1. Introduction

In the critical pursuit of ensuring global food security and addressing the increasing demand for agricultural output driven by population growth, the efficiency and reliability of modern agricultural machinery play an indispensable role [

1,

2,

3,

4]. Among these vital tools, the combine harvester stands as a pivotal piece of equipment for the efficient, low-loss harvesting of staple food crops such as rice, which feeds a significant portion of the world’s population [

5,

6,

7,

8,

9,

10]. The operational performance and long-term reliability of these machines directly impact agricultural productivity [

11], farmer profitability [

12,

13], and overall food security [

14,

15].

However, during harvesting operations, the header platform [

9,

16] of the combine harvester, serving as the primary interface between the machine and the crop, is subjected to relentless and complex interactions. This involves continuous contact not only with rice stalks and grains, but also with varying amounts of entrained soil, sand, and other field debris [

17,

18,

19]. This intricate tribological system leads to severe friction and wear, particularly on critical components such as the header platform’s bottom plate and the spiral auger. Such component degradation carries multi-faceted negative consequences: from an equipment perspective, it drastically shortens the machine’s service life, necessitates frequent maintenance, incurs high operational costs, and leads to unproductive downtime during peak harvesting seasons [

20,

21,

22]. From a broader agricultural perspective, the altered surface morphology due to wear can significantly impair the material flow efficiency within the header, potentially causing costly blockages, increasing power consumption, and leading to substantial grain losses [

23,

24,

25]. This reduction in harvest yield and increase in operational expenditure poses a significant challenge to the economic viability and sustainability of modern rice farming. Therefore, achieving an in-depth understanding and accurate prediction of the wear behavior of header platform components is not merely a mechanical engineering problem, but also a critical and pressing challenge within the interdisciplinary domain of agri-tribology.

Addressing such complex interactions, especially involving granular and particulate materials, has significantly benefited from advancements in computational science. In recent years, the Discrete Element Method (DEM) has emerged as a particularly powerful computational modeling paradigm for investigating the intricate interaction dynamics between agricultural bulk materials (e.g., grains, seeds, stalks, and soil) and various mechanical components [

26,

27,

28]. This method’s ability to model individual particles and their contacts makes it exceptionally well-suited for simulating the highly dynamic and heterogeneous environments found within agricultural machinery. Numerous researchers have successfully employed DEM to simulate material flow behavior in key agricultural processes such as grain cleaning, conveying systems (like augers and belt conveyors), and threshing units, leading to valuable insights. These simulations have proven effective in predicting phenomena like material segregation and blockages, optimizing operational parameters to enhance throughput and minimize damage, and ultimately improving the overall efficiency and design of agricultural processing equipment [

25,

29].

However, a significant limitation in the majority of existing DEM-based agricultural research has been its primary concentration on the macroscopic dynamic characteristics of materials, such as flow patterns, forces, and power consumption [

30,

31,

32,

33], rarely establishing a direct, quantitative, and predictive link between material flow trajectory and the resultant component wear distribution. For instance, studies like Huang et al. [

34], which examines centrifugal pump wear, focus on wear distribution within fluid–particle systems, but do not address agricultural soft abrasive wear mechanisms or integrate full-scale wear prediction with real-world validation. Similarly, work by Zhao et al. [

35] investigates wear in mulching devices through DEM, optimizing structural parameters for minimal wear, but does not delve into the specific micro-mechanisms of soft biological abrasives like rice. Other studies, such as Wang et al. [

36], analyze wear in cone crusher liners, focusing on the influence of load and sliding distance, which are distinct from a complex tribo-pair interaction with soft agricultural materials. The challenge of accurately predicting “component wear” from “material flow” using computational simulation, particularly under complex and often harsh agricultural operating conditions, remains a significant and largely unresolved issue that prevents comprehensive design optimization.

From a mechanistic standpoint, research into agricultural machinery wear has conventionally focused heavily on abrasive wear caused by hard, exogenous abrasives like soil and sand, which are typically much harder than common engineering steels [

37,

38]. While this remains a critical aspect of wear in agricultural environments, the wear mechanisms induced by the agricultural crops themselves (i.e., biomass materials such as stalks and grains) as abrasives are considerably more complex and less understood. These biomass materials are generally categorized as “soft abrasives” because their bulk hardness is substantially lower than that of the typical metal substrates used in machinery. Nevertheless, previous studies have unequivocally demonstrated that even soft abrasives like crops can cause significant wear on metal surfaces under specific conditions, through complex mechanisms involving micro-cutting, polishing, and various tribo-chemical synergistic effects [

39,

40]. This is particularly pertinent to rice, a crop known for the high silica content within both its stalks and husked grains, which can act as a more potent abrasive than other “soft” crops. Despite the widespread use of commonly available engineering steels like Q235 in combine harvester manufacturing, the specific wear mechanism resulting from the tribological interaction between silica-rich rice and such steel has not been systematically investigated or elucidated at the micro-level, leaving a critical knowledge gap in the field of agri-tribology. For instance, existing studies on wear in agricultural machinery often focus on hard-particle abrasion from soil [

41], or general wear prediction models [

35], without detailed characterization of soft biomass-induced wear at the micro-level. Similarly, research on flexible materials in soil removal components [

42] explores wear mechanisms like impact and abrasive wear but does not address the specific tribological interactions of silica-rich soft crops with steel.

For a more precise and comprehensive description and evaluation of complex wear states, modern surface metrology techniques have been increasingly introduced, notably those employing fractal dimension [

43,

44]. Fractal theory offers a powerful mathematical framework for the multi-scale quantitative characterization of the self-similar and intricate features inherent in irregular and complex surfaces, such as those generated by wear. In contrast to conventional, single-value roughness parameters like the arithmetic mean deviation of the profile (Ra) or root mean square roughness (Rq), fractal dimension provides a more holistic and comprehensive reflection of the geometric complexity, irregularity, and heterogeneity of a worn surface across multiple scales [

45,

46]. While fractal dimension has been successfully applied to characterize wear in various engineering fields, including metal cutting tools, bearings, and general material science, its detailed application to analyzing the subtle yet significant morphological changes induced by soft agricultural abrasive wear remains underexplored. Leveraging fractal analysis in this context could offer a more sensitive and objective quantitative tool for assessing wear severity and machine health in agricultural applications. Current applications of fractal analysis to wear, as seen in Wang et al. [

36], primarily focus on traditional abrasive wear in industrial settings, rather than the unique challenges posed by agricultural soft abrasives. Likewise, studies on ice-induced wear in marine vessels [

47] use DEM-CFD coupling for wear prediction, but their focus is on hard ice particles and macroscopic wear, not micro-level characterization of soft biological abrasives with fractal geometry.

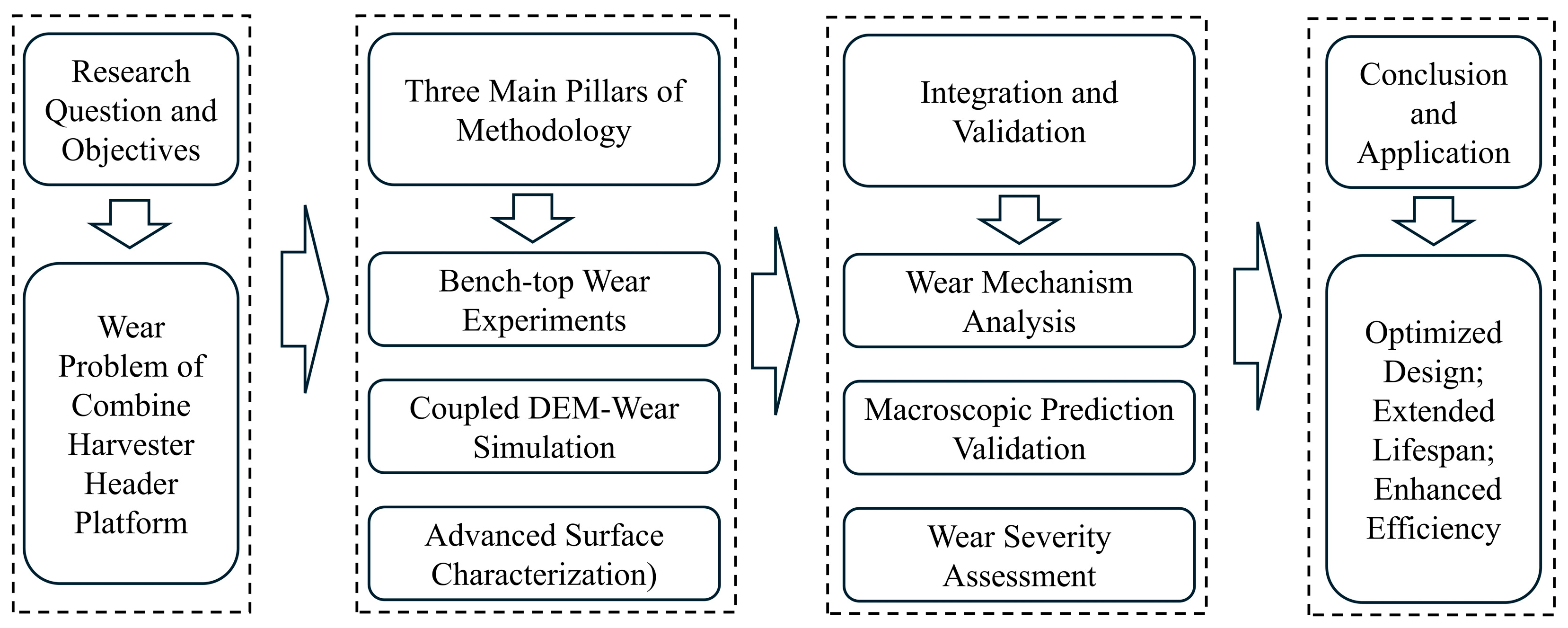

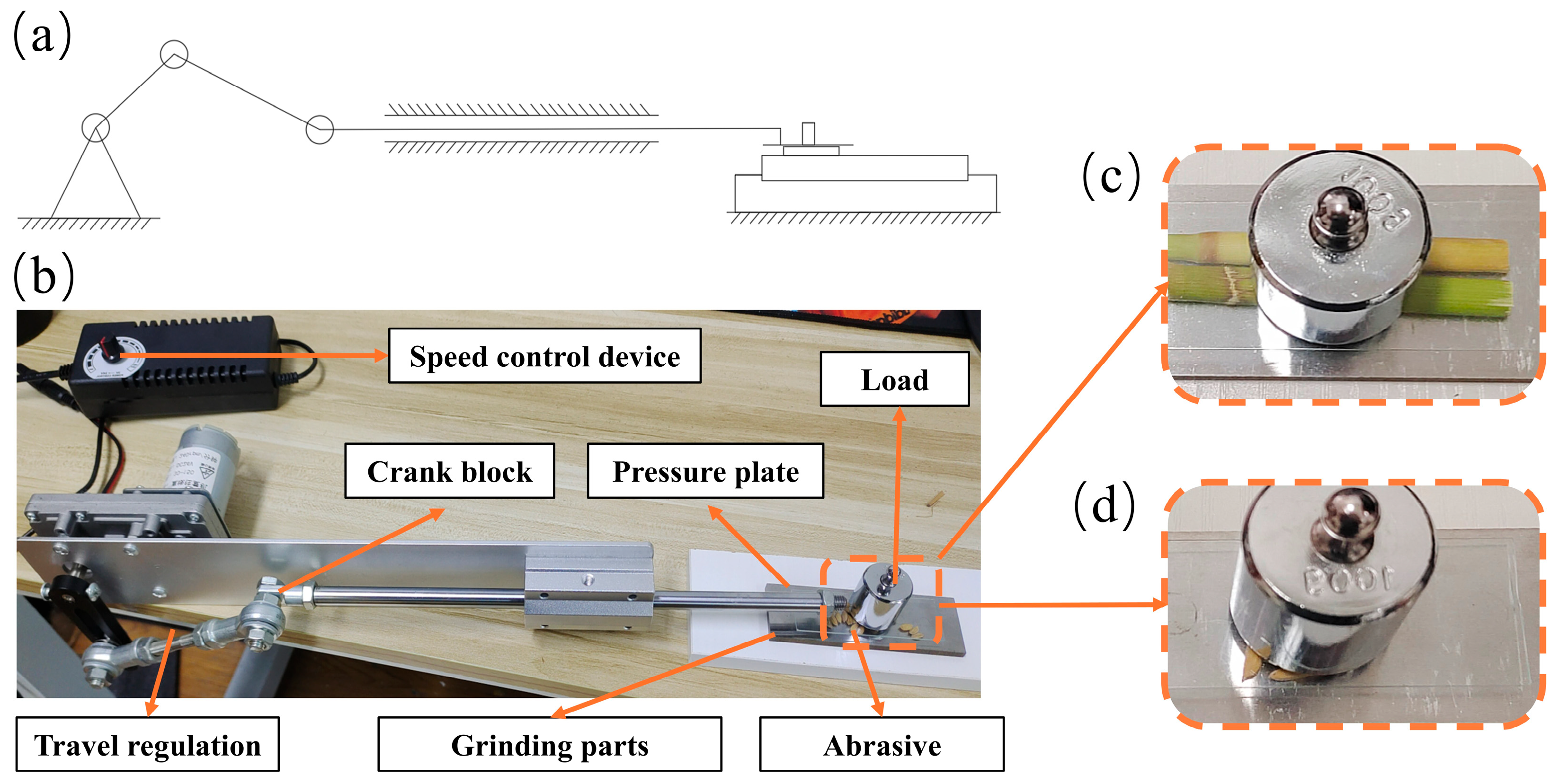

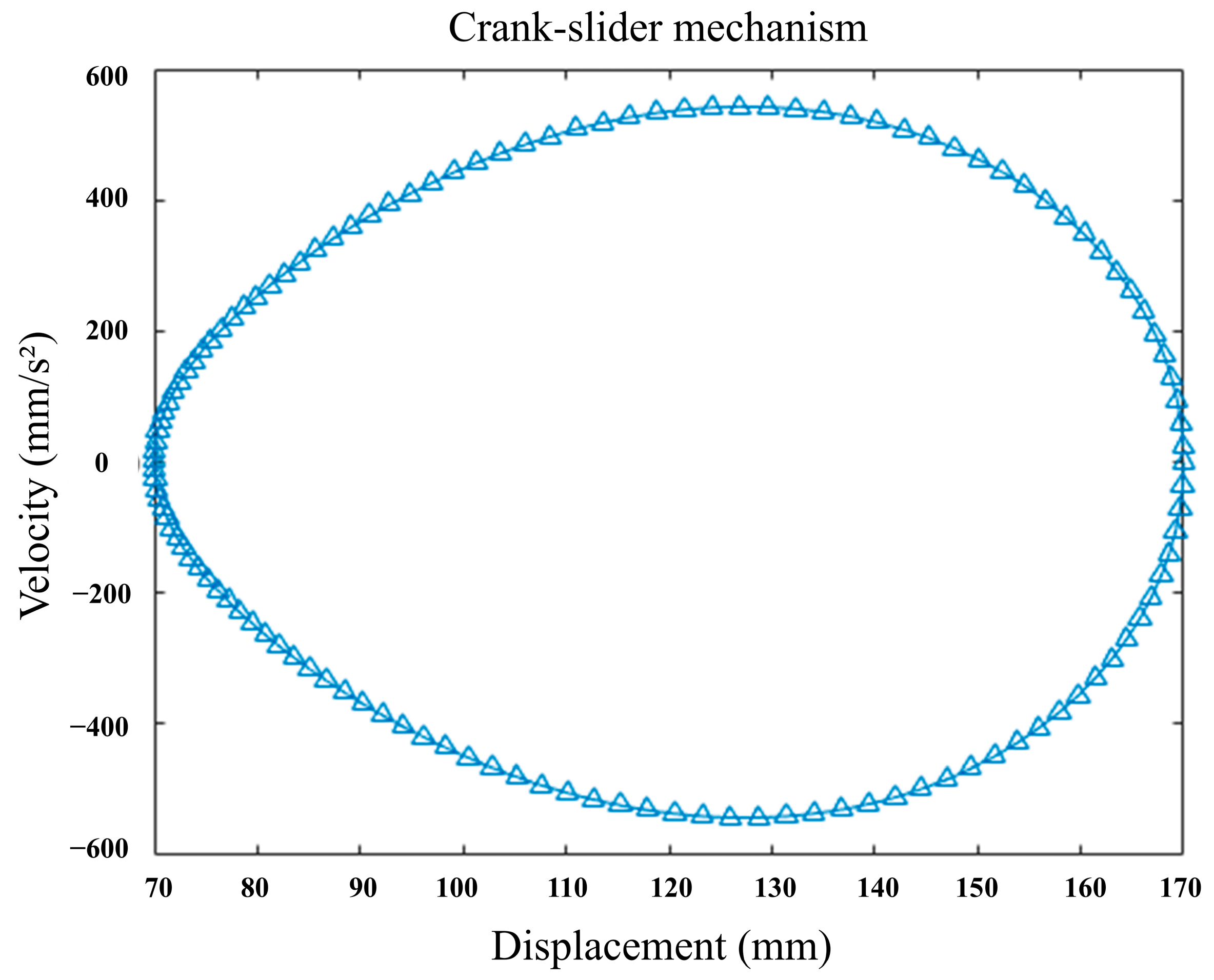

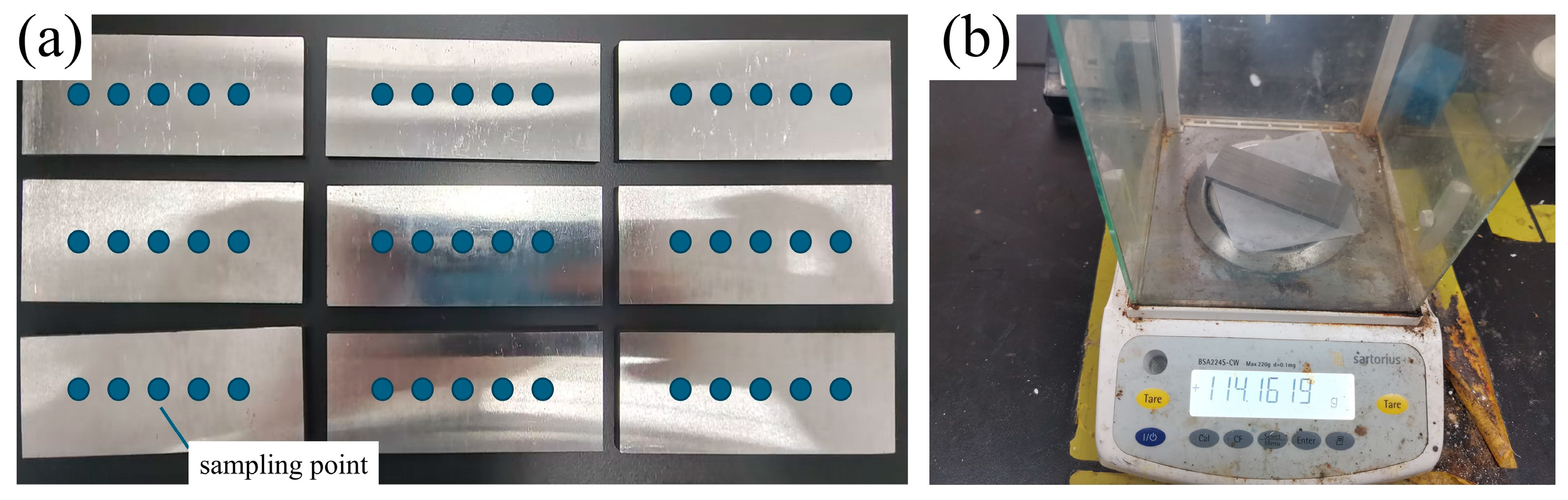

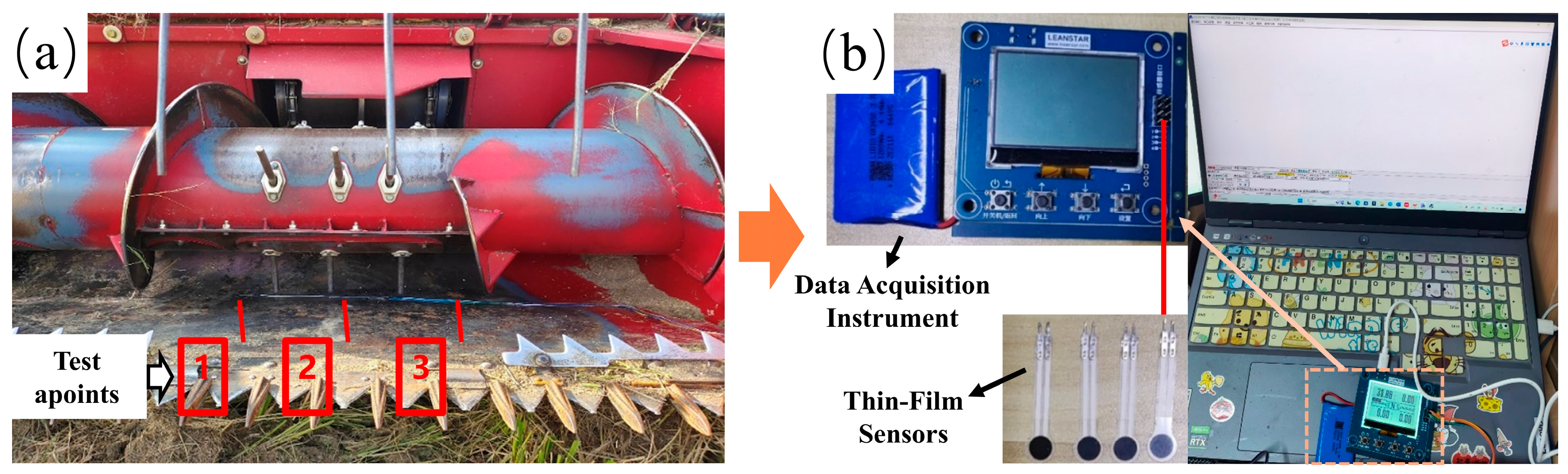

To comprehensively address these aforementioned research gaps and to provide a novel, integrated understanding of sustainable agricultural machinery design, this study systematically investigates the wear problem of the combine harvester header platform during rice harvesting. We employ a rigorous multi-scale framework that synergistically integrates bench-top experimentation, advanced coupled Discrete Element Method (DEM)-Wear simulation, and sophisticated surface characterization techniques. The overall multi-fidelity research framework and the interconnections between its main components are illustrated in

Figure 1 for a clearer understanding of the investigation’s steps. The primary scientific contributions and novelty of this paper, in comparison to the existing literature, are multi-fold:

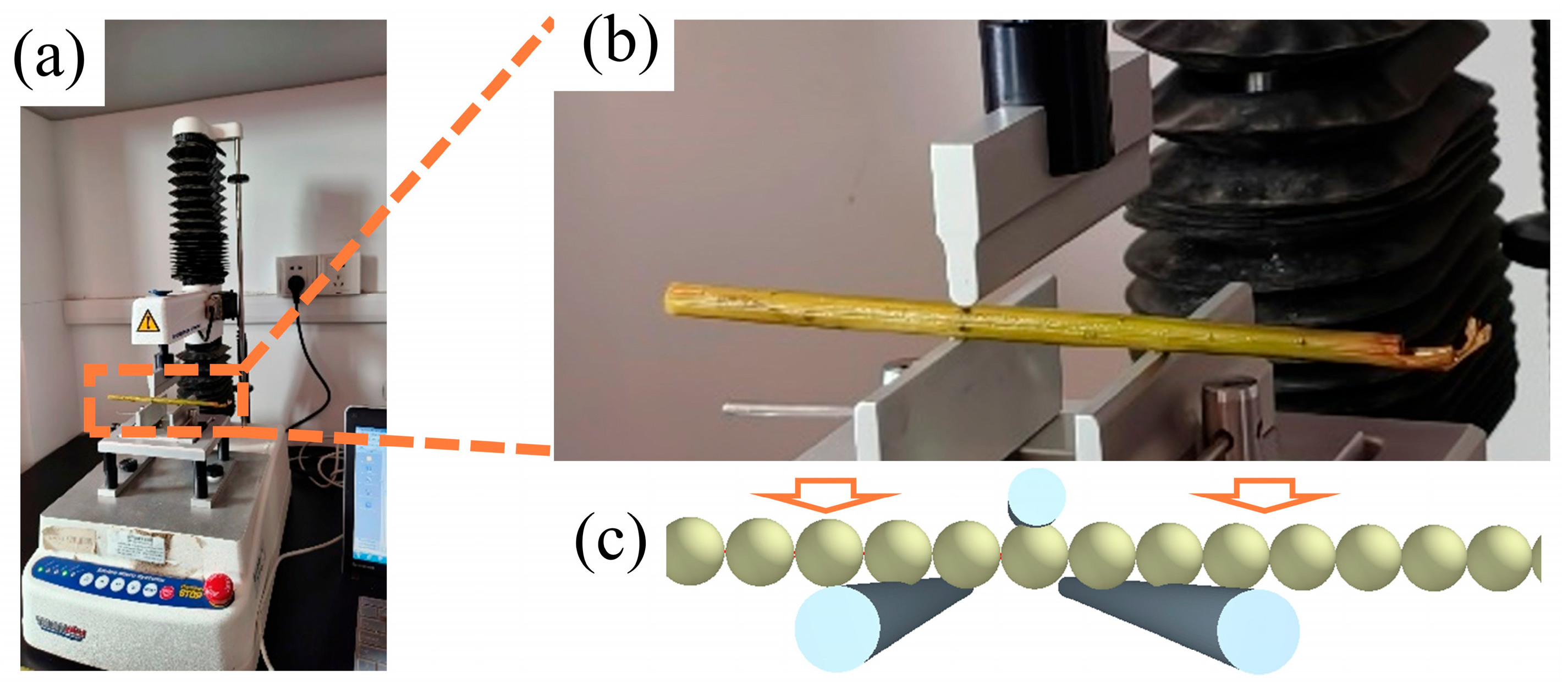

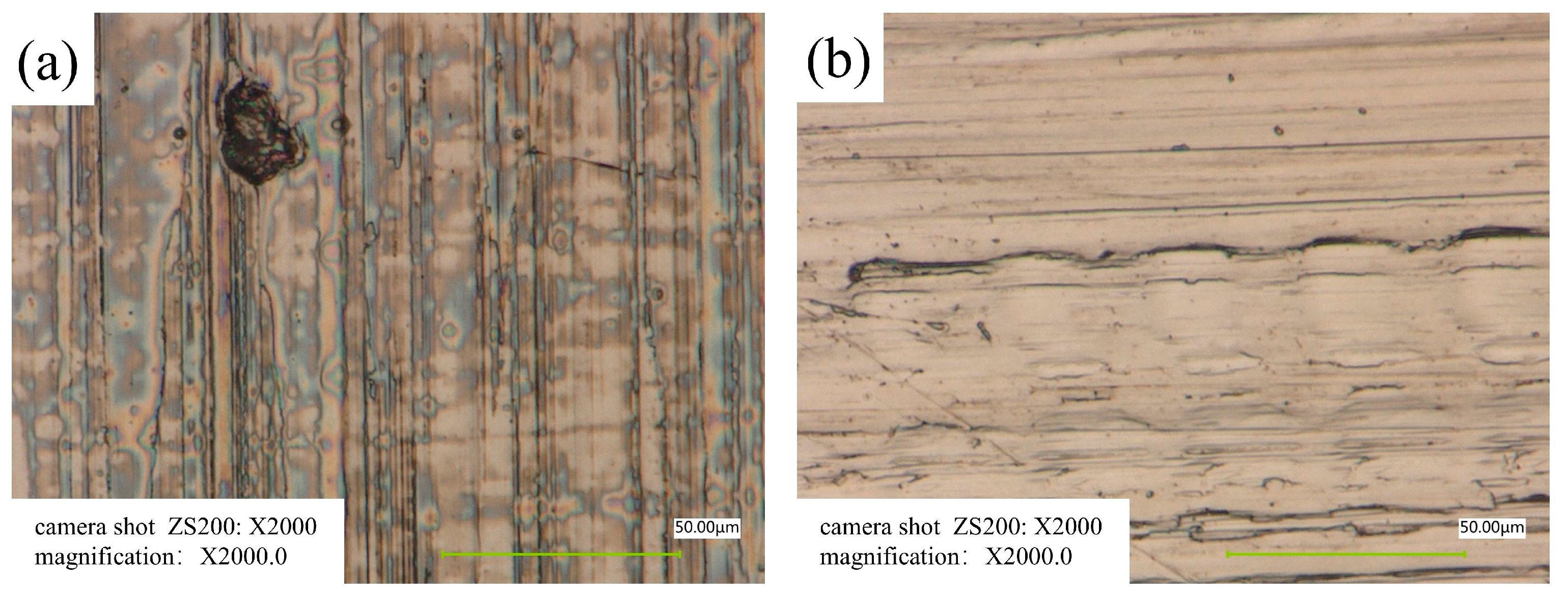

(1) For the first time, we systematically elucidate the complex soft abrasive wear mechanism of the rice–steel tribo-pair through rigorous bench tests. This fundamental understanding is crucial for guiding targeted material selection, surface engineering, and the development of more wear-resistant components in agricultural machinery design. Unlike previous studies that focus on hard particle wear or general wear prediction, this research specifically identifies and characterizes the transition from mechanical polishing to soft abrasive micro-cutting primarily driven by rice’s intrinsic silica particles, filling a critical knowledge gap in agri-tribology.

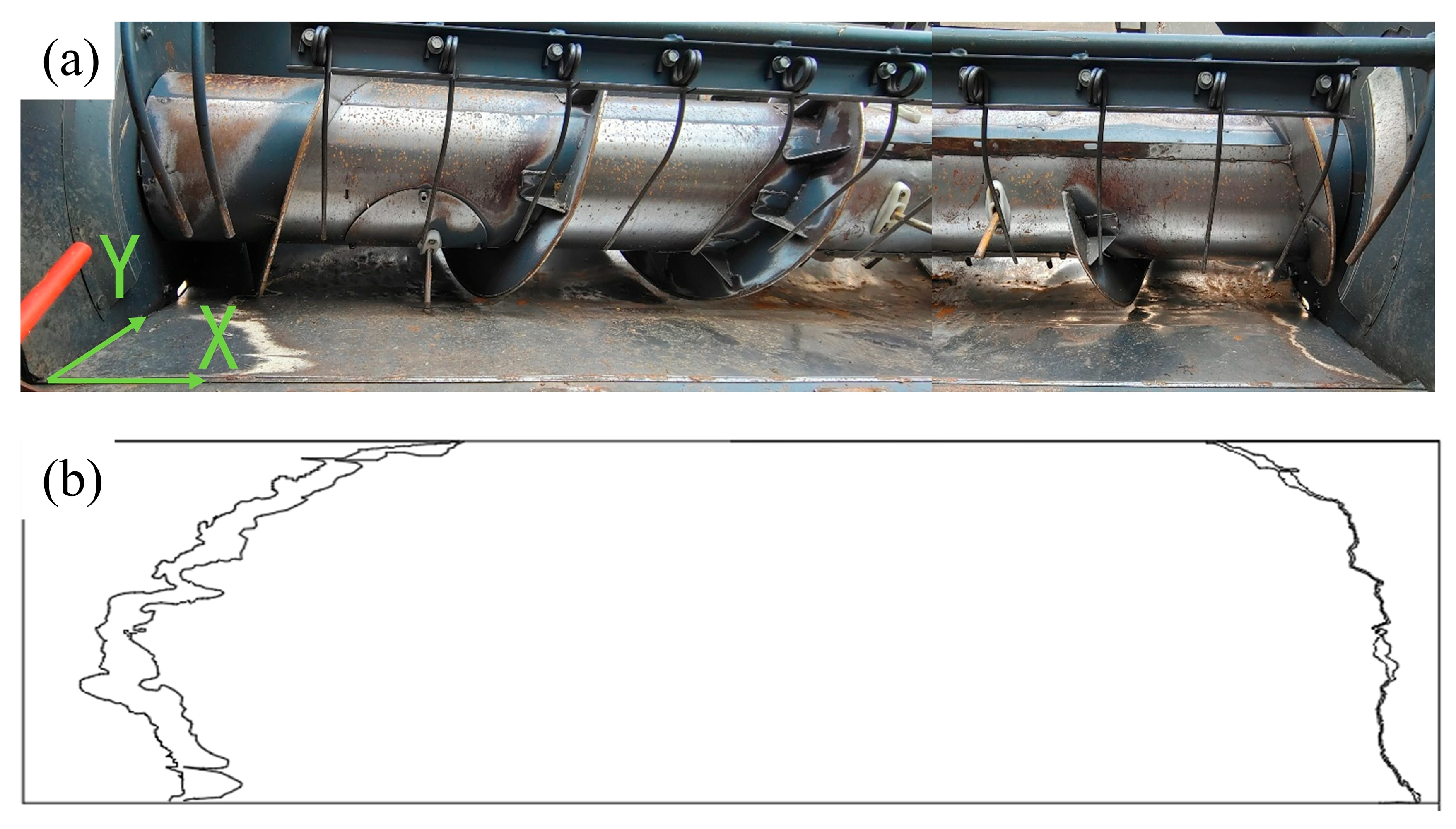

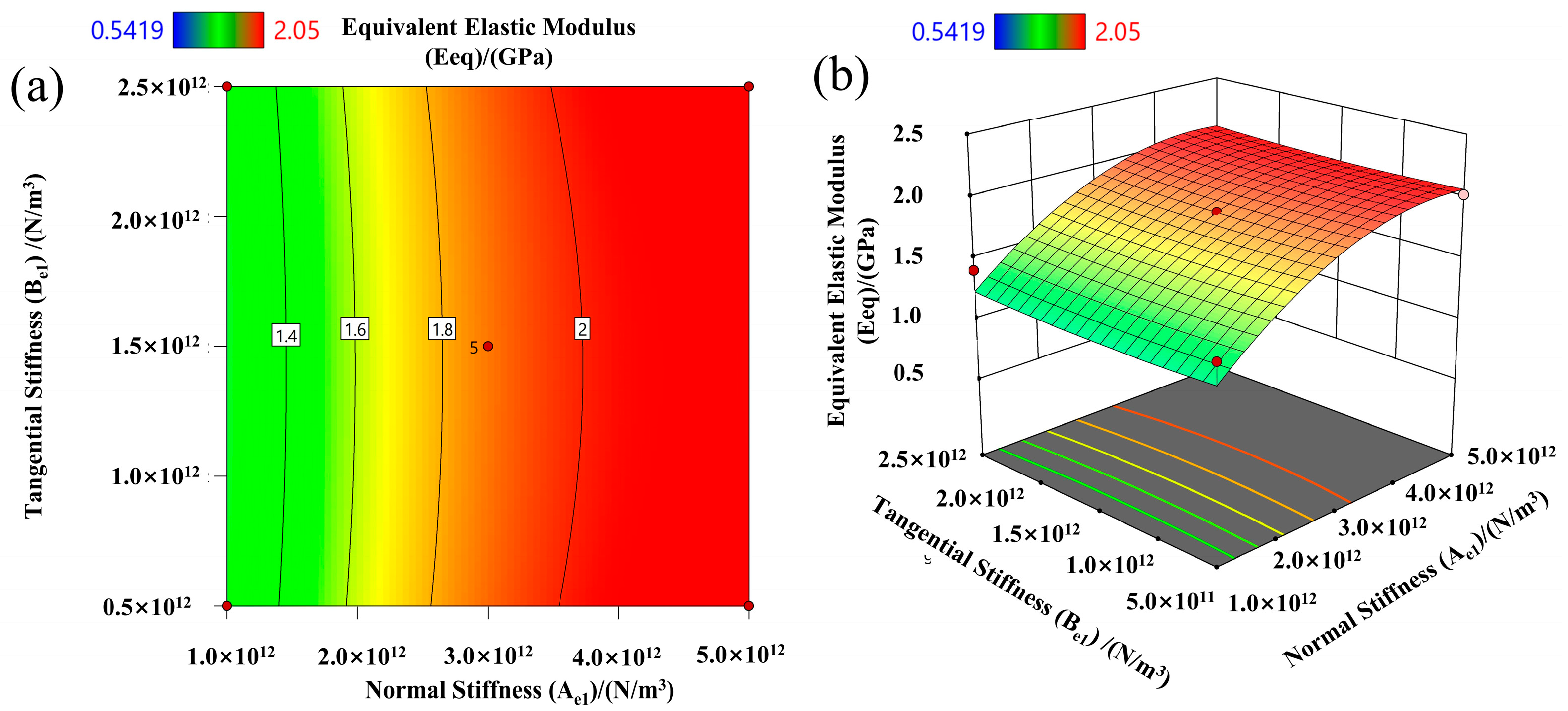

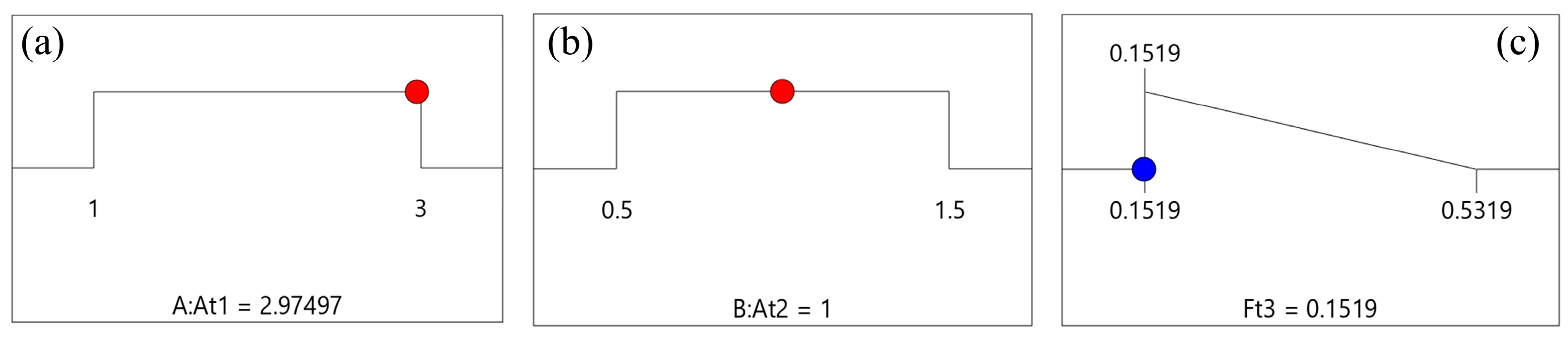

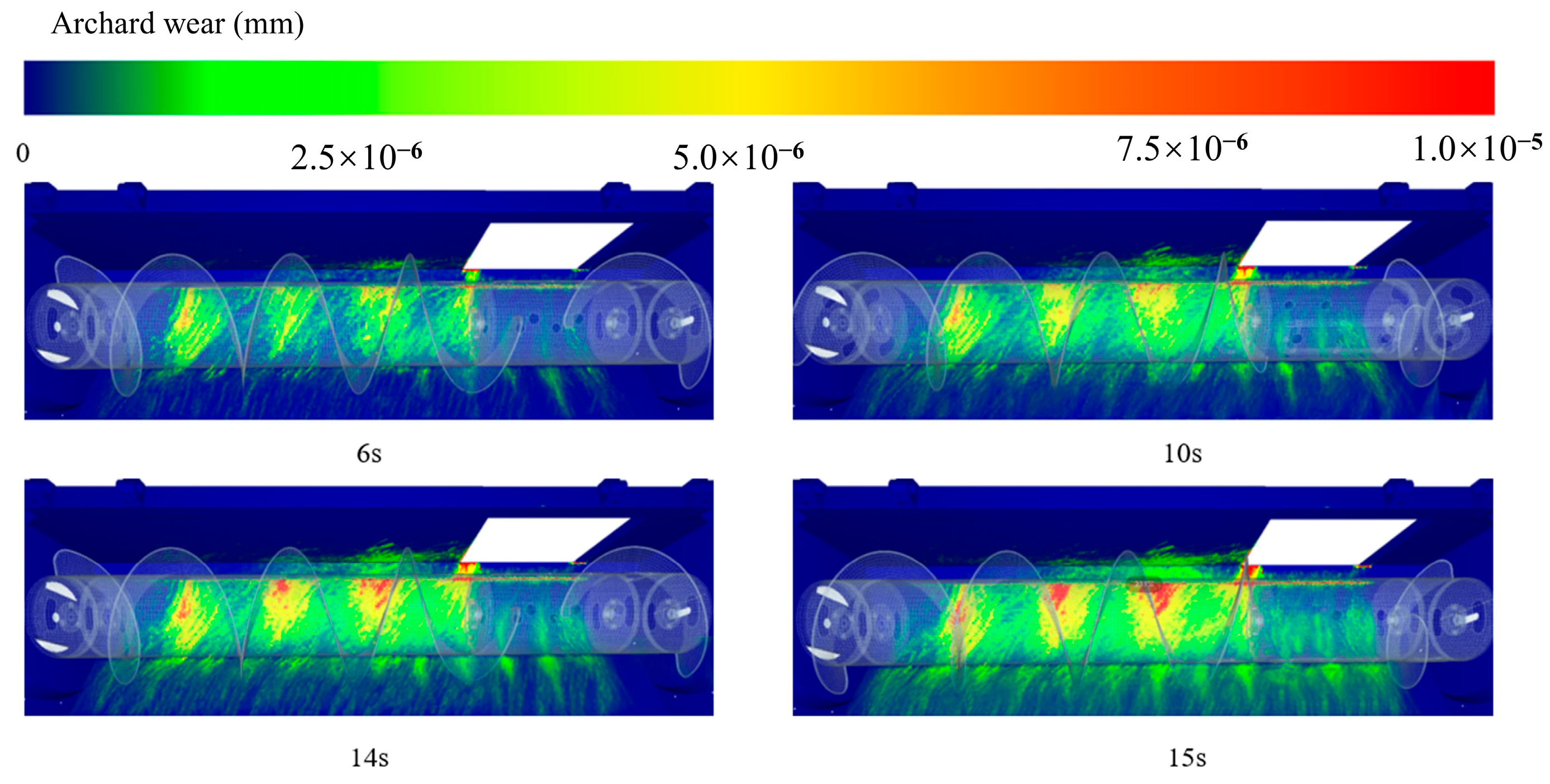

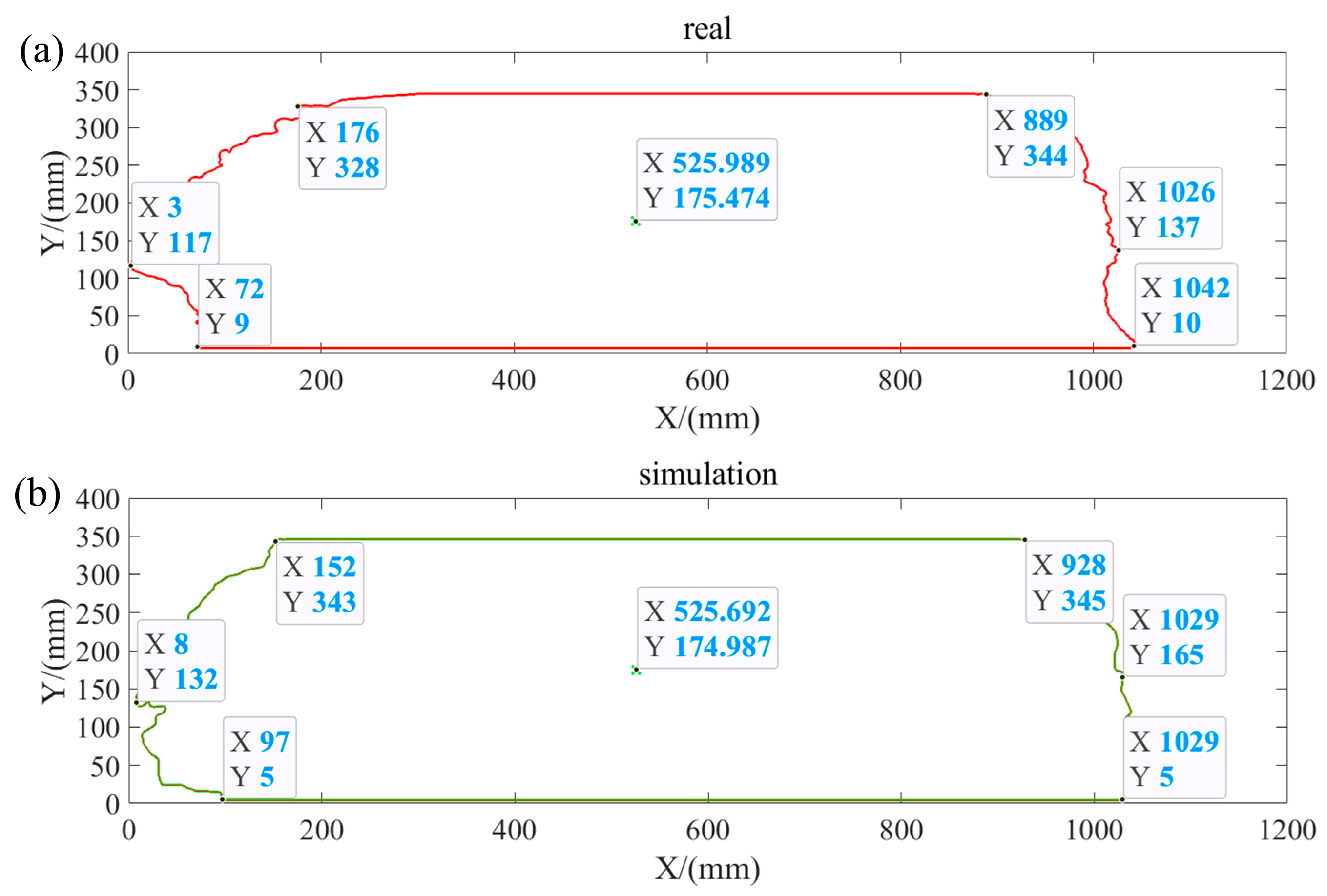

(2) We develop and validate a novel coupled Discrete Element Method (DEM)-Wear model, featuring a rigorously calibrated flexible rice stalk model. This model is capable of accurately predicting macroscopic wear “hot spots” on full-scale agricultural components, demonstrating excellent predictive fidelity and geometric similarity with real-world wear profiles observed on in-service combine harvesters. This provides agricultural engineers with a powerful, cost-effective digital tool for proactive design optimization and precise service life assessment, ultimately enhancing machinery reliability and significantly reducing operational costs for farmers. This is a significant advancement over existing DEM agricultural simulations, which primarily focus on material flow dynamics without establishing a direct, validated link to component wear prediction, particularly for complex full-scale agricultural machinery interacting with flexible biological materials. Furthermore, unlike studies using DEM-CFD for wear in other systems, this work specifically develops a robust flexible rice stalk model and validates its macroscopic wear predictions against real-world agricultural machinery.

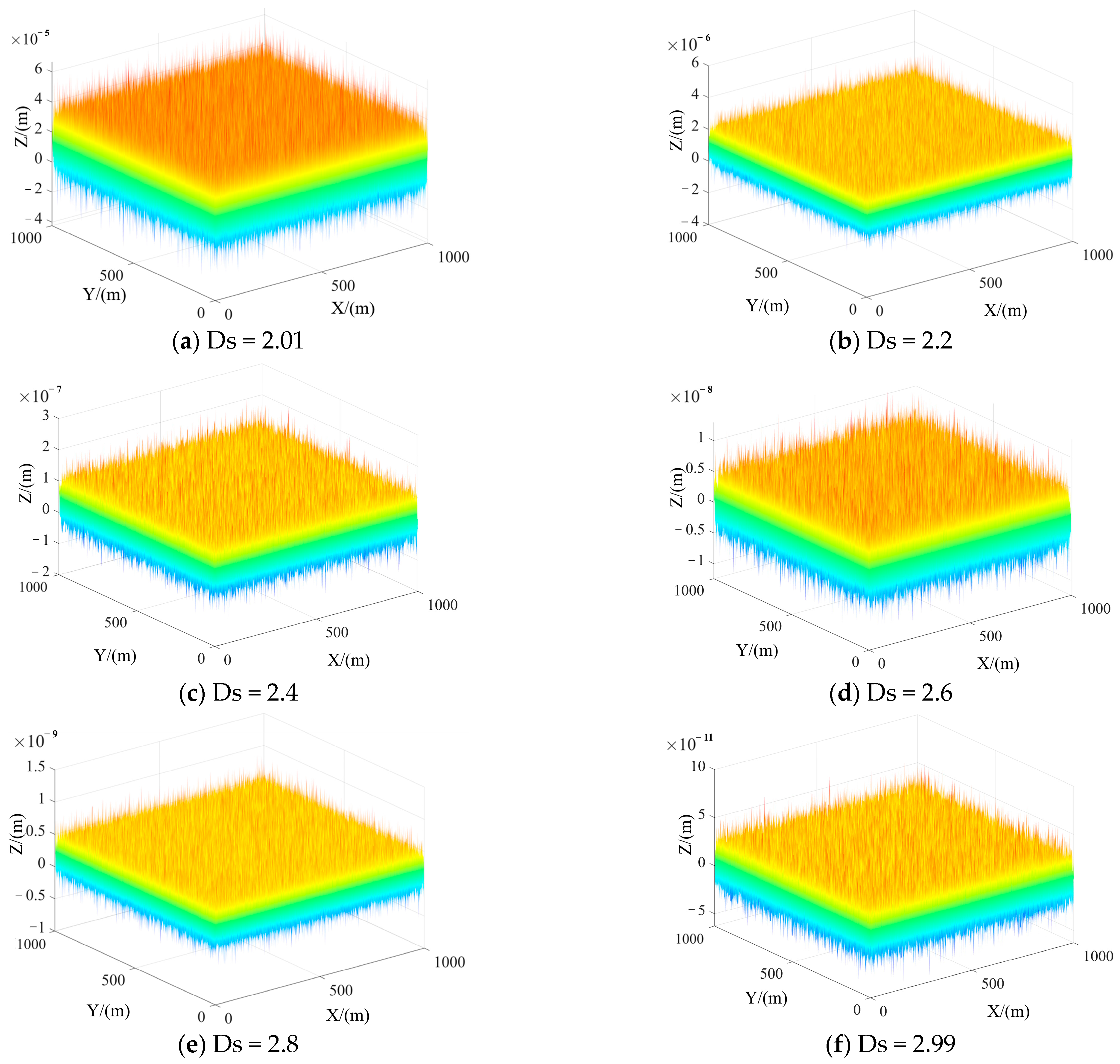

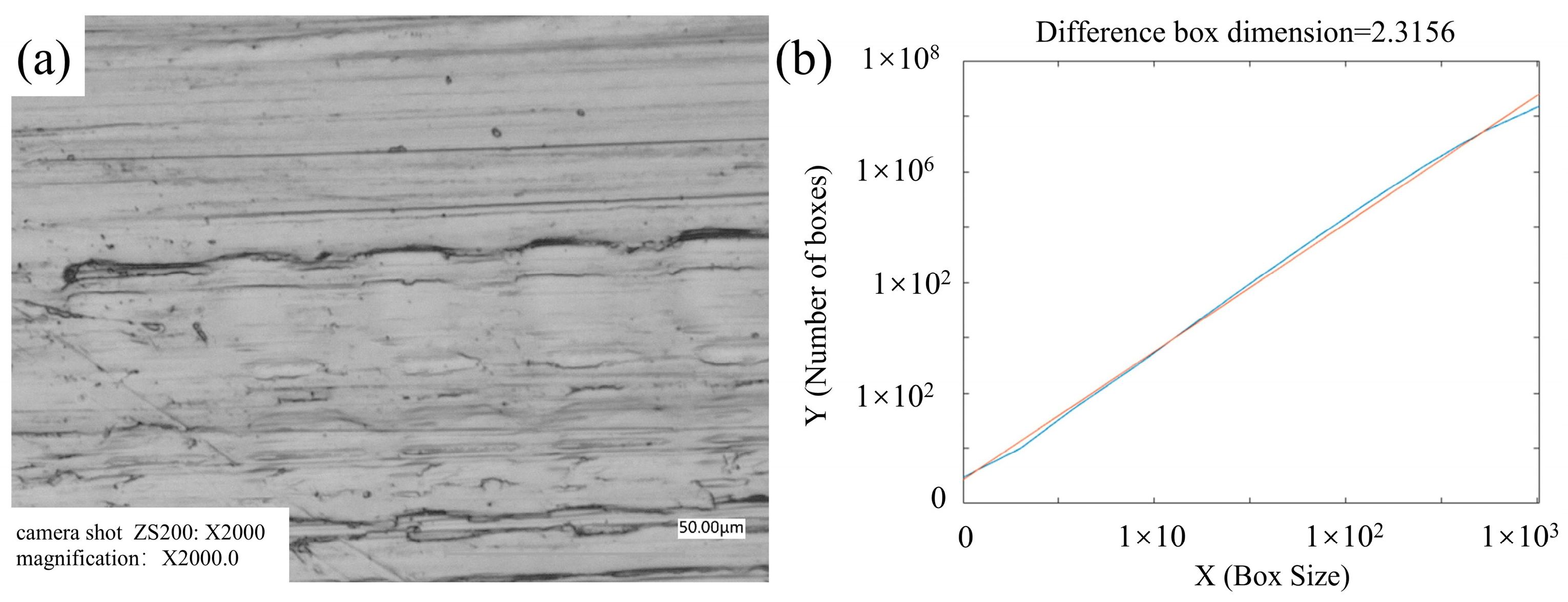

(3) This research successfully introduces and verifies fractal dimension as a robust quantitative metric for assessing the severity of agricultural soft abrasive wear. The study demonstrates that fractal dimension (Ds) is a sensitive indicator of wear severity, increasing significantly from approximately 2.17 on unworn surfaces to 2.3156 in the most severely worn regions, which directly correlates with the observed transition in wear mechanisms. This validated methodology offers a powerful digital tool for agricultural engineers, enabling the optimization of combine harvester component design, accurate prediction of service life, and ultimately enhancing the efficiency, reliability, and sustainability of rice harvesting operations. This novel application establishes fractal dimension as a refined method for characterizing topographical changes induced by soft agricultural abrasive wear, providing a more sensitive and objective tool than conventional roughness parameters, which is largely unexplored in this specific context. This goes beyond the typical use of fractal analysis in industrial wear, focusing on subtle yet significant morphological changes due to soft biological abrasives.

4. Conclusions

This study has systematically investigated the wear of the combine harvester header platform resulting from its interaction with rice, employing a multi-scale research framework that integrates bench wear tests, coupled Discrete Element-Wear (DEM-Wear) simulation, and advanced surface characterization techniques. Based on the results and discussion, the following main conclusions can be drawn:

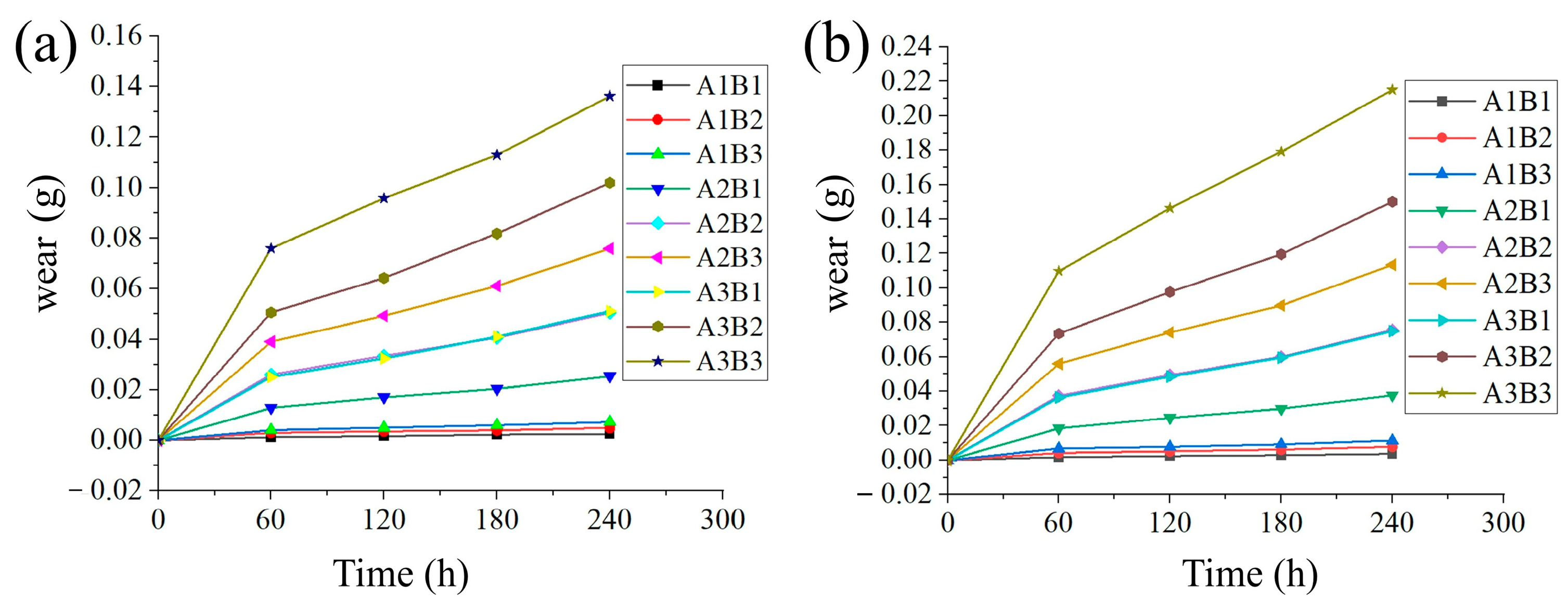

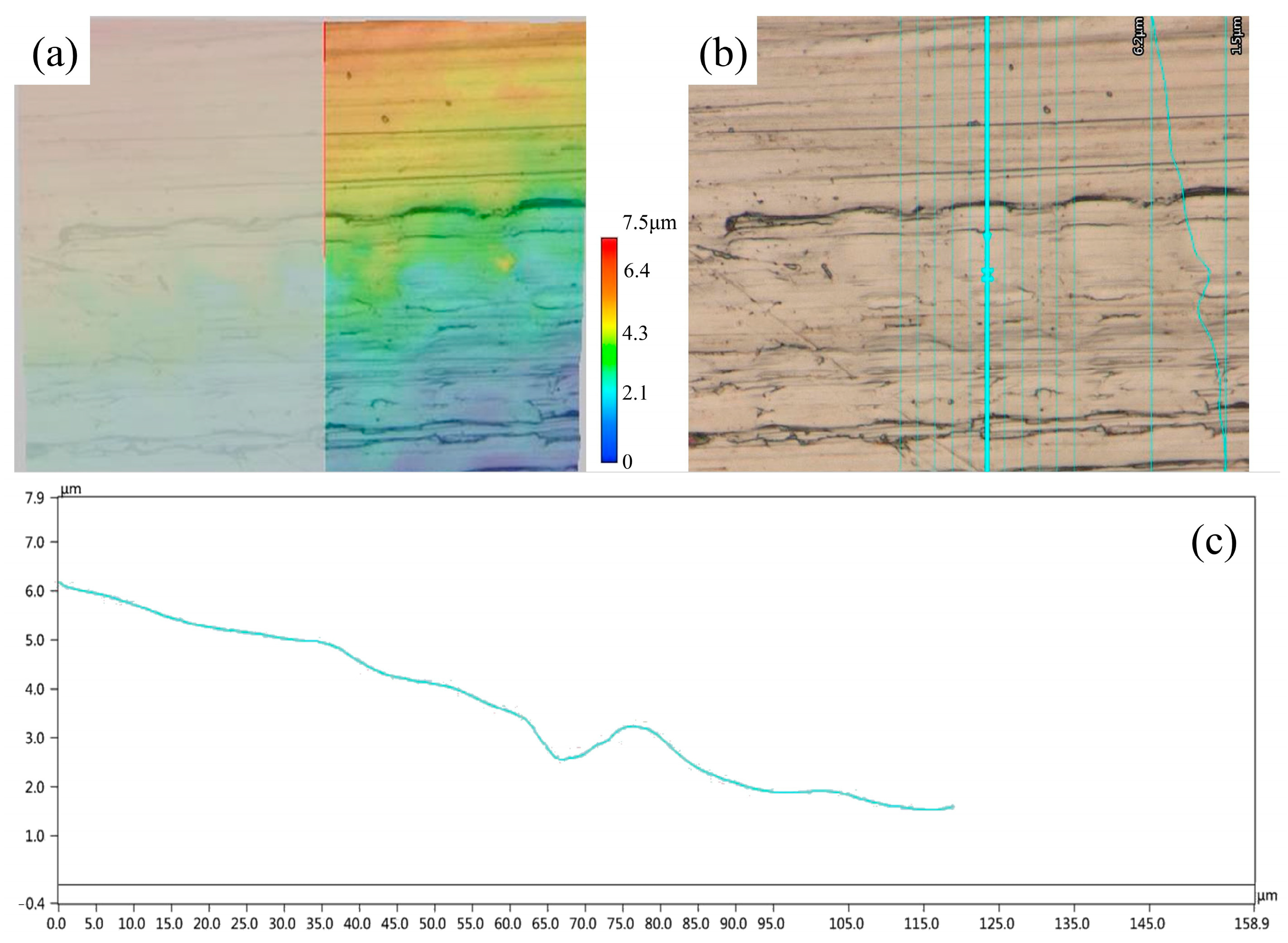

(1) This study systematically elucidated, for the first time, the complex wear mechanism of Q235 steel, a common material in agricultural machinery, induced by its interaction with rice. The process was identified as a composite mechanism, transitioning from mechanical polishing under low-load, low-velocity conditions to significant soft abrasive micro-cutting driven by the inherent silica particles within rice under high-load, high-velocity conditions. This fundamental understanding is crucial for selecting and designing more durable materials for agricultural applications.

(2) A robust coupled Discrete Element Method (DEM)-Wear model, incorporating a rigorously calibrated flexible rice stalk model, was successfully developed and extensively validated. This model accurately predicted macroscopic wear ‘hot spots’ on full-scale combine harvester header platforms, demonstrating excellent geometric similarity with wear profiles observed on in-service agricultural machinery. This provides agricultural engineers with a powerful and reliable computational tool for proactive design optimization and service life prediction of critical components, directly contributing to improved machinery reliability and reduced operational costs in the field.

(3) The research successfully applied fractal analysis to quantitatively characterize worn surfaces, demonstrating that the fractal dimension (Ds) serves as a sensitive and effective metric for agricultural wear severity. Ds consistently increased from approximately 2.17 on unworn surfaces to 2.3156 in the most severely worn regions, directly correlating with observed wear mechanism transitions. This direct correlation between wear loss and the increase in Ds values was quantitatively supported by the experimental results and statistical analyses presented in this article, confirming Ds as a robust indicator. This establishes fractal dimension as a novel and valuable quantitative tool for assessing the topographical changes and wear state of agricultural machinery surfaces.

5. Significance and Future Work

The significance of this research lies in its establishment of a comprehensive research paradigm for the field of agri-tribology, one that integrates micro-mechanisms, macroscopic prediction, and advanced characterization. The developed DEM-Wear model functions not merely as an explanatory tool but also as a predictive one, offering a rapid and cost-effective digital platform for wear-resistance optimization and service life prediction of critical agricultural machinery components. Using this model, engineers can evaluate the influence of different design parameters (such as the pitch and blade angle of the spiral auger) on wear distribution during the design stage. This allows for proactive optimization and reduces the need for costly physical prototyping and field trials. Consequently, the findings from this research directly inform practical component design guidelines for industry, enabling optimized material selection and geometric configurations for enhanced wear resistance and extended service life.

However, certain potential constraints exist within this study, mainly in the following aspects:

1. Material Simplification: The DEM models for rice stalks and grains are based on simplified particle representations (spherical particles and clumps). While their macroscopic bending behavior was validated through calibration, the models do not fully capture the complexity of their internal microstructure and anisotropic mechanical properties.

2. Wear Model Limitations: This study employed the Archard wear model, which is an empirical model assuming constant material hardness and a direct proportionality between wear amount, sliding distance, and normal load. It does not account for dynamic changes in surface topography and local material properties during wear, nor does it fully incorporate complex tribo-thermal effects.

3. Incomplete Consideration of Environmental Factors: The current model primarily focuses on mechanical wear and does not fully account for the synergistic effects of humidity, corrosive agents (e.g., rice stalk sap), and temperature variations present in actual field environments.

4. Limited Abrasive Scope: The research predominantly focused on wear induced by rice itself (stalks and grains) as the abrasive. However, hard exogenous abrasives such as soil and sand, which play a significant role in real-world agricultural operations, were not included in the DEM simulations or wear predictions. This focused approach was deliberate, allowing us to isolate and fundamentally characterize the unique soft abrasive wear mechanisms caused by silica-rich rice, which represents a critical knowledge gap addressed for the first time in this study.

Looking ahead, this research can be further advanced in the following directions:

Model Sophistication: Incorporating chemo-mechanical effects into the model to more comprehensively simulate the synergistic action of wear and corrosion in humid field environments. Furthermore, the model could be enhanced by introducing hard particles (e.g., sand) to investigate wear behavior under mixed-abrasive conditions. This will involve developing sophisticated multi-component DEM models that integrate granular mechanics with wear models for complex mixed-abrasive flows, thereby expanding the realism of the tribological system. Beyond current simplifications, future work could also explore more advanced constitutive models for rice stalks, accounting for their anisotropic properties and complex internal structures to enhance DEM simulation accuracy. Additionally, future research should investigate the tribological behavior of components with various rice varieties, beyond Nanjing 46. This expansion would quantify the influence of different rice properties (e.g., varying silica content, stalk hardness, grain morphology) on wear rates and mechanisms, thereby broadening the applicability of the findings and validating the universality of the identified wear principles.

Materials and Surface Engineering: The established experimental and simulation platform can be leveraged to evaluate the performance of various wear-resistant materials (e.g., high-chromium cast iron, surface coatings) under rice-induced wear conditions. This would provide a scientific basis for the application of novel materials.

Dynamic Wear Evolution: Future development could focus on a dynamic wear simulation model capable of real-time geometry updates. This would allow for simulation of the feedback effect of wear on material flow behavior, enabling more accurate predictions of wear evolution over longer time scales. Additionally, the model could be extended to predict wear on other critical components of agricultural machinery and for different crop types and environmental conditions.