Tribological Properties of the Lubricant Containing Titanium Dioxide Nanoparticles as an Additive

Abstract

:1. Introduction

2. Experimental Details

2.1. Materials, Blend Oil Process, and Characterization

2.2. Measurement of Anti-Wear and Friction-Reducing Properties, Analysis of the Friction Surface

- -

- First, three 12.7 mm diameter steel balls are clamped together and covered with 12.7 mL of OMV oil white 32 oil. The fourth 12.7-mm diameter ball, referred to as the “top ball”, is pressed with a force of 400 N (pc ≈ 2269.6 Pa) into the cavity formed by the three clamped balls and with three points of contact. The temperature of the wear-in lubricant is regulated at 75 °C; then, the top ball is rotated at 600 rpm (v = 1.25 m/s) for 60 min.

- -

- Second, white oil is discarded and balls cleaned. The WSD on each of the lower three balls is examined. If the wear scars average of the balls is 0.63 mm ± 0.03 mm, then the 12.7 mL of test fluid is added to the ball cup with the worn-in test balls in place. The temperature of the test lubricant is regulated at 75 °C, and the top ball is rotated at 600 rpm (v = 1.25 m/s) at 100 N (pc = 1429.1 Pa) for 10 min.

- -

- Third, the load is then increased by 100 N (pc = 1429.1 Pa) at the end of each successive 10 min interval. The friction coefficient is measured at the end of each 10 min interval.

3. Result and Discussion

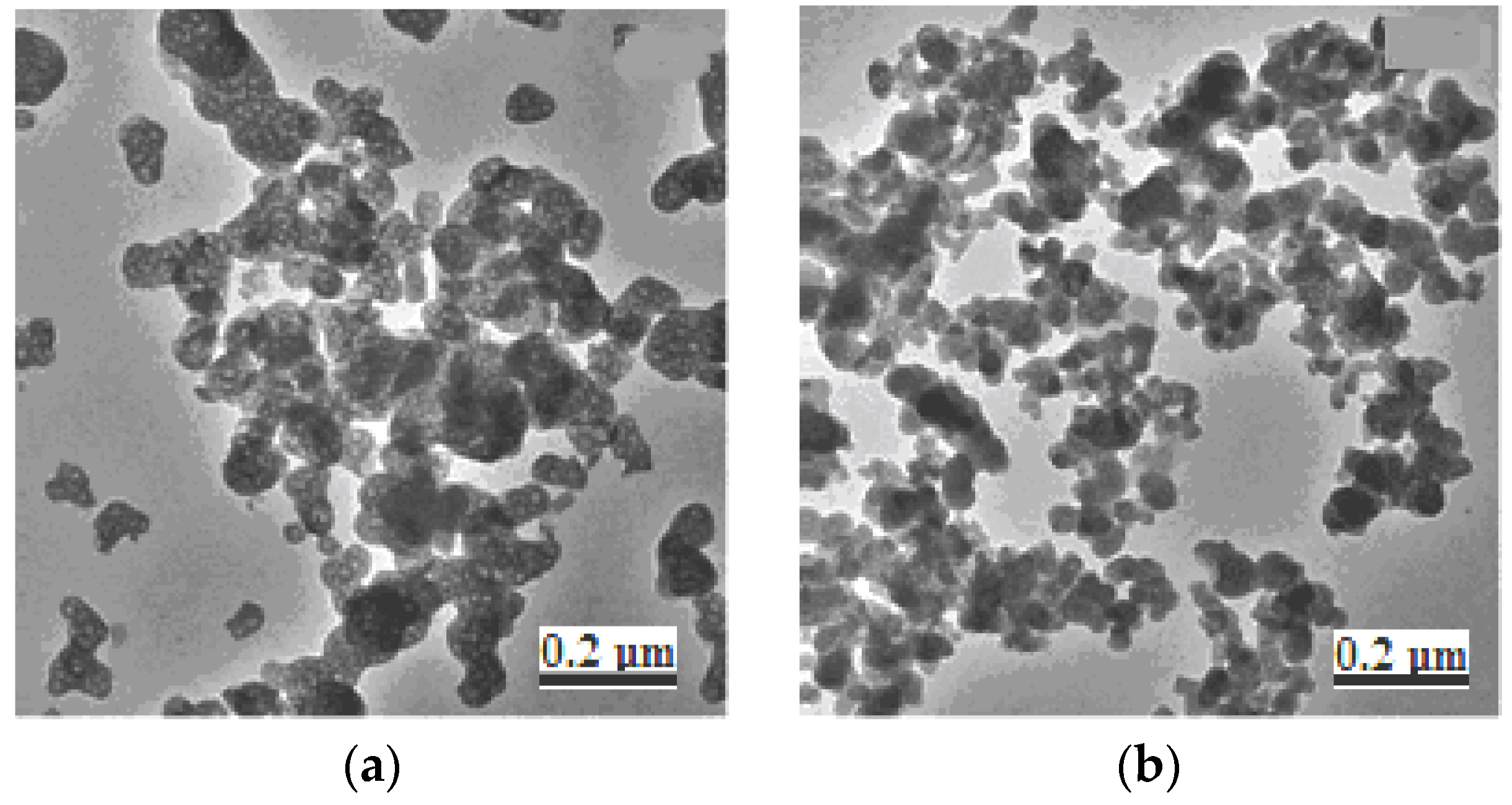

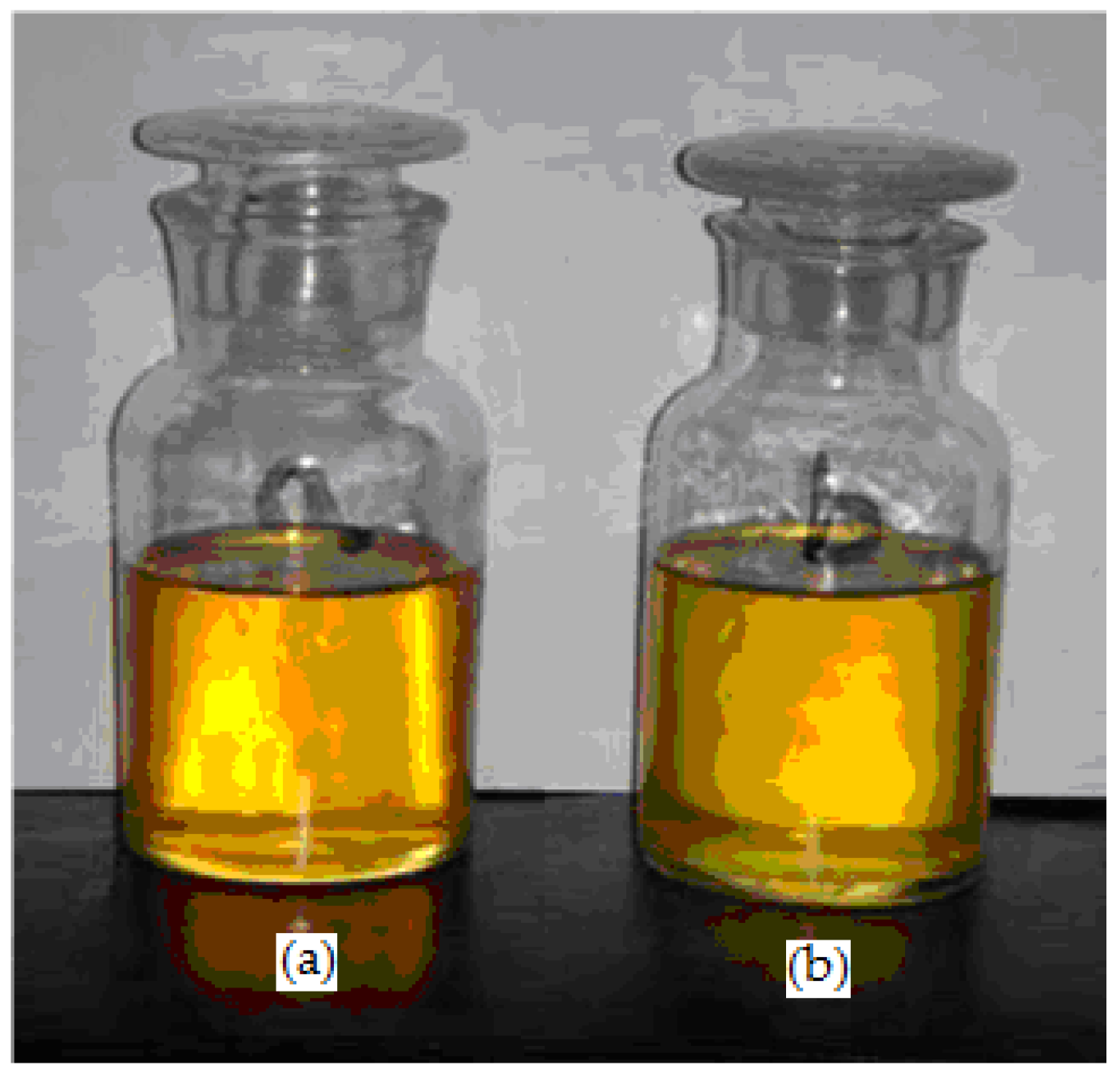

3.1. Structure and the Dispersing Stability of TiO2 Nanoparticles

- (1)

- Brownian movement caused by the impact of liquid molecules reduces the effect of gravity so that at a limiting size the nanoparticles will stay in suspension indefinitely.

- (2)

- The surface energy of the solid/liquid interface (TiO2 nanoparticles/base oil) increases with decreasing nanoparticle size.

- -

- First, the effect of surface modification of oleic acid contributes to the good dispersion property.

- -

- Second, weaker agglomerates were grossly eliminated by means of the ultrasound irradiation and direct insert during the novel blending process.

- -

- Third, the higher temperature accelerates the Brownian motion of lubricant, which is helpful to the dispersion of the nanoparticles.

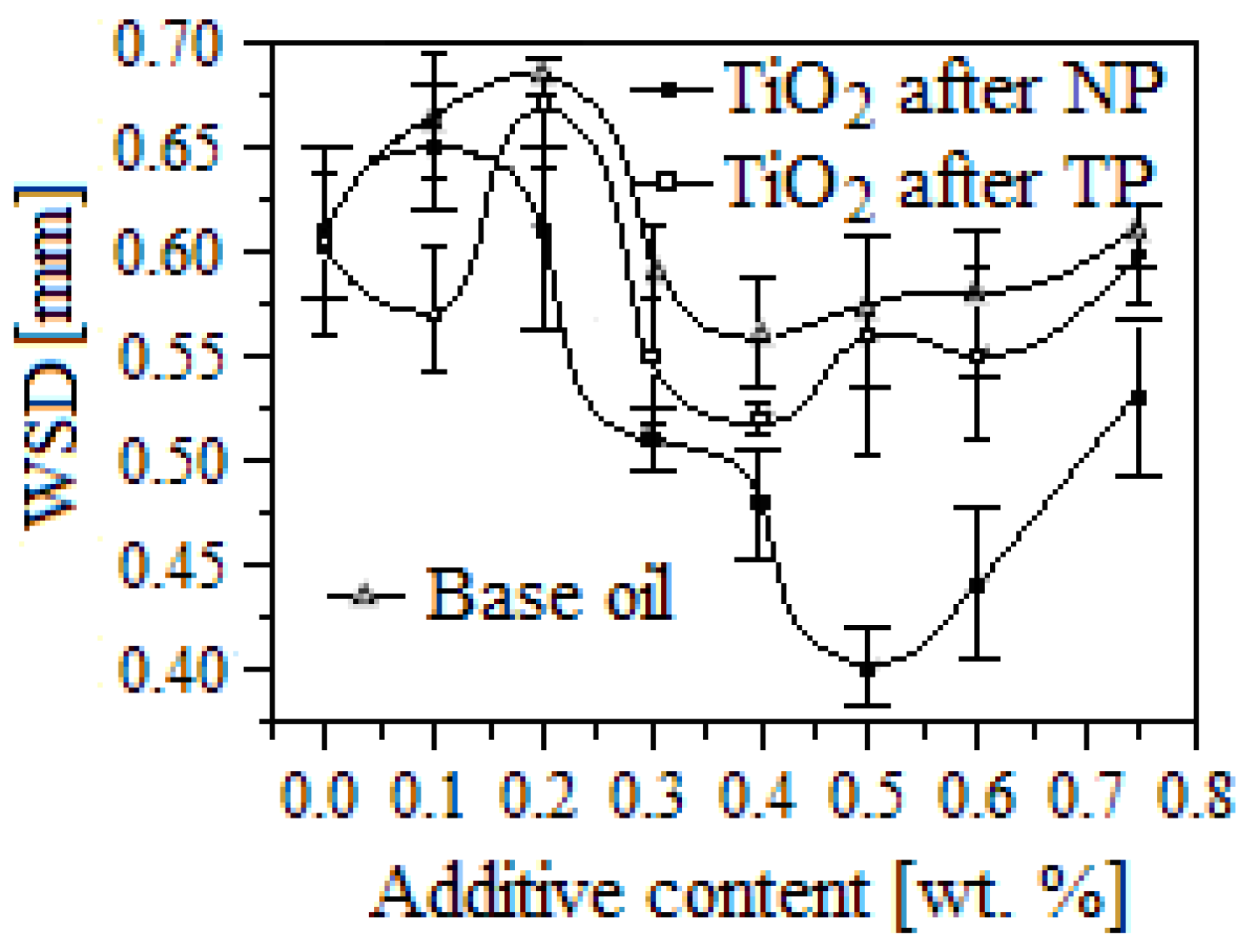

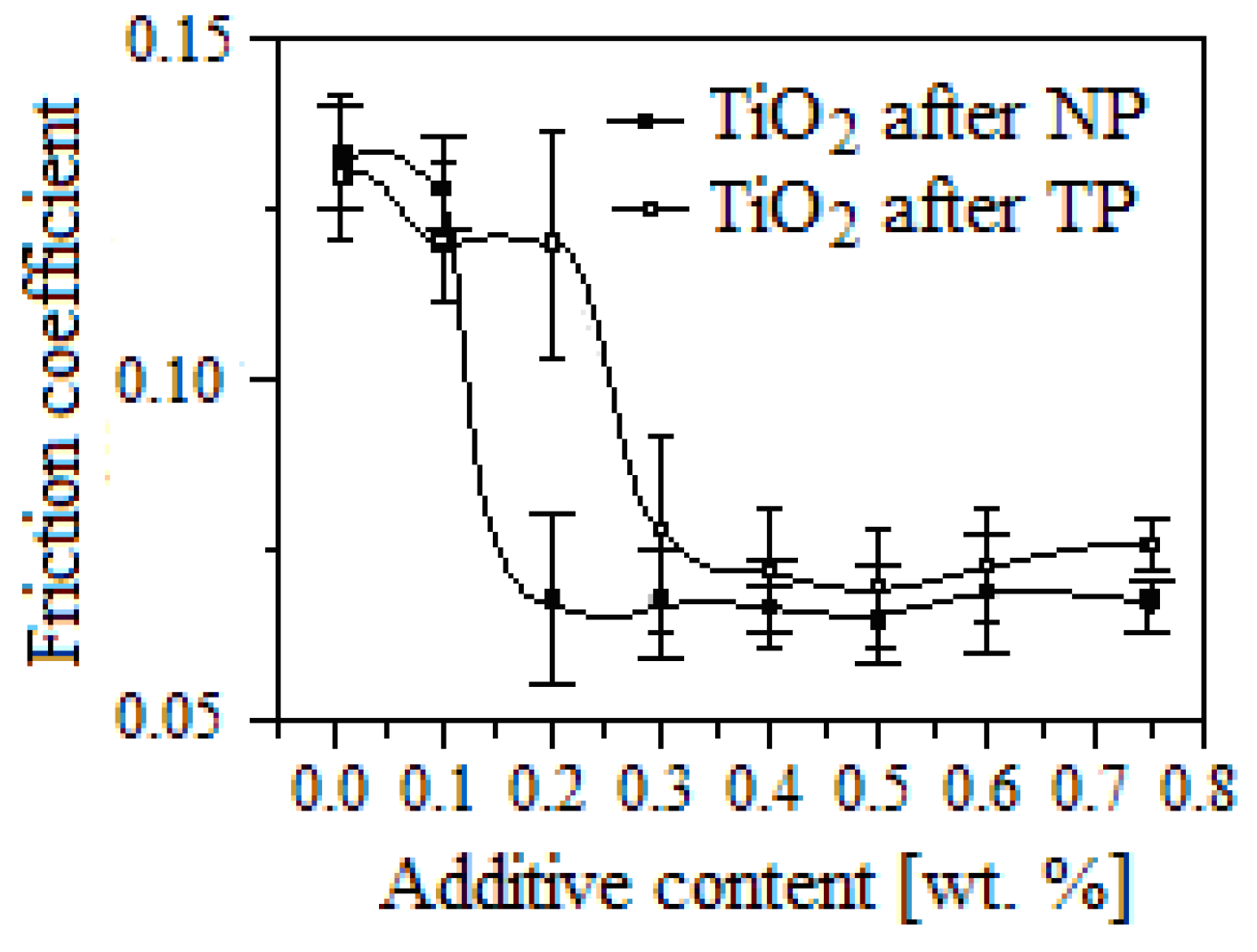

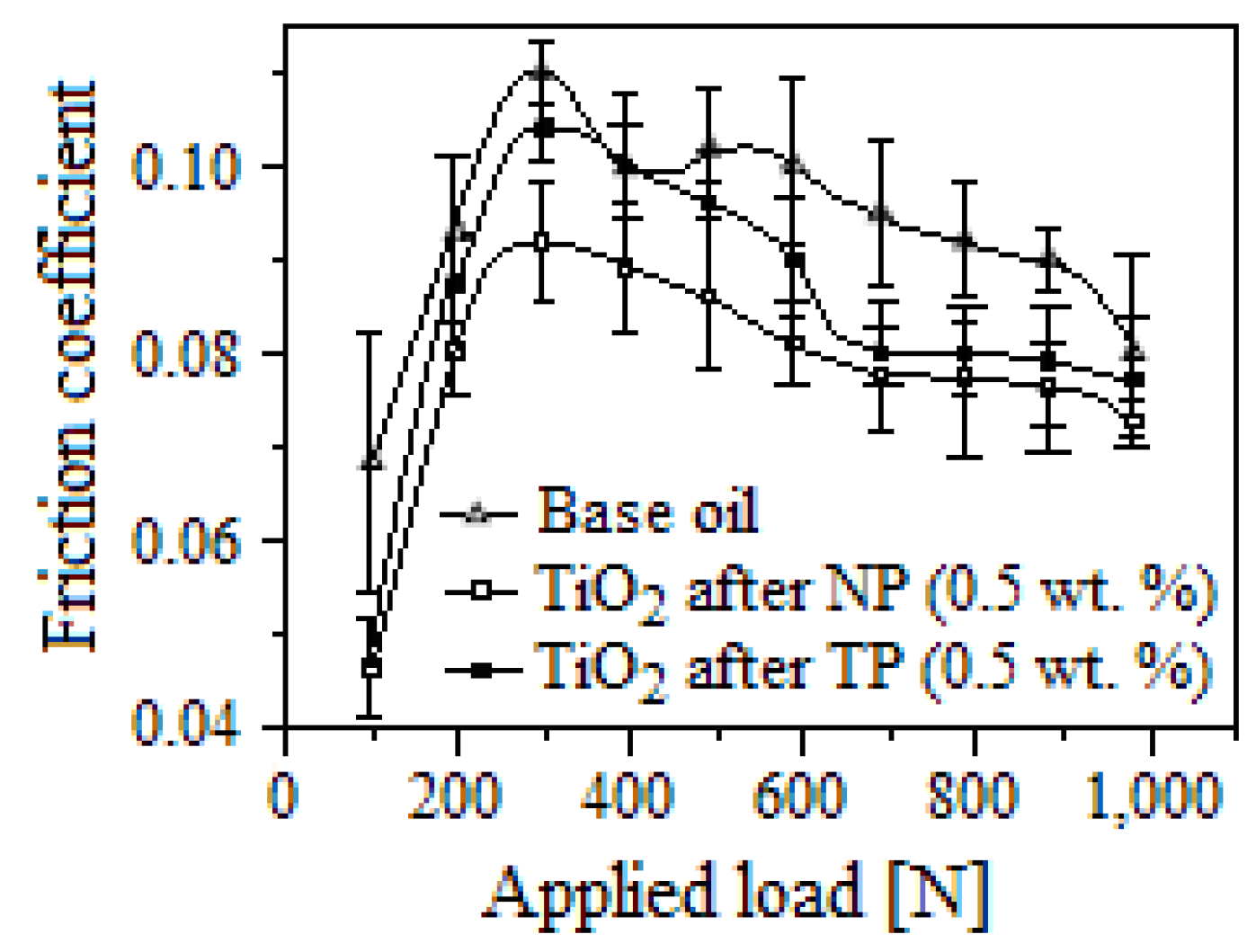

3.2. Anti-Wear and Friction-Reducing Properties of TiO2 Nanoparticles

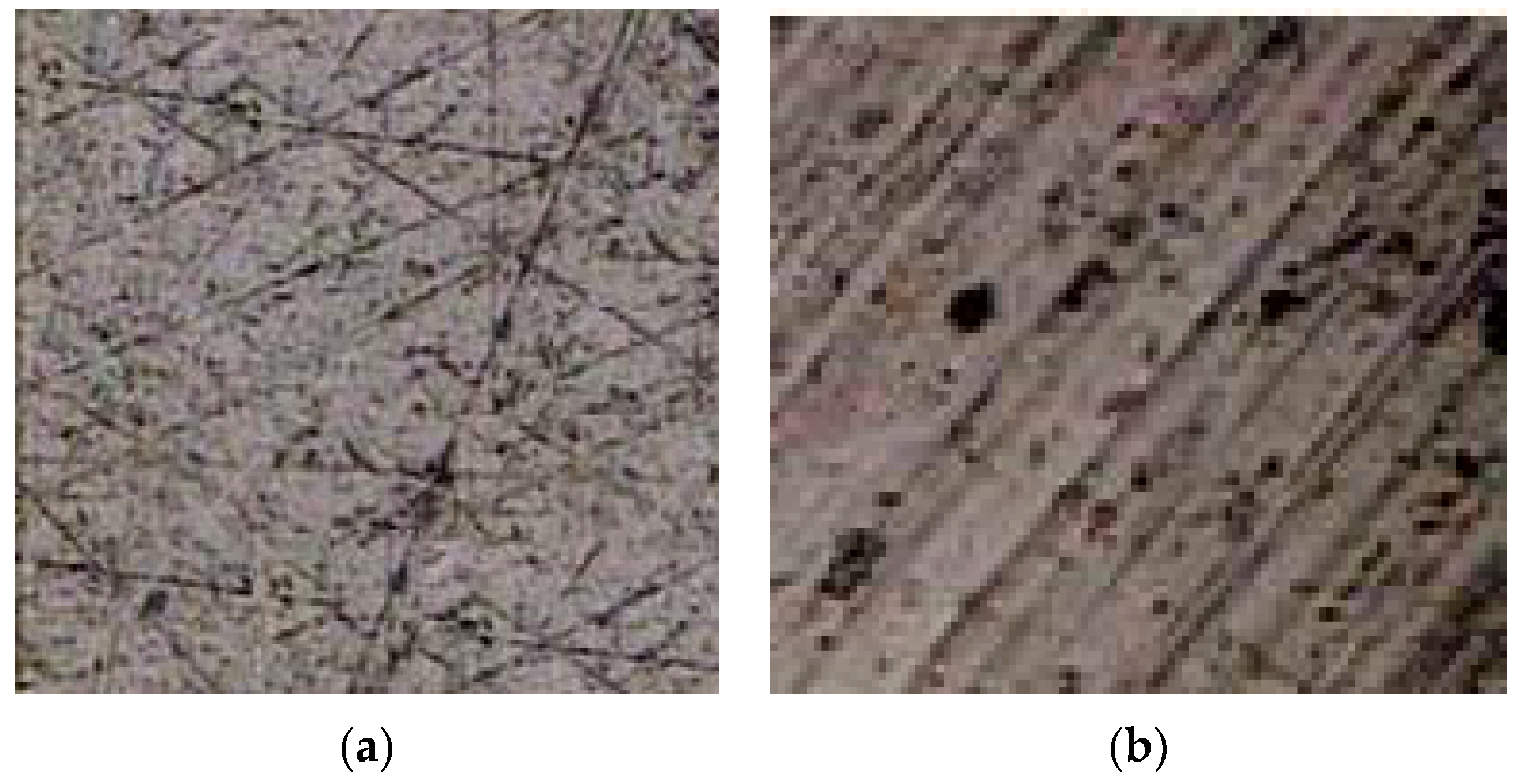

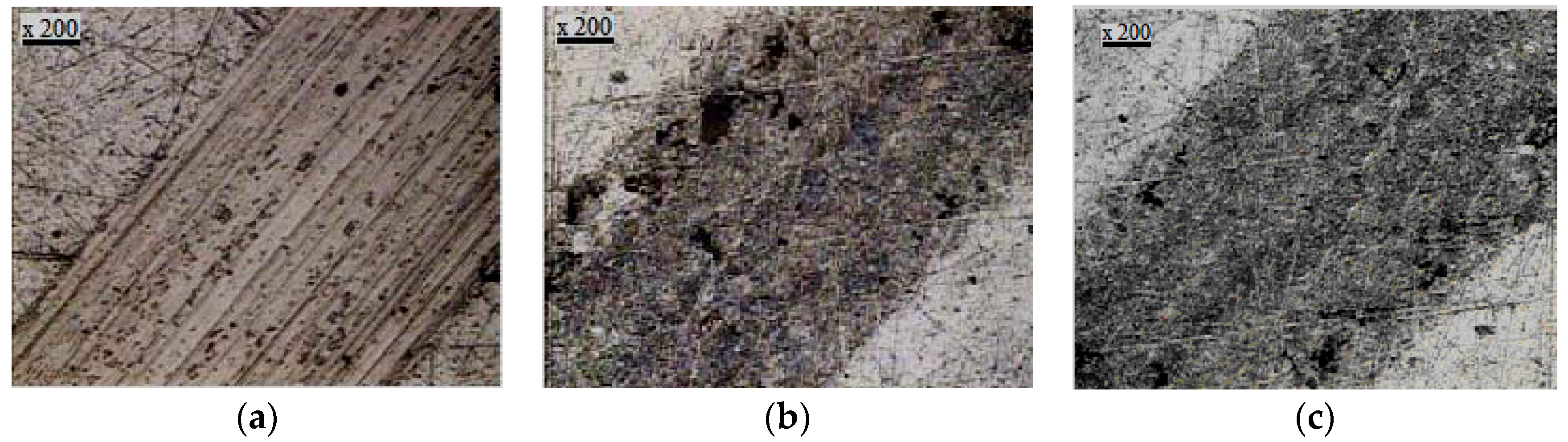

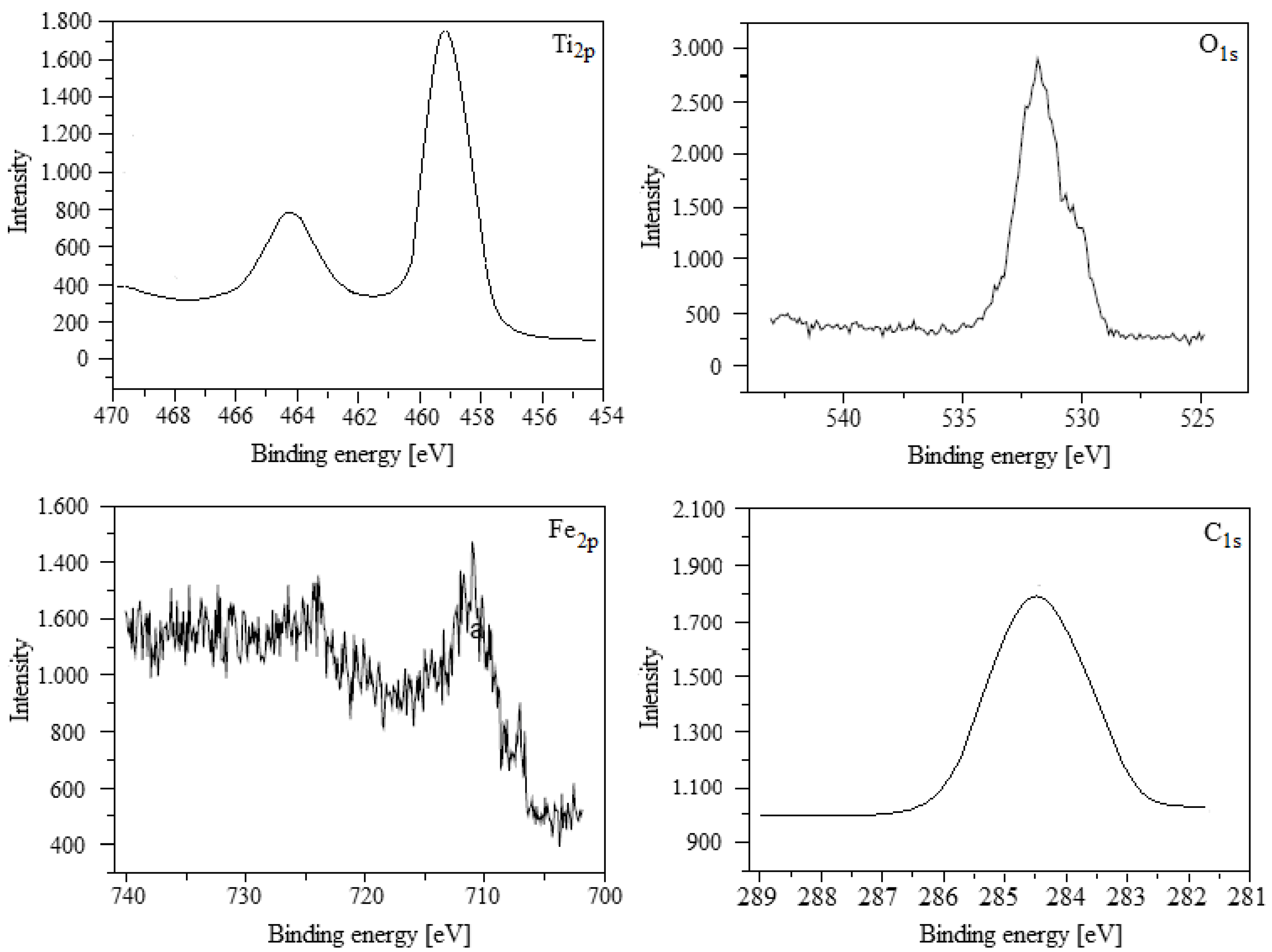

3.3. Tribological Mechanisms of TiO2 Nanoparticles

4. Conclusions

- Nanoparticles are not well dispersed in nonpolar organic solvents due to their oleo-philic property, which limits their applications in lubricant oils. A new technology for improving the poor oil solubility of TiO2 nanoparticles in base oil is thus suggested.

- Nanoparticles added in oil possessing excellent dispersing stability were obtained under the new technology. The nanoparticle suspensions tested exhibited reductions of friction and wear compared to the base oil. TiO2 suspensions under the NP and under the TP presented similar friction and wear behavior as a function of nanoparticle content. Such research might be helpful to overcome the difficulty of the usage of TiO2 nanoparticles in gear lubrication and cutting lubrication.

- The obtained results indicate that the average size of the prepared nanoparticles is in range of 50–100 nm, and the surface of the nanoparticles was altered from oleo-philic to oleo-phobic. In addition, the nanoparticles can be well dispersed in the base oil totally under the NP, which has no significantly negative effect on the anti-oxidation property.

- The results of the tribological experiments indicate that TiO2 nanoparticles under the NP show friction-reducing and better anti-wear property in the base oil compared to TiO2 nanoparticles under the TP.

- Based on the results of PM and XPS, it can be deduced that a continuous resistance film containing depositions and the tribochemical reaction products such as Ti2O3 and Fe2O3formed during the sliding process lead to excellent tribological properties of the nanoparticles in the base oil.

- The main aspect of the novelty of this research lies in dealing with the oil-solubility problem through the combination effect of surface modification and special blend process of lubricating oil, and this method was first used to prepare lubricants containing TiO2 nanoparticles. It should be helpful for the TiO2 nanoparticles used as additives in engine oil, gear oil, and other industrial lubricants.

Author Contributions

Conflicts of Interest

References

- Ponomarenko, A.G.; Burlov, A.S.; Boiko, M.V.; Shiryaeva, T.A.; Kalmykova, A.G.; Zaichenko, S.B.; Milutka, M.S. Investigation of tribochemical processes in lubricating compositions that contain coordination compounds of transition metals. J. Frict. Wear 2015, 36, 15–22. [Google Scholar] [CrossRef]

- Ilie, F. Energy Dissipation during Adhesion and Friction at the Atomic Scale of MoS2 Nanoparticles on the Surface of MoS2. J. Adv. Microsc. Res. 2013, 8, 270–275. [Google Scholar] [CrossRef]

- Zhang, Z.J.; Simionesie, D.; Schaschke, C. Graphite and Hybrid Nanomaterials as Lubricant Additives. Lubricants 2014, 2, 44–65. [Google Scholar] [CrossRef]

- Nagendramma, P. Study of pentaerythritol tetraoleate ester as industrial gear oil. Lubr. Sci. 2011, 23, 355–362. [Google Scholar] [CrossRef]

- Gili, F.; Igartua, A.; Luther, R.; Woydt, M. The impact of biofuels on engine oil performance. Lubr. Sci. 2011, 23, 313–330. [Google Scholar] [CrossRef]

- Ilie, F.; Covaliu, C.; Chişiu, G. Tribological Study of Ecological Lubricants Containing Titanium Dioxide Nanoparticles. Appl. Mech. Mater. 2014, 658, 323–328. [Google Scholar] [CrossRef]

- Hao, L.; Jiang, Z.; Cheng, X.; Zhao, J.; Wei, D.; Jiang, L.; Luo, S.; Luo, M.; Ma, L. Effect of extreme pressure additives on the deformation behavior of oxide scale during the hot rolling of ferritic stainless steel strips. Tribol. Trans. 2015, 58, 947–954. [Google Scholar] [CrossRef]

- Yousefpour, M.; Rahimi, A. Characterization and Selection of Optimal Parameters to Achieve the Best Tribological Performance of the Electrodeposited Cr Nanocomposite Coating. Mater. Des. 2014, 54, 382. [Google Scholar] [CrossRef]

- Hernández Battez, A.; Viesca, J.L.; González, R.; García, A.; Reddyhoff, T.; Higuera-Garrido, A. Effect of Shear Rate, Temperature, and Particle Concentration on the Rheological Properties of ZnO and ZrO2 Nanofluids. Tribol. Trans. 2014, 57, 489. [Google Scholar] [CrossRef]

- Hernández Battez, A.; Viesca, J.L.; González, R.; Blanco, D.; Asedegbega, E.; Osorio, A. Friction Reduction Properties of a CuO Nanolubricant Used as Lubricant for a NiCrBSi Coating. Wear 2010, 268, 325. [Google Scholar] [CrossRef]

- Reijnders, L. The Release of TiO2 and SiO2 Nanoparticles from Nanocomposites. Polym. Degrad. Stab. 2009, 94, 873. [Google Scholar] [CrossRef]

- Hernández Battez, A.; Viesca, J.L.; González, R.; Fernández, J.E.; Diaz Fernández, J.M.; Machado, A.; Chou, R.; Riba, J. CuO, ZrO2 and ZnO nanoparticles as antiwear additive in oil lubricants. Wear 2008, 265, 422. [Google Scholar] [CrossRef]

- Hernández Battez, A.; González, R.; Felgueroso, D.; Fernández, J.E.; del Rocío Fernández, Ma.; García, M.A.; Peñuelas, I. Wear prevention behaviour of nanoparticle suspension under extreme pressure conditions. Wear 2007, 263, 1568–1574. [Google Scholar] [CrossRef]

- Hernández Battez, A.; Fernandez Rico, J.E.; Navas Arias, A.; Viesca Rodriguez, J.L.; Chou Rodriguez, R.; Diaz Fernandez, J.M. The tribological behaviour of ZnO nanoparticles as an additive to PAO6. Wear 2006, 261, 256–263. [Google Scholar] [CrossRef]

- Bakunin, B.N.; Kuzmina, G.N.; Kasrai, M.; Parenago, O.P.; Bancroft, G.M. Tribological behavior and tribofilm composition in lubricated systems containing surface-capped molybdenum sulfide nanoparticles. Tribol. Lett. 2006, 22–23, 289–296. [Google Scholar] [CrossRef]

- Gao, Y.; Chen, G.; Oli, Y.; Zhang, Z.; Xue, Q. Study on tribological properties of oleic acid-modified TiO2 nanoparticle in water. Wear 2002, 252, 454–458. [Google Scholar] [CrossRef]

- Zhou, J.; Wu, Z.; Zhang, Z.; Liu, W.; Dang, H. Study on an antiwear and extreme pressure additive of surface coated LaF3 nanoparticles in liquid paraffin. Wear 2001, 249, 333–337. [Google Scholar] [CrossRef]

- Qiu, S.; Zhou, Z.; Dong, J.; Chen, G. Preparation of Ni nanoparticles and evaluation of their tribological performance as potential additives in oils. J. Tribol. 2001, 123, 441–443. [Google Scholar] [CrossRef]

- Dong, J.X.; Chen, G.; Qiu, S. Wear and friction behaviour of CaCO3 nanoparticles used as additives in lubricating oils. Lubr. Sci. 2000, 12, 205–212. [Google Scholar]

- Hu, Z.S.; Dong, J.X.; Chen, G.X.; He, J.Z. Preparation and tribological properties of nanoparticle lanthanum borate. Wear 2000, 243, 43–47. [Google Scholar] [CrossRef]

- Hu, Z.S.; Dong, J.X. Study on antiwear and reducing friction additive of nanometer titanium borate. Wear 1998, 216, 87–91. [Google Scholar] [CrossRef]

- Hu, Z.S.; Dong, J.X. Study on antiwear and reducing friction additives of nanometer titanium oxide. Wear 1998, 216, 92–96. [Google Scholar] [CrossRef]

- Chinas-Castillo, F.; Spikes, H.A. Mechanism of action of colloidal solid dispersions. J. Tribol. Trans. ASME 2003, 125, 552–557. [Google Scholar] [CrossRef]

- Wu, Y.Y.; Tsui, W.C.; Liu, T.C. Experimental analysis of tribological properties of lubricating oils with nanoparticle additives. Wear 2007, 262, 819. [Google Scholar] [CrossRef]

- Johnson, D.W.; Bachus, M.; Hils, J.E. Interaction between Lubricants Containing Phosphate Ester Additives and Stainless Steels. Lubricants 2013, 1, 48–60. [Google Scholar] [CrossRef]

- Asadauskas, S.J.; Brazinskiene, D.; Bikulcius, G.; Kreivaitis, R.; Padgurskas, J. Surfactant Influence on Stability and Lubrication Properties of Metal Nanoparticle Suspensions in Oil. In Surfactants in Tribology; Biresaw, G., Mittal, K.L., Eds.; CRC Press, Taylor & Francis Group: New York, NY, USA, 2014; Volume 4, pp. 150–189. [Google Scholar]

- Tuszynski, W.; Szczerek, M.; Michalczewski, R.; Osuch-Slomka, E.; Rogos, E.A. The potential of the application of biodegradable and non-toxic base oils for the formulation of gear oils—Model and component scuffing tests. Lubr. Sci. 2014, 26, 327–346. [Google Scholar] [CrossRef]

- Li, W.; Wu, Y.; Wang, X.; Liu, W. A study of P–N compound as multifunctional lubricant additive. Lubr. Sci. 2011, 23, 363–373. [Google Scholar] [CrossRef]

- Zhao, G.; Zhao, Q.; Li, W.; Wang, X.; Liu, W. Tribological properties of nano-calcium borate as lithium grease additive. Lubr. Sci. 2014, 26, 43–53. [Google Scholar] [CrossRef]

- Padgurskas, J.; Rukuiza, R.; Prosycevas, I. Tribological properties of lubricantadditivesof Fe, Cu and Conanoparticles. Tribol. Int. 2013, 60, 224–232. [Google Scholar]

- Xue, M.-Q.; Tang, H.; Li, C.-S. Synthesis and tribological properties of TiC micro and nanoparticles. Int. J. Surf. Sci. Eng. 2015, 9, 69–80. [Google Scholar] [CrossRef]

- Zaimovskaya, T.A.; Oganesova, E.Y.; Kuzmina, G.N.; Ezhov, A.A.; Ivanov, V.K.; Parenago, O.P. Titanium-containing compounds as efficient triboadditives to oils. J. Frict. Wear 2013, 34, 487–493. [Google Scholar] [CrossRef]

- Zhao, C. The Influence of Solid Additives on the Tribological Properties of Lubricants. PhD Thesis, University of Hertfordshire, Hatfield, UK, 27 June 2013. [Google Scholar]

- Xue, M.; Tang, H.; Song, H.; Li, C. Preparation and tribological properties of nanoaluminium fluoride as additives to base oil. Micro Nano Lett. 2014, 9, 225–228. [Google Scholar] [CrossRef]

- Zhang, W.; Zhou, M.; Zhu, H.; Tian, Y.; Wang, K.; Wei, J.; Ji, F.; Li, X.; Li, Z.; Zhang, P. Tribological properties of oleic acid-modified graphene as lubricant oil additives. J. Phys. D Appl. Phys. 2011, 44, 205303. [Google Scholar] [CrossRef]

- Zhang, L.; Chen, L.; Wa, H.; Chen, J.; Zhou, H. Synthesis and tribological properties of stearic acid-modified anatase (TiO2) nanoparticles. Tribol. Lett. 2011, 41, 409–416. [Google Scholar] [CrossRef]

- Lee, K.; Hwang, Y.; Cheong, S.; Choi, Y.; Kwon, L.; Lee, J.; Kim, S.H. Understanding the role of nanoparticles in nano-oil lubrication. Tribol. Lett. 2009, 35, 127–131. [Google Scholar] [CrossRef]

- Xue, Q.; Liu, W.; Zhang, Z. Friction and wear properties of a suface-modified TiO2 nanoparticle as an additive in liquid paraffin. Wear 1997, 213, 29. [Google Scholar] [CrossRef]

- Huang, Y.; Han, S.; Liu, S.; Wang, Y.; Li, J. Preparation and tribological properties of surface-modified calcium borate nanoparticles as additive in lubricating oil. Ind. Lubr. Tribol. 2014, 66, 143–150. [Google Scholar] [CrossRef]

- Ingole, S.; Charanpahari, A.; Kakade, A.; Umare, S.S.; Bhatt, D.V.; Menghani, J. Tribological behavior of nano TiO2 as an additive in base oil. Wear 2013, 301, 776. [Google Scholar] [CrossRef]

- Gu, Y.; Zhao, X.; Liu, Y.; Lv, Y.X. Preparation and Tribological Properties of Dual-Coated TiO2 Nanoparticles as Water-Based Lubricant Additives. J. Nanomater. 2014. [Google Scholar] [CrossRef]

- Qian, J.H.; Yin, X.Y.; Wang, N.; Liu, L.; Xing, J.J. Preparation and tribological properties of stearic acid-modified hierarchical anatase TiO2 microcrystals. Appl. Surf. Sci. 2011, 258, 2278. [Google Scholar] [CrossRef]

- Bapna, K.; Phase, D.M.; Choudhary, R.J. Study of valence band structure of Fe doped anatase TiO2 thin films. J. Appl. Phys. 2011, 110. [Google Scholar] [CrossRef]

- Bakunin, V.N.; Suslov, A.Y.; Kuzmina, G.N.; Parenago, O.P. Recent achievements in the synthesis andapplication of inorganic nanoparticles as lubricant components. Lubr. Sci. 2005, 127, 127–145. [Google Scholar] [CrossRef]

| Kinematic Viscosity [mm2/s]to: −40°C −100°C | 42.85 6.037 |

|---|---|

| Viscosity index | 80 |

| Pour point [°C] | −9 |

| Flash point [°C] | 199 |

| Acid value [mgKOH/g] | 0.05 |

| Sulfur content [%} | 0.03 |

| Degree of saturation [%] | 90 |

| Color | Yellowish |

| Symbol | C [%] | Si [%] | Mn [%] | P [%] | S [%] | Cr [%] | Mo [%] |

|---|---|---|---|---|---|---|---|

| Rul2 | 0.93–1.05 | 0.45–0.75 | 1.00–1.20 | max 0.025 | max 0.015 | 1.40–1.65 | max 0.10 |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ilie, F.; Covaliu, C. Tribological Properties of the Lubricant Containing Titanium Dioxide Nanoparticles as an Additive. Lubricants 2016, 4, 12. https://doi.org/10.3390/lubricants4020012

Ilie F, Covaliu C. Tribological Properties of the Lubricant Containing Titanium Dioxide Nanoparticles as an Additive. Lubricants. 2016; 4(2):12. https://doi.org/10.3390/lubricants4020012

Chicago/Turabian StyleIlie, Filip, and Cristina Covaliu. 2016. "Tribological Properties of the Lubricant Containing Titanium Dioxide Nanoparticles as an Additive" Lubricants 4, no. 2: 12. https://doi.org/10.3390/lubricants4020012

APA StyleIlie, F., & Covaliu, C. (2016). Tribological Properties of the Lubricant Containing Titanium Dioxide Nanoparticles as an Additive. Lubricants, 4(2), 12. https://doi.org/10.3390/lubricants4020012