Investigation of the Lubrication Performance of Petal-Shaped Micro-Pit Texture on the Surface of Stator Rubber in Screw Pumps

Abstract

1. Introduction

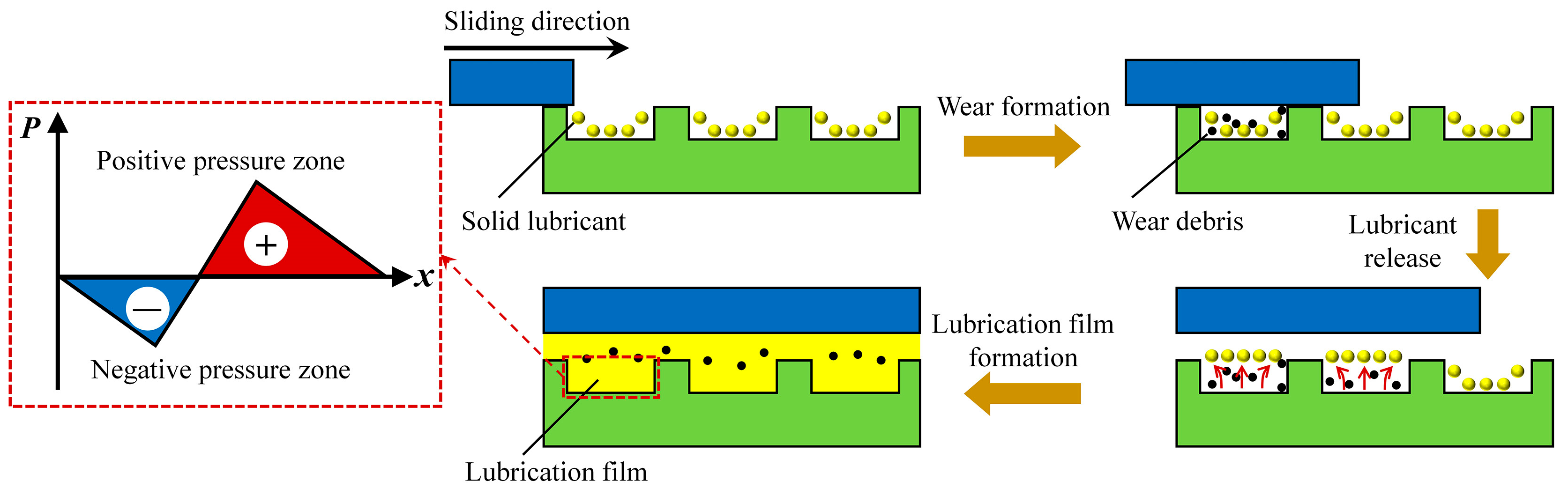

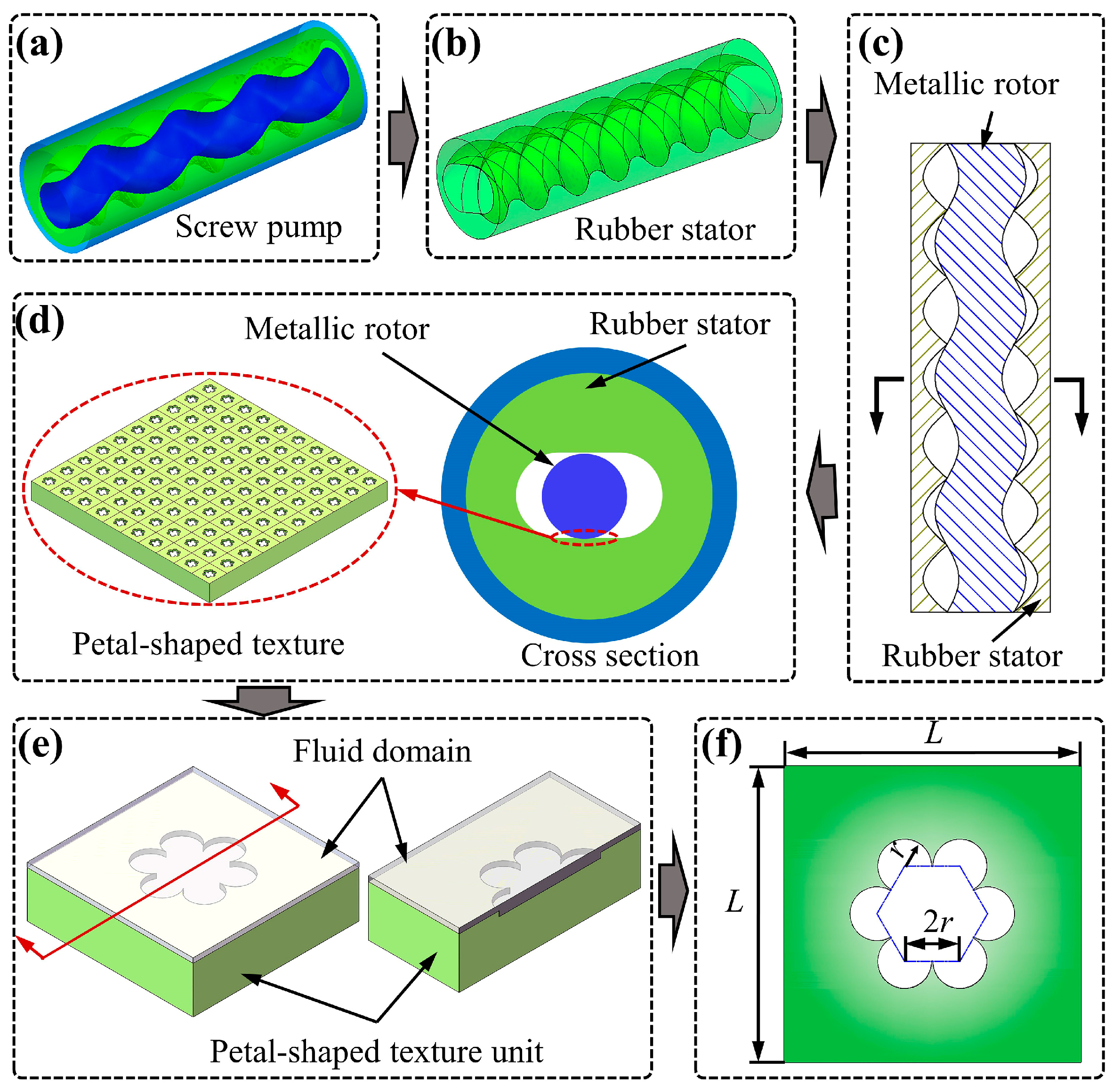

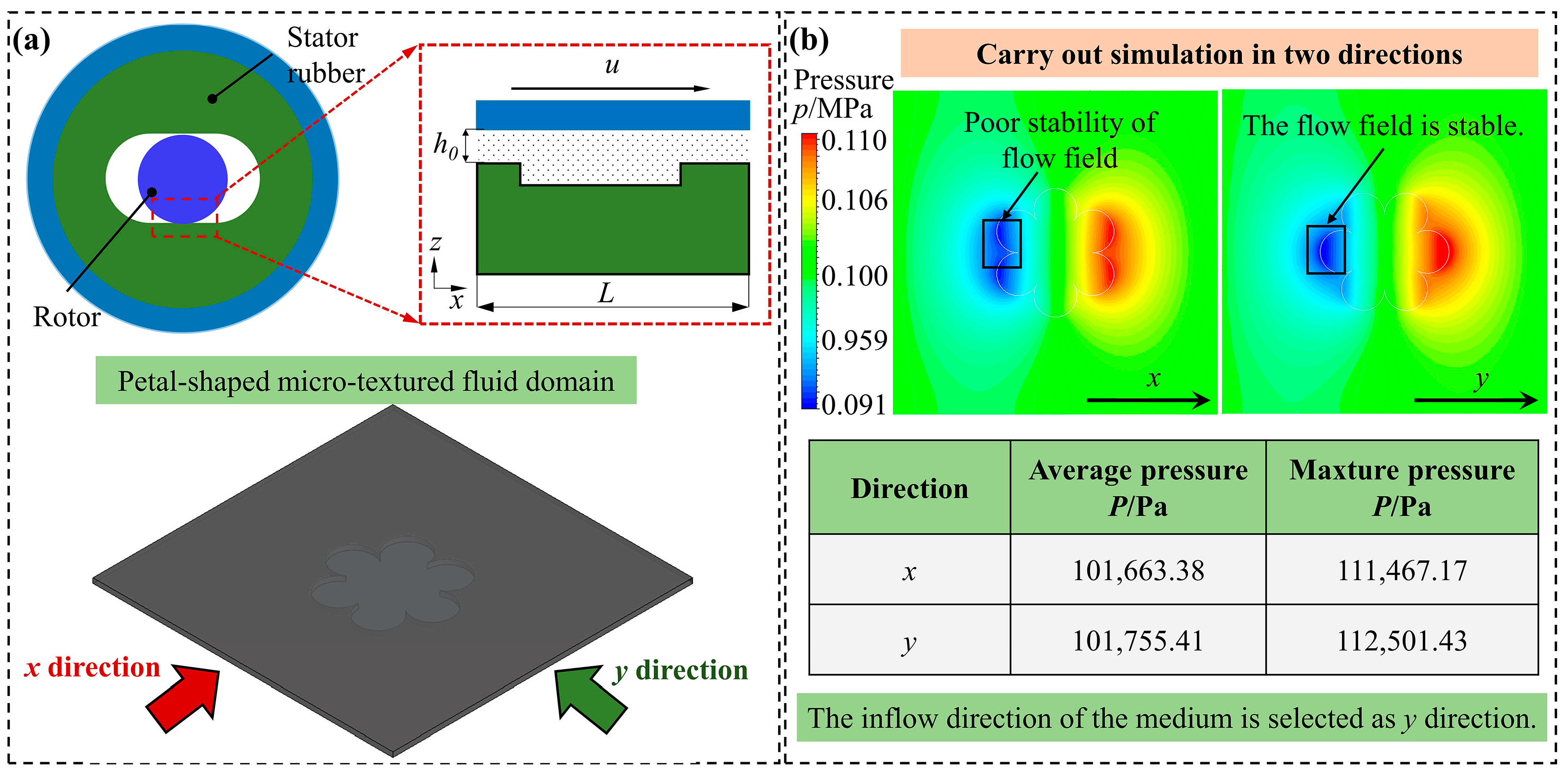

2. Analysis of the Petal-Shaped Micro-Pit Texture Model on the Rubber Surface of the Stator of Screw Pumps

2.1. Geometric Model of Petal-Shaped Micro-Pit Texture on the Inner Surface of the Stator Rubber of the Screw Pumps

2.2. Mathematical Model of the Hydrodynamic Lubrication Flow Field for the Micro-Pit Textured Surface of the Stator Rubber in the Screw Pumps

3. Simulation and Analysis of the Hydrodynamic Lubrication Flow Field of the Stator Rubber Petal-Shaped Micro-Pit Textured Surface

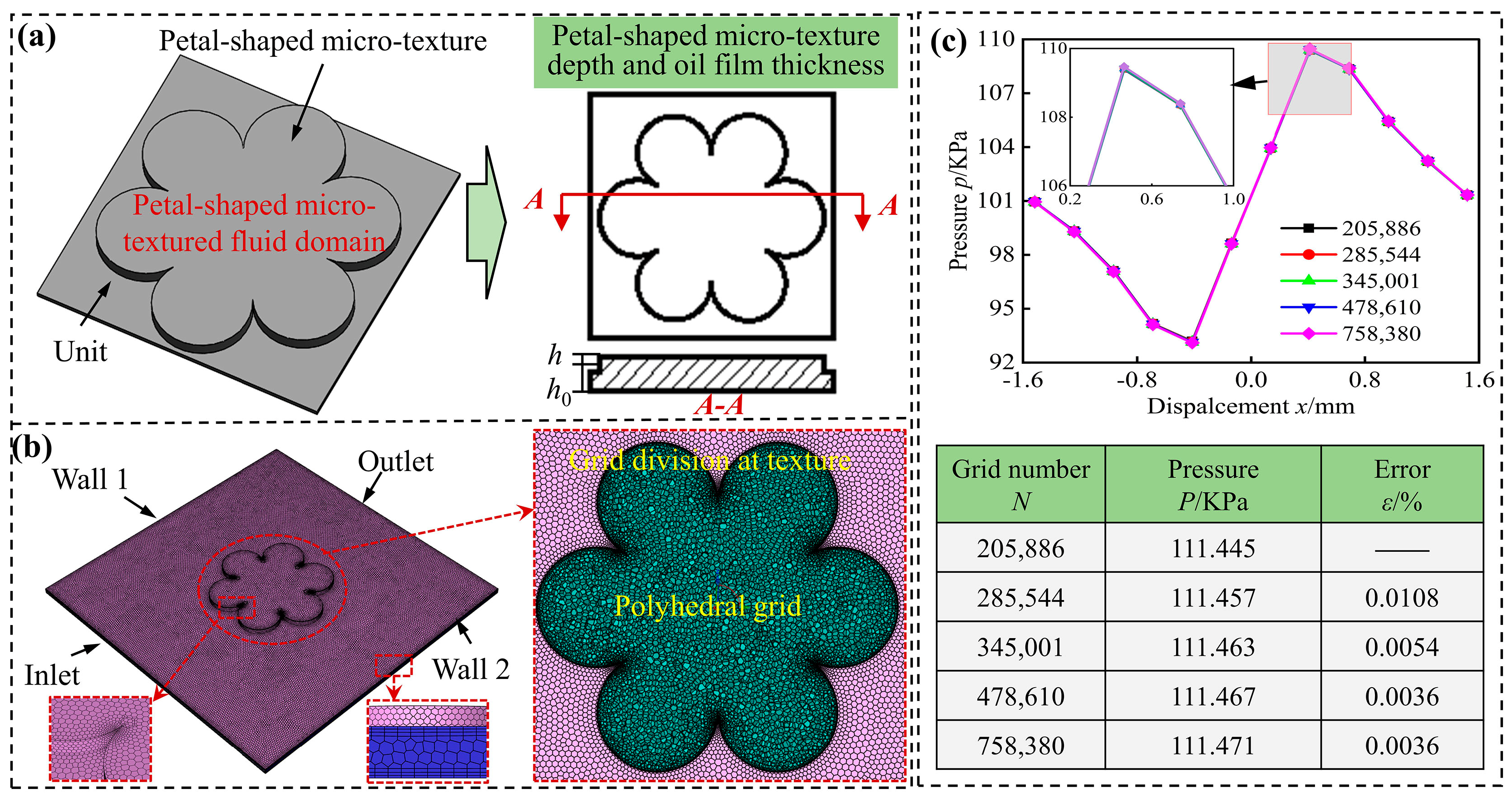

3.1. Simulation Model of the Hydrodynamic Lubrication Flow Field for Stator Rubber Textured Surface

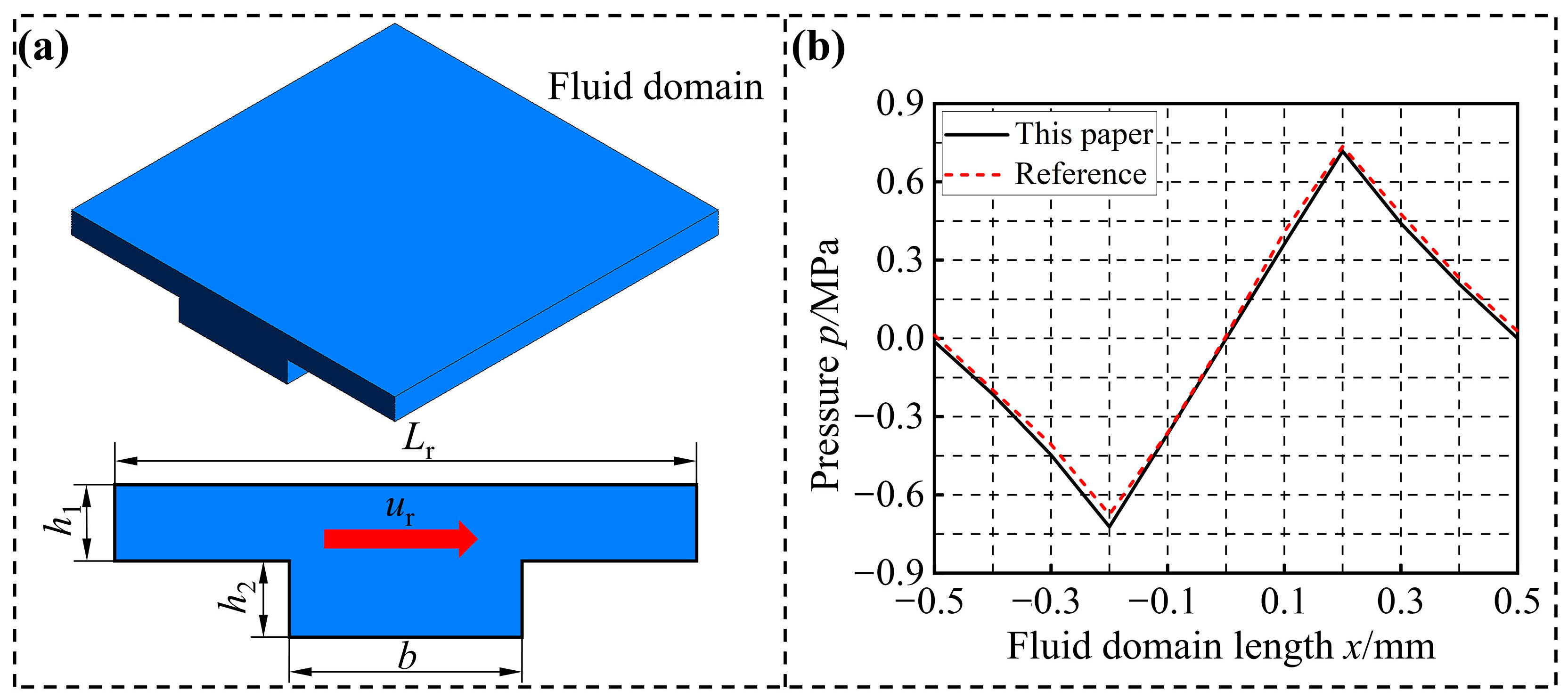

3.2. Validation of the Dynamic Pressure Lubrication Flow Field Simulation Model of the Stator Rubber Textured Surface

3.3. Analysis of the Hydrodynamic Lubrication Performance of Petal-Shaped Micro-Pit Texture Under Different Medium Flow Directions

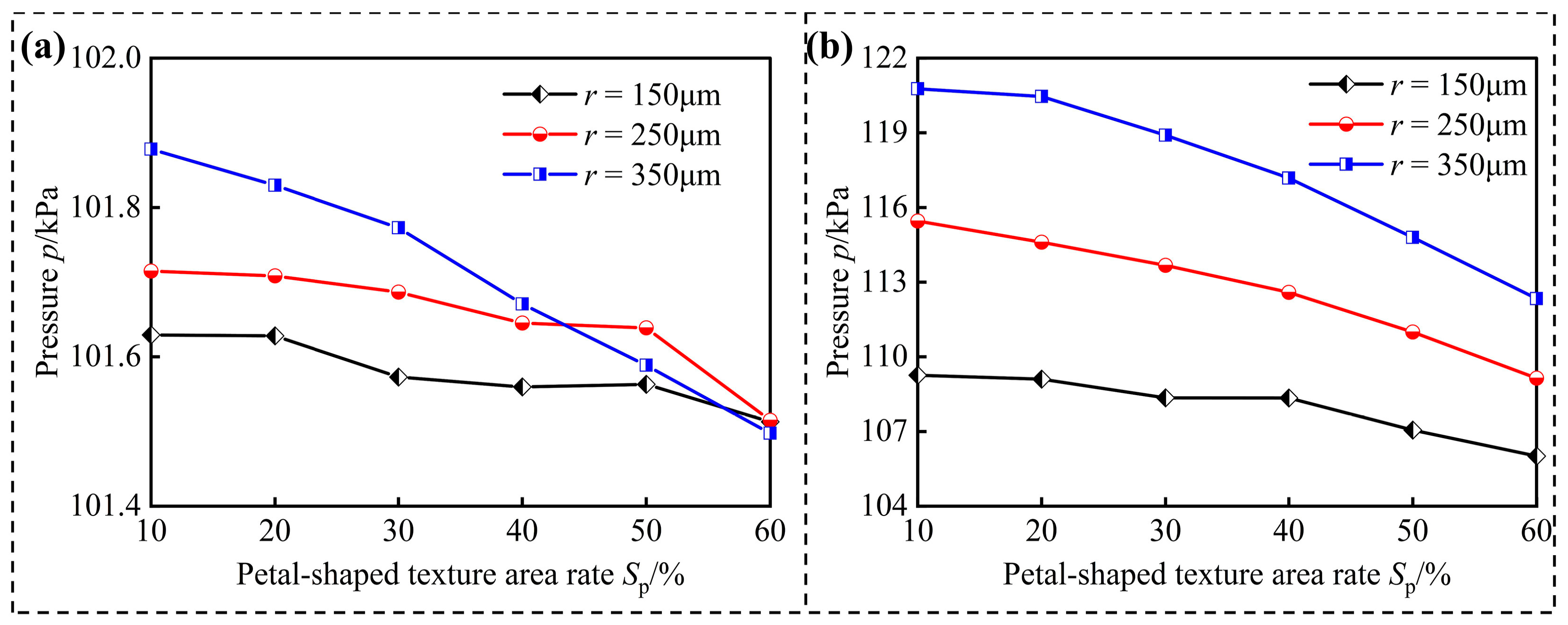

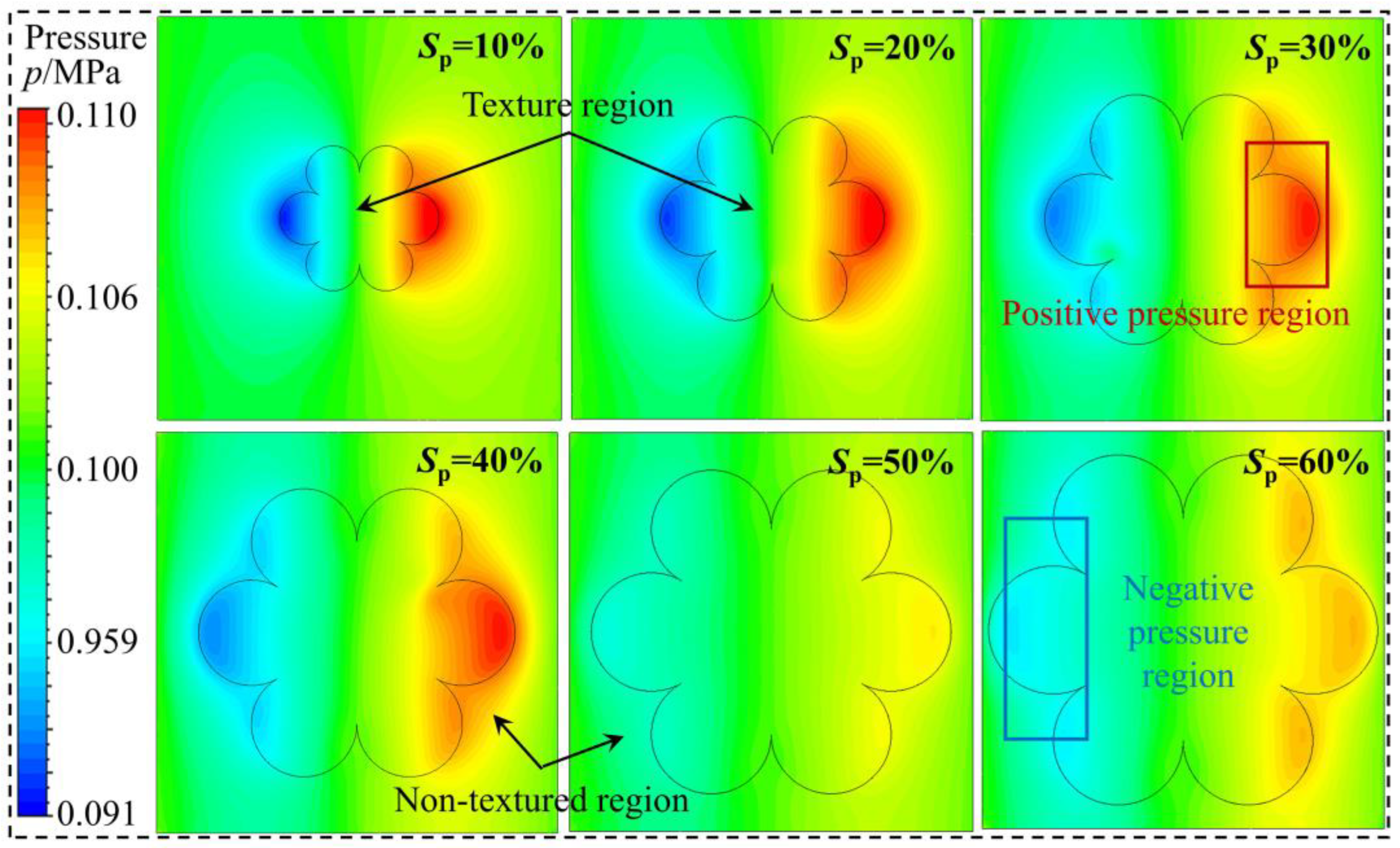

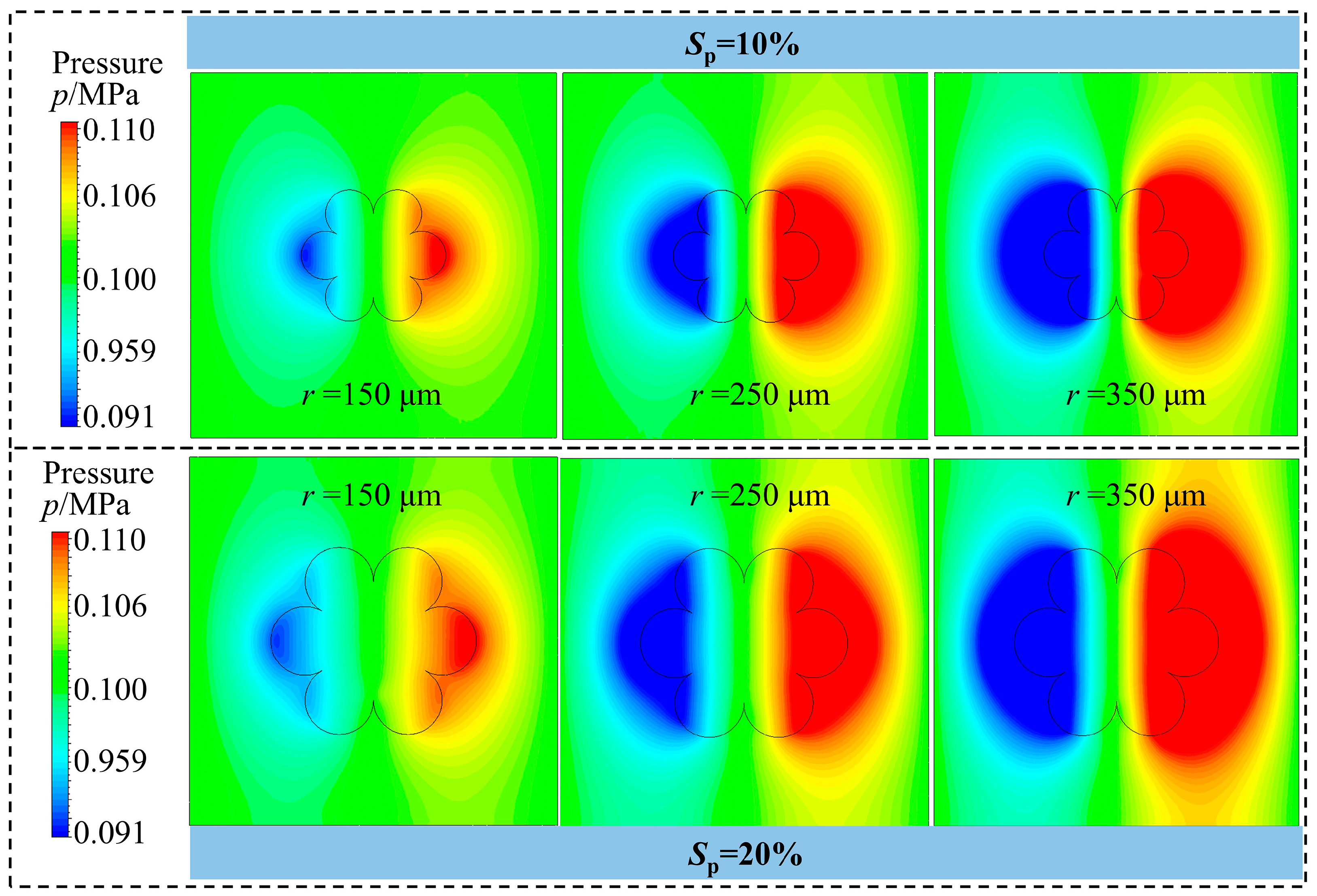

3.4. The Influence of the Size and Area Ratio of the Petal-Shaped Micro-Pit Texture on the Lubrication Performance of the Stator Rubber Surface

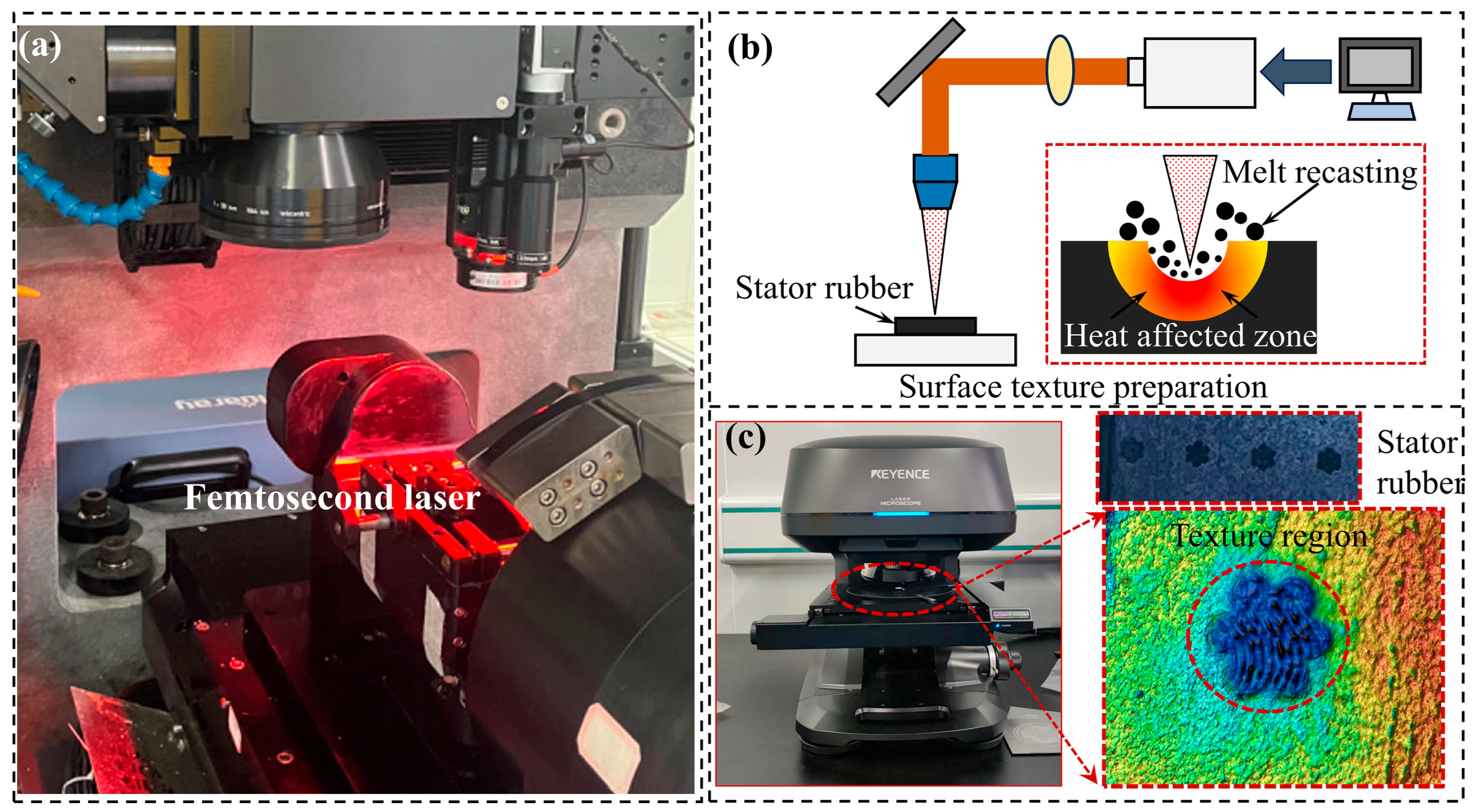

4. Friction Tests of Petal-Shaped Micro-Pit Texture on the Surface of Stator Rubber

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Liu, H.; Hao, Z.X.; Wang, L.G.; Cao, G. Current technical status and development trend of artificial lift. Acta Pet. Sin. 2015, 47, 1441–1448. [Google Scholar] [CrossRef]

- Zhou, J.; Xie, J.; Lu, L.; Sun, W.B. Multi-objective optimization of the structural parameters of an all-metal progressive cavity pump based on grey-taguchi relational analysis. J. Braz. Soc. Mech. Sci. Eng. 2025, 47, 299. [Google Scholar] [CrossRef]

- Wen, W.G.; Qin, J.Q.; Xu, X.R.; Mi, K.F.; Zhou, M. A model-driven approach to extract multi-source fault features of a screw pump. Processes 2024, 12, 2571. [Google Scholar] [CrossRef]

- Ramos, M.A.; Brown, J.C.; Rojas, M.; Kuyuco, O.; Flores, J.G. Producing extra-heavy oil from the Orinoco Belt, Cerro Negro Area, Venezuela, using bottom-drive progressive cavity pumps. SPE Prod. Oper. 2007, 22, 151–155. [Google Scholar] [CrossRef]

- Zhou, W.; Liu, X.F.; Wang, M.X.; Liu, C.H.; Hao, Z.X. A modern approach to the selection of electric submersible progressing cavity pumps for the pumping production systems. J. Braz. Soc. Mech. Sci. Eng. 2025, 47, 286. [Google Scholar] [CrossRef]

- Guagliano, M. Fatigue failure of a bar of a twin-screw extruder for plastics. Eng. Fail. Anal. 2004, 12, 950–962. [Google Scholar] [CrossRef]

- Borisova, K.; Ivanova, T.; Latypov, R. Study of screw pump stator and rotor working capacity to increase the output. Procedia Eng. 2017, 206, 688–691. [Google Scholar] [CrossRef]

- Chen, H.M.; Miao, C.W.; Lin, G.Y.; Yang, W.M.; Li, H.J. Design and optimization of the injection mold for rubber stators in oil production single-screw pumps. Polymers 2025, 17, 503. [Google Scholar] [CrossRef]

- Lv, X.R.; Wang, S.J.; Huo, X.Y. The effect of water content in crude oil on the tribological behavior of screw pump’s stator rubber. Chin. Sci. Bull. 2014, 59, 2868–2874. [Google Scholar] [CrossRef]

- Shi, C.S.; Zhu, X.H.; Chen, Y.K.; Tang, L.P. Failure analysis of general stator and uniform wall thickness stator. Eng. Fail. Anal. 2018, 94, 239–248. [Google Scholar] [CrossRef]

- Qian, C.; Li, Y.L.; Zhao, J.; Wang, S.J.; He, E.Q. Thermal-oxidative aging and tribological properties of carbon nanotube/nitrile butadiene rubber composites with varying acrylonitrile content: Molecular dynamics simulations. Polym. Eng. Sci. 2023, 63, 1516–1527. [Google Scholar] [CrossRef]

- Lv, X.R.; Wang, H.M.; Wang, S.J. Effect of swelling nitrile rubber in cyclohexane on its ageing, friction and wear characteristics. Wear 2015, 328–329, 414–421. [Google Scholar] [CrossRef]

- Yeo, Y.G.; Park, H.H.; Lee, C.S. A study on the characteristics of a rubber blend of fluorocarbon rubber and hydrogenated nitrile rubber. J. Ind. Eng. Chem. 2013, 19, 1540–1548. [Google Scholar] [CrossRef]

- Li, Y.F.; Nie, D.L.; Cai, Z.Q. The performance analysis of screw pump stator elastomers: Polyamide 6/hydrogenated nitrile blends: Mechanical, oil resistance and tribological properties. Polym. Test. 2023, 128, 108226. [Google Scholar] [CrossRef]

- Liu, X.F.; Shi, X.Z.; Hao, Z.X.; Wei, S.B.; Sun, Y.; Niu, X.L.; Li, M.; Li, Z.Z. Effect of complex well conditions on the swelling and tribological properties of high-acrylonitrile stator rubber in screw pumps. Polymers 2024, 16, 2036. [Google Scholar] [CrossRef]

- Naat, N.; Boutar, Y.; Naïmi, S.; Mezlini, S.; Akhavan-Safar, A.; Carbas, R.J.C.; Da Silva, L.F. Enhanced static and fatigue performance of FDM 3D-printed polycarbonate adhesive joints using bio-inspired surface textures. Eng. Fail. Anal. 2025, 176, 109626. [Google Scholar] [CrossRef]

- Zhao, X.D.; Zhang, Y.M.; Gao, S.Z. Analysis and evaluation of the synergistic effect of ceramic materials and surface texture on anti-abrasive particle wear under rolling conditions. Tribol. Int. 2024, 197, 109821. [Google Scholar] [CrossRef]

- Pawel, P.; Rafal, R.; Michal, W. Functional importance of surface texture parameters. Materials 2021, 14, 5326. [Google Scholar] [CrossRef] [PubMed]

- Bijani, D.; Deladi, E.L.; de Rooij, M.B.; Schipper, D.J. The influence of surface texturing on the frictional behaviour in starved lubricated parallel sliding contacts. Lubricants 2019, 7, 68. [Google Scholar] [CrossRef]

- Xia, S.Q.; Huang, C.; Ye, S.G.; Jiao, W.X.; Xia, Y.M. Study on the running-in tribological performance and mechanism of the valve plate with surface texture for axial piston pumps. Wear 2025, 574–575, 206085. [Google Scholar] [CrossRef]

- Wei, Y.; Yan, H.M.; Li, S.; Wang, X.M. Numerical and experimental study of a sector-shaped surface texture in friction reduction. Tribol. Lett. 2024, 72, 60. [Google Scholar] [CrossRef]

- Liu, X.F.; Liu, C.H.; Hou, G.X.; Guo, J.Y.; Hao, Z.X.; Shi, X.Z. Tribological behaviors of stator rubber with hexagonal micro-pit texture and enclosed groove of bionic honeycomb structure. iScience 2025, 28, 112421. [Google Scholar] [CrossRef] [PubMed]

- Shi, X.Z.; Liu, X.F.; Liu, C.H.; Hao, Z.X.; Huang, S.Z.; Sun, Y.; Niu, X.L. Numerical simulation of the lubrication performance of the stator and rotor friction pair surface rhombus-like texture in screw pumps. Lubricants 2025, 13, 157. [Google Scholar] [CrossRef]

- Zhang, J.J.; Zhang, J.G.; Rosenkranz, A.; Zhao, X.L.; Song, Y.L. Surface textures fabricated by laser surface texturing and diamond cutting-influence of texture depth on friction and wear. Adv. Eng. Mater. 2018, 20, 1700995. [Google Scholar] [CrossRef]

- Lu, C.; Ding, J.H.; Shi, P.Y.; Jia, J.H.; Xie, E.Q. Effects of texture density on the tribological properties of plasma electrolytic oxidation/polytetrafluoroethylene coatings formed on aluminum alloys. Macromol. Mater. Eng. 2021, 307, 2100678. [Google Scholar] [CrossRef]

- Li, D.; Yang, X.F.; Lu, C.Y.; Jian, C.; Wang, S.R. Tribological characteristics of a cemented carbide friction surface with chevron pattern micro-pit texture based on different texture density. Tribol. Int. 2020, 142, 106016. [Google Scholar] [CrossRef]

- Muchammad, M.; Hilmy, F.; Tauviqirrahman, M.; Jamari, J.; Schipper, D.J. CFD analysis of texture depth effect on the performance of hydrodynamic lubricated bearing. J. Phys. Conf. Ser. 2018, 1090, 012067. [Google Scholar] [CrossRef]

- Traore, M.M.; Wang, L. Influences of the flow speed and the micro-pit texture deepness on the dynamic lubrication performance characteristics. J. Comput. Theor. Nanosci. 2013, 10, 419–422. [Google Scholar] [CrossRef]

- Sheng, Z.W.; Zhu, H.; He, Y.; Shao, B.; Sheng, Z.; Wang, S.Q. Tribological effects of surface biomimetic micro-nano textures on metal cutting tools: A review. Biomimetics 2025, 10, 283. [Google Scholar] [CrossRef]

- Guo, Z.W.; Xie, X.; Yuan, C.Q.; Bai, X.Q. Study on influence of micro convex textures on tribological performances of UHMWPE material under the water-lubricated conditions. Wear 2019, 426–427, 1327–1335. [Google Scholar] [CrossRef]

- Li, M.; Shi, W.B.; Shi, J.; Wang, T.; Shi, L.P.; Wang, X.L. Regulation and control of wet friction of soft materials using surface texturing: A review. Friction 2023, 11, 333–353. [Google Scholar] [CrossRef]

- Tang, G.; Ho, J.K.; Dong, G.; Hua, M. Fabrication self-recovery bulge textures on TiNi shape memory alloy and its tribological properties in lubricated sliding. Tribol. Int. 2016, 96, 11–22. [Google Scholar] [CrossRef]

- Gherca, A.; Fatu, A.; Hajjam, M.; Maspeyrot, P. Influence of surface texturing on the hydrodynamic performance of a thrust bearing operating in steady-state and transient lubrication regime. Tribol. Int. 2016, 102, 305–318. [Google Scholar] [CrossRef]

- Guo, Z.W.; Yuan, C.Q.; Liu, P.; Peng, Z.X.; Yan, X.P. Study on influence of cylinder liner surface texture on lubrication performance for cylinder liner-piston ring components. Tribol. Lett. 2013, 51, 9–23. [Google Scholar] [CrossRef]

- Wang, Z.Q.; Ye, R.H.; Xiang, J.B. The performance of textured surface in friction reducing: A review. Tribol. Int. 2022, 177, 108010. [Google Scholar] [CrossRef]

- Ullah, M.Z.; Rizwan, M.; Raza, A.; Ahmed, A.; Abid, M. Effect of dimple shape and depth on tribological performance of textured surface. Int. Bhurban Conf. Appl. Sci. Technol. (IBCAST) 2021, 2021, 719–725. [Google Scholar] [CrossRef]

- Sasaki, S. Surface texturing for friction control: A review on existing technology and prospects: Review. Tribol. Online 2024, 19, 105–120. [Google Scholar] [CrossRef]

- Borghi, A.; Gualtieri, E.; Marchetto, D.; Moretti, L.; Valeri, S. Tribological effects of surface texturing on nitriding steel for high-performance engine applications. Wear 2008, 265, 1046–1051. [Google Scholar] [CrossRef]

- Wu, Z.; Bao, H.; Xing, Y.Q.; Liu, L. Tribological characteristics and advanced processing methods of textured surfaces: A review. Int. J. Adv. Manuf. Technol. 2021, 114, 1241–1277. [Google Scholar] [CrossRef]

- Zhang, H.; Hua, M.; Dong, G.Z.; Zhang, D.Y.; Chen, W.J.; Dong, G.N. Optimization of texture shape based on Genetic Algorithm under unidirectional sliding. Tribol. Int. 2017, 115, 222–232. [Google Scholar] [CrossRef]

- Yu, S.J.; Hu, X.J.; Cao, J.; Liu, L.; Huang, H.B.; Xie, Z.L.; Chen, X.Z.; Wang, X.C. Investigation of tribology and wear prediction of a polymer coating consisting of GO and WC on the surfaces of three textures. J. Mater. Sci. 2025, 60, 13765–13779. [Google Scholar] [CrossRef]

- Tang, X.S.; Lan, Y.F.; Bosiakov, S.; Zhuravkov, M.; He, T.; Xia, Y.; Lyu, Y.T. Investigation on the coupling effect of bionic micro-texture shape and distribution on the tribological performance of water-lubricated sliding bearings. Lubricants 2025, 13, 305. [Google Scholar] [CrossRef]

- Zhang, T.R.; Liu, C.L.; Li, X.M.; Guo, F.; Zhu, K.M. Fabrication of a composite groove array surface with gradient wettability which delivers enhanced lubrication performance. Lubricants 2025, 13, 193. [Google Scholar] [CrossRef]

- Jing, Z.G.; Jian, Y.S.; Guo, F.; Duan, P.H.; Wong, P.L.; Li, Z.Y. Surface wettability-driven oil film formation in slider-on-disc contact under limited lubrication. Friction 2025, 13, 9440990. [Google Scholar] [CrossRef]

- Uddin, M.; Liu, Y.W. Design and optimization of a new geometric texture shape for the enhancement of hydrodynamic lubrication performance of parallel slider surfaces. Biosurface Biotribology 2016, 2, 59–69. [Google Scholar] [CrossRef]

- Liu, X.F.; Sun, Y.; Liu, C.H.; Shi, X.Z.; Niu, X.L.; Zheng, G.; Wei, W.; Wei, S.B.; Huang, S.Z. Lubrication characteristics of a warhead-type irregular symmetric texture on the stator rubber surfaces of screw pumps. Lubricants 2024, 12, 397. [Google Scholar] [CrossRef]

- Jing, X.; Si, W.F.; Sun, J.; Zhou, J.K.; Lin, J.Q.; Yu, B.J.; Lu, M.M. Wettability and Droplet Directional spread investigation of crescent array surface inspired by slippery zone of nepenthes. Adv. Mater. Interfaces 2021, 9, 2101231. [Google Scholar] [CrossRef]

- Gui, C.; Meng, F.M. Comparative study of spherical dimple and bump effects on the tribological performances of journal bearing. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2019, 233, 139–157. [Google Scholar] [CrossRef]

- Li, K.M.; Jing, D.L.; Hu, J.; Ding, X.H.; Yao, Z.Q. Numerical investigation of the tribological performance of micro-dimple textured surfaces under hydrodynamic lubrication. Beilstein J. Nanotechnol. 2017, 8, 2324–2338. [Google Scholar] [CrossRef]

- Morris, N.J.; Shahmohamadi, H.; Rahmani, R.; Rahnejat, H.; Garner, C.P. Combined experimental and multiphase computational fluid dynamics analysis of surface textured journal bearings in mixed regime of lubrication. Lubr. Sci. 2018, 30, 161–173. [Google Scholar] [CrossRef]

- Lee, H.B.; Yeo, I.W.; Lee, K.K. The modified Reynolds equation for non-wetting fluid flow through a rough-walled rock fracture. Adv. Water Resour. 2013, 53, 242–249. [Google Scholar] [CrossRef]

- Pierart, G.F.; Santos, F.I. Steady state characteristics of an adjustable hybrid gas bearing-computational fluid dynamics, modified Reynolds equation and experimental validation. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2015, 229, 807–822. [Google Scholar] [CrossRef]

- Varela, C.A.; Santos, F.I. Validity of the modified Reynolds equation for incompressible active lubrication. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2016, 230, 1490–1502. [Google Scholar] [CrossRef]

- Wang, J.H.; Yan, Z.J.; Shen, Z.Y.; Pan, X.X. Three-dimensional CFD analysis of the influence of surface texture morphology parameters on lubrication performance. Lubr. Eng. 2021, 46, 37–43. [Google Scholar] [CrossRef]

| Operating Parameter | Value |

|---|---|

| Wavelength/nm | 1035 |

| Pulse width/fs | 222 |

| Frequency/kHz | 800 |

| Power/mW | 800 |

| Scanning speed/(mm/s) | 100 |

| Scanning times | 1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, X.; Liu, X.; Han, G.; Shi, X.; An, J.; Yin, X.; Geng, L. Investigation of the Lubrication Performance of Petal-Shaped Micro-Pit Texture on the Surface of Stator Rubber in Screw Pumps. Lubricants 2025, 13, 379. https://doi.org/10.3390/lubricants13090379

Wu X, Liu X, Han G, Shi X, An J, Yin X, Geng L. Investigation of the Lubrication Performance of Petal-Shaped Micro-Pit Texture on the Surface of Stator Rubber in Screw Pumps. Lubricants. 2025; 13(9):379. https://doi.org/10.3390/lubricants13090379

Chicago/Turabian StyleWu, Xiaoming, Xinfu Liu, Guoqing Han, Xiangzhi Shi, Jiuquan An, Xiaoli Yin, and Li Geng. 2025. "Investigation of the Lubrication Performance of Petal-Shaped Micro-Pit Texture on the Surface of Stator Rubber in Screw Pumps" Lubricants 13, no. 9: 379. https://doi.org/10.3390/lubricants13090379

APA StyleWu, X., Liu, X., Han, G., Shi, X., An, J., Yin, X., & Geng, L. (2025). Investigation of the Lubrication Performance of Petal-Shaped Micro-Pit Texture on the Surface of Stator Rubber in Screw Pumps. Lubricants, 13(9), 379. https://doi.org/10.3390/lubricants13090379