Effect of Laser Scanning Speed on Microstructure and Wear Resistance of TiC-TiB2-Reinforced 316L Laser-Clad Coatings

Abstract

1. Introduction

2. Materials and Methods

2.1. Sample Preparation

2.2. Laser Cladding Process

2.3. Sample Characterization

2.4. Vickers Hardness Testing

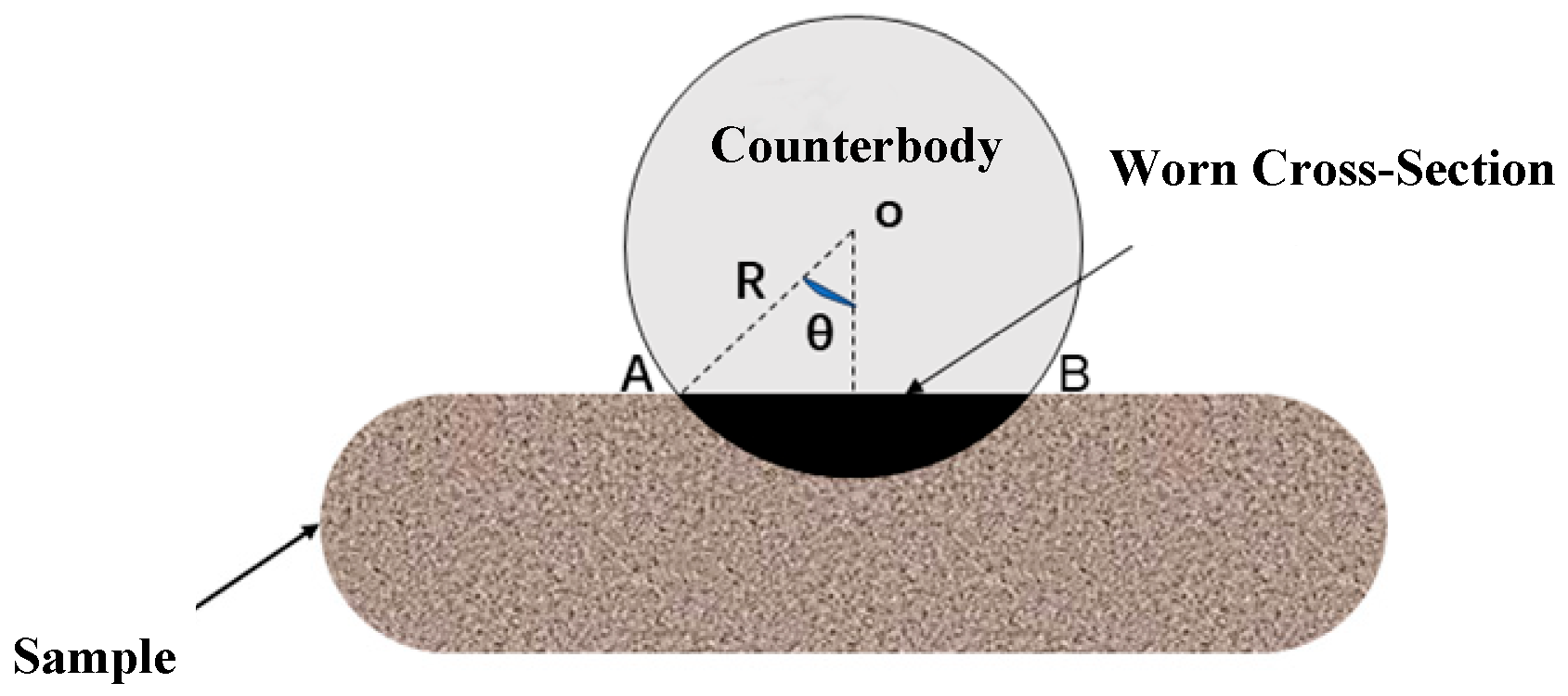

2.5. Wear Resistance Testing

3. Results and Discussion

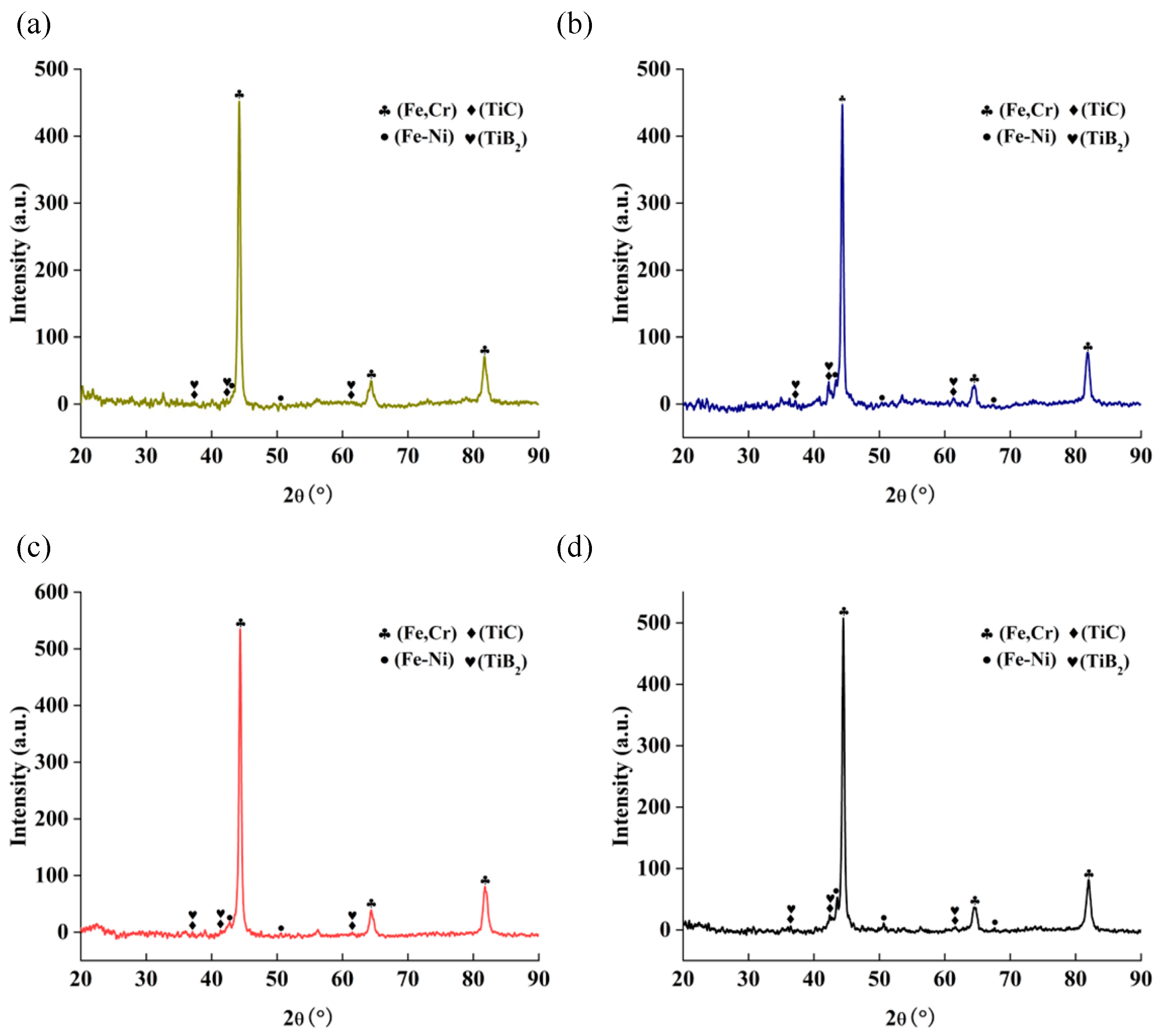

3.1. Phase Analysis by XRD

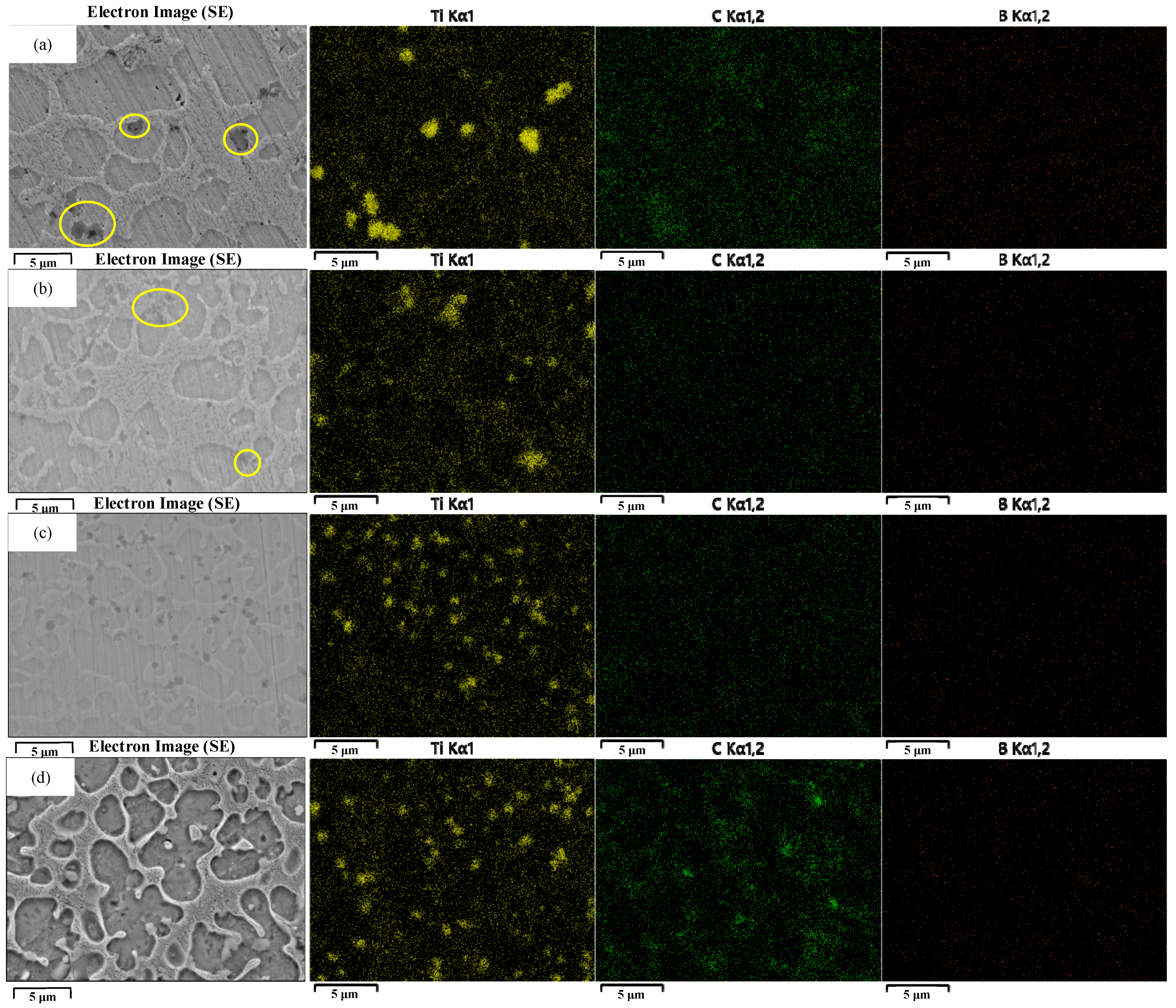

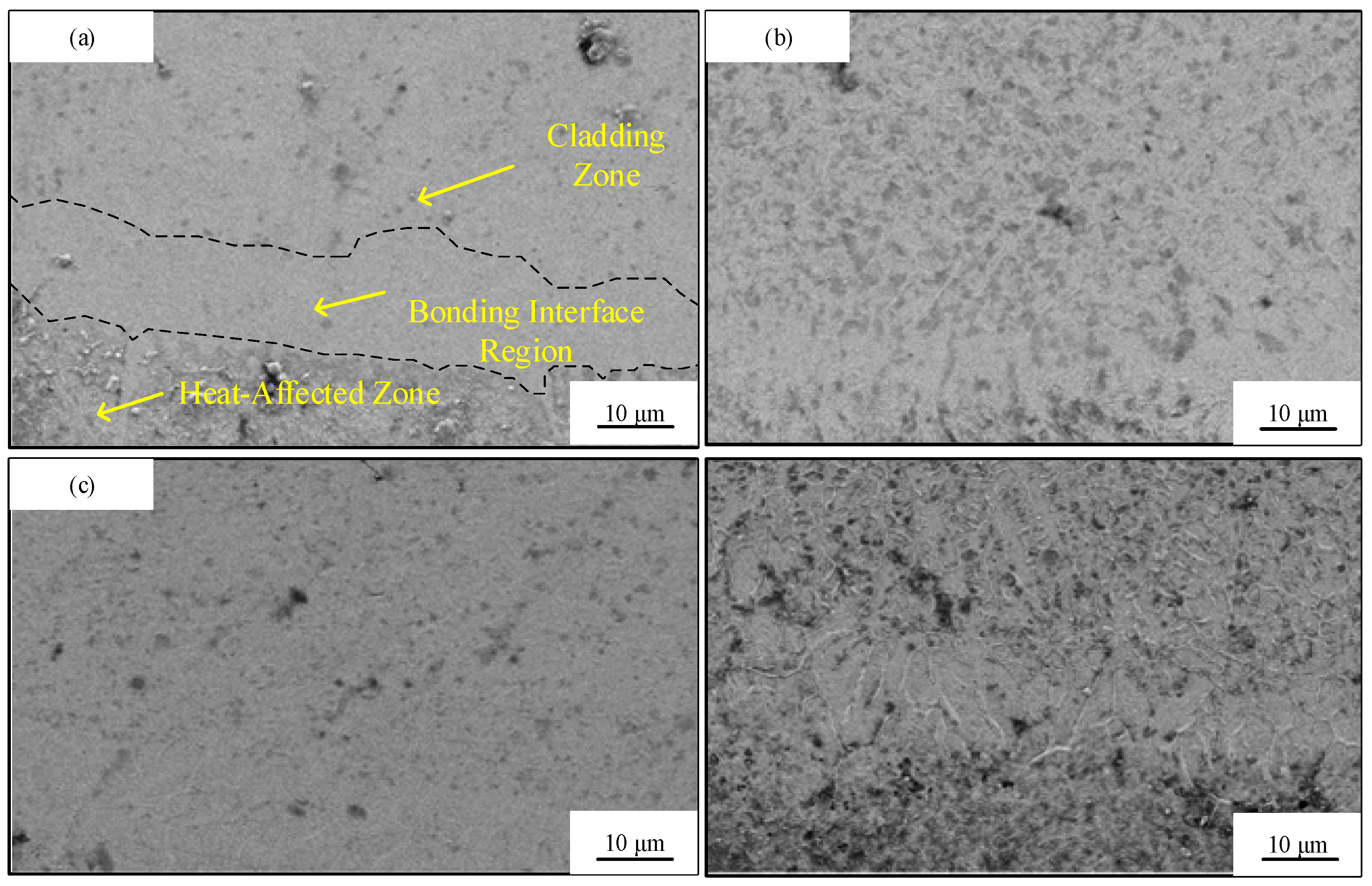

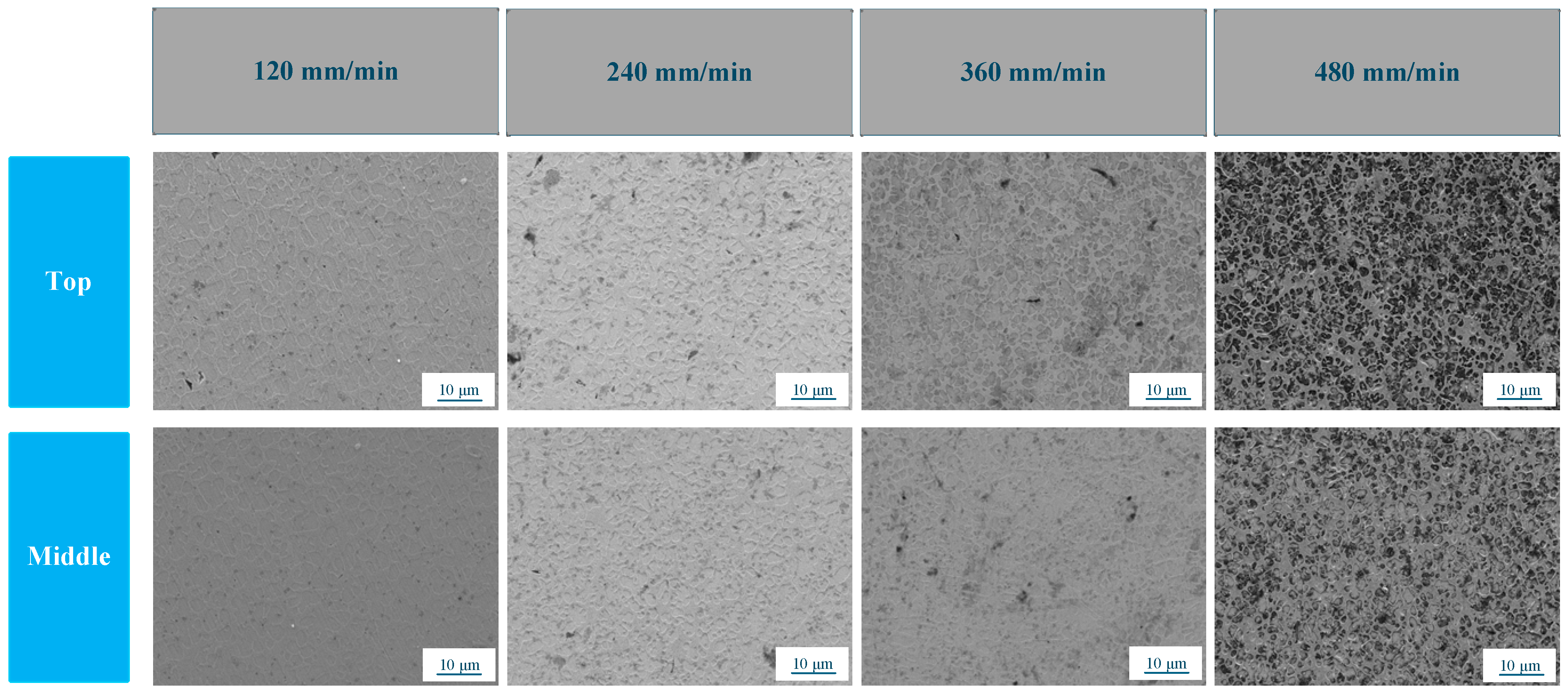

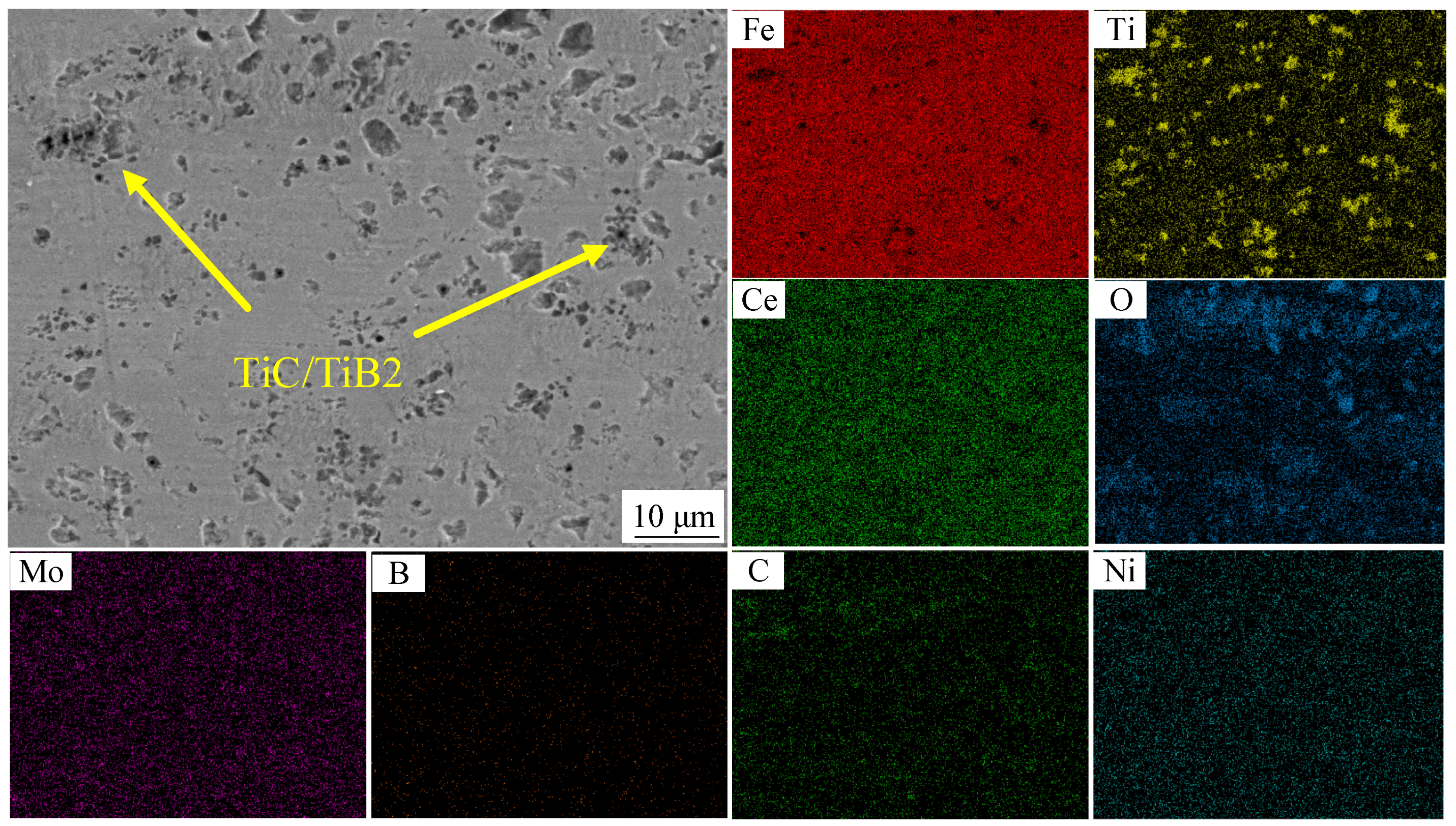

3.2. Microstructure of Coatings

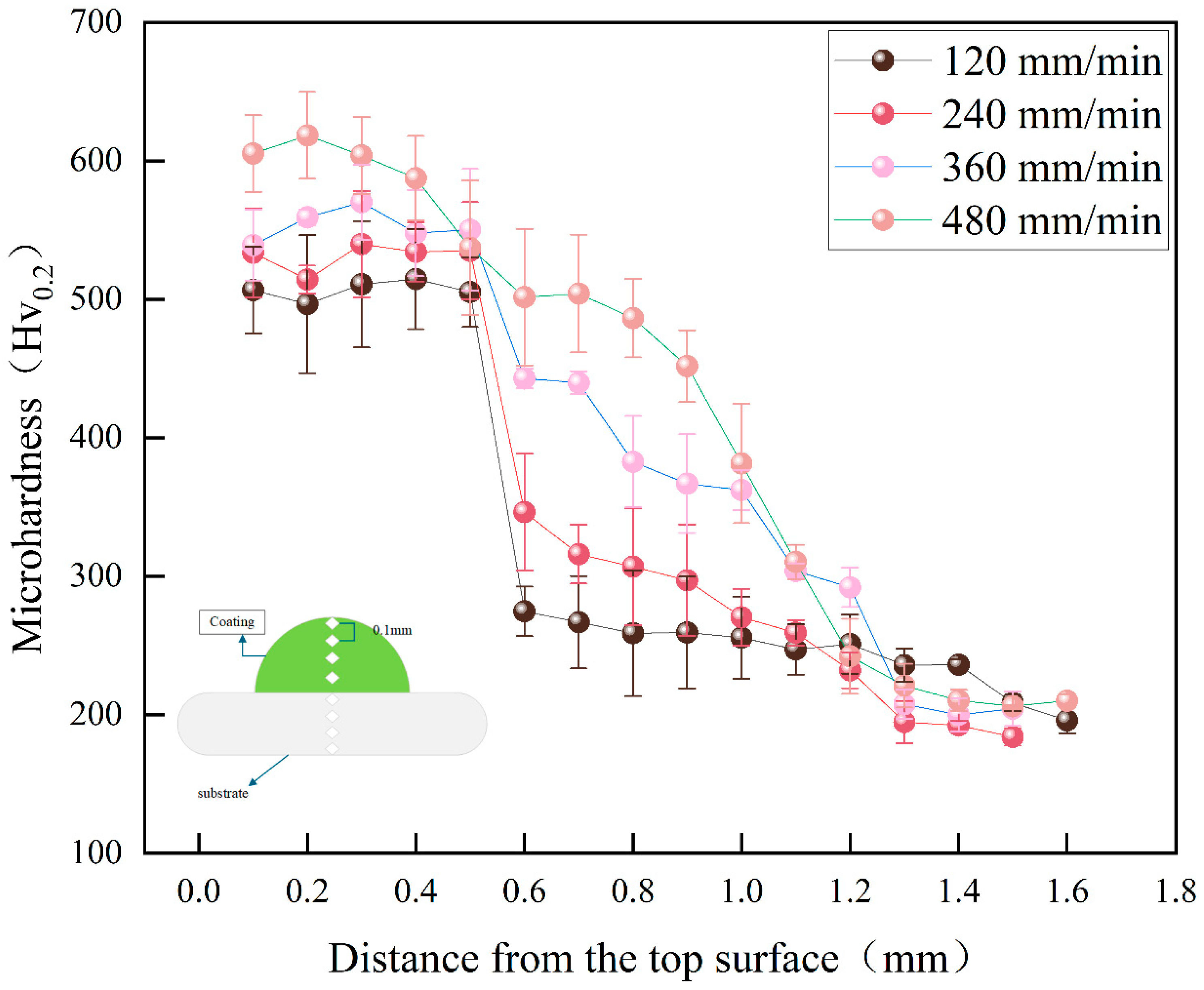

3.3. Vickers Hardness of Coatings

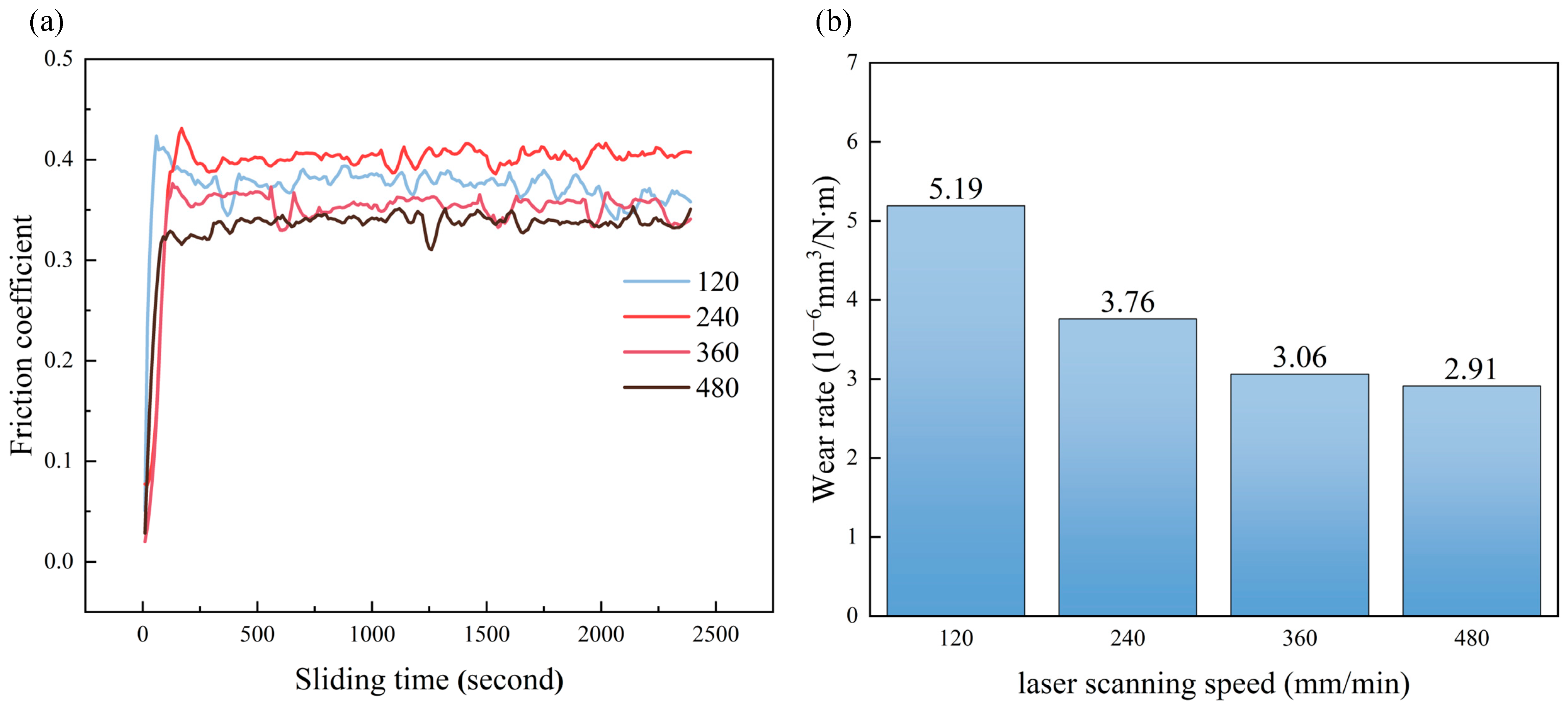

3.4. Tribological Properties of Coatings

4. Conclusions

- (1)

- Increased scanning speed induced a microstructural transition from cellular dendrites to equiaxed grains, concurrently enhancing the distribution homogeneity of the dual-scale ceramic particles. This refinement is attributed to rapid cooling, which promotes fine-grain strengthening alongside dispersion strengthening effects.

- (2)

- At the optimal scanning speed of 480 mm/min, the coating achieved a peak surface hardness of 618.4 HV0.2, representing a 22.0% enhancement over the value of 507 HV0.2 obtained at 120 mm/min. Concurrently, the coefficient of friction (COF) can be expected to decrease with increasing scanning speed, while the wear rate may decline significantly from 5.19 × 10−6 mm3/N·m to 2.91 × 10−6 mm3/N·m—a 58.6% reduction. This substantial decrease in wear rate corresponds to a transition in the dominant wear mechanism: from abrasive ploughing in coarse-grained regions to oxidative wear coupled with an asperity barrier effect within the refined microstructure.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Liang, Q.; Xu, Y.; Xu, B.; Chen, H.; Ma, B. Effect of in-situ synthesis of TiC/TiB2 particles by laser cladding on the microstructure and properties of Co-based coatings. Opt. Laser Technol. 2025, 192, 113620. [Google Scholar] [CrossRef]

- Mojaddarasil, M.; Tavakoli, M.R. Investigation of Polyamide 12 Powder Cooling Process Under Natural Convection via Porous Medium, Non-Porous Medium, and Experimental Approaches. J. Mater. Eng. Perform. 2025, 34, 9352–9373. [Google Scholar] [CrossRef]

- Mojaddarasil, M.; Kiani, A.; Tavakoli, M.R.; Badrossamay, M. A Parametric Study of Powder Bed Temperature Distribution in Selective Laser Sintering Process. J. Mater. Eng. Perform. 2023, 32, 3348–3367. [Google Scholar] [CrossRef]

- Ding, T.; Li, C.; Jing, W.; Di, X.; Hu, W. Influences of boron on the microstructural characteristics and wear performance of hypereutectic Fe-Cr-C-Mo-xB hardfacing alloy. Surf. Coat. Technol. 2024, 478, 130415. [Google Scholar] [CrossRef]

- Tao, J.; Dong, L.; Wu, Y.; Liu, X.; Xie, J.; Wu, H.; Ran, Q. Fabrication of room temperature self-healing, robust superhydrophobic coatings via spraying dual cross-linking supramolecular silicone polymer/SiO2 composite. Compos. Part B Eng. 2024, 273, 111245. [Google Scholar] [CrossRef]

- Yang, L.; Zhou, Z.; Feng, S.; Wang, J.; Chen, M.; Qiao, Y.; Zhu, S.; Wang, F. Oxidation behavior of NiCrAlY coatings with man-made IDZ fabricated by arc ion plating at 1050 °C. Surf. Coat. Technol. 2024, 478, 130426. [Google Scholar] [CrossRef]

- Narayanan, C.U.; Daniel, A.; Praveenkumar, K.; Manivasagam, G.; Suwas, S.; Prashanth, K.; Anand, P.S.P. Effect of scanning speed on mechanical, corrosion, and fretting-tribocorrosion behavior of austenitic 316L stainless steel produced by laser powder bed fusion process. J. Manuf. Process. 2024, 131, 1582–1593. [Google Scholar] [CrossRef]

- Wang, Z.; Liu, H.; Huang, J.; Zhuo, S.; Wu, Y.; Wang, G.; Zheng, Z.; Qiu, Z.; Zeng, D. Improving wear and corrosion resistance of HVAF sprayed 316L stainless steel coating by adding TiB2 ceramic particles and CeO2. J. Mater. Res. Technol. 2024, 31, 1313–1325. [Google Scholar] [CrossRef]

- Weng, F.; Yu, H.; Chen, C.; Liu, J.; Zhao, L. Microstructures and properties of TiN reinforced Co-based composite coatings modified with Y2O3 by laser cladding on Ti–6Al–4V alloy. J. Alloys Compd. 2015, 650, 178–184. [Google Scholar] [CrossRef]

- Zhang, L.; Zhao, Z.; Bai, P.; Du, W.; Li, Y.; Yang, X.; Wang, Q. Corrigendum to “In-situ synthesis of TiC/graphene/Ti6Al4V composite coating by laser cladding” [Mater. Lett. 270 (2020) 127711]. Mater. Lett. 2020, 271, 127787. [Google Scholar] [CrossRef]

- Dong, H.; Chai, L.; Wang, C.; Liu, H.; Hu, C.; Zhao, X.; Yang, Y.; Zhang, M. TiO2 addition induced grain refinement and hardening of laser-clad FeCrAl coating on T91 steel. Mater. Charact. 2025, 225, 115194. [Google Scholar] [CrossRef]

- Tiwari, V.; Mandal, V.; Sarkar, M.; Kumar, A.; Bhagyaraj, J.; Singh, M.K.; Mukherjee, S.; Mondal, K.; Ramkumar, J.; Jain, J.; et al. Enhanced mechanical properties and microstructure of TiC reinforced Stellite 6 metal matrix composites (MMCs) via laser cladding additive manufacturing. J. Alloys Compd. 2025, 1010, 178001. [Google Scholar] [CrossRef]

- Li, N.; He, D.; Liu, D.; Ma, L.; He, C.; Xu, Y.; Yu, J. In-situ TiB reinforced titanium matrix composite coatings prepared by laser cladding: Effect of TiB2 content on microstructure, hardness and wear properties. J. Alloys Compd. 2025, 1010, 178215. [Google Scholar] [CrossRef]

- Liu, Y.; Chen, H.; Han, R.; Peng, Y.; Wang, K.; Li, X. Investigating the microstructure and mechanical properties of 316L/TiB2 composites fabricated by laser cladding additive manufacturing. J. Mater. Res. Technol. 2024, 29, 28–39. [Google Scholar] [CrossRef]

- Yang, L.; Yu, T.; Li, M.; Zhao, Y.; Sun, J. Microstructure and wear resistance of in-situ synthesized Ti(C, N) ceramic reinforced Fe-based coating by laser cladding. Ceram. Int. 2018, 44, 22538–22548. [Google Scholar] [CrossRef]

- Sun, X.; Li, F.; Li, Y.; Du, J.; Qi, X.; Cui, W.; Niu, J. Enhancing the wear and high-temperature oxidation behavior of NiCrBSi coatings by collaboratively adding WC and Cr3C2. Surf. Coat. Technol. 2023, 473, 129968. [Google Scholar] [CrossRef]

- Zeinali Moghaddam, H.; Sharifitabar, M.; Roudini, G. Microstructure and wear properties of Fe–TiC composite coatings produced by submerged arc cladding process using ferroalloy powder mixtures. Surf. Coat. Technol. 2019, 361, 91–101. [Google Scholar] [CrossRef]

- Lin, Y.; Jiang, C.; Lin, Z.; Chen, Q.; Lei, Y.; Fu, H. Laser in-situ synthesis of high aspect ratio TiB fiber bundle reinforced titanium matrix composite coating. Opt. Laser Technol. 2019, 115, 364–373. [Google Scholar] [CrossRef]

- Lo, K.H.; Cheng, F.T.; Kwok, C.T.; Man, H.C. Improvement of cavitation erosion resistance of AISI 316 stainless steel by laser surface alloying using fine WC powder. Surf. Coat. Technol. 2003, 165, 258–267. [Google Scholar] [CrossRef]

- Zheng, Y.; Lian, G.; Lu, H.; Chen, C.; Huang, X. Defects, organization, and properties of TiB2–TiC Bi-ceramic phase by laser cladding in situ synthesis. Ceram. Int. 2024, 50, 41097–41116. [Google Scholar] [CrossRef]

- Liu, Z.; Wu, S.; Liu, W.; Wu, Y.; Liang, X. Optimization of multiple responses in the laser cladding process parameters. Mater. Manuf. Process. 2024, 39, 2139–2153. [Google Scholar] [CrossRef]

- Chen, C.; Huang, B.; Liu, Z.; Chen, L.; Li, Y.; Zou, D.; Chang, Y.; Cheng, X.; Zhou, R.; Liu, Y. Material extrusion additive manufacturing of WC-9Co cemented carbide. Addit. Manuf. 2024, 86, 104203. [Google Scholar] [CrossRef]

- Dai, X.; Wu, Q.; Li, X.; Wang, X.; Shi, Y.; Zhou, Y.; Wen, S.; Shi, Y. Crack suppression and ductility modification of additive manufactured Ti6Al4V/W heterostructure interface via Nano-TiC reinforcement. Eng. Fail. Anal. 2025, 180, 109852. [Google Scholar] [CrossRef]

- Feng, Z.; Tan, H.; Fang, Y.; Lin, X.; Huang, W. Selective laser melting of TiB2/AlSi10Mg composite: Processability, microstructure and fracture behavior. J. Mater. Process. Technol. 2022, 299, 117386. [Google Scholar] [CrossRef]

- Zheng, Y.; Wang, Y.; Li, B.; Bai, Y.; Xu, H.; Liu, L.; Song, B.; Li, X. High cooling rate solidification: Promoting uniform distribution of nano TiB2-TiC particles and enhancing the high-temperature mechanical properties of Al5Cu alloy. Mater. Charact. 2025, 225, 115182. [Google Scholar] [CrossRef]

- ASTM E407–07; Standard Practice for Microetching Metals and Alloys. ASTM International: West Conshohocken, PA, USA, 2015.

- Bhavan, J.S.; Amer, M.; Unnikrishnan, T.G. In situ X-ray Diffraction investigation of Graphene-Enhanced Sn-Ag solder Alloys: Insights into phase transformations. Mater. Sci. Eng. B 2025, 321, 118492. [Google Scholar] [CrossRef]

- Disha, S.A.; Sahadat Hossain, M.; Habib, M.L.; Ahmed, S. Calculation of crystallite sizes of pure and metals doped hydroxyapatite engaging Scherrer method, Halder-Wagner method, Williamson-Hall model, and size-strain plot. Results Mater. 2024, 21, 100496. [Google Scholar] [CrossRef]

- Zenou, V.Y.; Bakardjieva, S. Microstructural analysis of undoped and moderately Sc-doped TiO2 anatase nanoparticles using Scherrer equation and Debye function analysis. Mater. Charact. 2018, 144, 287–296. [Google Scholar] [CrossRef]

- Ertugrul, O.; Enrici, T.M.; Paydas, H.; Saggionetto, E.; Boschini, F.; Mertens, A. Laser cladding of TiC reinforced 316L stainless steel composites: Feedstock powder preparation and microstructural evaluation. Powder Technol. 2020, 375, 384–396. [Google Scholar] [CrossRef]

- Pamuk, U.; Baydoğan, M.; Nilüfer, B.; Çimenoğlu, H. An energetic approach to abrasive wear of a martensitic stainless steel. Scr. Mater. 2000, 42, 881–885. [Google Scholar] [CrossRef]

- AlMangour, B.; Grzesiak, D.; Yang, J.-M. Rapid fabrication of bulk-form TiB2/316L stainless steel nanocomposites with novel reinforcement architecture and improved performance by selective laser melting. J. Alloys Compd. 2016, 680, 480–493. [Google Scholar] [CrossRef]

- Sinha, S.K.; Reddy, S.U.; Gupta, M. Scratch hardness and mechanical property correlation for Mg/SiC and Mg/SiC/Ti metal–matrix composites. Tribol. Int. 2006, 39, 184–189. [Google Scholar] [CrossRef]

- Xu, X.; van der Zwaag, S.; Xu, W. The scratch and abrasive wear behaviour of a tempered martensitic construction steel and its dual phase variants. Wear 2016, 358–359, 80–88. [Google Scholar] [CrossRef]

- Ralls, A.M.; Leong, K.; Liu, S.; Wang, X.; Jiang, Y.; Menezes, P.L. Unraveling the friction and wear mechanisms of surface nanostructured stainless-steel. Wear 2024, 538–539, 205185. [Google Scholar] [CrossRef]

| Element | C | Si | Mn | Ni | Cr | Cu | Fe |

|---|---|---|---|---|---|---|---|

| Wt. % | 0.42~0.50 | 0.17~0.37 | 0.50~0.80 | ≤0.30 | ≤0.25 | ≤0.25 | balance |

| Materials | Average Particle Size | Purity (%) |

|---|---|---|

| 316L | 48 μm | ≥99.0% |

| TiB2 | 1 μm | ≥99.0% |

| TiC | 50 nm | ≥99.5% |

| Element | Cr | Si | B | C | Fe | Ni |

|---|---|---|---|---|---|---|

| wt. % | 14~17 | 3~4.5 | 2.5~4.5 | 0.6~1.0 | ≤15 | balance |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, D.; Jiang, J.; Liu, Y.; Li, H.; Zhang, Z. Effect of Laser Scanning Speed on Microstructure and Wear Resistance of TiC-TiB2-Reinforced 316L Laser-Clad Coatings. Lubricants 2025, 13, 359. https://doi.org/10.3390/lubricants13080359

Zhang D, Jiang J, Liu Y, Li H, Zhang Z. Effect of Laser Scanning Speed on Microstructure and Wear Resistance of TiC-TiB2-Reinforced 316L Laser-Clad Coatings. Lubricants. 2025; 13(8):359. https://doi.org/10.3390/lubricants13080359

Chicago/Turabian StyleZhang, Dongdong, Jingyu Jiang, Yu Liu, Haozhe Li, and Zhanhui Zhang. 2025. "Effect of Laser Scanning Speed on Microstructure and Wear Resistance of TiC-TiB2-Reinforced 316L Laser-Clad Coatings" Lubricants 13, no. 8: 359. https://doi.org/10.3390/lubricants13080359

APA StyleZhang, D., Jiang, J., Liu, Y., Li, H., & Zhang, Z. (2025). Effect of Laser Scanning Speed on Microstructure and Wear Resistance of TiC-TiB2-Reinforced 316L Laser-Clad Coatings. Lubricants, 13(8), 359. https://doi.org/10.3390/lubricants13080359