Tribological and Corrosion Effects from Electrodeposited Ni-hBN over SS304 Substrate

Abstract

1. Introduction

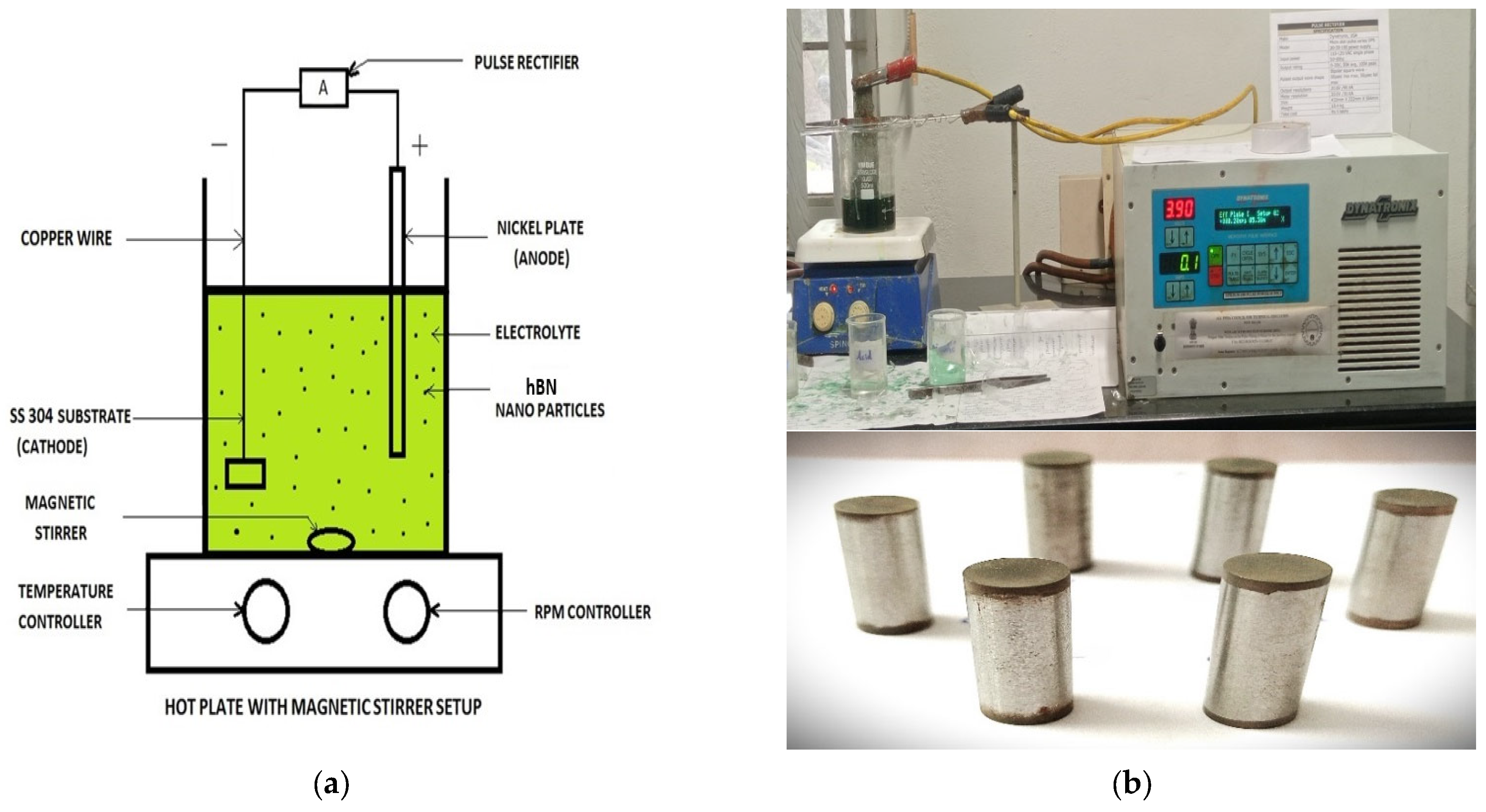

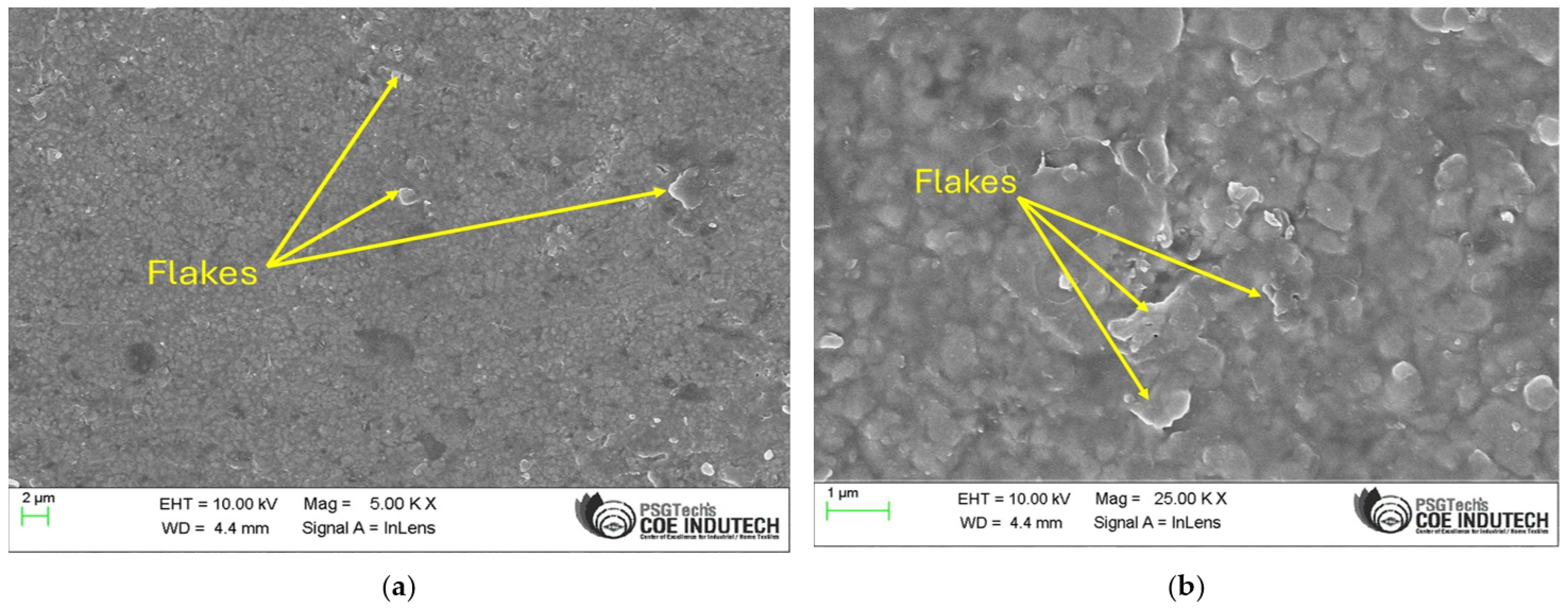

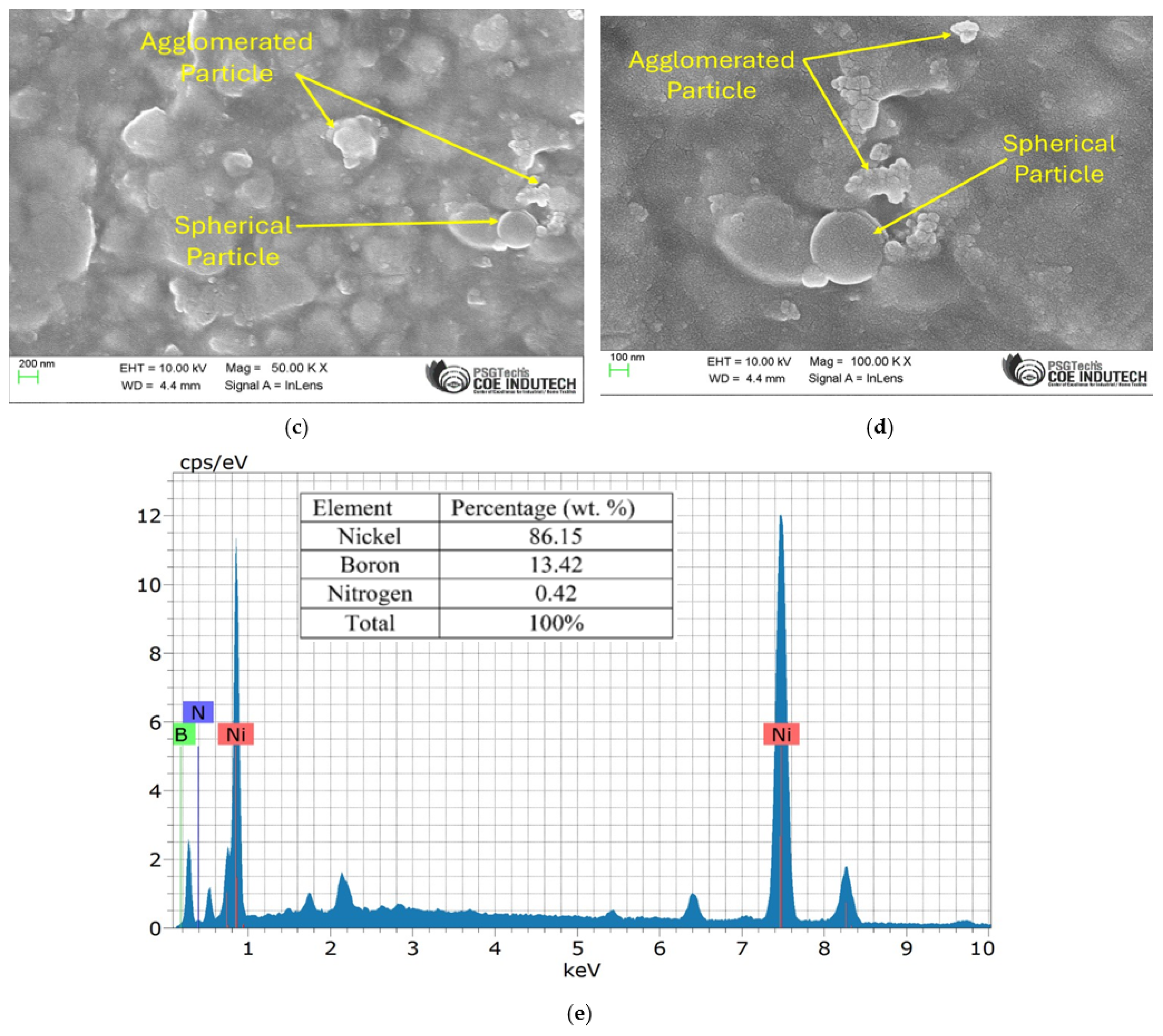

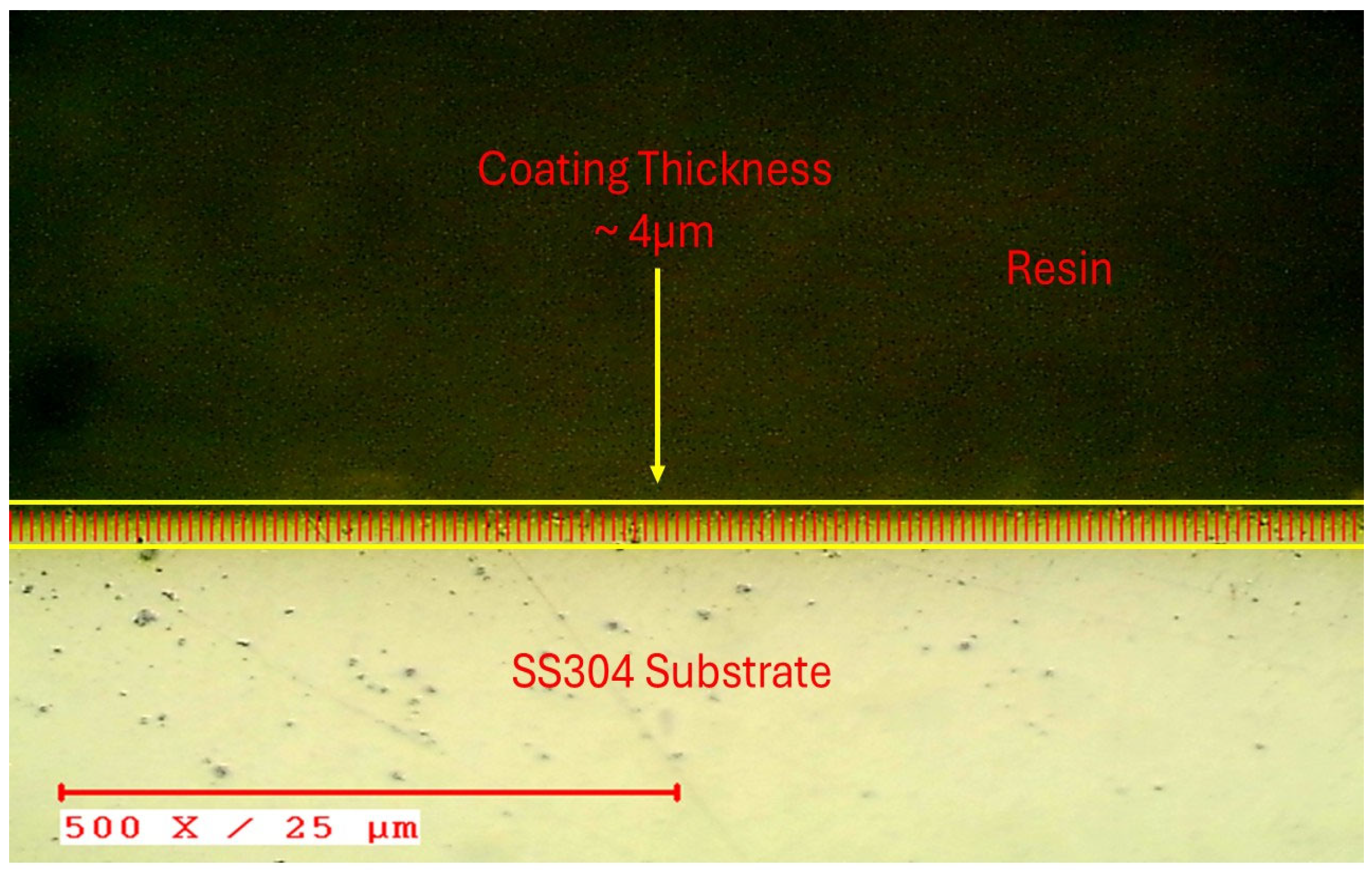

2. Experimental Procedure

2.1. Materials and Preparation of Samples

2.2. Mechanical Properties and Characterizations

3. Results and Discussion

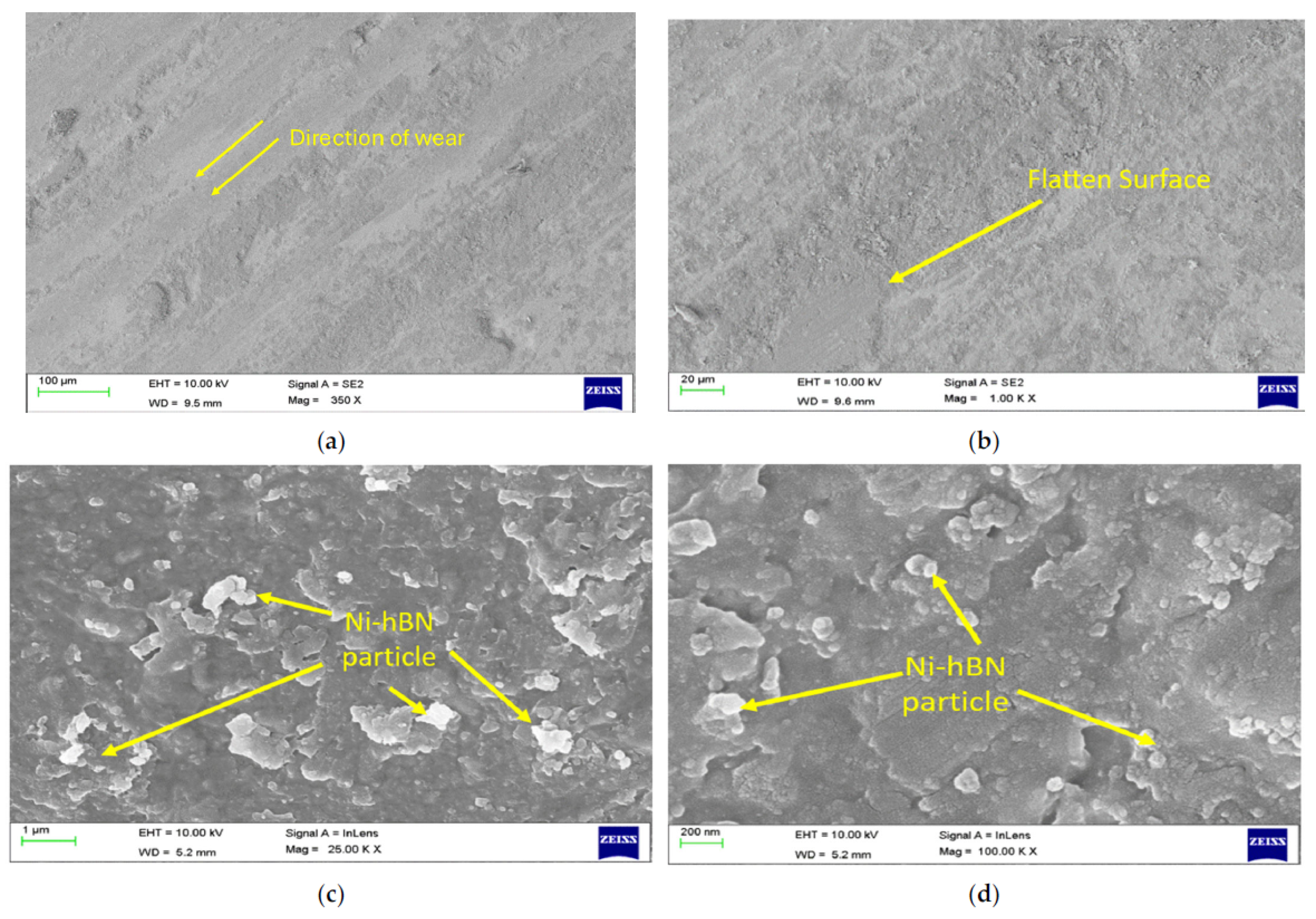

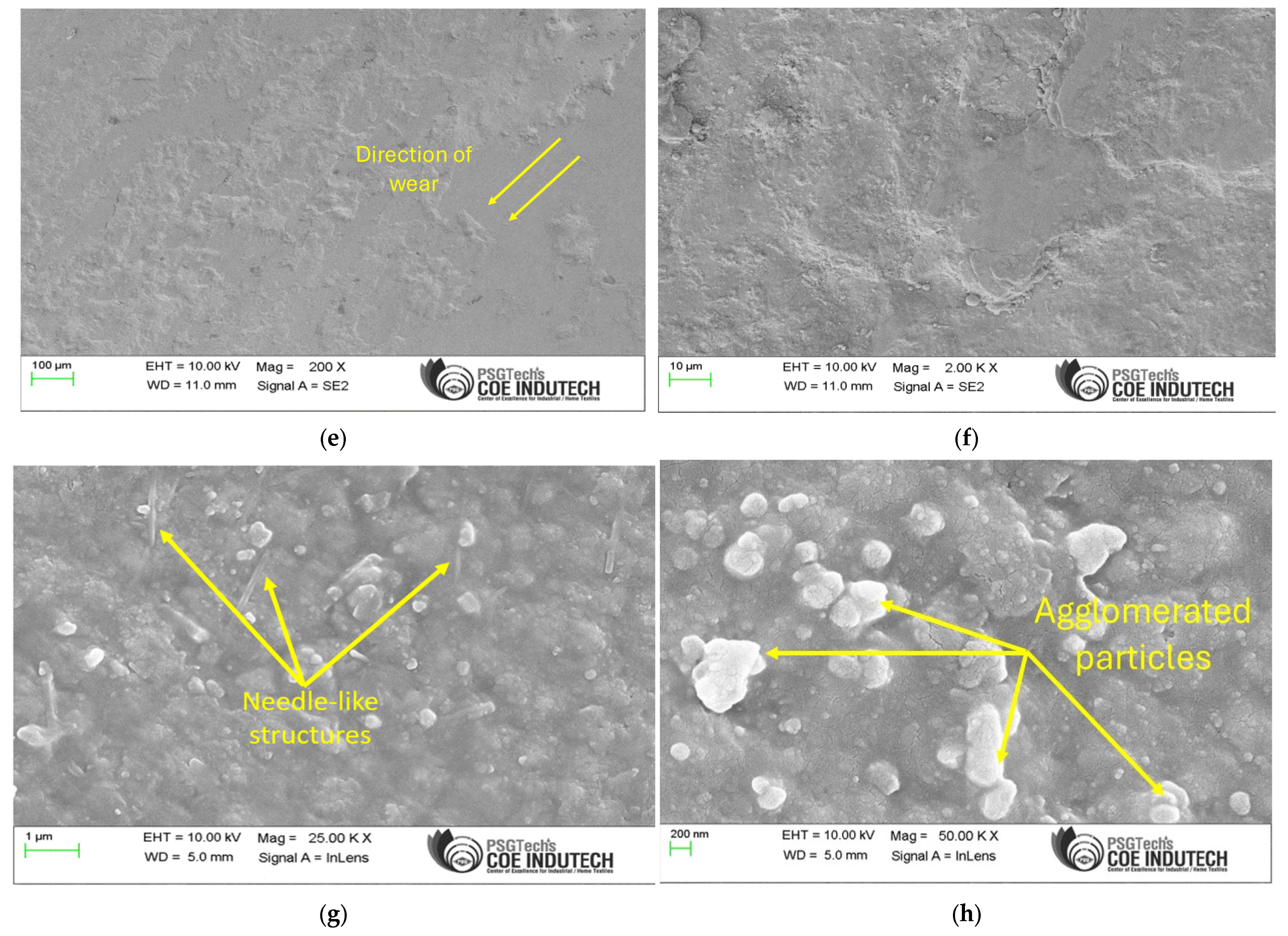

3.1. Microhardness and Wear Characteristics

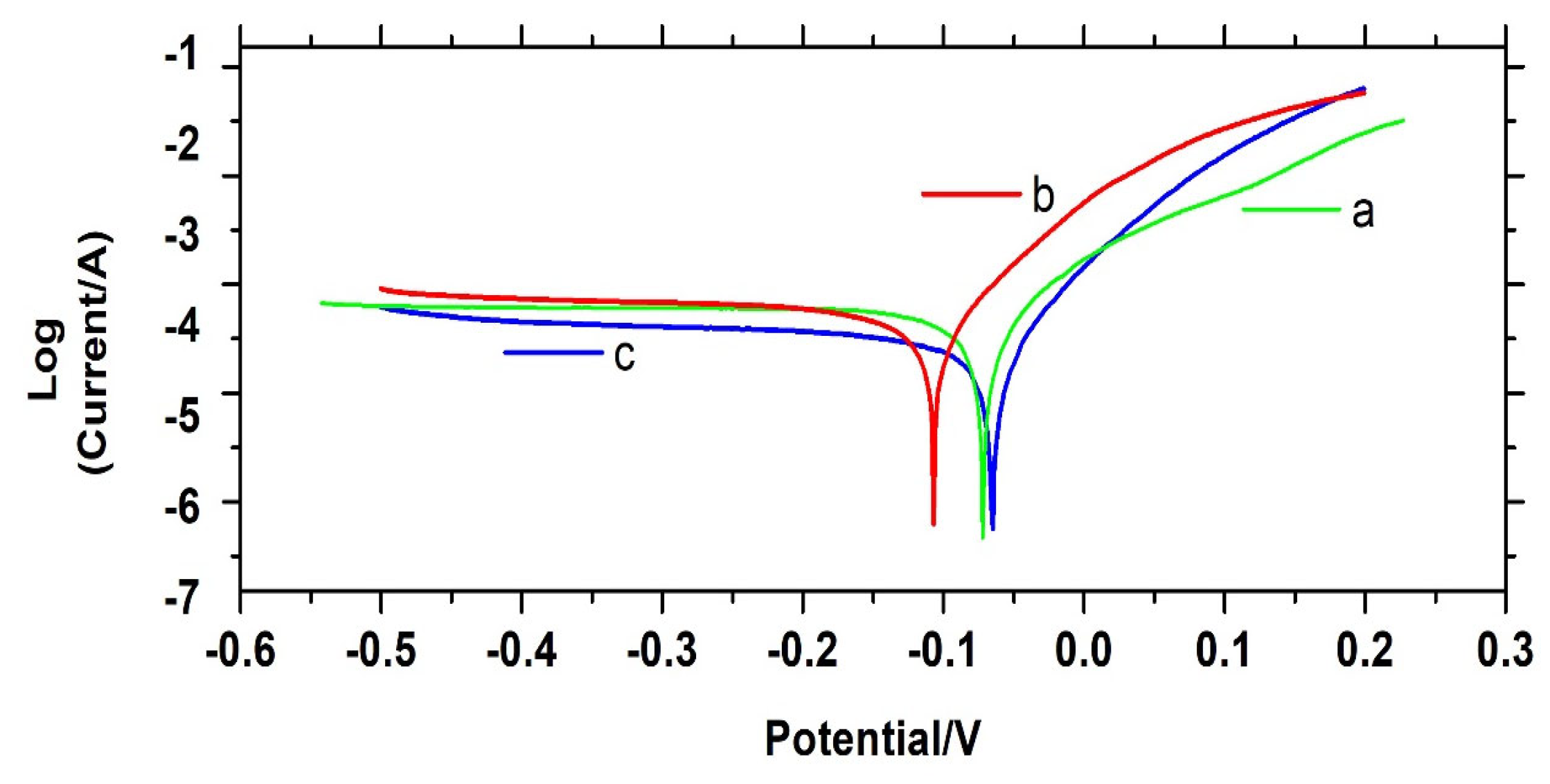

3.2. Corrosion Resistance

4. Conclusions

- The Ni-hBN coating significantly improved the microhardness of the substrate. The as-deposited sample exhibited a 48% increase in hardness compared to the bare SS304 surface, while the heat-treated (HT) sample showed an even greater improvement of 83.8%, attributed to the formation of densely packed grains during thermal treatment followed by quenching.

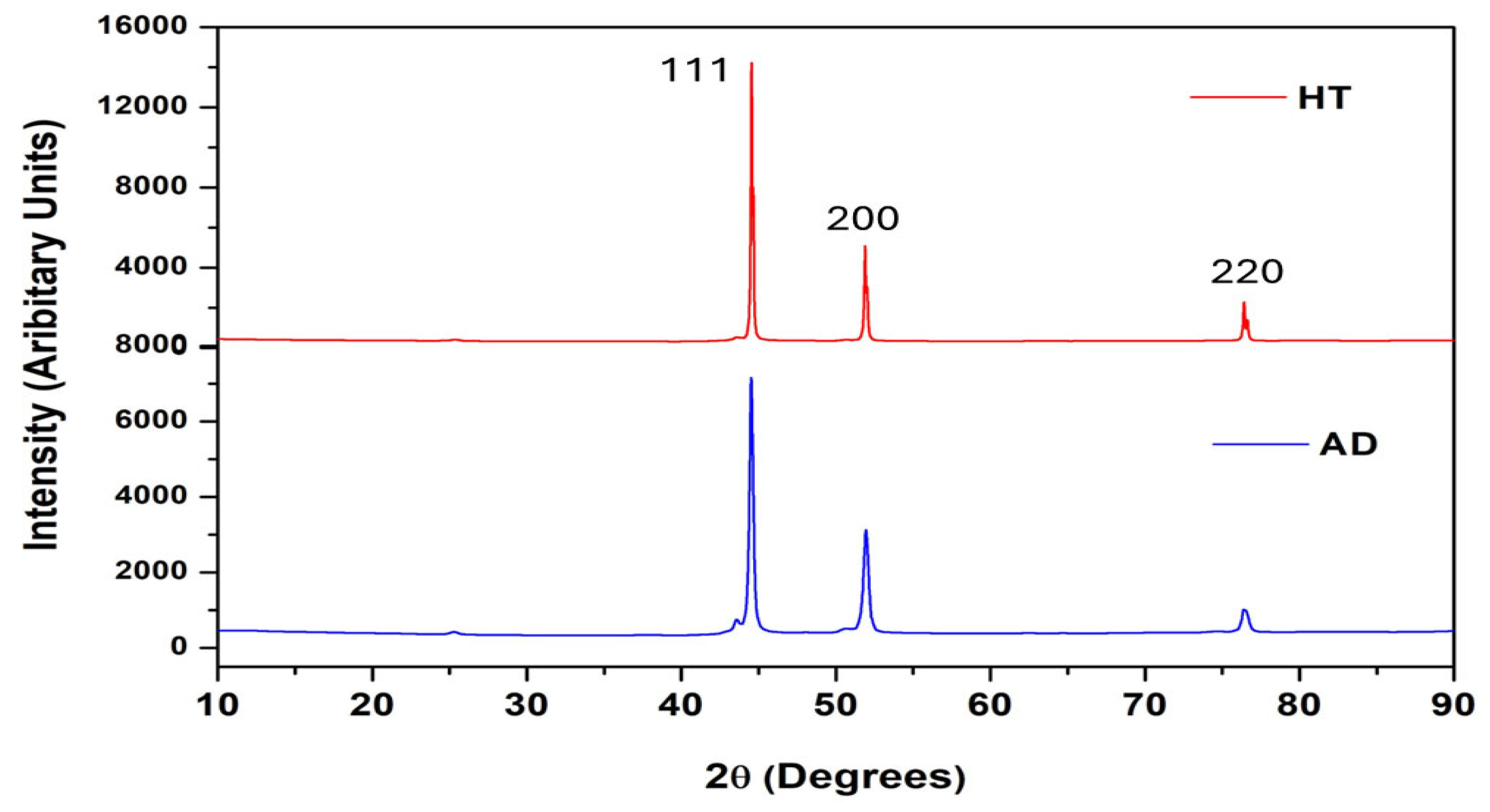

- The as-deposited coating exhibited finer grain structures than the uncoated substrate. After heat treatment, the average grain size increased slightly from 17.86 nm (as-deposited) to 19.6 nm, explained by the expansion–contraction mechanism induced by thermal cycling.

- The coated samples demonstrated marked improvements in both wear resistance and corrosion protection relative to the uncoated substrate. These enhancements were primarily attributed to the synergistic lubricating behavior of hexagonal boron nitride (hBN) within the Ni matrix.

- The corrosion rate of the as-deposited Ni-hBN coating was measured at 0.062 mm/year, a value notably lower than those reported in existing literature. The coating provided an overall corrosion protection efficiency of 96.23%.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| AD | As-deposited |

| Al2O3 | Aluminum dioxide |

| B | Boron |

| Ca/P | Calcium-to-phosphorus ratio |

| Co | Cobalt |

| CoF | Coefficient of friction |

| Cr2O3 | Chromium oxide |

| Cu K-α | Copper K-α x-ray |

| EDX | Energy dispersive X-ray spectrometry |

| FCC | Face-centered cubic |

| Fe2O3 | Ferric oxide |

| FESEM | Field emission scanning electron microscopy |

| GO | Graphene oxide |

| HVAF | High-velocity air fuel |

| hBN | Hexagonal boron nitride |

| HCl | Hydrochloric acid |

| H2SO4 | Dihydrogen sulfate (sulfuric acid) |

| HT | Heat-treated |

| MMC | Metal matrix composite |

| Mo | Molybdenum |

| N | Nitrogen |

| NaCl | Sodium chloride |

| Ni | Nickel |

| P | Phosphorus |

| PRED | Pulse-reverse electrodeposition |

| SCE | Saturated calomel electrode |

| SDS | Sodium dodecyl sulfate |

| SEM | Scanning electron microscopy |

| SiC | Silicon carbide |

| Si3N4 | Silicon nitride |

| SS304 | 304 stainless steel |

| Ti | Titanium |

| TiO2 | Titanium dioxide |

| WC | Tungsten carbide |

| XRD | X-ray diffraction |

| ZrO2 | Zirconium dioxide |

References

- Pradhan, K.K.; Matawale, C.R. Heat treatment analysis of SS304 for gas turbine application. Mater. Today Proc. 2020, 33, 5734–5739. [Google Scholar] [CrossRef]

- Ouyang, J.H.; Li, Y.F.; Zhang, Y.Z.; Wang, Y.M.; Wang, Y.J. High-temperature solid lubricants and self-lubricating composites: A critical review. Lubricants 2022, 10, 177. [Google Scholar] [CrossRef]

- Gyawali, G.; Adhikari, R.; Kim, H.S.; Cho, H.-B.; Lee, S.W. Effect of h-BN Nanosheets Codeposition on Electrochemical Corrosion Behavior of Electrodeposited Nickel Composite Coatings. ECS Electrochem. Lett. 2012, 2, C7–C10. [Google Scholar] [CrossRef]

- Bouzit, F.Z.; Nemamcha, A.; Moumeni, H.; Rehspringer, J.L. Morphology and Rietveld analysis of nanostructured Co-Ni electrodeposited thin films obtained at different current densities. Surf. Coat. Technol. 2017, 315, 172–180. [Google Scholar] [CrossRef]

- Khorsand, S.; Raeissi, K.; Ashrafizadeh, F.; Arenas, M.A.; Conde, A. Corrosion behaviour of super-hydrophobic electrodeposited nickel–cobalt alloy film. Appl. Surf. Sci. 2016, 364, 349–357. [Google Scholar] [CrossRef]

- Zhang, F.; Yao, Z.; Moliar, O.; Tao, X.; Yang, C. Nanocrystalline Ni coating prepared by a novel electrodeposition. J. Alloys Compd. 2020, 830, 153785. [Google Scholar] [CrossRef]

- Bigos, A.; Janusz-Skuza, M.; Szczerba, M.J.; Kot, M.; Zimowski, S.; Dębski, A.; Beltowska-Lehman, E. The effect of heat treatment on the microstructural changes in electrodeposited Ni-Mo coatings. J. Mater. Process. Technol. 2020, 276, 116397. [Google Scholar] [CrossRef]

- Yin, K.-M. Duplex diffusion layer model for pulse with reverse plating. Surf. Coat. Technol. 1997, 88, 162–164. [Google Scholar] [CrossRef]

- Bucur, A.I.; Linul, E.; Taranu, B.-O. Hydroxyapatite coatings on Ti substrates by simultaneous precipitation and electrodeposition. Appl. Surf. Sci. 2020, 527, 146820. [Google Scholar] [CrossRef]

- Tohidi, P.M.S.; Safavi, M.S.; Etminanfar, M.; Khalil-Allafi, J. Pulsed electrodeposition of compact, corrosion resistant, and bioactive HAp coatings by application of optimized magnetic field. Mater. Chem. Phys. 2020, 254, 123511. [Google Scholar] [CrossRef]

- Gopi, D.; Indira, J.; Kavitha, L. A comparative study on the direct and pulsed current electrodeposition of hydroxyapatite coatings on surgical grade stainless steel. Surf. Coat. Technol. 2012, 206, 2859–2869. [Google Scholar] [CrossRef]

- Drevet, R.; Benhayoune, H.; Wortham, L.; Potiron, S.; Douglade, J.; Laurent-Maquin, D. Effects of pulsed current and H2O2 amount on the composition of electrodeposited calcium phosphate coatings. Mater. Charact. 2010, 61, 786–795. [Google Scholar] [CrossRef]

- Li, J.; Lin, O.; Cheng, C.; Wang, W.; Xu, C.; Ren, L. Fabrication of a Ni/SiC composite coating on steel surface with excellent corrosion inhibition performance. J. Mater. Process. Technol. 2021, 290, 116987. [Google Scholar] [CrossRef]

- Chang, L.M. Diffusion layer model for pulse reverse plating. J. Alloys Compd. 2008, 466, L19–L22. [Google Scholar] [CrossRef]

- Li, J.; An, Z.; Wang, Z.; Toda, M.; Ono, T. Pulse-Reverse Electrodeposition and Micromachining of Graphene–Nickel Composite: An Efficient Strategy toward High-Performance Microsystem Application. ACS Appl. Mater. Interfaces 2016, 8, 3969–3976. [Google Scholar] [CrossRef]

- Cherevko, S.; Kulyk, N.; Chung, C.-H. Pulse-reverse electrodeposition for mesoporous metal films: Combination of hydrogen evolution assisted deposition and electrochemical dealloying. Nanoscale 2012, 4, 568–575. [Google Scholar] [CrossRef]

- Gurrappa, I.; Binder, L. Electrodeposition of nanostructured coatings and their characterization—A review. Sci. Technol. Adv. Mater. 2008, 9, 043001. [Google Scholar] [CrossRef]

- Suresh, V.; Jegan, A. Experimental studies on wear and corrosion resistance of pulse electrodeposited Ni-TiO2 nanocomposite coatings on AISI 304 stainless steel. Mater. Res. Express 2022, 9, 126401. [Google Scholar] [CrossRef]

- Jegan, A.; Venkatesan, R.; Arunachalam, R. Mechanical properties of Ni-nano-Al2O3 composite coatings on AISI 304 stainless steel by pulsed electrodeposition. Sci. Eng. Compos. Mater. 2014, 21, 351–358. [Google Scholar] [CrossRef]

- Jegan, A. Pulse eletrodeposition of Ni/nano-Al2O3 composite coatings on cast iron cylinder liner. Mater. Res. 2018, 21, e20180060. [Google Scholar] [CrossRef]

- Joshua, D.R.; Jegan, A.; Srinivasan, A. Multi Objective Optimization of Pulse Electrodeposition of nano Ni-TiO2 and Ni-Al2O3 Coating on Inconel 617. Int. J. Electrochem. Sci. 2022, 17, 220418. [Google Scholar] [CrossRef]

- Natarajan, P.; Jegan, A.; Ganesh, S.S. Development of numerical model for predicting the characteristics of Ni–SiC nano composite coatings on AISI 1022 substrate. Mater. Res. Express 2019, 6, 085048. [Google Scholar] [CrossRef]

- Chakraborty, S.; Langford, N.; Kohl, Y.; Varsou, D.D.; Stokes, W.; Papaioannou, E.; Wien, S.; Britton, A.; Ibrahim, B.; Afantitis, A.; et al. Are Ni–SiC nanoparticle electroplated coatings a safer alternative to hard chromium? A comprehensive aging, toxicity, and in silico study to assess safety by design. Environ. Sci. Nano 2025, 12, 894–908. [Google Scholar] [CrossRef]

- Zellele, D.M.; Yar-Mukhamedova, G.S.; Rutkowska-Gorczyca, M. A Review on Properties of Electrodeposited Nickel Composite Coatings: Ni-Al2O3, Ni-SiC, Ni-ZrO2, Ni-TiO2 and Ni-WC. Materials 2024, 17, 5715. [Google Scholar] [CrossRef] [PubMed]

- Ganesh, S.S.; Jegan, A. Response surface methodology optimization of pulse electrodeposited Ni-nano SiC coatings on Al 7075 substrate. J. Ceram. Process Res. 2023, 24, 486–494. [Google Scholar]

- Dadvand, M.; Savadogo, O. Effect of hBN on Corrosion and Wear Performances of DC Electrodeposited NiW and NiW–SiC on Brass Substrates. Coatings 2022, 12, 1011. [Google Scholar] [CrossRef]

- Lai, L.; Qian, F.; Bi, Y.; Niu, B.; Yu, G.; Li, Y.; Ding, G. Advancements in the Preparation and Application of Ni-Co System (Alloys, Composites, and Coatings): A Review. Nanomaterials 2025, 15, 312. [Google Scholar] [CrossRef]

- Nemane, V.; Misra, D.; Chatterjee, S. Development and Characterization of Nickel-Based Self-Lubricating Electroless Composite Coatings Involving SiC and hBN. J. Mater. Eng. Perform. 2025. [Google Scholar] [CrossRef]

- Eskandari, M.; Shanaghi, A.; Kamani, M.; Niari, M.A. Effect of nano-metal oxides (ZnO, Al2O3, CuO, and TiO2) on the corrosion behavior of a nano-metal oxide/epoxy coating applied on the copper substrate in the acidic environment. Appl. Nanosci. 2021, 11, 1605–1615. [Google Scholar] [CrossRef]

- Sharma, A.; Singh, A.K. Electroless Ni-P and Ni-P-Al2O3 Nanocomposite Coatings and Their Corrosion and Wear Resistance. J. Mater. Eng. Perform. 2013, 22, 176–183. [Google Scholar] [CrossRef]

- Bisht, A.K.; Vaishya, R.O.; Walia, R.S.; Singh, G. Nitrides ceramic coatings for tribological applications: A journey from binary to high-entropy compositions. Ceram. Int. 2024, 50, 8553–8585. [Google Scholar] [CrossRef]

- Siddaiah, A.; Kumar, P.; Henderson, A.; Misra, M.; Menezes, P.L. Surface energy and tribology of electrodeposited Ni and Ni–graphene coatings on steel. Lubricants 2019, 7, 87. [Google Scholar] [CrossRef]

- Guan, T.; Zhang, N. Recent Advances in Electrodeposition of Nickel-Based Nanocomposites Enhanced with Lubricating Nanoparticles. Nanomanuf. Metrol. 2024, 7, 25. [Google Scholar] [CrossRef] [PubMed]

- Ziyamukhamedova, U.; Wasil, S.; Kumar, S.; Sehgal, R.; Wani, M.F.; Singh, C.S.; Tursunov, N.; Gupta, H.S. Investigating friction and antiwear characteristics of organic and synthetic oils using h-bn nanoparticle additives: A tribological study. Lubricants 2024, 12, 27. [Google Scholar] [CrossRef]

- Zhao, M.; Li, J.; Li, C.; Li, Y.; Zhang, X. Study on Current-Carrying Friction Characteristics and Corrosion Resistance of Carbon Brush/Collector Ring by Copper–Graphene Electrodeposition Process. Lubricants 2025, 13, 162. [Google Scholar] [CrossRef]

- Gao, Q.; Liu, S.; Hou, K.; Li, Z.; Wang, J. Graphene-based nanomaterials as lubricant additives: A review. Lubricants 2022, 10, 273. [Google Scholar] [CrossRef]

- Makhesana, M.A.; Patel, K.M.; Bagga, P.J. Evaluation of surface roughness, tool wear and chip morphology during machining of nickel-based alloy under sustainable hybrid nanofluid-MQL strategy. Lubricants 2022, 10, 315. [Google Scholar] [CrossRef]

- Kumar, J.S.; Jegan, A. Tribological Investigation of Nickel Nanocomposite Coated Piston Rings Reinforced with Multi-Walled Carbon Nanotubes. Int. J. Electrochem. Sci. 2021, 16, 210429. [Google Scholar] [CrossRef]

- Fang, H.; Bai, S.-L.; Wong, C.P. ‘White graphene’—Hexagonal boron nitride based polymeric composites and their application in thermal management. Compos. Commun. 2016, 2, 19–24. [Google Scholar] [CrossRef]

- Zuo, K.; Wang, W.; Deshmukh, A.; Jia, S.; Guo, H.; Xin, R.; Elimelech, M.; Ajayan, P.M.; Lou, J.; Li, O. Multifunctional nanocoated membranes for high-rate electrothermal desalination of hypersaline waters. Nat. Nanotechnol. 2020, 15, 1025–1032. [Google Scholar] [CrossRef]

- Bányai, K.; Czagány, M.; Kovács, S.; Bognár, G. Characterisation of Tribological Properties and Morphologies of Ni-P and Ni-B Coatings. Lubricants 2025, 13, 168. [Google Scholar] [CrossRef]

- Rajagopal, I. Electroless and electrodeposition of nickel boron composites. Bull. Mater. Sci. 1983, 5, 323–331. [Google Scholar] [CrossRef]

- Raghavendra, C.R.; Basavarajappa, S.; Sogalad, I.; Kumar, S. A review on Ni based nano composite coatings. Mater. Today Proc. 2021, 39, 6–16. [Google Scholar] [CrossRef]

- Ahmadkhaniha, D.; Eriksson, F.; Leisner, P.; Zanella, C. Effect of SiC particle size and heat-treatment on microhardness and corrosion resistance of NiP electrodeposited coatings. J. Alloys Compd. 2018, 769, 1080–1087. [Google Scholar] [CrossRef]

- Kiran, K.U.V.; Arora, A.; Sunil, B.R.; Dumpala, R. Effect of heat treatment on the temperature dependent wear characteristics of electroless Ni–P–BN(h) composite coatings. SN Appl. Sci. 2020, 2, 1101. [Google Scholar] [CrossRef]

- Jiang, J.; Chen, H.; Zhu, L.; Qian, W.; Han, S.; Lin, H.; Wu, H. Effect of heat treatment on structures and mechanical properties of electroless Ni–P–GO composite coatings. RSC Adv. 2016, 6, 109001–109008. [Google Scholar] [CrossRef]

- ASTM G99-17; Standard Test Method for Wear Testing with a Pin-On-Disk Apparatus. ASTM: West Conshohocken, PA, USA, 2023. [CrossRef]

- Ünal, E.; Karahan, I.H. Effects of ultrasonic agitation prior to deposition and additives in the bath on electrodeposited Ni-B/hBN composite coatings. J. Alloys Compd. 2018, 763, 329–341. [Google Scholar] [CrossRef]

- ISO 1463:2004; Metallic and Oxide Coatings—Measurement of Coating Thickness—Microscopical Method. International Organization for Standardization: Geneva, Switzerland, 2004.

- ASTM G106-89; Standard Practice for Verification of Algorithms and Equipment for Electrochemical Impedance Measurements. ASTM: West Conshohocken, PA, USA, 2023. [CrossRef]

- Ismail, M.I. Periodic reverse current electroplating and surface finishing. J. Appl. Electrochem. 1979, 9, 407–410. [Google Scholar] [CrossRef]

- Canning, W. The Canning Handbook: Surface Finishing Technology, Integrated Design; Springer: Berlin/Heidelberg, Germany, 1982. [Google Scholar]

- Awasthi, S.; Pandey, C.P.; Balani, K. Synergistic role of carbonaceous reinforcements on multi length scale tribology of electrophoretically deposited nickel-boron nitride coatings. Mater. Res. Bull. 2018, 99, 61–72. [Google Scholar] [CrossRef]

- León, O.A.; Staia, M.H.; Hintermann, H.E. Wear mechanism of Ni–P–BN(h) composite autocatalytic coatings. Surf. Coat. Technol. 2005, 200, 1825–1829. [Google Scholar] [CrossRef]

- Shahri, Z.; Allahkaram, S.R. Effect of particles concentration and current density on the cobalt/hexagonal boron nitride nano-composite coatings properties. Iran. J. Mater. Sci. Eng. 2012, 9, 1–7. [Google Scholar]

- Feng, Q.; Li, T.; Teng, H.; Zhang, X.; Zhang, Y.; Liu, C.; Jin, J. Investigation on the corrosion and oxidation resistance of Ni–Al2O3 nano-composite coatings prepared by sediment co-deposition. Surf. Coat. Technol. 2008, 202, 4137–4144. [Google Scholar] [CrossRef]

- Ali, M.R.; Chowdhury, M.A.; Shahin, M.; Rahman, M.M.; Ali, M.O.; Gafur, M.A. Multi-physical and anti-corrosion properties of graphene-reinforced epoxy nanocomposite coatings for industrial applications. Arab. J. Chem. 2024, 17, 105424. [Google Scholar] [CrossRef]

- Kasturibai, S.; Kalaignan, G.P. Characterizations of electrodeposited Ni–CeO2 nanocomposite coatings. Mater. Chem. Phys. 2014, 147, 1042–1048. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, S.-J.; Shu, X.; Gao, W.; Lu, W.; Yan, B. Preparation and property of sol-enhanced Ni–B–TiO2 nano-composite coatings. J. Alloys Compd. 2014, 617, 472–478. [Google Scholar] [CrossRef]

- Kandeva, M.; Zagorski, M.; Nikolić, R.; Stojanović, B.; But, A.; Botko, F.; Piteľ, J.; Vencl, A. Friction Properties of the Heat-Treated Electroless Ni Coatings Embedded with c-BN Nanoparticles. Coatings 2022, 12, 1008. [Google Scholar] [CrossRef]

- León, O.A.; Staia, M.H.; Hintermann, H.E. Influence of the heat treatment on the tribological behavior of a Ni–P–BN(h) autocatalytic composite coating. Surf. Coat. Technol. 1999, 120–121, 641–645. [Google Scholar] [CrossRef]

- Pompei, E.; Magagnin, L.; Lecis, N.; Cavallotti, P.L. Electrodeposition of nickel–BN composite coatings. Electrochim. Acta 2009, 54, 2571–2574. [Google Scholar] [CrossRef]

- Wang, L.; Gao, Y.; Xue, Q.; Liu, H.; Xu, T. A novel electrodeposited Ni–P gradient deposit for replacement of conventional hard chromium. Surf. Coat. Technol. 2006, 200, 3719–3726. [Google Scholar] [CrossRef]

- Karadag, A.; Duru, E.; Uysal, M.; Akbulut, H.; Coban, A. Tribological performance of Ni-W/PTFE composite coating via pulse electrodeposition. Therm. Sci. 2022, 26, 2885–2893. [Google Scholar] [CrossRef]

- Ganvir, A.; Jahagirdar, A.R.; Mulone, A.; Örnfeldt, L.; Björklund, S.; Klement, U.; Joshi, S. Novel utilization of liquid feedstock in high velocity air fuel (HVAF) spraying to deposit solid lubricant reinforced wear resistant coatings. J. Mater. Process. Technol. 2021, 295, 117203. [Google Scholar] [CrossRef]

- Lu, X.L.; Liu, X.B.; Yu, P.C.; Zhai, Y.J.; Qiao, S.J.; Wang, M.D.; Wang, Y.G.; Chen, Y. Effects of heat treatment on microstructure and mechanical properties of Ni60/h-BN self-lubricating anti-wear composite coatings on 304 stainless steel by laser cladding. Appl. Surf. Sci. 2015, 355, 350–358. [Google Scholar] [CrossRef]

- Velayudham, S.; Natarajan, E.; Markandan, K.; Anbuchezhiyan, G.; Franz, G.; Mohan, D.G. Ni-Graphene Nanocomposite Coated Aluminum LM26 Substrate: Investigation Summary on Microhardness, Wear, and Corrosion Resistance. Arab. J. Sci. Eng. 2025, 1–11. [Google Scholar] [CrossRef]

| Chemicals Used | Operating Condition |

|---|---|

| Nickel sulfate (250 g/L, pH = 4 ± 0.2) | Mixing speed: 400 rpm |

| Nickel chloride (40 g/L) | Deposition time: 300 s |

| Boric acid (30 g/L) | Frequencies: 10 Hz, 20 Hz, and 30 Hz |

| Sodium Dodecyl Sulfate SDS (0.1 g/L) | Temperature: 55 ± 2 °C [10] |

| Duty cycles: 10%, 20%, and 30% Polarity ratio: 2 |

| Sample | Avg. Cry. Size nm | Microhardness HV | Surface Roughness µm | Avg. CoF | Volume Loss mm3 | Wear Rate mm3/N-m | Corrosion Potential V | Corrosion Current Density A/cm2 | Corrosion Rate mm/yr | Corrosion Protection Efficiency |

|---|---|---|---|---|---|---|---|---|---|---|

| Bare surface [18] | - | 250.0 | 0.48 | 0.845 | 4.13 × 10−6 | 3.311 × 10−5 | 0.166 | 2.19 × 10−4 | 1.675 | - |

| AD | 17.86 | 372.6 ± 5.0 | 0.43 ± 0.08 | 0.487 | 3.34 × 10−7 | 2.980 × 10−6 | −0.050 | 8.42 × 10−6 | 0.062 | 96.23 |

| HT | 19.60 | 459.6 ± 7.2 | 0.47 ± 0.02 | 0.310 | 7.64 × 10−8 | 6.800 × 10−7 | −0.650 | 1.12 × 10−5 | 0.083 | 94.99 |

| Substrate | Coating | AD/HT | Microhardness HV | CoF | Wear Rate mm3/N-m | Corrosion Rate mm/yr | Reference |

|---|---|---|---|---|---|---|---|

| SS 304 | Ni-TiO2 | HT | 446.4 | 0.200 | 3.20 × 10−7 | 0.091 | [18] |

| C45E steel | Ni-B | AD | 429 | 0.896 | n/a | n/a | [41] |

| Nickel | Ni-B | AD | 189 | 0.930 | 0.02 × 10−3 | n/a | [43] |

| AISI 316L | Electroless- Ni-P-BN (h) | AD | 456 | n/a | 1.24 × 10−6 | n/a | [54] |

| SS 304 | Ni-hBN | AD | 372.6 | 0.487 | 2.98 × 10−6 | 0.062 | Present work |

| SS 304 | Ni-hBN | HT @ 400 °C | 459.6 | 0.310 | 6.80 × 10−7 | 0.083 | Present work |

| AISI 316L | Ni-P-BN | HT @ 400 °C | n/a | 0.200 | 4.87 × 10−7 | n/a | [61] |

| Brass | Ni-cBN | AD | 480.0 | 0.580 | n/a | n/a | [62] |

| Steel | Ni-P | HT @ 400 °C | 900.0–1100.0 | ~0.460 | 3.50 × 10−5 | n/a | [63] |

| Steel | Hard chrome coating | AD | 980.0–1050.0 | ~0.560 | 4.20 × 10−5 | n/a | [63] |

| Steel | Ni-W/PTFE | AD | 459.6 | 0.420 | 3.30 × 10−7 | n/a | [64] |

| SSAB Domex 350LA | HVAF spraying-Cr3C2–NiCr -hBN | AD | 997 with 309 µm coating thickness | 0.260 | 1.50 × 10−5 | n/a | [65] |

| SS304 | Laser clad Ni60/h-BN | HT | 765.0 | 0.390 | n/a | n/a | [66] |

| LM26 | Ni-G | AD | 275.2 | 0.370 | n/a | 0.062 | [67] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Velayudham, S.; Natarajan, E.; Markandan, K.; Varadaraju, K.; Mozhuguan Sekar, S.; Franz, G.; Chouhan, A. Tribological and Corrosion Effects from Electrodeposited Ni-hBN over SS304 Substrate. Lubricants 2025, 13, 318. https://doi.org/10.3390/lubricants13070318

Velayudham S, Natarajan E, Markandan K, Varadaraju K, Mozhuguan Sekar S, Franz G, Chouhan A. Tribological and Corrosion Effects from Electrodeposited Ni-hBN over SS304 Substrate. Lubricants. 2025; 13(7):318. https://doi.org/10.3390/lubricants13070318

Chicago/Turabian StyleVelayudham, Suresh, Elango Natarajan, Kalaimani Markandan, Kaviarasan Varadaraju, Santhosh Mozhuguan Sekar, Gérald Franz, and Anil Chouhan. 2025. "Tribological and Corrosion Effects from Electrodeposited Ni-hBN over SS304 Substrate" Lubricants 13, no. 7: 318. https://doi.org/10.3390/lubricants13070318

APA StyleVelayudham, S., Natarajan, E., Markandan, K., Varadaraju, K., Mozhuguan Sekar, S., Franz, G., & Chouhan, A. (2025). Tribological and Corrosion Effects from Electrodeposited Ni-hBN over SS304 Substrate. Lubricants, 13(7), 318. https://doi.org/10.3390/lubricants13070318