The Recent Advancements in Minimum Quantity Lubrication (MQL) and Its Application in Mechanical Machining—A State-of-the-Art Review

Abstract

1. Introduction

2. Research Scope and Objectives

3. Minimum Quantity Lubrication

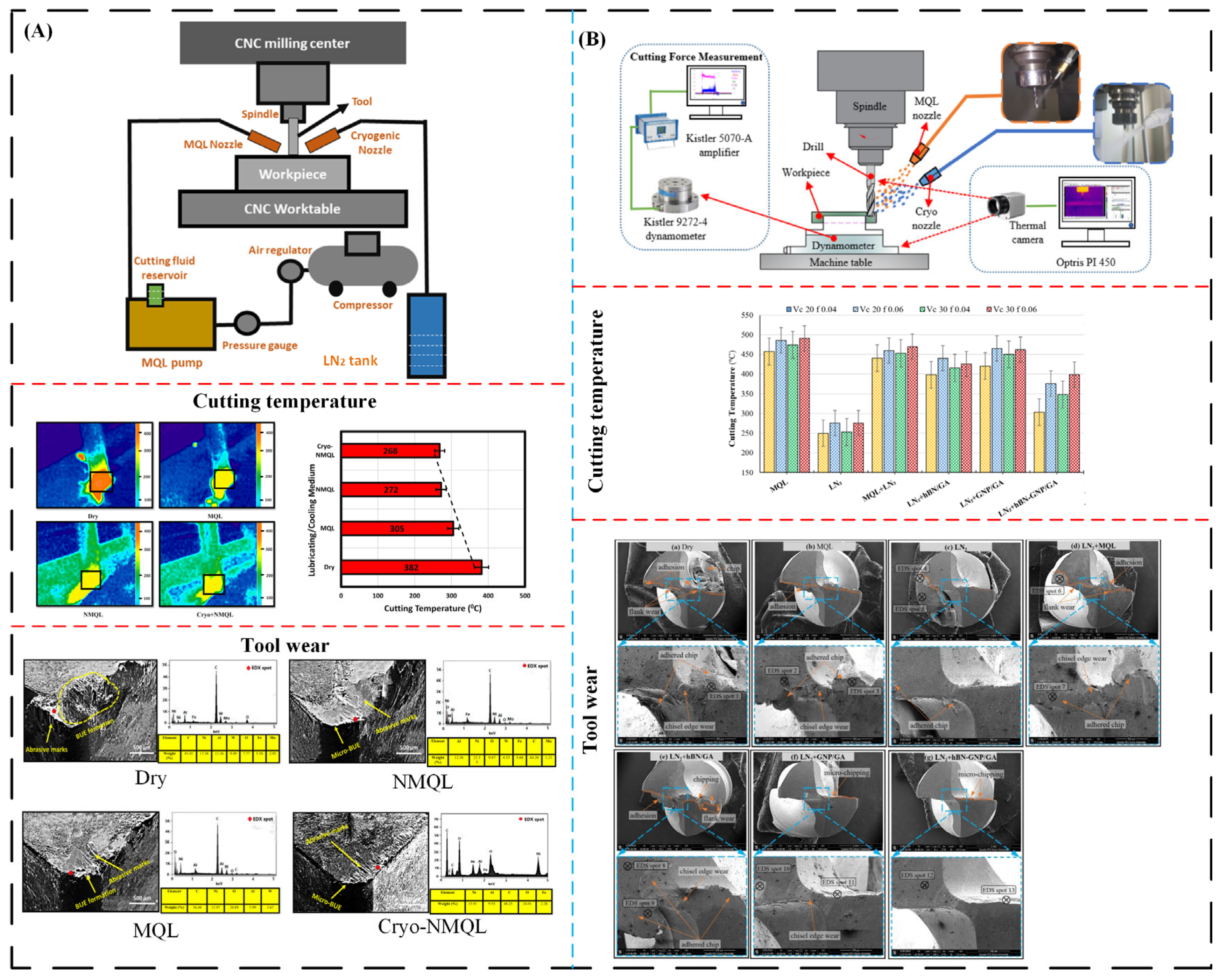

3.1. Basic Information About MQL

3.2. Advantages and Disadvantages of MQL

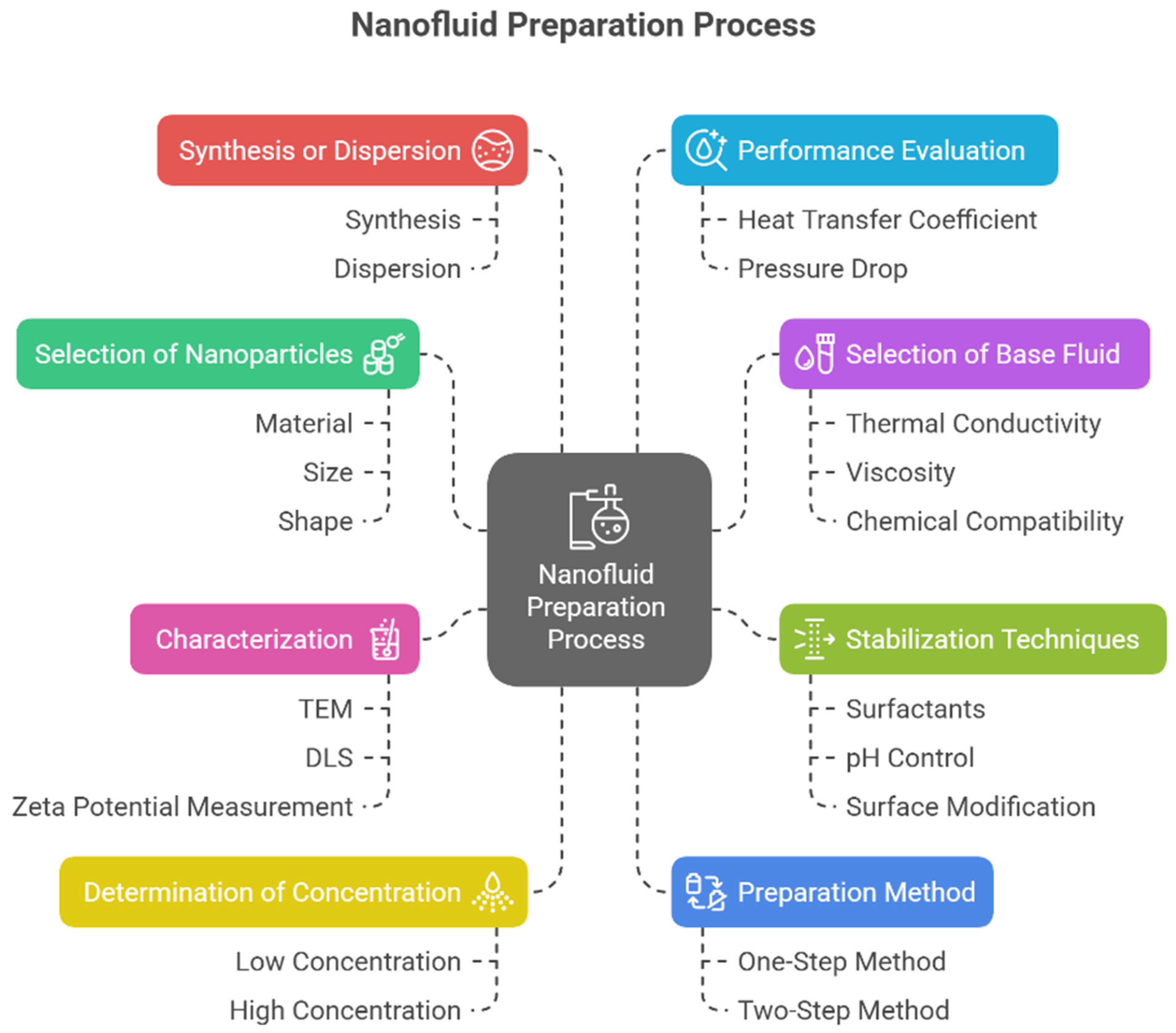

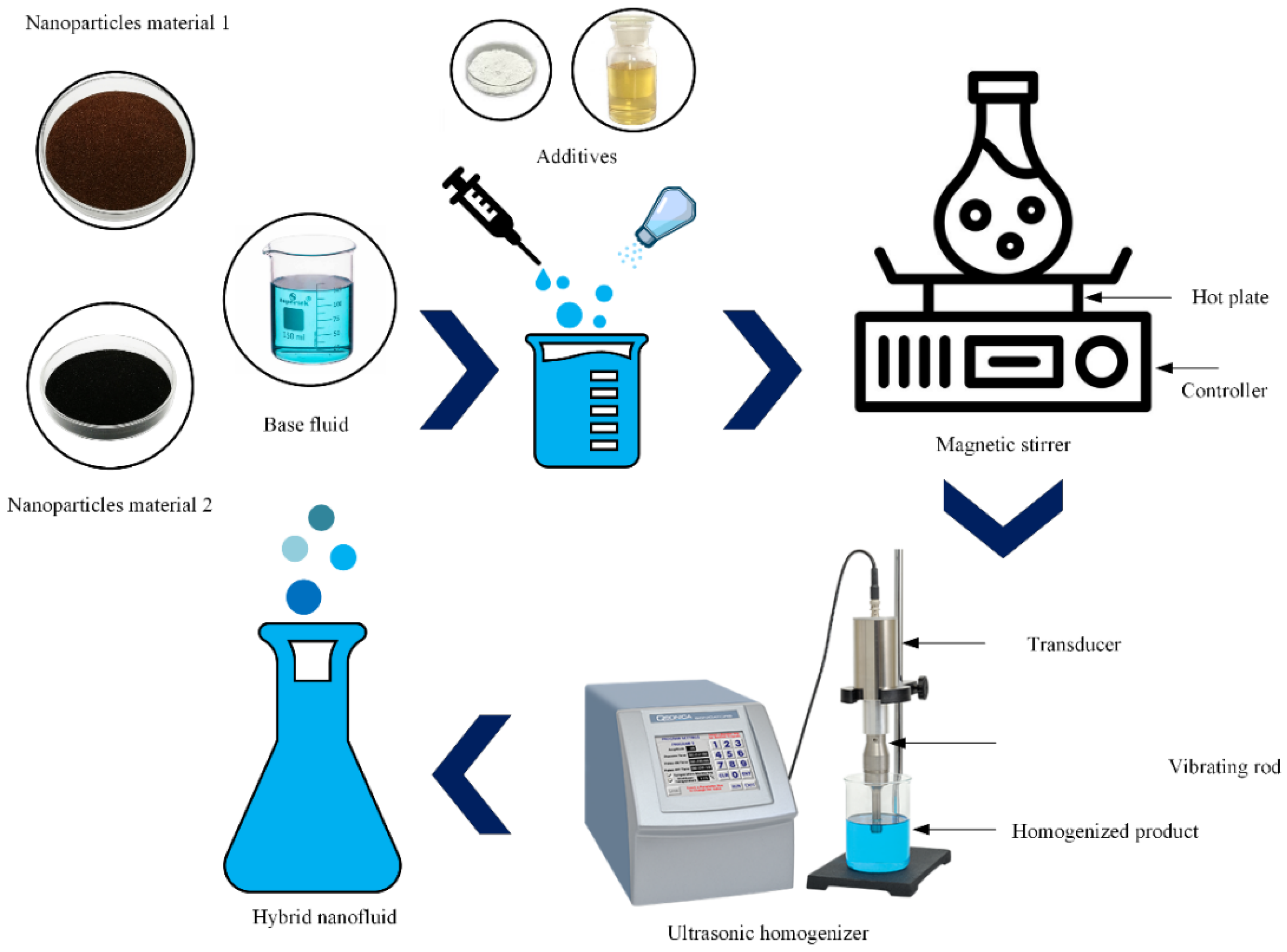

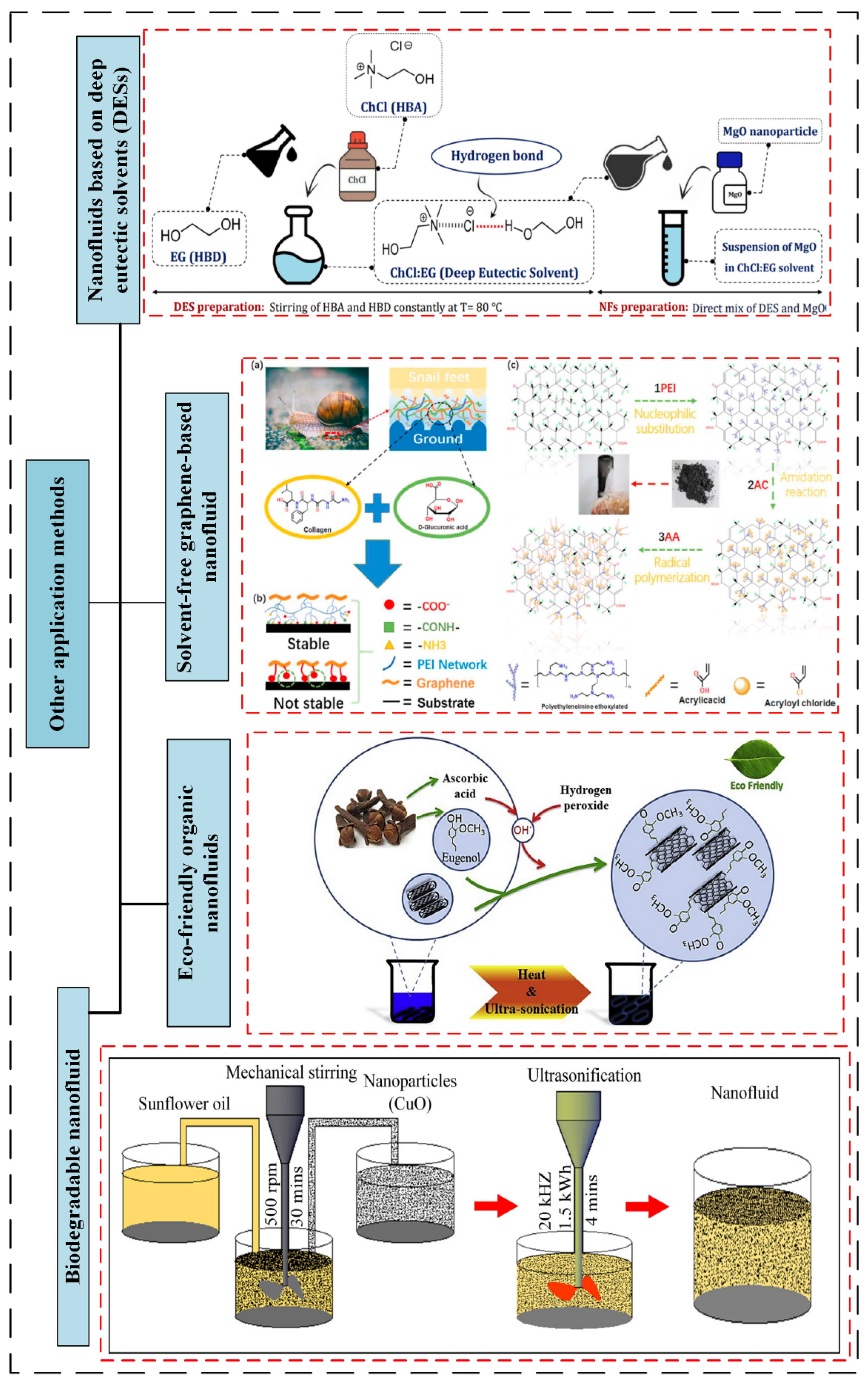

4. Nanofluid-Based MQL

4.1. Basic Information About Nanofluids

4.2. Properties of Nanofluids

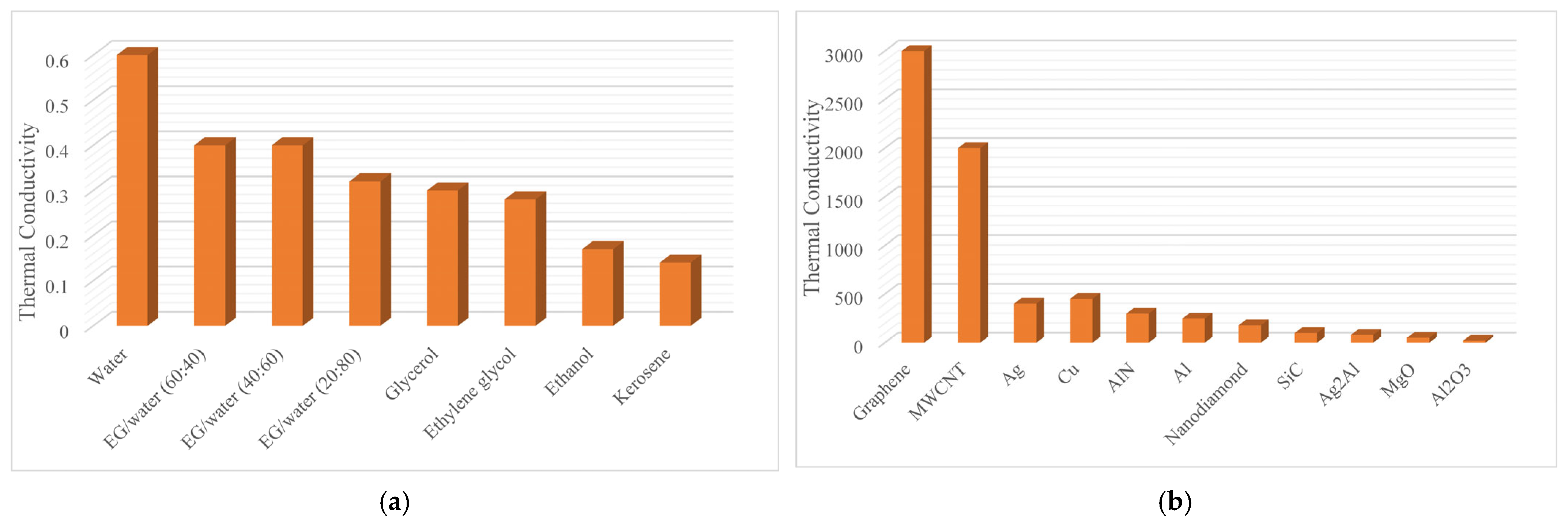

4.2.1. Thermal Conductivity

4.2.2. Viscosity

4.2.3. Convective Heat Transfer

4.2.4. Density

4.2.5. Pressure Drop

4.2.6. Specific Heat

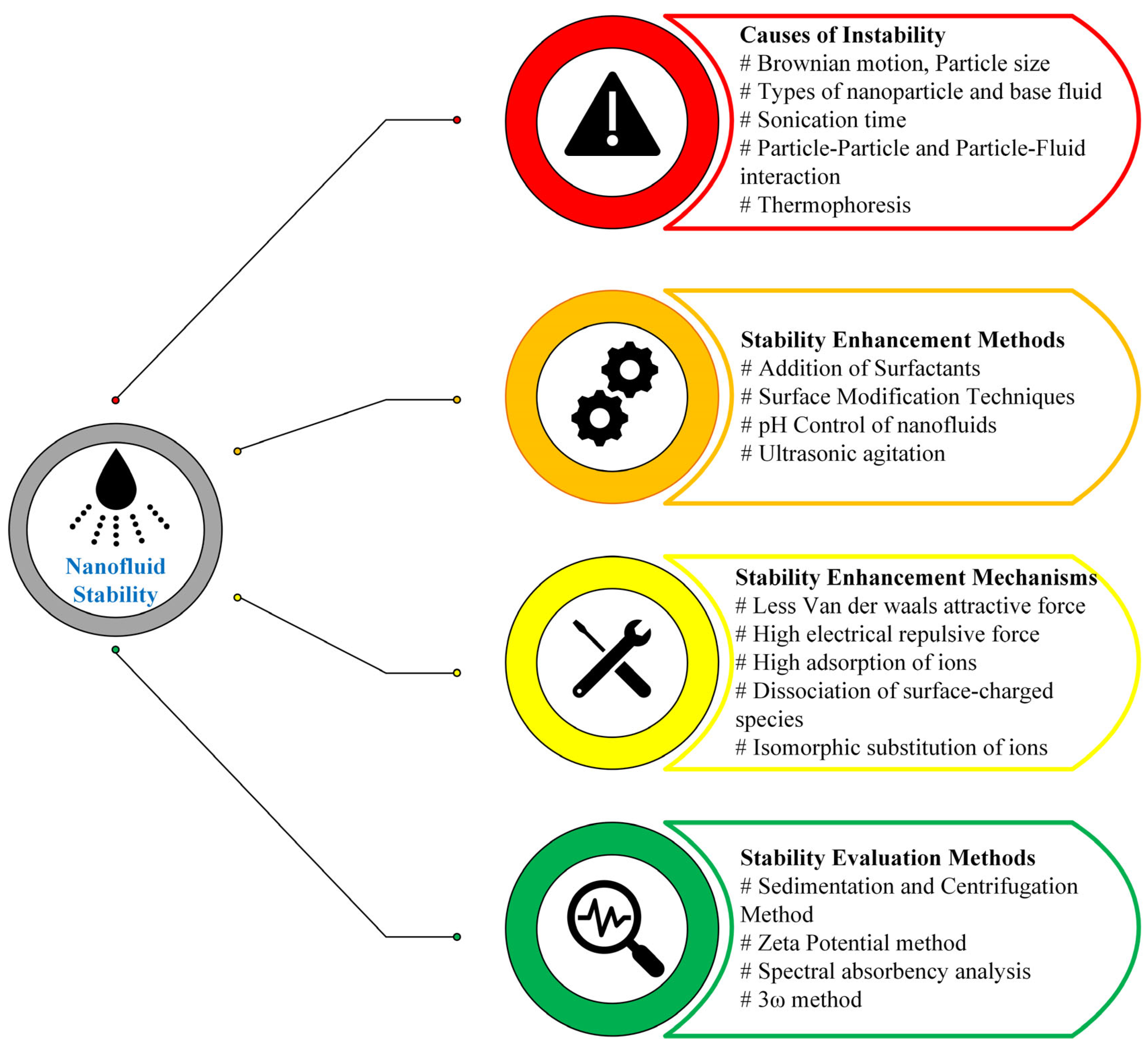

4.3. Stability of Nanofluids

4.3.1. Stability Evaluation Methods

Sedimentation and Configuration Method

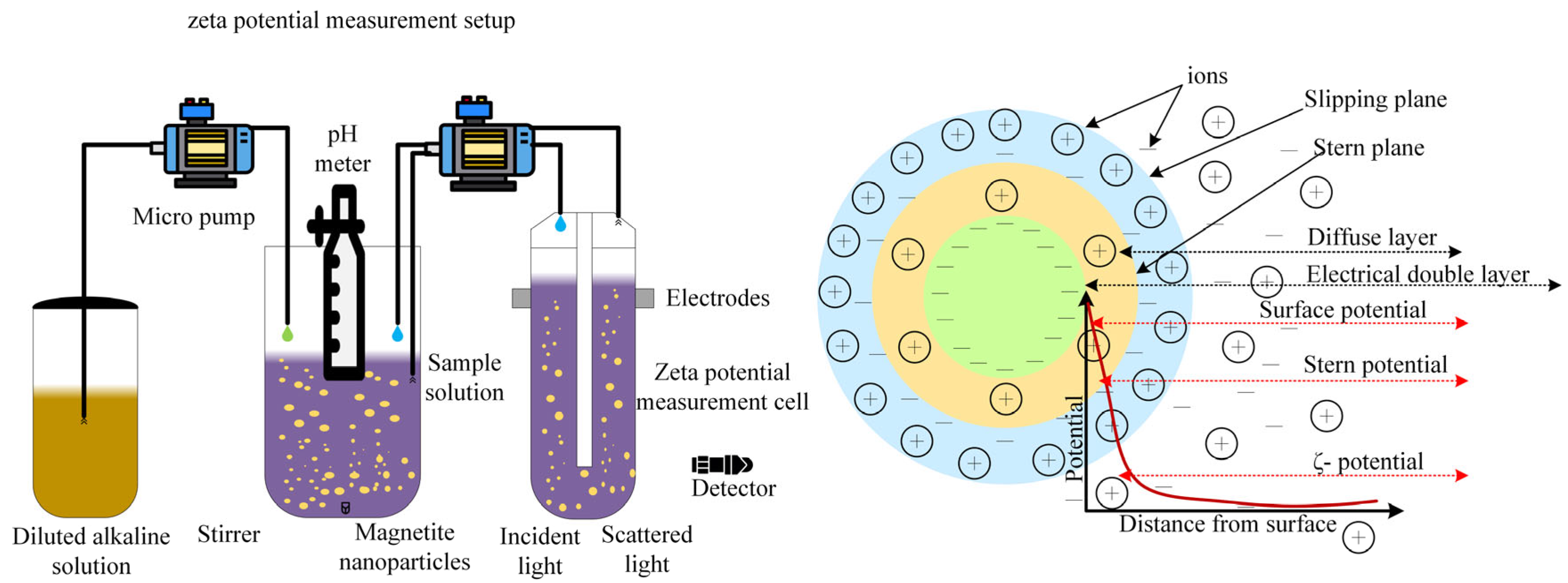

Zeta Potential Analysis

Spectral Absorbency Analysis

Non-Colloidal Properties Analysis

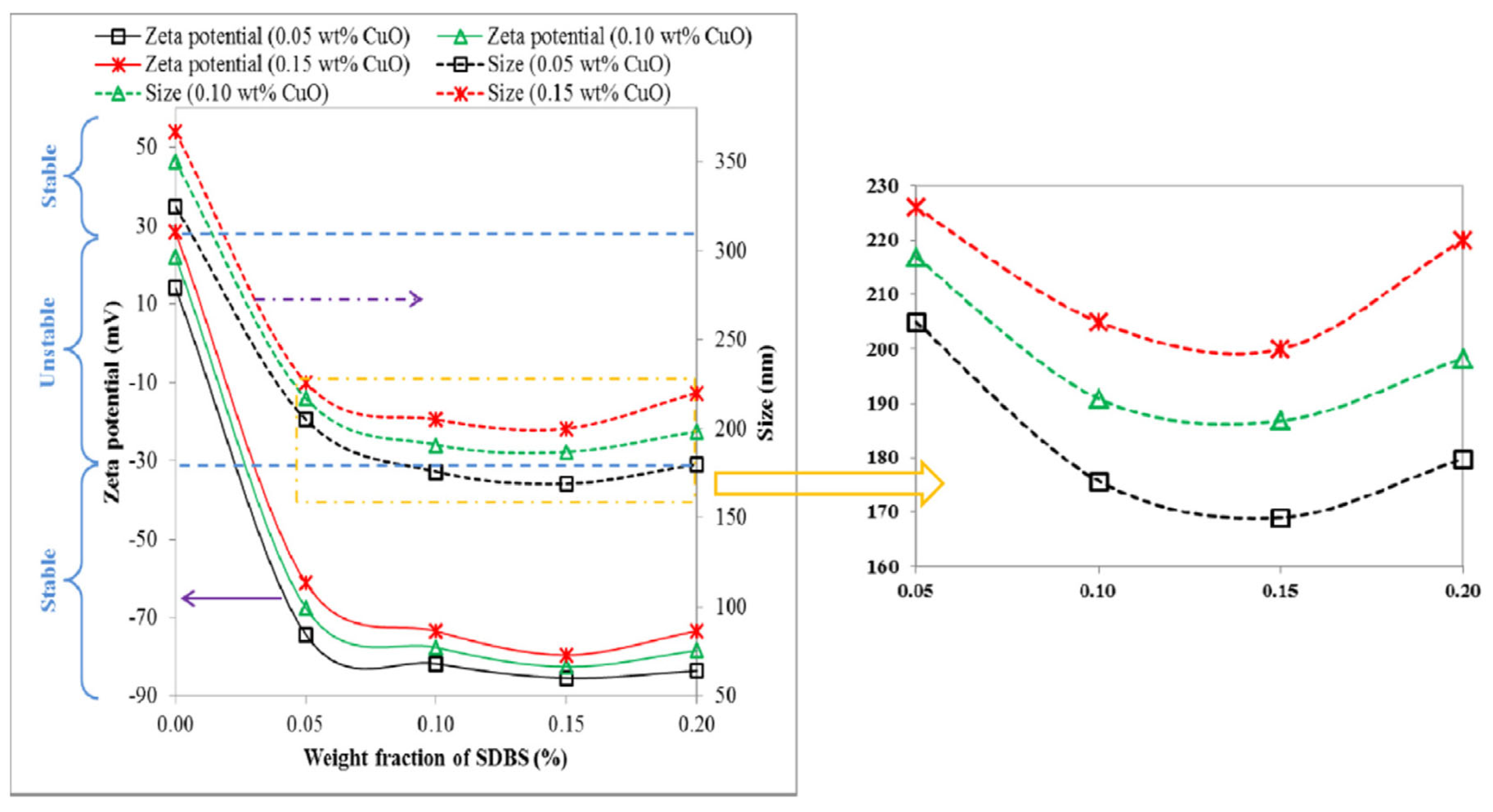

4.3.2. Enhancing Stability of Nanofluids

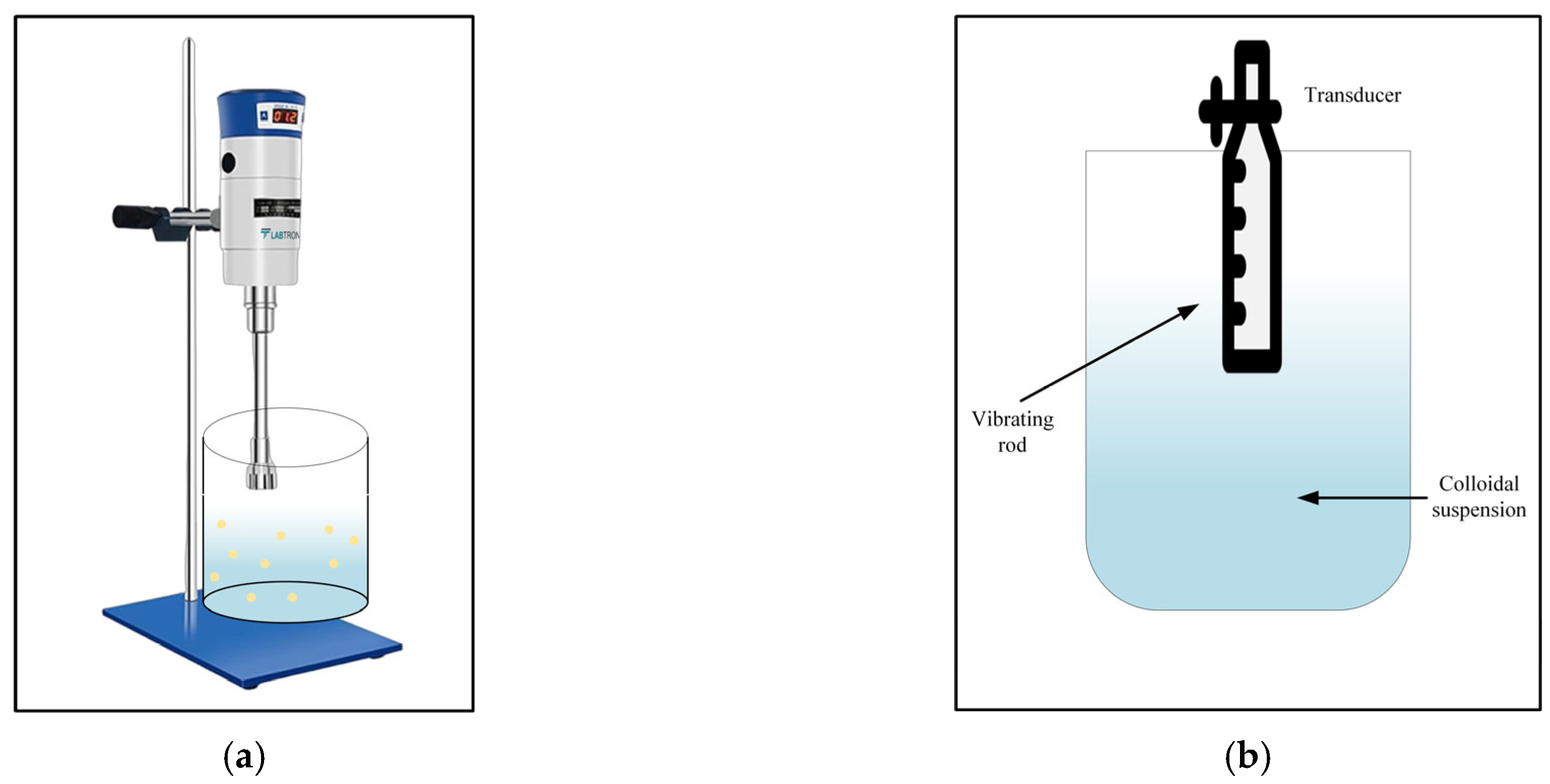

Physical Treatment Methods

Chemical Treatment Methods

4.3.3. Stability Mechanism of Hybrid Nanofluids

4.3.4. Future Challenges for the Stability of Hybrid Nanofluids

- Regarding the stability of hybrid nanofluids, a suspension of two different types of NP is a big challenge, and more efforts are needed to study the separation mechanism of two different types of nanoparticle.

- A lot of studies preach about the stability analysis of nanofluids before the experimentation. However, the consequences of the transferring nanofluids from the laboratory to the area of application have not been explored yet. What is the effect of distance and transferring medium on the stability of nanofluids?

- Somehow, phenomena of pressure drop during the application of hybrid nanofluids is still a black box. There has still been very little work to understand the effect of different particle sizes and densities of individual nanoparticles on the on the pressure drop and the pumping power.

- Production of nanoparticles is a costly process and it is important to develop new cost-effective methods of producing hybrid nanofluids. Nanofluids are considered and this is the main reason industry is reluctant to use them.

- In machining difficult-to-cut material, temperature is very high in the cutting zone, and application of nanofluids in the high-temperature zone is required. Similarly, application of nanofluids with cryogenics could also be demanded as a special requirement. So, it is very important to understand the stability of hybrid nanofluids in such severe environments.

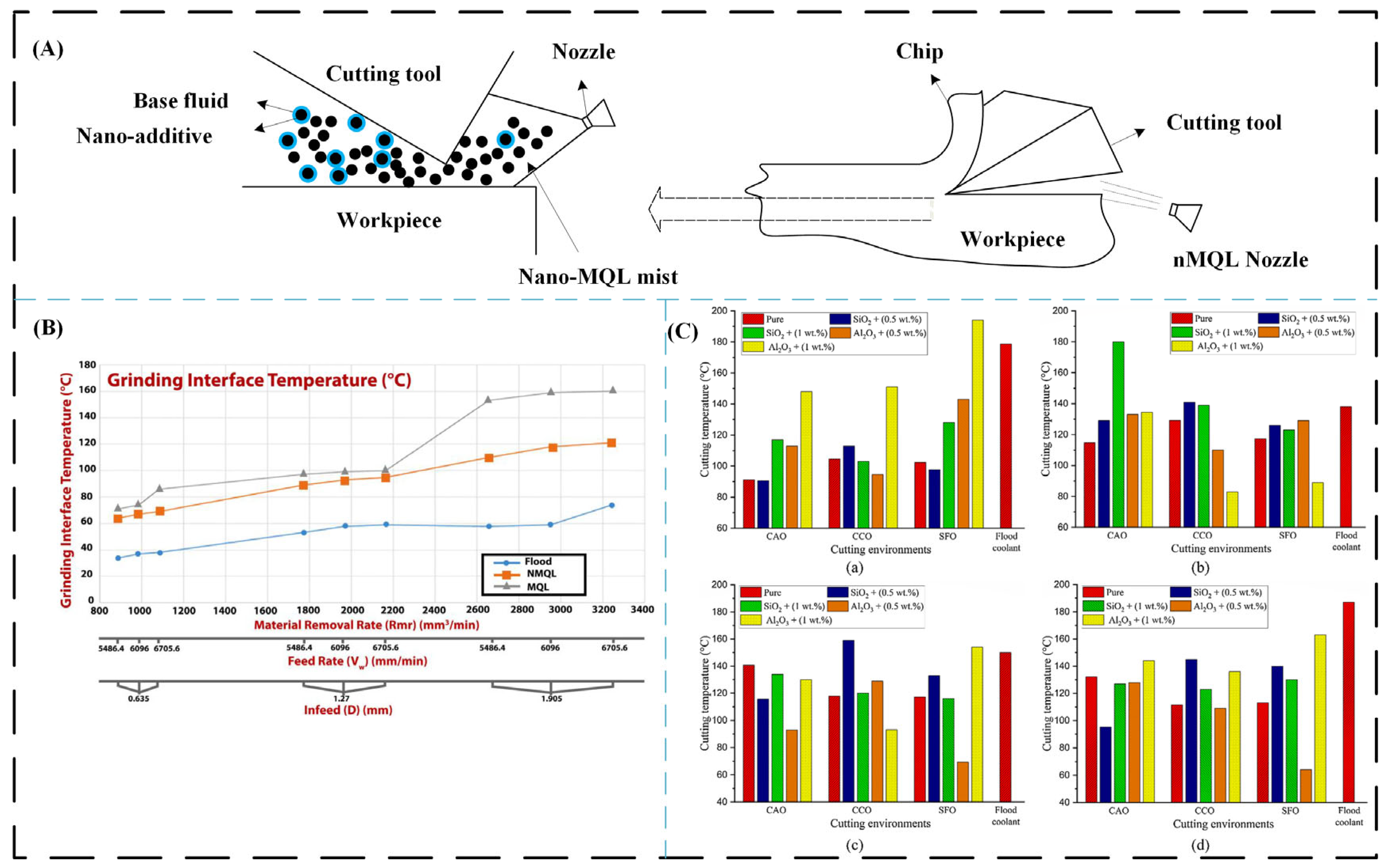

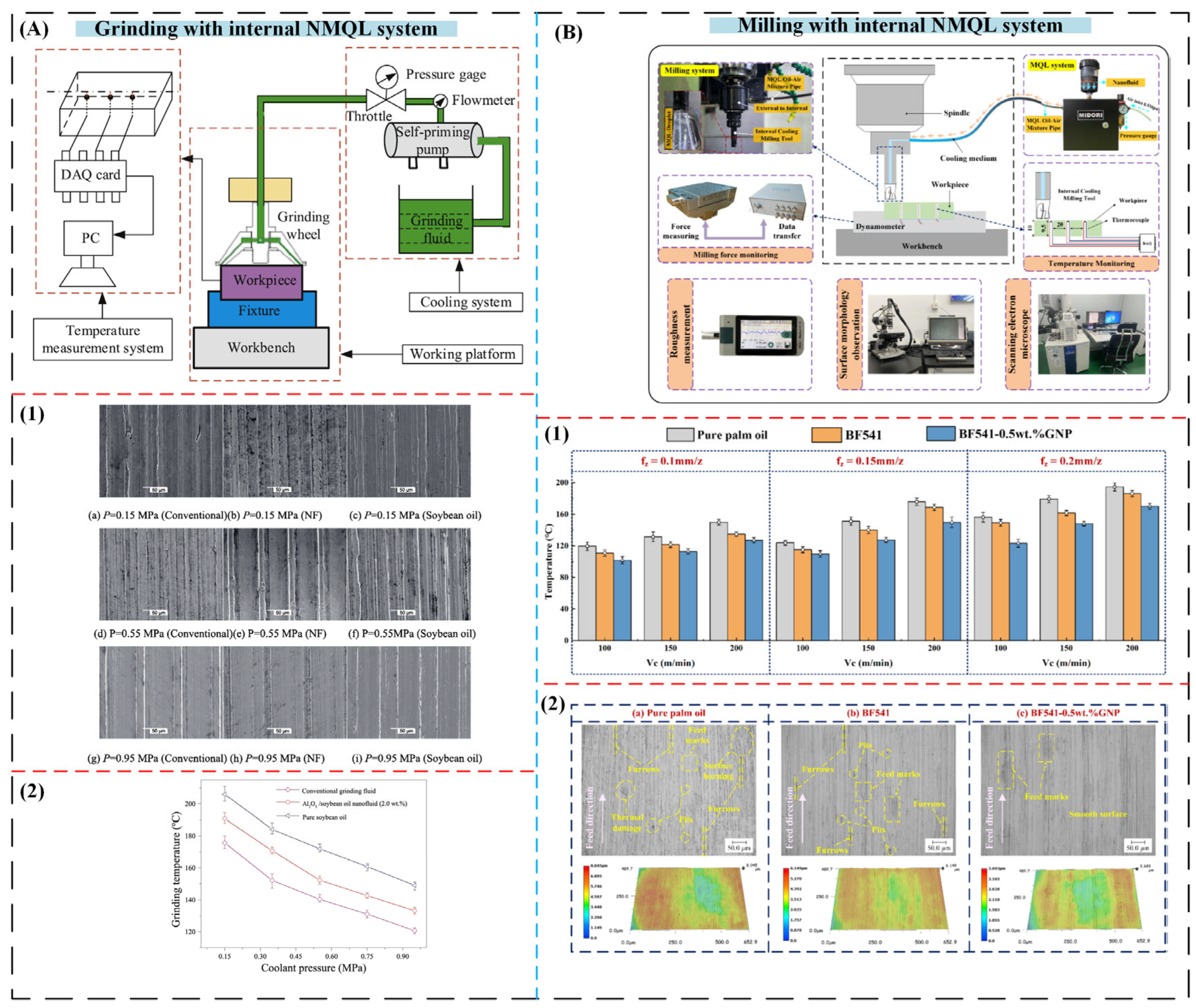

5. Nanofluid MQL Application in Machining Process

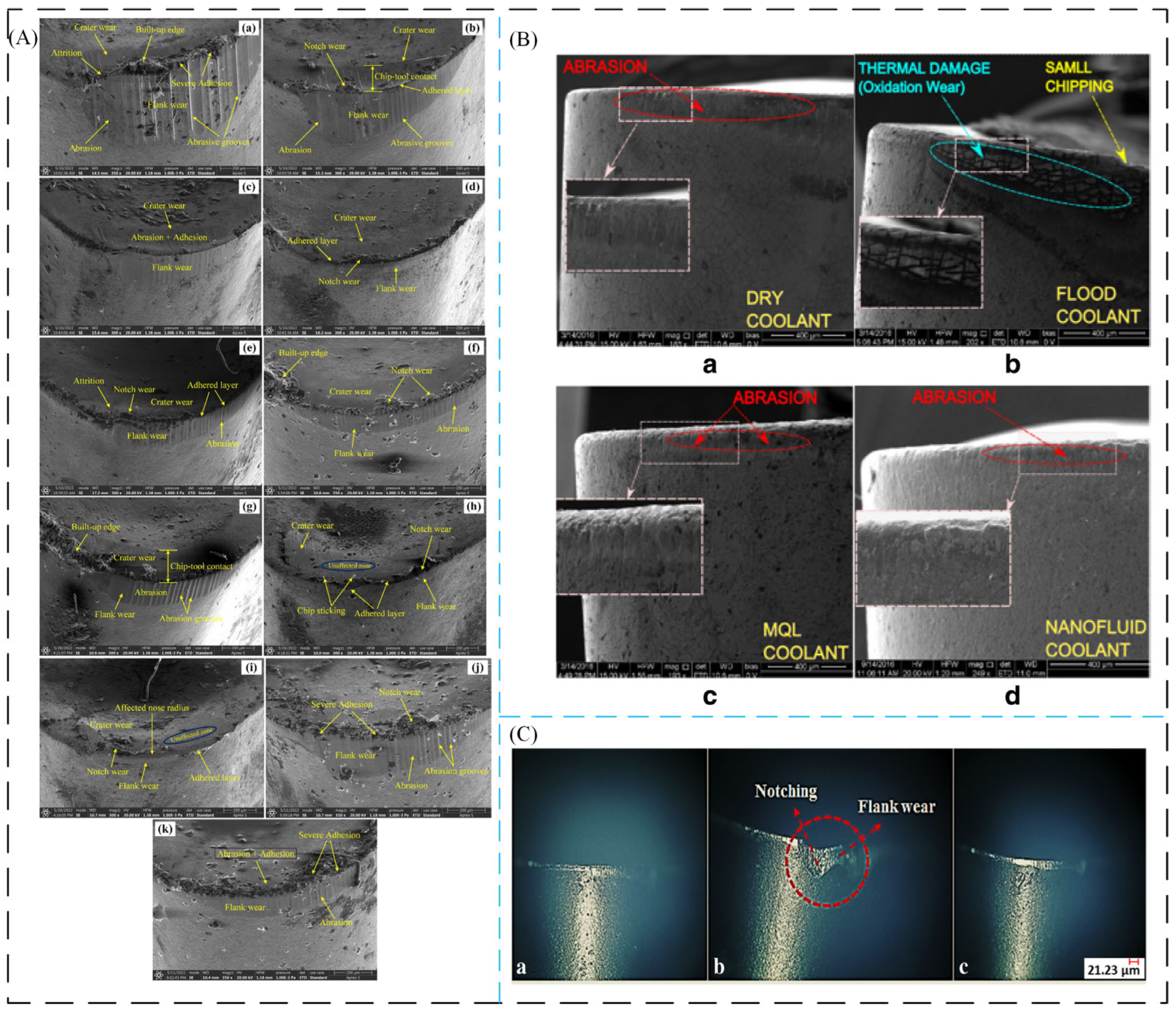

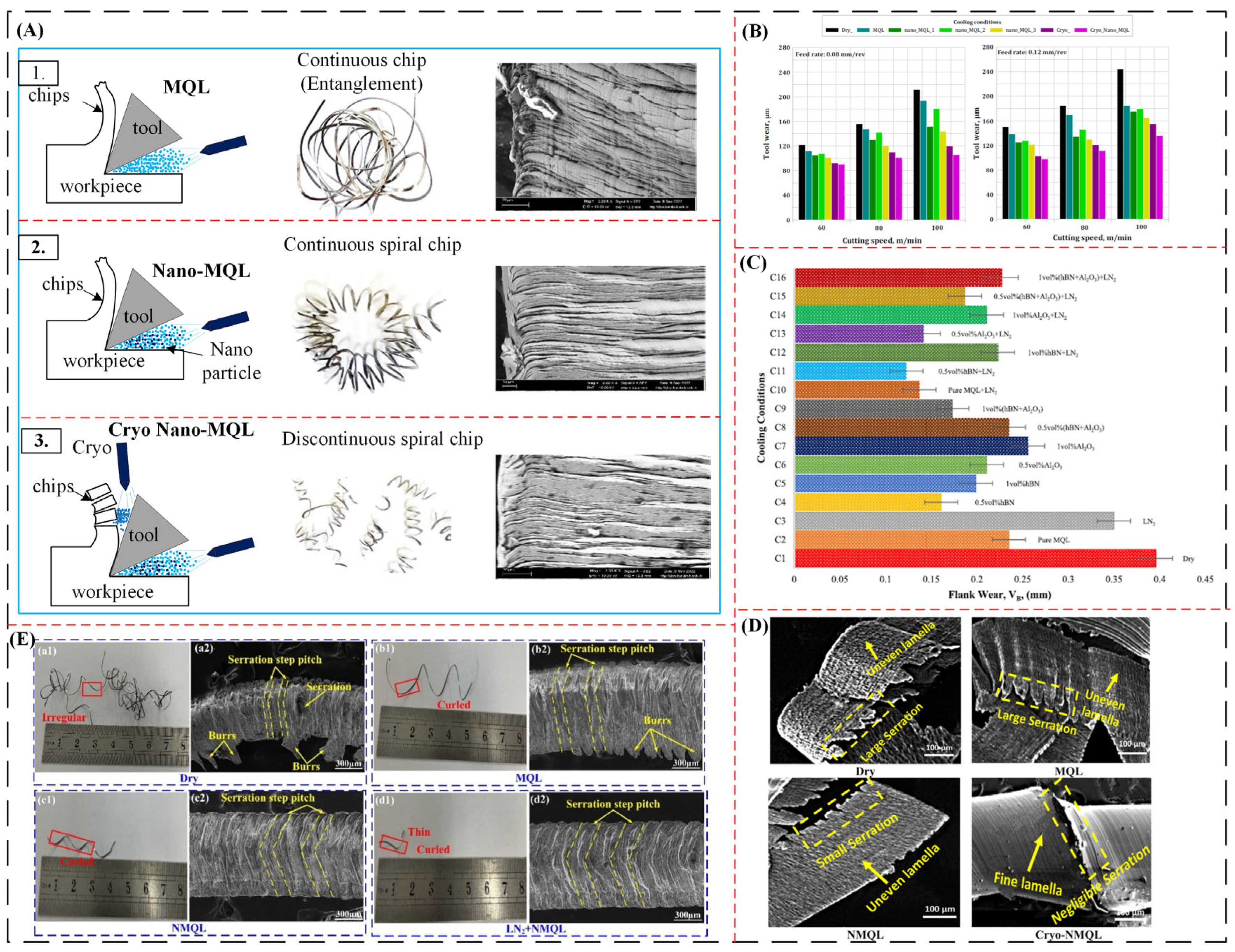

5.1. Application of Single NMQL

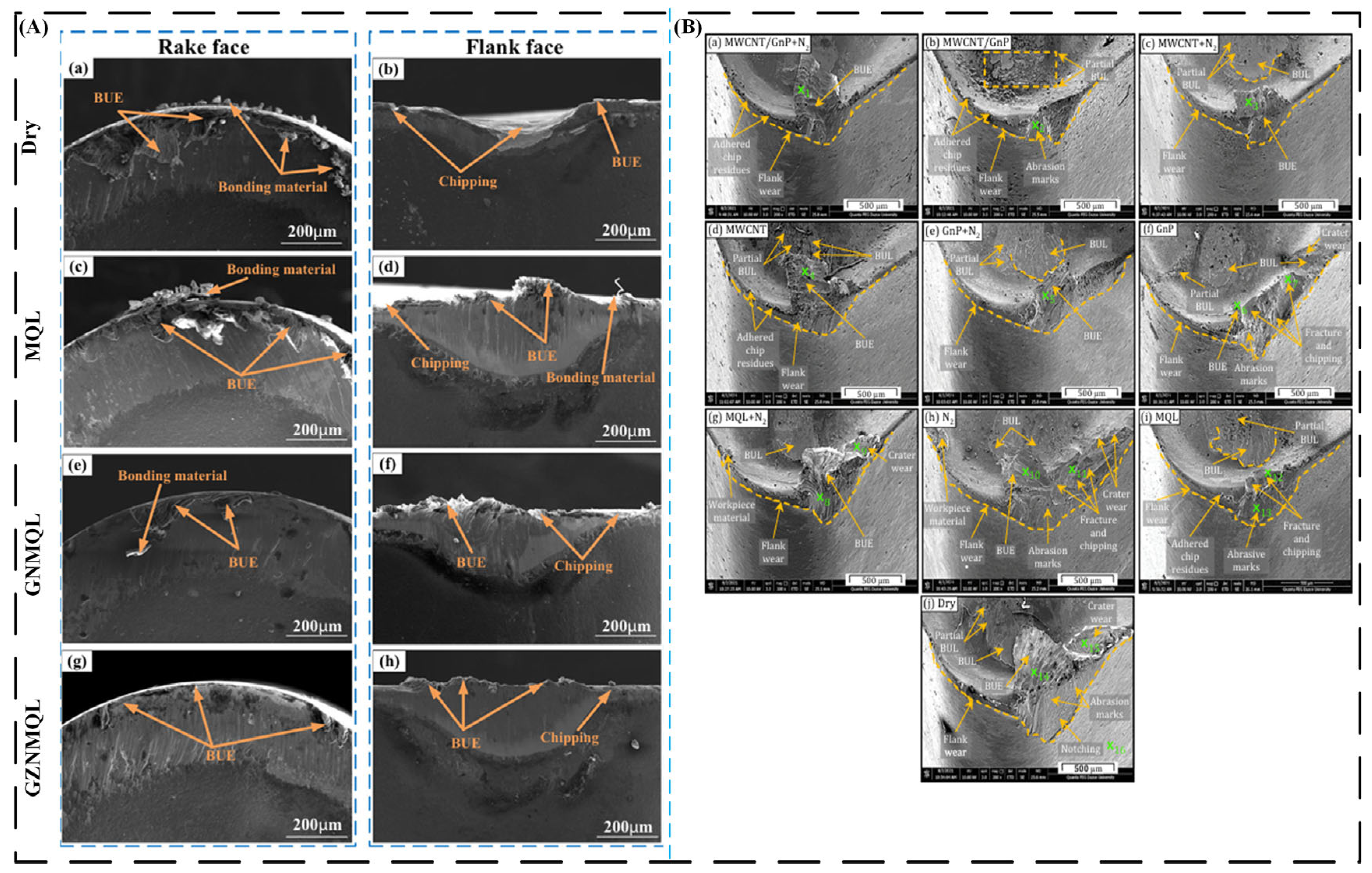

5.2. Application of Hybrid NMQL

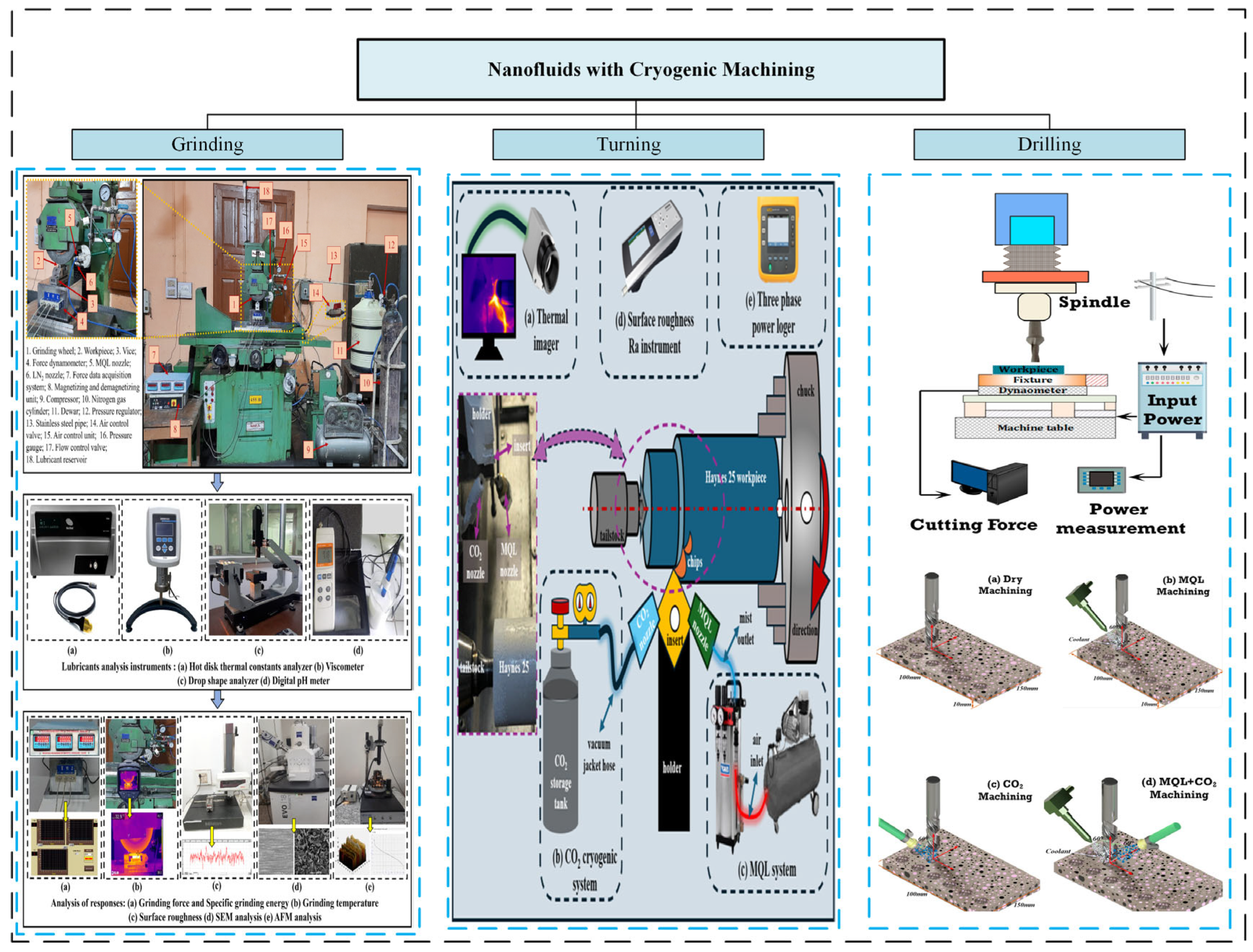

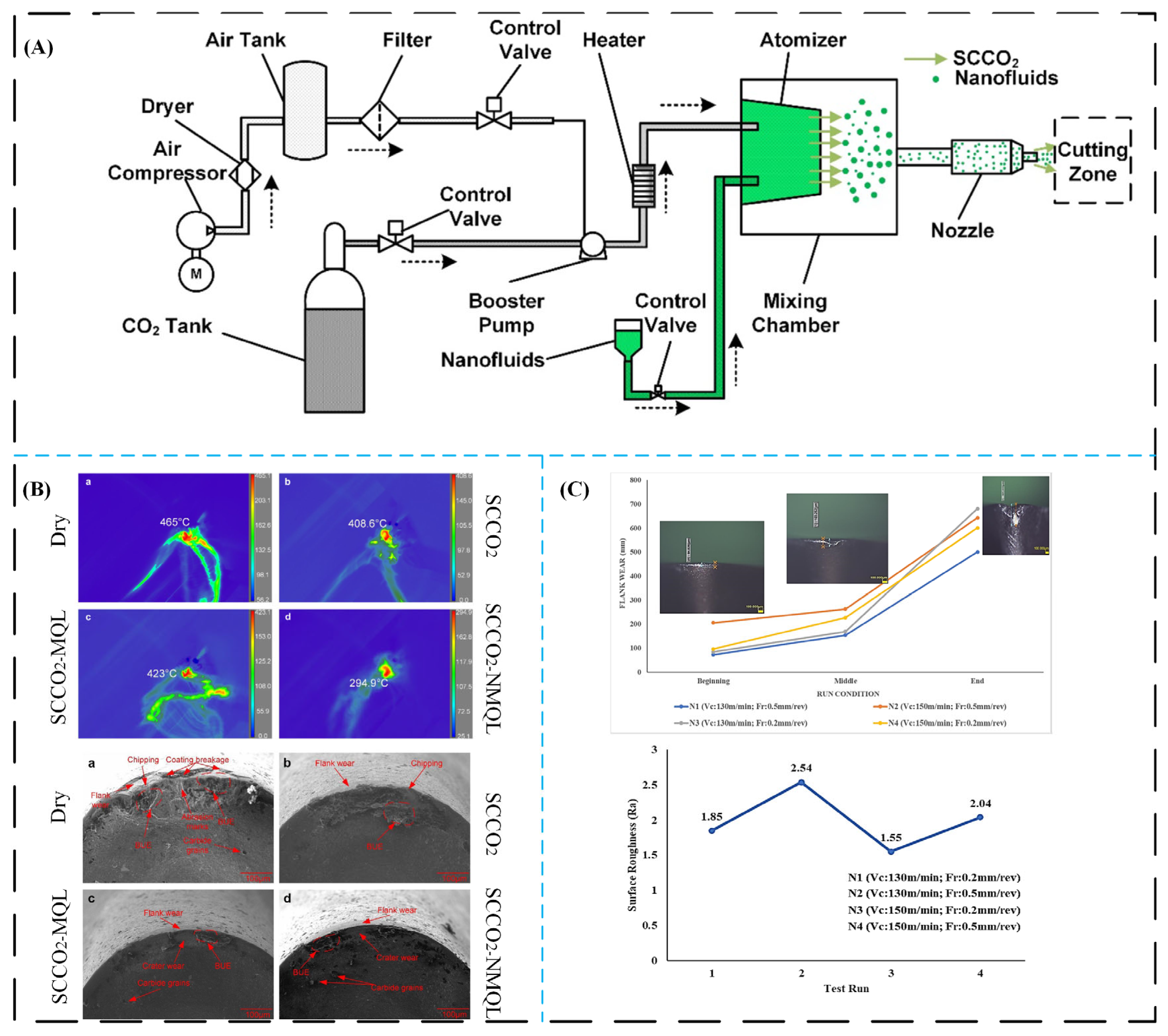

5.3. Synergy of NMQL with CO2-Based Cryogenic Machining

5.4. Synergy of NMQL with LN2-Based Cryogenic Machining

5.5. Synergy of NMQL with Hybrid Cryogenic

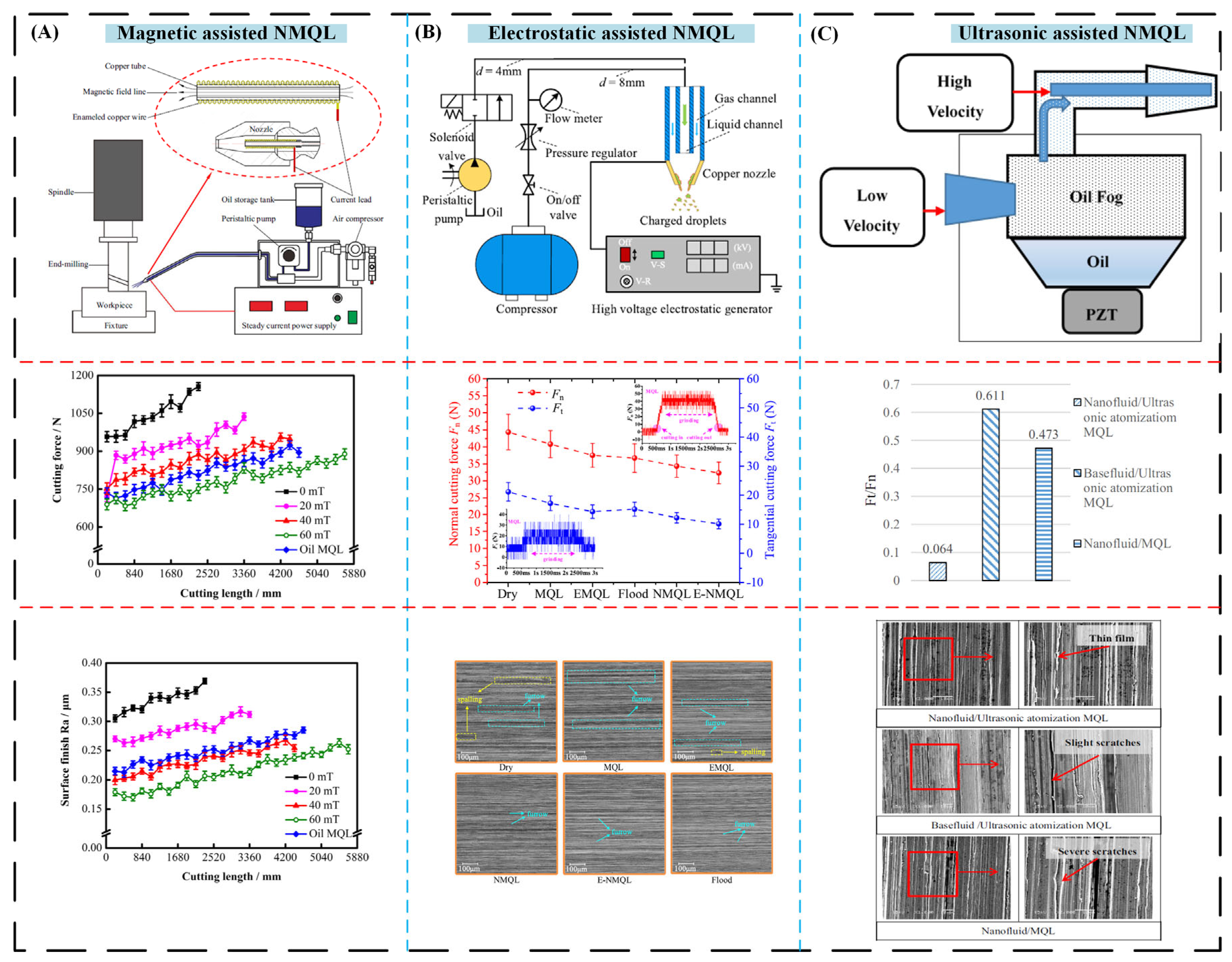

5.6. Application of Nanofluid with EMQL

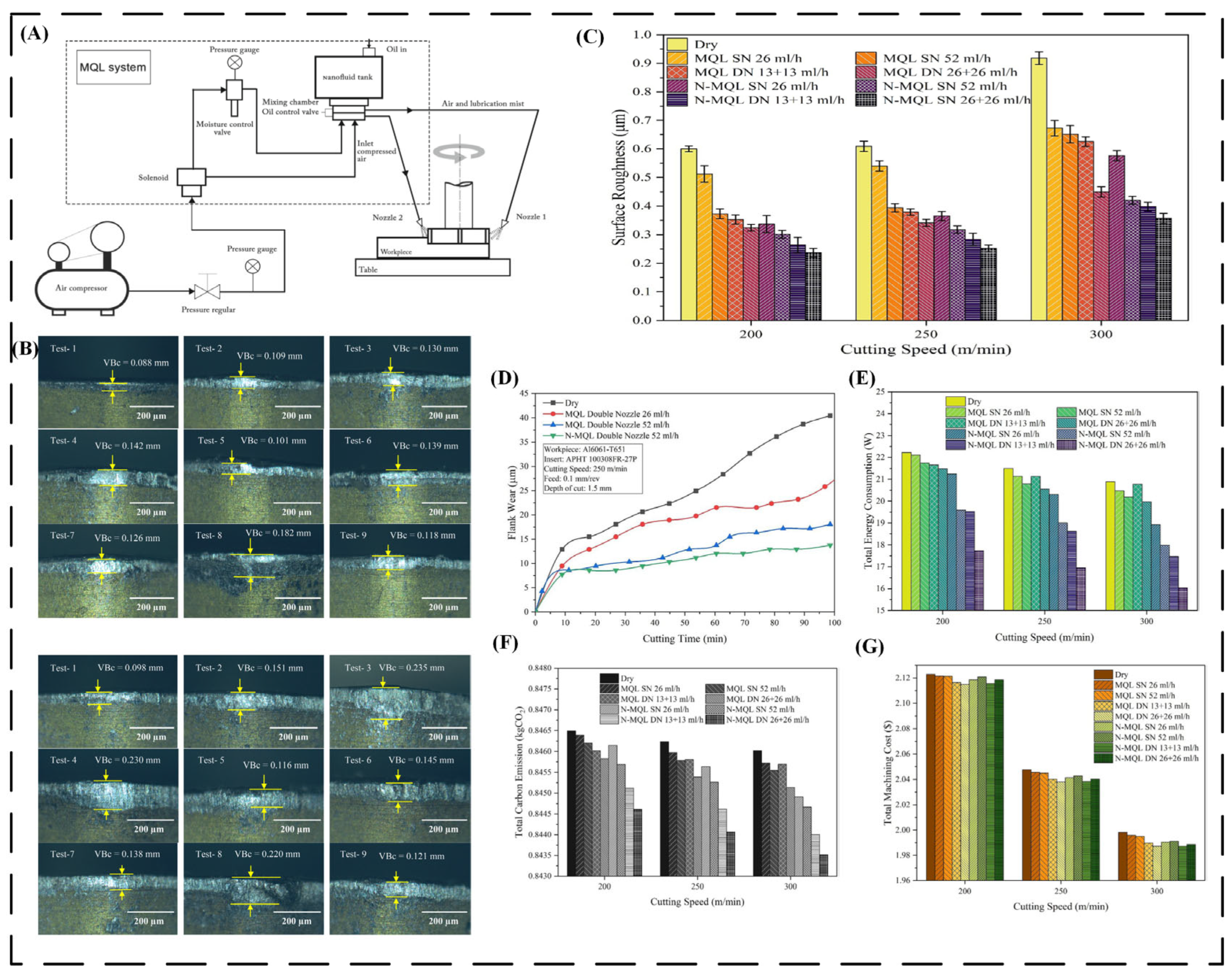

5.7. Application of Nanofluid with Multiple Nozzles

5.8. Application of Nanofluid Through Tool Delivery

5.9. Other Applications of NMQL Technology in Machining

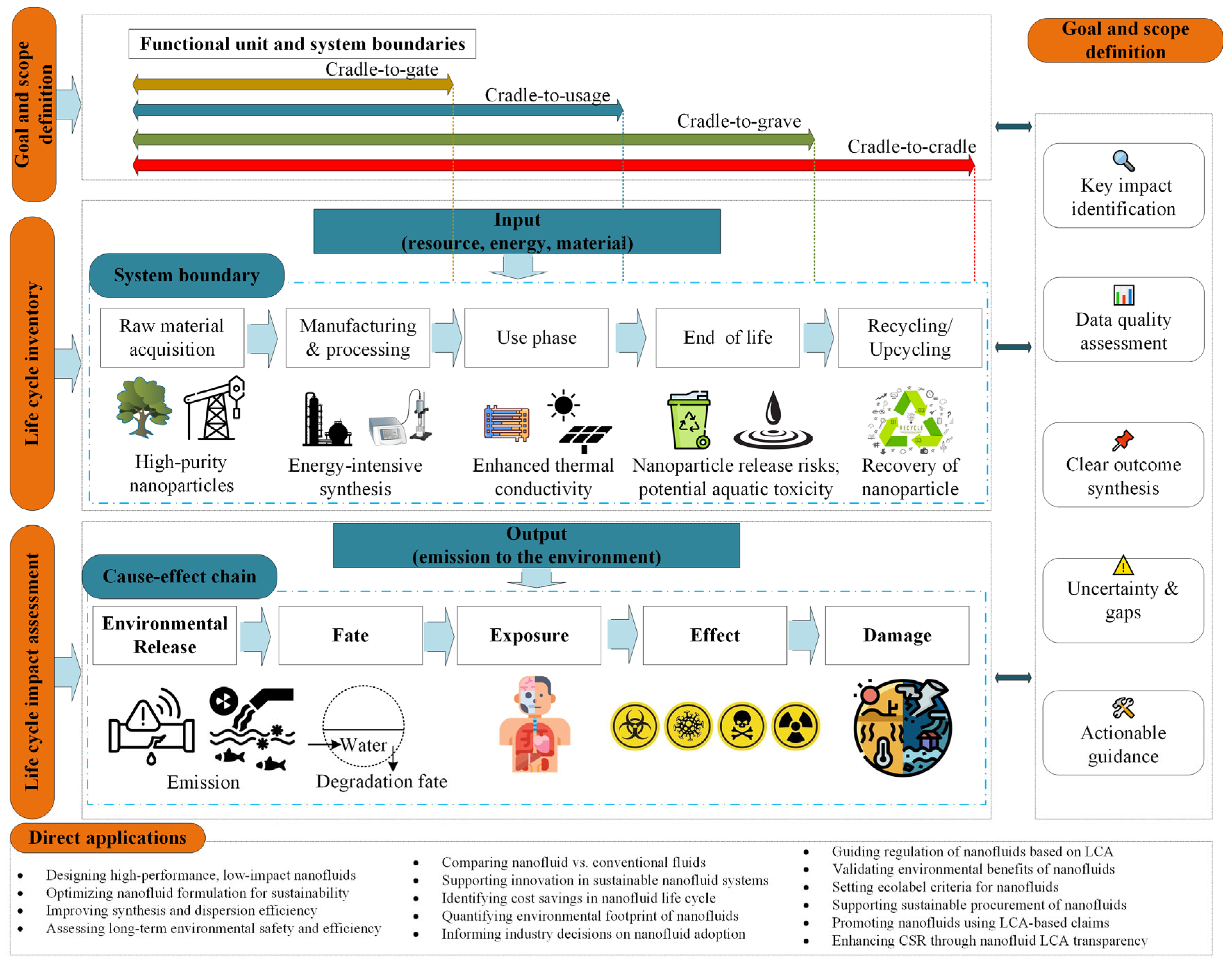

6. Sustainability in MQL Technologies

6.1. Environmental and Economic Assessment

6.2. Toxicology, Safety, and Disposal

6.2.1. Toxicology

6.2.2. Safety

6.2.3. Disposal

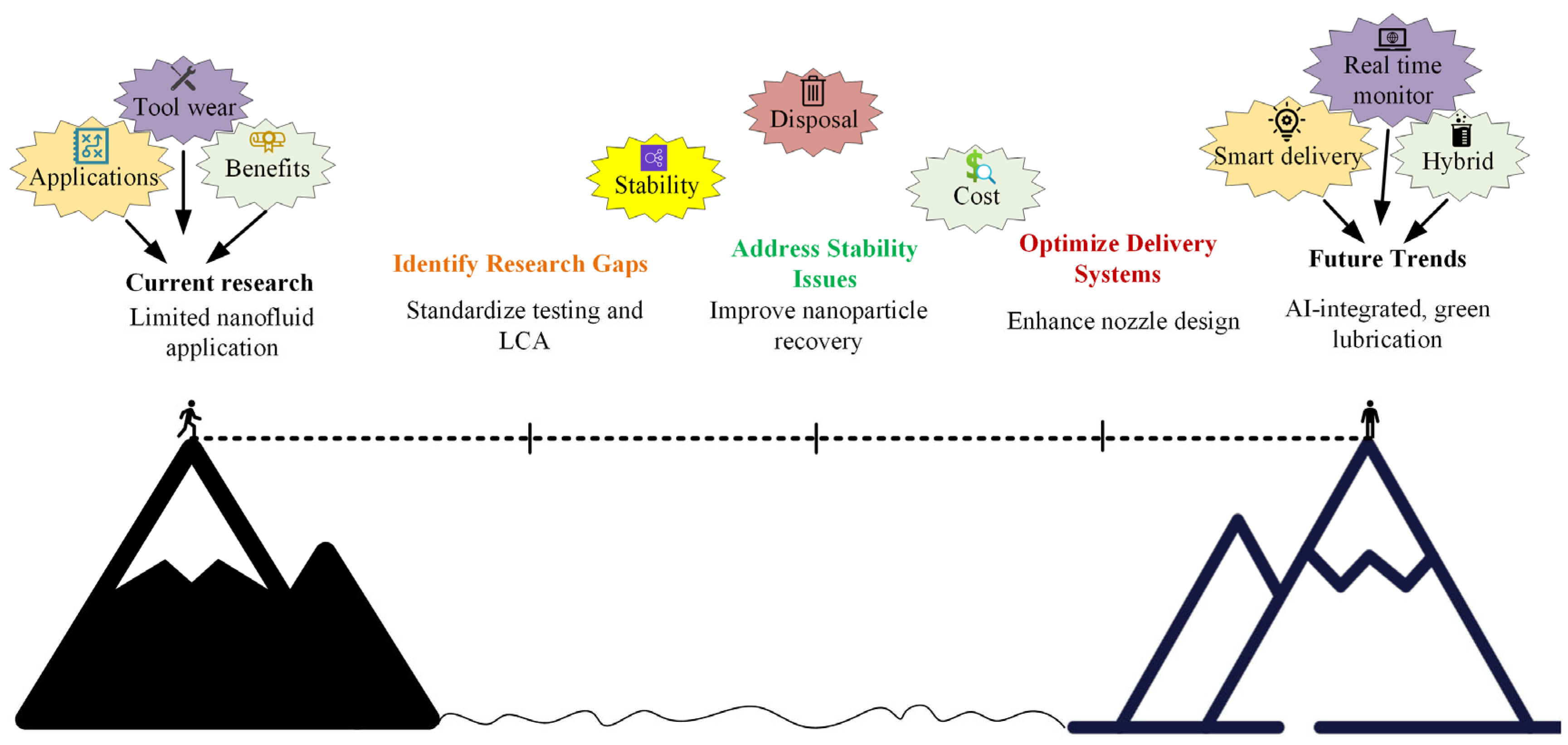

7. Research Trends and Future Directions

7.1. Lack of Real-Time LCA Data

7.2. Scalability of Nanosystems and Cost Barriers

7.3. Integration with AI/ML for Process Optimization

7.4. Policy and Standardization

8. Conclusions

Author Contributions

Funding

Conflicts of Interest

Abbreviations

| MQL | Minimum Quantity Lubrication |

| NDM | Near-Dry Machining |

| SQL | Small Quantity Lubrication |

| HTF | Heat Transfer Fluid |

| MWCNT | Multi-Walled Carbon Nanotube |

| Volume Fraction | |

| Viscosity of Nanoparticles | |

| Viscosity of Base Fluid | |

| Density of Nanofluid | |

| Density of Base Fluid | |

| Density of Solid Particles | |

| Nanofluid | |

| Base Fluid | |

| NF | Nanofluid |

| NP | Nanoparticle |

| CNT | Carbon Nanotube |

| DTAB | Dodecyl Trimethyl Ammonium Bromide |

| SDS | Sodium Dodecyl Sulfate |

| CTAB | Cetyl Trimethyl Ammonium Bromide |

| DES | Deep Eutectic Solvent |

| EG | Ethylene Glycol |

| FTIR | Fourier Transform Infrared |

| FSW | Friction Stir Welding |

| CDRX | Continuous Dynamic Recrystallization |

| C-MWCNT | Clove-Treated MWCNT |

| ANN | Artificial Neural Network |

| TOPSIS | Technique for Order of Preference by Similarity to Ideal Solution |

| LINMAP | Linear Programming Technique for Multidimensional Analysis of Preference |

| AI | Artificial Intelligence |

| ML | Machine Learning |

| PVP | Polyvinyl Pyrrolidone |

| IEP | Isoelectric Point |

| NMQL | Nanofluid MQL |

| MWF | Metalworking Fluid |

| FE | Finite Element |

| CFD | Computational Fluid Dynamics |

| ADI | Austempered Ductile Iron |

| HNMQL | Hybrid Nanofluid MQL |

| UVAM | Ultrasonic Vibration Assisted Machining |

| CM | Conventional Machining |

| CCF | Conventional Cutting Fluid |

| BVP | Boundary Value Problem |

| EEC | Engineering Equation Solver |

| GNP | Graphene Nanoparticle |

| Cryo-MQL | Cryogenic MQL |

| Cryo-NMQL | Cryogenic NMQL |

| ANOVA | Analysis of Variance |

| MORSM | Multi Objective Response Surface Methodology |

| mMQL | Magnetic MQL |

| WASPAS | Weighted Aggregated Sum Product Assessment |

| NCF | Nano-Cutting Fluid |

| TFC | Traditional Flood Cooling |

| LCA | Life Cycle Analysis |

| CCVD | Catalytic Chemical Vapor Deposition |

| DSSS | Double Slope Solar Still |

| PVT | Photovoltaic Thermal |

| CCHP | Combined Cooling Heating and Power |

| ROS | Reactive Oxygen Species |

| ENM | Engineered Nanomaterials |

| FSP | Flame Spray Pyrolysis |

References

- Chenn, N.; Liu, J.; He, N.; Xiao, X.; Zhao, J.; Jia, Y.; Yu, N. Fabrication of high aspect ratio grooves on aluminium nitride by laser and chemical milling enhanced micro milling. J. Mater. Process Technol. 2024, 325, 118299. [Google Scholar] [CrossRef]

- Yan, B.; He, N.; Chen, N.; Weigold, M.; Chen, H.; Sun, S.; Wu, Y.; Fu, S.; Li, L.; Abele, E. Achieving precise graphenization of diamond coatings below the interfacial thermal stress threshold. Int. J. Extrem. Manuf. 2025, 7, 015106. [Google Scholar] [CrossRef]

- Sharma, V.S.; Dogra, M.; Suri, N.M. Cooling techniques for improved productivity in turning. Int. J. Mach. Tools Manuf. 2009, 49, 435–453. [Google Scholar] [CrossRef]

- Weinert, K.; Inasaki, I.; Sutherland, J.W.; Wakabayashi, T. Dry Machining and Minimum Quantity Lubrication. CIRP Ann. 2004, 53, 511–537. [Google Scholar] [CrossRef]

- de Lacalle, L.N.L.; Angulo, C.; Lamikiz, A.; Sánchez, J.A. Experimental and numerical investigation of the effect of spray cutting fluids in high speed milling. J. Mater. Process Technol. 2006, 172, 11–15. [Google Scholar] [CrossRef]

- Race, A.; Zwerzak, I.; Secker, J.; Walsh, J.; Carrell, J.; Slatter, T.; Maurotto, A. Environmentally sustainable cooling strategies in milling of SA516: Effects on surface integrity of dry, flood and MQL machining. J. Clean. Prod. 2021, 288, 125580. [Google Scholar] [CrossRef]

- Sun, H.; Zou, B.; Chen, P.; Huang, C.; Guo, G.; Liu, J.; Li, L.; Shi, Z. Effect of MQL condition on cutting performance of high-speed machining of GH4099 with ceramic end mills. Tribol. Int. 2022, 167, 107401. [Google Scholar] [CrossRef]

- Tasdelen, B.; Thordenberg, H.; Olofsson, D. An experimental investigation on contact length during minimum quantity lubrication (MQL) machining. J. Mater. Process Technol. 2008, 203, 221–231. [Google Scholar] [CrossRef]

- Park, K.-H.; Suhaimi, M.A.; Yang, G.-D.; Lee, D.-Y.; Lee, S.-W.; Kwon, P. Milling of titanium alloy with cryogenic cooling and minimum quantity lubrication (MQL). Int. J. Precis. Eng. Manuf. 2017, 18, 5–14. [Google Scholar] [CrossRef]

- An, Q.L.; Fu, Y.C.; Xu, J.H. The Application of Cryogenic Pneumatic Mist Jet Impinging in High-Speed Milling of Ti-6Al-4V. Key Eng. Mater. 2006, 315–316, 244–248. [Google Scholar] [CrossRef]

- Şap, E.; Usca, Ü.A.; Değirmenci, Ü.; Şap, S.; Uzun, M. Evaluation of Machinability and Energy Consumption of CK45 Steel Using Synthetic-Based Nanofluid and Minimum Quantity Lubrication Cutting Fluid. Metals 2025, 15, 36. [Google Scholar] [CrossRef]

- Chen, N.; Chen, H.; Yan, B.; Mao, Z.; Imran, A.; Zhao, G.; He, N. Improving cutting performance of nickel-based alloy by graphene modified diamond tools. CIRP Ann. 2025, 74, 145–149. [Google Scholar] [CrossRef]

- Yapan, Y.F.; Türkeli, K.; Emiroğlu, U.; Bahçe, E.; Uysal, A. Machining and Sustainability Performance Comparison for the Milling Process of Al6082 Alloy Under Various Minimum Quantity Lubrication Conditions. Int. J. Precis. Eng. Manuf.-Green. Technol. 2025, 12, 409–430. [Google Scholar] [CrossRef]

- Sharma, P.; Singh, V.; Sinha, M.K. An in-depth analysis of MWCNTs and graphene nanofluids-based EDM: Investigating surface integrity in Inconel 825 superalloy. Precis. Eng. 2024, 91, 546–558. [Google Scholar] [CrossRef]

- Choi, S.U.S.; Eastman, J.A.; Eastman, J.A. Enhancing Thermal Conductivity of Fluids with Nanoparticles; Argonne National Laboratory (ANL): Argonne, IL, USA, 1935. [Google Scholar]

- Lee, J.-H.; Hwang, K.; Jang, S.; Lee, B.; Kim, J.; Choi, S.; Choi, C. Effective viscosities and thermal conductivities of aqueous nanofluids containing low volume concentrations of Al2O3 nanoparticles. Int. J. Heat. Mass. Transf. 2008, 51, 2651–2656. [Google Scholar] [CrossRef]

- Chandrasekar, M.; Suresh, S.; Bose, A.C. Experimental investigations and theoretical determination of thermal conductivity and viscosity of Al2O3/water nanofluid. Exp. Therm. Fluid. Sci. 2010, 34, 210–216. [Google Scholar] [CrossRef]

- Paul, G.; Philip, J.; Raj, B.; Das, P.K.; Manna, I. Synthesis, characterization, and thermal property measurement of nano-Al95Zn05 dispersed nanofluid prepared by a two-step process. Int. J. Heat. Mass. Transf. 2011, 54, 3783–3788. [Google Scholar] [CrossRef]

- Yu, W.; Xie, H.; Chen, L.; Li, Y. Enhancement of thermal conductivity of kerosene-based Fe3O4 nanofluids prepared via phase-transfer method. Colloids Surf. A Physicochem. Eng. Asp. 2010, 355, 109–113. [Google Scholar] [CrossRef]

- Suresh, S.; Venkitaraj, K.P.; Selvakumar, P.; Chandrasekar, M. Synthesis of Al2O3–Cu/water hybrid nanofluids using two step method and its thermo physical properties. Colloids Surf. A Physicochem. Eng. Asp. 2011, 388, 41–48. [Google Scholar] [CrossRef]

- Einstein, A. Über die von der molekularkinetischen Theorie der Wärme geforderte Bewegung von in ruhenden Flüssigkeiten suspendierten Teilchen. Ann. Phys. 1905, 322, 549–560. [Google Scholar] [CrossRef]

- Garg, J.; Poudel, B.; Chiesa, M.; Gordon, J.; Ma, J.; Wang, J.; Ren, Z.; Kang, Y.; Ohtani, H.; Nanda, J.; et al. Enhanced thermal conductivity and viscosity of copper nanoparticles in ethylene glycol nanofluid. J. Appl. Phys. 2008, 103, 074301. [Google Scholar] [CrossRef]

- Banisharif, A.; Aghajani, M.; Vaerenbergh, S.; Rashidi, A.; Estelle, P. Low Temperature Viscosity of Nanofluids with Water:Ethylene Glycol Base Fluid. 2019. Available online: https://www.researchgate.net/publication/339044549 (accessed on 26 June 2019).

- Heris, S.Z.; Etemad, S.G.; Esfahany, M.N. Experimental investigation of oxide nanofluids laminar flow convective heat transfer. Int. Commun. Heat. Mass. Transf. 2006, 33, 529–535. [Google Scholar] [CrossRef]

- Putra, N.; Roetzel, W.; Das, S.K. Natural convection of nano-fluids. Heat. Mass. Transf. 2003, 39, 775–784. [Google Scholar] [CrossRef]

- Peng, H.; Ding, G.; Jiang, W.; Hu, H.; Gao, Y. Measurement and correlation of frictional pressure drop of refrigerant-based nanofluid flow boiling inside a horizontal smooth tube. Int. J. Refrig. 2009, 32, 1756–1764. [Google Scholar] [CrossRef]

- Xuan, Y.; Li, Q. Investigation on Convective Heat Transfer and Flow Features of Nanofluids. J. Heat. Transf. 2003, 125, 151–155. [Google Scholar] [CrossRef]

- Razi, P.; Akhavan-Behabadi, M.A.; Saeedinia, M. Pressure drop and thermal characteristics of CuO–base oil nanofluid laminar flow in flattened tubes under constant heat flux. Int. Commun. Heat. Mass. Transf. 2011, 38, 964–971. [Google Scholar] [CrossRef]

- Teng, T.-P.; Hung, Y.-H.; Jwo, C.-S.; Chen, C.-C.; Jeng, L.-Y. Pressure drop of TiO2 nanofluid in circular pipes. Particuology 2011, 9, 486–491. [Google Scholar] [CrossRef]

- Suresh, S.; Venkitaraj, K.P.; Selvakumar, P.; Chandrasekar, M. Effect of Al2O3–Cu/water hybrid nanofluid in heat transfer. Exp. Therm. Fluid. Sci. 2012, 38, 54–60. [Google Scholar] [CrossRef]

- Xuan, Y.; Li, Q. Heat transfer enhancement of nanofluids. Int. J. Heat. Fluid. Flow. 2000, 21, 58–64. [Google Scholar] [CrossRef]

- Gosselin, L.; da Silva, A.K. Combined ‘heat transfer and power dissipation’ optimization of nanofluid flows. Appl. Phys. Lett. 2004, 85, 4160–4162. [Google Scholar] [CrossRef]

- Lee, J.; Mudawar, I. Assessment of the effectiveness of nanofluids for single-phase and two-phase heat transfer in micro-channels. Int. J. Heat. Mass. Transf. 2007, 50, 452–463. [Google Scholar] [CrossRef]

- Avsec, J.; Oblak, M. The calculation of thermal conductivity, viscosity and thermodynamic properties for nanofluids on the basis of statistical nanomechanics. Int. J. Heat. Mass. Transf. 2007, 50, 4331–4341. [Google Scholar] [CrossRef]

- Buongiorno, J. Convective Transport in Nanofluids. J. Heat. Transf. 2006, 128, 240–250. [Google Scholar] [CrossRef]

- Shin, D.; Banerjee, D. Enhancement of specific heat capacity of high-temperature silica-nanofluids synthesized in alkali chloride salt eutectics for solar thermal-energy storage applications. Int. J. Heat. Mass. Transf. 2011, 54, 1064–1070. [Google Scholar] [CrossRef]

- Li, D.; Kaner, R.B. Processable stabilizer-free polyaniline nanofiber aqueous colloids. Chem. Commun. 2005, 26, 3286–3288. [Google Scholar] [CrossRef] [PubMed]

- Wei, X.; Wang, L. Synthesis and thermal conductivity of microfluidic copper nanofluids. Particuology 2010, 8, 262–271. [Google Scholar] [CrossRef]

- Li, X.; Zhu, D.; Wang, X. Evaluation on dispersion behavior of the aqueous copper nano-suspensions. J. Colloid. Interface Sci. 2007, 310, 456–463. [Google Scholar] [CrossRef] [PubMed]

- Zhu, H.; Zhang, C.; Tang, Y.; Wang, J.; Ren, B.; Yin, Y. Preparation and thermal conductivity of suspensions of graphite nanoparticles. Carbon 2007, 45, 226–228. [Google Scholar] [CrossRef]

- Singh, A.K.; Raykar, V.S. Microwave synthesis of silver nanofluids with polyvinylpyrrolidone (PVP) and their transport properties. Colloid. Polym. Sci. 2008, 286, 1667–1673. [Google Scholar] [CrossRef]

- Zhu, D.; Li, X.; Wang, N.; Wang, X.; Gao, J.; Li, H. Dispersion behavior and thermal conductivity characteristics of Al2O3–H2O nanofluids. Curr. Appl. Phys. 2009, 9, 131–139. [Google Scholar] [CrossRef]

- Chen, L.; Xie, H. Properties of carbon nanotube nanofluids stabilized by cationic gemini surfactant. Thermochim. Acta 2010, 506, 62–66. [Google Scholar] [CrossRef]

- Kim, H.J.; Bang, I.C.; Onoe, J. Characteristic stability of bare Au-water nanofluids fabricated by pulsed laser ablation in liquids. Opt. Lasers Eng. 2009, 47, 532–538. [Google Scholar] [CrossRef]

- Huang, J.; Wang, X.; Long, Q.; Wen, X.; Zhou, Y.; Li, L. Influence of pH on the Stability Characteristics of Nanofluids. In Proceedings of the 2009 Symposium on Photonics and Optoelectronics, Wuhan, China, 14–16 August 2009; pp. 1–4. [Google Scholar] [CrossRef]

- Farahmandjou, M.; Sebt, S.A.; Parhizgar, S.S.; Aberomand, P.; Akhavan, M. Stability Investigation of Colloidal FePt Nanoparticle Systems by Spectrophotometer Analysis. Chin. Phys. Lett. 2009, 26, 027501. [Google Scholar] [CrossRef]

- Hwang, Y.; Lee, J.; Lee, C.; Jung, Y.; Cheong, S.; Lee, C.; Ku, B.; Jang, S. Stability and thermal conductivity characteristics of nanofluids. Thermochim. Acta 2007, 455, 70–74. [Google Scholar] [CrossRef]

- Galpaya, G.; Gunasena, M.; Induranga, D.; Priyadarshana, H.; Indupama, S.; Wijesekara, E.; Ishra, M.; Mantilaka, M.; Koswattage, K. Nanoparticle-Enhanced Engine Oils for Automotive Applications: Thermal Conductivity and Heat Capacity Improvements. Molecules 2025, 30, 2695. [Google Scholar] [CrossRef] [PubMed]

- Wang, S.; Zhang, H.; Cheng, Y.; Cao, Q.; Gao, Y.; Zhu, H.; Huang, H.; Yang, H.; Ji, Y. Investigation on high-temperature thermal conductivity in YTaO4 ceramics via 3-Omega method. AIP Adv. 2025, 15, 025105. [Google Scholar] [CrossRef]

- Abir, F.M.; Shin, D. Specific Heat Capacity of Solar Salt-Based Nanofluids: Molecular Dynamics Simulation and Experiment. Materials 2024, 17, 506. [Google Scholar] [CrossRef]

- Kumar, S.; Kumar, R. Tribological characteristics of synthesized hybrid nanofluid composed of CuO and TiO2 nanoparticle additives. Wear 2023, 518–519, 204623. [Google Scholar] [CrossRef]

- Hwang, Y.; Lee, J.; Lee, J.; Jeong, Y.; Cheong, S.; Ahn, Y.; Kim, S. Production and dispersion stability of nanoparticles in nanofluids. Powder Technol. 2008, 186, 145–153. [Google Scholar] [CrossRef]

- Bobbo, S.; Fedele, L.; Benetti, A.; Colla, L.; Fabrizio, M.; Pagura, C.; Barison, S. Viscosity of water based SWCNH and TiO2 nanofluids. Exp. Therm. Fluid. Sci. 2012, 36, 65–71. [Google Scholar] [CrossRef]

- Ruan, B.; Jacobi, A.M. Ultrasonication effects on thermal and rheological properties of carbon nanotube suspensions. Nanoscale Res. Lett. 2012, 7, 127. [Google Scholar] [CrossRef] [PubMed]

- Bowers, A.R.; Huang, C.P. Adsorption characteristics of polyacetic amino acids onto hydrous γ-Al2O3. J. Colloid. Interface Sci. 1985, 105, 197–215. [Google Scholar] [CrossRef]

- Pantzali, M.N.; Mouza, A.A.; Paras, S.V. Investigating the efficacy of nanofluids as coolants in plate heat exchangers (PHE). Chem. Eng. Sci. 2009, 64, 3290–3300. [Google Scholar] [CrossRef]

- Assael, M.J.; Metaxa, I.N.; Arvanitidis, J.; Christofilos, D.; Lioutas, C. Thermal Conductivity Enhancement in Aqueous Suspensions of Carbon Multi-Walled and Double-Walled Nanotubes in the Presence of Two Different Dispersants. Int. J. Thermophys. 2005, 26, 647–664. [Google Scholar] [CrossRef]

- Kakaç, S.; Pramuanjaroenkij, A. Review of convective heat transfer enhancement with nanofluids. Int. J. Heat. Mass. Transf. 2009, 52, 3187–3196. [Google Scholar] [CrossRef]

- Ding, Y.; Alias, H.; Wen, D.; Williams, R.A. Heat transfer of aqueous suspensions of carbon nanotubes (CNT nanofluids). Int. J. Heat. Mass. Transf. 2006, 49, 240–250. [Google Scholar] [CrossRef]

- Madni, I.; Hwang, C.-Y.; Park, S.-D.; Choa, Y.-H.; Kim, H.-T. Mixed surfactant system for stable suspension of multiwalled carbon nanotubes. Colloids Surf. A Physicochem. Eng. Asp. 2010, 358, 101–107. [Google Scholar] [CrossRef]

- Khairul, M.A.; Shah, K.; Doroodchi, E.; Azizian, R.; Moghtaderi, B. Effects of surfactant on stability and thermo-physical properties of metal oxide nanofluids. Int. J. Heat. Mass. Transf. 2016, 98, 778–787. [Google Scholar] [CrossRef]

- Wen, D.; Ding, Y. Experimental investigation into the pool boiling heat transfer of aqueous based γ-alumina nanofluids. J. Nanoparticle Res. 2005, 7, 265–274. [Google Scholar] [CrossRef]

- Jana, S.; Salehi-Khojin, A.; Zhong, W.-H. Enhancement of fluid thermal conductivity by the addition of single and hybrid nano-additives. Thermochim. Acta 2007, 462, 45–55. [Google Scholar] [CrossRef]

- Kim, J.-Y.; Kim, C.-S.; Chang, H.-K.; Kim, T.-O. Effects of ZrO2 addition on phase stability and photocatalytic activity of ZrO2/TiO2 nanoparticles. Adv. Powder Technol. 2010, 21, 141–144. [Google Scholar] [CrossRef]

- Aravind, S.S.J.; Ramaprabhu, S. Graphene wrapped multiwalled carbon nanotubes dispersed nanofluids for heat transfer applications. J. Appl. Phys. 2012, 112, 124304. [Google Scholar] [CrossRef]

- Esfe, M.H.; Arani, A.A.A.; Rezaie, M.; Yan, W.-M.; Karimipour, A. Experimental determination of thermal conductivity and dynamic viscosity of Ag–MgO/water hybrid nanofluid. Int. Commun. Heat. Mass. Transf. 2015, 66, 189–195. [Google Scholar] [CrossRef]

- Munkhbayar, B.; Tanshen, M.R.; Jeoun, J.; Chung, H.; Jeong, H. Surfactant-free dispersion of silver nanoparticles into MWCNT-aqueous nanofluids prepared by one-step technique and their thermal characteristics. Ceram. Int. 2013, 39, 6415–6425. [Google Scholar] [CrossRef]

- Aghabozorg, M.H.; Rashidi, A.; Mohammadi, S. Experimental investigation of heat transfer enhancement of Fe2O3-CNT/water magnetic nanofluids under laminar, transient and turbulent flow inside a horizontal shell and tube heat exchanger. Exp. Therm. Fluid. Sci. 2016, 72, 182–189. [Google Scholar] [CrossRef]

- Taha-Tijerina, J.J.; Edinbarough, I.A. Comparative Cutting Fluid Study on Optimum Grinding Parameters of Ti-6Al-4V Alloy Using Flood, Minimum Quantity Lubrication (MQL), and Nanofluid MQL (NMQL). Lubricants 2023, 11, 250. [Google Scholar] [CrossRef]

- Vardhanapu, M.; Chaganti, P.K.; Tarigopula, P. Characterization and machine learning-based parameter estimation in MQL machining of a superalloy for developed green nano-metalworking fluids. J. Braz. Soc. Mech. Sci. Eng. 2023, 45, 154. [Google Scholar] [CrossRef]

- Hegab, H.; Kishawy, H.A.; Umer, U.; Mohany, A. A model for machining with nano-additives based minimum quantity lubrication. Int. J. Adv. Manuf. Technol. 2019, 102, 2013–2028. [Google Scholar] [CrossRef]

- Eltaggaz, A.; Zawada, P.; Hegab, H.A.; Deiab, I.; Kishawy, H.A. Coolant strategy influence on tool life and surface roughness when machining ADI. Int. J. Adv. Manuf. Technol. 2018, 94, 3875–3887. [Google Scholar] [CrossRef]

- Hegab, H.; Umer, U.; Soliman, M.; Kishawy, H.A. Effects of nano-cutting fluids on tool performance and chip morphology during machining Inconel 718. Int. J. Adv. Manuf. Technol. 2018, 96, 3449–3458. [Google Scholar] [CrossRef]

- Kishawy, H.A.; Hegab, H.; Deiab, I.; Eltaggaz, A. Sustainability Assessment during Machining Ti-6Al-4V with Nano-Additives-Based Minimum Quantity Lubrication. J. Manuf. Mater. Process. 2019, 3, 61. [Google Scholar] [CrossRef]

- Agunsoye, J.O.; Nwoji, C.U.; Aigbodion, V.S. Machining performance of oil-based SiO2-derived rice husk ash nanofluid for the machining of aluminum alloy. Int. J. Adv. Manuf. Technol. 2021, 116, 1285–1295. [Google Scholar] [CrossRef]

- Tong, Y.; Ding, Y.; Guo, W.; Wang, S.; Cho, H. Heat transfer and lubrication performance of palm oil-Al2O3 nanofluid compared to traditional cutting fluid. ScienceAsia 2022, 48, 69–74. [Google Scholar] [CrossRef]

- Kumar, R.; Sahoo, A.K.; Mishra, P.C.; Das, R.K. Influence of Al2O3 and TiO2 nanofluid on hard turning performance. Int. J. Adv. Manuf. Technol. 2020, 106, 2265–2280. [Google Scholar] [CrossRef]

- Salimi-Yasar, H.; Heris, S.Z.; Shanbedi, M. Influence of soluble oil-based TiO2 nanofluid on heat transfer performance of cutting fluid. Tribol. Int. 2017, 112, 147–154. [Google Scholar] [CrossRef]

- Edelbi, A.; Kumar, R.; Sahoo, A.K.; Pandey, A. Comparative Machining Performance Investigation of Dual-Nozzle MQL-Assisted ZnO and Al2O3 Nanofluids in Face Milling of Ti–3Al–2.5V Alloys. Arab. J. Sci. Eng. 2023, 48, 2969–2993. [Google Scholar] [CrossRef]

- Huang, W.T.; Wu, D.H.; Lin, S.P.; Chen, J.T. Robust design of using MWCNTs in minimum quantity lubrication. In Applied Mechanics and Materials; Trans Tech Publications Ltd.: Wollerau, Switzerland, 2014; pp. 11–21. [Google Scholar] [CrossRef]

- Zhang, G.; Chen, H.; Xiao, G.; Yi, M.; Chen, Z.; Zhang, J.; Wang, G.; Xu, C. Effect of SiC nanofluid minimum quantity lubrication on the performance of the ceramic tool in cutting hardened steel. J. Manuf. Process 2022, 84, 539–554. [Google Scholar] [CrossRef]

- Li, W.; Zeng, Z.; Le, S.; Zhu, K.; Huang, X.; Hegab, H.; Ibrahim, A. Investigation of a green nanofluid added with graphene and Al2O3 nano-additives for grinding hard-to-cut materials. Tribol. Int. 2024, 195, 109580. [Google Scholar] [CrossRef]

- Ma, J.; Cui, E.; Zheng, G.; Li, W.; Cheng, X.; Liu, H. Investigation of the effects of GnP-ZrO2 hybrid nanofluids minimum quantity lubrication (NMQL) on the machinability of GH4169. Int. J. Adv. Manuf. Technol. 2024, 134, 5841–5853. [Google Scholar] [CrossRef]

- Şirin, Ş. Investigation of the performance of cermet tools in the turning of Haynes 25 superalloy under gaseous N2 and hybrid nanofluid cutting environments. J. Manuf. Process 2022, 76, 428–443. [Google Scholar] [CrossRef]

- Namlu, R.H.; Lotfi, B.; Kiliç, S.E. Multi-axial ultrasonic vibration-assisted machining of Inconel 718 using Al2O3-CuO hybrid nanofluid MQL. In Procedia CIRP; Elsevier B.V.: Amsterdam, The Netherlands, 2024; pp. 89–94. [Google Scholar] [CrossRef]

- Namlu, R.H.; Lotfi, B.; Kılıç, S.E. Enhancing machining efficiency of Ti-6Al-4V through multi-axial ultrasonic vibration-assisted machining and hybrid nanofluid minimum quantity lubrication. J. Manuf. Process 2024, 119, 348–371. [Google Scholar] [CrossRef]

- Nassef, B.G.; Pape, F.; Poll, G. Enhancing the Performance of Rapeseed Oil Lubricant for Machinery Component Applications through Hybrid Blends of Nanoadditives. Lubricants 2023, 11, 479. [Google Scholar] [CrossRef]

- Aberoumand, S.; Jafarimoghaddam, A. Tungsten (III) oxide (WO3)—Silver/transformer oil hybrid nanofluid: Preparation, stability, thermal conductivity and dielectric strength. Alex. Eng. J. 2018, 57, 169–174. [Google Scholar] [CrossRef]

- Gupta, M.; Singh, V.; Kumar, S.; Dilbaghi, N. Experimental analysis of heat transfer behavior of silver, MWCNT and hybrid (silver + MWCNT) nanofluids in a laminar tubular flow. J. Therm. Anal. Calorim. 2020, 142, 1545–1559. [Google Scholar] [CrossRef]

- Asadi, M.; Asadi, A. Dynamic viscosity of MWCNT/ZnO-engine oil hybrid nanofluid: An experimental investigation and new correlation in different temperatures and solid concentrations. Int. Commun. Heat. Mass. Transf. 2016, 76, 41–45. [Google Scholar] [CrossRef]

- Arif, M.; Di Persio, L.; Kumam, P.; Watthayu, W.; Akgül, A. Heat transfer analysis of fractional model of couple stress Casson tri-hybrid nanofluid using dissimilar shape nanoparticles in blood with biomedical applications. Sci. Rep. 2023, 13, 4596. [Google Scholar] [CrossRef] [PubMed]

- Arshad, M.; Alharbi, F.M.; Alhushaybari, A.; Eldin, S.M.; Ahmad, Z.; Galal, A.M. Exploration of heat and mass transfer subjected to first order chemical reaction and thermal radiation: Comparative dynamics of nano, hybrid and tri-hybrid particles over dual stretching surface. Int. Commun. Heat Mass Transf. 2023, 146, 106916. [Google Scholar] [CrossRef]

- Kashyap, S.; Sarkar, J.; Kumar, A. Performance enhancement of regenerative evaporative cooler by surface alterations and using ternary hybrid nanofluids. Energy 2021, 225, 120199. [Google Scholar] [CrossRef]

- Neto, O.M.P.; Calleja-Ochoa, A.; Ayesta, I.; Rodríguez, A.; González-Barrio, H.; de Lacalle, L.N.L. A Cleaner Milling Process Replacing Emulsion Coolant by Cryogenics CO2. Int. J. Precis. Eng. Manuf.-Green. Technol. 2024, 11, 21–32. [Google Scholar] [CrossRef]

- Velmurugan, K.V.; Mani, N. Enhanced machining performance using a hybrid cryogenic CO2 and TIO2 nanofluid minimum quantity lubrication (Cryomql) system. Mater. Res. Express 2025. [Google Scholar] [CrossRef]

- Sharma, A.; Chaudhari, A.; Diwakar, V.; Awale, A.S.; Yusufzai, M.Z.K.; Vashista, M. Implementation of hybrid CryoMQL sustainable lubri-cooling to enhance the grindability and surface integrity of tool steel. J. Manuf. Process 2024, 119, 16–31. [Google Scholar] [CrossRef]

- Serroune, S.A.; Khasani, I.R.; Merrier, S.; Devilliers, S.; Ryushi, T. Nanogeios Nanoliquid CO2—Performance Evaluation of Hybrid Nanofluid-Enhanced Liquid CO2 for advanced district and data center cooling applications. Int. J. Sci. Res. Arch. 2024, 13, 4251–4333. [Google Scholar] [CrossRef]

- Sarıkaya, M.; Yildirim, C.; Sirin, S.; Kara, M.; Sirin, E.; Kivak, T.; Krolczyk, G.; Atas, A. Performance and wear analysis in machining of Co-based Haynes 25/L605 superalloy using sustainable cooling/lubrication agencies. Sustain. Mater. Technol. 2025, 43, e01268. [Google Scholar] [CrossRef]

- Huang, H.; Liu, S.; Zhu, L.; Qing, Z.; Bao, H.; Liu, Z. Cooling and lubrication performance of supercritical CO2 mixed with nanofluid minimum quantity lubrication in turning Ti-6Al-4 V. Int. J. Adv. Manuf. Technol. 2022, 122, 2927–2938. [Google Scholar] [CrossRef]

- Hadi, M.A. Machinability and tribological investigation of nano-hybrid cryogenic-MQL during milling Ti-6Al-4V alloy. Abdul Hadi 2025, 44, 67–82. [Google Scholar]

- Dayana, N.; Mohd Noor, N.D. Cryogenic MQL in Milling Titanium Alloy; Universiti Malaysia Pahang Al-Sultan Abdullah: Pekan, Malaysia, 2023. [Google Scholar] [CrossRef]

- Sen, B.; Bhowmik, A. Application of minimum quantity GnP nanofluid and cryogenic LN2 in the machining of Hastelloy C276. Tribol. Int. 2024, 194, 109509. [Google Scholar] [CrossRef]

- Şirin, E.; Yıldırım, Ç.V.; Şirin, Ş.; Kıvak, T.; Sarıkaya, M. Comprehensive analysis of cutting temperature, tool wear, surface integrity and tribological properties in sustainable milling of Ti6Al4V alloy: LN2, nanofluid and hybrid machining. J. Manuf. Process 2024, 131, 1360–1371. [Google Scholar] [CrossRef]

- Suhaimi, M.A.; Yang, G.D.; Park, K.H.; Hisam, M.J.; Sharif, S.; Kim, D.W. Effect of Cryogenic Machining for Titanium Alloy Based on Indirect, Internal and External Spray System. In Procedia Manufacturing; Elsevier B.V.: Amsterdam, The Netherlands, 2018; pp. 158–165. [Google Scholar] [CrossRef]

- Şirin, E.; Yıldırım, Ç.V.; Kıvak, T.; Şirin, Ş.; Sarıkaya, M. Experimental research on sustainable drilling of Hastelloy X superalloy: Impact of hBN, GNP, LN2 and hybrid eco-friendly cooling/lubrication strategies. Tribol. Int. 2024, 200, 110070. [Google Scholar] [CrossRef]

- Korkmaz, M.E.; Rai, R.; Demirsöz, R.; Picak, S.; Vashishtha, G.; Günay, M. Studies on newly developed hBN/graphene-based nano-fluids supported by cryogenic cooling conditions in improving the tribological performance of Ti6Al4V alloy. J. Mol. Liq. 2024, 400, 124551. [Google Scholar] [CrossRef]

- Korkmaz, M.E.; Gupta, M.; Gunay, M.; Boy, M.; Yasar, N.; Demirsoz, R.; Ross, K.; Abbas, Y. Comprehensive analysis of tool wear, surface roughness and chip morphology in sustainable turning of Inconel-601 alloy. J. Manuf. Process 2023, 103, 156–167. [Google Scholar] [CrossRef]

- Yıldırım, Ç.V. Experimental comparison of the performance of nanofluids, cryogenic and hybrid cooling in turning of Inconel 625. Tribol. Int. 2019, 137, 366–378. [Google Scholar] [CrossRef]

- Ma, J.; Cui, E.; Zha, B.; Zheng, G.; Li, K.; Cheng, X.; Gu, L. Synergistic Effects of Multiphase Composite Nanofluids Minimum Quantity Lubrication and Cryogenic Cooling on the Machining Performance of GH4169. Available online: https://ssrn.com/abstract=5254137 (accessed on 28 May 2019).

- Lv, T.; Xu, X.; Yu, A.; Niu, C.; Hu, X. Ambient air quantity and cutting performances of water-based Fe3O4 nanofluid in magnetic minimum quantity lubrication. Int. J. Adv. Manuf. Technol. 2021, 115, 1711–1722. [Google Scholar] [CrossRef]

- Huang, W.T.; Chou, F.I.; Tsai, J.T.; Chou, J.H. Application of Graphene Nanofluid/Ultrasonic Atomization MQL System in Micromilling and Development of Optimal Predictive Model for SKH-9 High-Speed Steel Using Fuzzy-Logic-Based Multi-objective Design. Int. J. Fuzzy Syst. 2020, 22, 2101–2118. [Google Scholar] [CrossRef]

- Xu, W.; Li, C.; Cui, X.; Zhang, Y.; Yang, M.; Gao, T.; Liu, M.; Wang, X.; Zhou, Z.; Sharma, S.; et al. Atomization mechanism and machinability evaluation with electrically charged nanolubricant grinding of GH4169. J. Manuf. Process 2023, 106, 480–493. [Google Scholar] [CrossRef]

- Tusar, H. Investigations on Surface Grinding of Hardened Steels with Pulse Jet MQL Nanofluid Under Compressed Air Wheel Cleaning. Bachelor’s Thesis, Bowling Green State University, Bowling Green, OH, USA, 2019. [Google Scholar]

- Huang, W.T.; Tsai, J.T.; Hsu, C.F.; Ho, W.H.; Chou, J.H. Multiple Performance Characteristics in the Application of Taguchi Fuzzy Method in Nanofluid/Ultrasonic Atomization Minimum Quantity Lubrication for Grinding Inconel 718 Alloys. Int. J. Fuzzy Syst. 2022, 24, 294–309. [Google Scholar] [CrossRef]

- Ho, W.H.; Tsai, J.T.; Huang, W.T. Research on surface roughness of high-speed milling 7075-T6 aluminum alloy using nanofluid/ultrasonic atomization minimal quantity lubrication system. Sci. Prog. 2024, 107. [Google Scholar] [CrossRef] [PubMed]

- Cönger, D.B.; Yapan, Y.F.; Emiroğlu, U.; Uysal, A.; Altan, E. Influence of singular and dual MQL nozzles on sustainable milling of Al6061-T651 in different machining environments. J. Manuf. Process 2024, 109, 524–536. [Google Scholar] [CrossRef]

- Khatai, S.; Kumar, R.; Panda, A.; Sahoo, A.K. WASPAS Based Multi Response Optimization in Hard Turning of AISI 52100 Steel under ZnO Nanofluid Assisted Dual Nozzle Pulse-MQL Environment. Appl. Sci. 2023, 13, 62. [Google Scholar] [CrossRef]

- Pereira, O.; Rodriguez, A.; Calleja-Ochoa, A.; Celaya, A.; de Lacalle, L.; Fernandez-Valdivielso, A.; Gonzalez, H. Simulation of Cryo-cooling to Improve Super Alloys Cutting Tools. Int. J. Precis. Eng. Manuf.-Green. Technol. 2022, 9, 73–82. [Google Scholar] [CrossRef]

- Peng, R.; He, X.; Tong, J.; Tang, X.; Wu, Y. Application of a tailored eco-friendly nanofluid in pressurized internal-cooling grinding of Inconel 718. J. Clean. Prod. 2021, 278, 123498. [Google Scholar] [CrossRef]

- Peng, R.; Shen, J.; Tang, X.; Zhao, L.; Gao, J. Performances of a tailored vegetable oil-based graphene nanofluid in the MQL internal cooling milling. J. Manuf. Process 2025, 134, 814–831. [Google Scholar] [CrossRef]

- Sharmin, I.; Gafur, M.A.; Dhar, N.R. Preparation and evaluation of a stable CNT-water based nano cutting fluid for machining hard-to-cut material. SN Appl. Sci. 2020, 2, 626. [Google Scholar] [CrossRef]

- Jafari, K.; Fatemi, M.H.; Lugo, L. An experimental study of novel nanofluids based on deep eutectic solvents (DESs) by Choline chloride and ethylene glycol. J. Mol. Liq. 2022, 360, 119521. [Google Scholar] [CrossRef]

- Liu, J.; Wang, X.; Liu, Y.; Liu, X.; Fan, K. Bioinspired three-dimensional and multiple adsorption effects toward high lubricity of solvent-free graphene-based nanofluid. Carbon 2022, 188, 166–176. [Google Scholar] [CrossRef]

- Popat, K.D.; Venkatesh, M.A. Experimental Investigation on Effects of Thermal and Physical Properties of Biodegradable Hybrid Nanofluid Using Two Step Method. In Proceedings of the 5th National Conference on Recent Advancement in Physical Sciences, Uttarakhand, India, 19–20 December 2023. [Google Scholar] [CrossRef]

- ElBadawy, N.K.; Nassef, M.; Maher, I.; Nassef, B.; Daha, M.; Pape, F.; Nassef, G. Nano-Enhanced Cactus Oil as an MQL Cutting Fluid: Physicochemical, Rheological, Tribological, and Machinability Insights into Machining H13 Steel. Lubricants 2025, 13, 267. [Google Scholar] [CrossRef]

- Verma, S.; Wu, C.S.; Thakur, L.; Muhammad, N.A.; Li, S. Investigating the influence of biodegradable nanofluid process cooling on dynamic recrystallization and grain microstructure in friction stir welding of AA6082 alloy. J. Mater. Process Technol. 2025, 336, 118700. [Google Scholar] [CrossRef]

- Amani, M.; Amani, P.; Mahian, O.; Estellé, P. Multi-objective optimization of thermophysical properties of eco-friendly organic nanofluids. J. Clean. Prod. 2017, 166, 350–359. [Google Scholar] [CrossRef]

- Salem, A.; Hopkins, C.; Imad, M.; Hegab, H.; Darras, B.; Kishawy, H.A. Environmental analysis of sustainable and traditional cooling and lubrication strategies during machining processes. Sustainability 2020, 12, 8462. [Google Scholar] [CrossRef]

- Griffiths, O.G.; O’Byrne, J.P.; Torrente-Murciano, L.; Jones, M.D.; Mattia, D.; McManus, M.C. Identifying the largest environmental life cycle impacts during carbon nanotube synthesis via chemical vapour deposition. J. Clean. Prod. 2013, 42, 180–189. [Google Scholar] [CrossRef]

- Grubb, G.F.; Bakshi, B.R. Life Cycle of Titanium Dioxide Nanoparticle Production: Impact of Emissions and Use of Resources. J. Ind. Ecol. 2011, 15, 81–95. [Google Scholar] [CrossRef]

- Bai, Y.; Wu, F.; Gong, Y. Oxidation and adsorption of antimony(iii) from surface water using novel Al2O3-supported Fe-Mn binary oxide nanoparticles: Effectiveness, dynamic quantitative mechanisms, and life cycle analysis. Environ. Sci. Nano 2020, 7, 3047–3061. [Google Scholar] [CrossRef]

- Feijoo, S.; González-Rodríguez, J.; Fernández, L.; Vázquez-Vázquez, C.; Feijoo, G.; Moreira, M.T. Fenton and photo-fenton nanocatalysts revisited from the perspective of life cycle assessment. Catalysts 2020, 10, 23. [Google Scholar] [CrossRef]

- Gunasekara, C.; Sandanayake, M.; Zhou, Z.; Law, D.W.; Setunge, S. Effect of nano-silica addition into high volume fly ash–hydrated lime blended concrete. Constr. Build. Mater. 2020, 253, 119205. [Google Scholar] [CrossRef]

- Huseien, G.F.; Hamzah, H.; Mohd Sam, A.R.; Khalid, N.; Shah, K.; Deogrescu, D.; Mirza, J. Alkali-activated mortars blended with glass bottle waste nano powder: Environmental benefit and sustainability. J. Clean. Prod. 2020, 243, 118636. [Google Scholar] [CrossRef]

- Ingrao, C.; Vesce, E.; Evola, R.; Rebba, E.; Arcidiaconno, C.; Martra, G.; Beltramo, R. Chemistry behind leather: Life Cycle Assessment of nano-hydroxyapatite preparation on the lab-scale for fireproofing applications. J. Clean. Prod. 2021, 279, 123837. [Google Scholar] [CrossRef]

- Lee, J.; Ryu, K.H.; Ha, H.Y.; Jung, K.D.; Lee, J.H. Techno-economic and environmental evaluation of nano calcium carbonate production utilizing the steel slag. J. CO2 Util. 2020, 37, 113–121. [Google Scholar] [CrossRef]

- Petrakli, F.; Gkika, A.; Bonou, A.; Karayannis, P.; Koumoulos, E.; Semitekolos, D.; Tropeta, A.; Rocha, N.; Santos, R.; Simmonds, G.; et al. End-of-life recycling options of (nano)enhanced CFRP composite prototypes waste-a life cycle perspective. Polymers 2020, 12, 2129. [Google Scholar] [CrossRef]

- Rodrigues, N.P.; Scott-Fordsmand, J.J.; Amorim, M.J.B. Novel understanding of toxicity in a life cycle perspective—The mechanisms that lead to population effect—The case of Ag (nano)materials. Environ. Pollut. 2020, 262, 114277. [Google Scholar] [CrossRef] [PubMed]

- Rossi, F.; Parisi, M.L.; Maranghi, S.; Basosi, R.; Sinicropi, A. Environmental analysis of a nano-grid: A Life Cycle Assessment. Sci. Total Environ. 2020, 700, 134814. [Google Scholar] [CrossRef] [PubMed]

- Abadeh, A.; Rejeb, O.; Sardarabadi, M.; Menezo, C.; Passandideh-Fard, M.; Jemni, A. Economic and environmental analysis of using metal-oxides/water nanofluid in photovoltaic thermal systems (PVTs). Energy 2018, 159, 1234–1243. [Google Scholar] [CrossRef]

- Sahota, L.; Shyam; Tiwari, G.N. Energy matrices, enviroeconomic and exergoeconomic analysis of passive double slope solar still with water based nanofluids. Desalination 2017, 409, 66–79. [Google Scholar] [CrossRef]

- Stalin, P.M.J.; Arjunan, T.V.; Matheswaran, M.M.; Dolli, H.; Sadanandam, N. Energy, economic and environmental investigation of a flat plate solar collector with CeO2/water nanofluid. J. Therm. Anal. Calorim. 2020, 139, 3219–3233. [Google Scholar] [CrossRef]

- Hassani, S.; Saidur, R.; Mekhilef, S.; Taylor, R.A. Environmental and exergy benefit of nanofluid-based hybrid PV/T systems. Energy Convers. Manag. 2016, 123, 431–444. [Google Scholar] [CrossRef]

- Sharafeldin, M.A.; Gróf, G.; Abu-Nada, E.; Mahian, O. Evacuated tube solar collector performance using copper nanofluid: Energy and environmental analysis. Appl. Therm. Eng. 2019, 162, 114205. [Google Scholar] [CrossRef]

- Boyaghchi, F.A.; Chavoshi, M. Multi-criteria optimization of a micro solar-geothermal CCHP system applying water/CuO nanofluid based on exergy, exergoeconomic and exergoenvironmental concepts. Appl. Therm. Eng. 2017, 112, 660–675. [Google Scholar] [CrossRef]

- Lau, H.C.; Yu, M.; Nguyen, Q.P. Nanotechnology for oilfield applications: Challenges and impact. J. Pet. Sci. Eng. 2017, 157, 1160–1169. [Google Scholar] [CrossRef]

- Murugadoss, S.; Lison, D.; Godderis, L.; Van Den Brule, S.; Mast, J.; Brassinne, F.; Sebaihi, N.; Hoet, P. Toxicology of silica nanoparticles: An update. Arch. Toxicol. 2017, 91, 2967–3010. [Google Scholar] [CrossRef] [PubMed]

- McCarthy, J.; Inkielewicz-Stępniak, I.; Corbalan, J.J.; Radomski, M.W. Mechanisms of Toxicity of Amorphous Silica Nanoparticles on Human Lung Submucosal Cells in Vitro: Protective Effects of Fisetin. Chem. Res. Toxicol. 2012, 25, 2227–2235. [Google Scholar] [CrossRef]

- Zhang, X.Q.; Yin, L.H.; Tang, M.; Pu, Y.P. ZnO, TiO2, SiO2, and Al2O3 nanoparticles-induced toxic effects on human fetal lung fibroblasts. Biomed. Environ. Sci. 2011, 24, 661–669. [Google Scholar] [CrossRef]

- Kim, I.-S.; Baek, M.; Choi, S.-J. Comparative Cytotoxicity of Al2O3, CeO2, TiO2, and ZnO Nanoparticles to Human Lung Cells. J. Nanosci. Nanotechnol. 2010, 10, 3453–3458. [Google Scholar] [CrossRef]

- Karlsson, H.L.; Cronholm, P.; Gustafsson, J.; Möller, L. Copper Oxide Nanoparticles Are Highly Toxic: A Comparison between Metal Oxide Nanoparticles and Carbon Nanotubes. Chem. Res. Toxicol. 2008, 21, 1726–1732. [Google Scholar] [CrossRef]

- Lee, J.H.; Ju, J.; Kim, B.; Pak, P.; Lee, H.; Chung, N. Rod-shaped iron oxide nanoparticles are more toxic than sphere-shaped nanoparticles to murine macrophage cells. Env. Toxicol. Chem. 2014, 33, 2759–2766. [Google Scholar] [CrossRef]

- Anandha Babu, G.; Ravi, G.; Mahalingam, T.; Navaneethan, M.; Arivanandhan, M.; Hayakawa, Y. Size and Surface Effects of Ce-Doped NiO and Co3O4 Nanostructures on Ferromagnetism Behavior Prepared by the Microwave Route. J. Phys. Chem. C 2014, 118, 23335–23348. [Google Scholar] [CrossRef]

- Sun, B.; Pokhrel, S.; Dunphy, D.; Zhang, H.; Ji, Z.; Wang, X.; Wang, M.; Liao, Y.; Chang, C.; Dong, J.; et al. Reduction of Acute Inflammatory Effects of Fumed Silica Nanoparticles in the Lung by Adjusting Silanol Display through Calcination and Metal Doping. ACS Nano 2015, 9, 9357–9372. [Google Scholar] [CrossRef] [PubMed]

- Teoh, W.Y.; Amal, R.; Mädler, L. Flame spray pyrolysis: An enabling technology for nanoparticles design and fabrication. Nanoscale 2010, 2, 1324. [Google Scholar] [CrossRef] [PubMed]

- Charehsaz, M.; Coskun, S.; Unalan, H.; Reis, R.; Helvacioglu, S.; Giri, A.; Aydin, A. Genotoxicity study of high aspect ratio silver nanowires. Toxicol. Environ. Chem. 2017, 99, 837–847. [Google Scholar] [CrossRef]

- Ji, Z.; Wang, X.; Zhang, H.; Lin, S.; Meng, H.; Sun, B.; George, S.; Xia, T.; Nel, A.; Zink, J. Designed Synthesis of CeO2 Nanorods and Nanowires for Studying Toxicological Effects of High Aspect Ratio Nanomaterials. ACS Nano 2012, 6, 5366–5380. [Google Scholar] [CrossRef]

- Pérez-Salinas, C.; del Olmo, A.; de Lacalle, L.N.L.; Núñez, D.; Mayorga, L.; Ureña, M. Alternative lubrication-cooling approaches for broaching medium-carbon steel: Machining performance and life cycle analysis. Results Eng. 2025, 26, 104924. [Google Scholar] [CrossRef]

- Yi, S.; Li, J.; Zhu, J.; Wang, X.; Mo, J.; Ding, S. Investigation of machining Ti-6Al-4V with graphene oxide nanofluids: Tool wear, cutting forces and cutting vibration. J. Manuf. Process 2020, 49, 35–49. [Google Scholar] [CrossRef]

- Eltaggaz, A.; Ali, S.; Badwal, K.; Deiab, I. Influence of nanoparticle concentration in nanofluid MQL on cutting forces, tool wear, chip morphology when milling of Inconel 718. Int. J. Adv. Manuf. Technol. 2023, 129, 1787–1800. [Google Scholar] [CrossRef]

- Yıldırım, Ç.V.; Şirin, Ş.; Kıvak, T.; Sarıkaya, M. The effect of nanofluids reinforced with different surfactants on the machining and friction-wear properties of Waspaloy. Tribol. Int. 2023, 181, 108316. [Google Scholar] [CrossRef]

- Nguyen, T.-T.; Nguyen, T.-A.; Trinh, Q.-H.; Le, X.-B.; Pham, L.-H.; Le, X.-H. Artificial neural network-based optimization of operating parameters for minimum quantity lubrication-assisted burnishing process in terms of surface characteristics. Neural Comput. Appl. 2022, 34, 7005–7031. [Google Scholar] [CrossRef]

- Jogesh, K.S.; Bappy, M.A. Machine learning-guided design of nanolubricants for minimizing energy loss In mechanical systems. Glob. Mainstream J. 2024, 1, 1–16. [Google Scholar] [CrossRef]

- Farooq, M.U.; Kumar, R.; Khan, A.; Singh, J.; Anwar, S.; Verma, A.; Haber, R. Sustainable machining of Inconel 718 using minimum quantity lubrication: Artificial intelligence-based process modelling. Heliyon 2024, 10, e34836. [Google Scholar] [CrossRef]

| Researchers | Nanoparticles | Processing Conditions | Effects |

|---|---|---|---|

| Agunsoye et al. [75] | SiO2 | Turning of aluminum alloy | Nano-cutting fluid significantly reduced cutting force and flank wear, as well as improved surface quality (92.96%, 88.59%, and 93.40%, accordingly). |

| Tong et al. [76] | Al2O3 | Milling | At 1.0 vol% concentration and with 20 nm particles, the Al2O3–palm oil nanofluid demonstrated optimal heat transfer and lubricating capabilities. |

| Kumar et al. [77] | Al2O3, TiO2 | Turning of AISI D2 | The TiO2 nanofluid tool has 29% less flank wear than Al2O3, a 9.7% lower cutting temperature, and 14.3% lower Ra. |

| Hamid et al. [78] | TiO2 | Rotary drilling | TiO2-soluble oil nanofluid reduced drilling temperature. |

| Edelbi et al. [79] | Al2O3, ZnO | Milling of Ti-3Al-2.5V | ZnO nanofluids had lower cutting temperature as well as surface roughness than Al2O3 nanofluids, by 1% and 2%, accordingly. |

| Huang et al. [80] | MWCNTs | Milling of AISI P21 and 1050 | MWCNTs dramatically lower cutting temperatures and surface roughness improved by 9%. |

| Zhang et al. [81] | SiC | Turning of 40Cr | NMQL lowers wear by 55.1%, cutting temperature by 41.5%, and surface roughness by 19.2%. |

| Researchers | Nanofluids | Processing | Key Results |

|---|---|---|---|

| Aberoumand et al. [88] | Ag-WO3 | KD2 Pro | The thermal conductivity of hybrid nanofluids is increased by 41%. |

| Gupta et al. [89] | Ag + MWCNT | Forced convective experiment | To measure the improvement in heat transfer performance in NFs containing Ag, Ag MWCNTs, and MWCNTs, correlations were developed. The outcome showed that a higher degree of heat transfer enhancement was correlated with an increase in Re number. |

| Asadi et al. [90] | MWCNT/ZnO | Brookfield cone and plate viscometer | As the temperature increased, dynamic viscosity decreased by 85%, but it increased by 45% when the concentration of solids was increased. |

| Arif et al. [91] | Fe3O4−Zn Au (blood) | Casson fluid model with a couple stresses | Blood-based ternary hybrid, spherical-shaped Fe3O4, platelet-shaped (Zn) nanoparticles, and cylindrical-shaped gold (Au) nanoparticles all showed an increase in heat transfer of 8.05%, 4.63%, 8.984%, and 10.407%. |

| Arshad et al. [92] | Cu−Al2O3−TiO2 | MATLAB with boundary value problem method (BVP-4c) | Tri-hybrid nanofluids outperform hybrid and single nanofluids by 33% in terms of heat transfer rate and reduced skin friction. |

| Kashyap et al. [93] | 1. Al2O3-Cu-SiC 2. Al2O3 -Cu- MWCNT 3. Al2O3-Cu-Graphene 4. Al2O3-MWCNT-Graphene (Water as base fluid) | Engineering equation solver (EEC) | The combination of Al2O3/MWCNT/Graphene nanofluid reaches a maximum energy efficiency of 48.6%. |

| Researchers | Nanofluids | Impact | Method/Software |

|---|---|---|---|

| Yang et al. [131] | Fe-Mn@Al2O3 | Ozone depletion, GHG emissions, smog, acidification, eutrophication, carcinogenic and non-carcinogenic, respiratory effects, ecotoxicity, fossil fuel depletion. | TRACI 2.1/SimaPro version 8.5 Ecoinvent and US Life Cycle Inventory |

| Feijoo et al. [132] | Different magnetic nanoparticles (NPs) based on magnetite (Fe3O4) | Climate change, ozone depletion, acidification, eutrophication, toxicity, fossil fuel depletion. | IMPACT2001 and ReCiPe/SimaPro 8.2.0 Ecoinvent database |

| Gunasekara et al. [133] | HVFA–65 ns and HVFA–80 ns | GHG emissions, acidification, photochemical oxidant formation impact. | SimaPro Ecoinvent database |

| Huseien et al. [134] | BGWNP | CO2 emission, energy consumption, fuel consumption. | Laboratory-scale primary study data |

| Ingrao et al. [135] | Nano-HA | GHG emissions, non-renewable energy, respiratory inorganics, human health, climate change, resources, ecosystem quality. | IMPACT2002+/SimaPro |

| Lee et al. [136] | nNaCl | GHG emissions, CO2 emissions (sensitivity analysis included) | SimaPro Ecoinvent database |

| Petrakli et al. [137] | n-CFRP | depletion, GHG emissions, human health, ecotoxicity, acidification, eutrophication, land occupation, water consumption, NRE, mineral extraction, water turbine. | ILCD 2011 Midpoint +/SimaPro 8.0.4.26 Ecoinvent database |

| P. Rodrigues et al. [138] | AgNM | Water and soil emissions. | Toxicity Relationship Analysis Program (TRAPv1.22)/REST-MSC tool |

| Rossi et al. [139] | Nanogrid (NG) | Ecotoxicity, human health, resources (sensitivity analysis included). | ReCiPe 1.11 (2014)/OpenLCA version1.8 tool Ecoinvent database |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Khan, A.M.; Rahat, M.R.; Ahmed, U.; Jamil, M.; Ali, M.A.; Zhao, G.; Abellán-Nebot, J.V. The Recent Advancements in Minimum Quantity Lubrication (MQL) and Its Application in Mechanical Machining—A State-of-the-Art Review. Lubricants 2025, 13, 401. https://doi.org/10.3390/lubricants13090401

Khan AM, Rahat MR, Ahmed U, Jamil M, Ali MA, Zhao G, Abellán-Nebot JV. The Recent Advancements in Minimum Quantity Lubrication (MQL) and Its Application in Mechanical Machining—A State-of-the-Art Review. Lubricants. 2025; 13(9):401. https://doi.org/10.3390/lubricants13090401

Chicago/Turabian StyleKhan, Aqib Mashood, MD Rahatuzzaman Rahat, Umayar Ahmed, Muhammad Jamil, Muhammad Asad Ali, Guolong Zhao, and José V. Abellán-Nebot. 2025. "The Recent Advancements in Minimum Quantity Lubrication (MQL) and Its Application in Mechanical Machining—A State-of-the-Art Review" Lubricants 13, no. 9: 401. https://doi.org/10.3390/lubricants13090401

APA StyleKhan, A. M., Rahat, M. R., Ahmed, U., Jamil, M., Ali, M. A., Zhao, G., & Abellán-Nebot, J. V. (2025). The Recent Advancements in Minimum Quantity Lubrication (MQL) and Its Application in Mechanical Machining—A State-of-the-Art Review. Lubricants, 13(9), 401. https://doi.org/10.3390/lubricants13090401