Abstract

The processes taking place on the friction surface of high-alloyed aluminum alloys working with steel whilst replacing bronze journal bearings with aluminum are investigated. In this regard, eight experimental aluminum alloys with an Sn content from 5.4% to 11.0%, which also included Pb, Zn, Si, Mg, and Cu, were cast. The surface and subsurface layer of experimental aluminum bearings were studied before and after tribological tests with a 38HN3MA steel counterbody by scanning electron microscopy including energy-dispersive analysis. The best aluminum alloy, which had an Sn content of 5.8% after the friction tests, showed 6.5-times better wear resistance and steel counterbody wear rate than the bronze reference. Both structural and compositional changes in the surface layer were observed. It was revealed that secondary structures formed on the surface during the friction process and included all of the chemical elements in the tribosystem, which is a consequence of its self-organization. Generally, the secondary structures are thin metal-polymer films generated as a result of the high carbon and oxygen content. The interaction behavior of some of the chemical elements in the tribosystem is shown and discussed. In addition, the influence that Sn, Pb, Cu, and C content in the secondary structures has on the tribological properties of low-tin and medium-tin alloys is shown.

1. Introduction

Today, most cast monometallic journal bearings are made of antifriction bronzes of various grades. In railway transport, the most common of these is BrO4Z4S17 bronze (the closest equivalent being C83800 brass according to American Society for Testing and Materials standards ASTM B271, B505, B584) due to its mechanical and tribological properties, one and a half thousand tons of which is consumed each year. The task of increasing the economic efficiency of the production and operation of bearings always remains relevant, given the relatively high cost of copper, the main component of bronze. In this paper, the problem of replacing monometallic bronze journal bearings with bearings based on aluminum alloys is solved [1,2,3,4,5,6,7,8]. The transition from bronze to aluminum alloys is economically advantageous; aluminum is three times lighter than copper, and one kilogram of aluminum alloy is 2.5–2.7-times cheaper than bronze. Aluminum alloys are more fusible, and consequently, their casting is less energy consuming and takes less time, which makes it 15–20% cheaper. At the same time, the mechanical processing of bronze is 10–12% more expensive compared to that of aluminum alloys.

Another disadvantage of bronze bearings is the effects of the copper contained therein, which is a surfactant for steel. For this reason, untreated steel is destroyed under extreme friction conditions as a result of the Rebinder effect [9]. To avoid this, the steel must be subjected to additional chemical-thermal surface treatment. The application of aluminum journal bearings coupled with steel excludes the problems caused by the Rebinder effect.

In addition to the high tribological requirements, the materials which monometallic bearings are made of are required to be of high strength and hardness. This is partially achieved by increasing the thickness of the parts, but it is not cost effective. Monometallic bearings have mostly found application in large-sized units on railway, sea, and river transport, in the friction units of rolling mills, pumps, hydraulic drives, lifting and transport equipment, and machine tools and presses. However, as regards aluminum-based journal bearings, only bimetallic bearings with an antifriction layer made of AO20-1 (Sn-20%, Cu-1%) alloy on a steel body have become common worldwide [10,11].

The first works on aluminum journal bearings showed that multicomponent aluminum alloys can outperform those of bronze in tribological characteristics and have the potential to achieve the required mechanical properties [2,12]. The advantages of such aluminum alloys over BrO4Z4S17 bronze regarding their tribological properties are associated with a greater capacity for the self-organization of a complex aluminum alloy and the formation of a layer of protective secondary structures on its surface, unlike the initial state of the material [4,6,13]. For a more detailed understanding of the friction process, it is necessary to establish the principles of the interaction between the elements in the system regarding the formation of the secondary structures on the aluminum alloy surface.

The most common solution to the problem of improving the tribological and mechanical properties of aluminum alloys is to alloy them [14,15]. From the beginning of the investigations into this problem, the main components were tin and lead. Today, the alloying of aluminum alloys is becoming more complex, expanding the field of potential application. Thus, in Ref. [16], alloys of Al–Si–Cu–Sn–Pb and Al–Cu–Sn–Pb systems were investigated. In this study, the friction coefficient of the new alloys during testing was less than that of the reference AO20-1 alloy, which also showed the lowest wear rate. It was noted that the secondary structures formed by friction were saturated with various components and increased in thickness, acquiring the properties of a solid lubricant. However, the presence of any other elements, except oxygen, was not detected. The tests were carried out under boundary friction conditions with the lubricant Esso Turbo Diesel, the influence of which on the formation of secondary structures was not disclosed, the results fail to mention the lubricant components, mainly carbon. The composition, formation, and influence of secondary structures were not studied.

In another study [17], several aluminum alloys (Al–6Sn–2Pb–5Si–4Cu) were studied. Score-resistant tests showed results close to the reference BrO4Z4S17 bronze. Tribological tests were carried out without a lubricant. For this reason, the authors concluded that secondary structures are made up of smeared alloy components saturated with oxygen and the mass transfer of counterbody particles. Friction with a lubricant was not observed, nor were changes in the subsurface layer. Only theoretical conclusions on the influence of secondary structures on tribological properties were provided.

In Ref. [18], the alloy Al–6Sn–5Si–4Cu–2Pb–2Bi–1Fe was tested in dry conditions with steel. The authors point out that they obtained secondary structures on the surface by changing the elemental composition after friction. However, the presence of some elements, such as carbon, while the lubricant was absent is not explained.

Many scientists note that the processes at work on the friction surface are more complex and have more formation mechanisms than can be explained by oxygen saturation and mass transfer [19,20,21]. In particular, the occurrence of tribochemical reactions is common to all processes related to sliding friction [22]. Thus, today the development of aluminum alloys is often reduced to obtaining experimental compositions and the comparison of experimental data with equivalent studies. However, during the running-in process, secondary structures are formed which become the friction surface, determining the tribological properties of the alloy, and by studying the ways and common factors of their formation will help in the creation of alloys with better performance properties.

There is an approach in which the selection of optimal sliding bearings is based on the principle of least wear by introducing solid inclusions: carbides, oxides, and nitrides [23,24]. The disadvantage of this approach is the complete disregard for the wear intensification of the counterbody, which is usually the expensive steel shaft.

The aim of this project was to study the friction surface of experimental aluminum journal bearings in order to reveal the beneficial secondary structures which occur. In addition, it was necessary to study their composition and correlate it with the tribological properties of the alloys. Finally, the mechanisms of forming secondary structures were studied. The scientific data obtained within the project will contribute to the development of new and improved alloys, focusing on the specific tribological properties.

2. Materials and Methods

Eight experimental cast aluminum alloys were used in the study. The composition of each alloy included tin, lead, copper, silicon, magnesium, and zinc. The strength tests were carried out in accordance with Russian State Standard GOST 1497-84 on cylindrical samples with an estimated length of 30 mm and a diameter of 6 mm on an electromechanical test machine “Instron” (USA). Tribological tests were carried out in boundary friction conditions using a friction machine “SMC-2” with a loading device of up to 3000 N. The tests were performed on the rotating steel roller–fixed shoe of antifriction alloy (Figure 1). Generally, six tribological parameters for each sample were measured: score-resistance, conformability, alloy wear, steel counterbody wear, friction coefficient, and temperature. The samples were tested for 40 h coupled with a 38HN3MA counterbody with a permanent loading of 617 N and a lubricant supply rate of 0.2 g/min. M14V2 oil was used as lubricant. After the friction tests, the aluminum samples were exposed to multistage cleaning to remove lubricant residues. They were washed with warm water, degreased with carbon tetrachloride, kerosene, and acetone, and then washed again with cold water. The composition control of each alloy after casting was performed by emission spectrometer Spectrolab-S (Spectro Analytical Instruments GmbH, Kleve, Germany). The study of the initial state, friction surfaces, and secondary structures of the experimental alloys was performed on a Scanning Electron Microscope (SEM) “Tescan Vega 3” (Tescan a.s., Brno, Czech Republic) equipped with an Oxford Instruments (Abingdon, UK) energy-dispersive analysis (EDX) module with accuracy of up to hundredths of a percent. Before being placed in the microscope, the friction surfaces of the samples were rubbed with alcohol and dried, the cross-sections were further polished to remove the oxide film. All samples were examined at three magnifications: 100, 500, and 5000× using secondary and back-scattered electron detectors. For each of the specimens studied, EDX was used to compile maps of the chemical element distributions, the distribution of elements along the line, and the elemental composition in a local area of 1 μm2.

Figure 1.

(a) Kinematic configuration of the friction mechanism; (b) aluminum alloy shoe coupled with steel roller (the fragment was cut for research).

3. Results and Discussion

In this study, eight experimental alloys with different contents of alloying components were cast (Table 1). The lowest alloy weight wear and steel weight wear were determined to be the optimum criteria. Economically, it is wiser to use an alloy that wears the steel counterbody out slowly, whilst also wearing itself out slowly. According to the results of the tribological tests, the low-tin alloy No. 7 AO-5.8 with a tin content of 5.8% appeared to meet the criteria.

Table 1.

Composition and properties of experimental alloys.

The friction surface of the alloy after 40 h of run-in had significantly changed in both structure (Figure 2a,b) and in the qualitative elemental composition (Table 2). The results of these changes were the formation of secondary structures on the friction surface of the alloy. The formation of such secondary structures is a complex process of self-organization of the friction couple, in which all the objects of the tribosystem are involved: the bearing, the counterbody, and the lubricant. In this case, the data given in Table 1 are the average values over a visible area of 0.553 × 0.553 mm. However, the process of friction at the micro level can be represented as the friction of a number of separate local areas, different in mechanical and chemical properties. Thus, various conditions are locally provided for the formation of secondary structures, and as a result, their composition can differ significantly from one structural zone to another. Firstly, complex multicomponent alloying allows for an increase in the strength of the aluminum matrix, making it possible to use in monometallic bearing production. Secondly, the introduction of such elements as tin and lead leads to an improvement in the tribological properties. Tin, in its solid state as in aluminum, is practically insoluble and is present in aluminum alloy in the form of soft structural constituents.

Figure 2.

AO-5.8 alloy surface. (a) Scanning Electron Microscope (SEM) image of surface structure before friction; (b) SEM image of surface structure after friction; (c) tin distribution map (energy-dispersive analysis (EDX)) on the friction surface; (d) calcium distribution map (EDX).

Table 2.

AO-5.8 Element composition.

The distribution maps of elements (Figure 2c,d) on the friction surface of the alloy demonstrate that the formation of secondary structures in a number of cases is not accidental. In all samples of the experimental alloys, a match was found between the pairs of lead and sulfur elements, tin and calcium. In both cases, the alloy component reacted with the element from the lubricant, forming more stable compounds. Thus, the lubricant is able to decompose into components during the operation period, some of which react with the alloy elements, the other parts with the steel elements. These same processes explain the six-fold increase in the amount of carbon on the friction surface and the five-fold increase in oxygen. As a consequence, the secondary structures on the friction surface are metal-polymer films of different compositions [10,25].

Tin is capable of spreading over a considerable area during friction as a result of its ductility and fusibility, thus contributing to the mass transfer of other elements such as lead, which forms a low-melting eutectic with tin, and zinc, which increases the strength of this eutectic and its tribological properties [26,27]. This process, in turn, increases the localization of the formation of thin lead films capable of actively interacting with fatty acids and non-metals in the composition of lubricants to form lead soaps, which act like solid lubricant.

Copper, which is introduced into the alloy to increase its strength, forms a solid solution with aluminum, and is also present in the alloy as solid intermetallic inclusions of CuAl2 [28]. During the run-in process, such inclusions, as well as silicon ones, wear out more slowly than the aluminum matrix, realizing the Charpy principle on the surface and forming a beneficial oil-retaining microrelief, which also contributes to the formation of secondary structures. This makes it possible to increase the resistance score as a result of the reduction in the adhesion foci with steel, while at the same time its wear is increased because of the greater intensity of the transfer of iron-containing particles to the surface. This explains the increased iron content on the friction surface of the alloy.

In the subsurface layer of the alloy, the changes occur at a depth of up to 50 μm. In Figure 3a, the area of the aluminum matrix is seen with an outlet of tin inclusion at the surface. According to the geometry of the cavity containing it, this outlet was caused by plastic deformation of the surface layer and a physical decrease in the volume of the cavity, thus leaving only one possible direction for the output of the inclusion. However, it has been revealed that the components of a partially decomposed lubricant are not only able to form compounds on the friction surface, but are also able to penetrate by diffusion deep into the alloy (Figure 3b–d). First of all, this is true for tin, calcium, and potassium, as well as for a lead–sulfur pair.

Figure 3.

AO-5.8 alloy subsurface layer. (a) SEM image of subsurface structure after friction; (b) tin distribution map (EDX) on the friction surface; (c) calcium distribution map (EDX); (d) potassium distribution map (EDX).

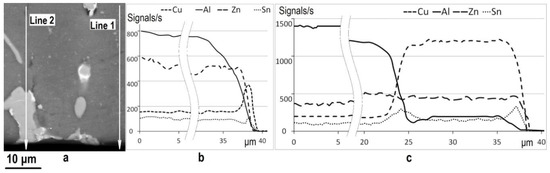

To determine the relative changes in the elements of the bearing material versus the depth of penetration, an energy-dispersive analysis was performed (Figure 4). The curve distribution character changes depending on the local area being analyzed (Figure 4b,c). In the area without inclusions, aluminum, the main component of the matrix, gradually wears out during the friction process (Figure 3b). The aluminum-depleted layer is about 5–7 micrometers thick. The same character of the distribution curves has the majority of alloying components, for example, zinc (Figure 4b). However, it is obvious that the surface content is higher relative to the matrix in which it is predominantly dissolved than it was in the initial state. The content of copper in the subsurface layer increases sharply. This is probably due to the difference in the wear rate of the softer aluminum matrix and copper inclusions: aluminum wears out at a faster rate, increasing the proportion of copper in the total composition of the subsurface layer. A small increase in content, accompanied by a small preliminary decrease, is shown by tin, and as a consequence, its satellites, calcium and potassium. If there were only an increase in the concentration of tin, it would enable it to be deposited from other sites through the “smearing” effect onto the surface. However, the presence of a depleted region on the graph allows us to infer the forced transfer (“pumping”) of this element from the subsurface layer to the friction surface.

Figure 4.

(a) AO-5.8 alloy elements distribution: (b) elements distribution along line 1; (c) elements distribution along line 2.

Tin, in the form of inclusions on the line being analyzed, was absent, but there were areas enriched by this element at the boundary of the aluminum matrix and copper inclusion, and also in the region where this inclusion enters the friction surface. Thus, the increased content of copper-based solid sections was accompanied by a more intense formation of secondary structures containing tin. Solid inclusions can increase the hardness of the alloy due to their mechanical properties, while in the process of friction, they also act as abrasive particles which increase the wear of the steel counterbody and increase the coefficient of friction. The tribosystem, in the process of self-organization, minimizes these negative aspects of friction by forming secondary structures that include tin alloy and lubricant components e.g., a polymer base, calcium, potassium. The thickness of such a film is 1 μm or less, so that electrons from the scanning microscope reaching the formations under the secondary structures allow the base signal to be recorded.

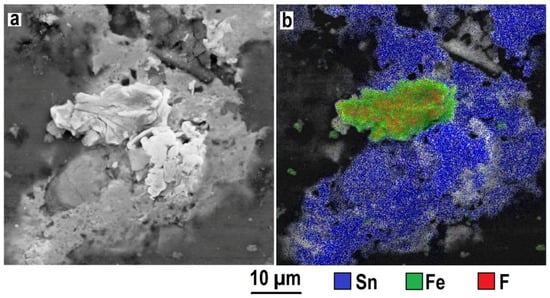

The formation of secondary structures is not always associated with the occurrence of tribochemical reactions during the friction process. Another mechanism for their formation is the mass transfer of steel-containing particles from a steel counterbody onto the surface of an aluminum alloy. The components of a solid lubricant, which are significantly distributed over the surface of the bearing, are not, however, able to completely eliminate the local foci of the friction bodies. If the grip area is small, then the fragment is detached from the object, and a mechanical run-in is realized. Such fragments can, for a while, appear as free abrasive particles, while they fall into the soft inclusions (“traps”) on the surface of the alloy (Figure 5). The larger the contact area, the less rough the steel surface becomes as a result of the detachment of the protrusions on the steel and their transfer to the mating surface. Thus, the higher the initial roughness, the more intensive the mass transfer of the steel.

Figure 5.

Steel-based fragment in tin outlet. (a) SEM image; (b) elements distribution map.

The element composition of both the steel inclusion and tin outlet significantly differed from the initial state (Table 3). Despite the fact that all the specimens were cleaned with a tetrachloromethane cleaning agent to remove any unstable lubricant waste after the friction process, an increase in the content of both carbon and oxygen was observed everywhere on the friction surface (Table 2 and Table 3). Thus, a polymer film must have formed during the friction process. Consequently, the majority of secondary structures were thin polymer films saturated with elements from each object of the tribosystem. The positive influence of polymer films on friction was observed before in Ref. [29,30,31].

Table 3.

Steel inclusion elements composition.

The composition of the steel inclusion corresponds to that of the initial state except for the presence of carbon, oxygen, and fluorine (Table 3). Taking into account the fact that the steel samples were prepared the same way, it can be concluded that polymer films as secondary structures were formed on steel surface as well. Furthermore, fluorine was only found on the steel inclusions, which reflects the fact that the secondary structures on steel were of a different type and their composition depended on the base material.

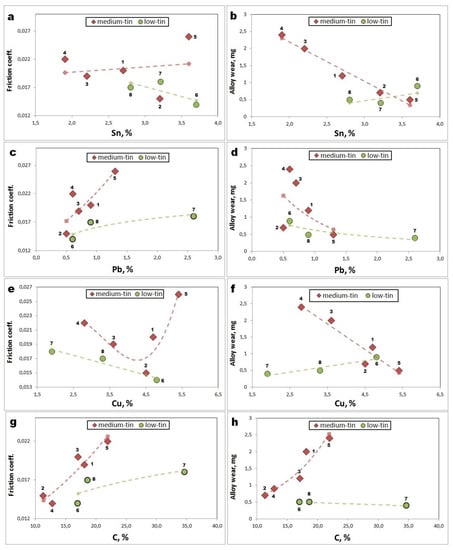

The self-organization process of aluminum alloy is considered to reduce the wear rate of a bearing. However, most engineers and researchers prefer the friction coefficient as the integral parameter to describe a bearing’s behavior. Since the alloys being studied were experimental, the influence of each component on the tribological properties, such as alloy wear and the friction coefficient, was determined within the research (Figure 6). All eight experimental alloys were divided into two groups: the first one contained medium-tin alloys with an Sn content of ≥7.6%; the second contained low-tin alloys with an Sn content of <7.6%. However, there is no strict rule on the tin content of medium-tin and low-tin aluminum alloys. The threshold makes it possible to obtain the most visible and ordered dependencies to help understand the contribution of each element. Otherwise, dependencies are not clearly observed.

Figure 6.

Dependence graphs of the component contents in the secondary structures on the tribological properties of alloys. (a) Tin influence on friction coefficient; (b) tin influence on alloy wear; (c) lead influence on friction coefficient; (d) lead influence on alloy wear; (e) copper influence on friction coefficient; (f) copper influence on alloy wear; (g) carbon influence on friction coefficient; (h) carbon influence on alloy wear.

An increase in tin content in the secondary structures of aluminum alloys caused a slight increase in the friction coefficient of the medium-tin alloys and a more pronounced decrease for the low-tin alloys. (Figure 6a,b). Contrary to expectations, the wear of the alloy does not correlate with the coefficient of friction and has the opposite tendency: a decrease of up to five times for medium-tin alloys and an increase of two times for low-tin alloys. It should be noted that the dependence of the wear of the alloy on the content of tin can be accurately described by linear equations. Probably, for alloys of the first group, tin performed the direct function of “solid lubrication”, reducing the wear of the alloy. In the second case, an excess of tin on the surface was the possible reason for its functions, as a result of which the soft and ductile metal was gradually worn out. A slight slope of the straight trend line indicates that this excess is insignificant.

Lead is another soft component of the “solid lubricant”. It has similar tendencies as regards an increase in the content for the medium-tin alloys, but the reverse character for low-tin alloys (Figure 6c,d). In the case of the first group of alloys, the mechanism described for the influence of tin seems to also explain the mechanism at work here.

Copper formed an intermetallic compound (CuAl2) with aluminum and was present in the alloy in the form of hard inclusions. The dependence of the friction coefficient on the copper content for the alloys of the first group can be described by a polynomial of the second degree and has a pronounced minimum of 4.5% Cu (Figure 6e,f). Copper and copper-based inclusions make the alloy stronger and harder, thus reducing its wear. This explains the almost rectilinear decrease in the wear parameters of the alloy by a factor of five with the increasing of the copper content. The coefficient of friction of the low-tin alloys decreased with the increasing copper content in the secondary structures, and therefore, the wear of the alloy increased.

For the three described elements in the low-tin alloys, attention is drawn to the fact that the wear curve of the alloy is a mirror image of the friction coefficient curve. Moreover, for lead, an increase in the friction coefficient was accompanied by a decrease in wear of the alloy. The increase in the friction coefficient can occur as a result of, for example, an increasing number of seizure areas on the coupled bodies. The theory of self-organization describes this process from the point of view of entropy production; the higher it is, the higher the wear [32]. The system self-organizes to maintain efficiency, in particular, by the onset of tribochemical reactions that can occur with a negative entropy production. A lack of resources for self-organization, or an excessive critical load, lead to the most severe wear of the friction body (the pre-score condition), followed by a score, whereby the friction body cannot completely wear out.

Carbon is the component of the lubricant which was found in every area on the friction surface. For medium-tin alloys there was an almost direct relationship between the friction coefficient and the wear of the alloy (Figure 6g,h). It can be considered that for medium-tin alloys, carbon is not that valuable in terms of reducing the wear rate, as the content of Sn and Pb is enough to perform the function. In the case of low-tin alloys, carbon is necessary to form beneficial metal-polymer films, thus decreasing the wear while the friction coefficient is slowly growing.

4. Conclusions

Eight experimental aluminum alloys of tribological application with a tin content of 5.4% to 11.0%, which also contained Pb, Mg, Zn, Si, and Cu, were cast. After friction tests, the AO-5.8 (Sn-5.8%) alloy showed the best wear rate, exceeding the reference bronze by 5–6 times. By means of electron microscopy and energy dispersive analysis, different areas of the friction surface were investigated. It was shown that different types of secondary structures were formed. The mechanisms involved in their formation are as follows:

- Smearing (tin, lead)

- Mass transfer (steel)

- Diffusion (oil components)

- Oxidation

- Surface polymerization (carbon-based secondary structures)

- Tribochemical reactions (tin–calcium, steel–fluorine)

During the running-in process, the friction surface undergoes not only structural changes, but also component composition changes through the formation of profitable secondary structures. In the formation of these structures, all the objects of the tribosystem are involved to various degrees, and the secondary structures themselves differ in composition in different areas of the alloy surface. Thus, the manufactured bearing is a “workpiece”, the final processing of which is carried out at the stage of running-in. In this stage, the friction surface is modified as a result of tribochemical reactions within the self-organization process. The mechanical running-in process also involves steel protrusions transferring onto the alloy causing a decrease in the roughness of the counterbody.

The self-organization processes affect medium-tin and low-tin alloys in differing ways. Furthermore, each component affects the tribological properties of the alloy differently, and can be adjusted in order to obtain the alloy with the highest conformability and the lowest rate of wear. The variety of alloying components determines the degree of freedom the tribosystem has for the formation of secondary structures.

Author Contributions

conceptualization, I.G. and A.M.; methodology, P.P. (Pavel Podrabinnik) and A.M.; validation, P.P. (Pavel Podrabinnik), A.M. and E.K.; formal analysis, A.M.; investigation, P.P. (Pavel Podrabinnik); resources, E.K, P.P. (Pavel Peretyagin), and A.M.; data curation, E.K.; writing—original draft preparation, P.P. (Pavel Podrabinnik); writing—review and editing, I.G. and A.M.; visualization, P.P. (Pavel Podrabinnik); supervision, I.G. and A.M.; project administration, I.G., P.P. (Pavel Peretyagin) and E.K.

Funding

We would like to thank the Ministry of Education and Science of the Russian Federation for supporting this work under contract No. 075-02-2018-140, unique identifier of contract RFMEFI57718X0288.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Lu, Z.C.; Gao, Y.; Zeng, M.Q. Improving Wear performance of dual-scale Al -Sn alloys. The role of Mg addition in enhancing Sn distribution and tribolayer stability. Wear 2014, 309, 216–225. [Google Scholar] [CrossRef]

- Stolyarova, O.O.; Muravyeva, T.I.; Kurbatkin, I.I.; Belov, N.A. Investigation of tribological properties and structure of new aluminum bearing alloys. Materialovedenie 2014, 8, 12–17. (In Russian) [Google Scholar]

- Belov, N.; Gershman, E.; Gershman, I.; Goryacheva, I.; Zagorsky, D.; Kotova, E.; Mahovskaya, Yu.; Merzin, A.; Mironov, A.; Muravyeva, T.; et al. Aluminum Alloys for Antifriction Applications, 1st ed.; MISIS: Moscow, Russia, 2016; p. 222. ISBN 978-5-906848-22-8. [Google Scholar]

- Mironov, A.E.; Gershman, I.S.; Gershman, E.; Zakharov, S.M.; Podrabinnik, P. Aluminum casting antifriction alloys with increased capacity to adaptability of friction surfaces. Vestnik 2017, 76, 336–340. [Google Scholar] [CrossRef]

- Babu, M.V.; Rama Krishna, A.; Suman, K.N.S. Review of Journal Bearing Materials and Current Trends. Am. J. Mater. Sci. Technol. 2015, 2, 72–83. [Google Scholar] [CrossRef]

- Fox-Rabinovich, G.; Veldhuis, S.C.; Kovalev, A.I.; Wainstein, D.L.; Gershman, I.S.; Korshunov, S.; Shuster, L.S.; Endrino, J.L. Features of self-organization in ion modified nanocrystalline plasma vapor deposited AlTiN coatings under severe tribological conditions. J. Appl. Phys. 2007, 102, 074305. [Google Scholar] [CrossRef]

- Rusin, M.; Skorentsev, A.L.; Kolubaev, E.A. Dry friction of pure aluminum against steel. J. Frict. Wear 2016, 37, 109–118. [Google Scholar] [CrossRef]

- Bertelli, F.; Freitas, E.S.; Cheung, N.; Arenas, M.A.; Conde, A.; de Damborenea, J.; Garcia, A. Microstructure, tensile properties and wear resistance correleations on directionally solidified Al-Sn-(Cu; Si) alloys. J. Alloys Compd. 2017, 695, 3621–3631. [Google Scholar] [CrossRef]

- Rebinder, P.; Shchukin, E. Surface Phenomena in Solids under Deformation and Fracture. Uspekhi Fizicheskih Nauk 1972, 108, 3–40. [Google Scholar] [CrossRef]

- Belov, N.; Akopyan, T.K.; Gershman, I.S.; Stolyarova, O.O.; Yakovleva, A.O. Effect of Si and Cu additions on the phase composition, microstructure and properties of Al-Sn alloys. J. Alloys Compd. 2016, 695, 2730–2739. [Google Scholar] [CrossRef]

- Liu, X.; Zeng, M.Q.; Ma, Y.; Zhu, M. Promoting the high-load carrying capability of Al-20wt% Sn bearing alloys through creating nanocomposite structure by mechanical alloying. Wear 2012, 294–295, 387–394. [Google Scholar] [CrossRef]

- Österreicher, J.A.; Papenberg, N.P.; Kumar, M.; Ma, D.; Schwarz, S.; Schlögl, C.M. Quantitative prediction of the mechanical properties of precipitation-hardened alloys with special application to Al–Mg–Si. Mater. Sci. Eng. A 2017, 703, 380–385. [Google Scholar] [CrossRef]

- Lu, Z.C.; Zeng, M.Q.; Xing, J.Q.; Zhu, M. Improving wear performance of CuSn5Bi5 alloys through forming self-organized graphene/Bi nanocomposite tribolayer. Wear 2016, 364–365, 122–129. [Google Scholar] [CrossRef]

- Bushe, N.A. Bearings of Aluminum Alloys; Transport: Moscow, Russia, 1974; p. 255. (In Russian) [Google Scholar]

- Khonsari, M.M.; Booser, E.R. Applied Tribology: Bearing Design and Lubrication, 3rd ed.; Wiley: New York, NY, USA, 2017; p. 672. ISBN 978-1-118-63724-1. [Google Scholar]

- Kurbatkin, I.I.; Belov, N.A.; Ozerskiy, O.N.; Muravyeva, T.I.; Stolyarova, O.O.; Alabin, A.N. Tribological and Structural study of new aluminum-based antifriction materials. J. Frict. Wear 2014, 35, 93–97. [Google Scholar] [CrossRef]

- Sachek, B.Y.; Mezrin, A.M.; Muravyeva, T.I.; Stolyarova, O.O.; Zagorskiy, D.L.; Belov, N.A. Investigation of the Tribological Properties of Antifrictional Aluminum Alloys using Sclerometry. J. Frict. Wear 2015, 36, 103–111. [Google Scholar] [CrossRef]

- Sachek, B.Y.; Mezrin, A.M.; Shcherbakova, O.O.; Muravyeva, T.I.; Zagorskiy, D.L. Studies on the Tribological Properties and Structure of Antifrictional Iron-Containing Aluminum Alloys. J. Frict. Wear 2018, 39, 206–214. [Google Scholar] [CrossRef]

- Bershadsky, L.I. On Self-organizing and concept of tribosystem. J. Frict. Wear 1992, 13, 101–114. [Google Scholar]

- Gershman, I.S.; Fox-Rabinovich, G.; Mironov, A.; Veldhuis, S. Self-Organization during Friction of Slide Bearing Antifriction Materials. Entropy 2015, 17, 7967–7978. [Google Scholar] [CrossRef]

- Fox-Rabinovich, G.S.; Yamamoto, K.; Beake, B.D.; Gershman, I.S.; Kovalev, A.I.; Veldhuis, S.C.; Aguirre, M.H.; Dosbaeva, G.; Endrino, J.L. Hierarchical adaptive nanostructured PVD coatings for extreme tribological applications: The quest for non-equilibrium states and emergent behavior. Sci. Technol. Adv. Mater. 2012, 13, 034001. [Google Scholar] [CrossRef] [PubMed]

- Nakayama, K.; Martin, J.-M. Tribochemical reactions at and in the vicinity of a sliding contact. Wear 2006, 261, 235–240. [Google Scholar] [CrossRef]

- Gorlenko, A.O.; Davydov, S.V.; Erokhin, A.N. Tribodiagnostics spherical plain bearings. Handbook 2017, 9–13. [Google Scholar] [CrossRef]

- Brizmer, V.; Stadler, K.; van Drogen, M.; Han, B.; Matta, C.; Piras, E. The tribological performance of black oxide coating in rolling/sliding contacts. Tribol. Trans. 2017, 60, 557–574. [Google Scholar] [CrossRef]

- Piskarev, A.S.; Sil’chenko, O.B.; Kuritsyna, V.V.; Siluyanova, M.V. Analysis of structural solutions at design of high-loaded sliding bearings with liquid lubricants. Vestnik Mashinostroeniya 2018, 5, 37–43. [Google Scholar]

- Springer, H.; Szczepaniak, A.; Raabe, D. On the role of zinc on the formation and growth of intermetallic phases during interdiffusion between steel and aluminium alloys. Acta Mater. 2015, 96, 203–211. [Google Scholar] [CrossRef]

- Kiran, T.S.; Prasannakumar, M.; Basavarajappa, S.; Viswanatha, B.M. Effect of heat treatment on tribological behavior of zinc aluminum alloy reinforced with graphite and SIC particles for journal bearing. Ind. Lubr. Tribol. 2015, 67, 292–300. [Google Scholar] [CrossRef]

- Menshikova, S.G.; Shirinkina, I.G.; Brodova, I.G.; Lad’yanov, V.I.; Suslov, A.A. A study of the structure and properties of aluminum alloys with copper produced under superfast cooling of melt. Met. Sci. Heat Treat. 2018, 3, 45–52. [Google Scholar] [CrossRef]

- Wang, Y.; Pu, J.; Wang, J.; Li, J.; Chen, J.; Xue, Q. Interlayer design for the graphite-like carbon film with high load-bearing capacity under sliding-friction condition in water. Appl. Surf. Sci. 2014, 311, 816–824. [Google Scholar] [CrossRef]

- Kajita, S.; Righi, M.C. A fundamental mechanism for carbon-film lubricity identified by means of ab initio molecular dynamics. Carbon 2016, 103, 193–199. [Google Scholar] [CrossRef]

- Furey, J. The formation of polymeric films directly on rubbing surfaces to reduce wear. Wear 1973, 26, 369–392. [Google Scholar] [CrossRef]

- Gershman, I.; Gershman, E.; Mironov, A.; Fox-Rabinovich, G.; Veldhuis, S. Application of the Self-Organization Phenomenon in the Development of Wear Resistant Materials—A Review. Entropy 2016, 18, 385. [Google Scholar] [CrossRef]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).