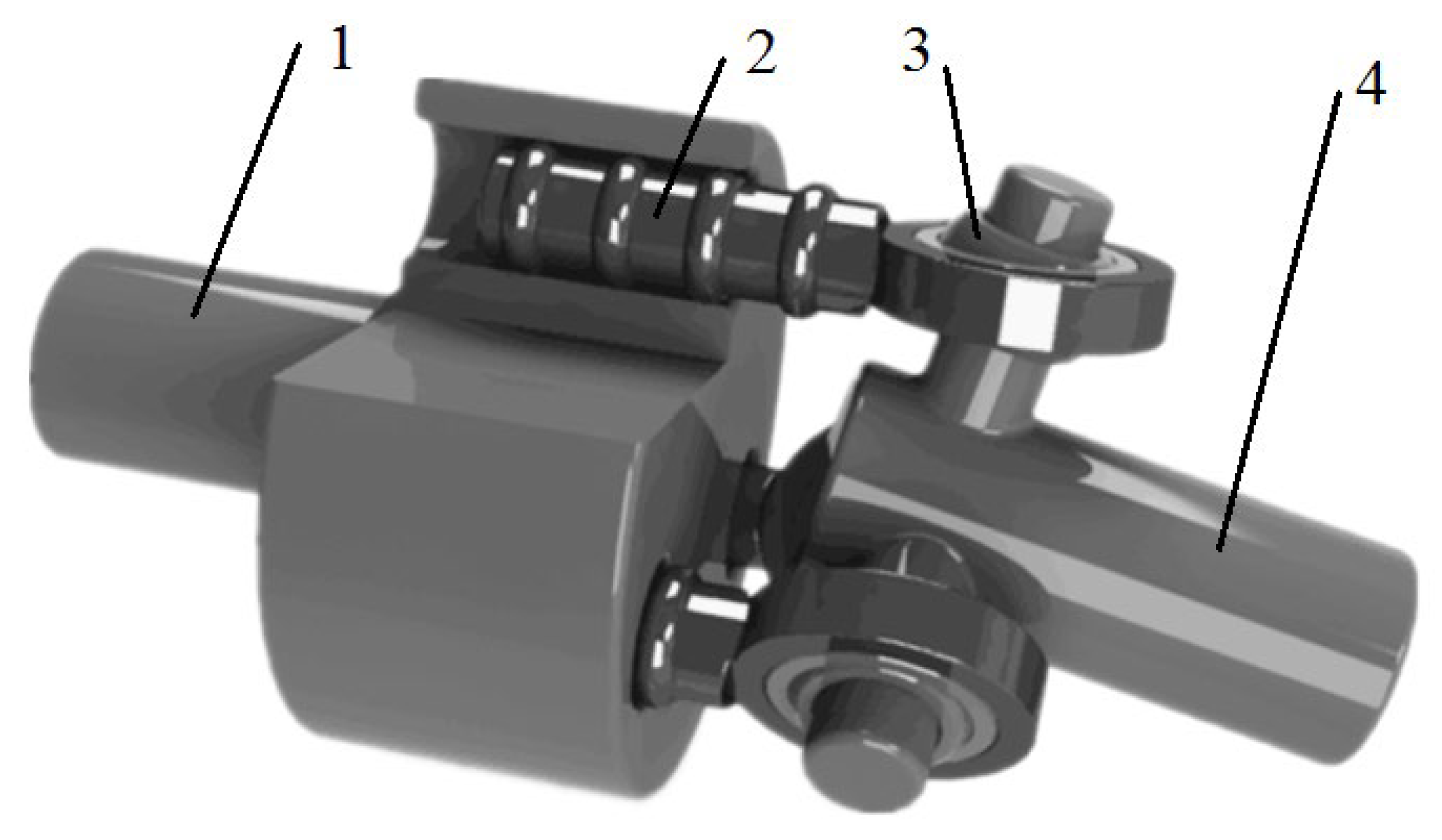

Thermal Elastohydrodynamic Lubrication Analysis of Grease in Tripod Sliding Universal Couplings

Abstract

1. Introduction

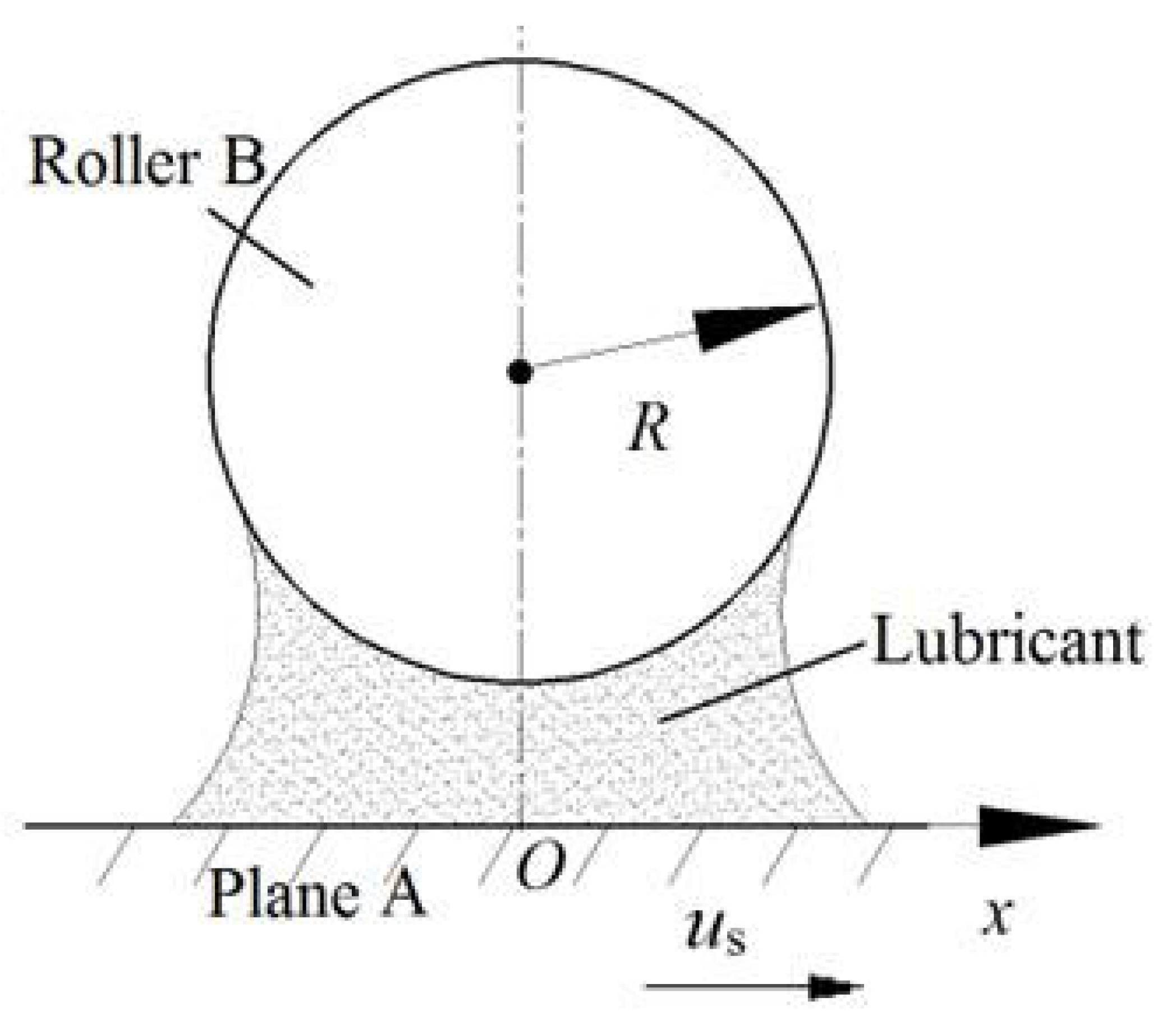

2. Numerical Simulation

2.1. Governing Equations

2.2. Numerical Method

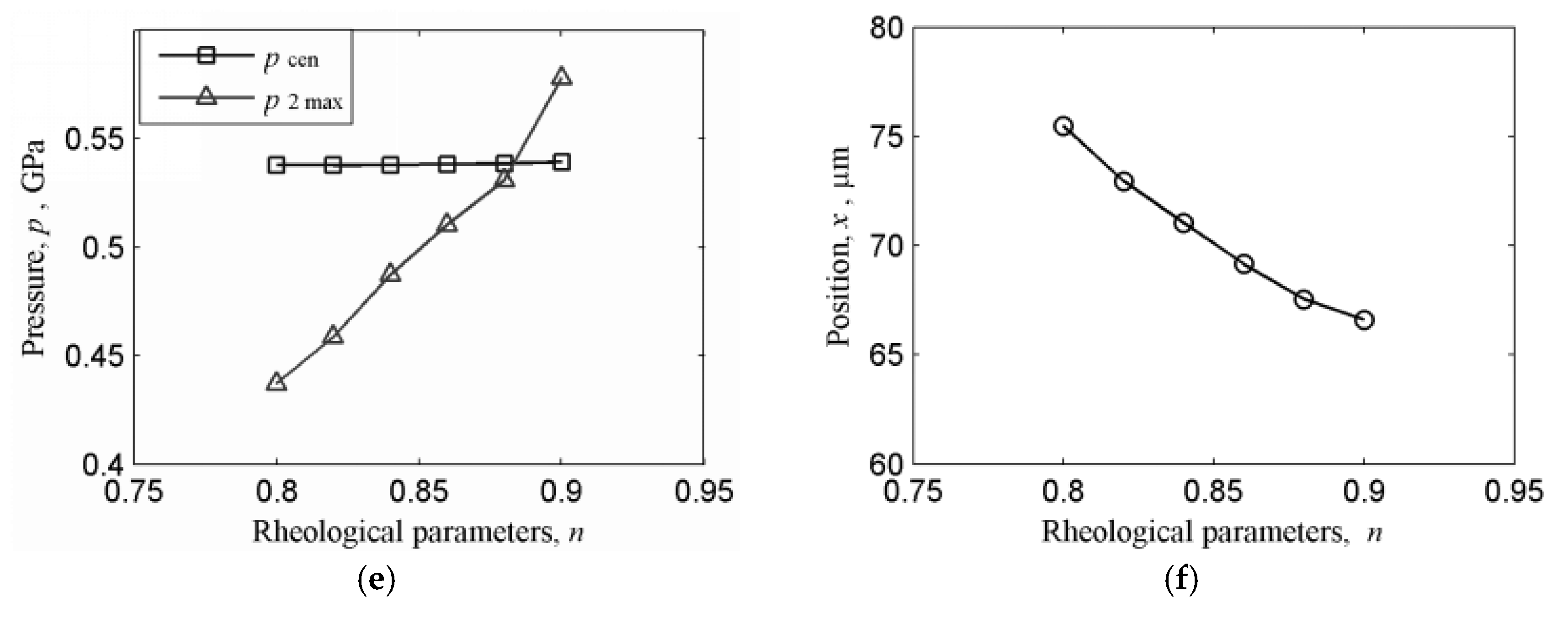

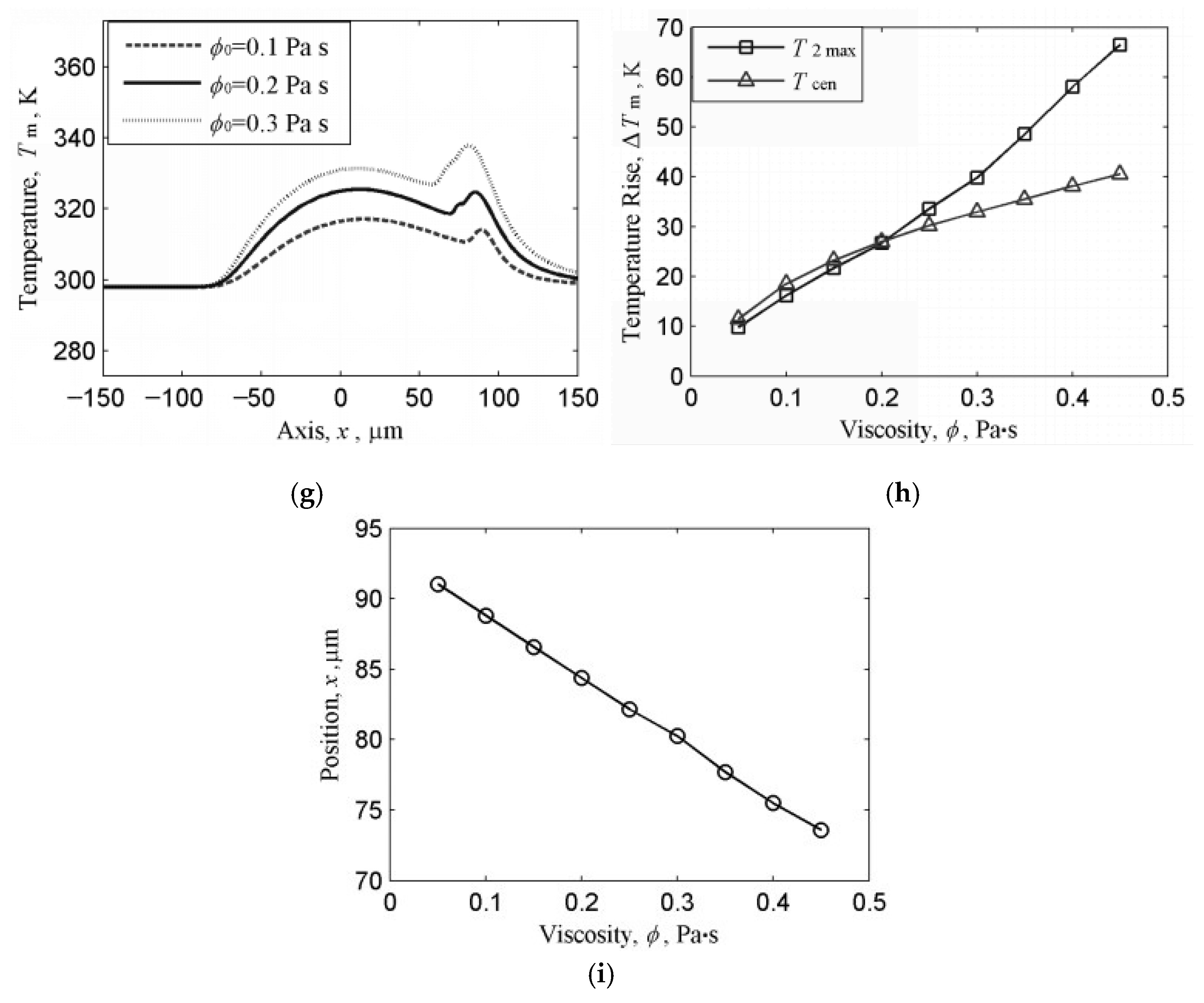

3. Results and Discussion

4. Conclusions

- (1)

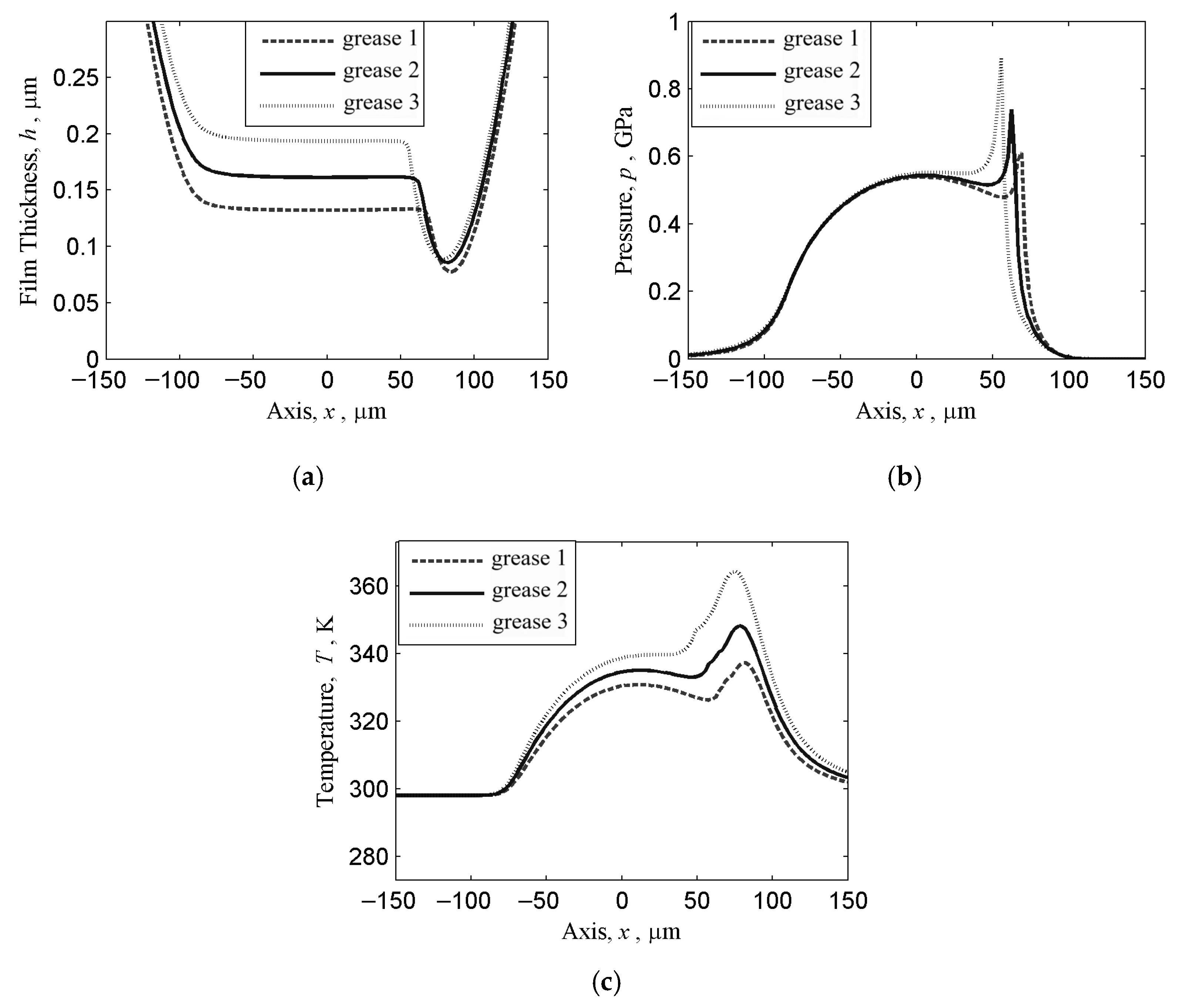

- Increasing the grease flow index enhances central and minimum film thicknesses by improving flowability. However, this elevates the amplitude of the secondary pressure peak, intensifying cyclic stress loading at the contact entry zone and promoting the propagation of surface fatigue. Future research should explore adaptive flow index control mechanisms to balance film thickness enhancement and stress oscillation suppression.

- (2)

- An elevated initial viscosity increases film thickness but amplifies viscous dissipation, leading to higher temperature distributions and power losses. This also shifts the secondary pressure peak toward the inlet, as the result of a delayed compressibility response in the fluid. Future studies should quantify viscosity–temperature thresholds for optimal film stability under dynamic loading conditions.

- (3)

- When three distinct types of grease were applied to the coupling, their lubrication properties diverged significantly. When different types of grease share similar pressure–viscosity coefficients and densities, the dominant performance factor shifts to their initial viscosity. Advanced machine learning models should be developed to predict such viscosity-dominated performance divergence in multi-grease systems.

Author Contributions

Funding

Conflicts of Interest

Notation

| A | Amplitude, m |

| c | Grease specific heat, J·kg−1·K−1 |

| c1 | Upper surface specific heat, J·kg−1·K−1 |

| c2 | Lower surface specific heat, J·kg−1·K−1 |

| E′ | Effective Young’s modulus, Pa |

| f | Frequency, Hz |

| h | Grease film thickness, m |

| h0 | Rigid body displacement, m |

| k | Grease thermal conductivity, W·m−1·K−1 |

| k1 | Upper surface thermal conductivity, W·m−1·K−1 |

| k2 | Lower surface thermal conductivity, W·m−1·K−1 |

| n | Grease flow index |

| p | Hydrodynamic pressure, Pa |

| R | Effective radius, m |

| s | Slide-to-roll ratio |

| t | Time, s |

| T | Temperature, K |

| T0 | Initial grease temperature, K |

| u | Surface velocity, m·s−1 |

| u1 | Upper surface velocity, m·s−1 |

| u2 | Lower surface velocity, m·s−1 |

| x | Horizontal coordinate, m |

| x0 | Inlet coordinate, m |

| xe | Outlet coordinate, m |

| α | Viscosity-pressure coefficient, Pa−1 |

| w | Load per unit length, N·m−1 |

| ω | Angular speed, ω = 2π f, rad·s−1 |

| φ | Grease base oil viscosity, Pa·s |

| φ0 | Initial base oil viscosity, Pa·s |

| ρ | Grease density, kg·m−3 |

| ρ0 | Initial grease density, kg·m−3 |

| ρ1 | Upper surface density, kg·m−3 |

| ρ2 | Lower surface density, kg·m−3 |

References

- Wang, X.F.; Chang, D.G. Numerical analysis on lubricating properties of tripod sliding universal couplings. Tribol. Trans. 2009, 52, 86–95. [Google Scholar] [CrossRef]

- Sadeghi, F.; Sui, P.C. Thermal elastohydrodynamic lubrication of rolling/sliding contacts. J. Tribol-T. ASME 1990, 112, 189–195. [Google Scholar] [CrossRef]

- Yoo, J.G.; Kim, K.W. Numerical analysis of grease thermal elastohydrodynamic lubrication problems using the Herschel-Bulkley model. Tribol. Int. 1997, 30, 401–408. [Google Scholar] [CrossRef]

- Kaneta, M.; Ogata, T.; Takubo, Y.; Naka, M. Effects of a thickener structure on grease elastohydrodynamic lubrication films. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2000, 214, 327–336. [Google Scholar] [CrossRef]

- Wang, J.; Kaneta, M.; Yang, P. Numerical analysis of TEHL line contact problem under reciprocating motion. Tribol. Int. 2005, 38, 165–178. [Google Scholar] [CrossRef]

- Yu, M.; Huang, P. Numerical analysis on thermal elastohydrodynamic grease lubrication in line contacts. Bearing 2011, 1, 8–12. [Google Scholar] [CrossRef]

- Wang, X.F.; Chang, D.G. Lubricating behavior of tripod sliding universal couplings. Ind. Lubr. Tribol. 2020, 62, 16–25. [Google Scholar] [CrossRef]

- Chang, D.G.; Wang, X.F.; Yang, F.Q.; Wang, J.Z. Lubricating properties of tripod sliding universal couplings considering thermal effect. Tribol. Trans. 2010, 53, 502–510. [Google Scholar] [CrossRef]

- Wang, X.F.; Hu, R.F.; Wang, K.S.; Cui, H.R. Effects of reciprocating motion parameters on lubricating properties of tripod sliding universal couplings. Ind. Lubr. Tribol. 2014, 66, 111–123. [Google Scholar] [CrossRef]

- Yang, F.Q.; Han, X.J.; Si, M.Q. Thermal elastohydrodynamic lubrication characteristics and optimisation of the ball-type tripod universal joint. Ind. Lubr. Tribol. 2021, 10, 1310–1318. [Google Scholar] [CrossRef]

- Yang, F.Q.; Xiao, Q.H.; Geng, C.H. Effect of surface micro-groove texture on lubrication performance of tripod universal coupling. Ind. Lubr. Tribol. 2021, 10, 1237–1247. [Google Scholar] [CrossRef]

- Laura, R.; Silvia, R.; Georg, J. Influence of temperature on wear performance of greases in rolling bearings. Ind. Lubr. Tribol. 2021, 73, 862–871. [Google Scholar] [CrossRef]

- Wang, L.L.; Zhang, W.; Zhao, X.T.; Ge, X. Optimization lubrication performance of journal bearings with microtexture. Ind. Lubr. Tribol. 2022, 74, 619–628. [Google Scholar] [CrossRef]

- Wang, W.Z.; Jin, Z.M.; Dowson, D.; Hu, Y.Z. A study of the effect of model geometry and lubricant rheology upon the elastohydrodynamic lubrication performance of metal-on-metal hip joints. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2008, 222, 493–501. [Google Scholar] [CrossRef]

- Ohno, N.; Yamada, S. Effect of high-pressure rheology of lubricants upon entrapped oil film behaviour at halting elastohydrodynamic lubrication. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2007, 221, 279–285. [Google Scholar] [CrossRef]

- Lin, J.R.; Teng, M.Y.; Ho, M.H. Effects of non-newtonian rheology on the film-height history between non-parallel sliding-squeezing surfaces. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2007, 221, 155–159. [Google Scholar] [CrossRef]

- Bair, S. Rheology and high-pressure models for quantitative elastohydrodynamics. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2009, 223, 617–628. [Google Scholar] [CrossRef]

- Karthikeyan, B.K.; Teodorescu, M.; Rahnejat, H.; Rothberg, S.J. Thermoelastohydrodynamics of grease-lubricated concentrated point contacts. Proc. Inst. Mech. Eng. Part J. 2009, 224, 683–895. [Google Scholar] [CrossRef]

- Huang, P. Numerical Calculation Methods of Elastohydrodynamic Lubrication; Tsinghua University Press: Beijing, China, 2013. [Google Scholar]

- Mo, H.; Hu, Y.; Quan, S. Thermo-Hydrodynamic Lubrication Analysis of Slipper Pair Considering Wear Profile. Lubricants 2023, 11, 190. [Google Scholar] [CrossRef]

- Wang, H.; Li, H.; Jin, Z.; Lin, J.; Cui, Y.; Li, C.; Tian, H.; Wang, Z. Simulation Analysis and Experimental Study on the Fluid–Solid–Thermal Coupling of Traction Motor Bearings. Lubricants 2024, 12, 144. [Google Scholar] [CrossRef]

- Deng, H.; Guo, B.; Huang, Z.; Xu, P.; Zhu, P. Thermal–Elastohydrodynamic Lubrication Characteristics of the Flow Distribution Pair of Balanced Double-Row Axial Piston Pumps. Lubricants 2024, 12, 342. [Google Scholar] [CrossRef]

| Grease | ϕ0 (Pa·s) | α (m2/N) | ρ0 (kg/m3) |

|---|---|---|---|

| Lubricating grease 1 | 0.289 | 2.923 × 10−8 | 889.2 |

| Lubricating grease 2 | 0.370 | 3.009 × 10−8 | 918.2 |

| Lubricating grease 3 | 0.451 | 3.077 × 10−8 | 897.8 |

| Grease | Central Film Thickness (µm) | Minimum Film Thickness (µm) | The Position of Minimum Film Thickness (µm) |

|---|---|---|---|

| Lubricating grease 1 | 0.1323 | 0.0774 | 84.367 |

| Lubricating grease 2 | 0.1613 | 0.0857 | 82.150 |

| Lubricating grease 3 | 0.2158 | 0.0885 | 77.707 |

| Grease | Central Pressure (GPa) | Secondary Peak Pressure (GPa) | The Position of the Secondary Pressure Peak (µm) |

|---|---|---|---|

| Lubricating grease 1 | 0.5386 | 0.6114 | 68.831 |

| Lubricating grease 2 | 0.5426 | 0.7384 | 62.171 |

| Lubricating grease 3 | 0.5503 | 0.8939 | 55.502 |

| Grease | Central Temperature Rise (K) | Temperature Rise in Secondary Temperature Peak (K) | The Position of Secondary Temperature Peak (µm) |

|---|---|---|---|

| Lubricating grease 1 | 32.3026 | 39.1958 | 82.150 |

| Lubricating grease 2 | 36.4881 | 50.0749 | 77.707 |

| Lubricating grease 3 | 46.6083 | 66.2494 | 75.490 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, X.; Xiu, X.; Zhou, Y.; Dong, C.; Chang, D. Thermal Elastohydrodynamic Lubrication Analysis of Grease in Tripod Sliding Universal Couplings. Lubricants 2025, 13, 400. https://doi.org/10.3390/lubricants13090400

Chen X, Xiu X, Zhou Y, Dong C, Chang D. Thermal Elastohydrodynamic Lubrication Analysis of Grease in Tripod Sliding Universal Couplings. Lubricants. 2025; 13(9):400. https://doi.org/10.3390/lubricants13090400

Chicago/Turabian StyleChen, Xinchen, Xia Xiu, Ye Zhou, Chenxin Dong, and Degong Chang. 2025. "Thermal Elastohydrodynamic Lubrication Analysis of Grease in Tripod Sliding Universal Couplings" Lubricants 13, no. 9: 400. https://doi.org/10.3390/lubricants13090400

APA StyleChen, X., Xiu, X., Zhou, Y., Dong, C., & Chang, D. (2025). Thermal Elastohydrodynamic Lubrication Analysis of Grease in Tripod Sliding Universal Couplings. Lubricants, 13(9), 400. https://doi.org/10.3390/lubricants13090400