the SEM/EDX microscopy results as well as 3D surface topography of AFM for selected samples. Figure 9a presents the bare sample’s SEM surface analysis (as obtained) without performing any friction test. This sample’s SEM micrograph shows a nearly blank surface without any wear scratches with an extremely fine average surface roughness of 5.96 nm. The elemental analysis (EDX) shows the primary alloying elements of pin material accompanied by a rough approximate elemental weight percentage at the surface.

Figure 9.

(SEM) micrograph with (EDX) analysis (a) bare sample, (b) Run # 6 (392 N- 0.5 m/s) Base Lubricant, (c) Run # 6 (392 N- 0.5 m/s) 0.2 wt.% CuO, (d) Run # 6 (392 N- 0.5 m/s) 0.5 wt.% CuO, (e) Run # 6 (392 N- 0.5 m/s) 1 wt.% CuO.

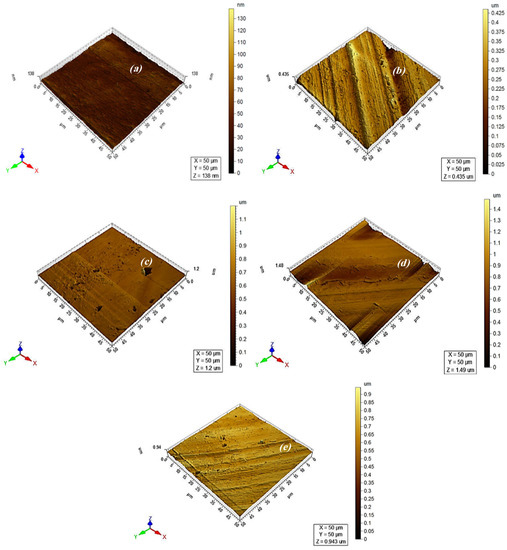

Figure 10.

3D surface topography of AFM (a) bare sample, (b) Run # 6 (392 N- 0.5 m/s) Base Lubricant, (c) Run # 6 (392 N- 0.5 m/s) 0.2 wt.% CuO, (d) Run # 6 (392 N- 0.5 m/s) 0.5 wt.% CuO, (e) Run # 6 (392 N- 0.5 m/s) 1 wt.% CuO.

Figure 9b shows the surface analysis of base lubricant under the condition of a high normal load. In this case, the high rate of interaction and deformation of asperities is the dominant situation, particularly at higher contact load, where a high lubricant breakdown occurs. This leads to the starvation of lubricant among asperities. Ploughing and scratching of asperities and micro pitting are the results in this case in the sliding direction. The development of deep and wide furrows could be distinguished clearly as a prominent remark resulted from high abrasive wear. The AFM could support these results in this case (Figure 10b), where the broad and deep furrows are shown at a three-dimensional roughness profile. The resulting surfaces were rough with 33 to 52 nm as average surface roughness for low and high load conditions. This could be rationalized by the high wear rate and coefficient of friction discussed in the previous section.

The EDX analysis also shows the alloying elements of pin metal at the tested surface. Figure 9c–e) show the surface analysis for nano lubricant tested with different concentrations of CuO sintered nanoparticles under the high normal load condition. From the first glance, the surface roughness of tested samples treated with nano lubricant was refined in contrast with base lubricant cases (Figure 9a).

The roughness 3D plot for each case is shown as peaks and valleys with dark brown color for low surface roughness ranging to bright yellow color for high surface roughness (Figure 10). At 0.2 wt.% CuO, the average surface roughness (Sa) is ranged from 29 to 31 nm. At 0.5 wt.% CuO, the average had been dropped down to the range from 17 to 22 nm. While, at 1 wt.% CuO, the average surface roughness was propagated to an extremely high range from 60 to 91 nm. This is considered an abnormal case of the CuO nano lubricant in contrast with the base lubricant. The rising of average surface roughness is correlated with the low dispersion of nanoparticles at high concentrations. For most cases of nano lubricant at 0.2 and 0.5 wt.% CuO, it can be shown that there is an improvement in the surface structure in contrast with low surface roughness and adequate wear characteristics at these concentrations. This elucidated the lubrication mechanisms of tribo-sintering and third body (nano-ball bearing) inherited by CuO nanoparticles. The surface of the tribo-film is shown to be a polished surface with no or minimum amount of surface furrows. This can be revealed from the arrangement and formation of the tribo-film for all samples treated under nano lubricant.

The formation of tribo-film would also be recognized at high concentrations with a high friction coefficient. This could be due to aggregated nano’s unequilibrium effect on the contact surface’s dispersion stability. On the contrary, if the nanoparticle concentration is low as in 0.2 wt.% CuO, there will not be enough nanoparticles to transfer the sliding friction into rolling friction as well as exfoliating and forming of tribo-film.

The above results disclose that an optimum concentration of CuO nanoparticles is required where the coefficient of friction and wear rate are minimum under different testing conditions of nano lubricant. This optimum concentration is expected to improve the tribological performance of the base lubricant effectively. Similar evolutions that resulted from this study are presented in literature [9,12,54,55].

The results of EDX are illustrated in each case of the tested sample, as shown with the elemental surface weight percentage. The copper tribo-film is shown as green spots afforded with a black ground of the tested area, as shown in results. The weight percentage of copper tribo-film depends on nanoparticle concentration (Figure 9). At 0.2 wt.% CuO, tribo-film surface concentration ranged from 0.12 to 0.29%. At 0.5 wt.% CuO, the concentration ranged from 0.32 to 0.38%. For 1 wt.% The concentration dropped down to 0.08% at low load conditions and steeped up to 0.81 at high load conditions.

The instability of tribo-film formation at a high concentration of CuO is correlated with nanoparticle aggregation. At high concentrations, nanoparticles would aggregate to form particles with a high weight compared to the nominal size. These aggregations would then experience some difficulty to get involved with the contact region managed by surface asperities. This will lead to a low quality of nano lubricant, which would aggravate the wear rate and friction coefficient.

The formation of tribo-films is believed to be attributed to the atomistic response resulting from the interaction between nanoparticles and the substrate material’s asperities. Theoretical analysis of the Lennard - Jones method and solid-liquid interaction through molecular dynamics simulations confirmed that nanoparticles were found to repair the substrate material’s surface by filling in vacancies between asperities [56].

4. Conclusions

In the present study, tribological properties are investigated for a mineral base oil (20 W-50) mixed with copper oxide (CuO) as nonadditive and oleic acid (OA) as a dispersing agent. Three concentration values by weight are used for the nano additive. The work is implemented using a test rig with a pin-on-disc system (ASTM G-99).

Based on surface analysis studies of bodies in contact, hypotheses on working mechanisms of CuO nanoparticles were proposed and compared with the literature. CuO nanoparticles can manifest two different lubrication mechanisms: the third body (nano-ball bearing) and Tribo-sintering mechanisms. The friction coefficient was found to be diminished by 37.9, 42.9, and 14.6% for the CuO Nano lubricant concentrations of 0.2, 0.5, and 1% wt., respectively. A dispersion analysis for nano lubricant was conducted through Zeta potential and sedimentation tests. The low value of zeta potential indicates a weak electrostatic repulsive stabilization between CuO nanoparticles capped by OA. In contrast, the sedimentation analysis recognizes that nanoparticles have good stability, inherited by the repulsive steric stabilization. OA can cover the CuO nanoparticles in steric stabilization to change them from hydrophilic to hydrophobic particle and then reduce the aggregation.

An optimum concentration of CuO nano lubricants was proposed to be 0.5 wt.% CuO. Conversely, when the CuO concentration was raised to 1%, aggregation was observed, leading to the aggravation of friction and dispersion aspects.

For future work, various study points are required. The dispersion analysis shall be more investigated to find the optimum ratio of the surfactant. The lubrication mechanisms hypotheses would be better studied under specialized simulation software to capture the exact chemical reaction that could be endeavored to form the tribo-film of CuO nanoparticles.

Author Contributions

Conceptualization, A.A.A.-R. and S.A.; Data curation, S.E.; Investigation, A.A.A.-R., S.A. and S.E.; Methodology, A.A.A.-R. and S.A.; Resources, A.A.A.-R. and S.E.; Supervision, A.A.A.-R.; Writing–original draft, A.A.A.-R., S.A. and S.E.; Writing–review & editing, S.A. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding. The APC was funded by The British University in Egypt (BUE).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The study did not report any data.

Acknowledgments

The authors would like to thank the NTRC Nano Technology Research Centre at the British university in Egypt (NTRC-BUE) for their support during the experimental work of this study.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Holmberg, K.; Andersson, P.; Erdemir, A. Global energy consumption due to friction in passenger cars. Tribol. Int. 2012, 47, 221–234. [Google Scholar] [CrossRef]

- Holmberg, K.; Erdemir, A. The impact of tribology on energy use and CO2 emission globally and in combustion engine and electric cars. Tribol. Int. 2019, 135, 389–396. [Google Scholar] [CrossRef]

- Demas, N.G.; Timofeeva, E.V.; Routbort, J.L.; Fenske, G.R. Tribological effects of BN and MoS2 nanoparticles added to polyalphaolefin oil in piston skirt/cylinder liner tests. Tribol. Lett. 2012, 47, 91–102. [Google Scholar] [CrossRef]

- Rosenkranz, A.; Liu, Y.; Yang, L.; Chen, L. 2D nano-materials beyond graphene: From synthesis to tribological studies. Appl. Nanosci. 2020, 10, 3353–3388. [Google Scholar] [CrossRef]

- Ali, M.K.A.; Xianjun, H.; Abdelkareem, M.A.A.; Gulzar, M.; Elsheikh, A.H. Novel approach of the graphene nanolubricant for energy saving via anti-friction/wear in automobile engines. Tribol. Int. 2018, 124, 209–229. [Google Scholar] [CrossRef]

- Wu, B.; Song, H.; Li, C.; Song, R.; Zhang, T.; Hu, X. Enhanced tribological properties of diesel engine oil with Nano-Lanthanum hydroxide/reduced graphene oxide composites. Tribol. Int. 2020, 141. [Google Scholar] [CrossRef]

- Charoo, M.S.; Hanief, M. Improving the tribological characteristics of a lubricating oil by nano sized additives. Mater. Today Proc. 2020, 28, 1205–1209. [Google Scholar] [CrossRef]

- Spikes, H. Friction modifier additives. Tribol. Lett. 2015, 60, 5. [Google Scholar] [CrossRef]

- Peña-Parás, L.; Taha-Tijerina, J.; Garza, L.; Maldonado-Cortés, D.; Michalczewski, R.; Lapray, C. Effect of CuO and Al2O3 nanoparticle additives on the tribological behavior of fully formulated oils. Wear 2015, 332–333, 1256–1261. [Google Scholar] [CrossRef]

- Mello, V.S.; Trajano, M.F.; Emilia, A.; Silva, D. Comparison between the action of nano-oxides and conventional EP additives in boundary lubrication. Lubricants 2020, 8, 54. [Google Scholar] [CrossRef]

- Ghaednia, H.; Jackson, R.L.; Khodadadi, J.M. Experimental analysis of stable CuO nanoparticle enhanced lubricants. J. Exp. Nanosci. 2015, 10, 1–18. [Google Scholar] [CrossRef]

- Thottackkad, M.V.; Perikinalil, R.K.; Kumarapillai, P.N. Experimental evaluation on the tribological properties of coconut oil by the addition of CuO nanoparticles. Int. J. Precis. Eng. Manuf. 2012, 13, 111–116. [Google Scholar] [CrossRef]

- Alves, S.M.; Mello, V.S.; Faria, E.A.; Camargo, A.P.P. Nanolubricants developed from tiny CuO nanoparticles. Tribol. Int. 2016, 1–9. [Google Scholar] [CrossRef]

- Li, C.C.; Chang, M.H. Colloidal stability of CuO nanoparticles in alkanes via oleate modifications. Mater. Lett. 2004, 58, 3903–3907. [Google Scholar] [CrossRef]

- Wu, L.; Zhang, Y.; Yang, G.; Zhang, S.; Yu, L.; Zhang, P. Tribological properties of oleic acid-modified zinc oxide nanoparticles as the lubricant additive in poly-alpha olefin and diisooctyl sebacate base oils. RSC Adv. 2016, 6, 69836–69844. [Google Scholar] [CrossRef]

- Clary, D.R.; Mills, G. Preparation and thermal properties of CuO particles. J. Phys. Chem. C 2011, 115, 1767–1775. [Google Scholar] [CrossRef]

- Ghasemi, R.; Fazlali, A.; Mohammadi, A.H. Effects of TiO2 nanoparticles and oleic acid surfactant on the rheological behavior of engine lubricant oil. J. Mol. Liq. 2018, 268, 925–930. [Google Scholar] [CrossRef]

- Ahmed Ali, M.K.; Xianjun, H.; Essa, F.A.; Abdelkareem, M.A.A.; Elagouz, A.; Sharshir, S.W. Friction and wear reduction mechanisms of the reciprocating contact interfaces using nanolubricant under different loads and speeds. J. Tribol. 2018, 140. [Google Scholar] [CrossRef]

- Bogunovic, L.; Zuenkeler, S.; Toensing, K.; Anselmetti, D. An oil-based lubrication system based on nanoparticular TiO2 with superior friction and wear properties. Tribol. Lett. 2015, 59, 1–12. [Google Scholar] [CrossRef]

- Mousavi, S.B.; Heris, S.Z.; Estellé, P. Experimental comparison between ZnO and MoS2 nanoparticles as additives on performance of diesel oil-based nano lubricant. Sci. Rep. 2020, 10, 1–17. [Google Scholar] [CrossRef]

- Moldovanu, D.; Molea, A.; Barabás, I. Preliminary results on nano-diamond and nano-graphite testing as additive for an engine lubrication oil. IOP Conf. Ser. Mater. Sci. Eng. 2020, 724. [Google Scholar] [CrossRef]

- Ali, M.K.A.; Hou, X.; Abdelkareem, M.A.A. Anti-wear properties evaluation of frictional sliding interfaces in automobile engines lubricated by copper/graphene nanolubricants. Friction 2019, 8, 905–916. [Google Scholar] [CrossRef]

- Ivanov, M.; Shenderova, O. Nanodiamond-based nanolubricants for motor oils. Curr. Opin. Solid State Mater. Sci. 2017, 21, 17–24. [Google Scholar] [CrossRef]

- Beig, G.; Sahu, S.K.; Singh, V.; Tikle, S.; Sobhana, S.B.; Gargeva, P.; Ramakrishna, K.; Rathod, A.; Murthy, B.S. Recent developments of nanoparticles additives to the consumables liquids in internal combustion engines: Part II: Nano-lubricants. Sci. Total Environ. 2019, 136126. [Google Scholar] [CrossRef]

- Srivyas, P.D.; Charoo, M.S. A review on tribological characterization of lubricants with nano additives for automotive applications tribology in industry. Tribol. Ind. 2018, 40, 594–623. [Google Scholar] [CrossRef]

- Chen, Y.; Renner, P.; Liang, H. Dispersion of nanoparticles in lubricating oil: A critical review. Lubricants 2019, 7, 7. [Google Scholar] [CrossRef]

- Mallakpour, S.; Madani, M. A review of current coupling agents for modification of metal oxide nanoparticles. Prog. Org. Coat. 2015, 86, 194–207. [Google Scholar] [CrossRef]

- Asnida, M.; Hisham, S.; Awang, N.W.; Amirruddin, A.K.; Noor, M.M.; Kadirgama, K.; Ramasamy, D.; Najafi, G.; Tarlochan, F. Copper (II) oxide nanoparticles as additve in engine oil to increase the durability of piston-liner contact. Fuel 2018, 212, 656–667. [Google Scholar] [CrossRef]

- Shah, R.; Woydt, M.; Huq, N.; Rosenkranz, A. Tribology meets sustainability. Ind. Lubr. Tribol. 2020. [Google Scholar] [CrossRef]

- Holmberg, K.; Erdemir, A. Influence of tribology on global energy consumption, costs and emissions. Friction 2017, 5, 263–284. [Google Scholar] [CrossRef]

- Gulzar, M.; Masjuki, H.; Varman, M.; Kalam, M.; Mufti, R.A.; Zulkifli, N.; Yunus, R.; Zahid, R. Improving the AW/EP ability of chemically modified palm oil by adding CuO and MoS2 nanoparticles. Tribol. Int. 2015, 88, 271–279. [Google Scholar] [CrossRef]

- Hernández Battez, A.; Viesca, J.L.; González, R.; Blanco, D.; Asedegbega, E.; Osorio, A. Friction reduction properties of a CuO nanolubricant used as lubricant for a NiCrBSi coating. Wear 2010, 268, 325–328. [Google Scholar] [CrossRef]

- Ran, X.; Yu, X.; Zou, Q. Effect of particle concentration on tribological properties of ZnO nanofluids. Tribol. Trans. 2017, 60, 154–158. [Google Scholar] [CrossRef]

- Yu, W.; Xie, H. A Review on nanofluids: Preparation, stability mechanisms, and applications. J. Nanomater. 2012, 2012, 1–17. [Google Scholar] [CrossRef]

- Ali, M.K.A.; Xianjun, H.; Elagouz, A.; Essa, F.A.; Abdelkareem, M.A.A. Minimizing of the boundary friction coefficient in automotive engines using Al2O3 and TiO2 nanoparticles. J. Nanoparticle Res. 2016, 18, 377. [Google Scholar] [CrossRef]

- Young, J.A. Chemical laboratory information profile: Oleic acid. J. Chem. Educ. 2002, 79, 24. [Google Scholar] [CrossRef]

- Holban, A.M.; Grumezescu, A.M.; Andronescu, E. Inorganic nanoarchitectonics designed for drug delivery and anti-infective surfaces. In Surface Chemistry of Nanobiomaterials; Elsevier: Oxford, UK, 2016; pp. 301–327. ISBN 9780323428613. [Google Scholar]

- Biresaw, K.L.M.G. Surfactants in Tribology, 1st ed.; Taylor & Francis Group: New York, NY, USA, 2019; ISBN 978-1-4200-6007-2. [Google Scholar]

- Martin, N.O.J.M. Nano Lubricants, 1st ed.; WILEY: Chichester, UK, 2008; ISBN 978-0-470-06552-5. [Google Scholar]

- Jama, M.; Singh, T.; Gamaleldin, S.M.; Koc, M.; Samara, A.; Isaifan, R.J.; Atieh, M.A. Critical review on nanofluids: Preparation, characterization, and applications. J. Nanomater. 2016, 2016, 1–22. [Google Scholar] [CrossRef]

- Totten, G.E.; Wedeven, L.; Anderson, M.; Dickey, J. Bench Testing of Industrial Fluid Lubrication and Wear Properties Used in Machinery Applications; Totten, G., Wedeven, L., Anderson, M., Dickey, J., Eds.; ASTM International: West Conshohocken, PA, USA, 2001; ISBN 978-0-8031-2867-5. [Google Scholar]

- Borda, F.L.G.; de Oliveira, S.J.R.; Lazaro, L.M.S.M.; Leiróz, A.J.K. Experimental investigation of the tribological behavior of lubricants with additive containing copper nanoparticles. Tribol. Int. 2018, 117, 52–58. [Google Scholar] [CrossRef]

- Woydt, M.; Kelling, N. Testing the tribological properties of lubricants and materials for the system “piston ring/cylinder liner” outside of engines. Ind. Lubr. Tribol. 2003, 55, 213–222. [Google Scholar] [CrossRef]

- Gulzar, M.; Masjuki, H.H.; Kalam, M.A.; Varman, M.; Zulkifli, N.W.M.; Mufti, R.A.; Zahid, R. Tribological performance of nanoparticles as lubricating oil additives. J. Nanoparticle Res. 2016, 18, 223. [Google Scholar] [CrossRef]

- Koshy, C.P.; Rajendrakumar, P.K.; Thottackkad, M.V. 74 Evaluation of the tribological and thermo-physical properties of coconut oil added with MoS2nanoparticles at elevated temperatures. Wear 2015, 330–331, 288–308. [Google Scholar] [CrossRef]

- Stachowiak, G.W.; Batchelor, A.W. Engineering Tribology, 4th ed.; Butterworth–Heinemann: Oxford, UK, 2014; ISBN 978-0-12-397047-3. [Google Scholar]

- Tiginyanu, I.M.; Lupan, O.; Ursaki, V.V.; Chow, L.; Enachi, M. Nanostructures of metal oxides. Compr. Semicond. Sci. Technol. 2011, 3, 396–479. [Google Scholar] [CrossRef]

- Sousa, V.S.; Teixeira, M.R. Aggregation kinetics and surface charge of CuO nanoparticles: The influence of pH, ionic strength and humic acids. Environ. Chem. 2013, 10, 313. [Google Scholar] [CrossRef]

- Ettefaghi, E.; Ahmadi, H.; Rashidi, A.; Mohtasebi, S.; Alaei, M. Experimental evaluation of engine oil properties containing copper oxide nanoparticles as a nanoadditive. Int. J. Ind. Chem. 2013, 4, 28. [Google Scholar] [CrossRef]

- Dhineshbabu, N.R.; Rajendran, V.; Nithyavathy, N.; Vetumperumal, R. Study of structural and optical properties of cupric oxide nanoparticles. Appl. Nanosci. 2016, 6, 933–939. [Google Scholar] [CrossRef]

- Zhu, D.; Wang, L.; Yu, W.; Xie, H. Intriguingly high thermal conductivity increment for CuO nanowires contained nanofluids with low viscosity. Sci. Rep. 2018, 8, 1–13. [Google Scholar] [CrossRef]

- Battez, A.H.; González, R.; Viesca, J.L.; Fernández, J.E.; Fernández, J.M.D.; Machado, A.; Chou, R.; Riba, J. CuO, ZrO2 and ZnO nanoparticles as antiwear additive in oil lubricants. Wear 2008, 265, 422–428. [Google Scholar] [CrossRef]

- Akbulut, M. Nanoparticle-based lubrication systems. J. Powder Metall. Min. 2012, 1, 1–3. [Google Scholar] [CrossRef]

- Azman, N.F.; Samion, S.; Sot, M.N.H.M. Investigation of tribological properties of CuO/palm oil nanolubricant using pin-on-disc tribotester. Green Mater. 2018, 6, 30–37. [Google Scholar] [CrossRef]

- Wu, Y.Y.; Tsui, W.C.; Liu, T.C. Experimental analysis of tribological properties of lubricating oils with nanoparticle additives. Wear 2007, 262, 819–825. [Google Scholar] [CrossRef]

- Pe, L.; García-Pineda, P.; Montemayor, O.E.; Nava, K.L.; Martini, A. Effects of substrate surface roughness and nano/micro particle additive size on friction and wear in lubricated sliding. Tribol. Int. 2018, 119, 88–98. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).