Effect of B Element Doping on High-Temperature Tribological Properties of WS2-Based Composite Coatings

Abstract

1. Introduction

2. Materials and Methods

2.1. Fabrication of B/WS2 Composite Coatings

2.2. Microstructure and Property Characterization of B/WS2 Composite Coatings

3. Results

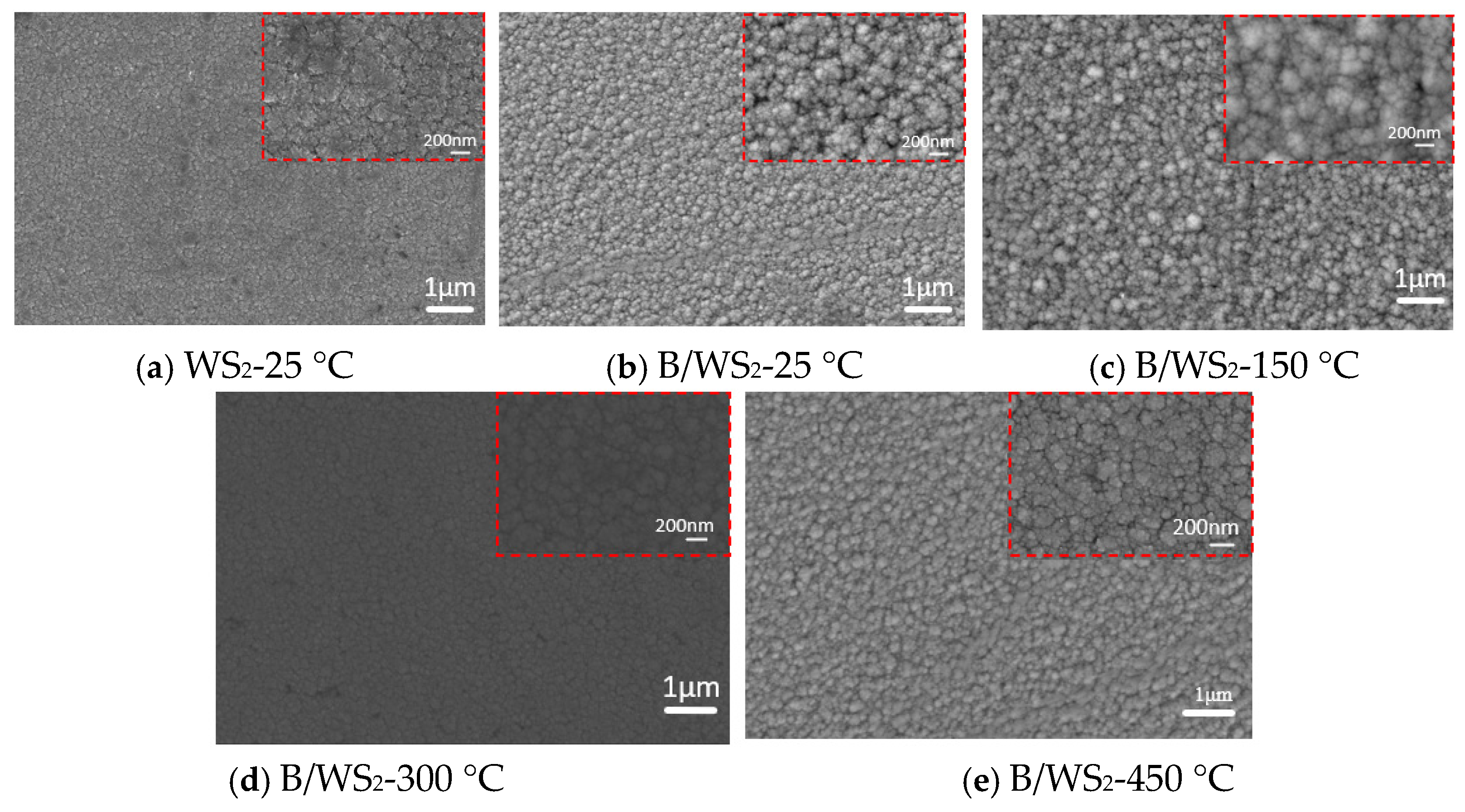

3.1. Morphology Analysis of B/WS2 Composite Coating

3.2. Phase Analysis of B/WS2 Composite Coatings

3.3. Analysis of Mechanical Properties of B/WS2 Composite Coatings

3.4. Analysis of Tribological Properties of B/WS2 Composite Coatings

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Guo, Q.; Liu, H.; Sun, C.; Cao, Y.; Lu, X.; Du, Y.; Ru, X.; Xu, H.; Song, K.; Fu, P.; et al. Dual-gradient structure enhances wear resistance of aero-engine bearing steel by suppressing strain localization. Acta Mater. 2025, 289, 120919. [Google Scholar] [CrossRef]

- Song, F.; Pu, J. Research Status of Low-friction Coatings in Wide Temperature Range. China Surf. Eng. 2022, 35, 1–15. [Google Scholar]

- Fan, X.; Shi, Y.; Cui, M.; Ren, S.; Wang, H.; Pu, J. MoS2/WS2 nanosheet-based composite films irradiated by atomic oxygen: Implications for lubrication in space. ACS Appl. Nano Mater. 2021, 4, 10307–10320. [Google Scholar] [CrossRef]

- Li, X.; Deng, J.; Yue, H.; Ge, D.; Zou, X. Wear performance of electrohydrodynamically atomized WS2 coatings deposited on biomimetic shark-skin textured surfaces. Tribol. Int. 2019, 134, 240–251. [Google Scholar] [CrossRef]

- Li, Z.; Wang, D.; Ye, Q.; He, J.; Sun, J.; Weng, L.; Hu, M.; Gao, X. The effect of oxygen introduced by WO3 on the structure and tribological performance of WSO sputtered films. Tribol. Int. 2024, 193, 109408. [Google Scholar] [CrossRef]

- Babuska, T.F.; Curry, J.F.; Thorpe, R.; Cjowdhury, M.; Strandwitz, N.C.; Krick, B.A. High-sensitivity low-energy ion spectroscopy with sub-nanometer depth resolution reveals oxidation resistance of MoS2 increases with film density and shear-induced nanostructural modifications of the surface. ACS Appl. Nano Mater. 2023, 6, 1153–1160. [Google Scholar] [CrossRef]

- Feng, X.; Zhou, H.; Zheng, Y.; Zhang, K.; Zhang, Y. Tribological behavior and wear mechanism of Ti/MoS2 films deposited on plasma nitrided CF170 steel sliding against different mating materials. Vacuum 2021, 194, 110623. [Google Scholar] [CrossRef]

- Yu, C.; Xie, L.; Wang, Q.; Niu, Y.; Chen, M.; Wang, F. Investigation of the Synergistic Effect of Cr and CeO2 on the Mechanical, Oxidation, and Tribological Properties of Ni-Based Self-lubricating Composites. Metall. Mater. Trans. A 2024, 55, 2773–2789. [Google Scholar] [CrossRef]

- Liu, J.; Yan, Z.; Hao, J.; Liu, W. The influence of proton radiation on the friction and wear of Ti: WS2/P201 composite lubricating materials for space application. Wear 2024, 538, 205190. [Google Scholar] [CrossRef]

- Kaushik, A.; Bisht, P.; Senapati, S.; Singh, J.P. Ag nanoparticle functionalized vertical WS2 nanoflakes as SERS substrate for chemical sensing. Surf. Interfaces 2024, 52, 104951. [Google Scholar] [CrossRef]

- Romanov, R.I.; Fominskii, D.V.; Kas’yanenko, V.A.; Gritskevich, M.D.; Fominskii, V.Y. Effect of Interface Ni and Ti Films on Antifriction Properties of Nanolayer Thin-Film WS2/g-C Coatings. Phys. At. Nucl. 2023, 85, 1816–1820. [Google Scholar] [CrossRef]

- Yang, J.; Wang, D.; Fu, Y.; Wang, Q.; Hu, M.; Jiang, D.; Gao, X.; Sun, J.; Weng, L. Improving the tribological and anti-corrosion property of the WS2 film through Ta doping. Vacuum 2021, 192, 110485. [Google Scholar] [CrossRef]

- Zhou, X.; Yuan, L.; Yue, Q.; Dan, Z.; Li, H. Structural regulation of WS2/XSe (X= Al, Ga, In) heterostructure from first-principles calculations for bandstructure engineering. Mater. Sci. Semicond. Process. 2025, 189, 109305. [Google Scholar] [CrossRef]

- Cao, H.; De Hosson, J.T.M.; Pei, Y. Effect of carbon concentration and argon flow rate on the microstructure and triboperformance of magnetron sputtered WS2/aC coatings. Surf. Coat. Technol. 2017, 332, 142–152. [Google Scholar] [CrossRef]

- Baglio, J.; Kamieniecki, E.; DeCola, N.; Struck, C.; Marzik, J.; Dwight, K.; Wold, A. Growth and characterization of n-WS2 and niobium-doped p-WS2 single crystals. J. Solid State Chem. 1983, 49, 166–179. [Google Scholar] [CrossRef]

- Cai, H.; Xue, Y.; Ye, J.; Wang, J.; Pang, B.; Li, H. Effect of Sputtering Power on High Temperature Tribological Behavior of La-Ti/WS2 Composite Films. RARE Met. Mater. Eng. 2023, 52, 1201–1209. [Google Scholar]

- Tian, C.; Cai, H.; Xue, Y. Effect of Working Pressure on Tribological Properties of Ce-Ti/MoS2 Coatings Using Magnetron Sputter. Coatings 2022, 12, 1576. [Google Scholar] [CrossRef]

- Xu, S.; Hu, M.; Sun, J.; Weng, L.; Liu, W.; Gao, X. A simple strategy to tailor the microstructure and wear-resistance of sputtered WS2 films. Mater. Lett. 2018, 216, 179–181. [Google Scholar] [CrossRef]

- Xu, S.; Gao, X.; Hu, M.; Wang, D.; Jiang, D.; Sun, J.; Zhou, F.; Weng, L.; Liu, W. Microstructure evolution and enhanced tribological properties of Cu-doped WS2 films. Tribol. Lett. 2014, 55, 1–13. [Google Scholar] [CrossRef]

- Xu, S.; Gao, X.; Hu, M.; Sun, J.; Jiang, D.; Wang, D.; Zhou, F.; Weng, L.; Liu, W. Dependence of atomic oxygen resistance and the tribological properties on microstructures of WS2 films. Appl. Surf. Sci. 2014, 298, 36–43. [Google Scholar] [CrossRef]

- Xu, S.; Gao, X.; Hu, M.; Sun, J.; Jiang, D.; Zhou, F.; Liu, W.; Weng, L. Nanostructured WS2–Ni composite films for improved oxidation, resistance and tribological performance. Appl. Surf. Sci. 2014, 288, 15–25. [Google Scholar] [CrossRef]

- Dai, M.; Wei, C.; Zhou, K.; Zhu, M.; Hou, H.; Lin, S.; Tong, X. Properties of W/DLC/W–S–C composite films fabricated by magnetron sputtering. Trans. Nonferrous Met. Soc. China 2015, 25, 3002–3011. [Google Scholar] [CrossRef]

- Hou, G.; Chen, J.; Chen, W.; Chen, J.; Cheng, J.; Zhu, S.; Yang, J. Wear compatibility of super-hard WB4-B tribo-pair materials in moist environments. Tribol. Int. 2025, 204, 110485. [Google Scholar] [CrossRef]

- Hou, G.; Zhu, S.; Tan, H.; Chen, W.; Chen, J.; Sun, Q.; Chen, J.; Cheng, J.; Li, P.; Yi, W.; et al. Near-zero-wear with super-hard WB4 and a self-repairing tribo-chemical layer. Commun. Mater. 2024, 5, 222. [Google Scholar] [CrossRef]

- Yue, X.; Chen, J.; Han, J.; Shan, Y.; Shen, S.; Wu, W.; Liu, B.; Li, L.; Chen, Y.; Zhang, R.; et al. Monitoring and engineering interface coupling between monolayer WS2 and substrate through controllably introducing interfacial strain. Sci. China Mater. 2024, 67, 3012–3020. [Google Scholar] [CrossRef]

- Zhen, Y.; Liu, J.; Shi, X.; Wang, C.; Lu, X.; Hao, J. Tribological properties and transfer behaviors of WS2-Ag nanocomposite films with structure evolution for aerospace application. Appl. Surf. Sci. 2024, 674, 160928. [Google Scholar] [CrossRef]

- Sara, R.; Zhang, C.; Harimkar, S.; Boesl, B.; Agarwal, A. Effect of WS2 addition on tribological behavior of aluminum at room and elevated temperatures. Tribol. Lett. 2017, 65, 76. [Google Scholar]

- Lulu, P.; Kang, B.; Cai, H.; Xue, Y. Excellent Tribological Properties of WS2 Films in Air by Doping Copper. Coatings 2025, 15, 173. [Google Scholar] [CrossRef]

- Cai, H.; Xue, Y.; Pang, B.; Wang, J.; Ye, J. Effect of rare earth La on friction and wear resistance of WS2-based composite coating at high temperature. J. Mater. Sci. 2022, 57, 16875–16891. [Google Scholar] [CrossRef]

- Ning, Z.; Wang, Y.; Chen, T.; Tan, Z.; Wen, M. Research progress of silver films/coatings deposited by magnetron sputtering. Rare Met. Mater. Eng. 2022, 51, 4773–4782. [Google Scholar]

- Gao, X.; Fu, Y.; Jiang, D.; Wang, D.; Yang, J.; Weng, L.; Hu, M.; Sun, J. Structural, mechanical, and tribological properties of WS2-Al nanocomposite film for space application. Tribol. Lett. 2018, 66, 137. [Google Scholar] [CrossRef]

- Hu, M.; Dong, Y.; Wang, Y.; Wang, D.; Jiang, D.; Fu, Y.; Weng, L.; Sun, J.; Gao, X. Low deposition temperature-induced changes of the microstructure and tribological property of WS2 film. Coatings 2019, 9, 227. [Google Scholar] [CrossRef]

- Zhang, K.; Deng, J.; Lei, S.; Yu, X. Effect of micro/nano-textures and burnished MoS2 addition on the tribological properties of PVD TiAlN coatings against AISI 316 stainless steel. Surf. Coat. Technol. 2016, 291, 382–395. [Google Scholar] [CrossRef]

- Long, Y.; Wu, Z.; Zheng, X.; Lin, H.; Zhang, F. Mechanochemical synthesis and annealing of tungsten di-and tetra-boride. J. Am. Ceram. Soc. 2020, 103, 831–838. [Google Scholar] [CrossRef]

- Qin, Z.; Gong, W.; Song, X.; Wang, M.; Wang, H.; Li, Q. Effect of pressure on the structural, electronic and mechanical properties of ultraincompressible W2B. RSC Adv. 2018, 8, 35664–35671. [Google Scholar] [CrossRef]

| Vacuum Degree/Pa | 5 × 10−4 |

| Sputtering power of target B/W | 70 |

| Argon flow rate/Sccm | 50 |

| Sputtering temperature/°C | 300 |

| WS2 target power/W | 200 |

| Deposition time/min | 60 |

| Friction and wear test temperature/°C | 25–450 |

| Sample Number | Coating Name | Target B Power | Test Temperature | Wear rate/mm3·N−1·m−1 | Wear Rate SD Rate | Average Friction Coefficient Curve |

|---|---|---|---|---|---|---|

| 1 | WS2 | 0 W | 25 °C | 3.63 × 10−6 | 1.56266 × 107 | 0.11 |

| 2 | B/WS2 | 70 W | 25 °C | 7.63 × 10−7 | 3.81655 × 108 | 0.071 |

| 3 | B/WS2 | 70 W | 150 °C | 1.89 × 10−7 | 9.46452 × 109 | 0.015 |

| 4 | B/WS2 | 70 W | 300 °C | 2.26 × 10−7 | 1.13475 × 108 | 0.024 |

| 5 | B/WS2 | 70 W | 450 °C | 8.96 × 10−7 | 4.4836 × 108 | 0.053 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, S.; Zhang, X.; Cai, H.; Huang, Z.; Xue, Y.; Pei, L.; Kang, B. Effect of B Element Doping on High-Temperature Tribological Properties of WS2-Based Composite Coatings. Lubricants 2025, 13, 332. https://doi.org/10.3390/lubricants13080332

Zhang S, Zhang X, Cai H, Huang Z, Xue Y, Pei L, Kang B. Effect of B Element Doping on High-Temperature Tribological Properties of WS2-Based Composite Coatings. Lubricants. 2025; 13(8):332. https://doi.org/10.3390/lubricants13080332

Chicago/Turabian StyleZhang, Songmin, Xiaopeng Zhang, Haichao Cai, Zixuan Huang, Yujun Xue, Lulu Pei, and Bowei Kang. 2025. "Effect of B Element Doping on High-Temperature Tribological Properties of WS2-Based Composite Coatings" Lubricants 13, no. 8: 332. https://doi.org/10.3390/lubricants13080332

APA StyleZhang, S., Zhang, X., Cai, H., Huang, Z., Xue, Y., Pei, L., & Kang, B. (2025). Effect of B Element Doping on High-Temperature Tribological Properties of WS2-Based Composite Coatings. Lubricants, 13(8), 332. https://doi.org/10.3390/lubricants13080332