Squeeze Flow of Bingham Fluids through Reticulated, Compressed Foams

Abstract

1. Introduction

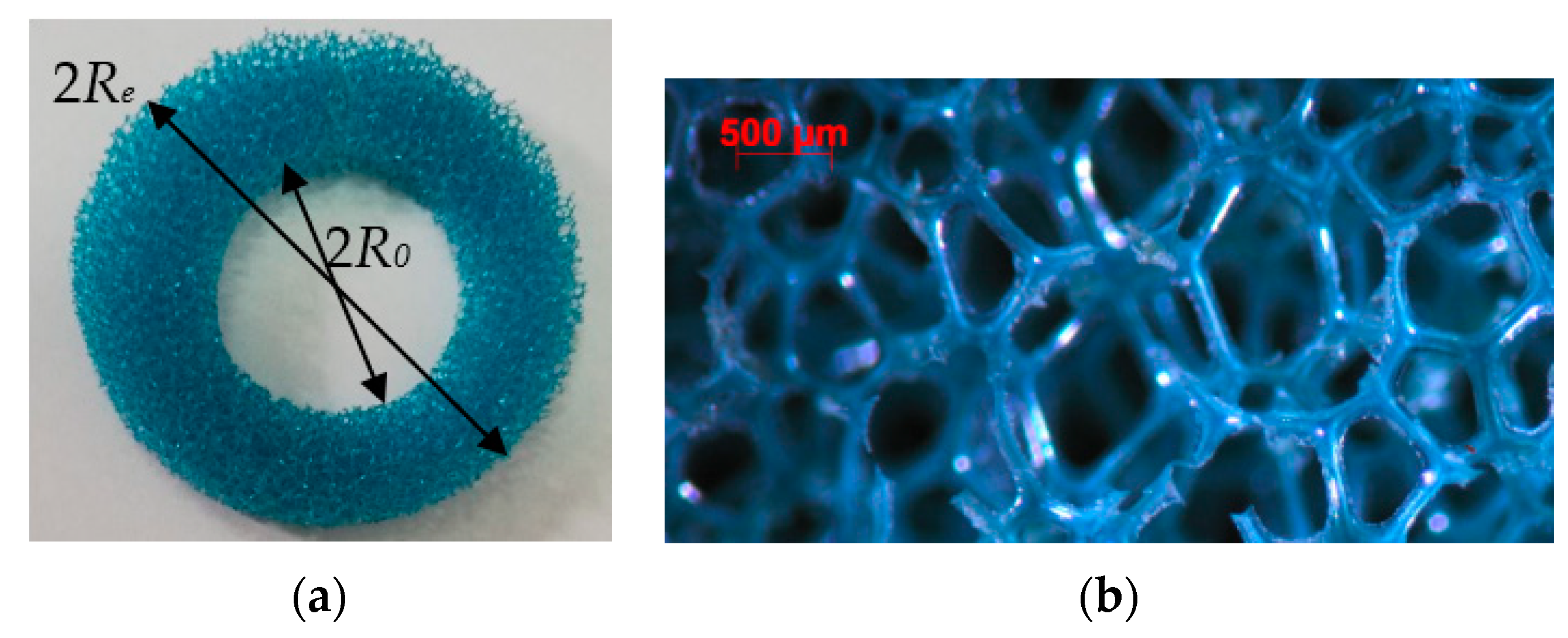

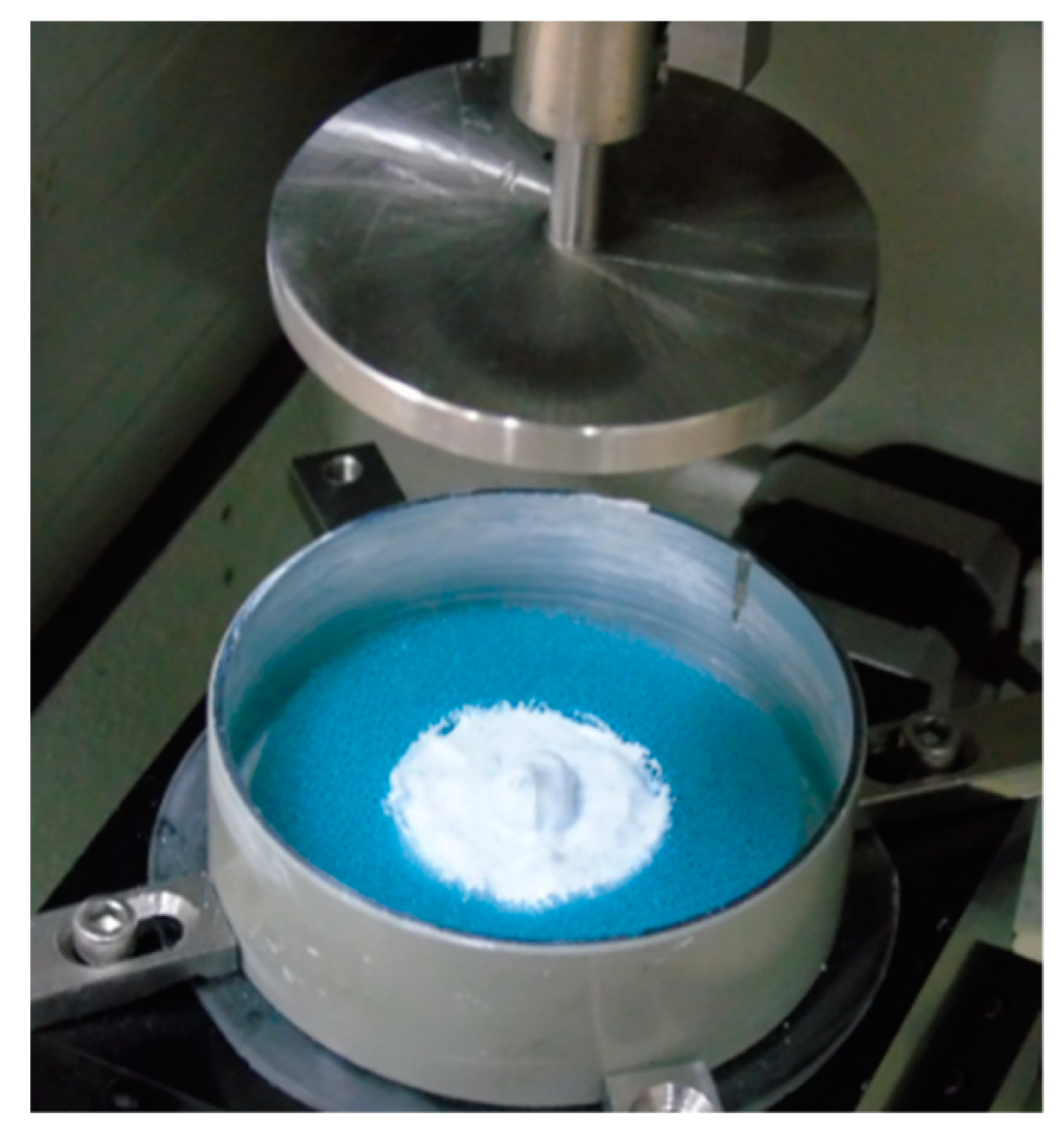

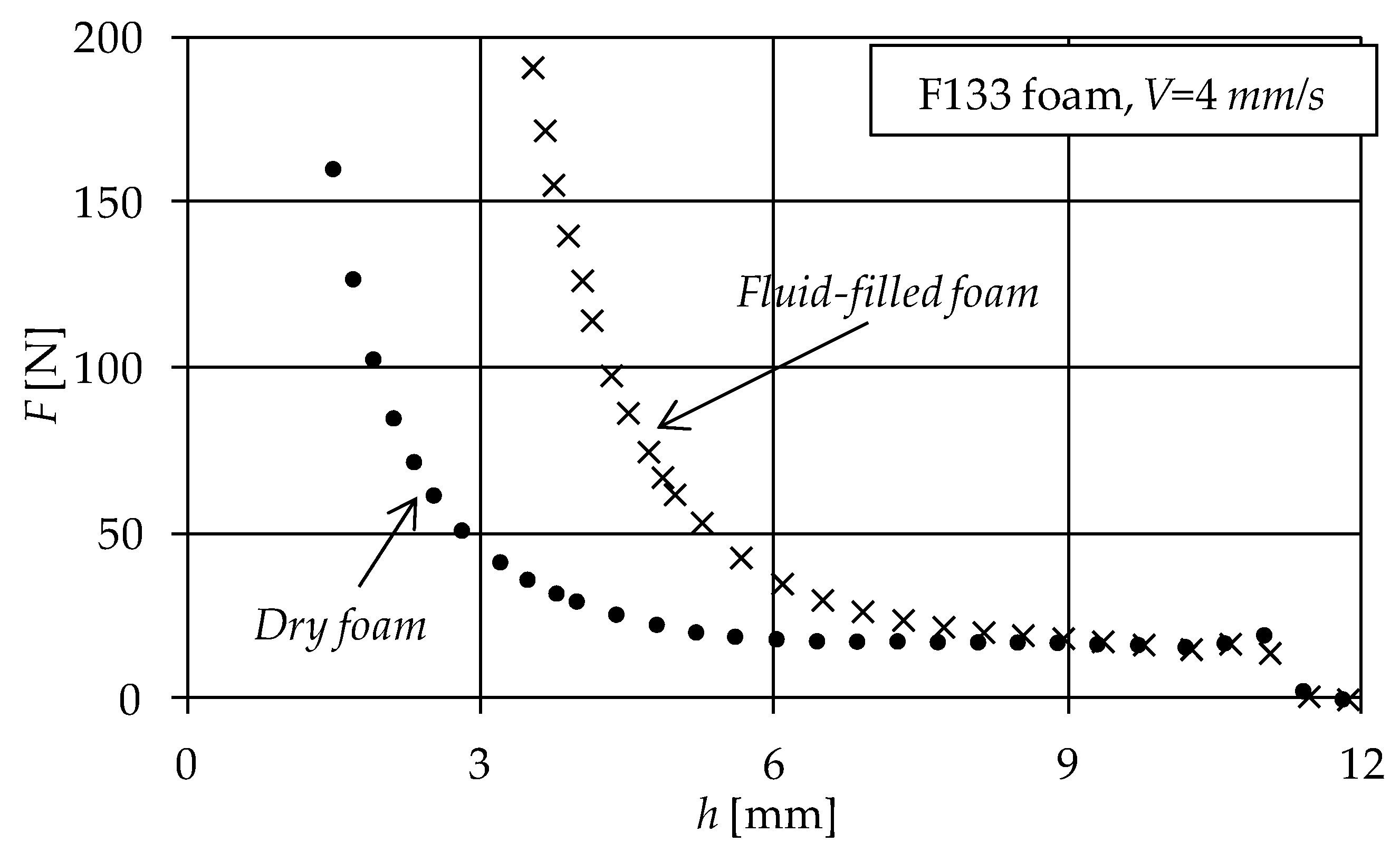

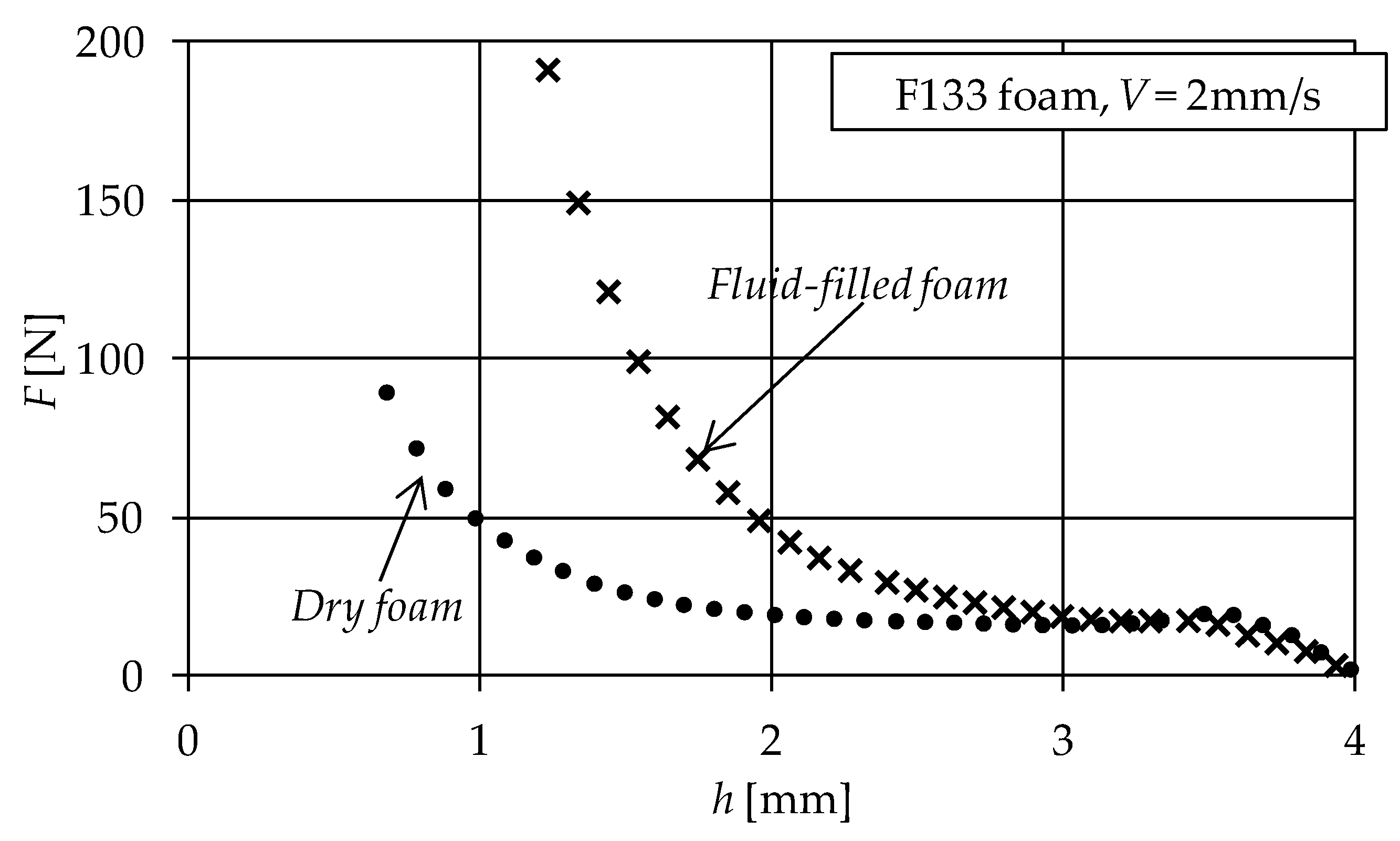

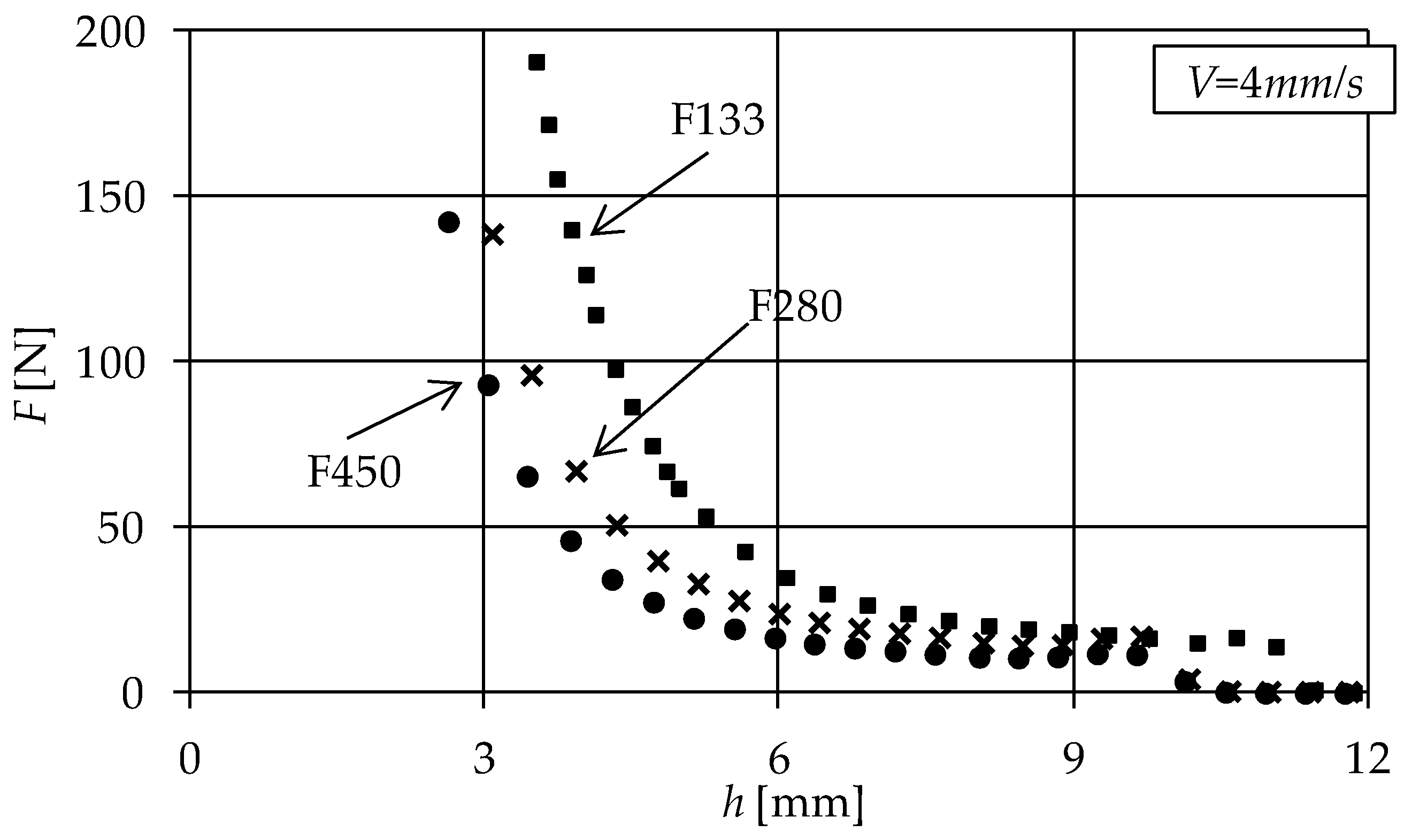

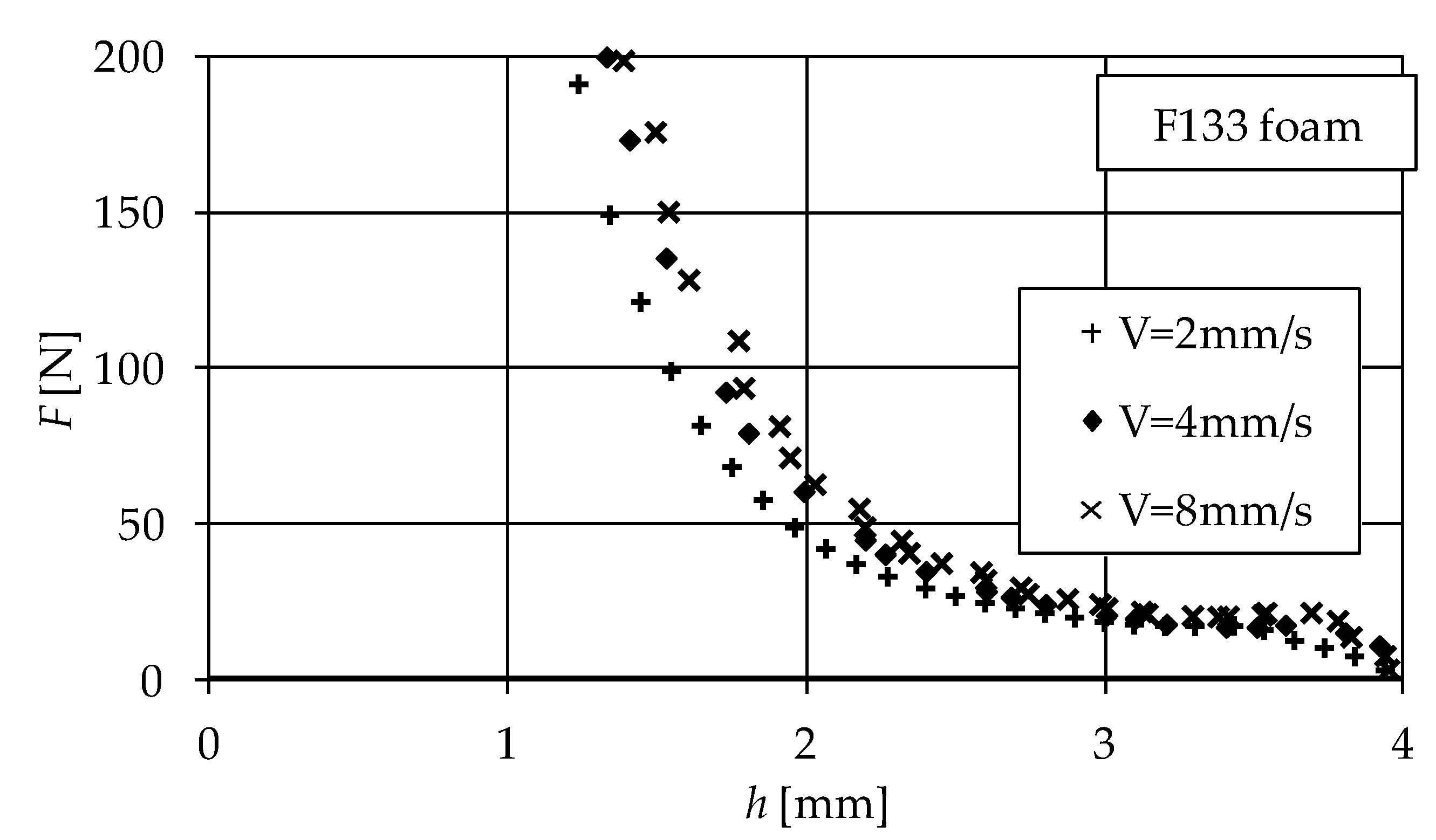

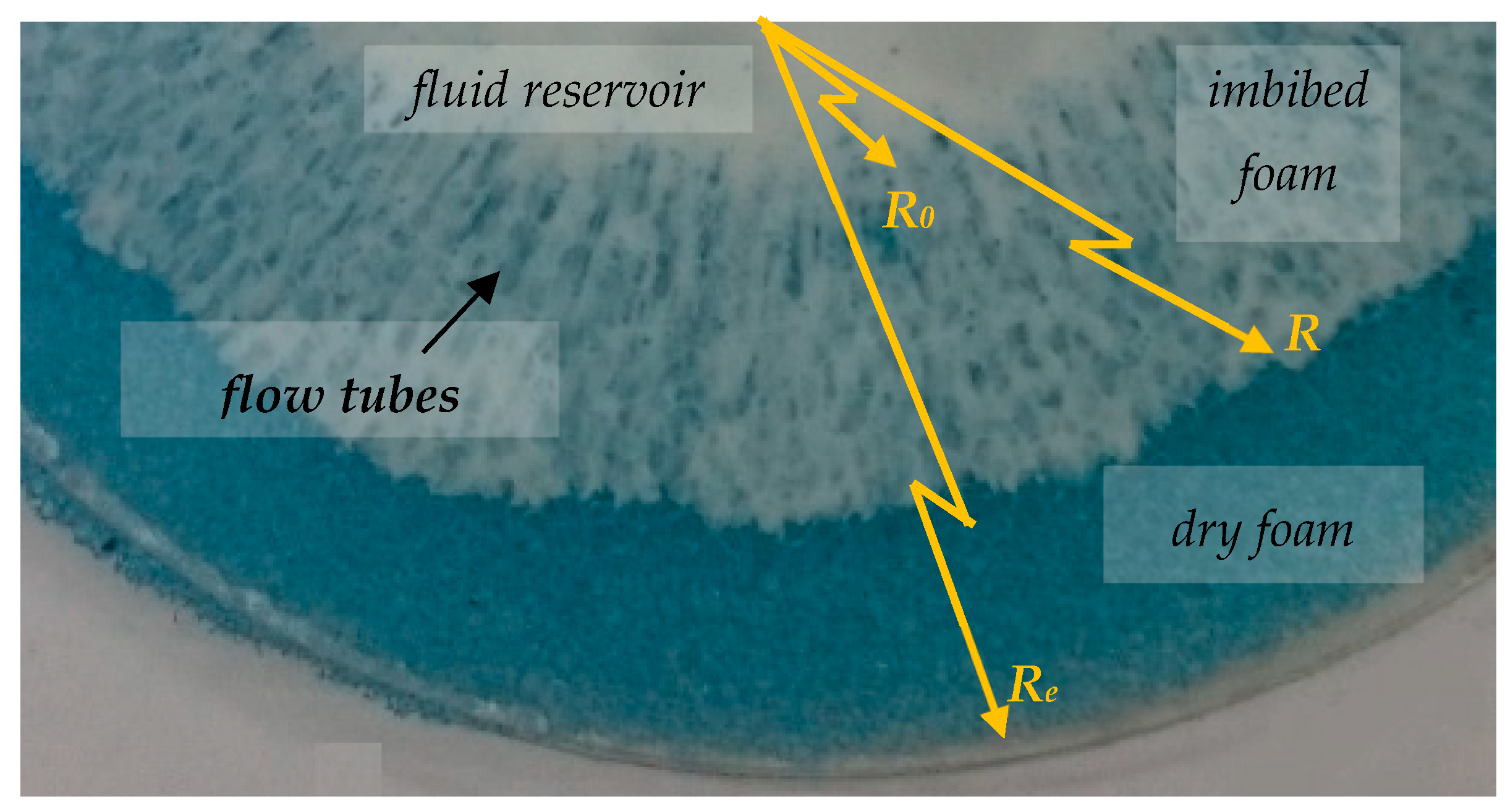

2. Experimental Evidence

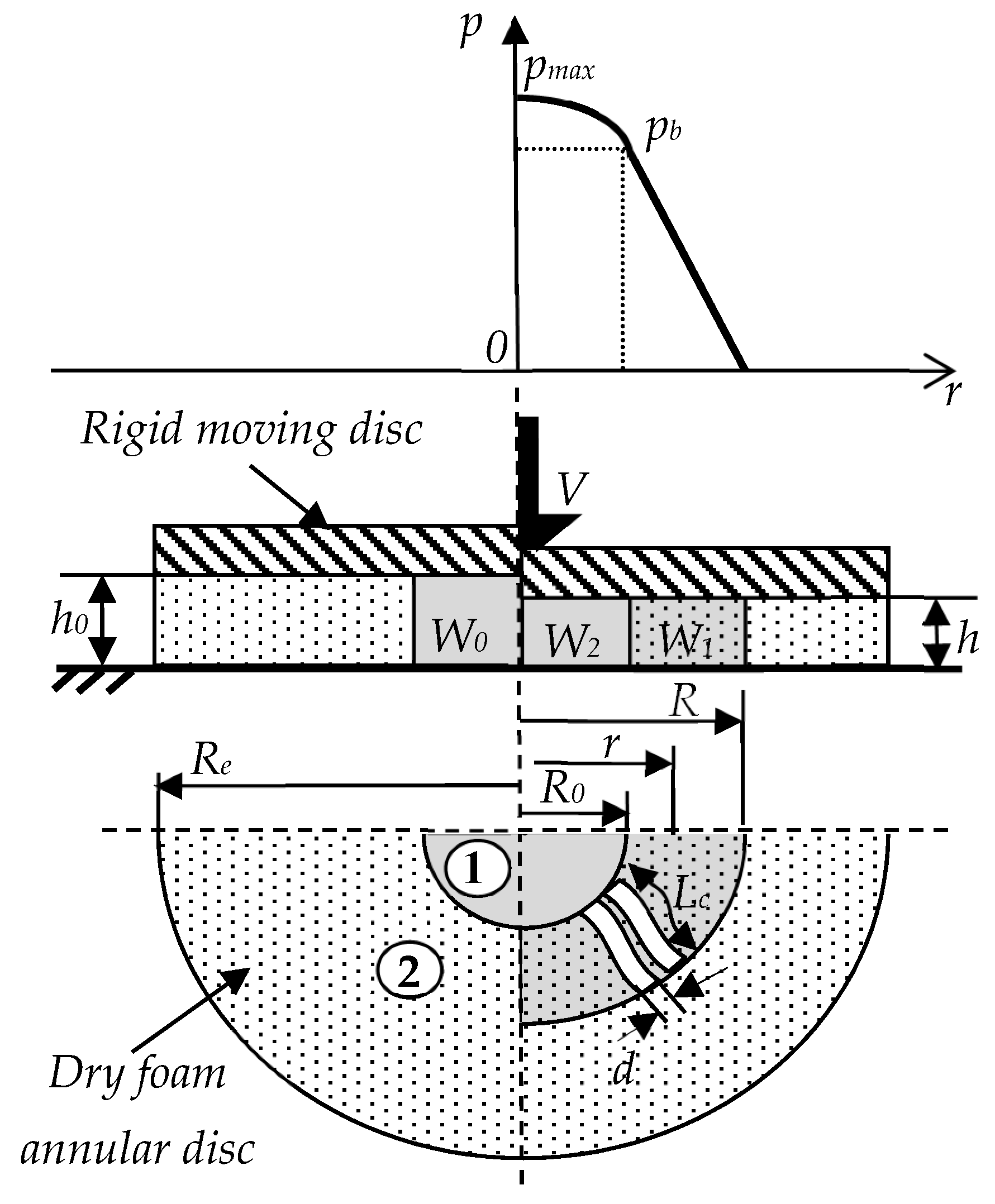

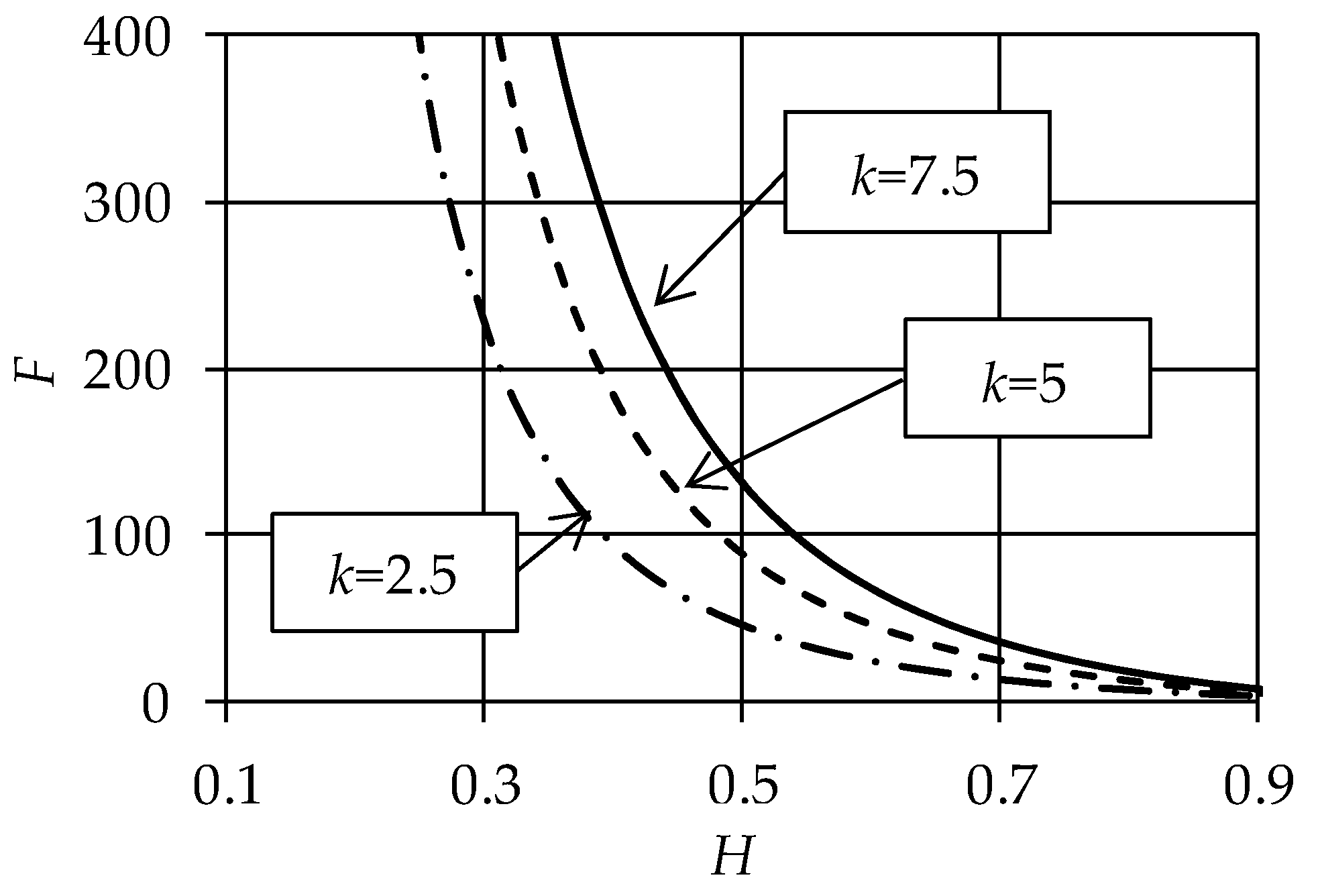

3. Analytical Model

3.1. Flow Model for Zone 1

3.2. Flow Model for Zone 2

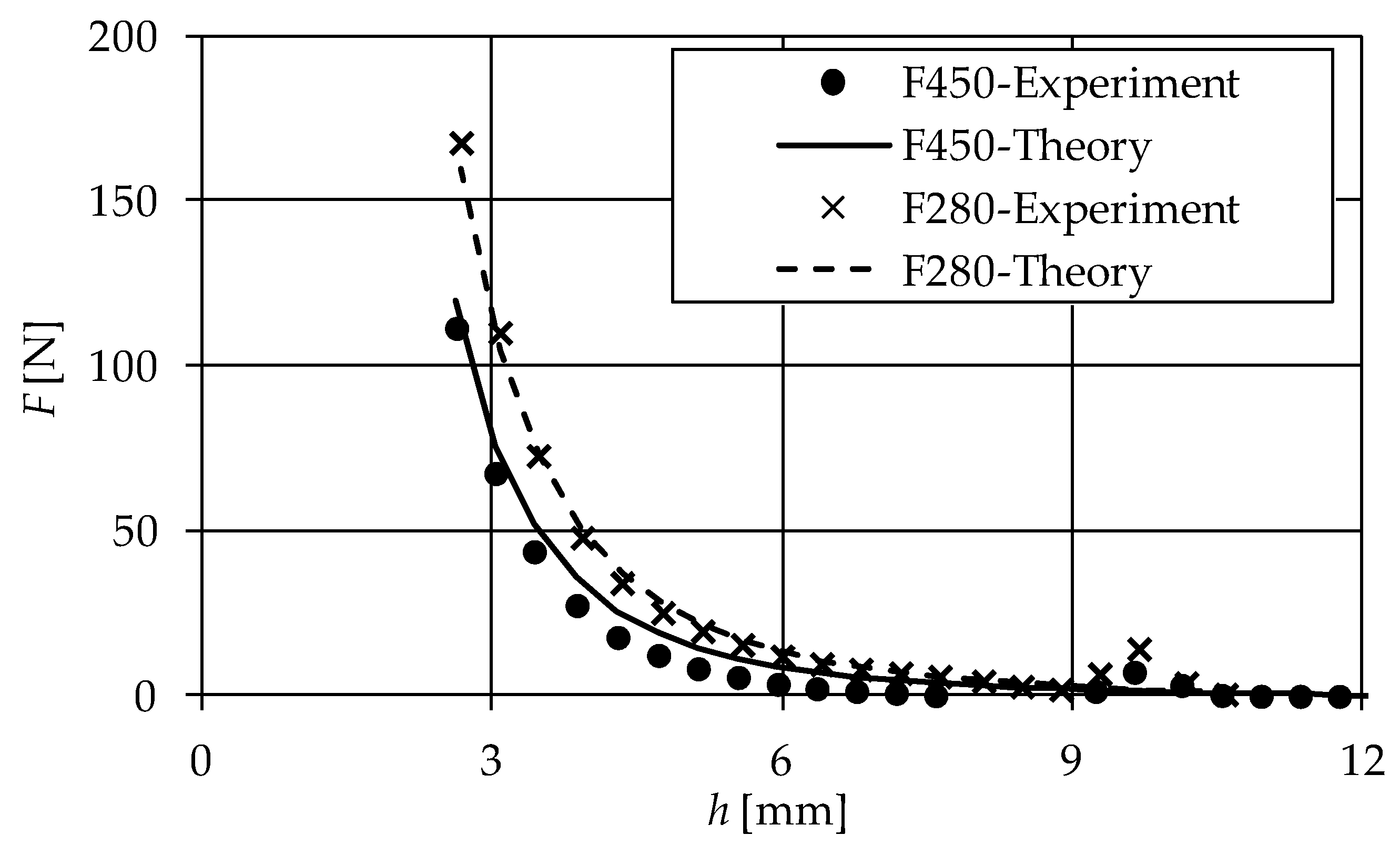

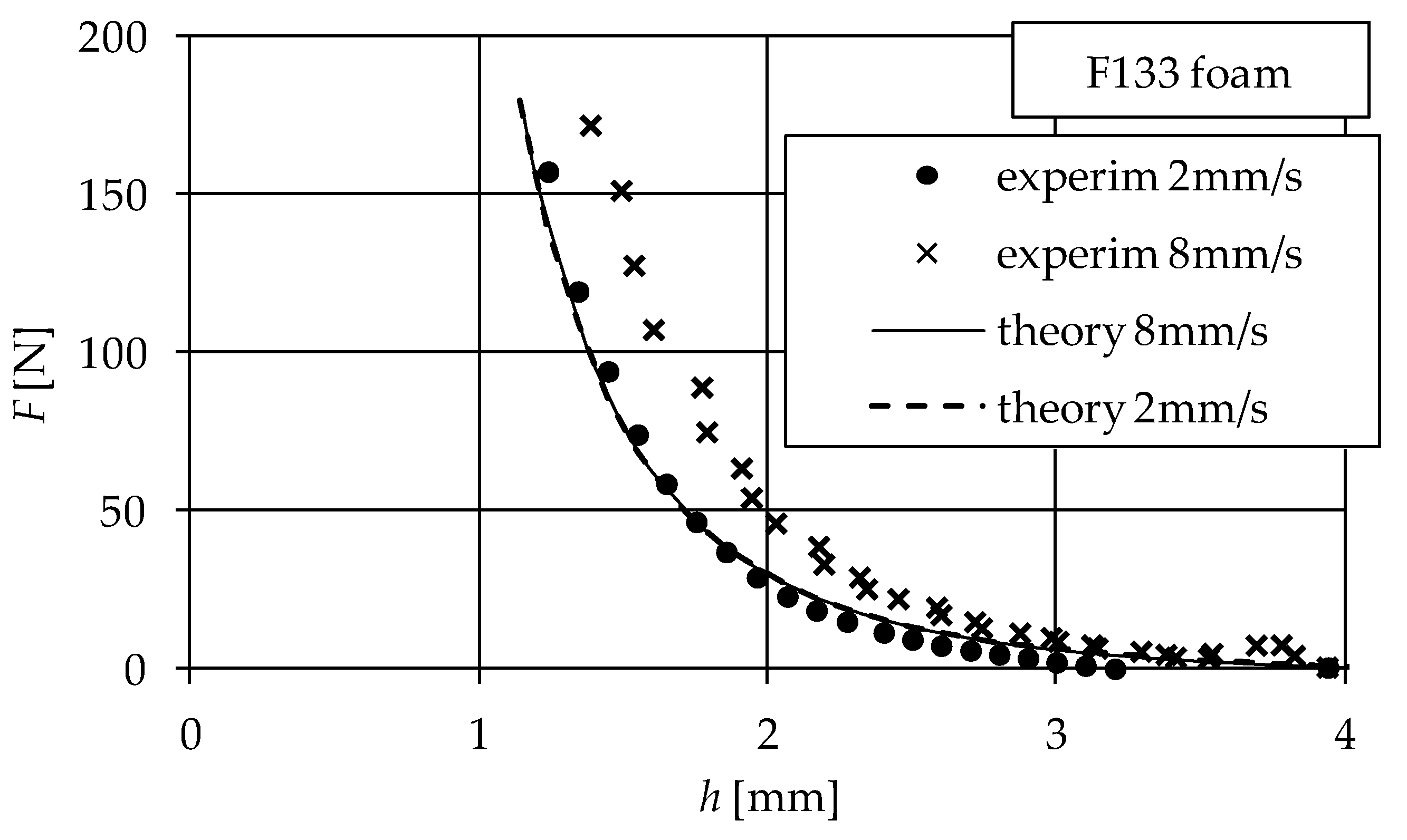

4. Model Validation

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

List of Notations

| Latin Alphabet Notations | |

| Bn | Bingham number, |

| d | average diameter of flow tube/pore |

| F | total force |

| dimensionless force, | |

| h | porous layer thickness |

| H | dimensionless layer thickness, |

| lc | length of elementary flow path |

| k | size factor, |

| p | pressure |

| pb | pressure at the boundary of the reservoir |

| r | radial coordinate |

| R | radius of the front of the flow |

| Re | outer radius of the annular disc |

| dimensionless relative radius of the front of the flow, | |

| S | plasticity number, |

| T | tortuosity, |

| um | fluid average velocity |

| V | squeeze speed |

| W | volume of fluid |

| Greek Alphabet Notations | |

| α | flow tube cross section area |

| β | tube cross section perimeter |

| ε | porosity |

| η | dynamic viscosity |

| ρ | hydraulic radius |

| τ0 | threshold/yield stress |

| Subscripts | |

| 0 | initial (corresponding to undeformed layer) |

| 1 | corresponding to zone 1 |

| 2 | corresponding to zone 2 |

Appendix A

References

- Pascovici, M.D.; Cicone, T. Squeeze-film of unconformal, compliant and layered contacts. Tribol. Int. 2003, 36, 791–799. [Google Scholar] [CrossRef]

- Pascovici, M.D.; Russu, C.; Cicone, T. Squeeze film of conformal, layered, compliant and porous contacts. Acta Teh. Napoc. Ser. Appl. Math. Mech. 2004, 47, 425–430. [Google Scholar]

- Radu, M.; Cicone, T. Squeeze effects of an infinitely long, rigid cylinder on a highly compressible porous layer imbibed with liquid. UPB Sci. Bull. Ser. D 2014, 76, 91–102. [Google Scholar]

- Pascovici, M.D.; Popescu, C.S.; Marian, V. Impact of a rigid sphere on a highly compressible porous layer imbibed with a Newtonian liquid. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2010, 224, 789–795. [Google Scholar] [CrossRef]

- Radu, M.; Cicone, T. Experimental determination of the damping capacity of highly compressible porous materials imbibed with water. J. Balkan Tribol. Assoc. 2014, 22, 390–400. [Google Scholar]

- Pascovici, M.D.; Cicone, T.; Marian, V. Squeeze process under impact, in highly compressible porous layers imbibed with liquids. Tribol. Int. 2009, 42, 1433–1438. [Google Scholar] [CrossRef]

- Melciu, C.; Cicone, T.; Pascovici, M.D. Saturated porous layers squeezed between parallel disks in enclosed cells. IOP Conf. Ser. Mater. Sci. Eng. 2017, 174, 012031. [Google Scholar] [CrossRef]

- Cicone, T.; Pascovici, M.D.; Melciu, C.; Turtoi, P. Optimal porosity for impact squeeze of soft layers imbibed with liquids. Tribol. Int. 2019, 138, 140–149. [Google Scholar] [CrossRef]

- Wu, Q.; Andreopoulos, Y.; Xanthos, S.; Weinbaum, S. Dynamic compression of highly compressible porous media with application to snow compaction. J. Fluid Mech. 2005, 542, 281–304. [Google Scholar] [CrossRef]

- Crawford, R.; Nathan, R.; Wang, L.; Wu, Q. Experimental study on the lift generation inside a random synthetic porous layer under rapid compaction. Exp. Therm. Fluid Sci. 2012, 36, 205–216. [Google Scholar] [CrossRef]

- Nabhani, M.; Khlifi, M.; Bou-Said, B. A general model for porous medium flow in squeezing film situations. Lubr. Sci. 2010, 22, 27–52. [Google Scholar] [CrossRef]

- Gbehe, O.S.T.; Khlifi, M.; Nabhani, M.; Bou-Said, B. Investigation of couple stress effects on poroelastic squeeze film of parallel plates. Lubr. Sci. 2017, 29, 93–113. [Google Scholar] [CrossRef]

- Dowson, M.A.; McKinley, G.H.; Gibson, L.J. The Dynamic Compressive Response of Open-Cell Foam Impregnated with a Non-Newtonian Fluid. J. Appl. Mech. 2009, 76, 061011. [Google Scholar] [CrossRef]

- Dawson, M.A. Modeling the Dynamic Response of Low-Density, Reticulated, Elastomeric Foam Impregnated with Newtonian and Non-Newtonian Fluids. Ph.D. Thesis, Massachusetts Institute of Technology, Cambridge, MA, USA, 2008. [Google Scholar]

- Vossen, B.G. Modeling the Application of Fluid Filled Foam in Motorcycle Helmets; Scientific Report; Eindhoven University of Technology: Eindhoven, The Netherlands, 2010. [Google Scholar]

- Chevalier, T.; Chevalier, C.; Clain, X.; Dupla, J.C.; Canou, J.; Rodts, S.; Coussot, P. Darcy’s law for yield stress fluid flowing through a porous medium. J. Non-Newton. Fluid Mech. 2013, 195, 57–66. [Google Scholar] [CrossRef]

- Pearson, J.R.A.; Tardy, P.M.J. Models for flow of non-Newtonian and complex fluids through porous media. J. Non-Newton. Fluid Mech. 2002, 102, 447–473. [Google Scholar] [CrossRef]

- Covey, G.H.; Stanmore, B.R. Use of the parallel-plate plastomer for the characterization of viscous fluids with a yield stress. J. Non-Newton. Fluid Mech. 1981, 8, 249–260. [Google Scholar] [CrossRef]

- Mitsoulis, E. Flows of viscoplastic materials: Models and computations. Rheol. Rev. 2007, 64, 135–178. [Google Scholar]

- Scheidegger, A.E. The Physics of Flow through Porous Media, 3rd ed.; University of Toronto Press: Toronto, ON, Canada, 1974. [Google Scholar]

- Delesse, M.A. Procede Mecanique Pour Determiner la Composition des Roches; Librarie de la Societe Geologique de France: Paris, France, 1866. [Google Scholar]

- Guyon, E.; Huliu, J.P.; Petit, L. Hydrodinamique Physique; EDP Sciences/CNRS Editions: Paris, France, 2001. [Google Scholar]

- Sun, Z.; Tang, X.; Cheng, G. Numerical simulation for tortuosity of porous media. Microporous Mesoporous Mater. 2013, 173, 37–42. [Google Scholar] [CrossRef]

- Salem, H.; Chilingarian, G. Influence of porosity and directional of flow on Tortuosity in unconsolidated porous media. Energy Sources 2000, 22, 207–213. [Google Scholar]

- Montillet, A.; Comiti, J.; Legrand, J. Determination of structural parameters of metallic foams from permeametry measurements. J. Mater. Sci. 1992, 27, 4460–4464. [Google Scholar] [CrossRef]

- Ortega, J.M. A porous media model for blood flow within reticulated foam. Chem. Eng. Sci. 2013, 99, 59–66. [Google Scholar] [CrossRef]

| Disc No. | Foam Symbol | Commercial Name | Pore size [mm] (1) | Initial Porosity, ε0 | Thickness h0 [mm] |

|---|---|---|---|---|---|

| 1 | F133 | FILTREN® TM 25133 | 1.06–1.66 | 0.976 | 12 |

| 2 | F280 | FILTREN® TM 25280 | 2.2–3.4 | 0.982 | 12 |

| 3 | F450 | FILTREN® TM 25450 | 3.4–5.6 | 0.997 | 12 |

| 4 | F133 | FILTREN® TM 25133 | 1.06–1.66 | 0.976 | 4 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Turtoi, P.; Pascovici, M.D.; Cicone, T. Squeeze Flow of Bingham Fluids through Reticulated, Compressed Foams. Lubricants 2019, 7, 86. https://doi.org/10.3390/lubricants7100086

Turtoi P, Pascovici MD, Cicone T. Squeeze Flow of Bingham Fluids through Reticulated, Compressed Foams. Lubricants. 2019; 7(10):86. https://doi.org/10.3390/lubricants7100086

Chicago/Turabian StyleTurtoi, Petrică, Mircea D. Pascovici, and Traian Cicone. 2019. "Squeeze Flow of Bingham Fluids through Reticulated, Compressed Foams" Lubricants 7, no. 10: 86. https://doi.org/10.3390/lubricants7100086

APA StyleTurtoi, P., Pascovici, M. D., & Cicone, T. (2019). Squeeze Flow of Bingham Fluids through Reticulated, Compressed Foams. Lubricants, 7(10), 86. https://doi.org/10.3390/lubricants7100086