Elastohydrodynamic Lubrication

Abstract

1. Introduction

1.1. Classical Theory

1.2. Digression: Factors of 2: Sums and Averages

2. First Attempts

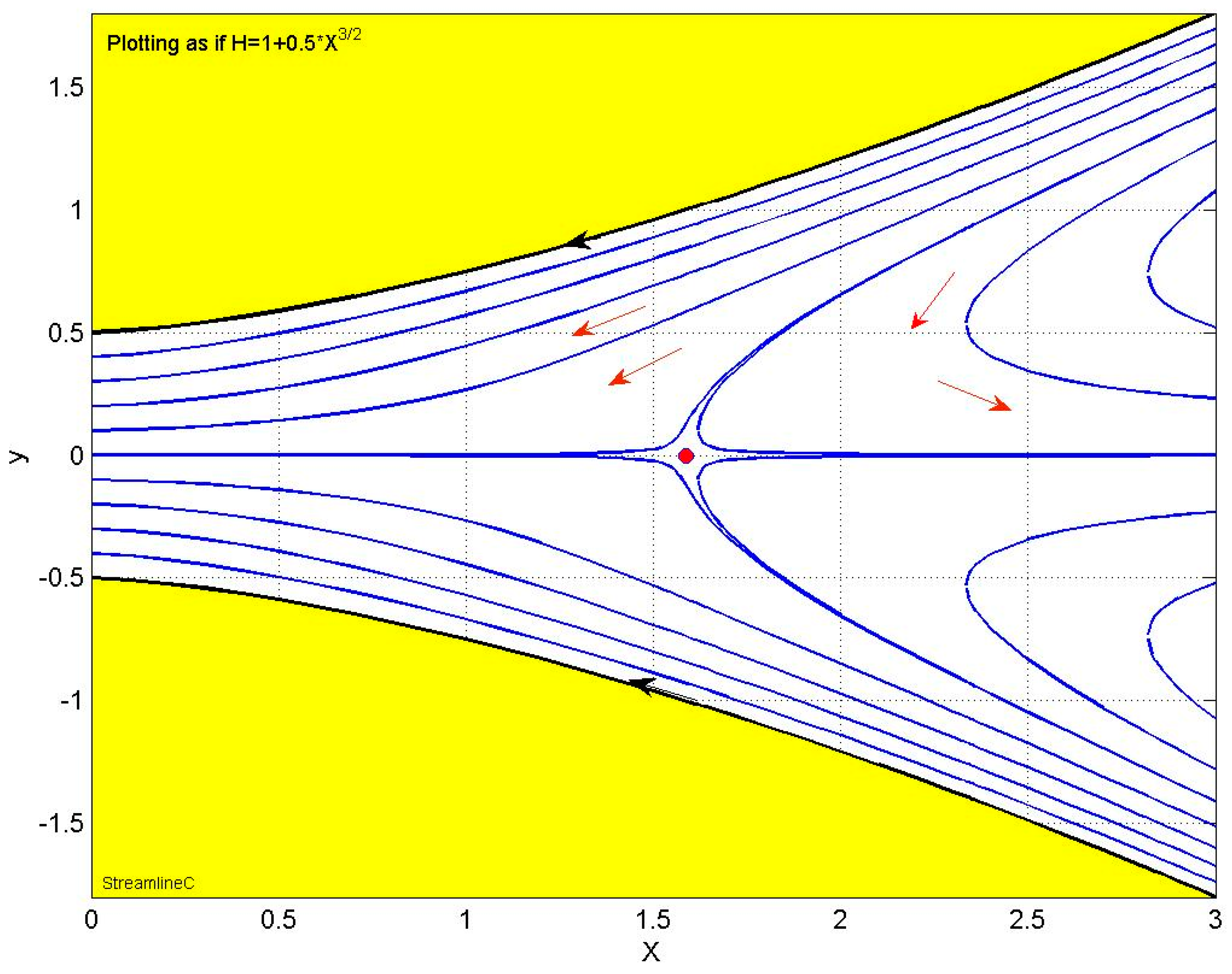

Kapitza’s Solution

3. The “Grubin” Theory and Its Extension

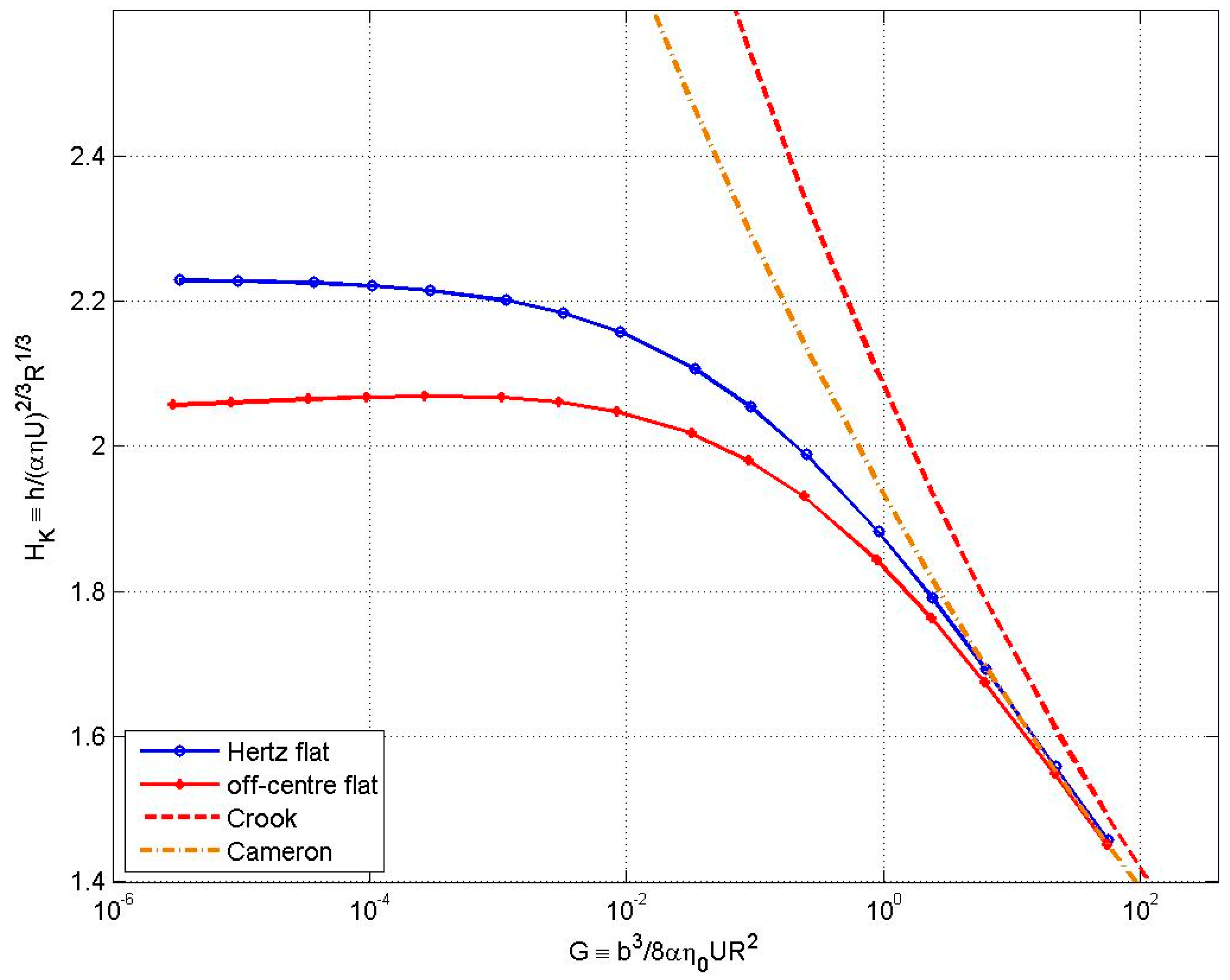

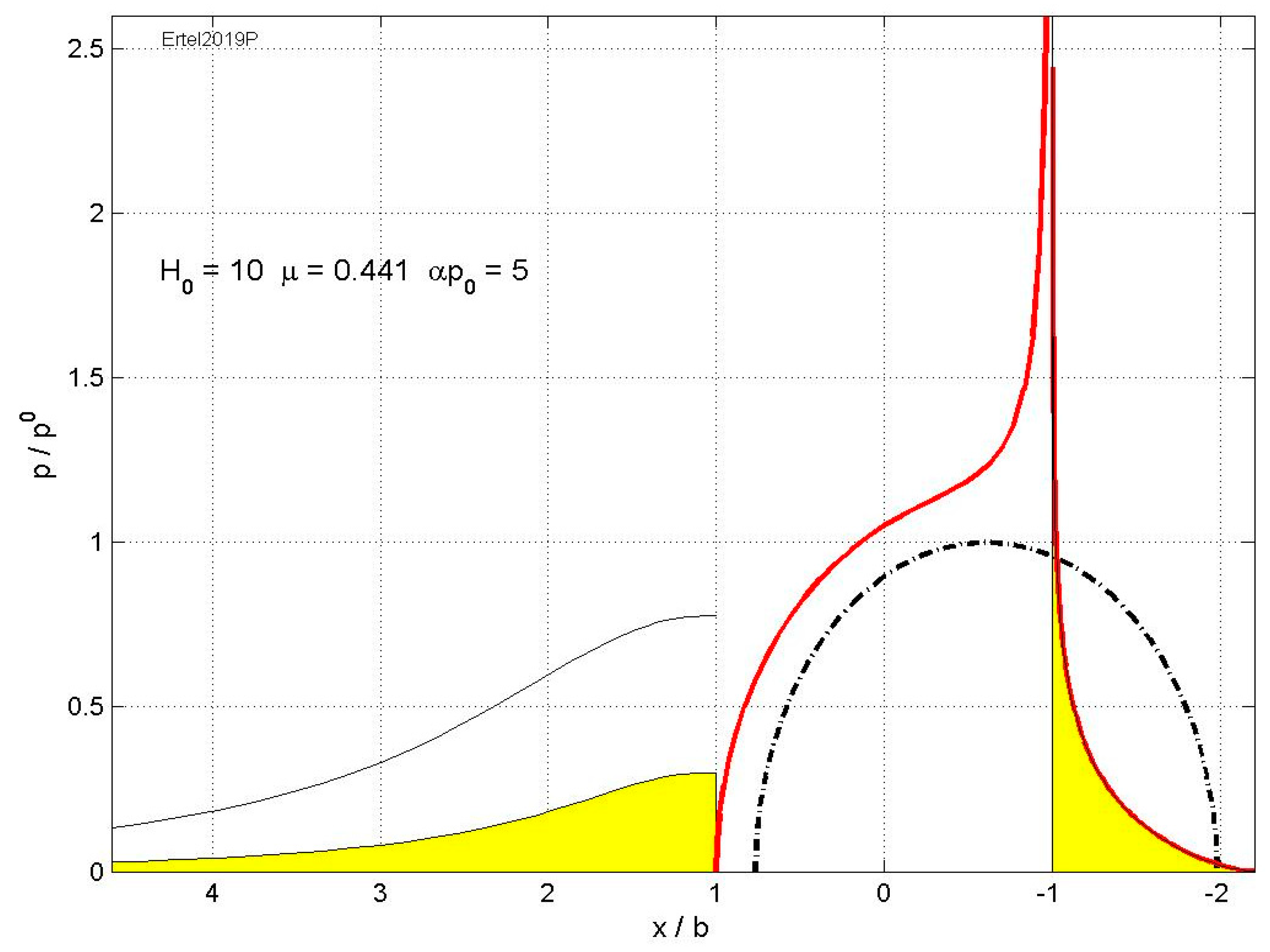

Extension to Ertel’s Theory

4. Numerical Solutions and Non-Dimensional Groups

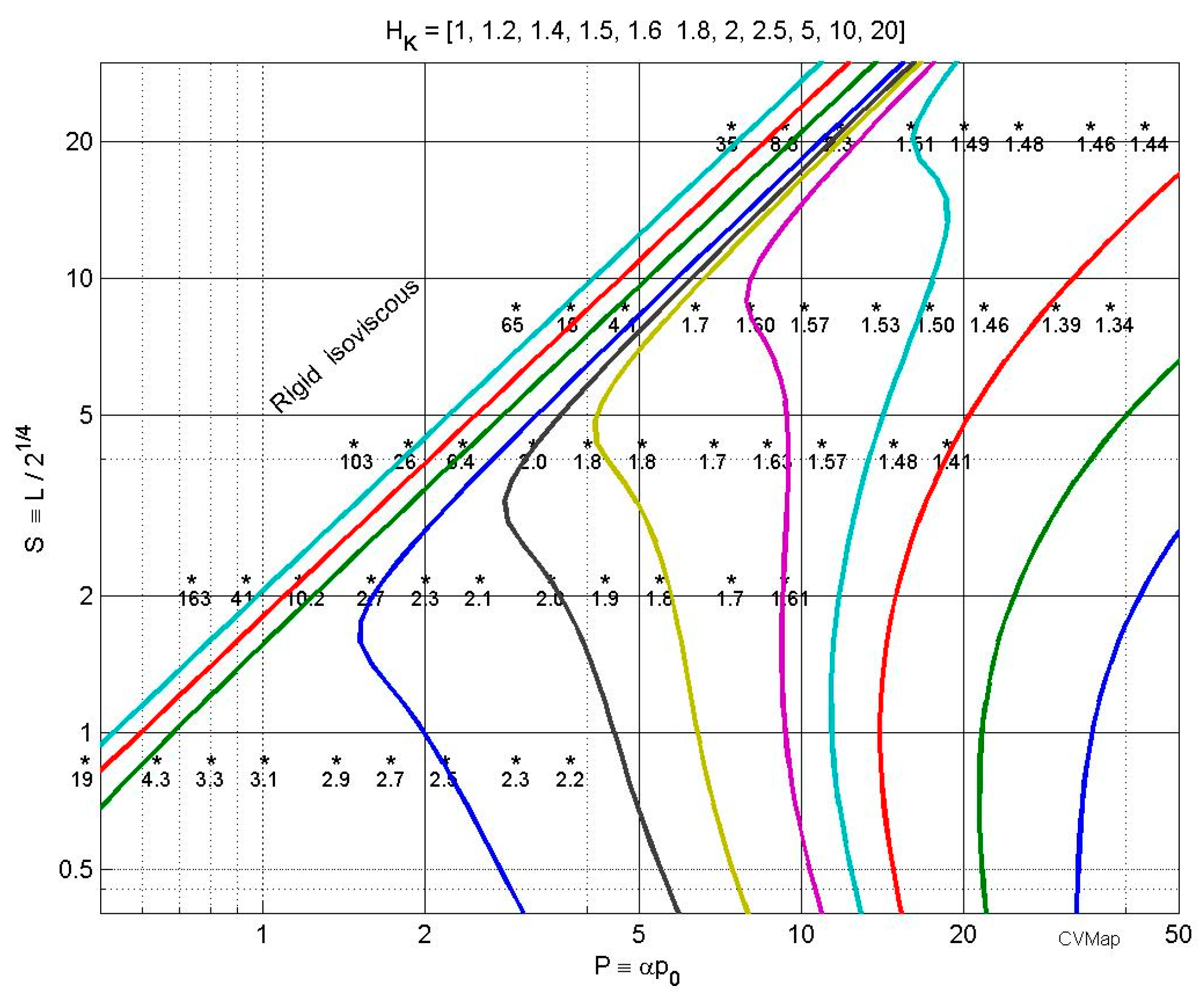

4.1. Regimes of Lubrication

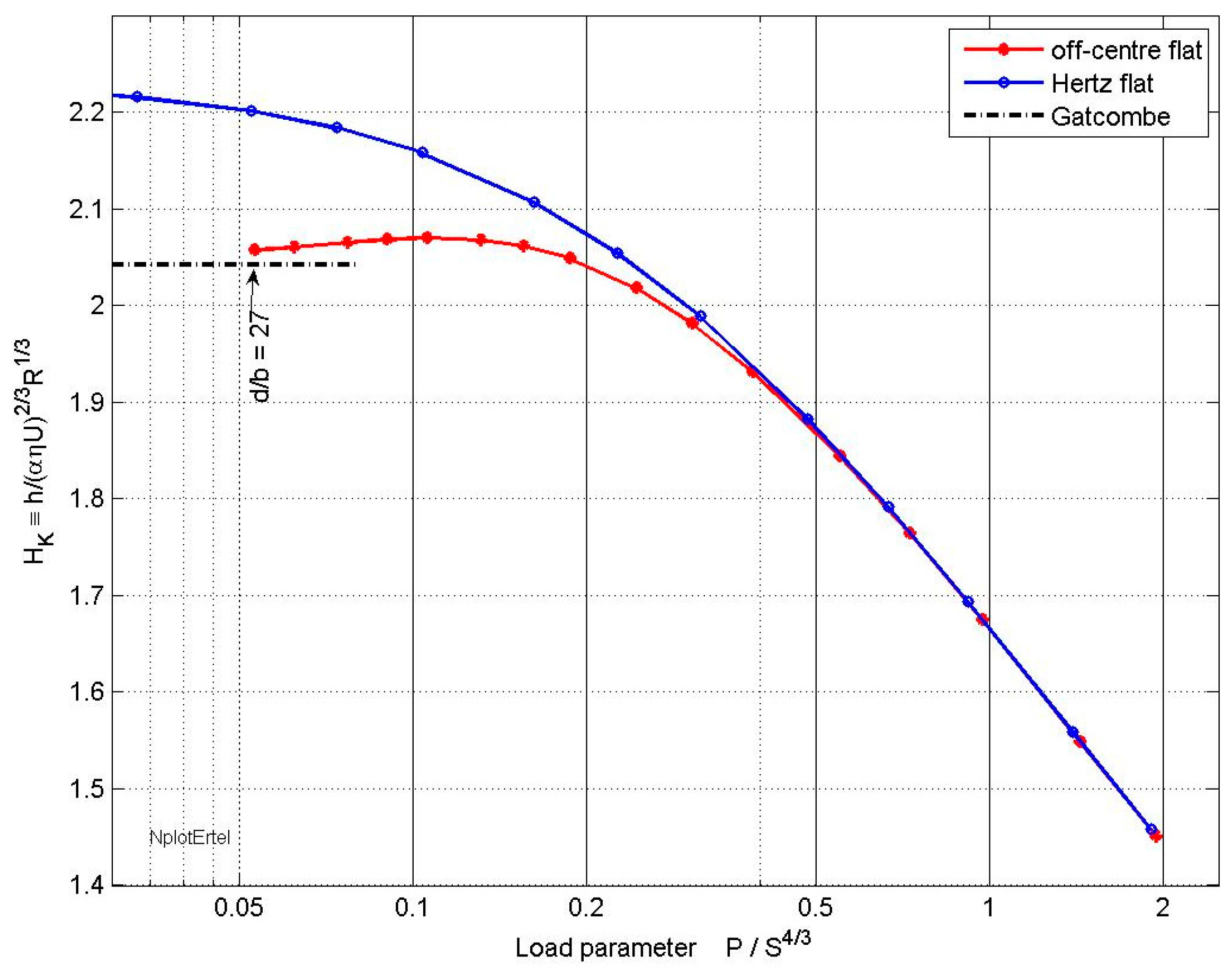

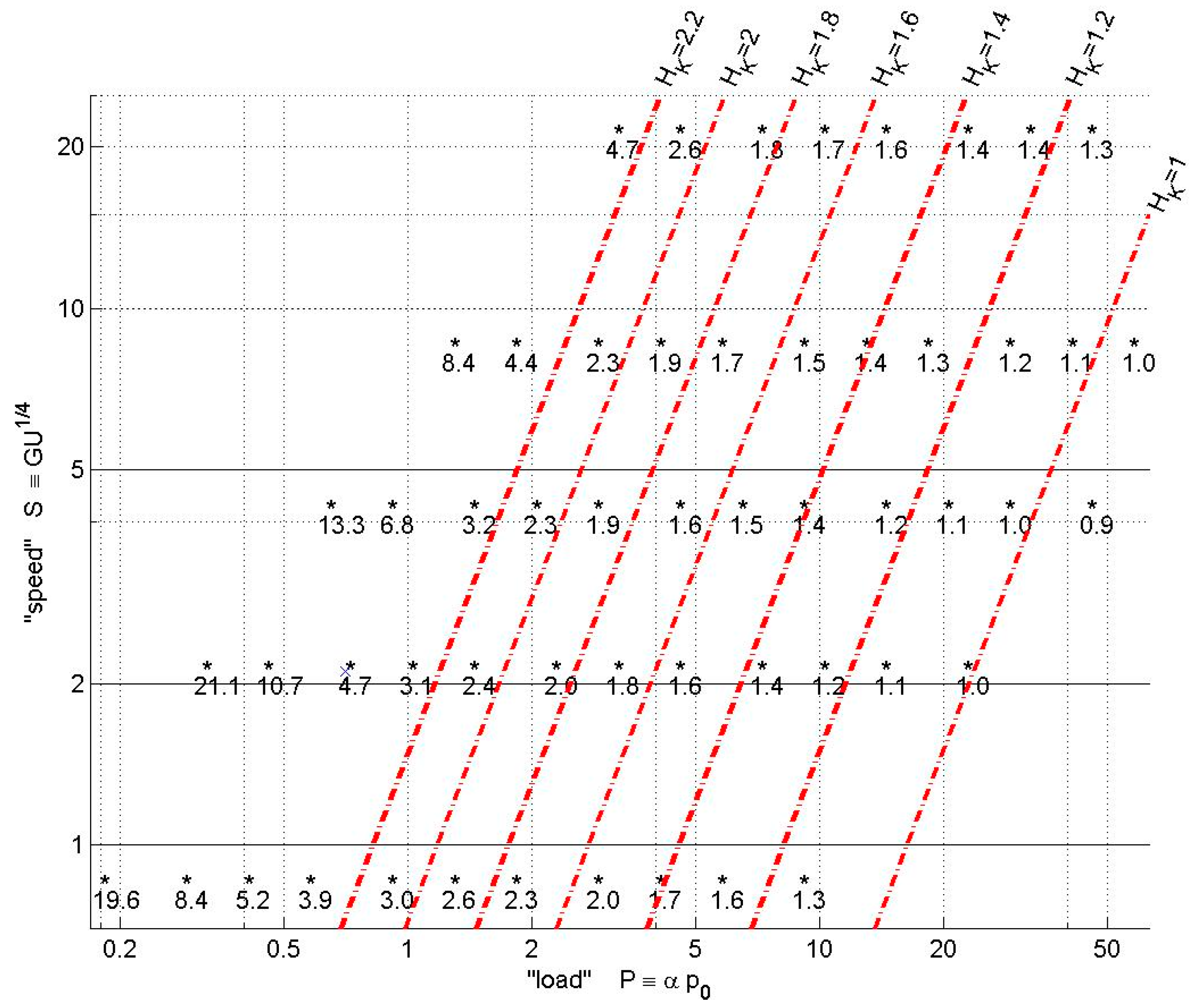

4.2. Line Contacts

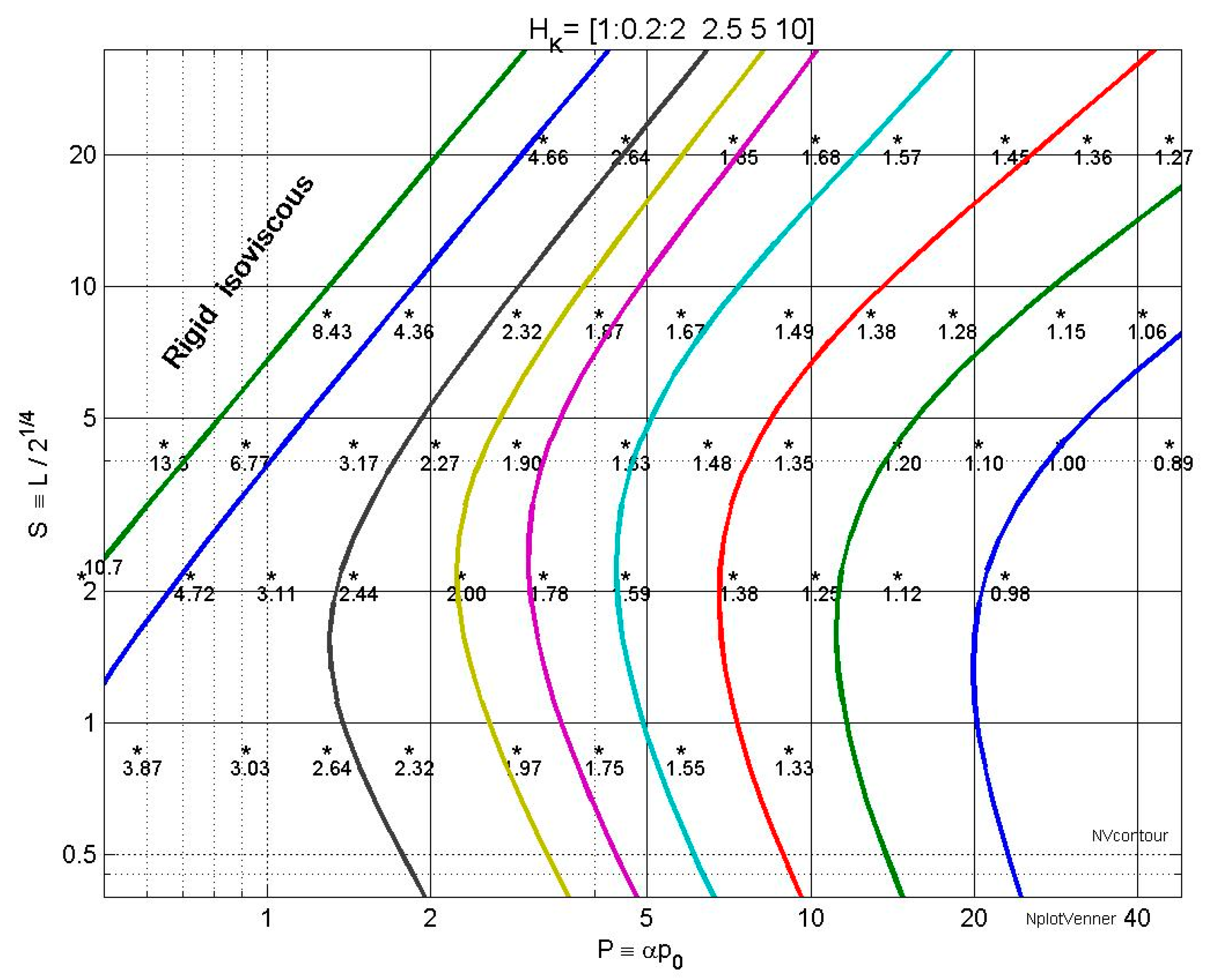

4.3. Circular Point Contacts

4.4. Elliptical Point Contacts and Side-Leakage

“Yet, Chittenden et al. varied the ellipticity ratio while keeping constant the dimensionless parameters (U, G, and W as defined by Hamrock and Dowson). Consequently, the actual load was varied in a large range together with the ellipticity, and the influence of the latter on film thickness could not be highlighted in itself.”

5. Experimental

5.1. Optical EHL

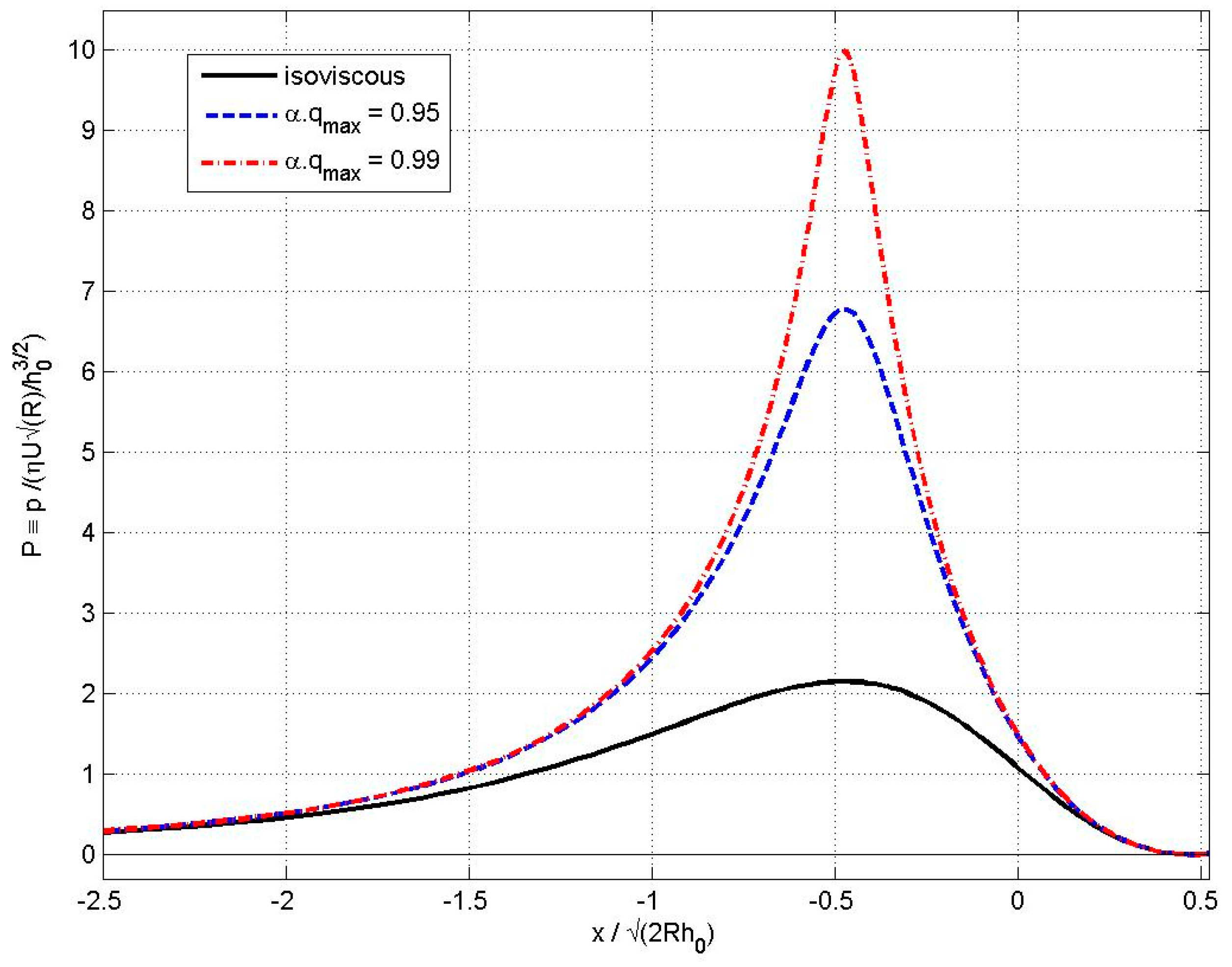

5.2. Pressure Spikes and Minimum Film Thickness

5.3. Effects of Sliding and Oil Properties

6. Surface Roughness

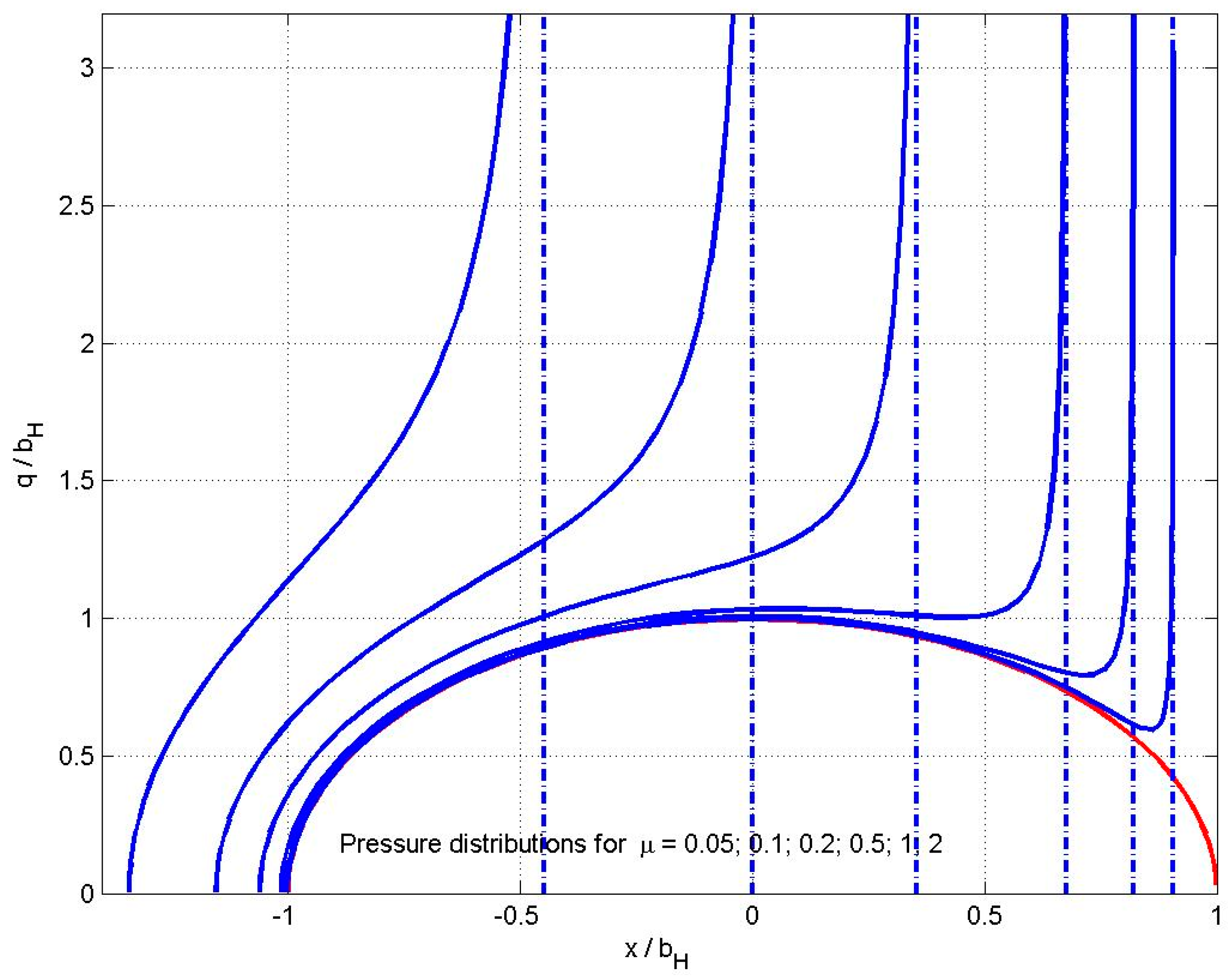

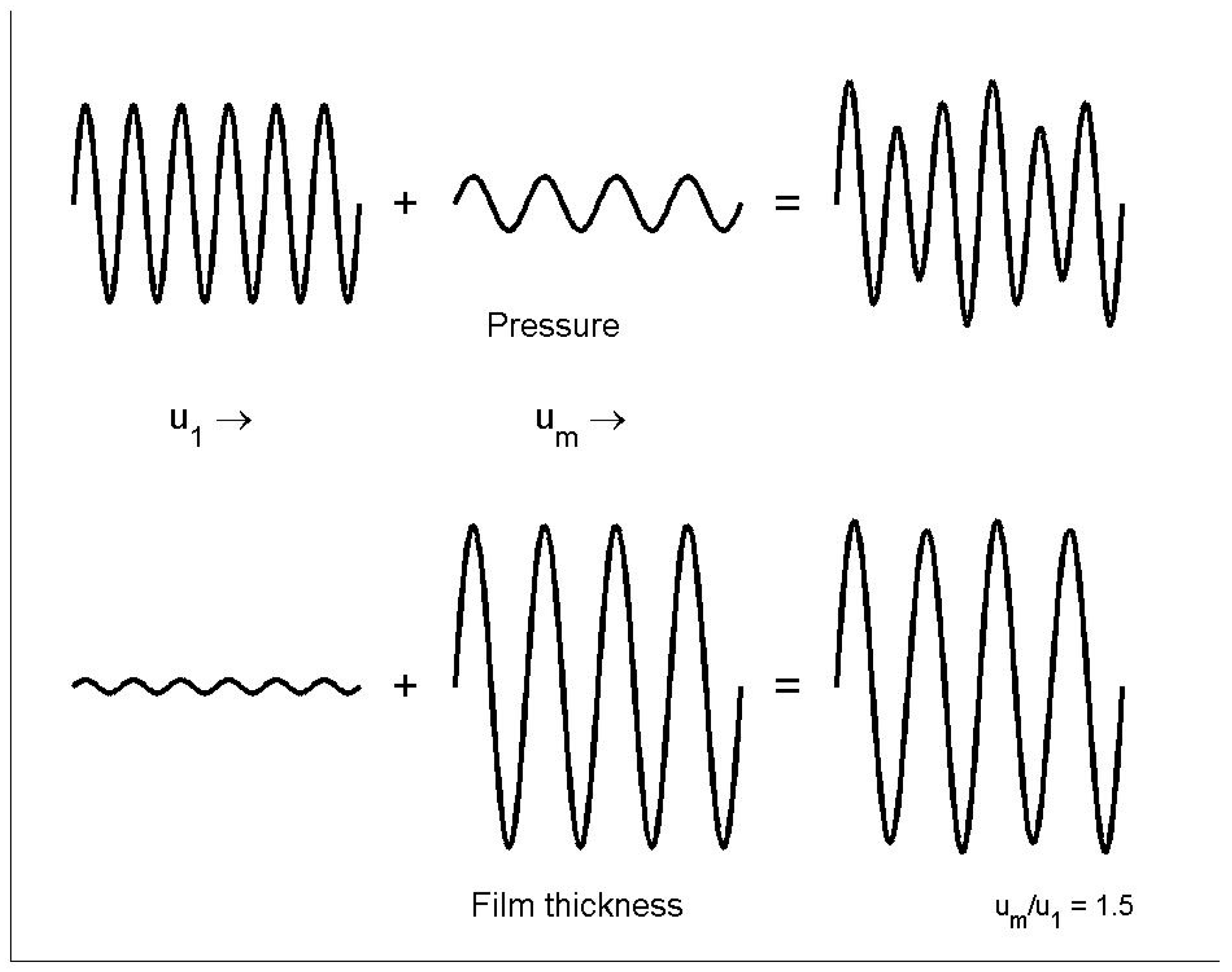

6.1. Moving Roughness

6.2. The Λ Ratio

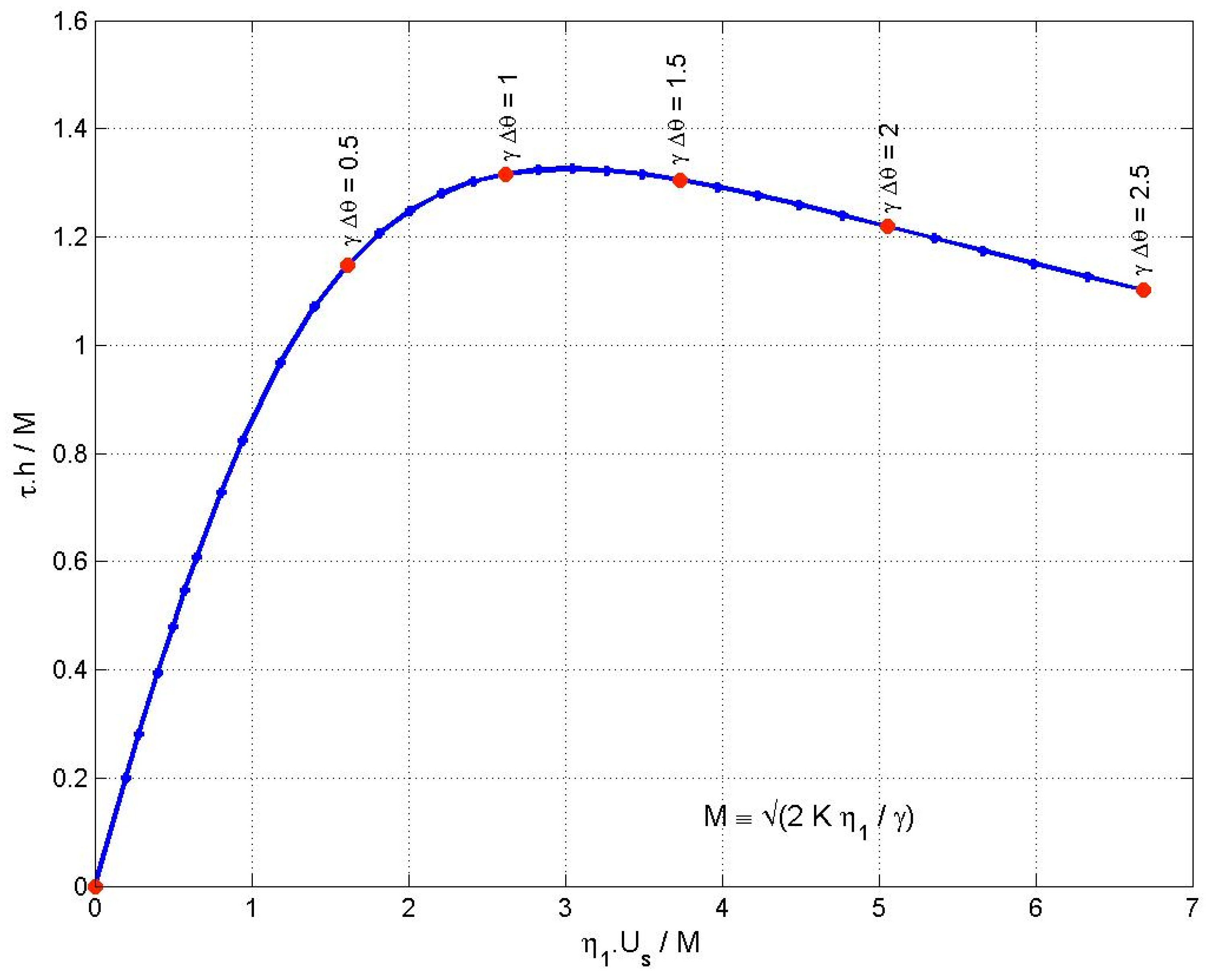

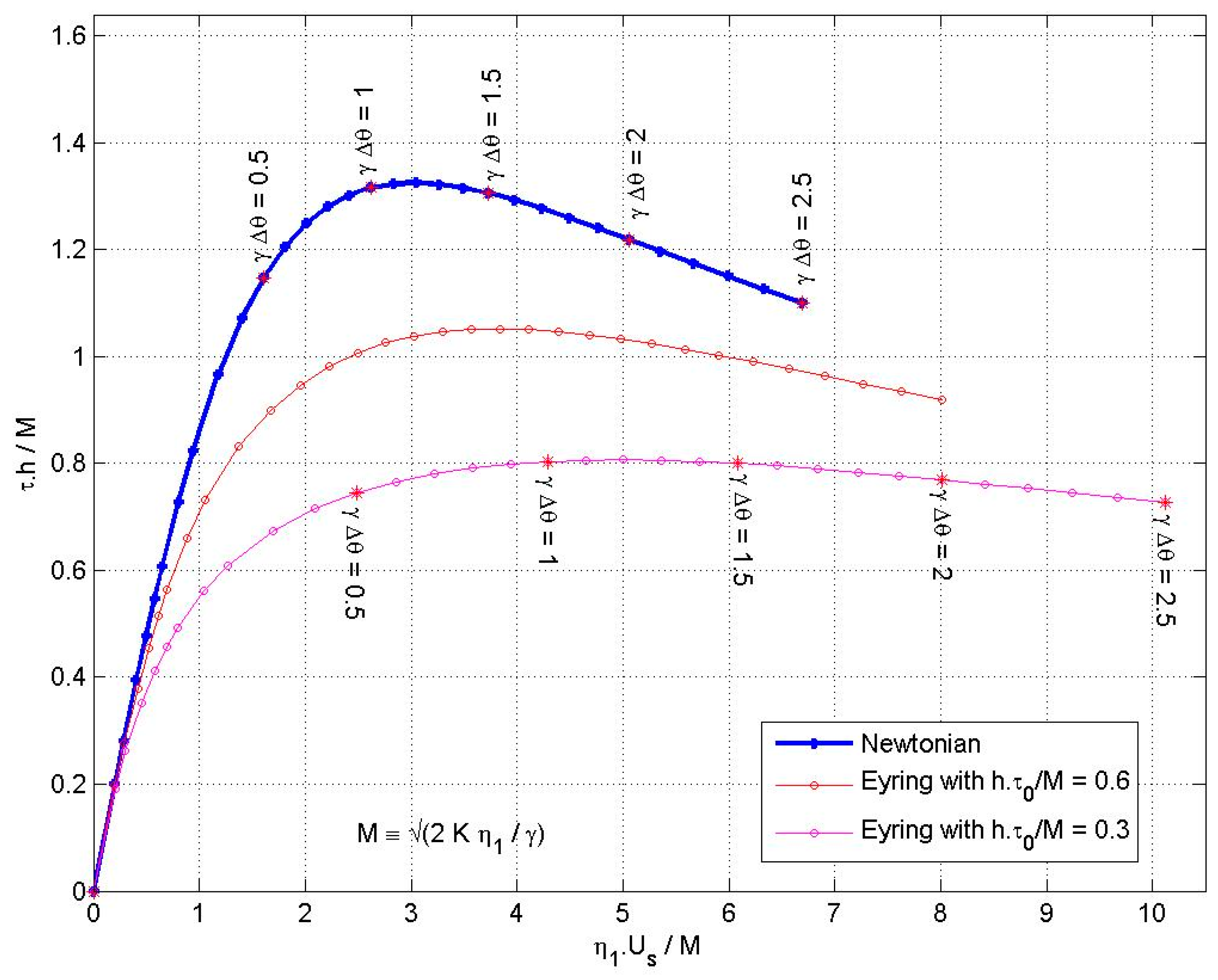

7. Friction

7.1. Thermal Effects

7.2. Non-Newtonian Behaviour

- (1)

- It is generally agreed that the Barus equation for the pressure dependence of the oil viscosity is inadequate. The initial exponential increase is not continued, and this is described by the Roelands (2-parameter) equation [61]. This correctly describes the viscosity up to 0.4 GN/m2 and is adequate for (central) film thickness predictions. However, the region where the traction is developed has much higher pressures, and direct measurements up to 1.4 GN/m2 in a falling ball viscometer show an upturn in the log(viscosity) curve, so that the Roelands viscosities are then too low, and the Yasutomi equation [62] should be used.

- (2)

- An equation for the dependence of the viscosity on temperature is needed to allow for the surface temperature rise. The simple is unjustified at high pressures, and values from the full Roelands equation (which then becomes a four-parameter equation) may be better. However, it is claimed that experimental values require the use of the full Yasutomi equation (which then has eight parameters). A full thermal analysis of the whole configuration to find the surface temperatures is needed.

- (3)

- Unless the neglect of temperature variations within the oil film is justified, an acceptable equation for the variation of the oil thermal conductivity with pressure and temperature is needed.

- (4)

- Which non-Newtonian model should be used, and what are its parameters? Are the Eyring stress (or the limiting shear stress) constants, or do they depend on temperature and pressure?

8. Conclusions

Funding

Conflicts of Interest

Appendix A. Minimising the Number of Governing Parameters

Reduction

References

- Williams, J.A. Engineering Tribology (Chapter 7); OUP: Oxford, UK, 1994. [Google Scholar]

- Martin, H.M. Lubrication of Gear Teeth. Eng. Lond. 1916, 102, 119–121. [Google Scholar]

- Johnson, K.L. Contact Mechanics (Chapter 4); CUP: Cambridge, UK, 1985. [Google Scholar]

- Dowson, D.; Higginson, G.R. Elasto-hydrodynamic Lubrication; Pergamon: Oxford, UK, 1977. [Google Scholar]

- Gatcombe, E.K. Lubrication characteristics of involute spur gears. Trans. ASME 1945, 67, 195. [Google Scholar]

- Blok, H. Discussion. The lubrication of gears. Gear Lubrication Symposium. J. Inst. Petrol. 1952, 38, 673. [Google Scholar]

- Kapitza, P.L. Hydrodynamic theory of lubrication during rolling. Zhurnal Tekhnicheskoi Fiziki 1955, 25, 747–762. [Google Scholar]

- Grubin, A.N. Investigation of the contact of machine components. Central Scientific Research Institute for Technology and Mechanical. Eng. Mosc. 1949, 30. [Google Scholar]

- Mohrenstein-Ertel, A. Berechnung der Hydrodynamischen Schmierung Gekrummter Oberflachen unter Hoher Belastung und Relativbewegung. In Fortschrittsberichte VDI.; Lang, O.R., Oster, P., Eds.; VDI Verlag: Dusseldorf, Germany, 1984. [Google Scholar]

- Crook, A.W. The lubrication of rollers - II. Film thickness with relation to viscosity and speed. Philos. Trans. R. Soc. Lond. Ser. A 1961, 254, 223–237. [Google Scholar]

- Greenwood, J.A. An extension of the Grubin theory of elastohydrodynamic lubrication. J. Phys. D Appl. Phys. 1972, 5, 2195–2211. [Google Scholar] [CrossRef]

- Dowson, D.; Higginson, G.R. A Numerical Solution to the Elasto-Hydrodynamic Problem. J. Mech. Eng. Sci. 1959, 1, 6. [Google Scholar] [CrossRef]

- Cheng, H.S. Isothermal Elastohydrodynamic Theory in Full Range of Pressure/Viscosity Coefficient. ASME J. Lubr. Technol. 1972, 94, 35–43. [Google Scholar] [CrossRef]

- Moes, H. Discussion of a paper by D. Dowson. Proc. Inst. Mech. Engrs. 1965, 180, 244–245. [Google Scholar]

- Moes, H. Optimum similarity analysis with applications to EHL. Wear 1992, 159, 57–66. [Google Scholar] [CrossRef]

- Pan, P.; Hamroch, B.J. Simple formulae for performance parameters used in elastohydrodynamic lubricated line contact. ASME J. Tribol. 1989, 111, 246–251. [Google Scholar] [CrossRef]

- Johnson, K.L. Regimes of elasto-hydrodynamic lubrication. J. Mech. Eng. Sci. 1970, 12, 9–16. [Google Scholar] [CrossRef]

- Greenwood, J.A. Film thicknesses in circular elastohydrodynamic contacts. Proc. I. Mech. Engrs. 1988, 202, 11–16. [Google Scholar] [CrossRef]

- ESDU 89045. Film Thicknesses in Lubricated Hertzian Contacts. Part 2: Point Contacts; IHS ESDU: London, UK, 1989; ISBN 978-0-85679-719-4. [Google Scholar]

- Venner, C.H. Multilevel Solution of the EHL Line and Point Contact Problems. Ph.D. Thesis, University of Twente, Enschede, The Netherlands, 1991. [Google Scholar]

- Hamrock, B.J.; Dowson, D. Isothermal elastohydrodynamic lubrication of point contacts: Part III—Fully flooded results. J. Lubr. Technol. 1977, 99, 264–275. [Google Scholar] [CrossRef]

- Lubrecht, A.A.; Venner, C.H.; Colin, F. Film thickness calculation in elasto-hydrodynamic lubricated line and elliptical contacts: The Dowson, Higginson, Hamrock contribution. Proc. I. Mech. Engrs. Part J: J. Eng. Tribol. 2009, 223, 511–515. [Google Scholar] [CrossRef]

- Wheeler, J.-D.; Fillot, N.N.; Vergne, P.; Philippon, D.; Morales Espejel, G.E. On the crucial role of ellipticity on elastohydrodynamic film thickness and friction. Proc. I. Mech. E Part J: J Eng. Tribol. 2016, 230, 1503–1515. [Google Scholar] [CrossRef]

- Wheeler, J.D.; Vergne, P.; Fillot, N.; Philippon, D. On the relevance of analytical film thickness EHD equations for isothermal point contacts: Qualitative or quantitative predictions? Friction 2016, 4, 369–379. [Google Scholar] [CrossRef]

- Chittenden, R.J.; Dowson, D.; Taylor, C.M. Elastohydrodynamic film thickness in concentrated contacts: Part 1: Experimental investigation for lubricant entrainment aligned with the major axis of the contact ellipse. Proc. R. Soc. Lond. 1985, 397, 245–269. [Google Scholar] [CrossRef]

- Masjedi, M.; Khonsari, M.M. On the effect of surface roughness in point-contact EHL: Formulas for film thickness and asperity load. Tribol. Intl. 2015, 82, 228–244. [Google Scholar] [CrossRef]

- Chittenden, R.J.; Dowson, D.; Dunn, J.F.; Taylor, C.M. Elastohydrodynamic lubrication of concentrated contacts—Part 2: General case, with lubricant entrainment along either principal axis of the hertzian contact ellipse. Proc. R. Soc. Lond. A 1985, 397, 271–294. [Google Scholar]

- Crook, A.W. The lubrication of rollers. Philos. Trans. R. Soc. Lond. Ser. A 1958, 250, 387. [Google Scholar]

- Sibley, L.B.; Orcutt, F.K. Elasto-hydrodynamic lubrication of rolling contact surfaces. Trans. Amer. Soc. Lub. Engrs. 1961, 4, 234. [Google Scholar] [CrossRef]

- Crook, A.W. Elasto-hydrodynamic lubrication of rollers. Nature 1961, 190, 1182. [Google Scholar] [CrossRef]

- Foord, C.A.; Wedeven, L.D.; Westlake, F.J.; Cameron, A. Optical Elastohydrodynamics (Part 1). Proc. I. Mech. Engrs. 1969, 184, 487–505. [Google Scholar] [CrossRef]

- Hamilton, G.M.; Moore, S.L. Deformation and pressure in an elastohydrodynamic contact. Proc. Roy. Soc. 1971, 322, 313–330. [Google Scholar]

- Hirst, W.; Moore, A.J. Non-Newtonian behaviour in elastohydrodynamic lubrication. Proc. Roy. Soc. 1974, 337, 101–121. [Google Scholar]

- Sperka, P.; Krupka, I.; Hartl, M. Analytical Formula for the Ratio of Central to Minimum Film Thickness in a Circular EHL Contact. Lubricants 2018, 6, 80. [Google Scholar] [CrossRef]

- Bair, S.; Liu, Y.; Wang, Q.J. The pressure–viscosity coefficient for Newtonian EHL film thickness with general piezoviscous response. J. Tribol. 2006, 128, 624–631. [Google Scholar] [CrossRef]

- Dyson, A. Discussion of Inlet shear heating in elastohydrodynamic lubrication by Greenwood J.A. & Kauzlarich J.J. J. Lub. Tech. 1973, 95, 417–423. [Google Scholar]

- Kweh, C.C.; Evans, H.P.; Snidle, R.P. Micro-Elastohydrodynamic Lubrication of an Elliptical Contact With Transverse and Three-Dimensional Sinusoidal Roughness. J. Tribol. 1989, 111, 577–584. [Google Scholar] [CrossRef]

- Kaneta, M.; Sakai, T.; Nishikawa, H. Effects of Surface Roughness on Point Contact EHL. Tribol. Trans 1993, 36, 605–612. [Google Scholar] [CrossRef]

- Greenwood, J.A.; Johnson, K.L. The Behaviour of Transverse Roughness in a Sliding Elastohydrodynamically Lubricated Contact. Wear 1992, 153, 107–117. [Google Scholar] [CrossRef]

- Greenwood, J.A.; Morales-Espejel, G.E. The behaviour of real transverse roughness in a sliding EHL contact. In 19th Leeds-Lyon Symposium: Thin Films in Tribology; Dowson, D., Taylor, C.M., Childs, T.H.C., Godet, M., Dalmaz, G., Eds.; Elsevier Science Publishers B.V.: Amsterdam, The Netherlands, 1993. [Google Scholar]

- Hooke, C.J. Surface Roughness Modification in Elastohydrodynamic Line Contacts operating in the Elastic Piezoviscous Regime. Proc. Inst. Mech. Engrs: Part J 1998, 212, 145–162. [Google Scholar] [CrossRef]

- Hooke, C.J. The Behaviour of Low-Amplitude Surface Roughness under Line Contacts: Non-Newtonian Fluids. Proc. Inst. Mech. Engrs. Part J: J. Eng. Tribol. 2000, 214, 253–265. [Google Scholar] [CrossRef]

- Šperka, P.; Kǔpka, I.; Hartl, M. Experimental study of roughness effect in a rollingsliding EHL contact. Part I: Roughness deformation. Tribol. Trans. 2016, 59, 267–276. [Google Scholar] [CrossRef]

- Venner, C.H.; Lubrecht, A.A. Transient Analysis of Surface Features in an EHL Line Contact in the Case of Sliding. J. Tribol. 1994, 116, 186–193. [Google Scholar] [CrossRef]

- Kaneta, M.; Kanada, T.; Nishikawa, H. Optical Interferometric Observations of the Effects of a Moving Dent on Point Contact EHL. In Elastohydrodynamics 96, Proceedings of the 23rd Leeds-Lyon Symposium on Tribology; Elsevier Tribology Series 32; Elsevier: Amsterdam, The Netherlands, 1997. [Google Scholar]

- Greenwood, J.A.; Morales-Espejel, G.E. The behaviour of transverse roughness in EHL. Proc. Instn. Mech. Engrs (Part J): J. Eng. Tribol. 1994, 208, 121–132. [Google Scholar] [CrossRef]

- Hooke, C.J.; Li, K.Y.; Morales-Espejel, G. Rapid Calculation of the Pressures and Clearances in Rough, Rolling-Sliding Elastohydrodynamically Lubricated Contacts. Part 1: Low-Amplitude, Sinusoidal Roughness. Proc. I. Mech. Engrs. Part C: J. Mech. Eng. Sci. 2007, 221, 535–550. [Google Scholar] [CrossRef]

- Lubrecht, A.A.; Graille, D.; Venner, C.H.; Greenwood, J.A. Waviness Amplitude Reduction in EHL Line Contacts Under Rolling-Sliding. J. Tribol. 1998, 120, 705–709. [Google Scholar] [CrossRef]

- Šperka, P.; Kǔpka, I.; Hartl, M. Experimental study of roughness effect in a rolling-sliding EHL contact. Part II: Complementary effects. Tribol. Trans. 2016, 59, 277–285. [Google Scholar] [CrossRef]

- Morales-Espejel, G.E.; Quiñonez, A.F. On the complementary function amplitude for film thickness in Micro-EHL. Tribol. Int. 2019, 131, 631–636. [Google Scholar] [CrossRef]

- Hansen, J.; Björling, M.; Larsson, R. Topography transformation due to running-in of rolling-sliding non-conformal surfaces. Tribol. Int. 2020, 144, 106126. [Google Scholar] [CrossRef]

- Cann, P.; Ionnides, E.; Jacobsen, B.; Lubrecht, A.A. The lambda ratio—A critical re-examination. Wear 1994, 175, 177–188. [Google Scholar] [CrossRef]

- Jacobson, B. Thin film lubrication of real surfaces. Tribol. Int. 2000, 33, 205–210. [Google Scholar] [CrossRef]

- Clarke, A.; Weeks, I.J.; Evans, H.P.; Snidle, R.W. An investigation into mixed lubrication conditions using electrical contact resistance techniques. Tribol. Int. 2016, 93, 709–716. [Google Scholar] [CrossRef]

- Zapletal, T.; Šperka, P.; Kǔpka, I.; Hartl, M. The effect of surface roughness on friction and film thickness in transition from EHL to mixed friction. Tribol. Int. 2018, 128, 356–364. [Google Scholar] [CrossRef]

- Crook, A.W. The lubrication of rollers Pt. III: A theoretical discussion of friction and the temperatures in the oil film. Philos.Trans. R. Soc. Lond. Ser. A 1961, 254, 237–258. [Google Scholar]

- Crook, A.W. The lubrication of rollers Pt. IV: Measurements of friction and effective viscosity. Philos. Trans. R. Soc. Lond. Ser. A 1963, 255, 281–312. [Google Scholar]

- Johnson, K.L.; Cameron, R. Shear behaviour of elastohydrodynamic oil films at high rolling contact pressure. Proc. Inst. Mech. Engrs 1967, 182, 12–24. [Google Scholar] [CrossRef]

- Johnson, K.L.; Greenwood, J.A. Thermal analysis of an Eyring fluid in elastohydrodynamic traction. Wear 1980, 61, 353–374. [Google Scholar] [CrossRef]

- Conry, T.F.; Wang, S.; Cusano, C. A Reynolds-Eyring Equation for Elastohydrodynamic Lubrication in Line Contacts. ASME J. Tribol. 1987, 109, 648–654. [Google Scholar] [CrossRef]

- Roelands, C.J.A.; Vlugter, J.C.; Waterman, H.I. The viscosity-pressure-temperature relationships of lubricating oils. Trans. ASME J. Basic Eng. 1963, 85, 601–607. [Google Scholar] [CrossRef]

- Yasutomi, S.; Bair, S.; Winer, W. An Application of a Free Volume Model to Lubricant Rheology. ASME J. Tribol. 1984, 106, 291–303. [Google Scholar] [CrossRef]

- Jacod, B.; Venner, C.H.; Lugt, P.M. A Generalized Traction Curve for EHL Contacts. ASME J. Tribol. 2001, 123, 248–253. [Google Scholar] [CrossRef]

- Lugt, P.M.; Morales-Espejel, G.E. A review of elastohydrodynamic lubrication theory. Tribol. Trans. 2011, 54, 470–496. [Google Scholar] [CrossRef]

- Jacod, B.; Venner, C.H.; Lugt, P.M. Extension of the Friction Mastercurve to Limiting Shear Stress Models. ASME J. Tribol. 2003, 125, 739–746. [Google Scholar] [CrossRef]

- Habchi, W.; Vergne, P.; Bair, S.; Andersson, O.; Eyheramendy, D.; Morales-Espejel, G.E. Influence of pressure and temperature dependence of thermal properties of a lubricant on the behaviour of circular TEHD contacts. Tribol. Int. 2010, 43, 1842–1850. [Google Scholar] [CrossRef]

- Liu, H.C.; Zhang, B.B.; Bader, N.; Li, X.M.; Terwey, T.; Poll, G. Fast Traction Prediction In Rolling/Sliding Ehl Contacts. In Proceedings of the 46th Leeds-Lyon Symposium on Tribology, Lyon, France, 2–4 September 2019. [Google Scholar]

- Habchi, W.; Bair, S.; Vergne, P. On friction regimes in quantitative elastohydrodynamics. Tribol. Int. 2013, 58, 107–117. [Google Scholar] [CrossRef]

| Ry/Rx | 1 | 2 | 5 | 10 | 20 | 50 | 100 | Mean |

|---|---|---|---|---|---|---|---|---|

| P = 7.9; S = 5.15 | 1.631 | 1.690 | 1.711 | 1.664 | 1.662 | 1.659 | 1.657 | 1.668 |

| P = 15.8; S = 10.3 | 1.471 | 1.536 | 1.561 | 1.553 | 1.553 | 1.545 | 1.540 | 1.537 |

© 2020 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Greenwood, J.A. Elastohydrodynamic Lubrication. Lubricants 2020, 8, 51. https://doi.org/10.3390/lubricants8050051

Greenwood JA. Elastohydrodynamic Lubrication. Lubricants. 2020; 8(5):51. https://doi.org/10.3390/lubricants8050051

Chicago/Turabian StyleGreenwood, James A. 2020. "Elastohydrodynamic Lubrication" Lubricants 8, no. 5: 51. https://doi.org/10.3390/lubricants8050051

APA StyleGreenwood, J. A. (2020). Elastohydrodynamic Lubrication. Lubricants, 8(5), 51. https://doi.org/10.3390/lubricants8050051