The Influence of Lubricant Conductivity on Bearing Currents in the Case of Rolling Bearing Greases

Abstract

:1. Introduction

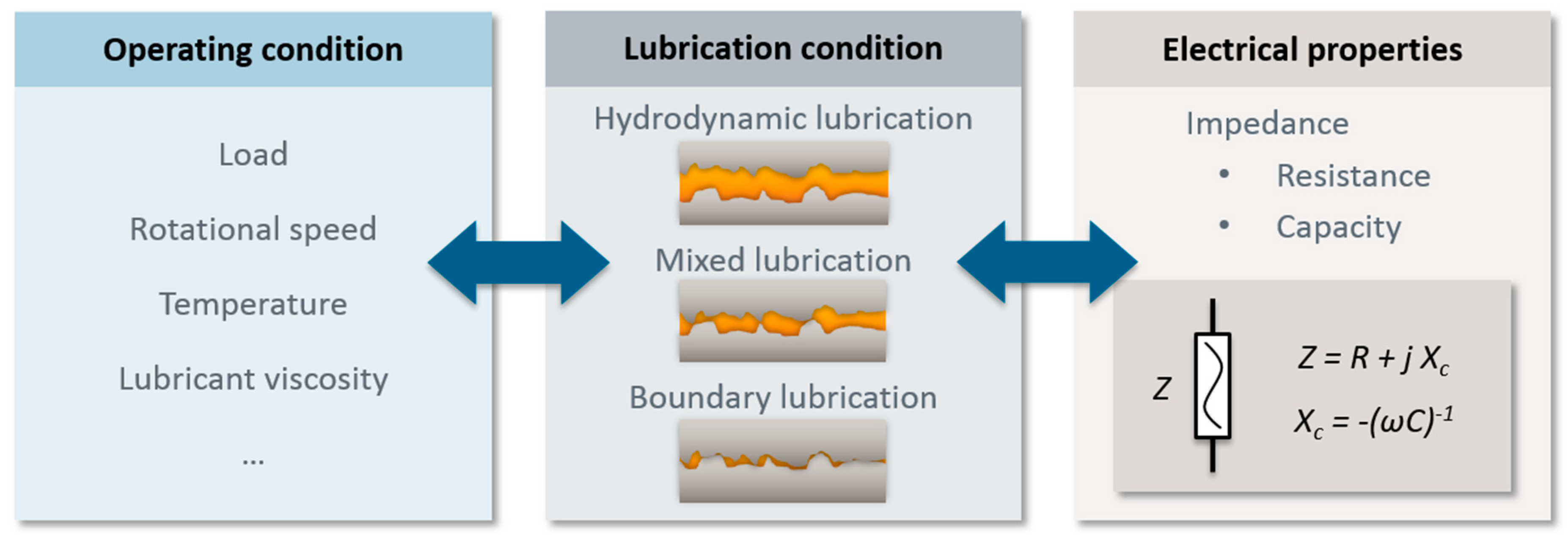

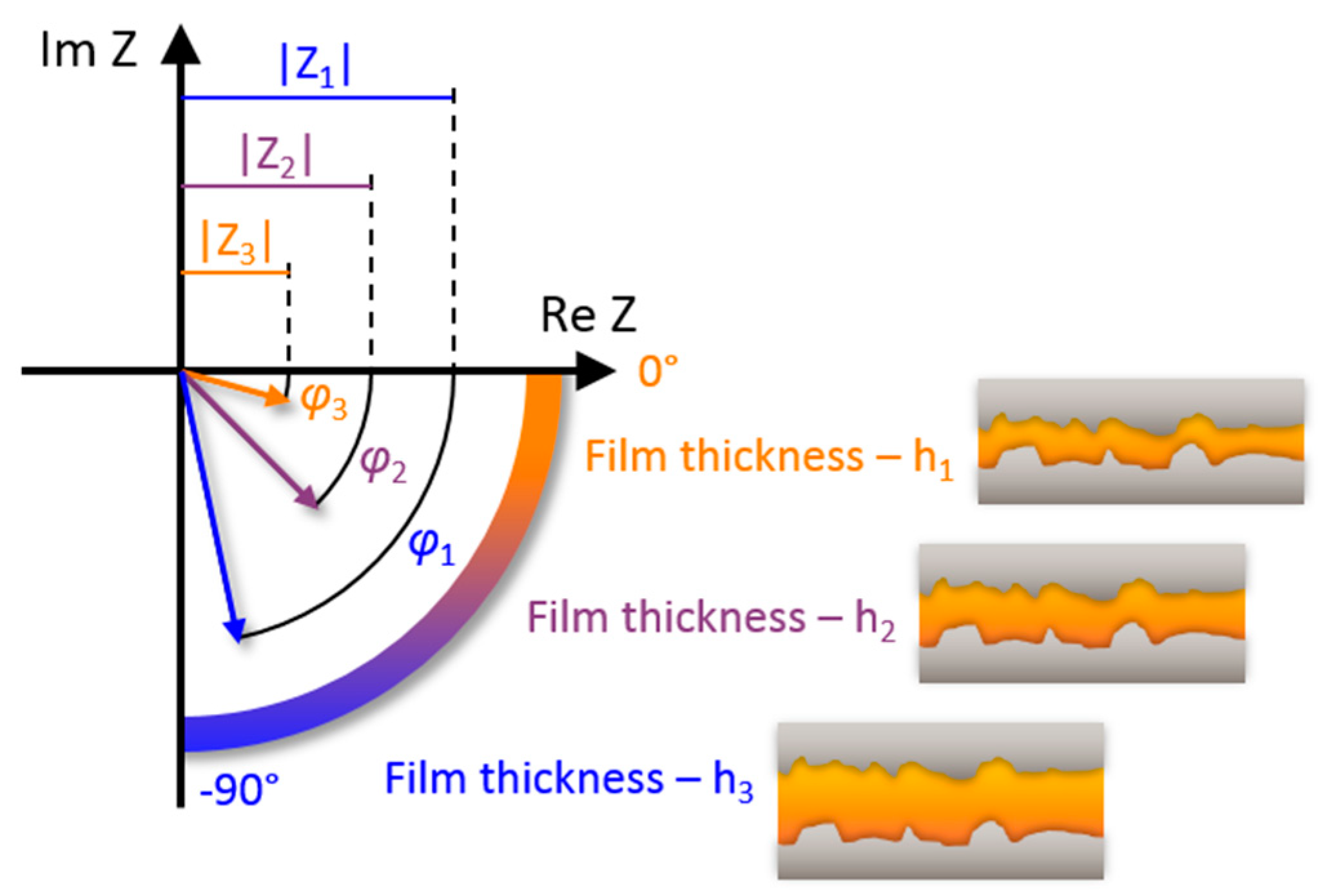

2. Basics

2.1. Lubricant as Electrical Isolator

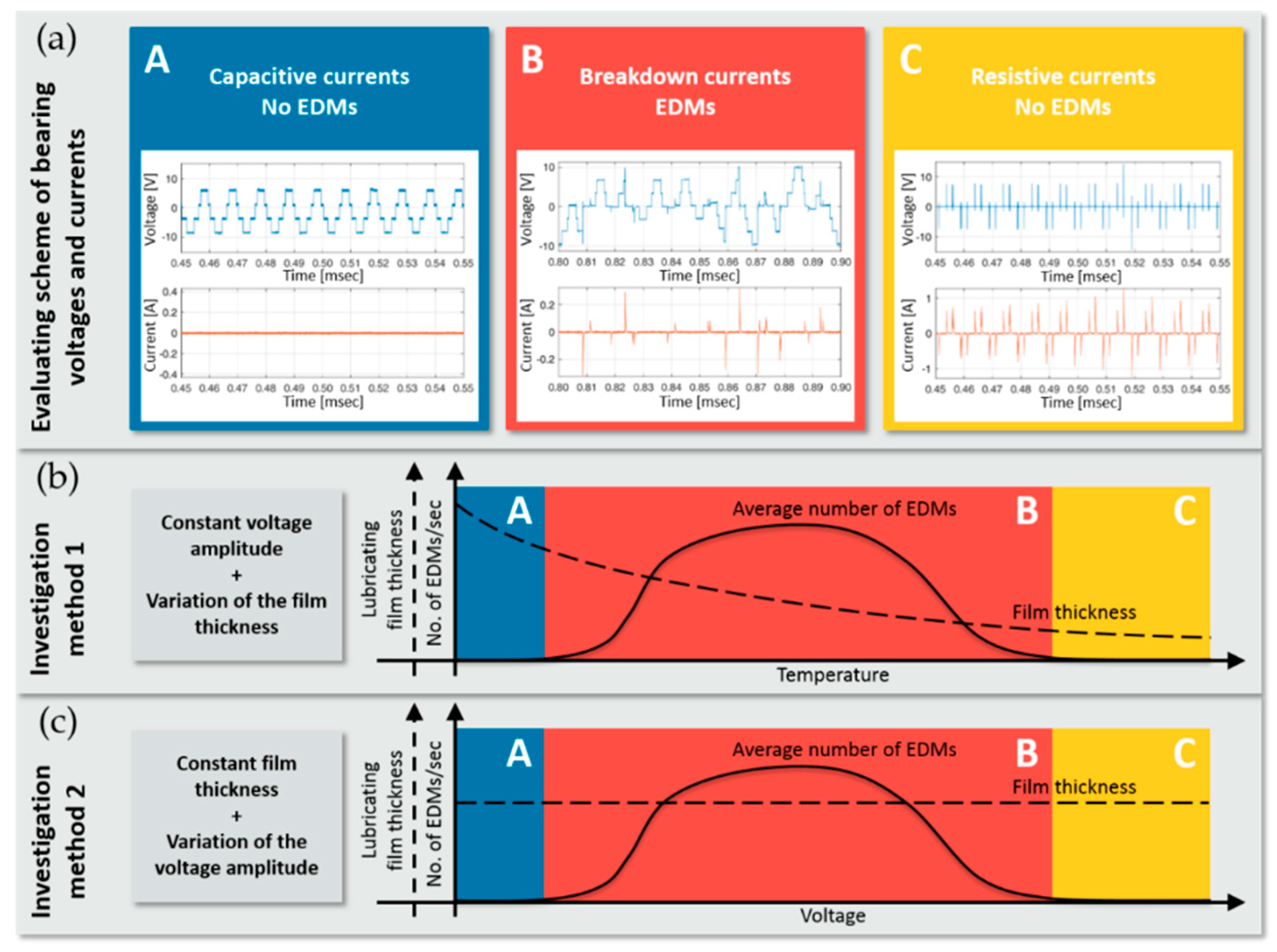

2.2. Electric Discharge Machining (EDM) Breakdowns and EDM Currents

3. Investigated Greases

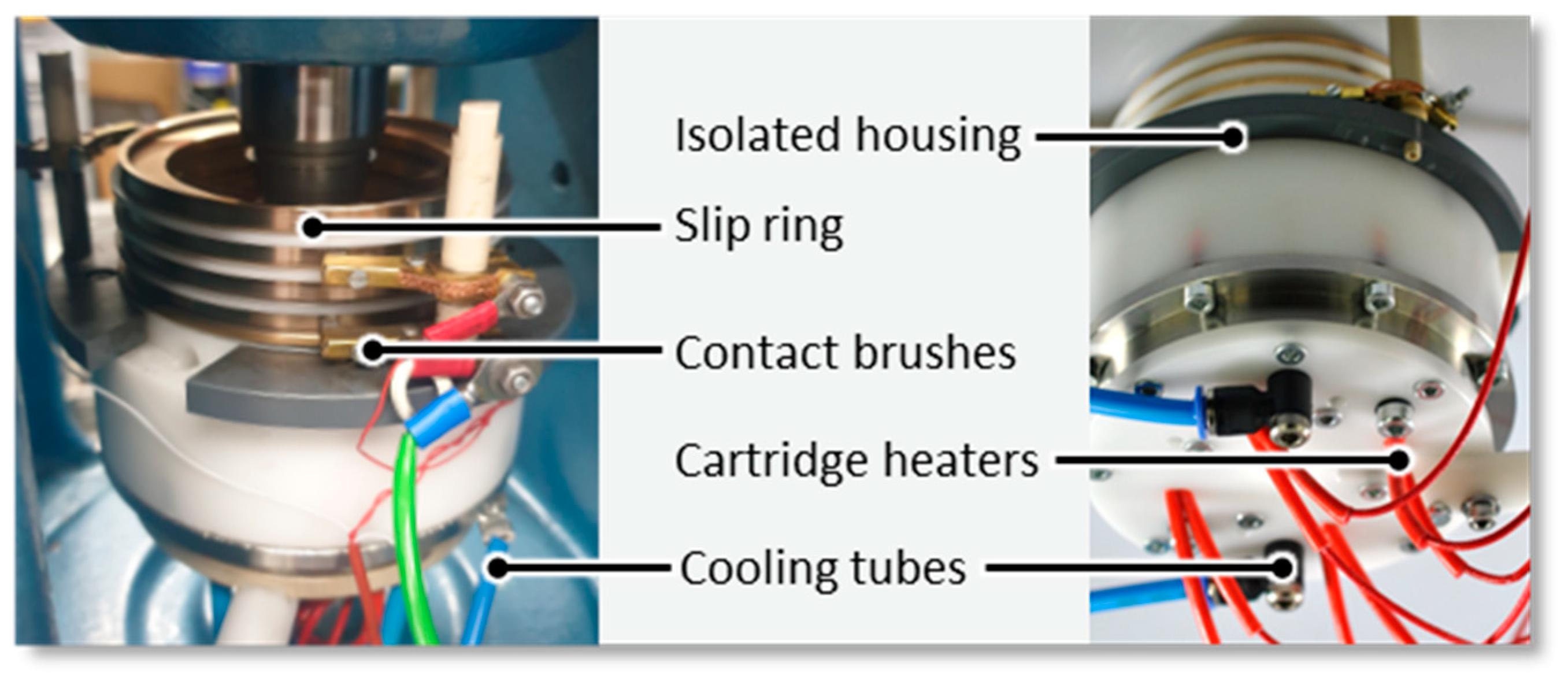

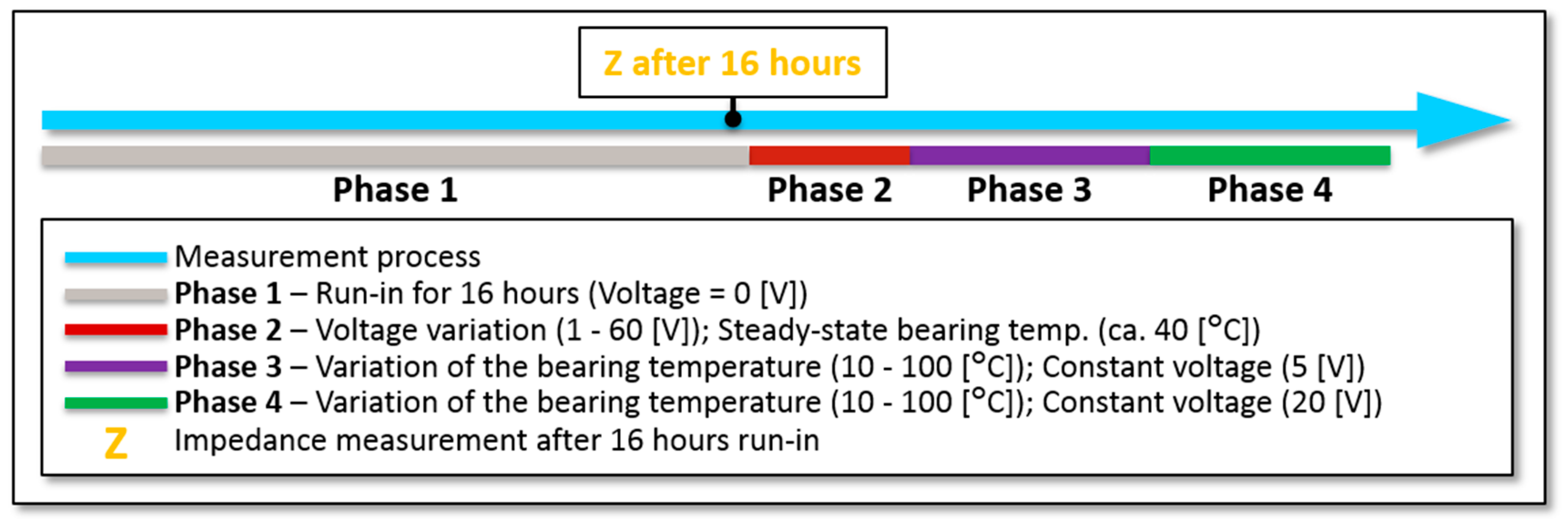

4. Test Bench and the Measurement Process

5. Results

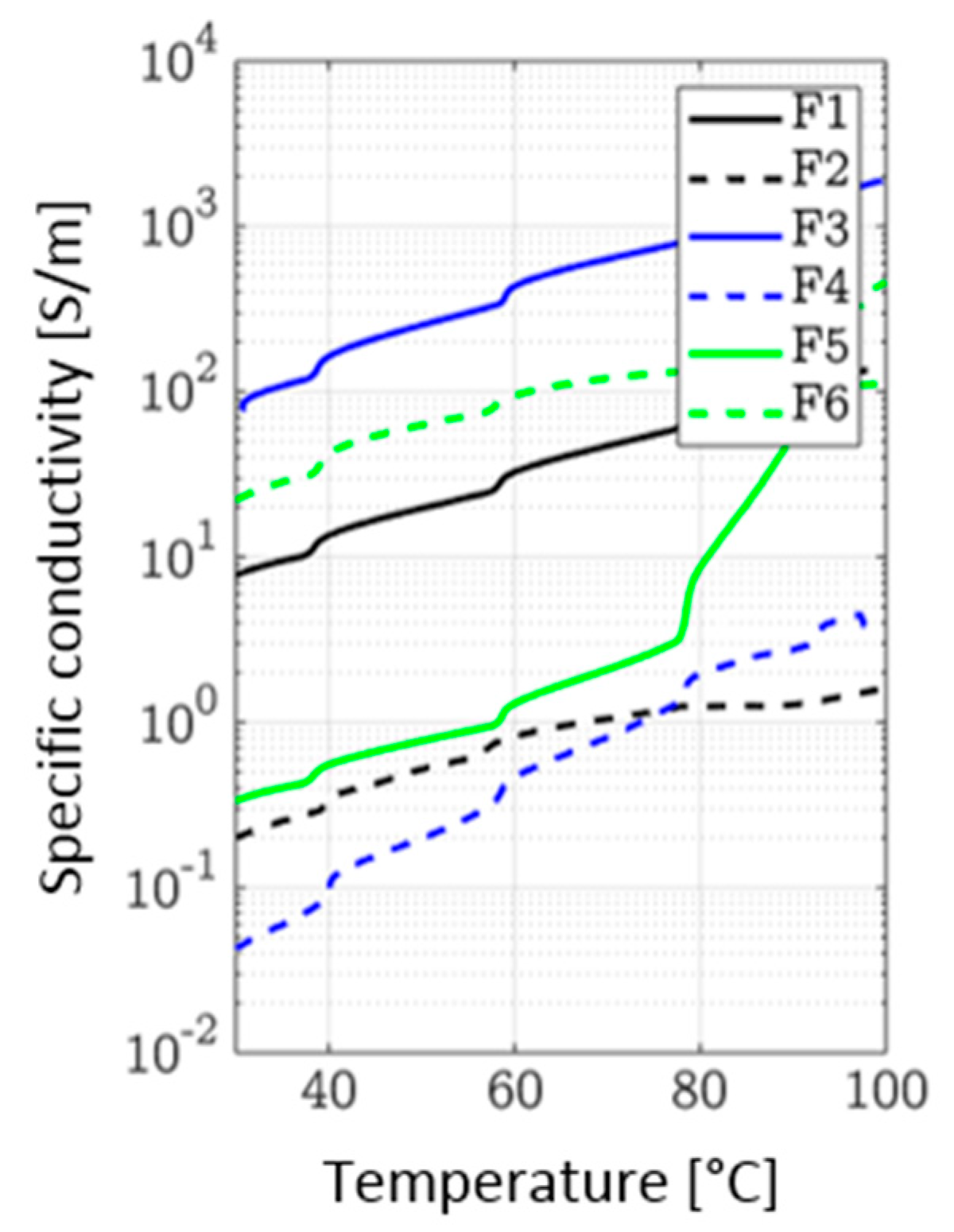

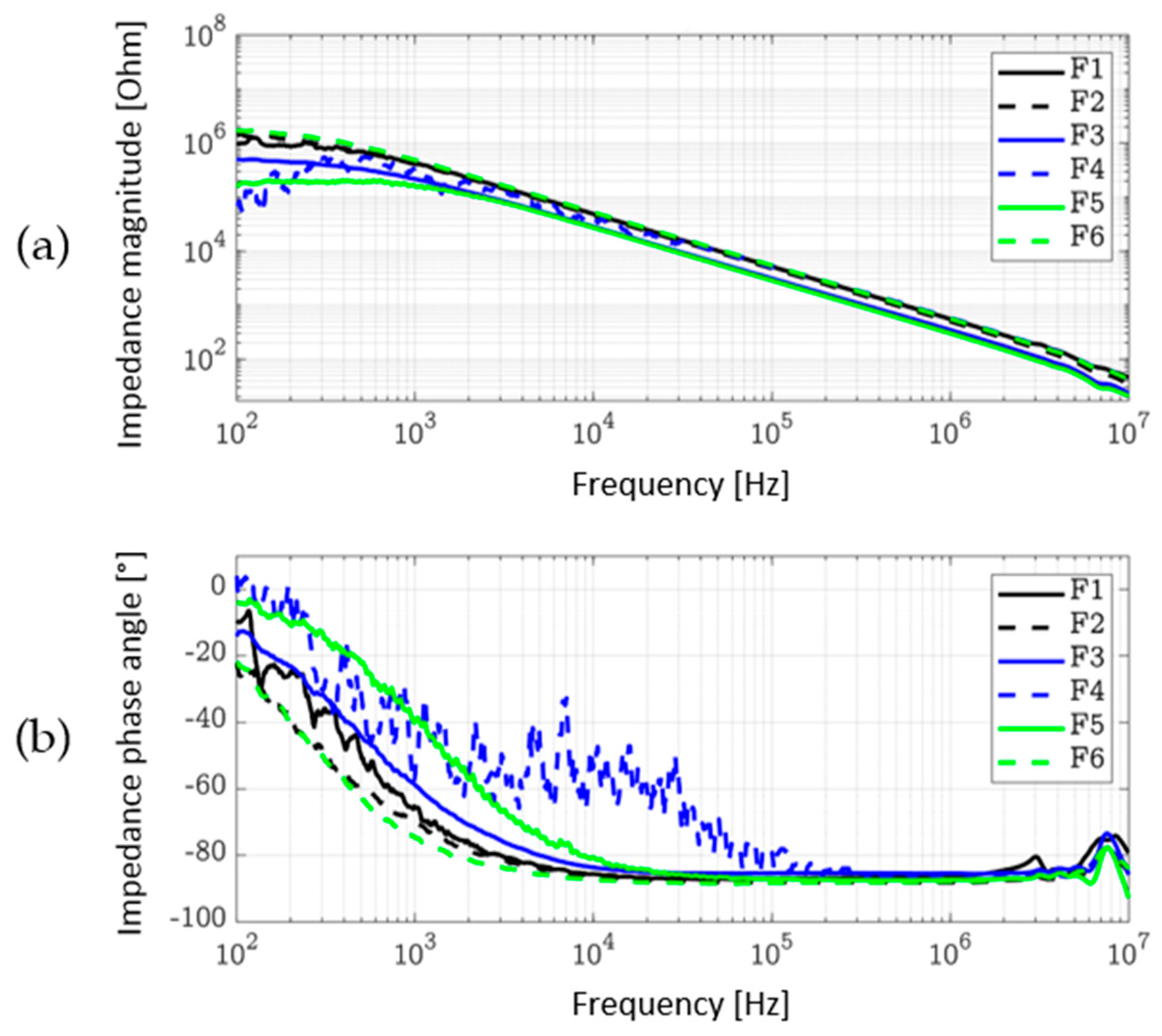

5.1. Results of the Preliminary Investigations

5.2. Results of Phase 1

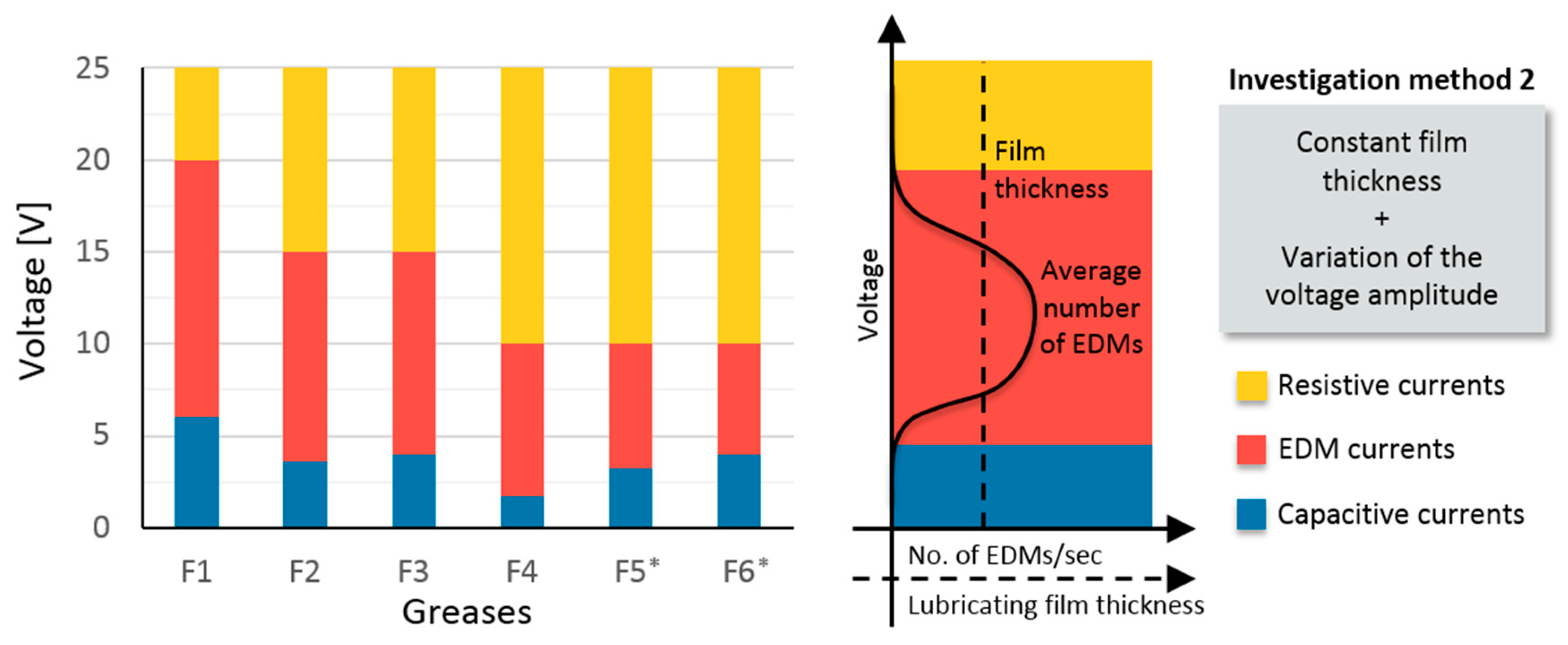

5.3. Results of Phase 2

- Capacitive, EDM and resistive currents occur with all of the investigated greases.

- With conductive grease, ohmic currents already occur at a lower applied voltage and the EDM-domain can be shortened.

5.4. Results of Phase 3 and Phase 4

- In the case of low applied voltage amplitude (5 V), the influence of conductive lubricants is low. The mean and maximum EDM voltage of conductive lubricants is lower compared to insulating lubricants, but the differences are not significant.

- When a high test voltage (20 V) is applied, the capacitive currents are prevented in the temperature domain investigated using conductive lubricants. Predominantly ohmic currents flow.

6. Summary and Outlook

Author Contributions

Funding

Conflicts of Interest

References

- Preisinger, G. Cause and Effect of Bearing Currents in Frequency Converter Drive Electrical Motors—Investigation of Electrical Properties of Rolling Bearings. Ph.D. Thesis, TU Wien, Wien, Austria, 2002. [Google Scholar]

- Muetze, A. Bearing Currents in Inverter-Fed AC Motors. Ph.D. Thesis, TU Darmstadt, Darmstadt, Germany, 2004. [Google Scholar]

- Romanenko, A. Study of Inverter-Induced Bearing Damage Monitoring in Variable-Speed-Driven Motor Systems. Ph.D. Thesis, Lappeenranta University of Technology, Lappeenranta, Finland, 2017. [Google Scholar]

- Zika, T. Electric Discharge Damaging in Lubricated Rolling Contact. Ph.D. Thesis, TU Wien, Wien, Austria, 2010. [Google Scholar]

- Tischmacher, H.; Gattermann, S. Einflussgrößen auf Lagerströme bei umrichtergespeisten Elektromotoren. VDI Ber. 2013, 2202, 45–59. [Google Scholar]

- Tischmacher, H. Systemanalysen zur elektrischen Belastung von Wälzlagern bei umrichtergespeisten Elektromotoren. Ph.D. Thesis, Universität Hannover, Hannover, Germany, 2017. [Google Scholar]

- Radnai, B.; Gemeinder, Y.; Sauer, B.; Binder, A. Schädlicher Stromdurchgang, Untersuchung des Schädigungsmechanismus und der Zulässigen Lagerstrombelastung von (isolierten) Wälzlagern in E-Motoren und Generatoren Verursacht durch Parasitäre Hochfrequente Lagerströme; Abschlussbericht zum FVA-Forschungsvorhaben Nr. 650 I; Forschungsvereinigung Antriebstechnik e.V.: Frankfurt/Main, Germany, 2015. [Google Scholar]

- Radnai, B. Wirkmechanismen bei Spannungsbeaufschlagten Wälzlagern. Ph.D. Thesis, TU Kaiserslautern, Kaiserslautern, Germany, 2016. [Google Scholar]

- Bechev, D.; Kiekbusch, T.; Radnai, B.; Sauer, B. Untersuchung der Auswirkungen von Leitenden und Nichtleitenden Schmierfetten auf die Oberflächeneigenschaften bei Spannungsbeaufschlagten Wälzlagern; GfT-Tagung: Göttingen, Germany, 2017. [Google Scholar]

- Bechev, D.; Gonda, A.; Capan, R.; Sauer, B. Untersuchung der Oberflächenmutationen und der Riffelbildung bei Spannungsbeaufschlagten Wälzlagern 13; VDI-Fachtagung–Gleit- und Wälzlagerungen: VDIVerlag GmbH, Düsseldorf, 2019; ISBN 978-3-18-092348-2. [Google Scholar]

- Foldyna, J.; Chmelík, K.; Mišák, S. Influence of electric discharges on bearings of electric machines. Adv. Electr. Electron. Eng. 2006, 5, 258–262. [Google Scholar]

- DIN EN 60247: Isolierflüssigkeiten—Messung der Permittivitätszahl, des dielektrischen Verlustfaktors (tan δ) und des spezifischen Gleichstrom-Widerstandes; Beuth Verlag: Berlin, Germany, 2005.

- DIN EN 60156: Isolierflüssigkeiten, Bestimmung der Durchschlagspannung bei Netzfrequenz; Beuth Verlag: Berlin, Germany, 1996.

- DIN 51412: Prüfung von Mineralölerzeugnissen—Bestimmung der elektrischen Leitfähigkeiten; Beuth Verlag: Berlin, Germany, 2013.

- Capan, R.; Bechev, D.; Sauer, B. Untersuchungen zum Stromdurchgang und zu den Elektrischen Eigenschaften von Schmierstoffen im Wälzkontakt; GfT-Tagung: Göttingen, Germany, 2019. [Google Scholar]

- Lugt, P.M. Grease Lubrication in Rolling Bearings; John Wiley & Sons Ltd.: West Sussex, UK, 2013; ISBN 9781118483961. [Google Scholar] [CrossRef]

- Jablonka, K. Study of Film Thickness in Elastohydrodynamic Contacts by Electrical Capacitance. Ph.D. Thesis, University of Sussex, Brighton, UK, 2015. [Google Scholar]

- Joshi, A. Electrical Characterisation of Bearings. Ph.D. Thesis, Chalmers University of Technology, Göteborg, Sweden, 2019. [Google Scholar]

- Bechev, D.; Gonda, A.; Capan, R.; Sauer, B. Method for the investigation of the EDM breakdown voltage of grease and oil on rolling bearings. Bear. World J. 2019. under review. [Google Scholar]

- Joshi, A.; Blennow, J. Investigation of the Static Breakdown Voltage of the Lubricating Film in a Mechanical Ball Bearing. In Proceedings of the Nordic Insulation Symposium—Nord-IS 13, Trondheim, Norway, 9–12 June 2013. [Google Scholar]

- Beroual, A.; Khaled, U.; Noah, P.S.M.; Sitorus, H. Comparative Study of Breakdown Voltage of Mineral, Synthetic and Natural Oils and Based Mineral Oil Mixtures under AC and DC Voltages. Energies 2017, 10, 511. [Google Scholar] [CrossRef]

- Stache, H.; Petri, S. Vor Entladungsschäden Schützen—Elektrisch leitfähiges Wälzlagerfett Vermeidet Spannungsüberschlag, Der Konstrukteur—Sonderheft Antreiben—Steuern—Bewegen; Vereinigte Fachverlage GmbH: Mainz, Germany, 2008; pp. 106–107. [Google Scholar]

- Schuster, K.D. Kampf der Elektroerosion. In Produkte und Anwendungen; Vereinigte Fachverlage GmbH: Mainz, Germany, 2017. [Google Scholar]

- Bechev, D.; Sauer, B. Systematische Untersuchungen des Stromdurchgangs in Wälzlagern und der Elektrischen Schmierstoffeigenschaften; GfT-Tagung: Göttingen, Germany, 2018. [Google Scholar]

| Test Grease | Temperature Range (°C) | Base Oil Viscosity at 40 °C (mm²/s) | Base Oil Viscosity at 100 °C (mm²/s) | Type of Base Oil | Type of Thickener | Electric Conductivity |

|---|---|---|---|---|---|---|

| F1 | −40 to 200 | 130 | 20 | Perfluorpolyether, Ester oil | Polytetra-fluorethylen, Polyurea | Not specified |

| F2 | −30 to 160 | 165 | 18 | Mineral oil, Synth. Hydrocarbon | Polyurea | Not specified |

| F3 | −45 to 180 | 72 | 9.5 | Ester oil | Polyurea | Not specified |

| F4 | −50 to 260 | 190 | 34 | Perfluorpolyether | Polytetra-fluorethylen, Polyurea | Not specified |

| F5 | −40 to 180 | 90 | 9 | Polyalphaolefin/Ester oil | Polyurea | Yes |

| F6 | −35 to 140 | 82 | 12.5 | Mineral oil, Synth. Hydrocarbon | Lithium | Yes |

| Phases | Rotational Speed (min−1) | Axial Load (N) | Applied Voltage (V) | Switching Frequency (kHz) | Bearing Temp. (°C) | Bearing Type |

|---|---|---|---|---|---|---|

| Phase 1 | 1000 | 240 | - | - | Steady-state | 51208 |

| Phase 2 | 200 | 1–60 | 10 | Steady-state | ||

| Phase 3 | 200 | 5 | 10 | 10–100 | ||

| Phase 4 | 200 | 20 | 10 | 10–100 |

| Test Greases | F1 | F2 | F3 | F4 | F5 * | F6 * |

|---|---|---|---|---|---|---|

| Steady-state temperature (°C) | 40 | 42 | 41 | 55 | 40 | 38 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gonda, A.; Capan, R.; Bechev, D.; Sauer, B. The Influence of Lubricant Conductivity on Bearing Currents in the Case of Rolling Bearing Greases. Lubricants 2019, 7, 108. https://doi.org/10.3390/lubricants7120108

Gonda A, Capan R, Bechev D, Sauer B. The Influence of Lubricant Conductivity on Bearing Currents in the Case of Rolling Bearing Greases. Lubricants. 2019; 7(12):108. https://doi.org/10.3390/lubricants7120108

Chicago/Turabian StyleGonda, Attila, Resat Capan, Dani Bechev, and Bernd Sauer. 2019. "The Influence of Lubricant Conductivity on Bearing Currents in the Case of Rolling Bearing Greases" Lubricants 7, no. 12: 108. https://doi.org/10.3390/lubricants7120108

APA StyleGonda, A., Capan, R., Bechev, D., & Sauer, B. (2019). The Influence of Lubricant Conductivity on Bearing Currents in the Case of Rolling Bearing Greases. Lubricants, 7(12), 108. https://doi.org/10.3390/lubricants7120108