Lubricants for Metal Belt Continuously Variable Transmissions

Abstract

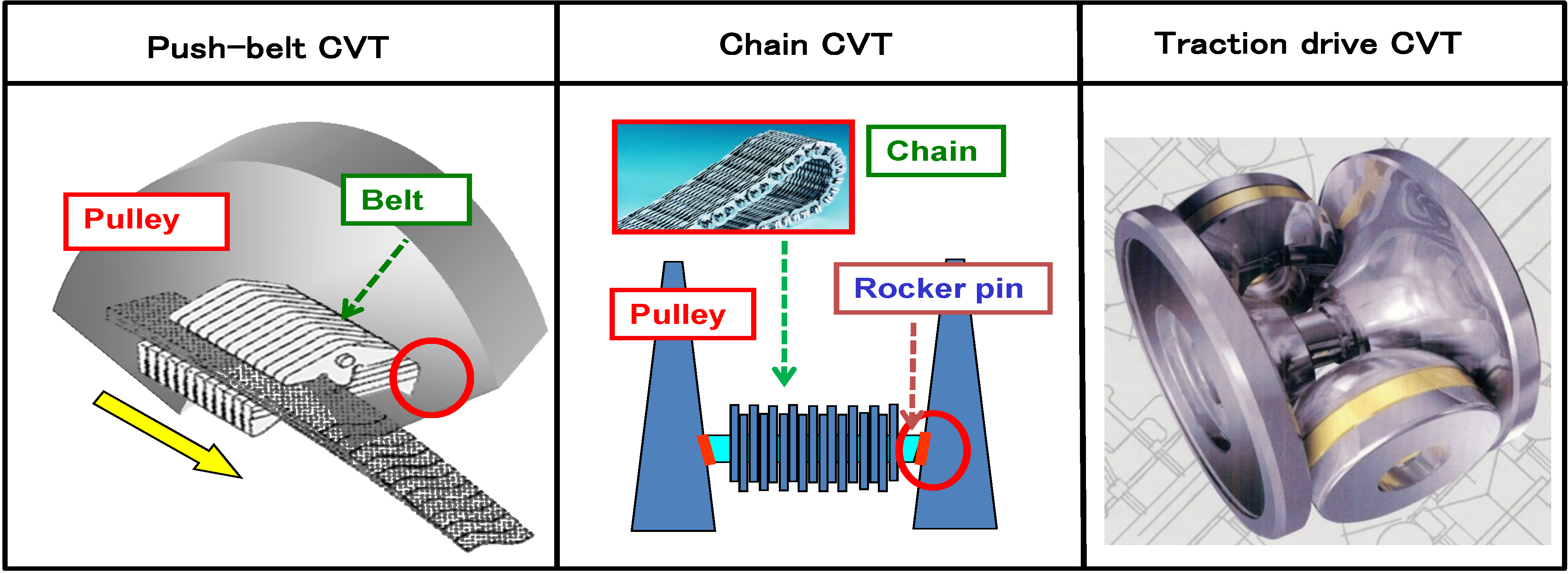

:1. Introduction

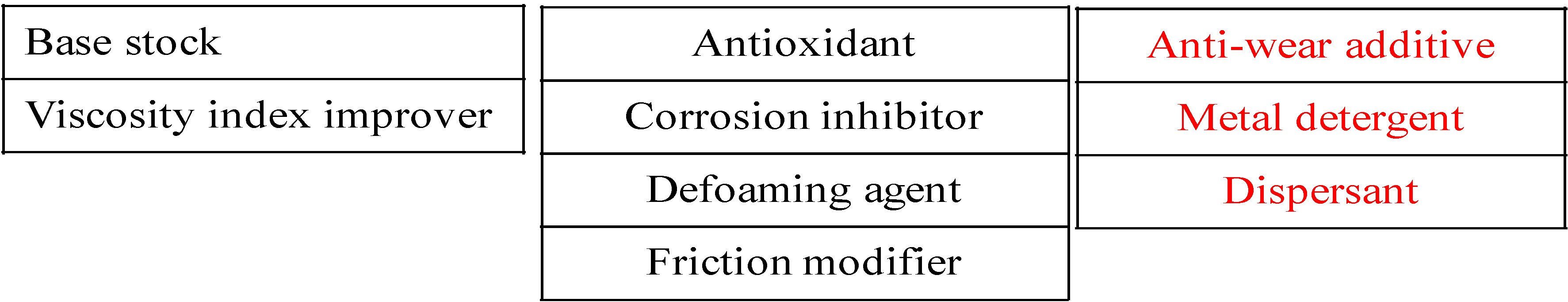

2. Effect of CVT Lubricant Additives on the Metal-Metal Friction Characteristics

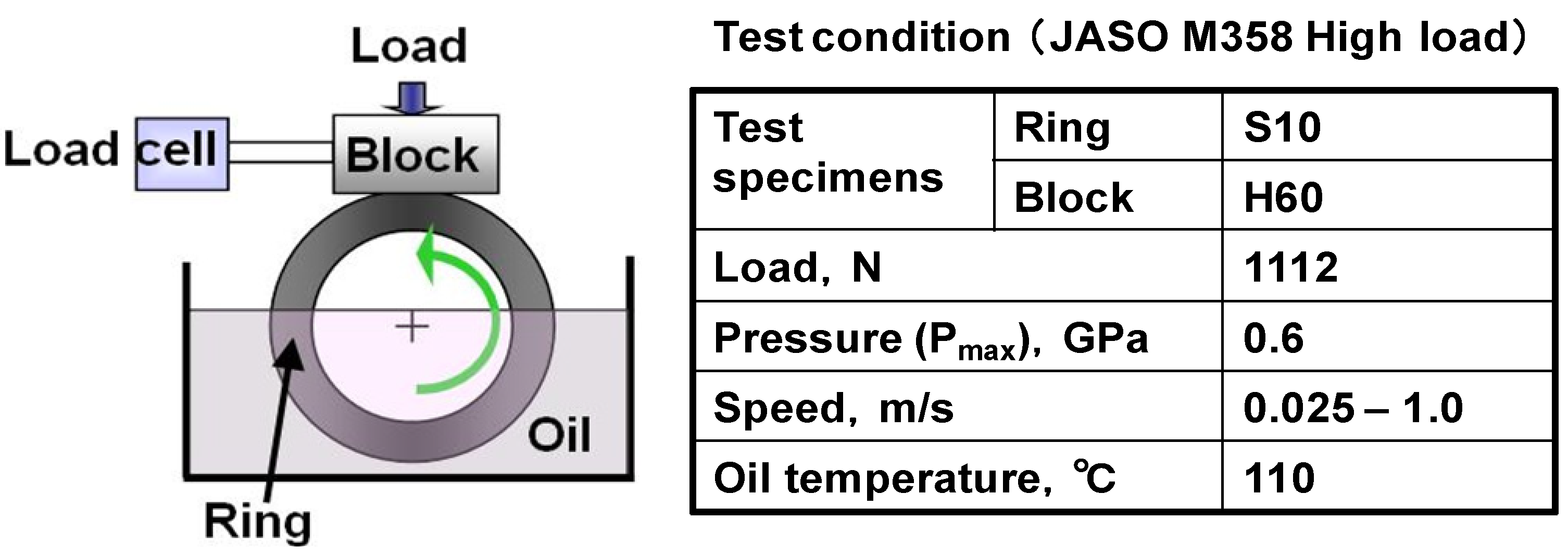

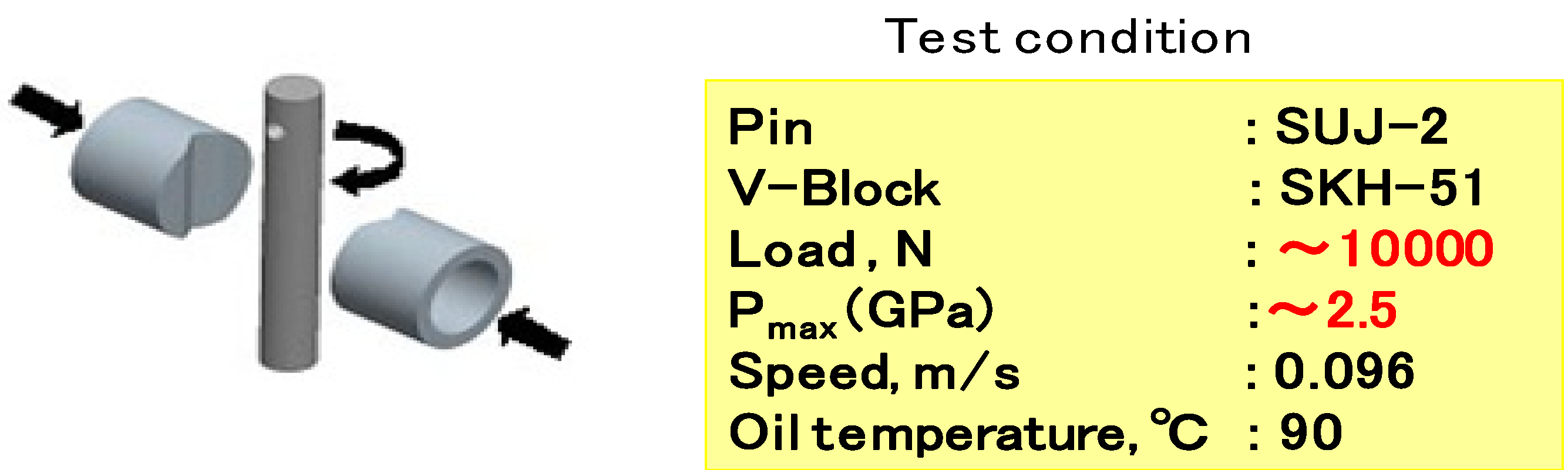

2.1. Test Method for Evaluating the Friction Characteristics between Metals

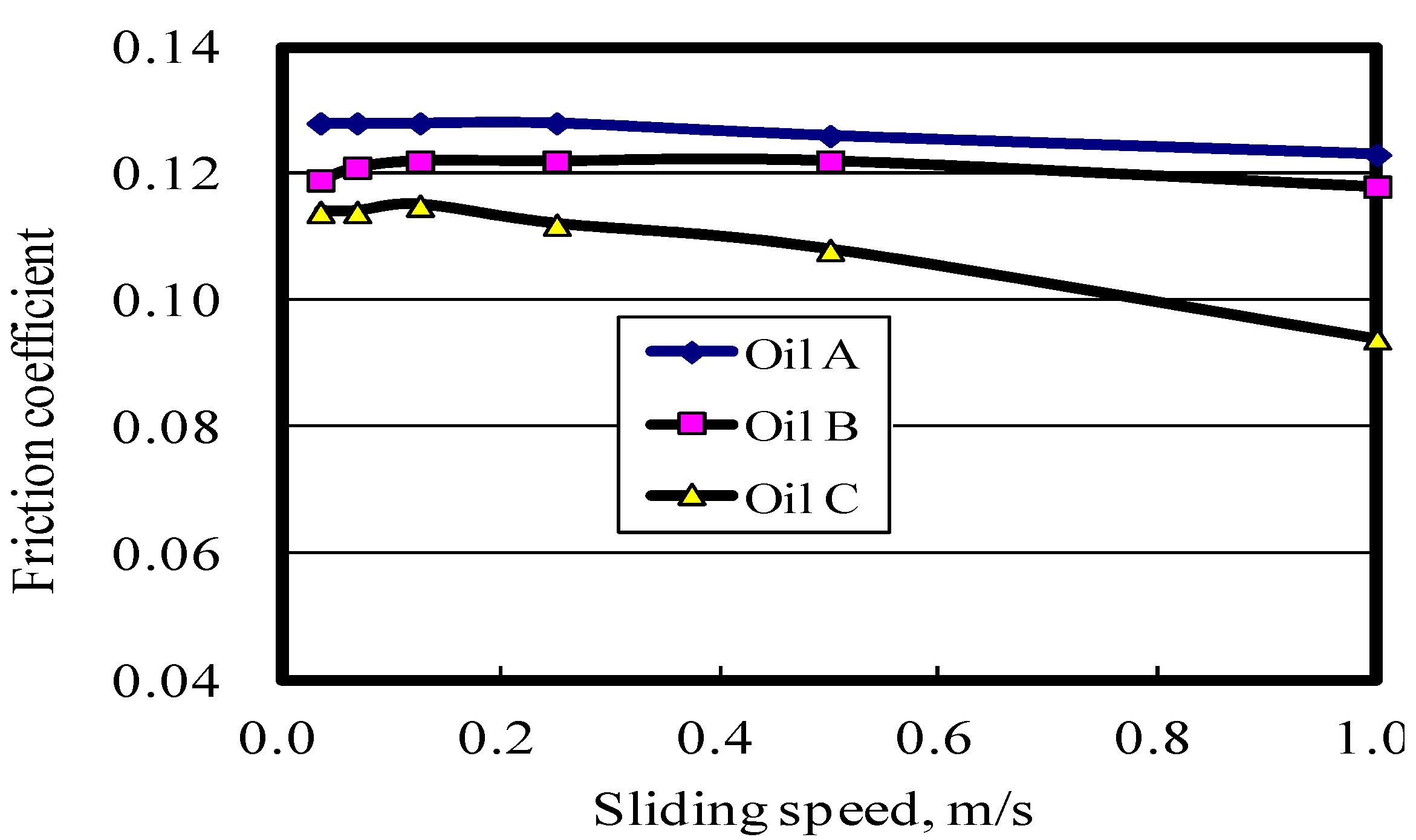

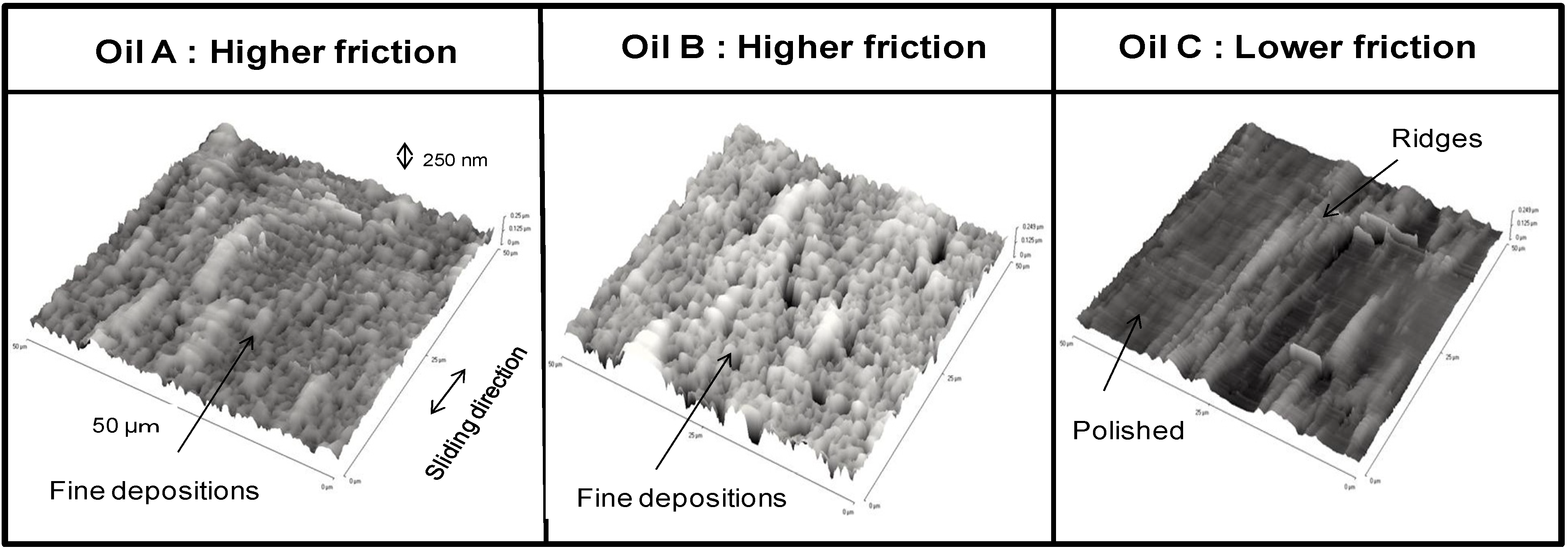

2.2. Evaluation Results of Metal-Metal Friction Characteristics Tested by LFW-1

| Oil A | Oil B | Oil C | |

|---|---|---|---|

| Phosphorus additive | √ | √ | √ |

| Calcium detergent | √ | √ | √ |

| Dispersant | √ | √ | √ |

| Friction modifier A | √ | ||

| Friction modifier B | √ | ||

| Ca (mass%) | 0.06 | 0.06 | 0.06 |

| P (mass%) | 0.06 | 0.06 | 0.06 |

| B (mass%) | 0.01 | 0.01 | 0.01 |

| Viscosity (mm2/s 100 °C) | 7.1 | 7.1 | 7.1 |

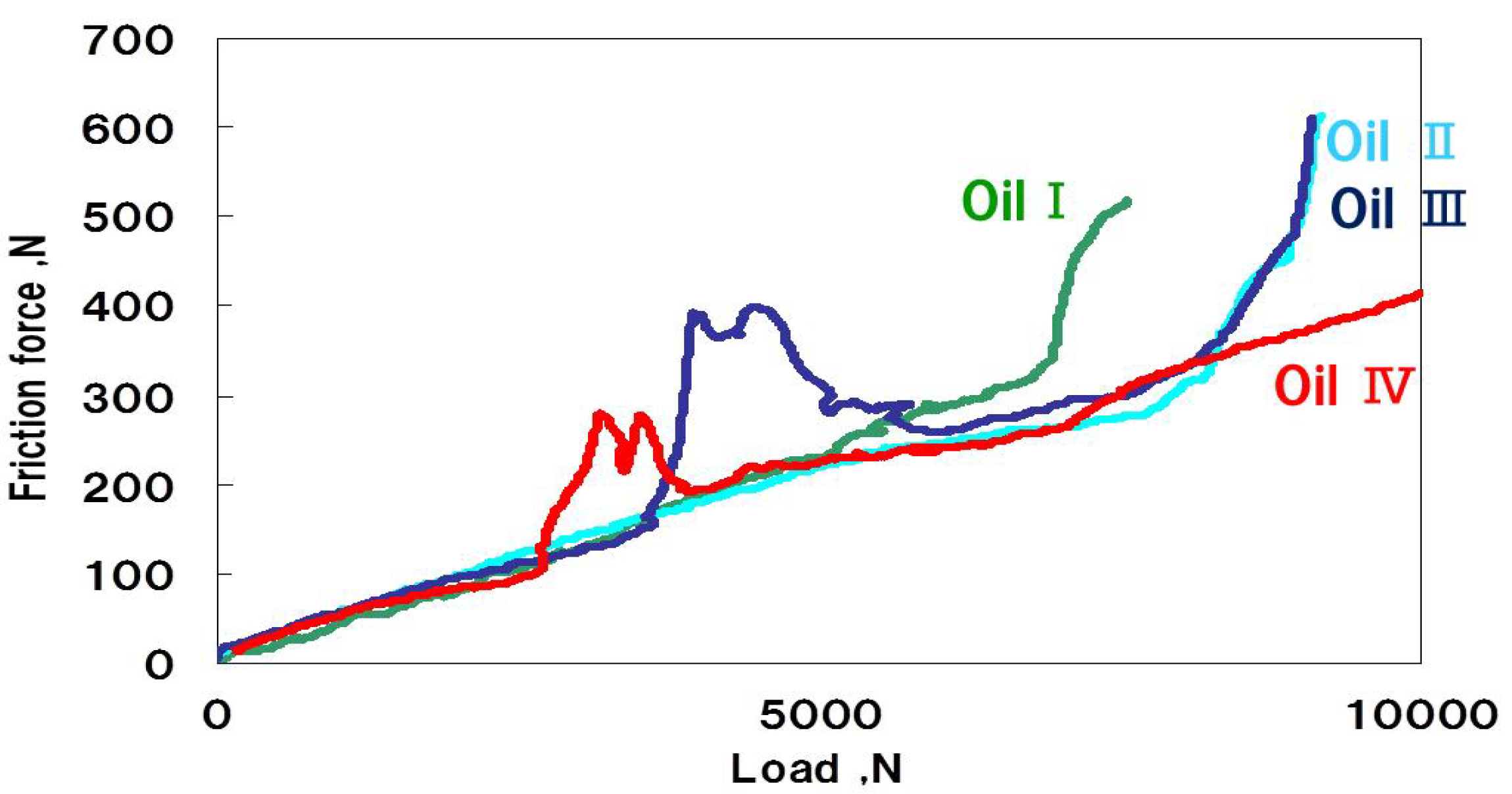

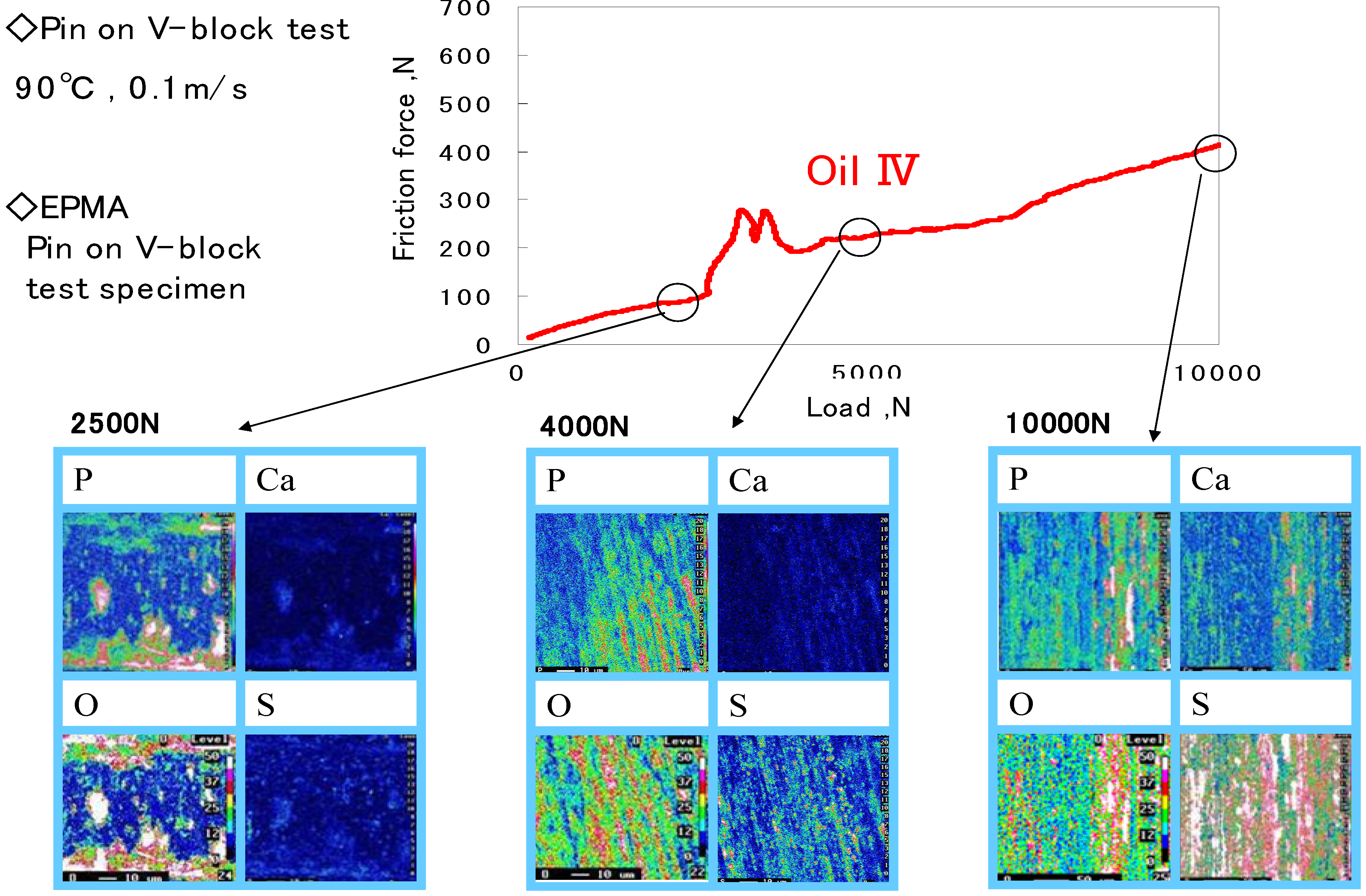

2.3. Evaluation of Anti-Seizure Properties by Pin on V Block Test

| Oil I | Oil II | Oil III | Oil IV | |

|---|---|---|---|---|

| Phosphorus anti-wear additive | ○ | ○ | ○ | ○ |

| Calcium detergent | ○ | ○ | ○ | |

| Dispersant | ○ | ○ | ||

| Sulfur-phosphorus extreme pressure agent | ○ | |||

| 100 °C viscosity (mm2/s) | 7.0 | 7.0 | 7.0 | 7.0 |

| Phosphorus (mass%) | 0.02 | 0.02 | 0.02 | 0.03 |

| Sulfur (mass%) | 0.03 | 0.03 | 0.03 | 0.04 |

| Calcium (mass%) | - | 0.03 | 0.03 | 0.03 |

3. Effect of Base Stock on the Torque Capacity of Belt CVT Transmissions

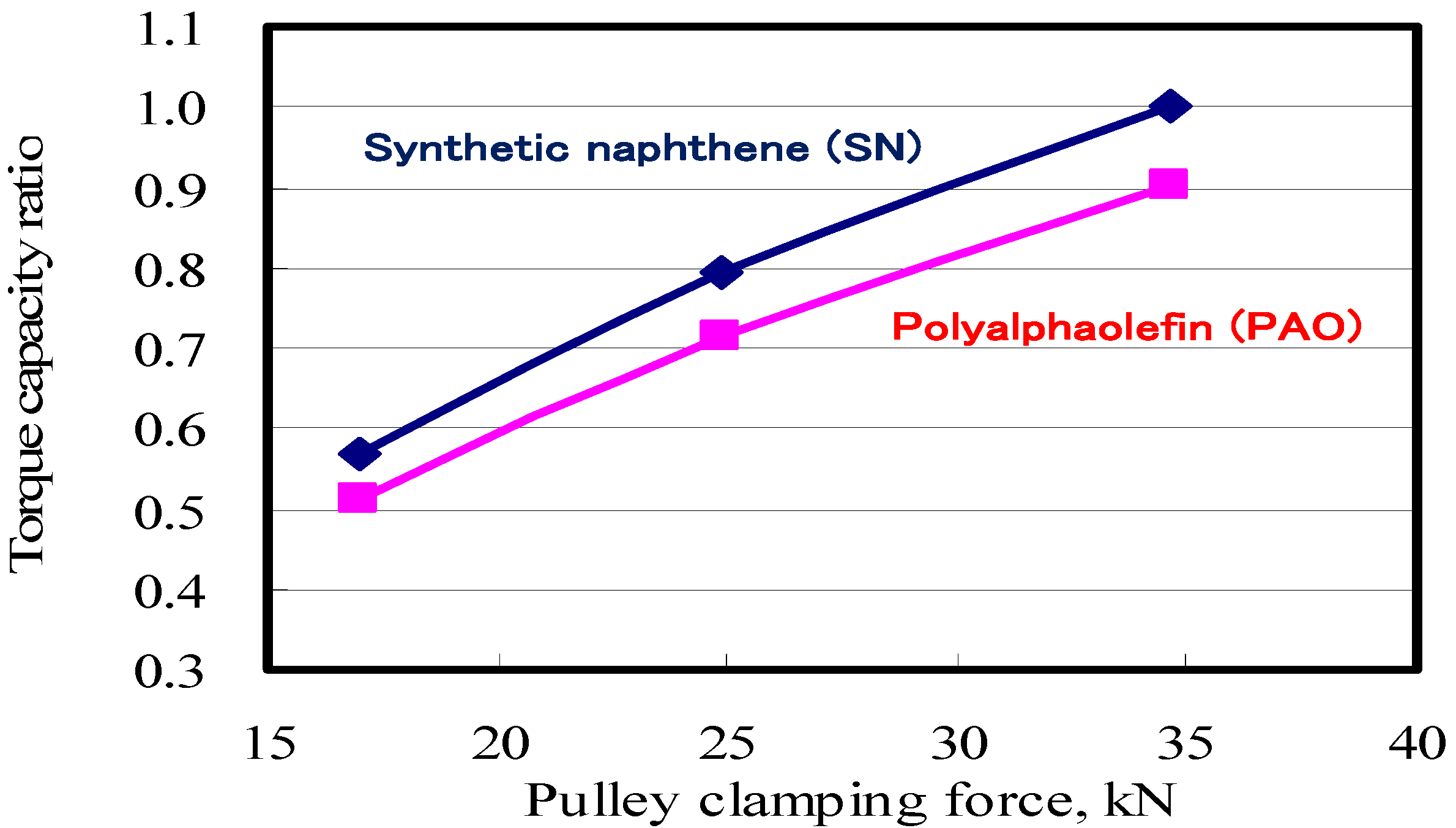

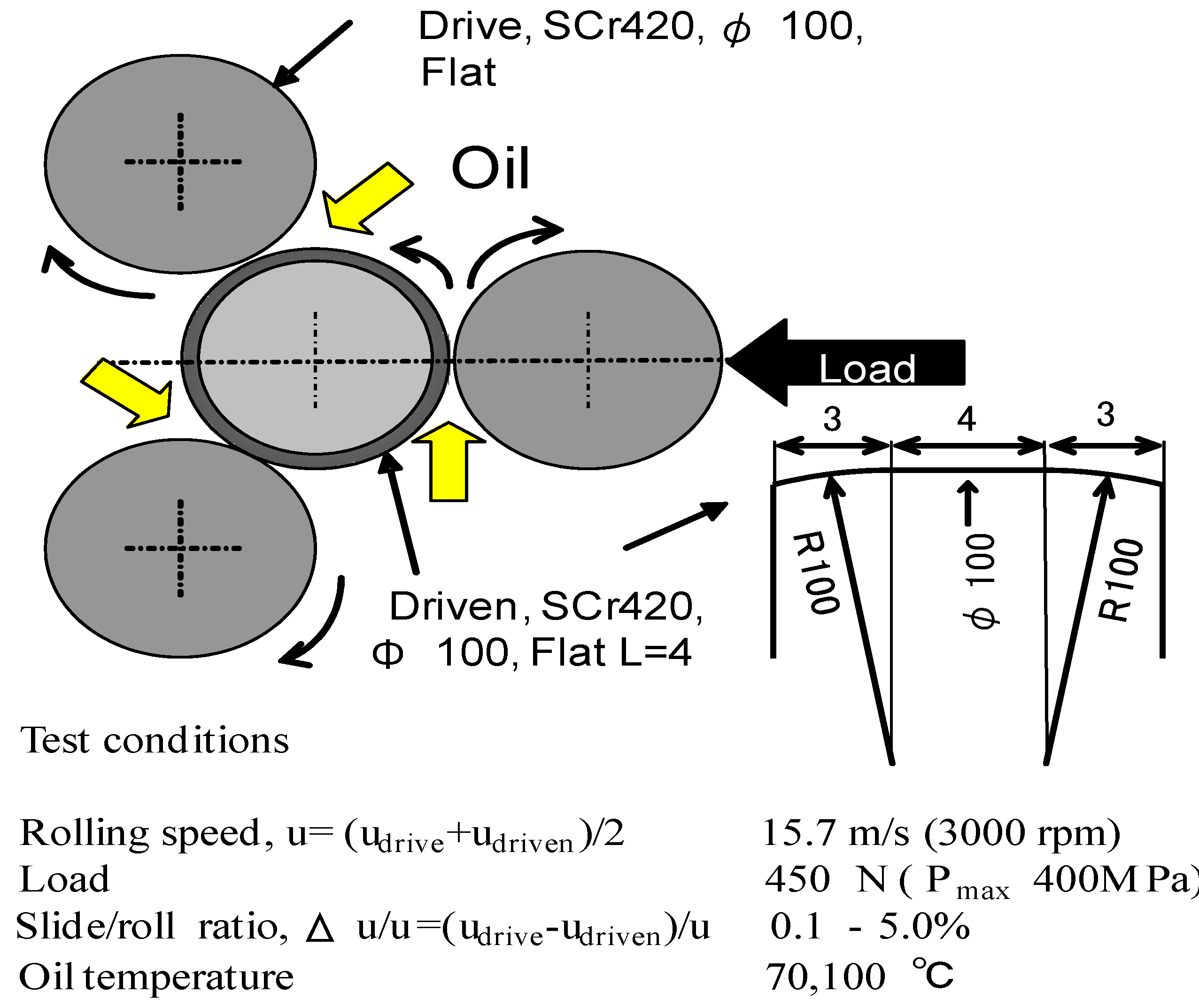

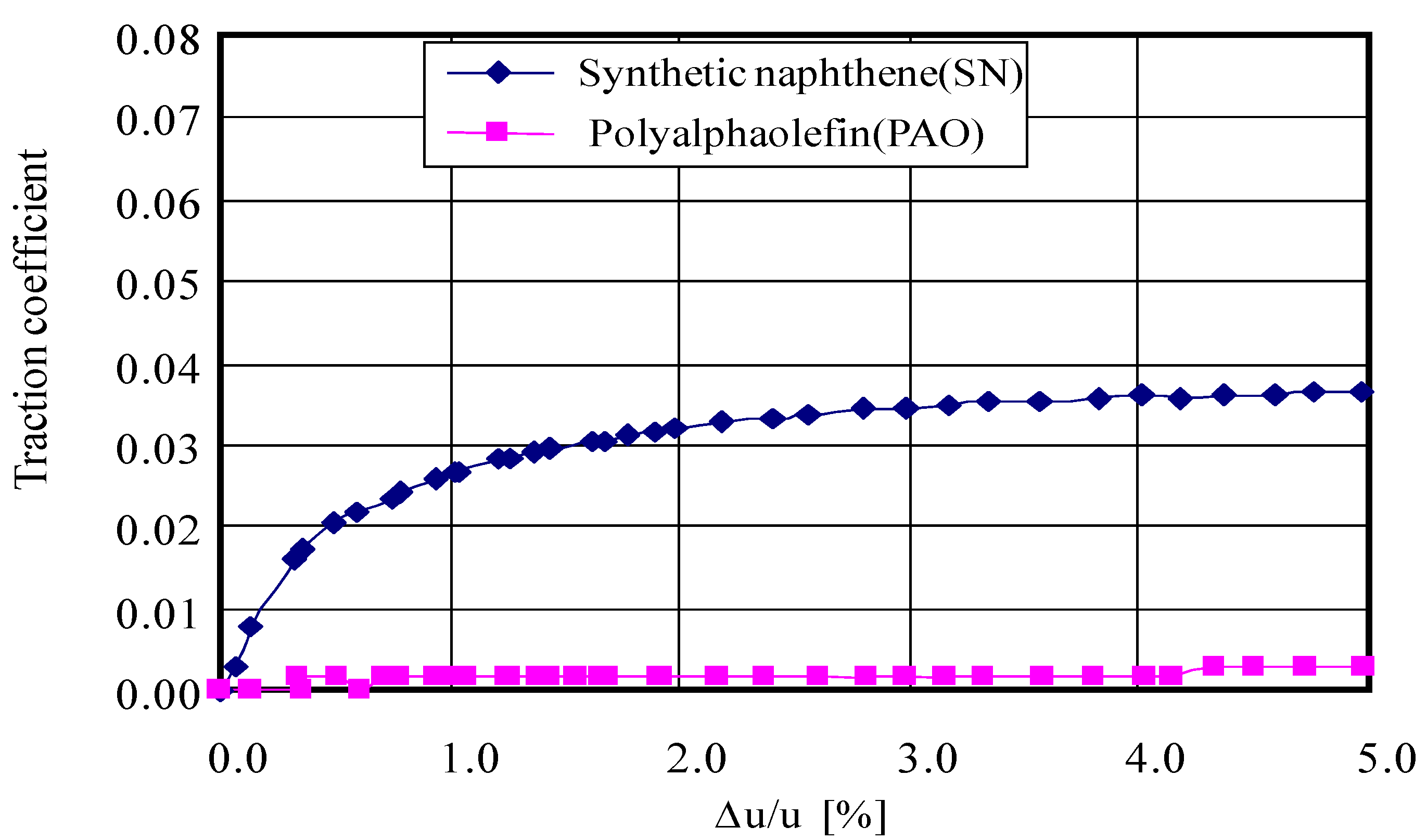

Evaluation of Transmission Torque Capacity Using an Actual Belt CVT

4. Conclusions

- (1)

- An additive formulation consisting of a combination of a phosphorus anti-wear additive, a calcium detergent improves the friction coefficient between the metals. The post-test surface derived from these additives exhibits clearly dense depositions. Because this film is rougher, it is assumed there is a higher friction coefficient. By further adding a sulfur-phosphorus extreme pressure agent, it will be possible to improve anti-seizure properties while maintaining a higher friction coefficient.

- (2)

- Examining the effect of base stock on the transmission torque capacity of actual belt CVTs revealed that SN (synthetic naphthene) exhibited a 10% higher torque capacity than that of PAO (polyalphaolefin). It is believed that the difference in the oil-film shearing force was generated by the relative sliding between the belt and pulley.

Conflicts of Interest

References

- Murakami, Y. Half a century of automatic transmissions for vehicles. Jpn. Soc. Tribol. 2005, 50, 665–670. [Google Scholar]

- Mitsui, H. Trends and requirements of fluids for metal pushing belt type CVTs. J. Jpn. Soc. Tribol. 2000, 45, 13–18. [Google Scholar]

- Ishikawa, T.; Murakami, Y.; Yauchibara, R.; Sano, A. The effect of belt drive CVT fluid on the friction coefficient between metal components. SAE Trans. 1997, 106, 1290–1297. [Google Scholar]

- Fijita, H.; Spikes, H.A. The formation of zinc dithiophosphate antiwear film. Proc. Inst. Mech. Eng. 2004, 218, 265–277. [Google Scholar]

- Bec, S.; Tonk, A.; George, J.M.; Coy, R.C.; Bell, J.C.; Roper, G.W. Relationship between mechanical properties and structures of zinc dithiophosphate anti-wear films. Proc. R. Soc. Lond. 1999, 455, 4181–4203. [Google Scholar] [CrossRef]

- Yin, Z.; Karsai, M.; Fuller, M.; Bancroft, G.M.; Fyfe, K.; Colainanni, M.L.; Tan, K.H. Application of soft X-ray absorption spectroscopy in chemical characterization of antiwear films generated by ZDDP Part I: The effects of physical parameters. Wear 1997, 202, 172–191. [Google Scholar] [CrossRef]

- Martin, J.M.; Grossiord, C.; Monge, T.L.; Bec, S.; Tonck, A. The two-layer structure of Zndtp tribofilms: Part 1: AES, XPS and XANES analysis. Tribol. Int. 2001, 34, 523–530. [Google Scholar] [CrossRef]

- Muraki, M.; Oshima, A. Friction-velocity characteristics of oils containing ZDDP and analysis of their tribofilms. J. Jpn. Soc. Tribol. 2011, 56, 523–529. [Google Scholar]

- Narita, K.; Iwai, T.; Takekawa, D. Lubricants additives for improving the performance of metal V-belt type CVTs. Tribol. Online 2012, 7, 152–158. [Google Scholar] [CrossRef]

- Narita, K.; Iwai, T. Study on the use of metal belt CVT lubricant to improve transmission torque capacity. Idemitsu Tribol. Rev. 2011, 33, 2080–2086. [Google Scholar]

- Narita, K.; Tamoto, Y. Effect of Lubricating Base Stocks on the Transmittable Torque Capacity of Metal V-Belt Pushing Type CVT. In Proceedings of the JSME International Conference on Motion and Transmissions, Sendai, Japan, 13 May 2009; pp. 614–619.

- Fewkes, R.; Gunsing, J.; Sumiejski, J.L. Lubricants as construction element in the VDT push-belt CVT system. SAE Paper 1993. [Google Scholar] [CrossRef]

- Japanese Automobile Standard Organization. M358-2005. In Standard Test Method for Metal Friction Characteristics of Belt CVT Fluids; JASO: Tokyo, Japan, 2005. [Google Scholar]

- Taylor, L.; Spikes, H.A. Friction-enhancing properties of ZDDP anti-wear additives: Part 1—Friction morphology of ZDDP reaction films. Tribol. Trans. 2003, 46, 303–309. [Google Scholar] [CrossRef]

© 2014 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/3.0/).

Share and Cite

Narita, K. Lubricants for Metal Belt Continuously Variable Transmissions. Lubricants 2014, 2, 11-20. https://doi.org/10.3390/lubricants2010011

Narita K. Lubricants for Metal Belt Continuously Variable Transmissions. Lubricants. 2014; 2(1):11-20. https://doi.org/10.3390/lubricants2010011

Chicago/Turabian StyleNarita, Keiichi. 2014. "Lubricants for Metal Belt Continuously Variable Transmissions" Lubricants 2, no. 1: 11-20. https://doi.org/10.3390/lubricants2010011

APA StyleNarita, K. (2014). Lubricants for Metal Belt Continuously Variable Transmissions. Lubricants, 2(1), 11-20. https://doi.org/10.3390/lubricants2010011