Abstract

Under certain operating conditions, rolling contacts have been shown to experience some challenges when lubricated with engine oils containing zinc dialkyldithophosphate (ZDDP) anti-wear additive. In order to better understand the main damage mechanisms during various operating conditions, further studies are needed. This article studies micro-pitting and wear damages of bearing steel surfaces under mixed lubrication conditions in a ball-on-disc setup, lubricated with different engine oils. Based on the results, micro-pitting and wear damage is shown to be highly case-dependent. In general, PAO-based engine oil tends to eliminate micro-pitting damage compared to mineral-based engine oil at less severe lubricating conditions. Moreover, a critical lambda was found for both oils, where the highest micro-pitting damage was observed.

1. Introduction

A crankshaft roller bearing engine presents a step into the future of internal combustion engines (ICEs). Current ICEs employ sliding bearings and their efficiency is far from optimal. Typically, the total engine friction is responsible for more than 10 percent of fuel energy losses in passenger cars [1]. By replacing sliding bearings with rolling element bearings, the engine efficiency can be improved up to 5 percent or more and, therefore, can directly reduce CO2 emissions [2,3,4]. However, in order to successfully employ rolling element bearings, further investigations are required for a smooth and durable operation. Baubet et al. [2] highlighted probable failure modes of crankshaft roller bearings lubricated with engine oils. It was shown that micro-pitting and wear present the most likely failure modes when the anti-wear additive zinc dialkyldithophosphate (ZDDP) is present. They concluded that ZDDP additive promotes micro-pitting and is beneficial for tribology of sliding contacts but detrimental for rolling contacts.

Nevertheless, micro-pitting and wear damage do not represent actual component failures but certainly can be the root causes of resulting failures. In this case, surface-initiated rolling contact fatigue that results in pitting may develop from such root causes, as previously shown by Rycerz et al. [5]. Having this in mind, throughout this investigation the term “micro-pitting” damage is used to quantify the progression of surface-initiated fatigue, i.e., advanced state of micro-pitting, which was not removed by wear that leads to pitting. Therefore, it is important to assess and understand the root causes of such surface-initiated fatigue in order to prevent such premature failure. Vrcek et al. [6] presented a methodology to assess micro-pitting and wear of bearing steel surfaces under reduced lubrication conditions in a ball-on-disc configuration. They assessed different engine oils, containing ZDDP additives, in terms of micro-pitting and wear damage in order to improve oil formulation and to further understand the complexity of such tribological contacts.

However, attempts to isolate the role of the ZDDP additive on micro-pitting and/or wear have been conducted in numerous studies [7,8,9,10,11,12,13,14,15]. Based on these studies, it can be concluded that the ZDDP additive protects the surfaces from wear and can promote micro-pitting formation. Numerous studies have been done on the action of ZDDP additives [11,12,13,14,15,16,17,18]. In general, the ZDDP additive protects the steel surface by forming a tribolayer that prevents metal-to-metal contact and thereby controls the wear process. The tribolayer formation was shown to have four main stages [15]: activation, saturation, wearing-out and an equilibrium stage. The thickness of the tribofilm is mostly governed by the operating conditions [11]. It was shown that pressure, roughness, and temperature are the main factors governing the growth and final tribolayer thickness.

Many experimental studies have isolated the operating conditions and studied their effect on micro-pitting and wear. For example, sliding increases the severity of both micro-pitting and wear through increased numbers of micro-stress cycles induced by the rougher surface, until a certain threshold where the micro-pitting severity is reduced, along with a further increase in wear due to sliding [19,20]. This competition between micro-pitting and wear determines the outcome for certain operating conditions. Furthermore, Laine et al. [8] showed that the roughness lay has an important effect on micro-pitting wear; the transverse roughness accelerates micro-pitting wear compared to the longitudinal roughness lay. However, how this affects both the micro-pitting and wear behaviour was not studied. Morales et al. [20,21] studied micro-pitting and wear damage both numerically and experimentally, where they suggested that a general trend for micro-pitting damage is a function of wear and lambda ratio. Where the lambda ration (Λ) is defined as the ratio of the minimum EHL film thickness and the composite surface roughness. They suggest that in the presence of wear, micro-pitting damage is the highest at an intermediate value of the lambda ratio, i.e., micro-pitting is less at low or high lambda. However, no actual experimental verification was provided.

Concerning the actual application, Hultqvist et al. [22] numerically studied the elastohydrodynamic lubrication for the finite line contact during transient events. Typically, such events are present in ICEs. Nevertheless, they showed that during transient events, film thickness fluctuations were induced, leading to oscillations of the lambda ratio within the contact. This, in turn, can have a significant effect on both micro-pitting and wear behaviour. Therefore, a further understanding of how lambda ratios affect micro-pitting and wear is required. Vrcek et al. [6] experimentally showed that micro-pitting and wear damage is sensitive to which type of base oil is used, such as PAO or mineral oil, although such behaviour was not observed in the previous study by Laine et al. [8]. A numerical work by Hultqvist et al. [23] suggests that a stiffer oil, in this case, a mineral oil, can, during a transient event, move the location of the maximum stresses from a subsurface region to the surface region. This would, in turn, enhance the fatigue process of the surface and may lead to higher wear and micro-pitting damage compared to less stiff oil.

Nevertheless, the expected operating conditions for the actual application are more likely to favour the mixed lubrication conditions. Numerous studies [5,6,7,8,9,10,11,24], have been conducted to explore the effect of the ZDDP additive on micro-pitting and/or wear in boundary lubrication. Therefore, the aim of this study is to investigate how engine oils with different types of base oils, such as mineral and PAO, affect micro-pitting and wear behavior for different lambda ratios. In addition, different roughness lays were studied to see their effect on wear and micro-pitting damage.

2. Methodology

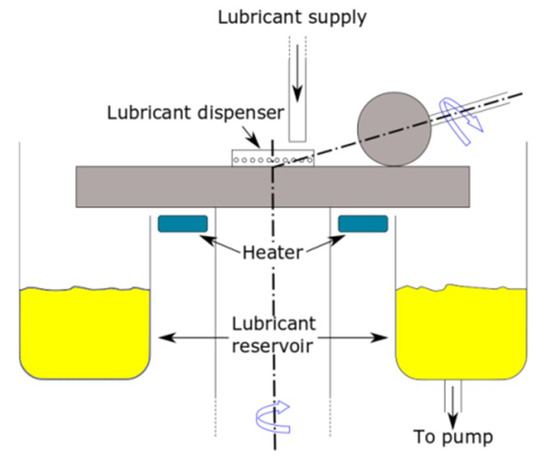

A ball-on-disc test machine, Wedeven Associates Machine (Wedeven Associates, Inc., Newtown Square, PA, USA), was utilized in this study. The schematic of the contact configuration is depicted in Figure 1. Both the ball and the disc are independently driven by electrical motors up to a speed of 25,000 and 12,000 RPM, respectively. The standard ball and disc specimen have a diameter of 20.63 and 101.00 mm, respectively. The lubricant flows into the contact from the lubricant reservoir through the lubricant dispenser in the middle of the disc to be evenly spread over the disc surface. The current setup measures three temperatures: the bulk lubricant temperature (reservoir), the lubricant outlet temperature from the lubricant supply, and the lubricant film temperature on the disc (next to the lubricant dispenser). For more details about the machine, see reference [6].

Figure 1.

Schematic of contact configuration for the Wedeven Associated Machine (WAM) machine [6].

2.1. Test Lubricants and Specimens

Two different engine oils were employed for this study: standard production engine oil A and prototype engine oil B. Table 1 summarizes the information about these two oils.

Table 1.

Description of testing oils [6].

Both oils are based on the base oil mixture of Group III and polyalphaolefins (PAO) and contain the same standard additive package, including an anti-wear additive known as the ZDDP additive. The prototype engine oil B is optimized for rolling contacts without viscosity modifiers and a much higher PAO base oil blend viscosity to have similar viscosity as oil A. By doing so, oil B has a higher ratio of PAO to mineral base oil compared to the standard production oil A. Generally, PAO base oils tend to have lower pressure-viscosity coefficient (, compared to the mineral base oils (. Typically, an oil having a lower pressure-viscosity coefficient will result in lower EHL friction coefficient [25].

All specimens are 100Cr6 bearing steel. Table 2 summarizes the information of all specimens used in this study.

Table 2.

Specimens and specifications of initial surface roughness and hardness.

2.2. Testing Procedure

Prior to testing, the device and specimens were thoroughly cleaned with heptane and ethyl alcohol. Specimens were also cleaned and submerged in an ultrasonic bath containing heptane for 5 min before and after the test. Before the test, the device and the specimens were gradually heated up to 100 °C and maintained at this temperature for 30 min in order to ensure temperature stability. After that, a load of 335 N was applied followed by the pure rolling calibration. Once this was done, the test was launched. A more detailed description about the testing procedure is described in [6].

The testing conditions are summarized in Table 3. All tests were performed at the maximum contact pressure pmax = 2.0 GPa. The slide-to-roll ratio (SRR) ratio, defined simply as the ratio between the speed difference and the mean entrainment speed, was warried from +5 percent (ball rotates faster) to −5 percent (disc rotates faster).

Table 3.

Testing conditions to investigate micro-pitting and wear damage.

The entrainment speed was varied to achieve the desired lambda ratios and is calculated as:

where is the minimum film thickness of the lubricant film in the contact, and and represent the initial surface roughness of the ball and disc specimen, respectively. The Hamrock-Dowson equation for lubricated point contacts [26] was used to calculate the minimal film thickness, using a pressure-viscosity coefficient α of 20 GPa−1 [27]. The chosen pressure-viscosity coefficient served as an estimate only, since the exact pressure-viscosity coefficients for studied oils are unknown. Therefore, slight variations in the lambda ratios might be possible, depending on the oil used.

For all tests, balls were exposed to the same number of cycles and sliding distance in order to compare overall micro-pitting and wear damages. The testing matrix is depicted in Table 4. In total, thirteen tests were performed, in which the lambda ratio, SRR, and roughness lay were varied to examine their effect on micro-pitting and wear performance.

Table 4.

Testing matrix to assess micro-pitting and wear damage for different operating conditions.

2.3. Post Analysis

Micro-pitting and wear damages of ball surface were assessed by using an optical interferometer, Zygo 7300 (Zygo Corporation, Middlefield, CT, USA). In addition, light optical microscope (LOM) was employed to generate images of the wear track. The percentage of global micro-pitting damage, Am, was assessed within the observed area domain (0.555 mm × 0.522 mm) simply as the ratio of projected micro-pitted area and the observed area domain (width similar to the Hertzian contact width). The exact methodology to assess global micro-pitting and wear damage is described in [6].

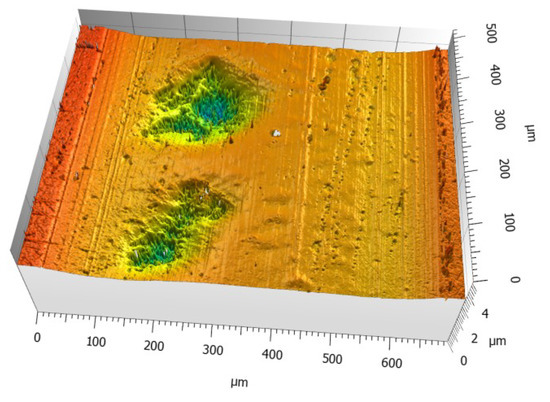

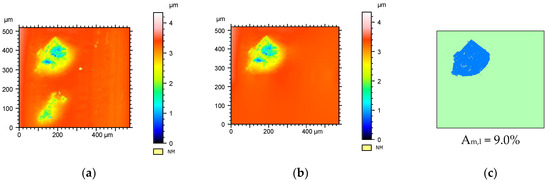

The local micro-pitting damage is assessed within the same area domain. However, local damage is considered as a single micro-pit. An example of micro-pitted damage and assessment of local micro-pitting damage is depicted in Figure 2 and Figure 3, respectively. For the surface shown in Figure 3, case (a), micro-pitting damage is located and captured within the area domain; for case (b), the largest single micro-pit is isolated; and (c), the ratio of the local micro-pitted area (percentage of local micro-pitting) to the area domain is determined. The assessments were only done on the balls as micro-pitting always develops on the smoother surface, in this case, the ball [20].

Figure 2.

Example of 3D image of micro-pitted damage.

Figure 3.

Example of assessment of local micro-pitting damage: (a) original surface topography, (b) all irregularities, except the largest micro-pit are removed, (c) image analysis leading to a size estimate of the local micro-pitting.

For assessing the global micro-pitting, ten random measurements were taken along the ball wear track and were averaged to obtain the mean global micro-pitting. This also made it possible to estimate the statistical variation. For assessing the local micro-pitting damage, three maximum damages were captured along the ball wear track and were averaged to get the mean local micro-pitting damage. The local micro-pitting damage was considered zero when the micro-pitting percentage was less than 0.1 percent.

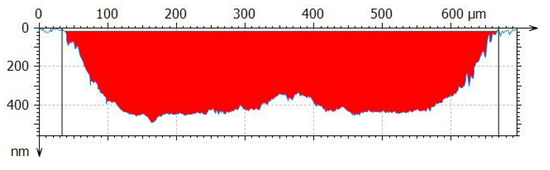

In addition, wear damage was calculated by measuring the worn area of the cross-section of the wear track as depicted in Figure 4. Again, ten random measurements were taken along the ball wear track and were averaged to obtain the mean wear damage. The cross-section wear area was very constant along the ball wear track, leading to very low standard deviation. Furthermore, the mean wear damage was normalized using a ratio between the maximum run diameter of the disc and the actual run diameter as it was shown that the magnitude of wear damage correlates with the run diameter of the disc [6].

Figure 4.

Example of wear measurement from Test 1 showing the cross-section of a wear track. This results in wear damage, = 231 µm2, after normalization = 284 µm2, which correspond to the normalized loss of material in volume, = 0.018 mm3.

3. Results and Discussion

The effects of the lambda ratio, surface roughness lay, type of base oil and sliding direction on micro-pitting and wear damage are presented in the following sections.

3.1. Effects of Lambda, Roughness Lay and Type of Base Oil on Micro-Pitting and Wear

Three different lambda ratios have been investigated for this study to explore how this will affect micro-pitting and wear damage: 0.15, 0.4 and 0.8. Tests carried out at a low lambda condition (Λ = 0.15, SRR = 5%, transverse roughness) showed homogeneous micro-pitting damage along the ball wear track regardless of the oil used. Therefore, assessing global micro-pitting damage was considered a reliable technique to quantify the micro-pitting damage. As reported in an earlier work [6], the global micro-pitting damage at Λ = 0.15 was 2.3 and 1.3 percent, for oil A and B respectively.

However, by increasing the lambda ratio, global micro-pitting damage was completely eliminated. Nevertheless, local micro-pitting damage was still present for both oils although the severity of local micro-pitting was less homogeneously spread along the ball wear track. Therefore, assessing global micro-pitting damage in such a case was not feasible. Therefore, only local damage was assessed, as described in Section 2.3.

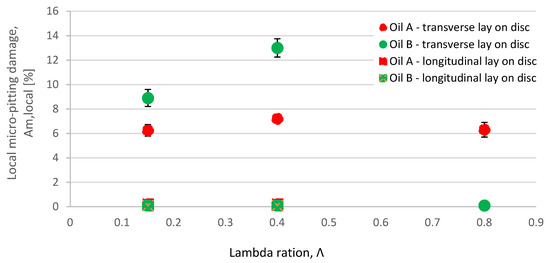

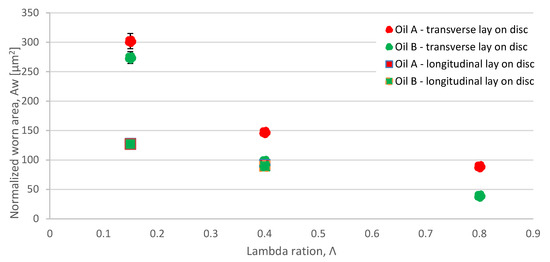

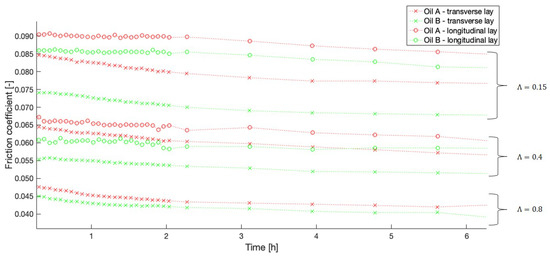

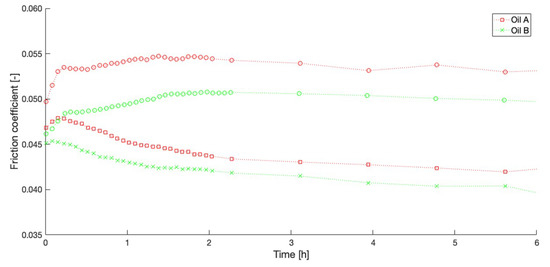

The local micro-pitting and the global normalized wear damage for all lambda ratios are depicted in Figure 5 and Figure 6, respectively. Moreover, the friction coefficient for all lambda ratios for the first 6 h of tests is depicted in Figure 7.

Figure 5.

Local micro-pitting damage for oil A and B as a function of lambda ratio and roughness lay on disc. Each point/square represents a single test. Error bars represent standard deviation.

Figure 6.

Normalized wear damage for oil A and B as a function of lambda ratio and roughness lay. Each point/square represents a single test. Error bars represent standard deviation.

Figure 7.

Friction coefficient for all lambda ratios for the first 6 h of tests.

As seen in Figure 5, the local micro-pitting damage for the transverse lay is the highest at the intermediate lambda for both oils. On the other hand, the local micro-pitted damage for the longitudinal lay was almost completely eliminated for all lambda ratios, except for Λ = 0.8 since this test was not conducted, and no clear difference was observed between both tested oils. It appears evident that the local micro-pitting damage is definitely a function of roughness lay, where transverse lay induces more fatigue micro-cycles and, in turn, accelerates micro-pitting damage. Furthermore, it was also shown that under the same operating conditions, longitudinal roughness deforms more than transverse roughness, and by doing so promoting better lift-off [28,29]. Clearly, the lay direction of the pattern has an influence on micro-pitting formation.

Wear damage, on the other hand, reduces with increasing lambda ratios for both oils, regardless of roughness lay, as shown in Figure 6. In general, the contact conditions are more severe in low lambda regions, where more asperity-to-asperity interactions take place. This, in turn, increases the wear, which is responsible for constantly removing fatigued surface layers. During this process, micro-pits that might form on the surface are continuously removed and the progression of such pits is mostly controlled by wear.

For the transverse lay, when there is a high friction coefficient, between 0.07–0.09 (see Figure 7), and high wear, the growth of local micro-pitting damage is retarded at low lambda due to high wear. At the intermediate lambda with a moderate friction coefficient, between 0.065–0.055, and moderate wear, the local micro-pitting damage is the highest. Here, the friction is lower and the wear is half of that at low lambda. Due to this, the growth of local micro-pitting is the highest, since wear is unable to suppress the micro-pitting growth. At high lambda, both the wear and the friction coefficient, between 0.04–0.045, are much lower compared to previous cases. This suppresses the local micro-pitting growth since the conditions are more towards full-film, and the resulting friction is mostly governed by EHL friction. Furthermore, the local micro-pitting damage is completely eliminated when using oil B.

Nevertheless, wear damage seems to show dependence on roughness lay, and the transverse roughness lay is dependent on oil used. In the case of using a different roughness lay, the wear damage is higher for the transverse lay compared to the longitudinal, as previously shown [8]. It seems that not only micro-pitting but also wear damage is enhanced due to transverse roughness lay. This can be again contributed to worse lift-off behaviour [28,29] and more induced fatigue micro-cycles for the transverse lay. When comparing both oils for transverse lay, wear is higher for oil A compared to oil B. Type of base oil affects the wear process for the transverse roughness lay but does not necessarily affect the wear process for the longitudinal lay.

Both oils have similar viscosity for the tested condition and the same additive package, therefore, higher wear for mineral oil (oil A) can be related to having higher pressure-viscosity coefficient than PAO based oil. Higher pressure-viscosity coefficient does increase the severity of the contact by having higher pressure gradients [23]. This, in turn, enhances the action of ZDDP additive by, in this case, promoting wear. In addition, at higher lambda ratios, both oils tend to have a larger difference in wear damage compared to the low lambda ratio. This might suggest that the effect of base oil type is less pronounced during low lambda conditions and more pronounced in better lubrication conditions.

The local micro-pitting damage tends to be higher for oil B, compared to oil A, at low and intermediate lambda ratios. Since the wear damage is higher for oil A (transverse lay), one may say that the micro-pitting damage will be lower due to the competitive nature of these two damage mechanisms. Based on the observations, a higher blend of PAO oil (oil B) increases the severity of the local micro-pitting tendency, compared to a higher blend of mineral oil (oil A), due to having lower wear. However, at a higher lambda ratio, the tendency towards local micro-pitting is completely eliminated for oil B. PAO base oil is known to have a lower pressure-viscosity coefficient [23] and lower EHL friction [25]. This, in turn, reduces the tendency towards micro-pitting by reducing the stresses close to the surface.

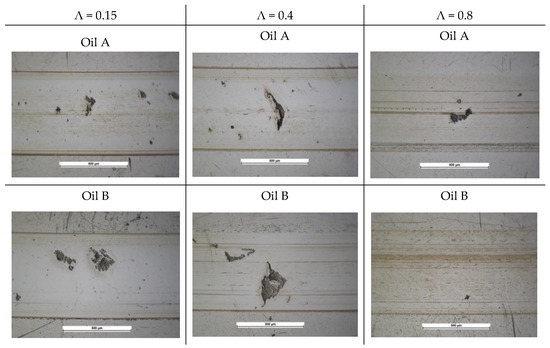

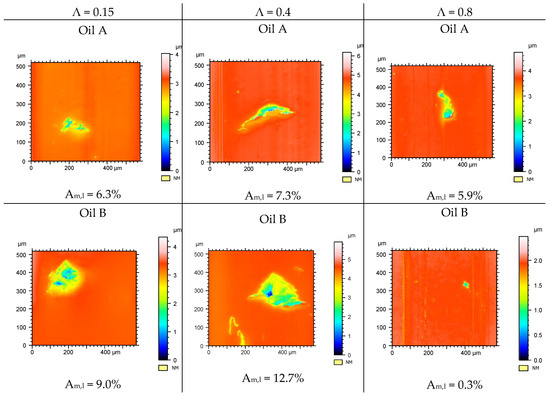

An example of local micro-pitting damage of ball surfaces lubricated with two different oils for transverse roughness lay at different lambda ratios is depicted in Figure 8 and Figure 9. Where, Figure 8 presents light optical images of micro-pitted surface (over-rolling direction from right to left) and Figure 9 shows the same surface (rotated for 90° counter-clockwise) captured with the optical 3D profilometer with local micro-pitting damage assessment.

Figure 8.

Light optical microscope (LOM) images—Example of local micro-pitting damage of ball surfaces lubricated with two different oils for transverse roughness lay at different lambda ratios.

Figure 9.

Optical 3D profilometer images—Example of local micro-pitting damage of ball surfaces lubricated with two different oils for transverse roughness lay at different lambda ratios.

Based on these observations, one can say that most of the depicted micro-pits tend to grow in a V-shape, Figure 8 and Figure 9 (both oils for Λ = 0.15 and 0.4). Such surface-initiated rolling contact fatigue growth can typically result in a spalling or pitting failure, where a generated pit covers all the Hertzian contact area, as previously observed by Rycerz P. et al. [5]. It is likely that such micro-pits will further grow and eventually form a pit: the end life of a rolling component. Nevertheless, larger and longer micro-pits are observed for both oils at an intermediate lambda (Λ = 0.4).

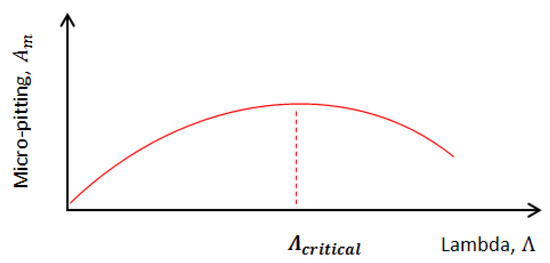

This further explains the maximum local damage at such conditions due to the competitive nature of micro-pitting and wear, as observed by [8,10,20]. Both oils tend to have an intermediate or critical lambda where the local micro-pitting damage is the highest. By reducing or further increasing the lambda, the severity of local micro-pitting damage drops due to the aforementioned conditions. Such behaviour was previously reported numerically by Morales-Espejel G.E. et al. [20,21], illustrating such trends (see Figure 10), although, to the authors’ knowledge, no experimental verification was provided up until now. Of course, the exact location of such intermediate lambda and the shape of corresponding curve are highly dependent on the lubricant chemistry and surface topography.

Figure 10.

A schematic illustration of the expected trend in micro-pitting behavior in relationship to lambda ratio for case with wear [21].

In the previous work conducted by Vrcek A. et al. [6], it was shown that oil A had a higher mean global micro-pitting damage (Am,g std = 0.4) compared to oil B (Am,g, std = 0.3). This was attributed to a better lubricant chemistry for oil B. However, when assessing the severity of mean local micro-pitting damage oil B actually shows higher mean local damage (Am,g, std = 1.0) compared to oil A (Am,g, std = 1.4). A better lubricant chemistry does improve the tendency towards micro-pitting but does not necessarily improve the progression of local micro-pitting damage. In this case, better lubricant chemistry lead to lower wear, which is responsible for removing fatigue layers of material, and, in turn, increased the progression of local micro-pitting damage. Based on the observations, oil B may develop pitting failure mode faster than oil A due to lower wear and higher progression of local micro-pits. On the other hand, oil A may faster develop critical loss of diameter due to higher wear which can, again, lead to premature failure. Nevertheless, one must take into consideration both failure modes when designing rolling components for certain operating conditions in order to prevent premature failures.

3.2. Effect of Sliding Direction on Micro-Pitting and Wear Damage

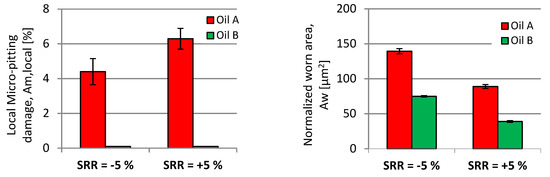

Two different slide-to-roll ratios were selected for this study: +5 and −5 percent in order to see how this affects micro-pitting and wear damage. Other operating conditions were kept constant at lambda 0.8 using the transvers roughness lay on the disc. Table 5 shows how many revolutions perform the ball and the disc, for both negative and positive SRR. For this investigation, only sliding distance was set constant for both tests, this, in turn, lead to constant number of micro-revolutions induced by the roughness. The local micro-pitting and wear damage for both oils are depicted in Figure 11.

Table 5.

Sliding distance and number of revolutions for ball and disc as a function of slid-to-roll ratio (SRR).

Figure 11.

The local micro-pitting and wear damage for both oils at the highest lambda value and with transverse roughness.

A negative SRR was chosen to see whether it enhanced micro-pitting damage or not. Based on the observations, the negative SRR reduced the micro-pitting tendency by promoting wear damage. On the other hand, the ball for the positive SRR was exposed to slightly more overall revolutions that could yield higher micro-pitting damage. Nevertheless, for negative SRR wear damage was almost twice of that at positive SRR (oil B) and slightly less for oil A. In contrast, the difference in local micro-pitting damage for both SRR is less pronounced. However, in order to better understand the influence of sliding direction on both micro-pitting and wear damage, one should also observe the behaviour of the friction coefficient.

Negative SRR showed a higher friction coefficient compared to the positive SRR, as depicted in Figure 12. An increase in friction, with respect to SRR, has already been observed in previous work [15]. However, no explanation was provided. Depending on whether the smoother or rougher surface is faster, this directly impacts the friction and, in turn, both micro-pitting and wear damage, as observed. From Figure 12, when the smoother surface was faster, the friction coefficient increased in the first 15 min, followed by a decrease in friction. When the rougher surface was faster, the increase in friction was prolonged to 1.5 h, followed by a decrease in friction. Based on the previous studies [11,15], the increase in friction was observed when a ZDDP tribofilm was forming and may be directly associated with the tribofilm thickness buildup on top of the asperity summits. This makes surfaces rougher and thus also lower lambda and higher friction.

Figure 12.

Coefficient of friction for both oils and sliding direction.

One may say that this explains the increase of friction at the beginning of the test followed by a slight decrease in friction as an equilibrium state is obtained. The equilibrium state represents the stage of the reaction layer formation process, as introduced by [15], where the rate of deposition of tribolayer is the same as the rate of its removal. Furthermore, they showed that for the negative sliding, tribolayer formation is activated faster and its final thickness is enhanced compared to the positive sliding. This could provide the explanation for the current investigation. Following the same analogy, for the negative sliding, tribolayer is activated faster and, at the beginning, forms a thicker tribolayer compared to the positive sliding. This directly influences the friction coefficient, being much higher for negative sliding. Since the ZDDP additive is more active for the negative sliding, higher wear is obtained as was shown that it can enhance wear [8]. Nevertheless, further studies are required to show and understand this behaviour to a greater degree.

4. Conclusions

Micro-pitting and wear performance of 100Cr6-bearing steel surfaces were investigated in a ball-on-disc configuration lubricated with PAO and mineral-based engine oils containing the same standard additive package. The effect of the lambda ratio, surface roughness lay, different base oils, and sliding direction on the aforementioned performance were presented and discussed. Based on this investigation, the following conclusions can be drawn:

- Micro-pitting damage is more evenly distributed at a low lambda ratio (Λ = 0.15) which is accompanied by relatively high wear. This, in turn, reduces the size of a single micro-pitting damage, which is the highest at a critical/intermediate lambda (Λ = 0.4). Further increase in lambda reduces the severity of the contact, thus, reduces micro-pitting and wear damage.

- For transverse roughness lay, PAO base oil completely eliminates micro-pitting damage at a high lambda ratio (Λ = 0.8) in comparison to mineral base oil. However, at lower lambda ratios, micro-pitting damage is present for both base oils and the size of a single micro-pitting damage is higher for PAO base oil compared to mineral oil, due to lower wear.

- Longitudinal roughness lay, almost completely eliminates the tendency towards micro-pitting compared to transverse lay. In addition, wear damage is lower for longitudinal lay at low lambda (Λ = 0.15). Different base oil type does not show any clear difference in wear damage for longitudinal roughness lay.

- The negative sliding reduces the micro-pitting tendency by increasing friction and wear compared to positive sliding.

- Experimentally shown that there exists a lambda critical, where micro-pitting damage is the highest, as numerically shown by Morales et al. [20,21].

Author Contributions

Conceptualization, A.V., Y.B. and P.M.; methodology, A.V., Y.B. and M.B.; software and validation, T.H.; formal analysis, investigation, data curation, writing—original draft preparation, visualization and project administration, A.V.; resources, Y.B.; writing—review and editing, T.H., Y.B., M.B., P.M. and R.L.; supervision, Y.B., P.M. and R.L.; funding acquisition, P.M. and R.L.

Funding

This research was funded by the Swedish Energy Agency within the framework program P41215-1 (FFI), People Program (Marie Curie Actions) of the European Union’s Seventh Framework Program FP7/2007-2013/ under REA grant agreement no. 612603 and the Swedish Research Council, VR: Project no. 2017-04914.

Acknowledgments

The authors gratefully acknowledge the collaboration and support from Volvo Car Corporation (VCC), especially from Tomas Johannesson. In addition, the authors thank SKF for providing with testing methodology and specimens. Also, the authors thank researchers within SKF for their support, especially Christine Matta and Marcel van Eijk.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Holmberg, K.; Andersson, P.; Erdemir, A. Global energy consumption due to friction in passenger cars. Tribol. Int. 2012, 47, 221–234. [Google Scholar] [CrossRef]

- Baubet, Y.; Pisani, C.; Carden, P.; Molenaar, L.; Reedman, A. Rolling Elements Assessment on Crankshaft Main Bearings of Light Duty Diesel Engine. Sae Int. J. Engines 2014, 7, 1401–1413. [Google Scholar] [CrossRef]

- Tiemann, C.; Orlowsky, K.; Steffens, C.; Bick, W.; Kalenborn, M. The roller bearing engine—A cost effective contribution to CO2 reduction. In Proceedings of the Spring Technical Conference of the ASME Internal Combustion Engine Division, Aachen, Germany, 7–10 May 2006. [Google Scholar]

- Tiemann, C.; Kalenborn, M.; Orlowsky, K.; Steffens, C.; Bick, W. An effective way to the consumption reduction of rolling bearing in the internal combustion engine|Ein effektiver Weg zur Verbrauchsreduktion Wälzlagerung im Verbrennungsmotor. MTZ Mot. Z. 2007, 68, 286–293. [Google Scholar] [CrossRef]

- Rycerz, P.; Olver, A.; Kadiric, A. Propagation of surface initiated rolling contact fatigue cracks in bearing steel. Int. J. Fatigue 2017, 97, 29–38. [Google Scholar] [CrossRef]

- Vrcek, A.; Hultqvist, T.; Baubet, Y.; Björling, M.; Marklund, P.; Larsson, R. Micro-pitting and wear assessment of engine oils operating under boundary lubrication conditions. Tribol. Int. 2019, 129, 338–346. [Google Scholar] [CrossRef]

- Benyajat, C.; Olver, A.V. The Effect of a ZnDTP Anti-Wear Additive on the Micropitting Resistance of Carburised Steel Rollers; AGMA Tech. Pap.; American Gear Manufacturers Association (AGMA): Alexandria, VA, USA, 2004. [Google Scholar]

- Laine, E.; Olver, A.; Beveridge, T. Effect of lubricants on micropitting and wear. Tribol. Int. 2008, 41, 1049–1055. [Google Scholar] [CrossRef]

- Laine, E.; Olver, A.V.; Lekstrom, M.F.; Shollock, B.A.; Beveridge, T.A.; Hua, D.Y. The Effect of a Friction Modifier Additive on Micropitting. Tribol. Trans. 2009, 52, 526–533. [Google Scholar] [CrossRef]

- Brizmer, V.; Pasaribu, H.R.; Morales-Espejel, G.E. Micropitting Performance of Oil Additives in Lubricated Rolling Contacts. Tribol. Trans. 2013, 56, 739–748. [Google Scholar] [CrossRef]

- Brizmer, V.; Matta, C.; Nedelcu, I.; Morales-Espejel, G.E. The Influence of Tribolayer Formation on Tribological Performance of Rolling/Sliding Contacts. Tribol. Lett. 2017, 65, 815. [Google Scholar] [CrossRef]

- Shimizu, Y.; Spikes, H.A. The Influence of Slide–Roll Ratio on ZDDP Tribofilm Formation. Tribol. Lett. 2016, 64, 1–11. [Google Scholar] [CrossRef]

- Cen, H.; Morina, A.; Neville, A. Effect of slide to roll ratio on the micropitting behaviour in rolling-sliding contacts lubricated with ZDDP-containing lubricants. Tribol. Int. 2018, 122, 210–217. [Google Scholar] [CrossRef]

- Suarez, A.N.; Grahn, M.; Pasaribu, R.; Larsson, R. The influence of base oil polarity on the tribological performance of zinc dialkyl dithiophospate additives. Tribol. Int. 2010, 43, 2268–2278. [Google Scholar] [CrossRef]

- Naveira-Suarez, A.; Tomala, A.; Grahn, M.; Zaccheddu, M.; Pasaribu, R.; Larsson, R. The influence of base oil polarity and slide–roll ratio on additive-derived reaction layer formation. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2011, 225, 565–576. [Google Scholar] [CrossRef]

- Taylor, L.J.; Spikes, H.A. Friction-Enhancing Properties of ZDDP Antiwear Additive: Part I—Friction and Morphology of ZDDP Reaction Films. Tribol. Trans. 2003, 46, 303–309. [Google Scholar] [CrossRef]

- Fujita, H.; Spikes, H.A. The formation of zinc dithiophosphate antiwear films. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2004, 218, 265–278. [Google Scholar] [CrossRef]

- Fujita, H.; Spikes, H.A. Study of Zinc Dialkyldithiophosphate Antiwear Film Formation and Removal Processes, Part II: Kinetic Model. Tribol. Trans. 2005, 48, 567–575. [Google Scholar] [CrossRef]

- Rabaso, P.; Gauthier, T.; Diaby, M.; Ville, F. Rolling Contact Fatigue: Experimental Study of the Influence of Sliding, Load, and Material Properties on the Resistance to Micropitting of Steel Discs. Tribol. Trans. 2013, 56, 203–214. [Google Scholar] [CrossRef]

- Morales-Espejel, G.E.; Brizmer, V. Micropitting Modelling in Rolling–Sliding Contacts: Application to Rolling Bearings. Tribol. Trans. 2011, 54, 625–643. [Google Scholar] [CrossRef]

- Morales-Espejel, G.E.; Rycerz, P.; Kadiric, A. Prediction of micropitting damage in gear teeth contacts considering the concurrent effects of surface fatigue and mild wear. Wear 2017, 398–399, 99–115. [Google Scholar] [CrossRef]

- Hultqvist, T.; Shirzadegan, M.; Vrcek, A.; Baubet, Y.; Prakash, B.; Marklund, P.; Larsson, R. Elastohydrodynamic lubrication for the finite line contact under transient loading conditions. Tribol. Int. 2018, 127, 489–499. [Google Scholar] [CrossRef]

- Hultqvist, T.; Vrcek, A.; Prakash, B.; Marklund, P.; Larsson, R. Influence of Lubricant Pressure Response on Subsurface Stress in Elastohydrodynamically Lubricated Finite Line Contacts. J. Tribol. 2018, 141, 031502. [Google Scholar] [CrossRef]

- Olver, A.V.; Macpherson, P.B.; Spikes, H.A. Wear in rolling contacts. Wear 1986, 112, 121–144. [Google Scholar]

- Johansson, J.E.; Devlin, M.T.; Guevremont, J.M.; Prakash, B. Effects of Gear Oil Properties on Pitting Life in Rolling Four-Ball Test Configuration. Tribol. Trans. 2013, 57, 104–113. [Google Scholar] [CrossRef]

- Hamrock, B.J.; Dowson, D. Isothermal Elastohydrodynamic Lubrication of Point Contacts Part 1—Theoretical Formulation The. J. Lubr. Technol. 1976, 99, 223–228. [Google Scholar] [CrossRef]

- Van Leeuwen, H. The determination of the pressure–viscosity coefficient of a lubricant through an accurate film thickness formula and accurate film thickness measurements. Part 2: High L values. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2011, 225, 449–464. [Google Scholar] [CrossRef]

- Venner, C.H.; Lubrecht, A.A. Amplitude Reduction of Non-Isotropic Harmonic Patterns in Circular EHL Contacts, under Pure Rolling. Tribol. Ser. 1998, 34, 151–162. [Google Scholar]

- Morales-Espejel, G.E. Surface roughness effects in elastohydrodynamic lubrication: A review with contributions. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2014, 228, 1217–1242. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).