Experimental Investigation of the Mechanical and Surface Properties of Sub-Micron Carbon Spheres

Abstract

1. Introduction

2. Experimental Methods

2.1. Material Synthesis

2.2. Characterization Techniques

3. Results and Discussion

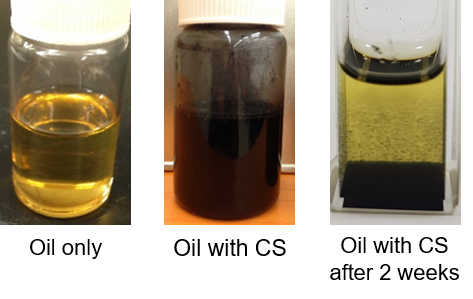

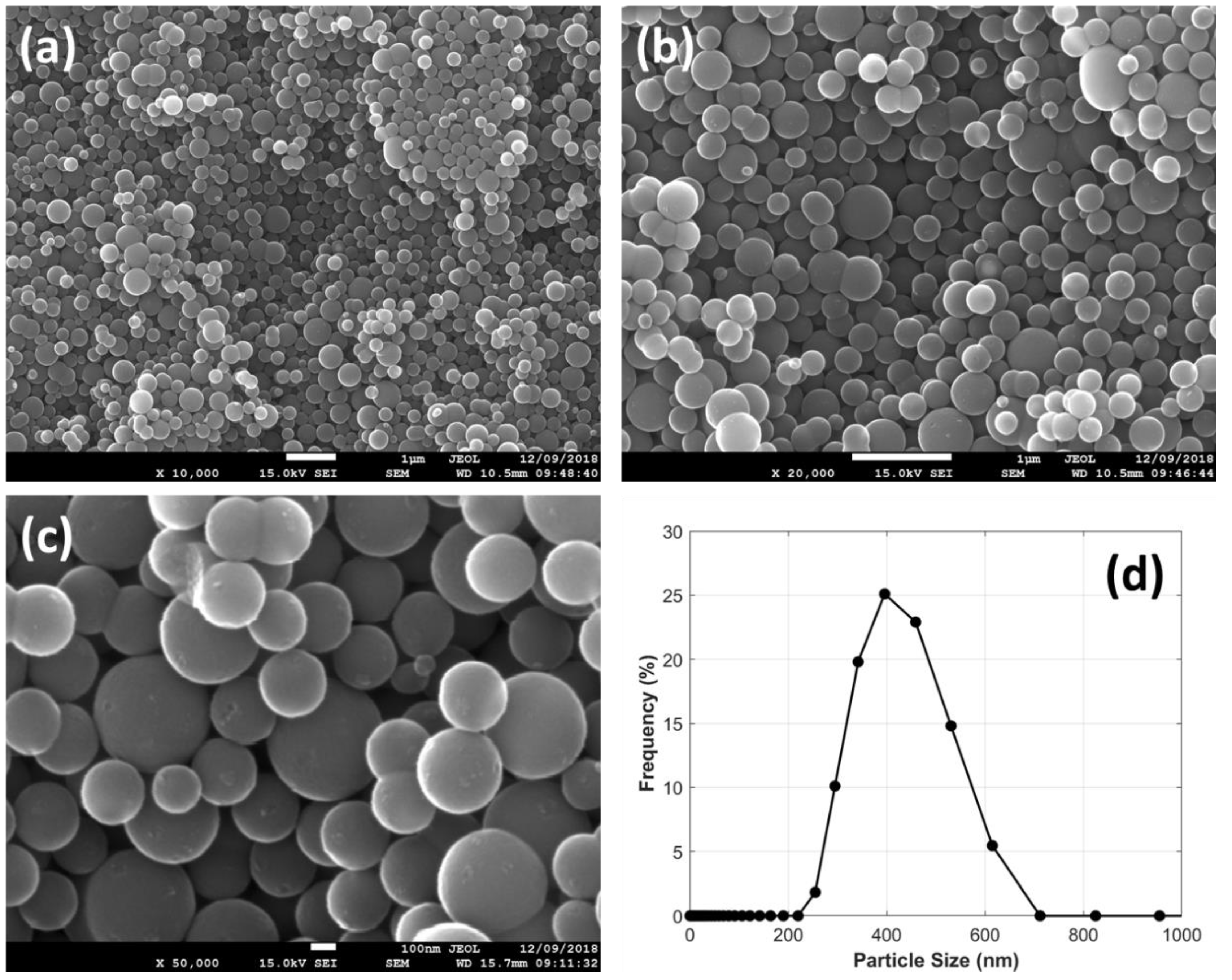

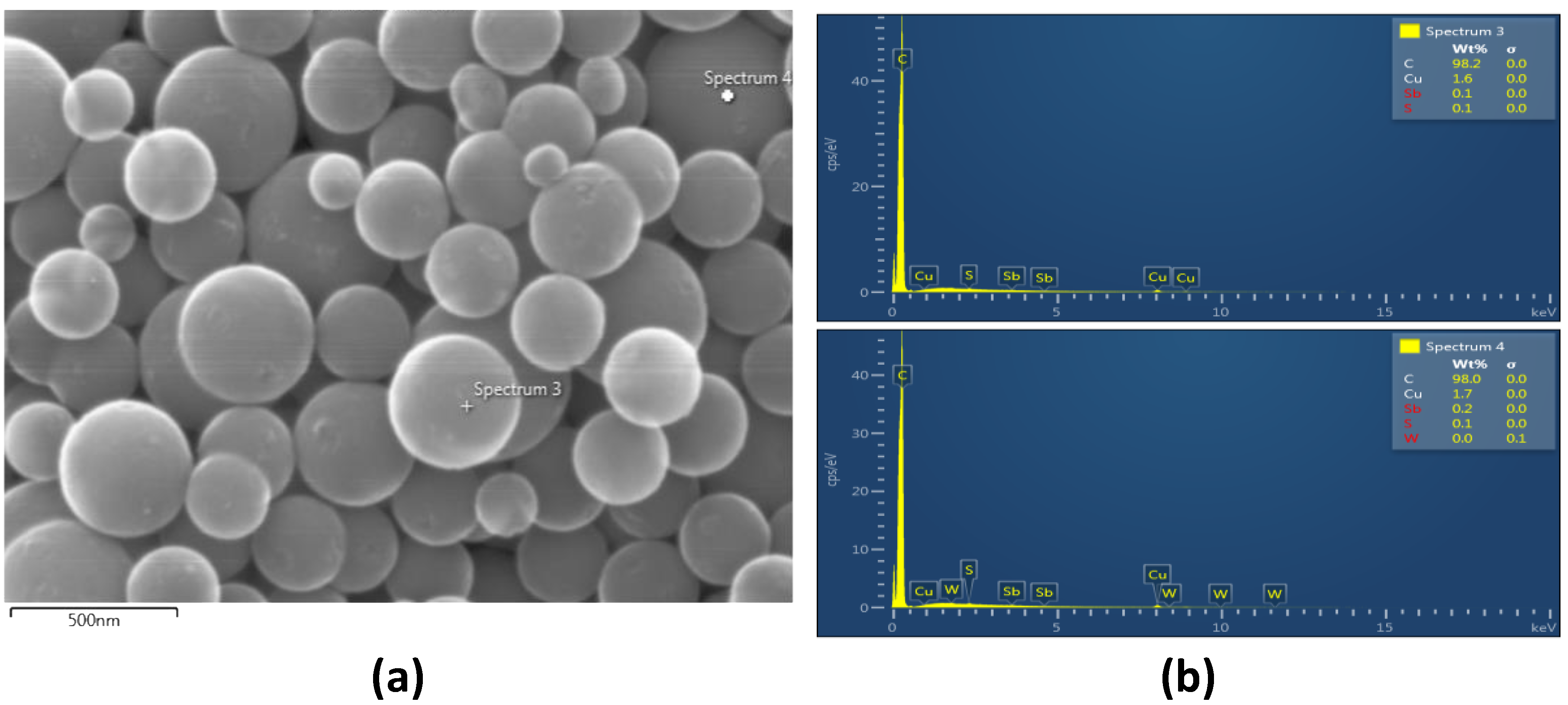

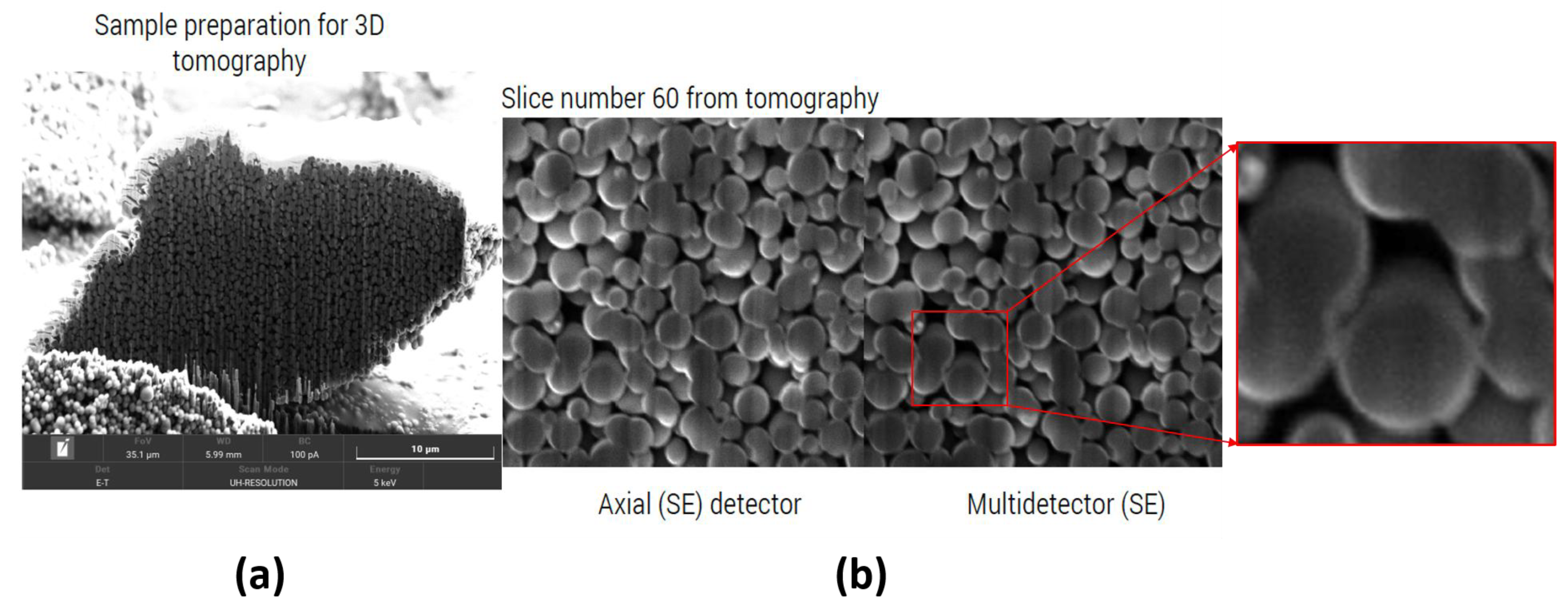

3.1. Scanning Electron Microscopy and EDS

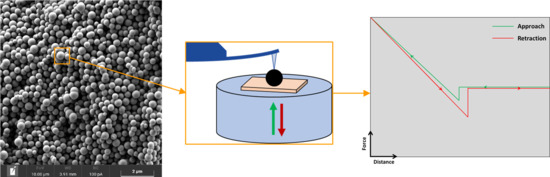

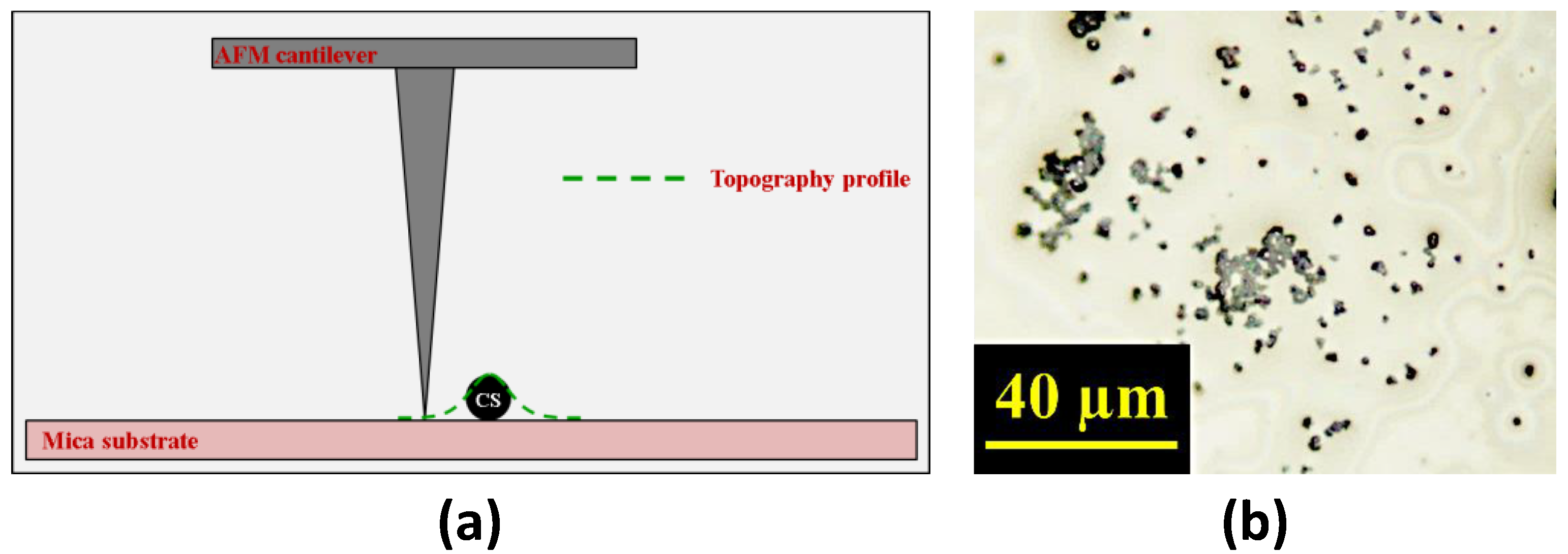

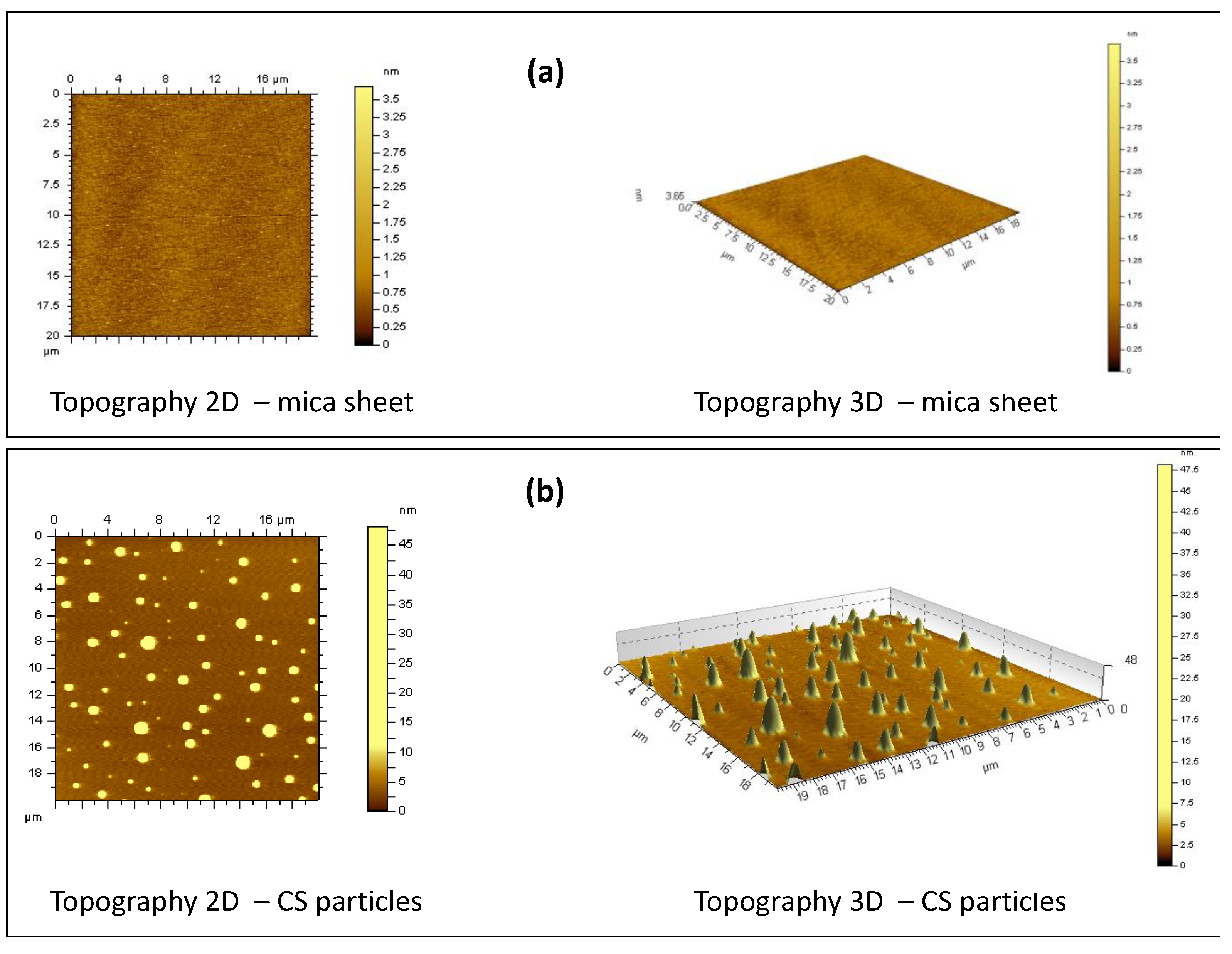

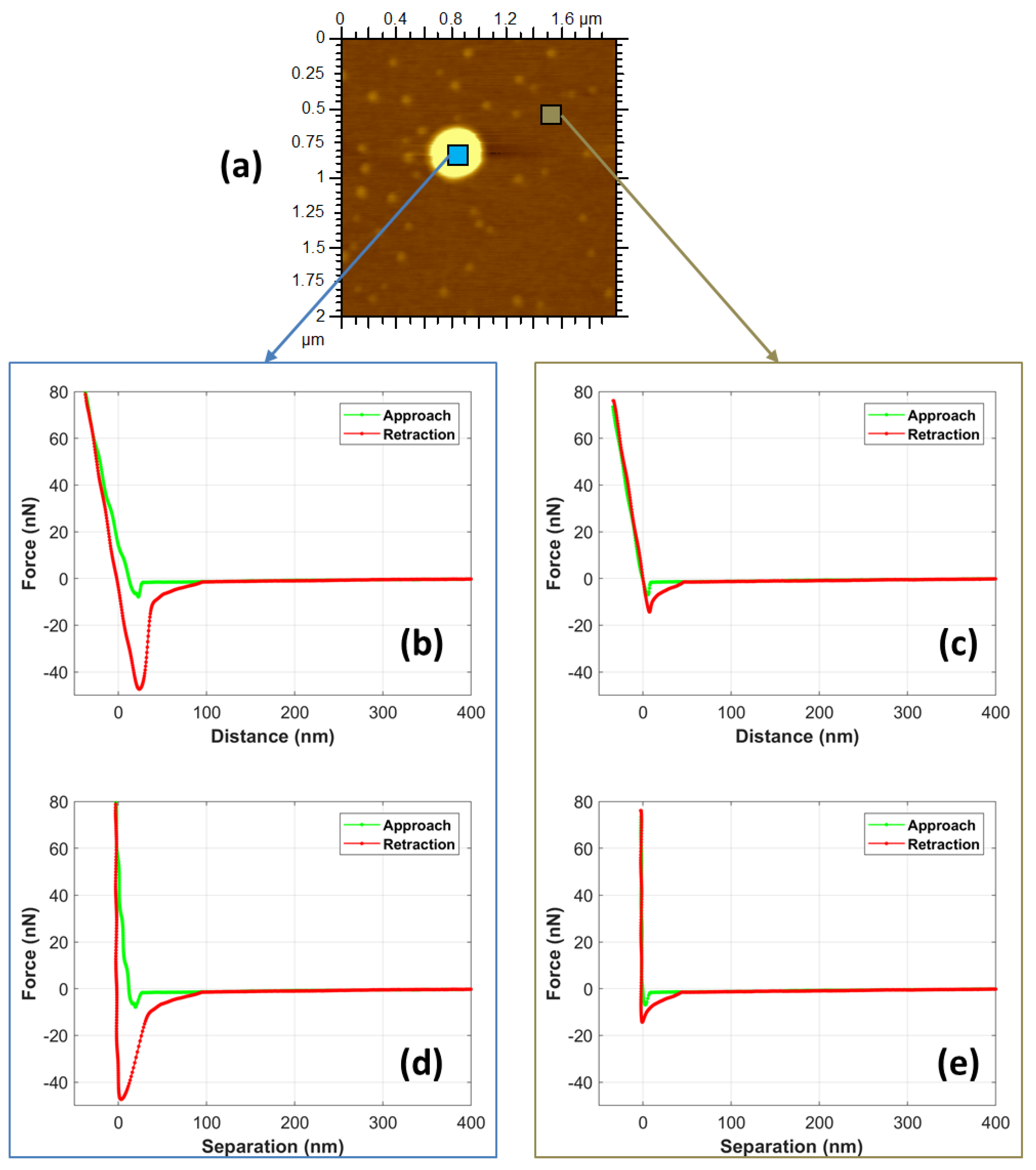

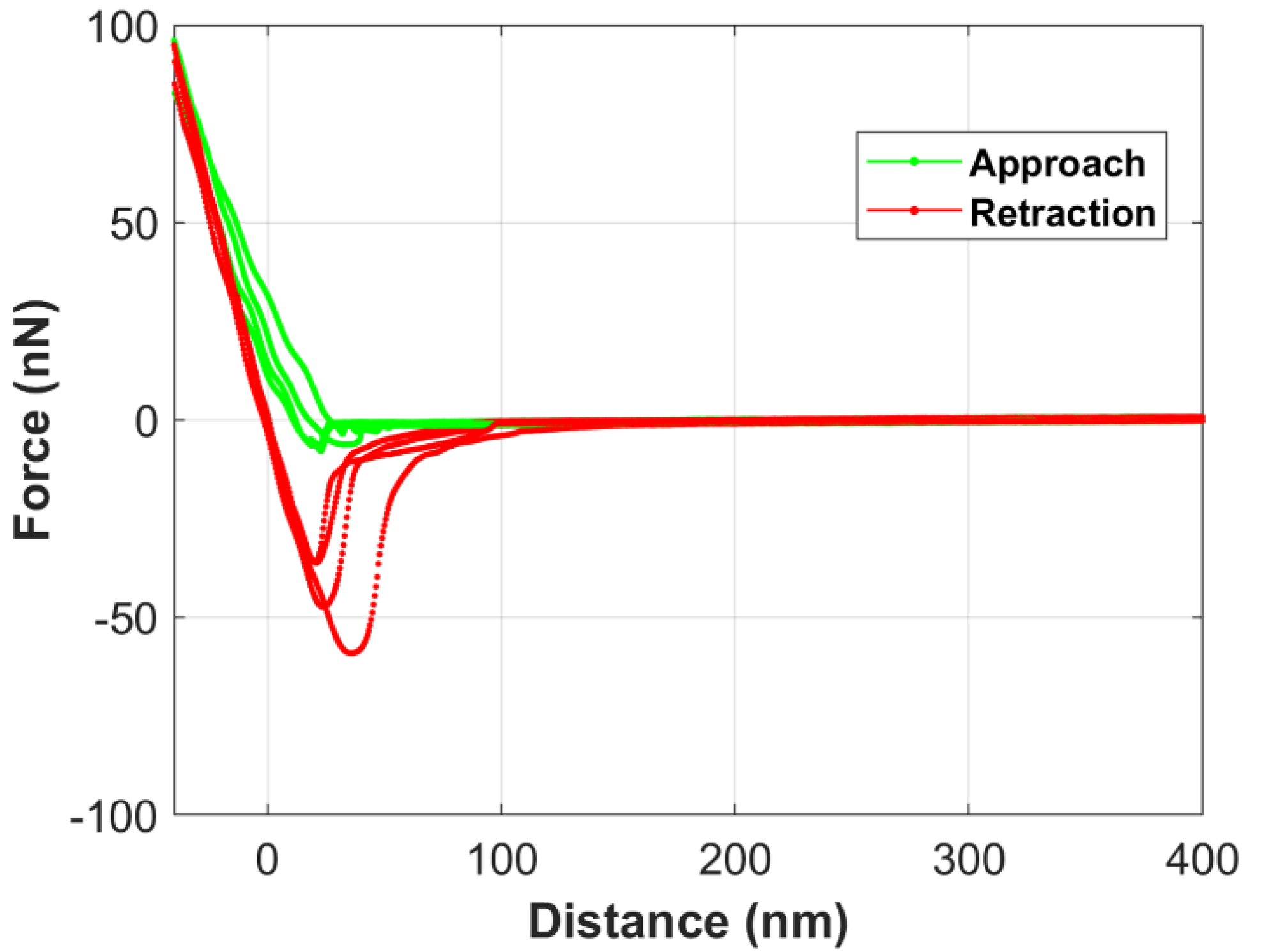

3.2. Atomic Force Microscopy

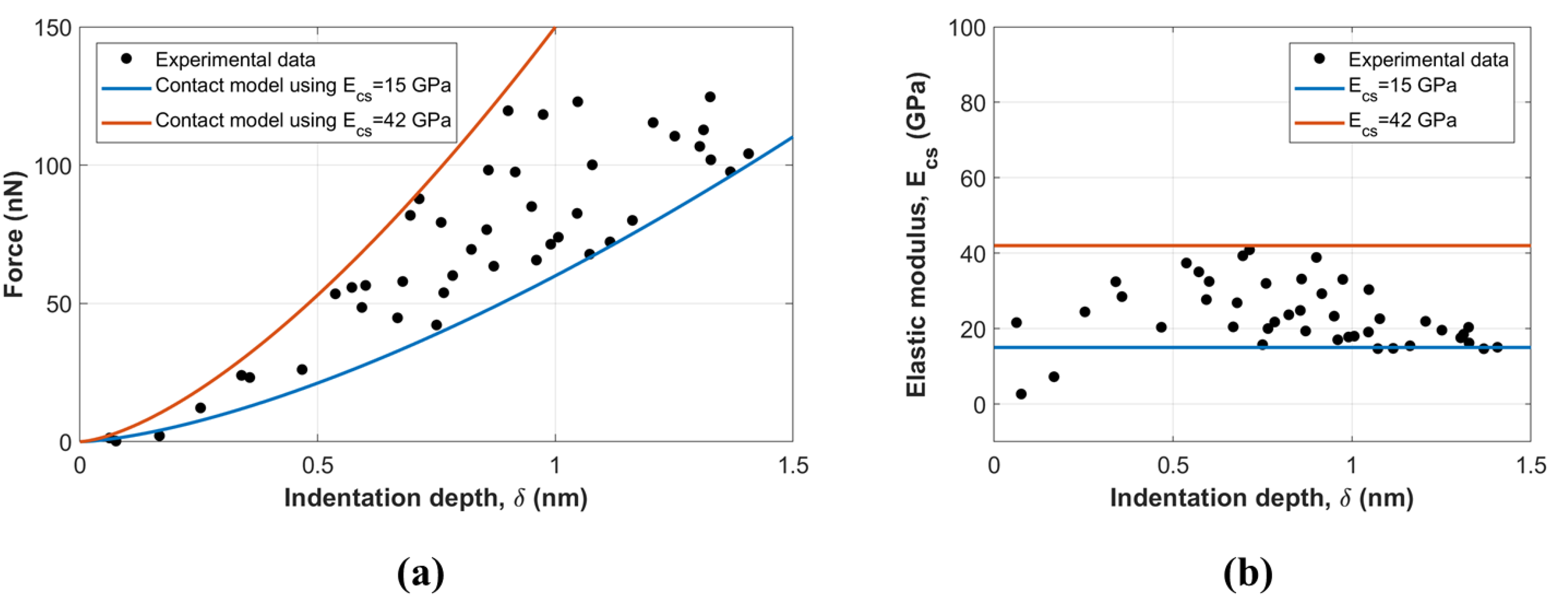

3.3. Nano-Indentation Experiments

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Cha, C.; Shin, S.R.; Annabi, N.; Dokmeci, M.R.; Khademhosseini, A. Carbon-Based Nanomaterials: Multifunctional Materials for Biomedical Engineering. ACS Nano 2013, 7, 2891–2897. [Google Scholar] [CrossRef] [PubMed]

- Zhai, W.; Srikanth, N.; Kong, L.B.; Zhou, K. Carbon nanomaterials in tribology. Carbon 2017, 119, 150–171. [Google Scholar] [CrossRef]

- Mauter, M.S.; Elimelech, M. Environmental applications of carbon-based nanomaterials. Environ. Sci. Technol. 2008, 42, 5843–5859. [Google Scholar] [CrossRef] [PubMed]

- Lu, G.; Lu, G.M.; Xiao, Z.M. Mechanical properties of porous materials. J. Porous Mater. 1999, 6, 359–368. [Google Scholar] [CrossRef]

- Yang, Y.H.; Li, W.Z. Radial elasticity of single-walled carbon nanotube measured by atomic force microscopy. Appl. Phys. Lett. 2011, 98, 041901. [Google Scholar] [CrossRef]

- Cesano, F.; Cravanzola, S.; Brunella, V.; Scarano, D. Porous carbon spheres from poly (4-ethylstyrene-co-divinylbenzene: Role of ZnCl2 and KOH agents in affecting porosity, surface area and mechanical properties. Microporous Mesoporous Mater. 2019, 288, 109605. [Google Scholar] [CrossRef]

- Trompeta, A.F.A.; Koumoulos, E.P.; Kartsonakis, I.A.; Charitidis, C.A. Advanced characterization of by-product carbon film obtained by thermal chemical vapor deposition during CNT manufacturing. Manuf. Rev. 2017, 4, 7. [Google Scholar] [CrossRef]

- Pol, S.V.; Pol, V.G.; Sherman, D.; Gedanken, A. A solvent free process for the generation of strong, conducting carbon spheres by the thermal degradation of waste polyethylene terephthalate. Green Chem. 2009, 11, 448–451. [Google Scholar] [CrossRef]

- Etacheri, V.; Wang, C.; O’Connell, M.J.; Chan, C.K.; Pol, V.G. Porous carbon sphere anodes for enhanced lithium-ion storage. J. Mater. Chem. A 2015, 3, 9861–9868. [Google Scholar] [CrossRef]

- Fan, X.; Li, W.; Fu, H.; Zhu, M.; Wang, L.; Cai, Z.; Liu, J.; Li, H. Probing the function of solid nanoparticle structure under boundary lubrication. ACS Sustain. Chem. Eng. 2017, 5, 4223–4233. [Google Scholar] [CrossRef]

- Alazemi, A.A.; Etacheri, V.; Dysart, A.D.; Stacke, L.E.; Pol, V.G.; Sadeghi, F. Ultrasmooth submicrometer carbon spheres as lubricant additives for friction and wear reduction. ACS Appl. Mater. Interfaces 2015, 7, 5514–5521. [Google Scholar] [CrossRef] [PubMed]

- Alazemi, A.A.; Dysart, A.D.; Phuah, X.L.; Pol, V.G.; Sadeghi, F. MoS2 nanolayer coated carbon spheres as an oil additive for enhanced tribological performance. Carbon 2016, 110, 367–377. [Google Scholar] [CrossRef]

- Ivanova, O.; Williams, C.; Campbell, T. Additive manufacturing (AM) and nanotechnology: Promises and challenges. Rapid Prototyp. J. 2013, 19, 353–364. [Google Scholar] [CrossRef]

- Holmberg, K.; Erdemir, A. Global impact of friction on energy consumption, economy and environment. Fme Trans. 2015, 43, 181–185. [Google Scholar]

- Ren, B.; Gao, L.; Li, M.; Zhang, S.; Ran, X. Tribological properties and anti-wear mechanism of ZnO@ graphene core-shell nanoparticles as lubricant additives. Tribol. Int. 2020, 144, 106114. [Google Scholar] [CrossRef]

- Kotia, A.; Ghosh, G.K.; Srivastava, I.; Deval, P.; Ghosh, S.K. Mechanism for improvement of friction/wear by using Al2O3 and SiO2/Gear oil nanolubricants. J. Alloy. Compd. 2019, 782, 592–599. [Google Scholar] [CrossRef]

- Zhang, F.; Zhang, X.; Zhang, F.; Tang, G.; Li, C.; Xu, J. 3D/1D heterostructure of flower-like MoS2 nanospheres anchored on carbon nanotubes for enhanced friction and wear properties as oil additives. Mater. Res. Express 2020, 6, 1250f9. [Google Scholar] [CrossRef]

- Beheshti, A.; Huang, Y.; Ohno, K.; Blakey, I.; Stokes, J.R. Improving tribological properties of oil-based lubricants using hybrid colloidal additives. Tribol. Int. 2020, 144, 106130. [Google Scholar] [CrossRef]

- Akbulut, M. Nanoparticle-based lubrication systems. J. Powder Metall. Min. 2012, 1, 1–3. [Google Scholar] [CrossRef]

- Butt, H.J.; Cappella, B.; Kappl, M. Force measurements with the atomic force microscope: Technique, interpretation and applications. Surf. Sci. Rep. 2005, 59, 1–152. [Google Scholar] [CrossRef]

- Wagner, R.; Moon, R.; Pratt, J.; Shaw, G.; Raman, A. Uncertainty quantification in nanomechanical measurements using the atomic force microscope. Nanotechnology 2011, 22, 455703. [Google Scholar] [CrossRef] [PubMed]

- Wagner, R.; Moon, R.; Pratt, J.; Shaw, G.; Raman, A. Radial elasticity of multiwalled carbon nanotubes. Phys. Rev. Lett. 2005, 94, 175502. [Google Scholar]

- Lee, C.; Wei, X.; Kysar, J.W.; Hone, J. Measurement of the elastic properties and intrinsic strength of monolayer graphene. Science 2008, 321, 385–388. [Google Scholar] [CrossRef] [PubMed]

- Pol, V.G.; Shrestha, L.K.; Ariga, K. Tunable, Functional Carbon Spheres Derived from Rapid Synthesis of Resorcinol-Formaldehyde Resins. ACS Appl. Mater. Interfaces 2014, 6, 10649–10655. [Google Scholar] [CrossRef] [PubMed]

- Tze, W.; Wang, S.; Rials, T.; Pharr, G.; Kelley, S. Nanoindentation of wood cell walls: Continuous stiffness and hardness measurements. Compos. Part A Appl. Sci. Manuf. 2007, 38, 945–953. [Google Scholar] [CrossRef]

- Konnerth, J.; Gierlinger, N.; Keckes, J.; Gindl, W.; Gindl-Altmutter, W. Actual versus apparent within cell wall variability of nanoindentation results from wood cell walls related to cellulose microfibril angle. J. Mater. Sci. 2009, 44, 4399–4406. [Google Scholar] [CrossRef]

- Alazemi, A.A. Experimental Investigation of Friction Fundamentals at the Microscale; Purdue University: West Lafayette, IN, USA, 2017. [Google Scholar]

- Hertz, H. Ueber die Berührung fester elastischer Körper. J. Reine Angew. Math. 1882, 1882, 156–171. [Google Scholar]

- Guo, D.; Li, J.; Xie, G.; Wang, Y.; Luo, J. Elastic Properties of Polystyrene Nanospheres Evaluated with Atomic Force Microscopy: Size Effect and Error Analysis. Langmuir 2014, 30, 7206–7212. [Google Scholar] [CrossRef] [PubMed]

- Johnson, K.L.; Johnson, K.L. Contact Mechanics; Cambridge University Press: Cambridge, UK, 1987. [Google Scholar]

- Chizhik, S.A.; Huang, Z.; Gorbunov, V.V.; Myshkin, N.K.; Tsukruk, V.V. Micromechanical Properties of Elastic Polymeric Materials As Probed by Scanning Force Microscopy. Langmuir 1998, 14, 2606–2609. [Google Scholar] [CrossRef]

- Leyland, A.; Matthews, A. Design criteria for wear-resistant nanostructured and glassy-metal coatings. Surf. Coat. Technol. 2004, 177, 317–324. [Google Scholar] [CrossRef]

- Ashby, M.F.; Cebon, D. Materials selection in mechanical design. MRS Bull. 2005, 30, 995. [Google Scholar] [CrossRef]

| Hardness, H (GPa) | Reduced Modulus, Er (GPa) | Elastic Modulus of CS, Ecs (GPa) | |

|---|---|---|---|

| Mean | 1.2 | 16.6 | 16.5 |

| Standard Deviation | 0.6 | 4.7 | 4.8 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alazemi, A.A.; Dysart, A.D.; Pol, V.G. Experimental Investigation of the Mechanical and Surface Properties of Sub-Micron Carbon Spheres. Lubricants 2020, 8, 77. https://doi.org/10.3390/lubricants8070077

Alazemi AA, Dysart AD, Pol VG. Experimental Investigation of the Mechanical and Surface Properties of Sub-Micron Carbon Spheres. Lubricants. 2020; 8(7):77. https://doi.org/10.3390/lubricants8070077

Chicago/Turabian StyleAlazemi, Abdullah A., Arthur D. Dysart, and Vilas G. Pol. 2020. "Experimental Investigation of the Mechanical and Surface Properties of Sub-Micron Carbon Spheres" Lubricants 8, no. 7: 77. https://doi.org/10.3390/lubricants8070077

APA StyleAlazemi, A. A., Dysart, A. D., & Pol, V. G. (2020). Experimental Investigation of the Mechanical and Surface Properties of Sub-Micron Carbon Spheres. Lubricants, 8(7), 77. https://doi.org/10.3390/lubricants8070077