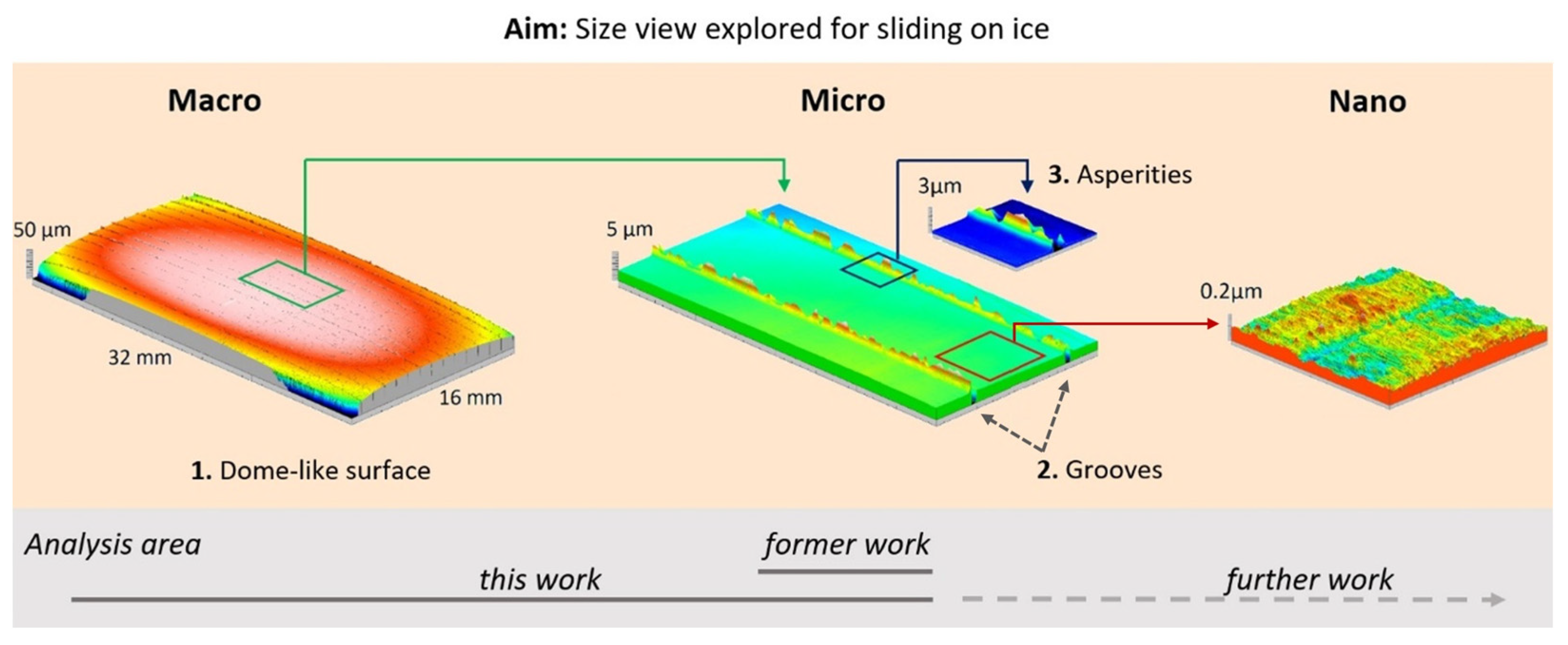

Surface Hierarchy: Macroscopic and Microscopic Design Elements for Improved Sliding on Ice

Abstract

1. Introduction

Contact Area and Surface Topography

2. Materials and Methods

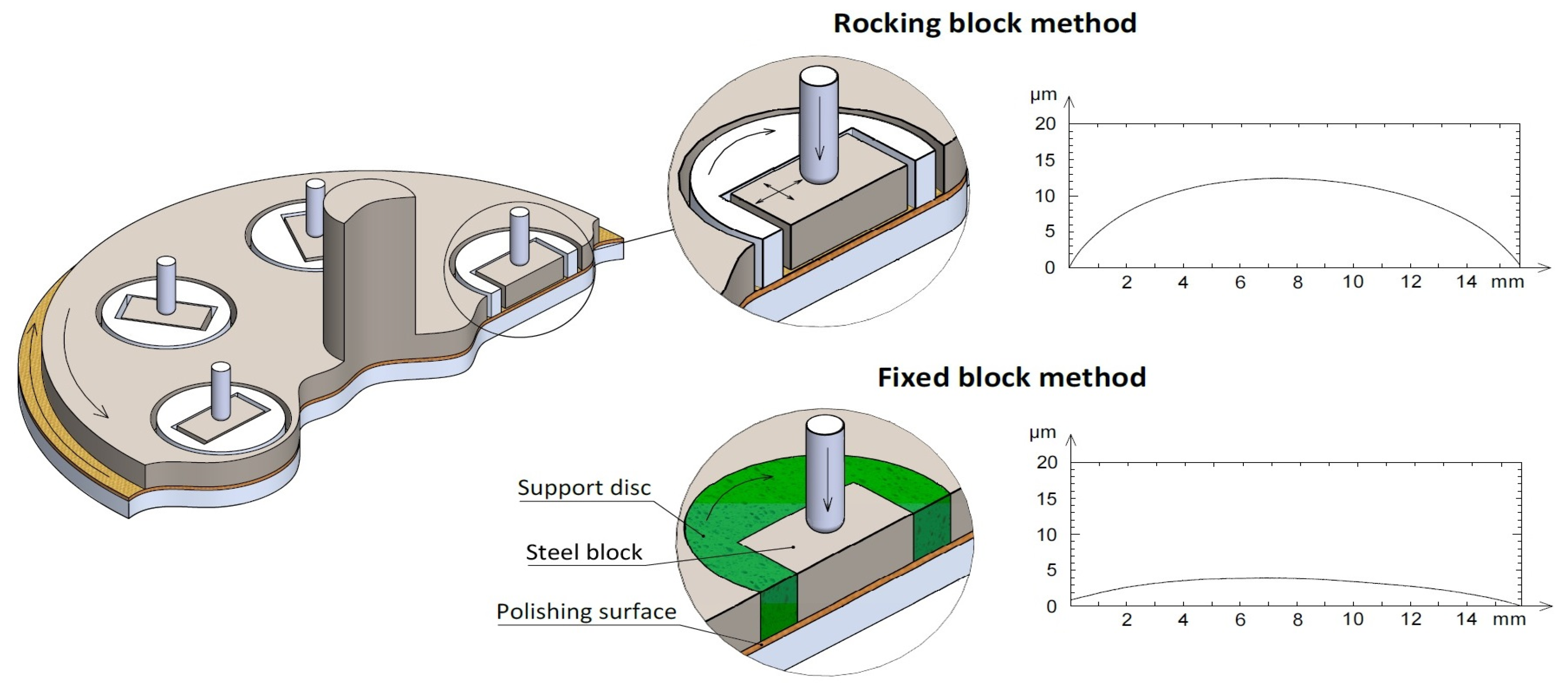

2.1. Preparation of the Sliding Block

2.1.1. Polishing for a Curved Sliding Base

2.1.2. Milling and Final Polishing

2.1.3. Laser Machining

2.2. Measurement of Texture

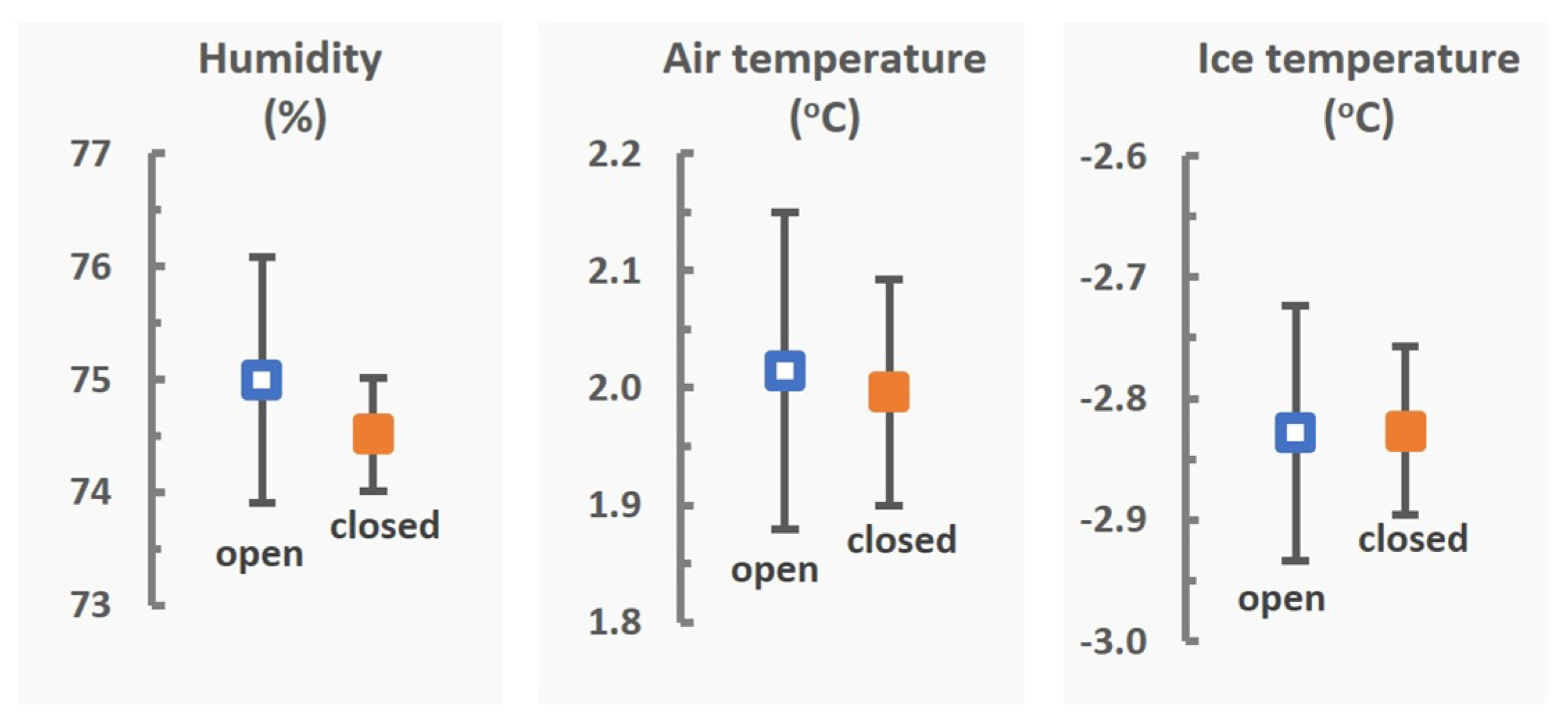

2.3. Sliding Speed

3. Results and Discussion

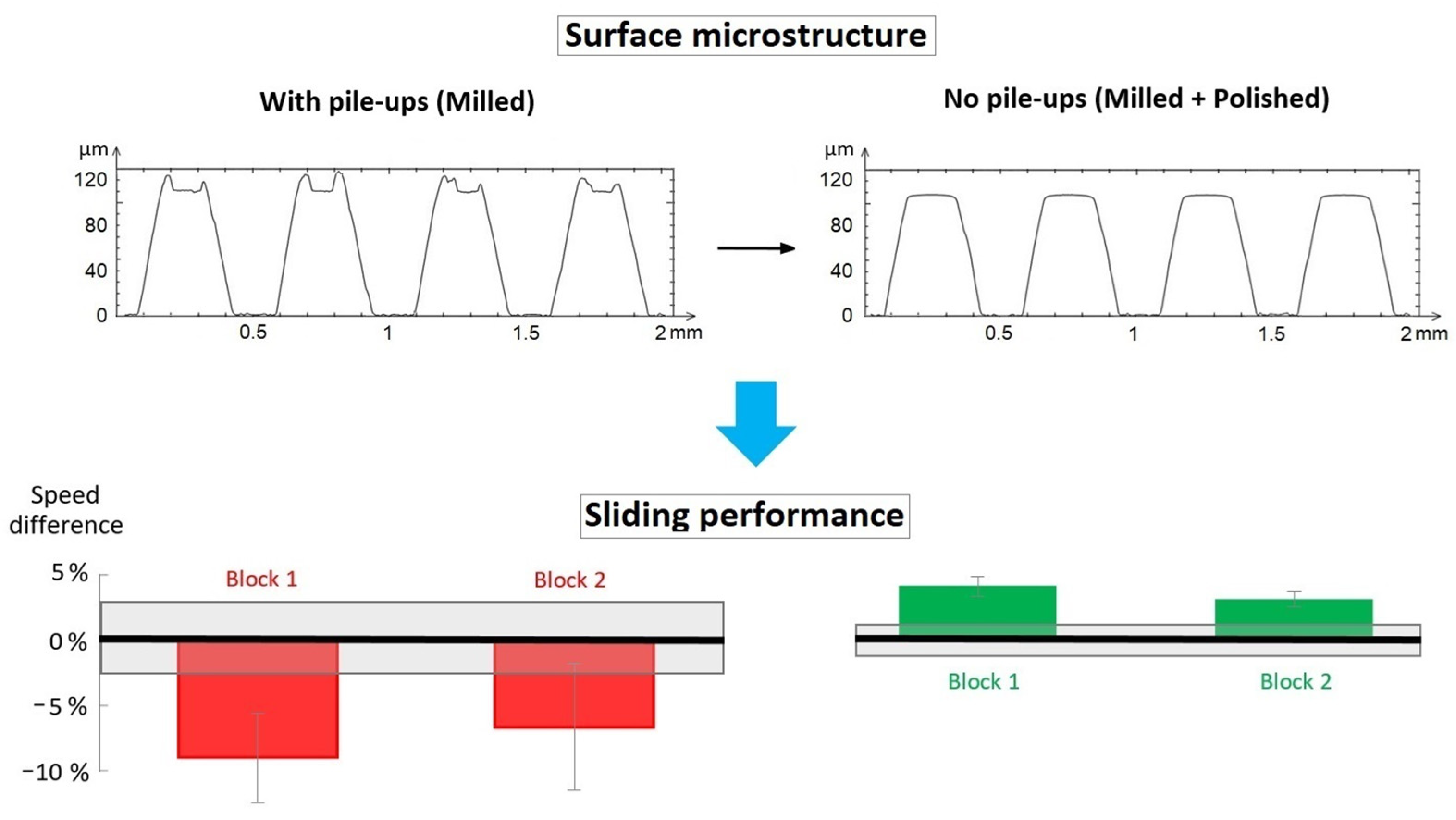

3.1. Milled Surface Grooves Influence Sliding Speed

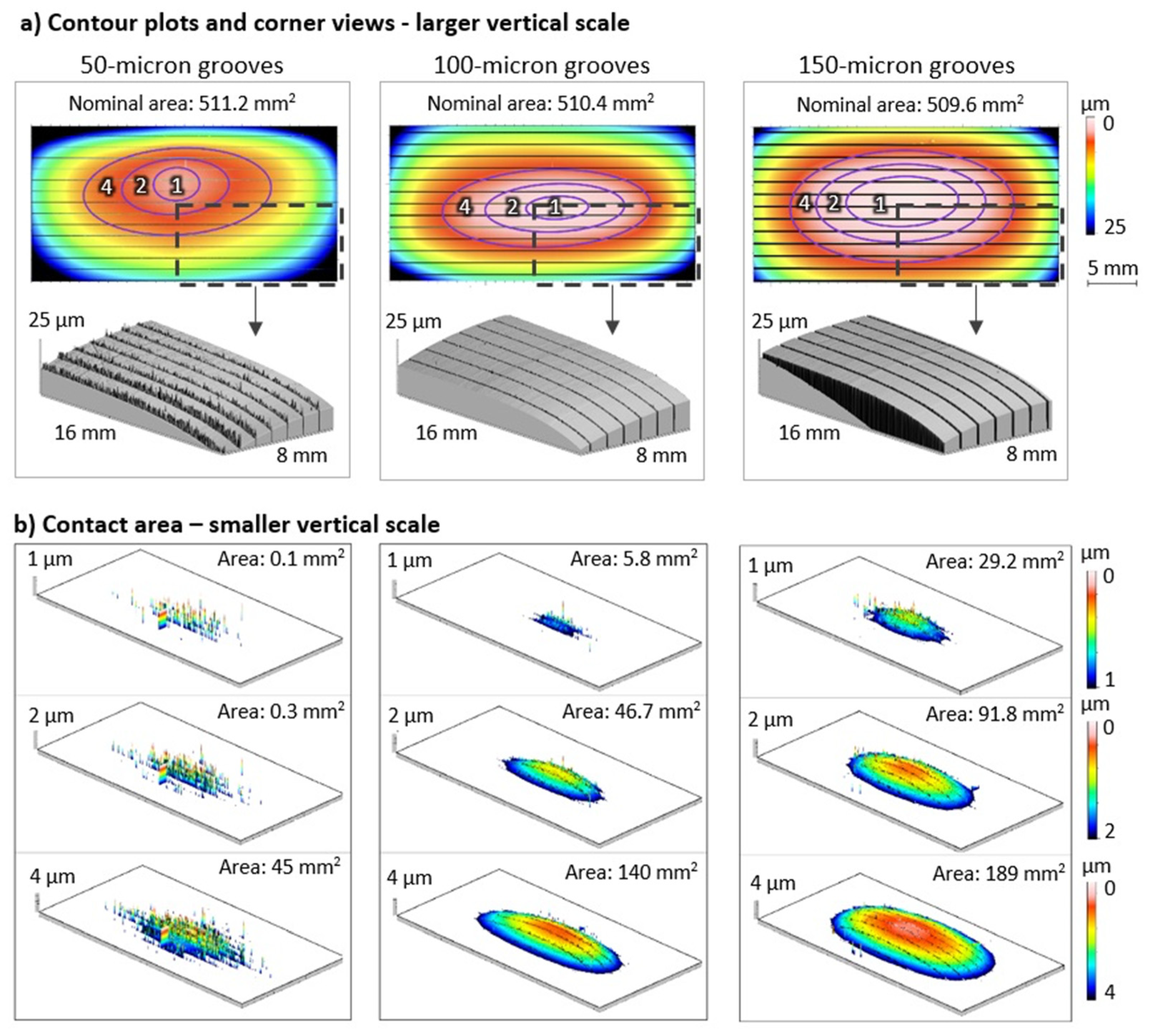

3.2. Characterization of Laser-Grooved Blocks

- Sa—the arithmetic mean height of asperities.

- Ssk—skewness to indicate peaks or holes above the mean plane.

- Sku—kurtosis to represent the sharpness of peaks.

- Spd—density of peas per unit area.

- Spc—the arithmetic mean peak curvature shows whether the asperity is pointed or rounded.

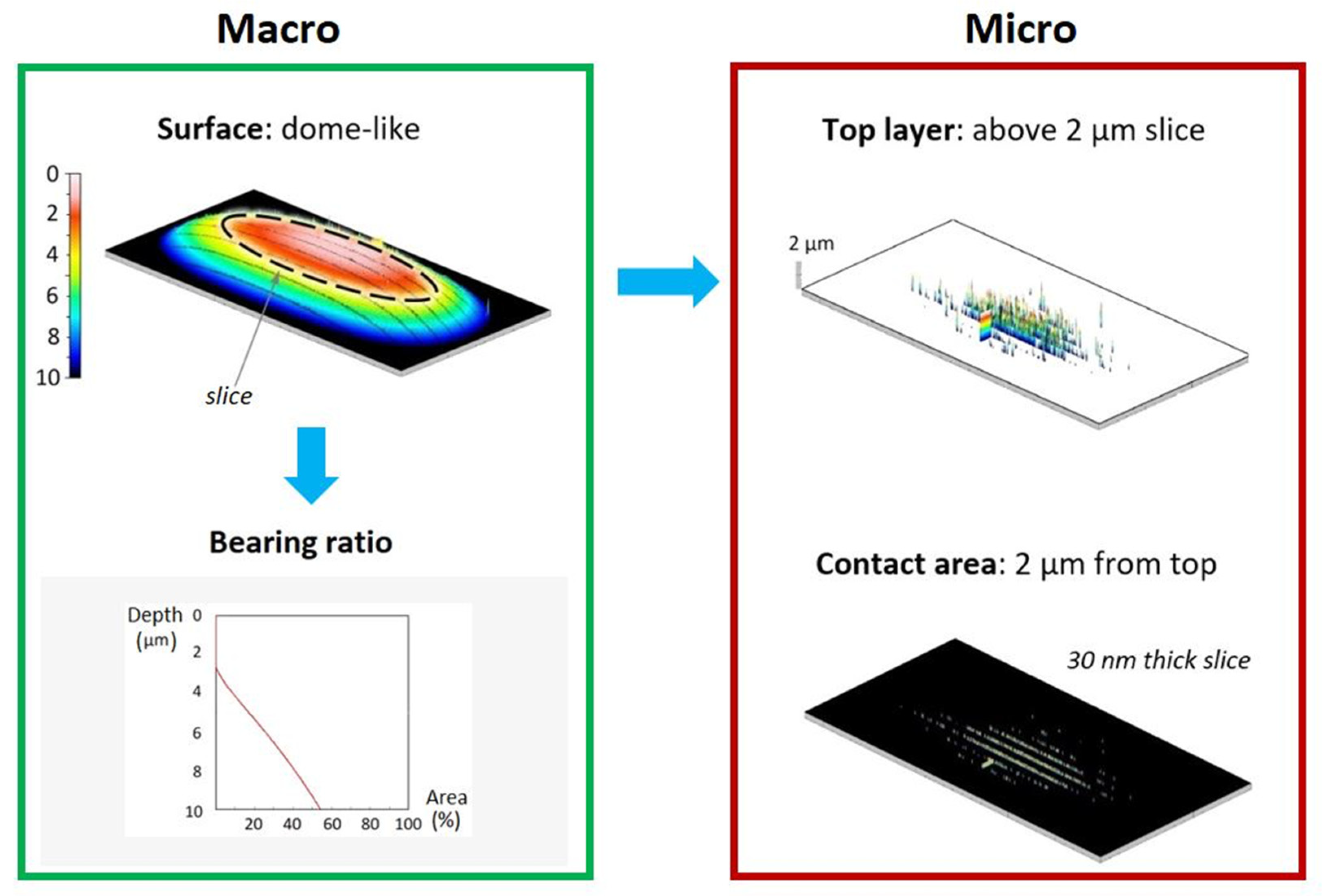

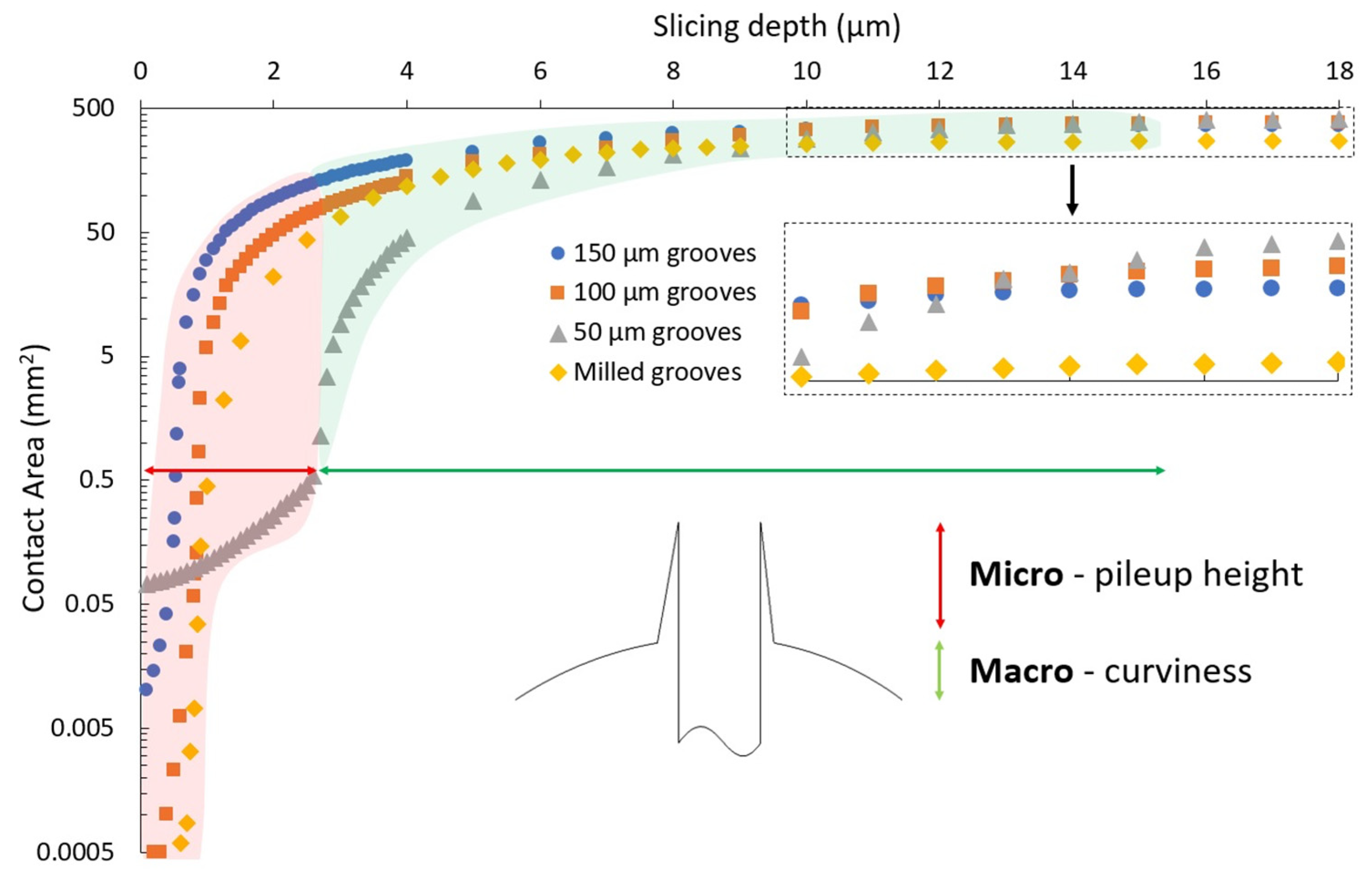

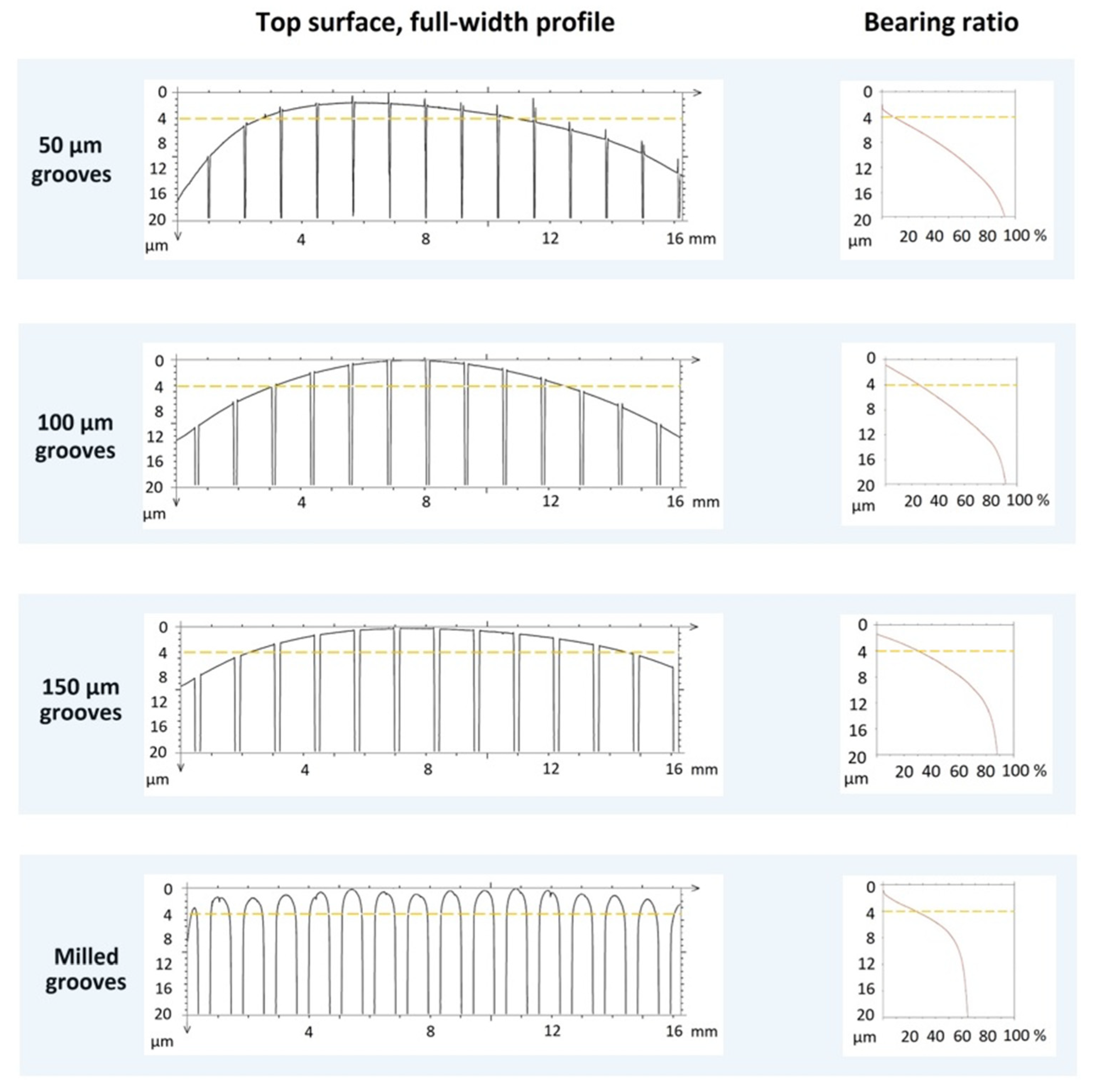

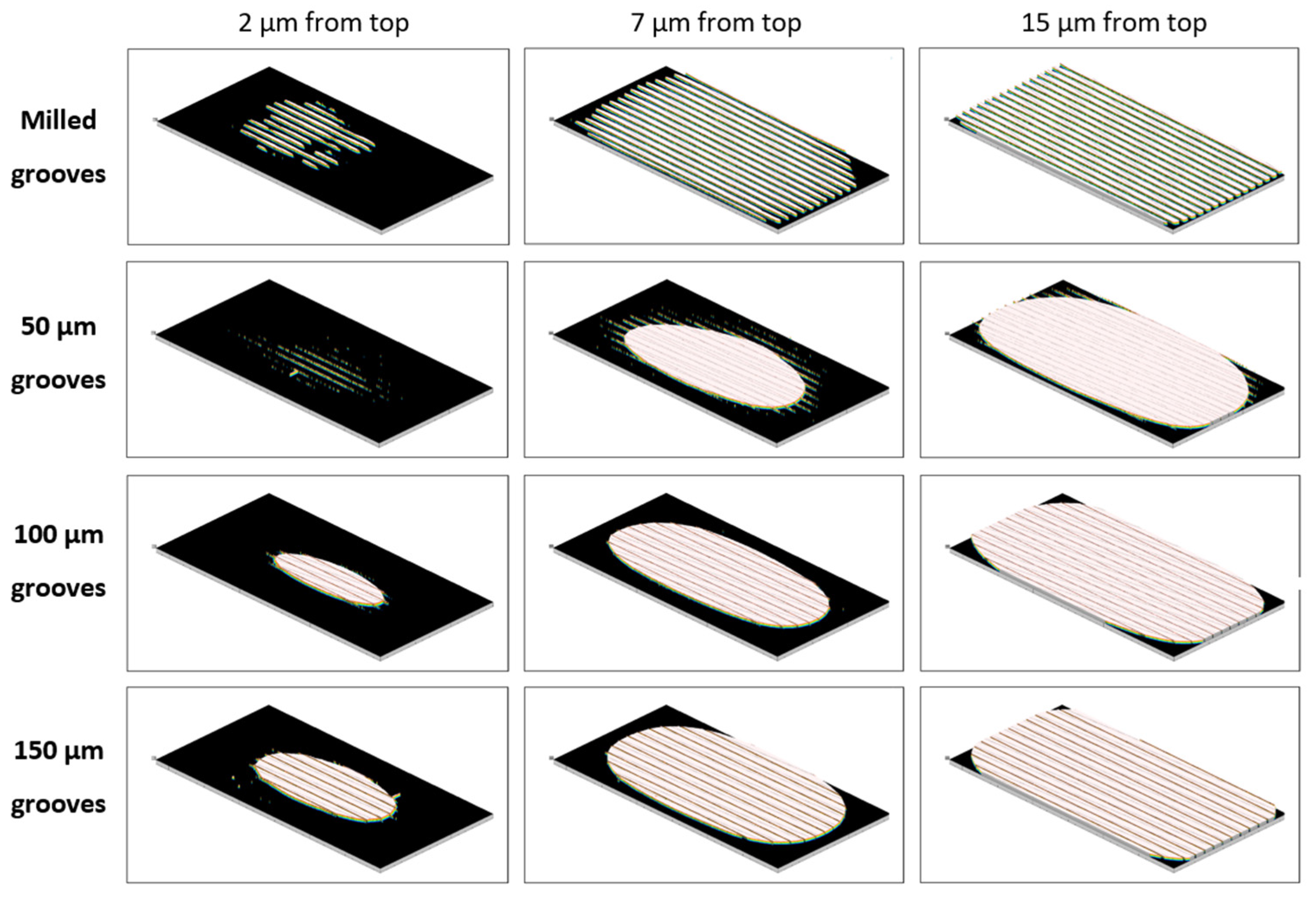

3.3. Quantification of Contact Area

3.4. Sliding Speed of Laser-Grooved Blocks

3.5. Further Considerations on the Contact Area

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kietzig, A.-M.; Hatzikiriakos, P.; Englezos, P. Physics of ice friction. J. Appl. Phys. 2010, 107, 081101. [Google Scholar] [CrossRef]

- Makkonen, L.; Tikanmäki, M. Modeling the friction of ice. Cold Reg. Sci. Technol. 2014, 102, 84–93. [Google Scholar] [CrossRef]

- Bowden, F.P.; Hughes, T.P. The mechanism of sliding on ice and snow. Proc. R. Soc. Lond. Ser. A Math. Phys. Sci. 1939, 172, 280–298. [Google Scholar] [CrossRef]

- Bäurle, L.; Szabó, D.; Fauve, M.; Rhyner, H.; Spencer, N.D. Sliding friction of polyethylene on ice: Tribometer measurements. Tribol. Lett. 2006, 24, 77–84. [Google Scholar] [CrossRef]

- Yun, C.; Choi, J.W.; Kim, H.; Kim, D.; Kim, H.-Y. Sliding on ice: Real contact area, melted film thickness, and friction force. Int. J. Heat Mass Transf. 2020, 160, 120166. [Google Scholar] [CrossRef]

- Lungevics, J.; Jansons, E.; Gross, K.A. Skeleton runner roughness and surface contact area influence on sliding ability: Field experiments. Key Eng. Mater. 2019, 800, 303–307. [Google Scholar] [CrossRef]

- Lozowski, E.P.; Szilder, K.; Maw, S.; Morris, A. A model of ice friction for skeleton sled runners. In Proceedings of the The Twenty-fourth International Ocean and Polar Engineering Conference; Busan, Korea, 15 June 2014. [Google Scholar]

- Hertz, H. Uber die beruhrung fester elastischer korper (On the contact of elastic solids). J. Reine Angew. Math. 1882, 92, 156–171. (In German) [Google Scholar]

- Spagni, A.; Berardo, A.; Marchetto, D.; Gualtieri, E.; Pugno, N.M.; Valeri, S. Friction of rough surfaces on ice: Experiments and modeling. Wear 2016, 368–369, 258–266. [Google Scholar] [CrossRef]

- Scherge, M.; Böttcher, R.; Spagni, A.; Marchetto, D. High-Speed measurements of steel–ice friction: Experiment vs. calculation. Lubricants 2018, 6, 26. [Google Scholar] [CrossRef]

- Jansons, E.; Lungevičs, J.; Jerāne, I.; Gross, K.A. A Smaller bearing ratio, as a surface texture measure, promotes faster sliding on ice. J. Biotribol. 2021, 143, 111801. [Google Scholar] [CrossRef]

- Abbott, E.J.; Firestone, F.A. Specifying surface quality: A method based on accurate measurement and comparison. Mech. Eng. 1933, 55, 569–572. [Google Scholar] [CrossRef][Green Version]

- Hanna, G.; Jon, W.; Barnes, W.P.J. Adhesion and Detachment of the toe pads of tree frogs. J. Exp. Biol. 1991, 155, 103–125. [Google Scholar] [CrossRef]

- Brian, D.; Bharat, B. Shark-skin surfaces for fluid-drag reduction in turbulent flow: A review. Philos. Trans. R. Soc. A Math. Phys. Eng. Sci. 2010, 368, 4775–4806. [Google Scholar] [CrossRef]

- Motta, P.; Habegger, M.L.; Lang, A.; Hueter, R.; Davis, J. Scale morphology and flexibility in the shortfin mako Isurus oxyrinchus and the blacktip shark Carcharhinus limbatus. J. Morphol. 2012, 273, 1096–1110. [Google Scholar] [CrossRef] [PubMed]

- Bixler, G.D.; Bhushan, B. Bioinspired rice leaf and butterfly wing surface structures combining shark skin and lotus effects. Soft Matter 2012, 8, 11271–11284. [Google Scholar] [CrossRef]

- De-yuan, Z.; Yue-hao, L.; Xiang, L.I.; Hua-wei, C. Numerical simulation and experimental study of drag-reducing surface of a real shark skin. J. Hydrodyn. 2011, 23, 204–211. [Google Scholar] [CrossRef]

- Bhushan, B. Biomimetics inspired surfaces for drag reduction and oleophobicity/philicity. Beilstein J. Nanotechnol. 2011, 2, 66–84. [Google Scholar] [CrossRef]

- Zhao, D.-Y.; Huang, Z.-P.; Wang, M.-J.; Wang, T.; Jin, Y. Vacuum casting replication of micro-riblets on shark skin for drag-reducing applications. J. Mater. Process. Technol. 2012, 212, 198–202. [Google Scholar] [CrossRef]

- Mielonen, K.; Jiang, Y.; Voyer, J.; Diem, A.; Hillman, L.; Suvanto, M.; Pakkanen, T.A. Sliding friction of hierarchically micro-micro textextured polymer surfaces on ice. Cold Reg. Sci. Technol. 2019, 163, 8–18. [Google Scholar] [CrossRef]

- Scherge, M.; Böttcher, R.; Richter, M.; Gurgel, U. High-speed ice friction experiments under lab conditions: On the influence of speed and normal force. ISRN Tribol. 2013, 2013, 703202. [Google Scholar] [CrossRef]

- Rohm, S.; Hasler, M.; Knoflach, C.; Van Putten, J.; Unterberger, S.H.; Schindelwig, K.; Lackner, R.; Nachbauer, W. Friction between steel and snow in dependence of the steel roughness. Tribol. Lett. 2015, 59, 12552. [Google Scholar] [CrossRef]

- Lungevics, J.; Jansons, E.; Gross, K.A. An Ice Track Equipped with Optical Sensors for Determining the Influence of Experimental Conditions on the Sliding Velocity. Latv. J. Phys. Tech. Sci. 2018, 55, 64–75. [Google Scholar] [CrossRef]

- Gross, K.A.; Lungevics, J.; Zavickis, J.; Pluduma, L. A comparison of quality control methods for scratch detection on polished metal surfaces. Measurement 2018, 117, 397–402. [Google Scholar] [CrossRef]

- ISO 25178-2:2012: Geometric Product Specifications (GPS)–Surface texture: Areal–Part 2: Terms, Definitions and Surface Tecture Parameters. Available online: https://www.google.com.hk/url?sa=t&rct=j&q=&esrc=s&source=web&cd=&cad=rja&uact=8&ved=2ahUKEwjG9IO3sMTzAhUYad4KHSY7DPMQFnoECAgQAQ&url=https%3A%2F%2Fwww.iso.org%2Fstandard%2F42785.html&usg=AOvVaw3djfoVhu7A6Ftev2Xxtm7g (accessed on 12 October 2021).

- Jansons, E.; Irbe, M.; Gross, K.A. Influence of weather conditions on sliding over ice at a push-start training facility. Biotribology 2021, 25, 100152. [Google Scholar] [CrossRef]

- Kim, S.; Kang, H.; Kim, D.; Lee, Y.-Z.; Lee, J. Measurement of sliding friction coefficient of micro-line patterned surfaces on ice. Appl. Phys. Lett. 2017, 111, 211601. [Google Scholar] [CrossRef]

- Kietzig, A.-M.; Hatzikiriakos, S.G.; Englezos, P. Ice friction: The effects of surface roughness, structure, and hydrophobicity. J. Appl. Phys. 2009, 106, 024303. [Google Scholar] [CrossRef]

- Hutchings, I.M. Leonardo da Vinci’s studies of friction. Wear 2016, 360–361, 51–66. [Google Scholar] [CrossRef]

- Ahmmed, K.M.T.; Grambow, C.; Kietzig, A.-M. Fabrication of micro/nano structures on metals by femtosecond laser micromachining. Micromachines 2014, 5, 1219–1253. [Google Scholar] [CrossRef]

- Kietziga, A.-M.; Mirvakilia, M.N.; Kamalb, S.; Englezosa, P.; Hatzikiriakosa, S.G. Nanopatterned metallic surfaces: Their wettability and impact on ice friction. J. Adhes. Sci. Technol. 2011, 25, 1293–1303. [Google Scholar] [CrossRef]

- Jendoubi, H.; Smerdova, O.; Brunetière, N. Unexpected frictional behavior of laser-textured hydrophobic surfaces. Lubricants 2021, 9, 31. [Google Scholar] [CrossRef]

- Jaber, S.B.; Hamilton, A.; Xu, Y.; Kartal, M.E.; Gadegaard, N.; Mulvihill, D.M. Friction of flat and micropatterned interfaces with nanoscale roughness. Tribol. Int. 2021, 153, 106563. [Google Scholar] [CrossRef]

- Huang, Y.; Zhang, X.; Ma, Z.; Zhou, Y.; Zheng, W.; Zhou, J.; Sun, C.Q. Hydrogen-bond relaxation dynamics: Resolving mysteries of water ice. Coord. Chem. Rev. 2015, 285, 109–165. [Google Scholar] [CrossRef]

- Zhang, X.; Huang, Y.; Ma, Z.; Niu, L.; Sun, C.Q. From ice superlubricity to quantum friction: Electronic repulsivity and phononic elasticity. Friction 2015, 3, 294–319. [Google Scholar] [CrossRef]

- Weber, B.; Nagata, Y.; Ketzetzi, S.; Tang, F.; Smit, W.J.; Bakker, H.J.; Backus, E.H.G.; Bonn, M.; Bonn, D. Molecular insight into the slipperiness of ice. J. Phys. Chem. Lett. 2018, 9, 2838–2842. [Google Scholar] [CrossRef] [PubMed]

- Celano, U.; Hantschel, T.; Giammaria, G.; Chintala, R.C.; Conard, T.; Bender, H.; Vandervorst, W. Evaluation of the electrical contact area in contact-mode scanning probe microscopy. J. Appl. Phys. 2015, 117, 214305. [Google Scholar] [CrossRef]

- Weber, B.; Suhina, T.; Junge, T.; Pastewka, L.; Brouwer, A.M.; Bonn, D. Molecular probes reveal deviations from Amontons’ law in multi-asperity frictional contacts. Nat. Commun. 2018, 9, 888. [Google Scholar] [CrossRef]

- Petrova, D.; Weber, B.; Allain, C.; Audebert, P.; Bonn, D.; Brouwer, A.M. Fast 3D microscopy imaging of contacts between surfaces using a fluorescent liquid. ACS Appl. Mater. Interfaces 2018, 10, 40973–40977. [Google Scholar] [CrossRef]

- Poirier, L.; Lozowski, E.P.; Thompson, R.I. Ice hardness in winter sports. Cold Reg. Sci. Technol. 2011, 67, 129–134. [Google Scholar] [CrossRef]

- Liefferink, R.W.; Hsia, F.-C.; Weber, B.; Bonn, D. Friction on ice: How temperature, pressure, and speed control the slipperiness of ice. Phys. Rev. X 2021, 11, 011025. [Google Scholar] [CrossRef]

- Seymour-Pierce, A.; Lishman, B.; Sammonds, P. Recrystallization and damage of ice in winter sports. Philos. Trans. R. Soc. A Math. Phys. Eng. Sci. 2017, 375, 20150353. [Google Scholar] [CrossRef]

- Lungevics, J.; Jansons, E.; Boiko, I.; Velkavrh, I.; Voyer, J.; Wright, T. A holistic approach towards surface topography analyses for ice tribology applications. Front. Mech. Eng. 2021, 9, 691485. [Google Scholar] [CrossRef]

- Irbe, M.; Gross, K.A.; Viba, J.; Cerpinska, M. Unveiling ice friction and aerodynamic drag at the initial stage of sliding on ice: Faster sliding in winter sports. Tribol. Int. 2021, 160, 106967. [Google Scholar] [CrossRef]

- Link, J.M.; Salinas, E.Y.; Hu, J.C.; Athanasiou, K.A. The tribology of cartilage: Mechanisms, experimental techniques, and relevance to translational tissue engineering. Clin. Biomech. 2020, 79, 104880. [Google Scholar] [CrossRef] [PubMed]

| Conditions | Milled Block | Laser-Machined Blocks | ||

|---|---|---|---|---|

| Milled | Repolished | Ice1 | Ice2 | |

| Air humidity | 65% | 63% | 68% | 63% |

| Air temperature | −1.0 °C | −3.0 °C | −1.2 °C | −4.3 °C |

| Ice temperature | −4.0 °C | −8.0 °C | −2.2 °C | −7.8 °C |

| Texture Parameters | |||||

|---|---|---|---|---|---|

| Sa Nm | Ssk | Sku | Spd pks/mm2 | Spc 1/m | |

| Laser-grooved block, along pileups | |||||

| 50 μm | 581.1 | 1.04 | 3.53 | - | - |

| 100 μm | 65.3 | 0.15 | 5.03 | - | - |

| 150 μm | 49.4 | 1.23 | 8.51 | - | - |

| Laser-grooved block, polished zone | |||||

| 50 μm | 7.7 | −0.02 | 3.09 | 7971 | 0.029 |

| 100 μm | 6.3 | −0.09 | 2.97 | 5440 | 0.026 |

| 150 μm | 6.4 | 0.02 | 2.89 | 3823 | 0.021 |

| Milling-grooved block | |||||

| polished | 13.4 | −0.96 | 10.7 | 20654 | 0.126 |

| Environmental Conditions | Sliding Block Surface | Sliding | Error | |||

|---|---|---|---|---|---|---|

| Control | Tice (°C) | Preparation (Groove Width) | Form (mm) | Sa (mm) | Speed (m/s) | (%) |

| w/o enclosure | −4.0 | milled 400 mm | 2 | - | - | 0.96 |

| “ | −8.0 | milled 400 mm, polished | 2 | 13 | 2.216 | 0.80 |

| enclosure | −2.2 | polished, laser 50 mm | 16 | 581 | 2.101 | 0.33 |

| “ | −2.2 | “ 100 mm | 12 | 65 | 2.139 | 0.70 |

| “ | −2.2 | “ 150 mm | 10 | 49 | 2.187 | 0.36 |

| “ | −7.8 | “ 50 mm | 16 | 581 | 2.159 | 0.55 |

| “ | −7.8 | “ 100 mm | 12 | 65 | 2.181 | 0.50 |

| “ | −7.8 | “150 mm | 10 | 49 | 2.220 | 0.22 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gross, K.A.; Lungevics, J.; Jansons, E.; Jerane, I.; Wood, M.J.; Kietzig, A.-M. Surface Hierarchy: Macroscopic and Microscopic Design Elements for Improved Sliding on Ice. Lubricants 2021, 9, 103. https://doi.org/10.3390/lubricants9100103

Gross KA, Lungevics J, Jansons E, Jerane I, Wood MJ, Kietzig A-M. Surface Hierarchy: Macroscopic and Microscopic Design Elements for Improved Sliding on Ice. Lubricants. 2021; 9(10):103. https://doi.org/10.3390/lubricants9100103

Chicago/Turabian StyleGross, Karlis Agris, Janis Lungevics, Ernests Jansons, Ilze Jerane, Michael J. Wood, and Anne-Marie Kietzig. 2021. "Surface Hierarchy: Macroscopic and Microscopic Design Elements for Improved Sliding on Ice" Lubricants 9, no. 10: 103. https://doi.org/10.3390/lubricants9100103

APA StyleGross, K. A., Lungevics, J., Jansons, E., Jerane, I., Wood, M. J., & Kietzig, A.-M. (2021). Surface Hierarchy: Macroscopic and Microscopic Design Elements for Improved Sliding on Ice. Lubricants, 9(10), 103. https://doi.org/10.3390/lubricants9100103