Abstract

Skin-pass cold rolling is a crucial step in sheet metal production, modifying the sheet surface topography, ensuring thickness uniformity, and enhancing tribological performance. A key factor in this process is the surface texturing of work rolls, which, when transferred to the rolled sheet, directly affects lubrication distribution and formability in subsequent stamping operations. Properly textured sheets promote lubricant retention, reducing friction and wear, while roll wear can compromise texture transfer, leading to defects in the final product. This review presents a holistic view of surface texturing from the roll topography to the final product. First, it explores different texturing methods for work rolls, analyzing their efficiency, durability, and impact on texture transfer. Then, alternative texturing techniques and coatings are discussed as strategies to mitigate roll wear. By assessing the relationship between roll texturing and sheet drawability, this study provides insights to improve industrial processes, enhance product quality, and promote more sustainable manufacturing solutions.

1. Introduction

Skin-pass cold rolling applies a slight thickness reduction of about 1% to the cold-rolled sheet, commonly using a large-diameter mill (duo configuration) in a single pass [1]. This process refines the surface, making it smoother and more reflective, ensures uniform thickness, and increases surface hardness. Moreover, it minimizes yield point elongation (Lüders bands), which is crucial for preventing wrinkles in the next forming stage, such as deep drawing [2,3,4]. The process is usually performed under dry conditions, which leads to higher friction between the roll and the sheet compared to lubricated rolling [5].

Surface topography of the rolled sheet plays a crucial role in subsequent forming operations, affecting the storage, transport, and distribution of the lubricant, as well as contributing to the capture of wear particles. In this context, the sheets can be textured by employing textured rolls in the skin-pass stage. Textured sheets are expected to demonstrate superior tribological performance when they are further processed. Therefore, sheet surface texturing during the skin-pass rolling is a strategy to optimize tribological performance in processes such as metal sheet stamping [6]. To mitigate roll wear and ensure the effective transfer of the texture from the roll to the rolled sheet, the surface of the rolls may be coated [7].

In cold rolling processes of metal sheets, tribological phenomena play an important role in the durability of the rolls [8]. For textured sheets to provide the expected benefits, the surface must contain lubrication pockets that are closed by the die during forming, preventing premature lubricant loss. Deterministic textures are advantageous because they prevent the overlap of pockets, maximizing lubricant pressure. However, to enable their industrial application, it is essential to minimize wear of the textured rolls [2]. It is known that electroplated hard chrome coating on rolls with textured surfaces, whether stochastic or deterministic, increases the lifetime and performance of these components [9]. Currently, some studies are proposing new methods and/or coatings for texturing rolling mill rolls. In this context, work roll surfaces textured by the MECT method and coated with NiP have shown promising results [7,10]. These topics will be further discussed in Section 2.

Furthermore, the mechanisms involved in how the texture is transferred from the roll to the sheet during skin-pass rolling are complex and not yet fully understood. This complexity is due to various factors, including the contact between surfaces, which occurs randomly due to the irregular distribution of asperities. The sheet topography undergoes continuous evolution throughout the process, from the bite to the exit. The manufacturing of textured sheets involves multiple interdependent stages, such as roll texturing, the progressive wear of the rolls during use, and texture transfer in the skin pass. Analyzing these processes separately presents significant challenges as well as their interactions [11,12]. These issues are further discussed in Section 3.

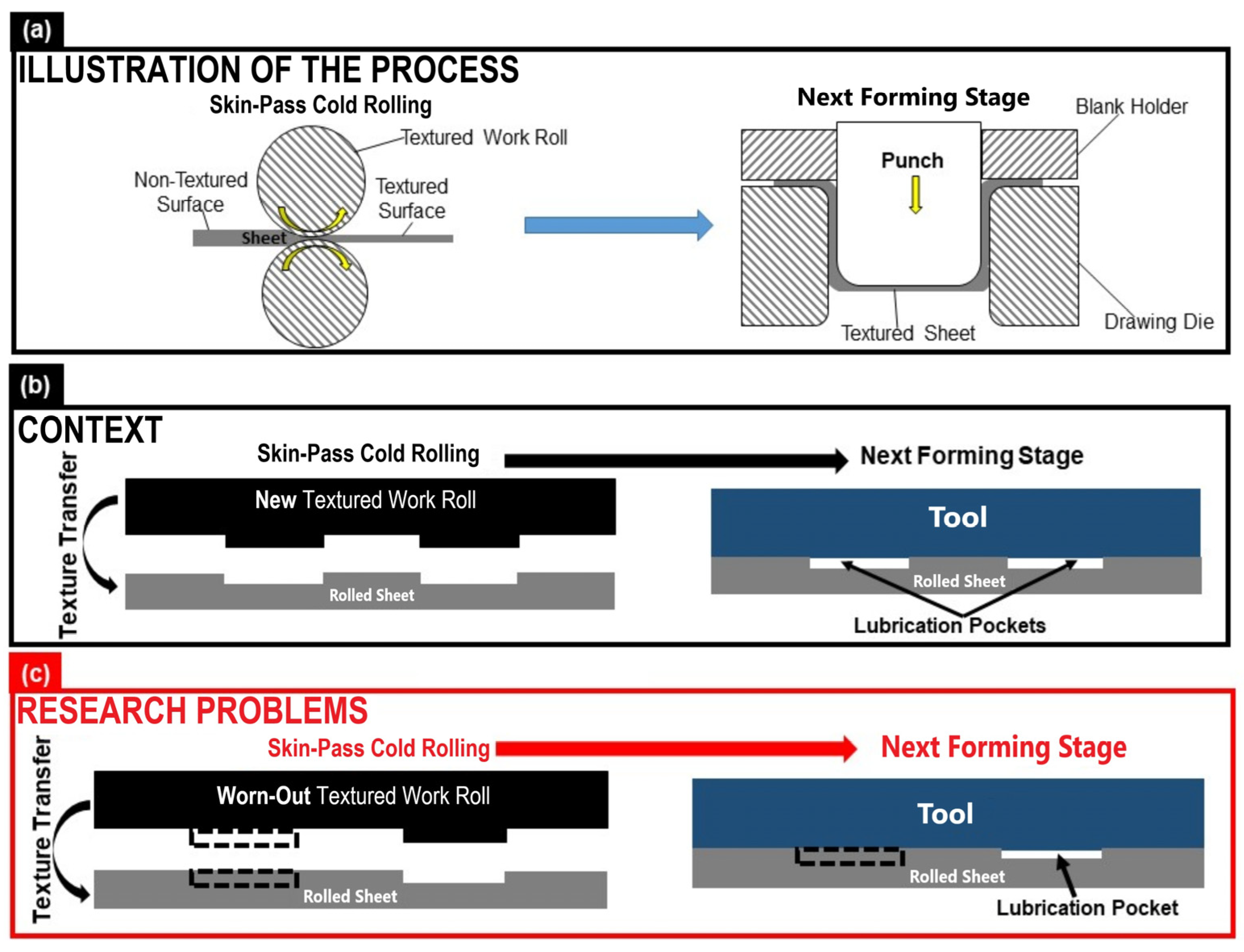

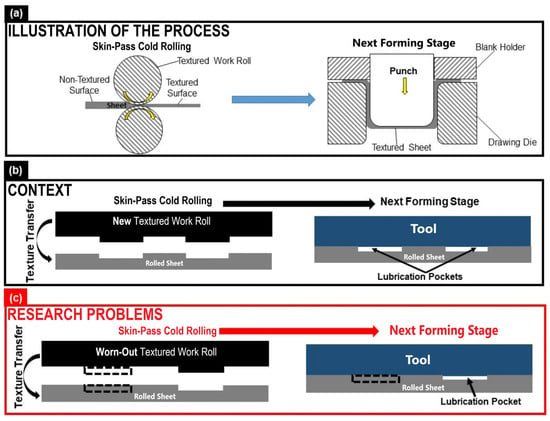

Figure 1 presents an explanatory diagram of the effects of skin-pass cold rolling on a subsequent forming process, such as deep drawing. The illustration covers both the ideal context (for a newly textured roll) and research problems related to the wear of textured rolls. Figure 1a illustrates the skin-pass cold rolling process, where a textured work roll transfers its surface texture to the metal sheet. This texture plays a key role in the next forming stage (deep drawing in this case). Figure 1b shows the ideal context, where the new work roll has a well-defined and homogeneous texture, ensuring efficient texture transfer to the sheet for lubrication pocket formation. This leads to more controlled stamping, reduced friction, and improved surface quality. According to the scope of this review, Figure 1c highlights some research problems. When the work roll is worn out, the texture transferred to the sheet becomes irregular or insufficient, compromising lubrication pocket formation. This can increase friction during stamping, leading to defects such as excessive tool wear, material adhesion, thus resulting in failures. Overall, Figure 1 emphasizes the importance of maintaining the textures on the work rolls to ensure proper stamping performance. Lubrication pockets are crucial for reducing friction and preventing defects in stamped parts. As the roll wears out, challenges arise in industrial production, thus the need to optimize roll durability and develop strategies to maintain effective textures for a longer period.

Figure 1.

Schematic representation of the skin pass cold rolling process and its implications for subsequent forming stages: (a) Illustration of the process, showing texture transfer from the work roll to the sheet and the next forming stage. (b) Context, depicting the texture transfer with a new textured work roll, leading to the formation of lubrication pockets. (c) Research problems, highlighting the effects of a worn-out textured work roll on texture transfer and lubrication conditions. The dashed rectangles indicate areas affected by texture wear. The removal of a textured region from the work roll surface reduces the formation of lubrication pockets on the sheet surface.

The transition from conventional texturing methods and coatings to more cost-effective and sustainable alternatives still faces challenges related to the durability and efficiency of these new solutions. In this context, this study aims to synthesize knowledge on surface texturing methods for work rolls in the skin-pass process. Additionally, innovative approaches to mitigate texture wear are discussed, as well as the feasibility of replacing traditional coatings with more eco-friendly and durable alternatives. This review demonstrates how the roll texturing method affects the formation of surface textures on the sheet and, consequently, its drawability. By integrating these aspects, we propose strategic directions to enhance the efficiency and sustainability of industrial processes.

This review is structured as follows: Section 2 presents the main texturing methods used for rolling mill rolls, highlighting their advantages and limitations. Section 3 discusses the texture transfer from the roll to the sheet, analyzing the factors that influence this process. Section 4 examines the impact of surface textures on the drawability of metal sheets. Finally, Section 5 presents surface texturing as a technology that contributes to a more environmentally sustainable future.

2. Surface Texturing of Work Rolls for Skin-Pass Cold Rolling

2.1. Work Roll Texturing Methods

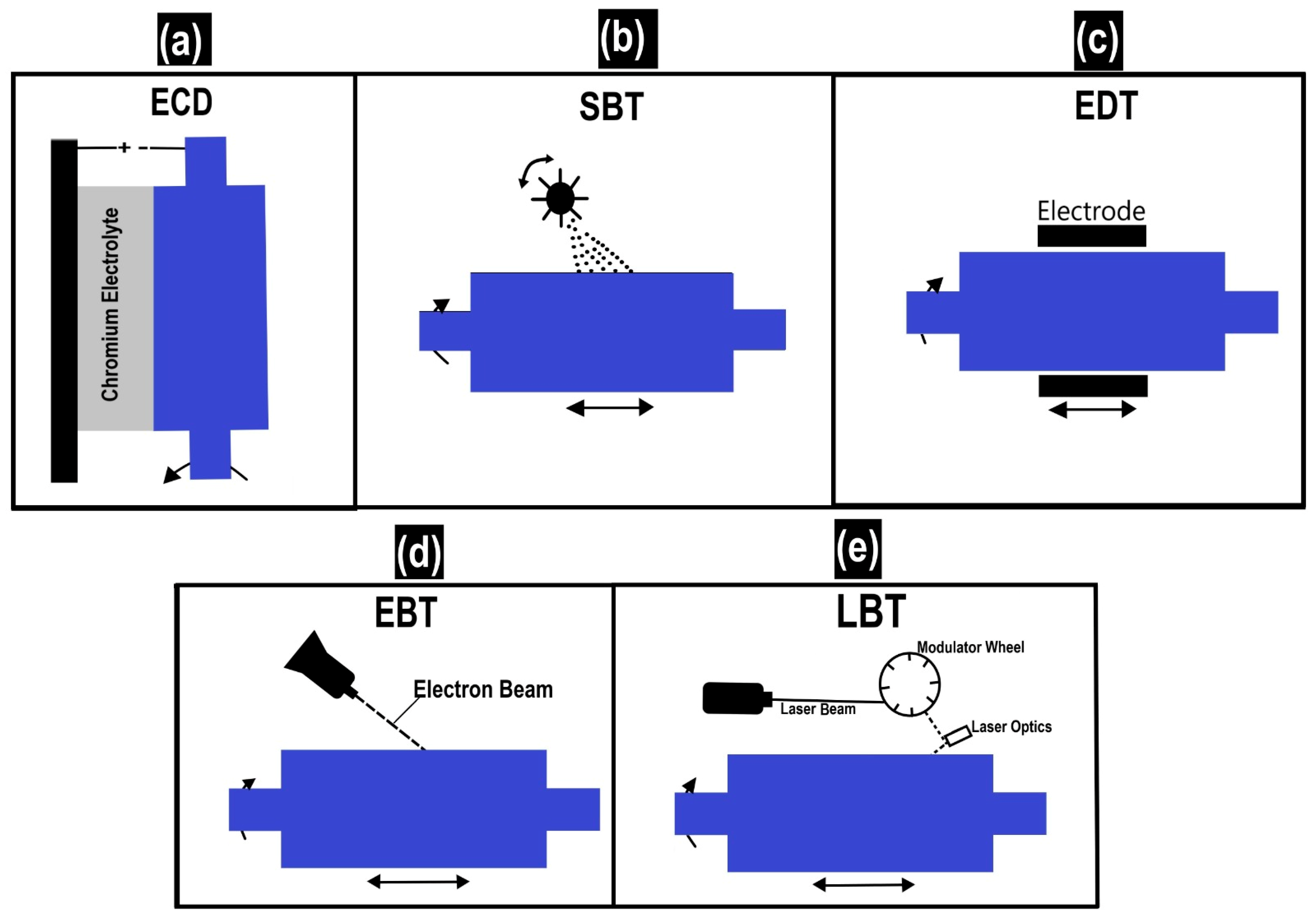

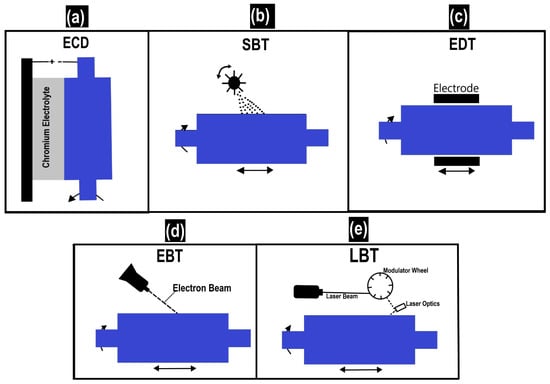

The most common texturing methods for skin-pass cold rolls are as follows: electro-chromium deposition (ECD), shot blasting texturing (SBT), electrical discharge texturing (EDT), electron beam texturing (EBT), and laser beam texturing (LBT) [2,13,14]. Figure 2 shows a schematic overview of the roll texturing techniques used today.

Figure 2.

Schematic overview of traditional roll texturing techniques: (a) in electro-chromium deposition (ECD), the roll is immersed in a chrome-plating electrolyte inside a reactor, forming characteristic half-dome calottes on the surface; (b) in shot blasting texturing (SBT), particles are blasted against the roll surface by the blades of a rotating wheel, producing a stochastic distribution of craters; (c) electrical discharge texturing (EDT) uses the principles of EDM, where material is removed through plasma discharges formed in a small gap between the electrode and the work roll surface, forming a stochastic distribution of valleys and bumps; (d) In electron beam texturing (EBT), a focused electron beam is used to create small dimples on the roll surface; (e) laser beam texturing (LBT) involves localized ablation of the surface using a finely focused laser beam that is chopped by a rotating wheel to generate arrays of dimples.

The electro-chromium deposition (ECD) consists of hard chrome electroplating, which results in hemispherical protuberances randomly distributed on the surface of the work roll (Figure 2a). In this way, when the sheet is rolled, the generated textures on the sheet surface have the aspect of small depressions [15,16]. There are not many experimental studies available in the literature that deal with the ECD method, although some authors [17,18] point out that it has superior performance to other traditional methods in terms of texture durability, probably due to the high hardness of the hard chrome coating.

In shot blasting texturing (SBT), a shot of particles (usually metallic) is blasted against the work roll surface (Figure 2b) to create a stochastic distribution of craters [19]. The process mainly involves random plastic deformation [20]. The SBT method is one of the least controllable processes for surface finishing, which can result in a non-uniform subsequent paint finish. Since its efficiency depends on the relative hardness between the shot and the work roll, the texturing of very hard surfaces can be limited. The main advantages of this method are simplicity and low cost compared to other methods [20,21]. The SBT method has been partially replaced by the EDT method in recent decades [17,22].

Electrical discharge texturing (EDT) is based on the principles of electrical discharge machining (EDM), as shown in Figure 2c. Material removal occurs due to a plasma formed across a small gap between the electrode and the surface to be treated (work roll). The gap is filled with a dielectric fluid, and then a plasma is generated by an electrical discharge. Material ablation creates tiny craters randomly distributed on the work roll surface. The EDT method is widely used, producing sheets with adequate topographies for automotive components when the process parameters are properly adjusted. Among the main advantages of the EDT method are the wide range of possible process parameters and a uniform surface relief [4,20,21,23].

The electron beam texturing (EBT) method basically uses an electron beam to create small dimples on the surface of the work roll (Figure 2d). In EBT, the distribution of texture patterns can be carried out in an organized manner, i.e., periodically structured (deterministic textures). The control of several process parameters enables a variety of texture patterns to be achieved. However, the process is expensive and must be carried out in a vacuum [18,24].

In laser beam texturing (LBT), the surface texture is produced by localized ablation using a finely focused laser beam. It is common to use a rotating wheel to chop the laser beam, while the roll also rotates, as shown in Figure 2e, which simplifies the technique. The texture pattern can be controlled by convenient manipulations of process parameters, e.g., laser beam energy and pulse [25]. Similar to the EBT method, LBT can produce deterministic textures [4]. According to Yuan et al. [26], the LBT technique is highly accurate and can be applied to a variety of materials. The complexity of the equipment and the energy consumption of powerful laser systems must be taken into account when choosing this method [18]. Furthermore, the texture pockets are usually produced in a serial manner, making the time required to texture large areas excessively long [27].

According to Costa and Hutchings [27], depending on the underlying physical principles, texturing methods can be divided as follows: material addition, which occurs when the modification of topography is carried out by adding material to the desired surface, which is the case, for example, of the ECD method; material removal, where the removal of material from the surface produces small areas of recesses, and this category includes the EBT, LBT and EDT methods; material movement, when the redistribution of material occurs from some regions of the surface to others through plastic deformation, and this group includes the SBT method; and self-formation, when the surface contains regions with different hardness, so that the change in surface topography occurs due to the wear of the less hard regions, which become protruding.

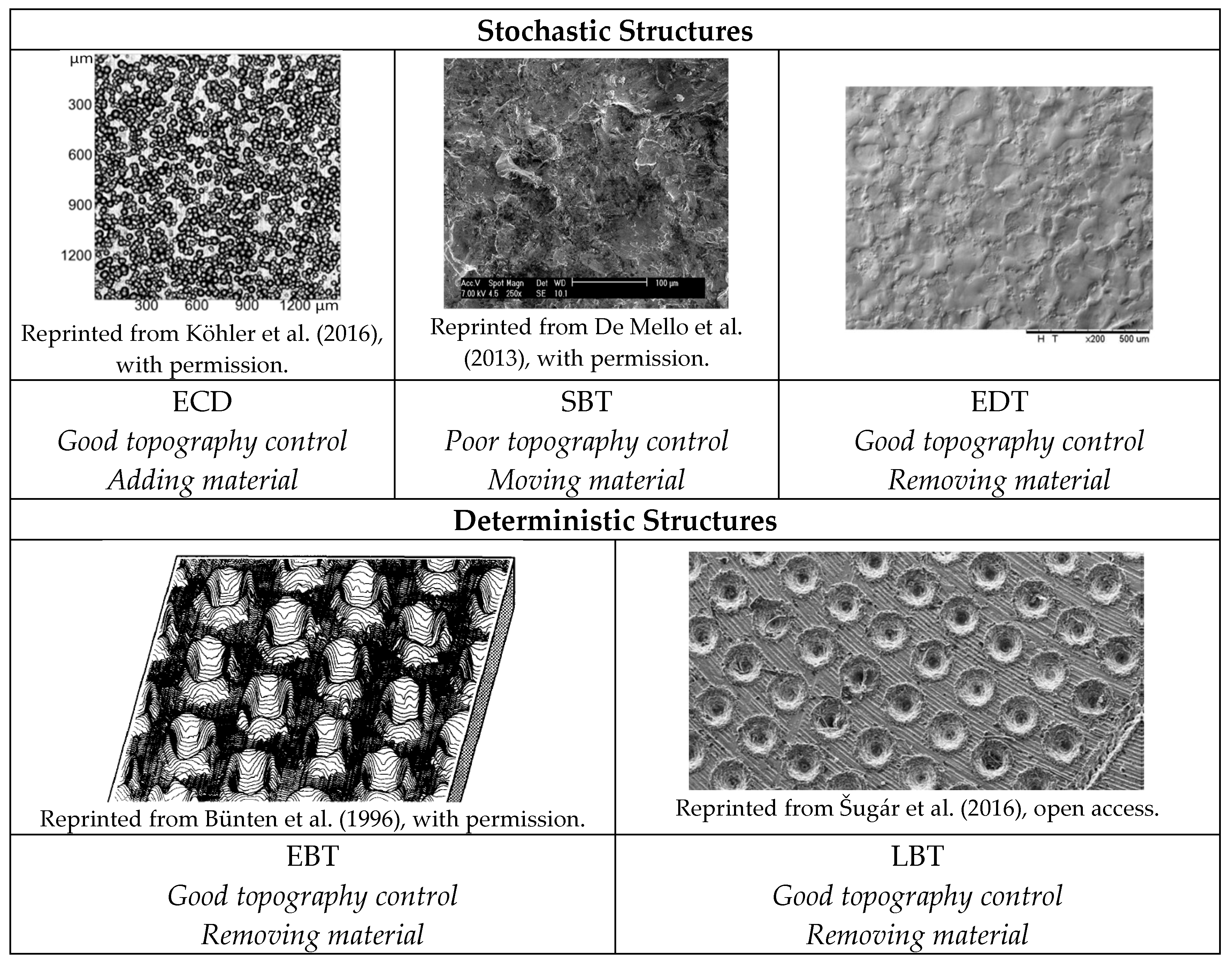

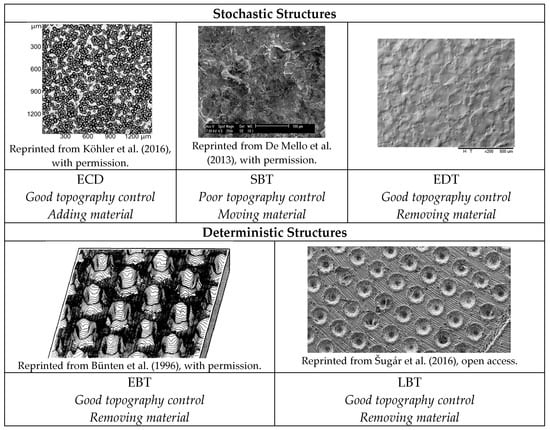

Figure 3 summarizes the surfaces produced by the presented methods. The SBT method leads to a high dispersion of topographic parameters compared to other methods, making it difficult to control the texture of the rolled sheet [17,21]. EBT and LBT enable more control, but the skilled labor required to operate the equipment and the costs of the equipment itself can be limiting factors for their use. EDT can produce textured surfaces with a relatively low dispersion of topographic parameters in comparison with SBT [13,16,21,28].

Figure 3.

Comparison between the traditional texturing methods used on work rolls for skin-pass cold rolling, including typical images of surfaces textured by these methods. The methods were classified according to the type of texture they produce: stochastic and deterministic [16,19,29,30].

The surface of the rolled sheet must exhibit empty pockets for lubricant storage, which can be closed by the die surface in a subsequent forming process, creating closed pockets [31,32]. If this does not occur, the lubricant escapes prematurely without increasing the load capacity. One advantage of using deterministic textures instead of stochastic textures is that it avoids the overlapping of pockets, which would inhibit the effects of increased pressure on closed pockets [2,33]. However, the wear of these textures must be mitigated for their successful application in industrial production [7]. One main reason why rolls with deterministic textures are not widely used in industrial applications is the limited lifetime of the textures. Wear causes a continuous smoothing of the topography of the textured roll, leading to a gradual reduction in the texture transfer to the sheet. Although this is a general problem with all texturing techniques, the case of deterministic structures is often even worse. Subsequently, the use of electroplated hard chrome for texturing to increase the work roll lifetime is one way to reduce this problem, but it is criticized in terms of environmental impact and operators’ health [2,34,35].

In LBT, part of the surface can be melted. Thus, new phases with limited wear resistance can be formed. Kümmel et al. [36] explain that, when nanosecond pulse lasers are used, adjacent protrusions can form because a part of the melted material is pushed by the vaporized material. To eliminate these irregularities, the surface of the material must be polished, or shorter peaks (femtoseconds) must be used. As experimentally verified by Pawelski et al. [14], these protrusions contributed to limited texture transfer to the sheet. They were prematurely worn away in the skin pass, since the protrusions are stress concentrators and have a different microstructure in relation to the unmelted regions.

Among the methods presented so far, the ECD method was more recently developed [16,24,37]. Unlike other methods, in which plastic deformation (SBT) or material removal (EDT, EBT, and LBT) mainly occurs, ECD involves material addition. The protrusions formed on the work roll surface are primarily transferred as circular dimples to the sheets during the finishing pass. However, the application of this method still requires the use of hard chrome [16], which contradicts the demand for more sustainable solutions [38,39].

2.2. New Methods for Work Roll Texturing

So far, we have discussed the texturing methods that are industrially used in cold rolling work rolls during the skin pass. Alternatively, the literature has proposed the use of other texturing methods. Moreover, alternative coating techniques have been evaluated to ensure the durability of textures without the need to use the health-hazardous hard chrome coating.

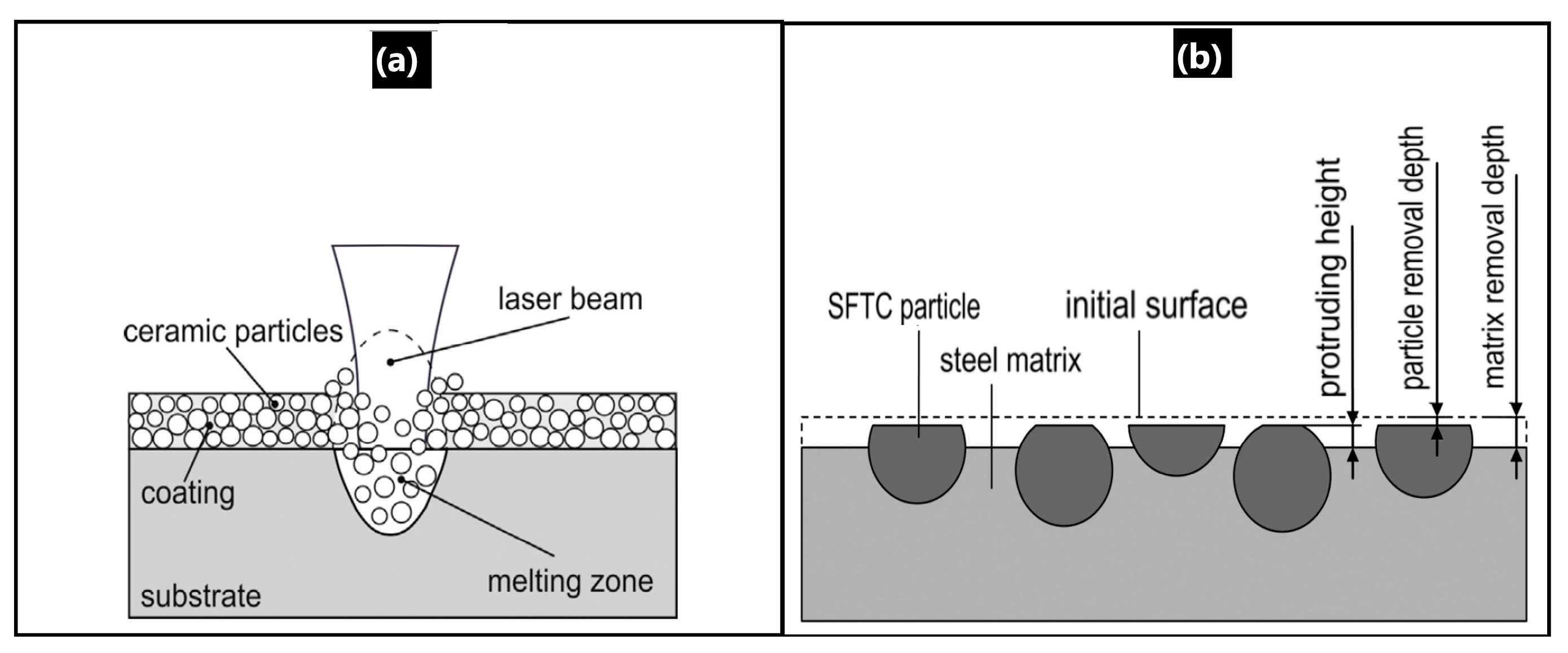

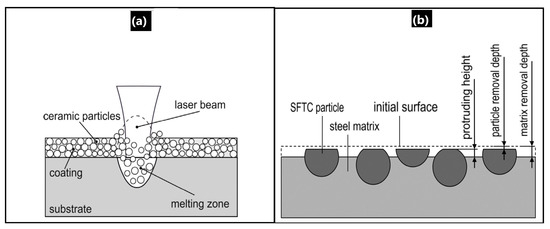

Steinhoff [40] proposed the use of a discontinuous laser to disperse ceramic particles onto surfaces in order to create textures. The pulsed laser melts the surface at specific regions, while ceramic particles are distributed into the weld pool, supplied by a pre-applied coating or a powder nozzle. The aim is to alter local wear resistance without directly affecting the surface topography, with the final texture created later by shot blasting or polishing. Further research by Hilgenberg et al. [41] demonstrated that pulsed laser scattering could directly form raised, hardened spots with controlled geometry. This approach, called Laser Implantation Texturing (LIT), was applied by Hilgenberg and Steinhoff [2] to create textures on rolls used in the skin pass. Raised, separate, dome-shaped structures were created on the rolls (Figure 4a). Lubricated wear tests were performed in a twin-disk test rig. The textures produced by the new approach showed higher durability compared to those produced by shot blasting.

Figure 4.

(a) LIT method: Ceramic particles mixed with an organic binder are first deposited onto the surface. Then, laser-induced implants are created point by point; reprinted from Hilgenberg and Steinhoff [2] (2015), with permission. (b) Surface treated via HSLMI, followed by either laser ablation or electrolytic etching. After the HSLMI process, an additional step is necessary to create a protruding height difference between the SFTC particles and the metallic matrix by selectively removing the matrix, which is less resistant than the SFTC particles; reprinted from Warneke et al. [35] (2024), open access.

Warneke et al. [35] used a high-speed laser melt injection (HSLMI) method to produce metal matrix composite (MMC) layers containing spherical fused tungsten carbide (SFTC) particles on rolls for the skin-pass cold rolling. To produce more pronounced bumpy textures after applying the HSLMI technique and subsequent grinding, it was necessary to perform additional processes, consisting of either laser ablation or electrolytic etching (Figure 4b). In the case of electrolytic etching, the removal of a large portion of the matrix material caused some SFTC particles to rupture. In addition, some electrolytically etched surfaces showed a drastic decrease in the arithmetic mean roughness (Ra) during rolling. It should be highlighted that the costs of either laser ablation or electrolytic corrosion should be considered for the use of the HSLMI method at an industrial scale.

Instead of proposing new texturing methods, some authors have been proposing the use of non-traditional coatings in the rolling industry to improve the durability of the textures [10,39]. The most traditional coating for rolling is the electroplated hard chrome, typically with a thickness of 5 to 10 µm [8]. Hard chrome has a hardness between 800 and 1000 HV when used in the metalworking industry. Its surface often develops a network of cracks, since this coating has limited elasticity and is subjected to high residual stresses, which increase with the thickness of the deposited layer [9]. Hard chrome ensures friction control at values that are satisfactory for rolling applications. In addition, it offers good corrosion resistance under various environments and does not significantly alter the topography of the rolling roll. However, there are serious concerns regarding the environment and the health of operators, since the plating process involves hexavalent chromium (Cr(VI)), which is a well-known carcinogen. Due to strict regulations imposed by many countries, the industrial sector has been focused on possible replacements for hard chrome [38].

Alternative coatings for work rolls in the recent literature have been presenting similar or better characteristics than hard chrome in laboratory tests. These coatings are less harmful to the environment and to the health of operators. As a result, they could potentially completely replace hard chrome in the near future. Ould et al. [8] studied TiN, TiBN, and CrN coatings deposited through physical vapor deposition (PVD) for application on cold rolling rolls used with high-carbon steel strips. The authors compared the results with those corresponding to electroplated hard chrome coatings. Tribological evaluation of the coatings was carried out using lubricated tests under variable load in a device with a configuration consisting of a plate with reciprocating movement on a ring rotating at constant speed (plate-on-ring test). The results showed that for TiN the coefficient of friction increased significantly at relatively low loads, not reaching the maximum test load (2000 N) and showing a lower performance than the tests for the uncoated high-speed steel samples. For TiBN, CrN, and Cr, the tests reached the maximum test load, and no severe adhesive wear occurred. The friction coefficient for TiBN stabilized at 0.085, while those corresponding to CrN and Cr stabilized at 0.085 and 0.1, respectively. The analyses also showed that, under the conditions studied, CrN and TiBN have anti-adhesive properties similar to those of hard chrome and better than those of high-speed steel. However, in the work of Ould et al. [42], unlike the conclusions regarding high-carbon steel strips shown previously, TiN showed superior tribological properties for the case of stainless steel strips. In other words, this demonstrates the systemic nature of tribology. Therefore, it is essential to select the coatings according to the nature of the material to be rolled, among other variables [43].

Electroless nickel (NiP) coatings are obtained by autocatalytic deposition, where the electrons needed to reduce the metal cation (e.g., Ni2+) are provided by a reducing agent present in the electrolyte, without the application of an electric current. As a result, an alloy is deposited; phosphorus is incorporated into the coating via the use of sodium hypophosphite as a reducing agent [38,44,45,46]. Gonçalves Jr et al. [10] evaluated low-phosphorus NiP coating compared to hard chrome as coatings for textured (EDT) cold rolling mill rolls. The tests were performed using cylinder-on-plane tribotests using a reciprocating sliding line contact. The test parameters were chosen in order to replicate the topographic characteristics found in rolling mill roll surfaces after their use in the rolling industry [47]. The use of NiP was found to promote the formation of a protective tribolayer on both the body and the counterbody. It contributed to the reduction in friction coefficient and wear rate of the system. The textured surfaces that were subsequently coated with NiP also showed the smallest changes in topographic parameters as a function of tribological tests, which may mean that work rolls with these surface modifications could have a longer service life compared to work rolls coated with hard chrome.

In skin pass, the roll wear can be characterized as microwear, since the initial depth of the textures is not significantly changed by surface mass loss; thus, empirically, roll wear is usually described as a loss of roughness [7,11]. Monteiro et al. [7] used the test methodology proposed by Gonçalves et al. [47] to evaluate the durability of NiP-coated textures based on the variation in roughness parameters. However, they used shorter test times in order to evaluate the evolution of roughness changes in the textured surfaces. Moreover, whereas Gonçalves Jr et al. [10] evaluated only stochastic textures, Monteiro et al. [7] proposed the use of the MECT (Maskless Electrochemical Texturing) method, which forms deterministic structures on the textured rolls.

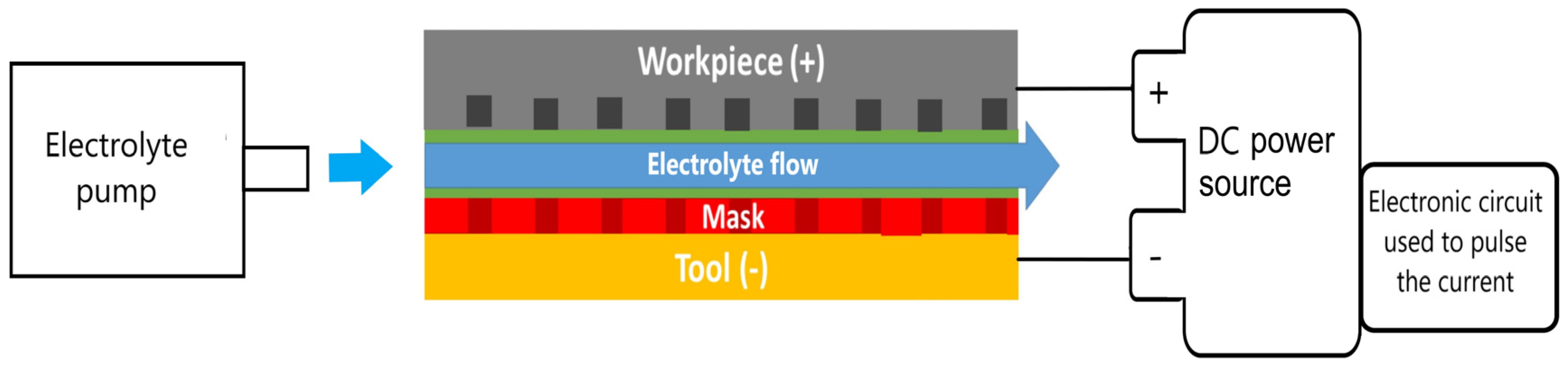

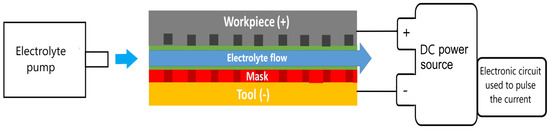

The MECT method is based on the principles of electrochemical machining [48]. Figure 5 illustrates a chamber used for texturing samples via Masked Electrochemical Texturing (MECT). The electrolyte flows through the gap between the workpiece surface (anode) and the tool surface (cathode). A laser-perforated polymer adhesive mask is applied to the cathode. The perforations have diameters similar to those desired for the pockets to be formed on the workpiece surface. The tool can be reused across multiple processes, eliminating the need for individual masking of each workpiece for every proposed texturing operation. This allows deterministic texturing according to the pattern defined by the mask. A pulsed current circuit is used to remove anodic dissolution products, such as oxides, during the pulse-off intervals [49,50,51]. Figure 5 also shows the key components of the setup for the electrochemical dissolution process, including the DC power source, pulsed current control circuit, and electrolyte circulation pump. More details can be found in the studies of [51,52,53].

Figure 5.

MECT method: the electrolyte flows parallel to the tool surface (cathode, negative pole) and the workpiece surface (anode, positive pole). The cathode mask (in red) has darker areas showing perforations. The workpiece (in gray) has darker areas showing the surface textures. A DC power source supplies voltage and current for electrochemical dissolution, with the tool acting as the cathode and the workpiece as the anode. An electronic circuit pulses the current, while a pump circulates the electrolyte between the tool and the workpiece; adapted from Monteiro et al. [7] (2025), with permission.

The advantages of this method include its simplicity and low cost. Furthermore, it is suitable for relatively large areas, typically cm2 or dm2 [51]. A disadvantage of the technique is that it can only be applied to conducting materials. Also, the resolution of the texture pockets is limited at its current stage of development, since there is a certain amount of electrochemically dissolved excess metal. For example, in the study of Da Silva and Costa [53], the smallest dimensions of the pockets obtained were around 200 µm. Moreover, the regions between the dimples are roughened due to some electrochemical dissolution [51]. However, the technique should be suitable for textured rolls, since the contact area in forming processes is large; thus, in general, the textures do not need to be made up of very small pockets. Finally, it is important to mention that the texturing time is short enough to be used at an industrial scale [48,51].

In the work of Monteiro et al. [7], samples of rolls textured via MECT showed improved tribological performance when coated with NiP compared to uncoated or hard chrome-coated samples. The test results showed that the electroless nickel coating acted to reduce the wear rate of the counterbody and attenuate the occurrence of abrasive wear on the sample. In addition, the average friction coefficient of textured surfaces coated with NiP was approximately 16% lower than that of uncoated textured surfaces and 19% lower than that of textured surfaces coated with hard chrome. In particular, nickel oxide has shown lubricious behavior in the literature [54].

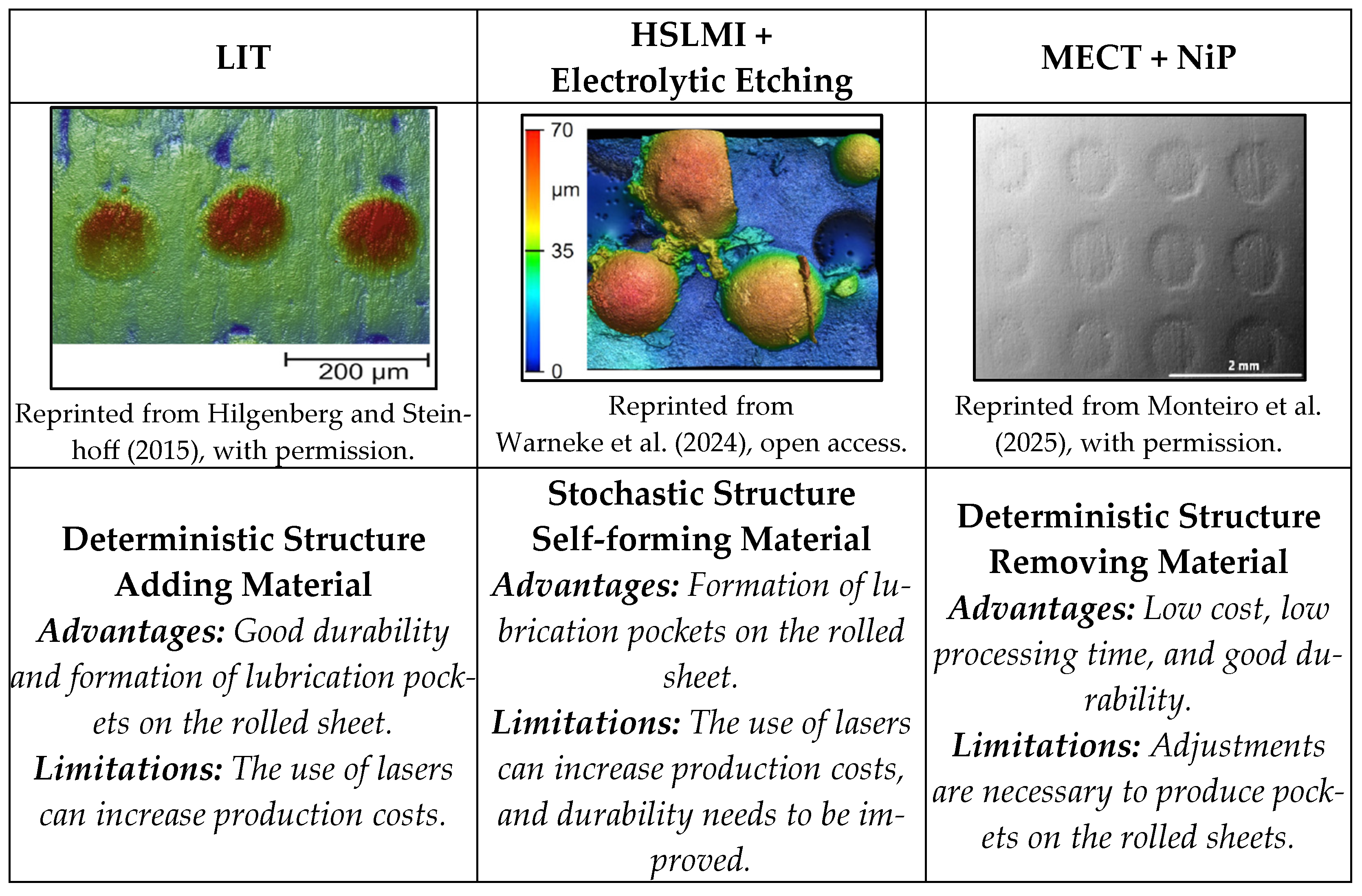

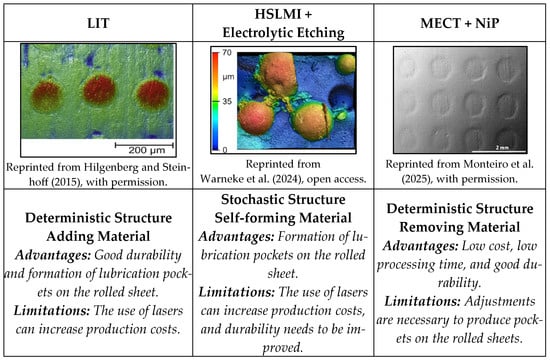

2.3. Comparative Summary Between the New Methods for Work Roll Texturing

The LIT and HSLMI methods aim to create protrusions on the surface of work rolls. The key advantage of this approach is that, when the textures are transferred to the sheets, they form lubrication pockets [2,35]. However, both LIT and HSLMI rely on laser technology, which could significantly increase production costs compared to the MECT method. Additionally, the HSLMI technique used by Warneke et al. [35] requires improvements in durability. In contrast, the study by Monteiro et al. [7] reported promising results regarding the durability of NiP-protected textures in the MECT method. However, the authors did not assess whether these circular dimples were successfully transferred to the sheets. It is likely that these dimple-shaped textures are transferred as pillars to the sheet, which may not be ideal for enhancing the lubricant load capacity during the stamping process. To address this issue, modifying the surface texture patterns of the work rolls could help ensure the formation of lubrication pockets on the sheet instead of pillars. Figure 6 compares these methods, outlining their respective advantages and disadvantages.

Figure 6.

Comparison of the new texturing methods for cold rolling work rolls, outlining their respective advantages and disadvantages. The images show surfaces textured by these methods [2,7,35].

2.4. Industrial Practices and Recommendations

Industrial practices in skin-pass rolling are still largely based on stochastic texturing. The most commonly used methods are electrical discharge texturing (EDT) and shot blasting texturing (SBT) [7,10,55]. These methods are typically applied to steel rolls coated with hard chrome [19,38]. However, texture geometry is not precisely controlled. The process results in random distributions of peaks and valleys. As a result, lubricant retention is less efficient. In general, deterministic texturing methods allow for more precise control of lubricant pocket geometry, which is essential for improving drawability in high-precision forming operations [2]. Deterministic textured rolls are not widely adopted in industry mainly due to their limited durability. Wear gradually smooths the roll surface, reducing texture transfer to the sheet. While this affects all texturing methods, it is often more critical for deterministic patterns. Applying electroplated hard chrome can extend roll life but raises environmental and health concerns [2,7]. Consequently, alternative approaches like LIT and MECT, capable of producing deterministic textures in a more cost-effective manner, are of great interest.

In contrast, the new approaches discussed in this review offer potential advantages (see Figure 6). These include the MECT method with NiP coating and the LIT method, both used to produce deterministic textures. Although HSLMI does not produce deterministic textures, it has been developed to become a faster method than the LIT technique. Despite these advantages, industrial adoption remains limited. Key challenges include scalability issues.

In the LIT method, each implant is generated using, for example, titanium diboride in a two-step process: pre-deposition of the powder with a binder, followed by laser-induced implantation. This deterministic texturing is time consuming, as each implant is formed individually [2]. Additionally, laser beam speeds of around 2 m/min have been reported in the literature for conventional laser implantation [35]. In contrast, HSLMI achieves speeds up to 100 m/min and processed areas of up to 1000 cm2/min when implanting spherical fused tungsten carbide (SFTC) into tool steel used in skin-pass rolls [35,56]. While LIT requires pre-coating, which increases preparation complexity [57], HSLMI involves a post-processing step such as laser ablation or electrochemical etching. This second step may raise costs, and electrochemical etching may reduce texture durability.

The MECT method has limited resolution. This is due to uncontrolled electrochemical dissolution at the pocket edges (over-etching) [52]. Moreover, although anodic dissolution localization where the mask is perforated prevails, there is some residual dissolution between the holes in the mask, so the roughness in regions between the pockets increases [51]. However, this slight roughening should not have a negative impact on the sheet and its subsequent tribological behavior. The method is restricted to conductive materials. One of the main challenges in the current stage of MECT development is the fabrication of the cathode mask. Initially, insulating paint was used [51,52]. Later, Dias et al. [50] introduced a laser-perforated polymer adhesive as a cathode mask. Monteiro et al. [7] applied this method and successfully produced surface textures. However, both the paint and adhesive degrade after a limited number of tests. This limits the repeatability of the process. Photolithography has recently been explored as a masking strategy in other electrochemical applications [58]. Although further investigation is needed, such approaches may offer useful insights for improving cathode masking in MECT.

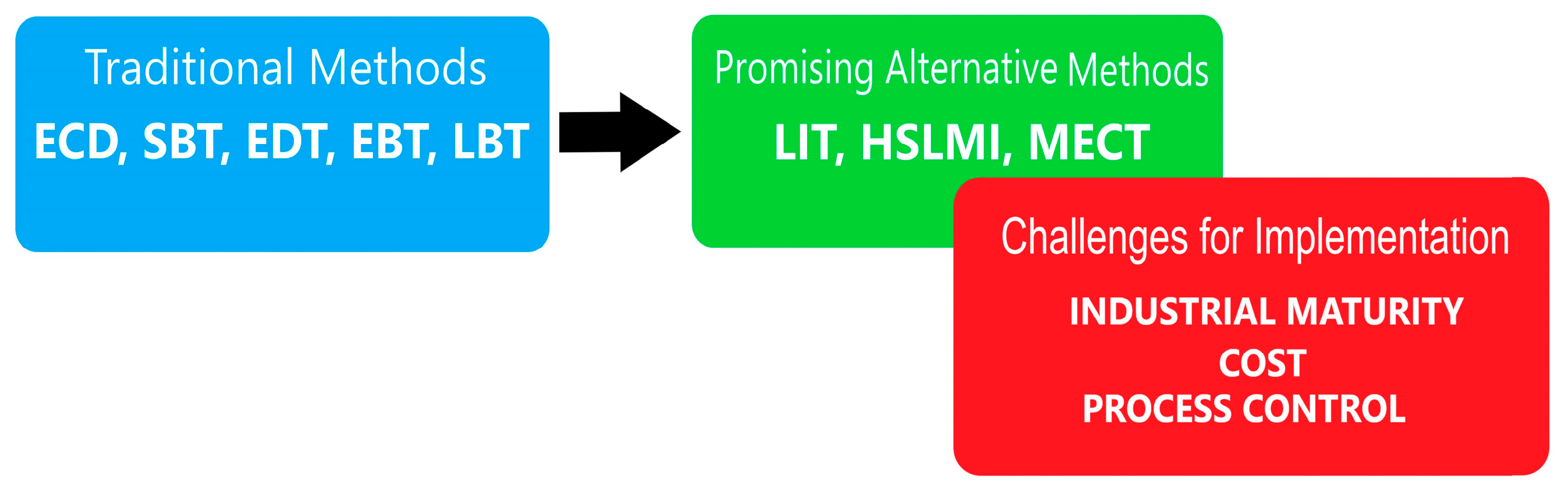

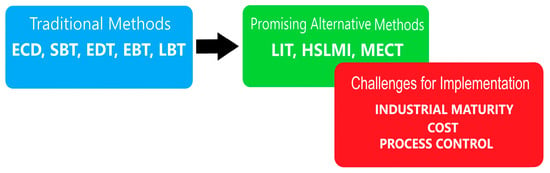

These findings indicate that several technical issues still need to be resolved before the LIT, HSLMI, and MECT methods can be applied at an industrial scale. Key factors for the industrial implementation of a new technique include industrial maturity, cost, and process control (Figure 7), as highlighted by Łach [59]. Traditional methods tend to be more mature, widely available, and cost-effective, with established process control. Emerging techniques, while offering potential advantages in surface functionality, often face challenges such as limited industrial validation, specialized equipment needs, higher costs for implementation, and less predictable process behavior [56,60,61].

Figure 7.

Schematic of the transition from traditional texturing methods to promising alternatives. While methods such as LIT, HSLMI, and MECT offer advantages in performance and surface control, their implementation is still limited by challenges including industrial maturity, cost, and process control.

The use of statistical analysis-based methods such as Six Sigma may be an effective strategy for optimizing processes with well-established experimental data. For instance, Evin et al. [62] implemented the Six Sigma methodology in the electro-discharge texturing process of cold mill work rolls. This enabled predictive modeling of the arithmetic average roughness (Ra) based on input parameters such as current, voltage, and time. On the other hand, machine learning techniques such as artificial neural networks (ANNs) and support vector machines (SVMs) can be applied to model wear and lubrication phenomena. These methods are particularly effective in handling complex, nonlinear systems, identifying hidden patterns, and accurately predicting tribological performance. Conventional statistical and mathematical tools such as response surface methodology and full factorial design provide a well-established framework. They are effective for controlling and optimizing well-understood processes. In contrast, machine learning expands the frontiers of knowledge. It holds great promise for the development of new materials, the optimization of texture geometries, and predictive maintenance strategies [63,64].

3. Texture Transfer from the Roll to the Rolled Sheet

A crucial aspect of surface texturing performance in skin-pass cold rolling is how the texture of the roll surface is transferred to the rolled sheet. Steinhoff et al. [65] investigated the transfer of textures produced via EBT. Using finite element method (FEM) simulations, they verified that surface structure transfer in the skin-pass rolling process is governed by two primary mechanisms: penetration processes and the reverse extrusion phenomenon. Penetration occurs when the peaks of the roll roughness press against the sheet, inducing localized deformation that imprints the roll surface texture. Reverse extrusion phenomenon occurs when the sheet material in contact with the asperities of the roll is compressed downward, specifically the melted rings, while the material inside these rings moves upward. The predominance of one process or another depends on the work roll texturing method, among other factors. Thus, for example, when dealing with rolls textured by the EDT, reverse extrusion is unlikely due to the geometries of the textures formed on the roll [11]. Nevertheless, revealing the actual texture transfer mechanisms in skin-pass rolling has been challenging due to the complexity of the events occurring at the roll/sheet interface [66]. Contact occurs between randomly distributed asperities on both the roll and sheet surfaces. While the plastic deformation of the sheet surface asperities is usually significant, the surface asperities on the work roll typically undergo much smaller elastic deformation. This is because the work roll material has greater hardness than the sheet material. Additionally, the sheet experiences different deformation zones along the contact arc [12].

The rolling conditions in the skin-pass process differ from those in conventional cold rolling. This stage constitutes the final step in manufacturing thin steel sheets. Conventional cold rolling involves high reductions and assumes a circular roll shape, whereas the skin pass applies smaller reductions. The contact length significantly exceeds the sheet thickness, and the roll radius remains large in relation to the contact length. Additionally, dry rolling is typically employed, resulting in higher friction between the roll and the sheet compared to lubricated rolling [5,67,68].

In this context, this section initially addresses the contact conditions in the skin-pass process. Subsequently, it examines the influence of rolling conditions and roll wear on the transfer of the texture from the work rolls to the sheets.

3.1. Contact Conditions on Skin-Pass Cold Rolling

Fleck and Johnson [69], followed by Fleck et al. [70], presented a theory for the rolling of thin metal strips. The authors stated that the roll could deform into a non-circular profile. Moreover, they proposed that, in the contact between the work roll and the sheet, finite regions of non-slip may occur. The theory predicts plastic reduction in two zones separated by a flat neutral zone, with no slip or further plastic deformation. According to Yuen et al. [71], since the reductions in skin-pass rolling are relatively small and a large part of the contact between the work roll and the sheet is deformed into a flat profile, the theory proposed by Fleck and Johnson [69] is applicable [72]. In their theoretical analysis, Yuen et al. [71] assumed that the pressure distribution on the work roll is similar to that of a Hertzian contact. Furthermore, they supposed that the flat profile contact prevails in most of the contact between the rolling roll and the sheet. The model was validated with data collected from several rolling mills, and the results showed reasonable agreement.

Sun et al. [67] performed simulations of the skin-pass process using FEM. In their model, the elastic deformation of the roll and the plastic deformation of the sheet are determined simultaneously with the corresponding contact pressure and shear stress. The results showed that, under certain conditions, there is an apparently flat region with almost zero reduction in the center of the contact arc. In this region, the reduction in the sheet is minimal, and the plastic deformation is of similar magnitude to the elastic deformation. Furthermore, the central flat region appears for a reduction of 2%. Under low friction conditions, the contact arc tends to retain a circular shape; however, as the friction coefficient increases, the central flat region becomes more pronounced. Additionally, it was observed that, when the yield stress of the sheet reaches a certain threshold, the central flat region also appears. Finally, in the central region of the contact arc, the contact pressure reaches its highest values, while the shear stress approaches zero.

Kijima [73] evaluated transfer mechanisms using experiments and computer simulations. The results showed that texture transfer in skin-pass rolling occurs under specific conditions where the work roll diameter must be sufficiently large relative to the reduction in sheet thickness. This behavior results in a high contact length and a high-peak hydrostatic pressure at the center. As a consequence, texture transfer can be modeled as vertical compression, and the aforementioned peak pressure can be estimated using Hertzian contact theory. Some authors have conducted tests with normal load (compression tests) of a tool on a sheet to study localized deformations [68] and texture transfer [22] in skin-pass cold rolling.

3.2. Influence of the Rolling Conditions

Since the skin-pass cold rolling is usually performed under dry conditions, the absence of lubricating oil increases the roughness transfer rate from the roll to the sheet [74]. However, adhesion between the roll and sheet surface can be problematic at this stage. To prevent this, a lubricant with low lubrication capacity may be used. This lubricant also helps prevent corrosion on the sheet and keeps the roll surface clean [75].

Pawelski et al. [14] conducted a comparative study of the texture transfer characteristics for different texturing techniques, evaluating the SBT, EDT, EBT, and LBT methods in an industrial mill. Both dry and lubricated tests demonstrated that both the roll texturing method and elongation significantly influenced the texture transfer from the roll to the sheet. The texture transfer was more pronounced at higher elongations, likely due to the increased penetration of the roll topography into the sheet surface. In lubricated tests, texture transfer was less pronounced for deterministic textures (EBT and LBT), which can be attributed to the formation of closed hydrostatic lubrication pockets on the roll surface, preventing lubricant escape. This phenomenon impedes both penetration and reverse extrusion. For stochastic textures (EDT and SBT), the formation of these pockets depends on the homogeneity of the lubricant distribution, while for deterministic textures, the pockets are induced by the texture geometry.

Kijima [73] performed dry and lubricated tests with ground work rolls. The results indicated that, up to approximately 1% of elongation, there was an increase in Rvk (reduced valley depth), which can be related to the formation of recesses on the surface of the sheet. Beyond this point, Rvk remained almost constant. However, no effect of the lubricant on this topography parameter was observed. In contrast, above this elongation, it was observed that the transfer of Rk (core roughness depth) was greater for dry tests. Thus, it appears that the lubricant trapped in the valleys delayed the topography transfer.

Çolak and Kurgan [74] investigated roughness transfer in skin-pass rolling and found that the roll rotation and the type of lubricant influence the process. They used diamond roughening as the texturing method. The tests showed that higher rotation corresponded to more processed material, increasing rolling force and roughness transfer. The texture transfer was greater in dry tests due to the higher rolling force, pressing the roll surface peaks into the sheet, causing deeper craters. In lubricated tests, roughness distribution was more uniform, likely due to hydrodynamic lubrication reducing the rolling force. Smaller reductions produced a more homogeneous surface because the smaller peaks in the roll did not contact the sheet, thus not contributing to texturing. At higher reductions, these peaks formed craters, negatively affecting the roughness distribution.

Rodrigues et al. [51] evaluated roughness transfer in skin-pass rolling using dry compression tests. A high-formability steel sheet was compressed between two tool steel dies, one polished and the other laser-textured. The microtexture patterns consisted of circular dimples with and without overlap. The authors analyzed the transfer of Ra and peak count (Rpc) based on the effective contact pressure (ECP), defined as the nominal contact pressure divided by the substrate yield strength. Ra transfer increased approximately linearly with ECP, reaching nearly 50% for overlapping textures. Rpc transfer reached about 94% for overlapping textures and around 130% for non-overlapping textures before decreasing when ECP exceeded 300%. The authors attributed these differences to variations between overlapping and non-overlapping textures and differences in the bearing area between the die and the sheet. Thus, both the texturing method and the spatial arrangement of textures influenced topography transfer.

Several studies analyzed how rolling parameters influence topography transfer [4,76,77]. While most agree on the effects of sheet reduction and lubrication, findings on other parameters vary. Some studies suggest that rolling speed has little effect [12,78], while others indicate that higher speeds increase transfer [74,79]. These differences are expected, as rolling results depend on variables such as material properties and surface finish of the roll and sheet. Table 1 summarizes the influence of reduction ratio, rolling speed, and lubrication on topography transfer, with corresponding references.

Table 1.

Effects of the rolling parameters on the topography transfer.

3.3. Influence of the Roll Wear

In skin-pass rolling, a central flat region may form in the contact arc, where relative motion is theoretically absent [67]. However, the tribological conditions in this process are critical, as wear plays a key role. Roll surface wear inevitably affects the topography transfer to the sheet [80].

Wu et al. [81] identified a key challenge in modeling topography transfer in skin-pass rolling: it depends on both the macroscopic deformation of the work roll and the microscopic elastic deformation of asperities. To analyze roll surface wear, they applied the Archard’s equation in computational simulations, considering topographic evolution based on contact pressure, relative motion, and surface hardness at the roll/sheet interface. Using FEM simulation, they examined microscale surface contact, macroscale roll deformation, and plastic sheet deformation. The results showed that wear occurs mainly in the sliding regime, while surface wear is minimal in the non-sliding regime, where the pressure peak is located. At lower contact pressures, wear is concentrated at the asperity tips as sliding distance increases. Finally, the study found that Rq (root mean square roughness) of the rolled sheet decreases as the work roll surface wears.

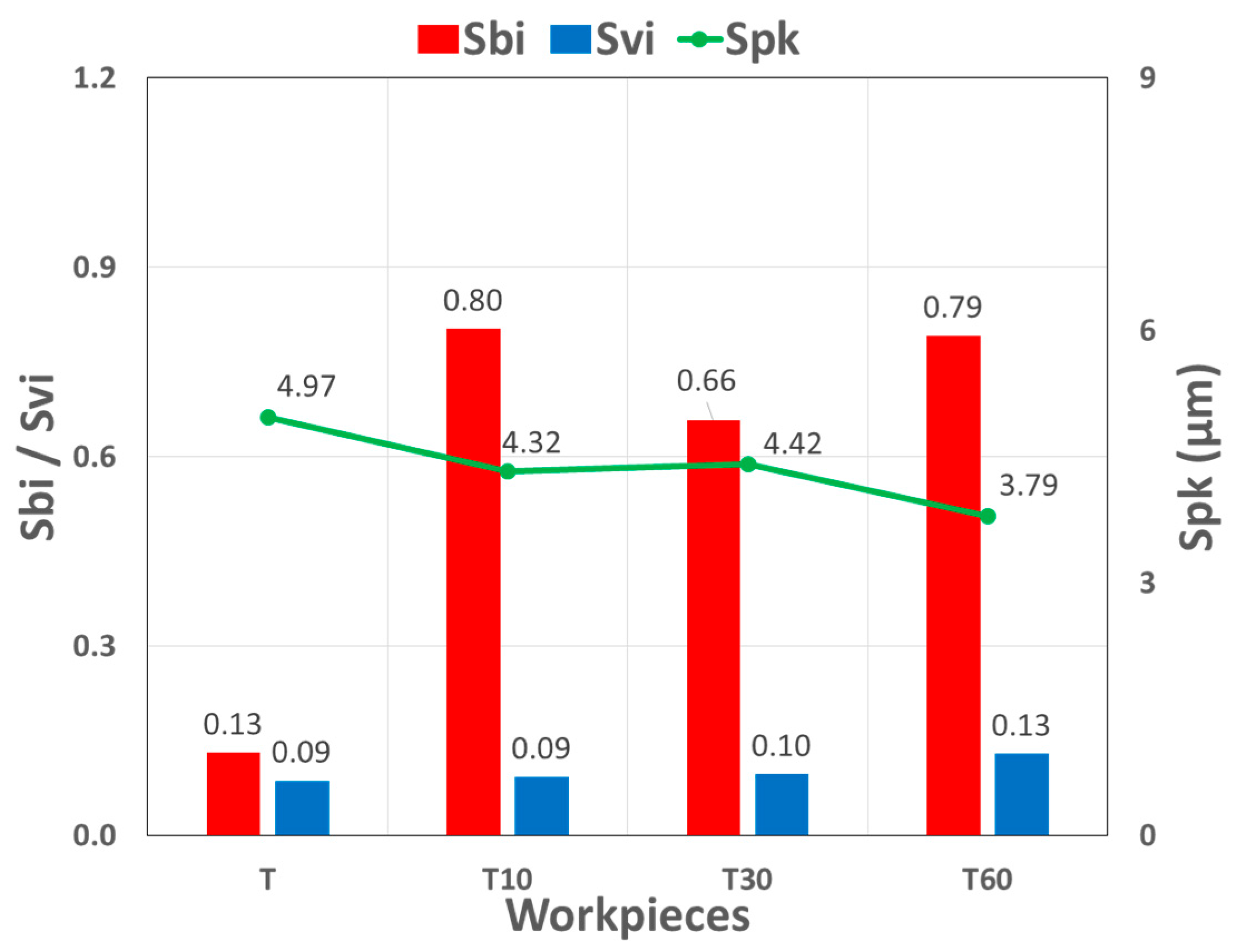

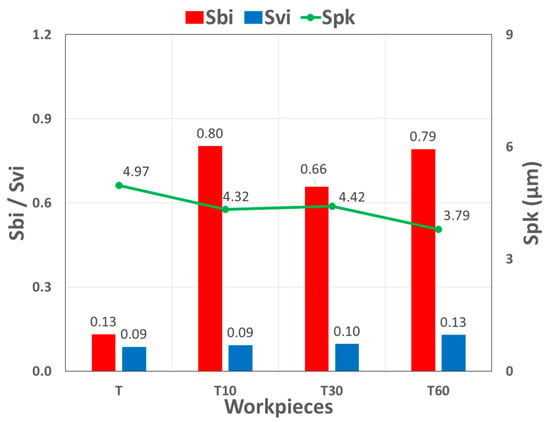

Monteiro et al. [7] evaluated wear in samples extracted from rolling work rolls and textured with dimples using the MECT method. Reciprocating sliding tests were conducted following the methodology of Gonçalves et al. [47], with test durations of 10, 30, and 60 min. As shown in Figure 8, the Sbi (3D load-bearing index) parameter was lower for the untested samples, whereas after the tests, no differences were detected as the test time increased. This suggests that sliding tests smoothed the surface, increasing mechanical support capacity. The Svi (3D valley index) parameter showed no significant variation, indicating that the fluid retention capacity in the valleys remained stable with increased test time. The Spk (3D peak index) parameter exhibited a decreasing trend as the test time increased, suggesting that test durations were sufficient to wear out the highest surface peaks.

Figure 8.

Sbi, Svi, and Spk parameters on the work roll surface samples: T (untested), T10 (tested for 10 min), T30 (tested for 30 min), and T60 (tested for 60 min); reproduced from Monteiro et al. [7] (2025), with permission.

Wentink et al. [11] conducted experiments to describe microwear and topography transfer in the skin-pass analyzing the bearing area, which is independent of the material. They recorded line profiles in the same areas of a roll surface in the virgin state and after the rolling of sheets with lengths of 2500 and 4000 m in a pilot mill. The most prominent peaks were removed early in the process, after which wear slowed down. Additionally, higher specific rolling forces made the sheet surface more similar to the negative of the roll. Based on these results, a topography transfer model was developed, considering roll wear and the bearing area of the roll and sheet. The model assumes that the work roll presses into the sheet until their contact area reaches the desired bearing area curve, assuming that the sheet surface is perfectly flat before rolling. These conditions apply only to small reductions, as expected in skin-pass rolling. Numerical simulations indicated a decline in Ra and Rpc under the evaluated conditions. As microwear on the work roll surface increased, both parameters decreased. The findings of Monteiro et al. [7] are consistent with those of Wentink et al. [11] and Wu et al. [81]. These studies demonstrated that the highest peaks play an important role in the skin pass, consequently affecting the topography transfer to the sheet.

4. Textured Surfaces and Sheet Formability

Different mechanisms contribute to friction and wear reduction due to surface textures: (i) increased lubricant load-carrying capacity due to hydrodynamic effects and (ii) wear debris entrapment, minimizing surface degradation in the tribological pair; and (iii) lubricant storage [82]. Therefore, the improved formability of textured sheets results mainly from lubrication effects on the material surface under plastic deformation [83].

This section addresses the influence of surface texturing on the formability of metal sheets. Initially, the lubrication micromechanisms (MPHSL and MPHDL) that may occur in these processes are presented. Subsequently, the impact of sheet textures produced by different methods on sheet performance in stamping processes are highlighted. Finally, it is shown that die texturing can be an alternative to improve the tribological performance of processes such as stamping and deep drawing.

4.1. Lubricant Escape Mechanism: MPHSL and MPHDL

In metal forming, the most common lubrication regimes are mixed and boundary lubrication [84]. In mixed lubrication, two mechanisms may occur: MPHSL (microplasto-hydrostatic lubrication) and MPHDL (microplasto-hydrodynamic lubrication) [85]. MPHSL occurs in closed pockets under plastic deformation when lubricant pressure exceeds local contact pressure. The lubricant escapes toward the lower-pressure region if the pocket moves to areas of lower contact pressure, causing lubricant flow in the direction of relative velocity (forward flow). MPHDL results from hydrodynamic pressure generated by relative motion, forcing the lubricant out in the opposite direction of the relative velocity (backward flow). MPHDL is favored by high sliding velocities and high-viscosity lubricants. These mechanisms are influenced by relative sliding velocity, lubricant viscosity, initial lubricant film thickness, and texture geometry [86,87,88].

For these lubrication mechanisms to be effective, certain surface geometry prerequisites must be met. The surface must contain closed and isolated voids, known as lubrication pockets, which allow proper sealing against the die during the forming process. If this contact does not occur, the lubricant may escape before pressure build-up occurs [9]. To close the pockets, textures must be smaller than the tribological contact. Hutchings and Shipway [38] confirmed this by defining deterministic texturing as the topographical patterning of a surface, typically with dimples or grooves, at a scale much smaller than the tribological contact.

Shimizu et al. [33] evaluated lubrication micromechanisms (MPSDL and MPHSL) in textured surfaces in strip drawing tests. Pyramidal pockets were manufactured by electropolishing. Transparent tools and a CCD camera were used to observe the phenomena. The study found that a large curvature radius at the rear edge (relative to the movement direction) and a small wall inclination angle (relative to the edge plane) promote lubricant escape in the direction opposite to the sliding direction, due to MPHDL. Smaller angles and higher speeds increased hydrodynamic pressure, enhancing MPHDL. When the curvature radius was smaller, MPHDL was limited, leading to MPHSL, which directed the lubricant forward, following the sliding direction. Experimental results correlated well with theoretical predictions, validating the mathematical model. The authors emphasized that the convergent geometry between surfaces plays a key role in increasing hydrodynamic pressure through the wedge effect, which occurs when the lubricant is displaced from the pocket due to relative surface movement.

Therefore, the lubrication micromechanisms (MPHSL and MPHDL) can directly influence the tribological characteristics of forming processes, such as stamping. Their effectiveness depends on surface topography, lubricant viscosity, and sliding velocity. The precise control of texturing is essential to promote these micromechanisms.

4.2. Influence of the Surface Texturing Method on the Sheet Drawability

During sheet rolling in the skin-pass, the roll texture is transferred to the sheet. The roll texturing method influences the topography of the rolled sheet, affecting its formability [83,89]. Due to the complexity of surface topographies and their interactions, quantifying the influence of topographic parameters on the formability of metal sheets remains a challenge [90].

According to Liu et al. [91], the isotropic and stochastic nature of EDT surfaces in aluminum sheets can be altered during the texture transfer occurring in the skin-pass rolling. They analyzed how the rolling direction influences the surface morphology of AA6016 aluminum sheets with electro-discharge textured (EDT) surfaces during forming. Strip drawing tests were conducted at sliding angles from 0° to 90° relative to the rolling direction using different lubricants. Topographical analysis showed a significant impact on friction: the highest coefficient occurred at 0°, the lowest at 30°, with strong adhesion between the sheet and tool at 45°. After testing, all surfaces exhibited reductions in 3D topography parameters, such as peak-valley height (St) and 3D arithmetic mean roughness (Sa). Texture orientation affected lubricant retention and friction regime, highlighting the anisotropic tribological behavior. Controlling the rolling direction in forming processes can optimize formability, reduce defects, and improve the final product quality.

Coello et al. [92] investigated the friction behavior of zinc-coated TRIP 700 steel sheets textured by electron beam treatment (EBT) during forming processes, focusing on the influence of pressure and velocity on the coefficient of friction (COF) under different lubrication conditions. Friction tests were conducted using a sheet drawing friction system, analyzing material response across various pressure and velocity combinations. Surface changes were characterized by 3D roughness parameters, with emphasis on the Abbott–Firestone curves. Results showed that pressure significantly affects the COF due to micro-hydrodynamic effects generated by the plastic deformation of the zinc coating, creating hydrostatic pressure in the retained lubricant. EBT improved lubricant retention, promoting mixed lubrication and reducing wear. The study concluded that combining zinc coating with EBT enhances lubrication and reduces friction under optimal pressure and velocity conditions, benefiting steel sheet forming processes. This makes the material promising for deep drawing applications, improving efficiency and quality in the automotive industry.

Burdek [90] analyzed the influence of surface topography parameters of steel sheets (Grades DC03, DC04, DC05, and AISI 430 stainless steel) on drawability. Due to experimental challenges related to interrupting industrial production, a physical model was used, employing abrasive blasting with quartz sand, aluminum oxide, and glass balls to replicate the effects of skin-pass rolling on the sheet surface. In the Swift test, results indicated that glass ball blasting modified the surface of DC05 sheets in a way that created a strong relationship between most analyzed topography parameters and the Limit Drawing Ratio (K). However, the same effect was not observed for other abrasives. Based on these results and other studies, the authors concluded that sheet metal forming depends on the interaction between surface peaks and valleys rather than just average values such as Sa or Sq. A higher Sv/Sp ratio increases formability. Taller, sharper peaks can be detrimental as they wear away quickly and push lubricant out of the valleys, hindering the process.

Zabala et al. [82] investigated how surface texture affects friction and galling in the deep drawing of aluminum. They studied different texture levels (rolling reduction ratio) on AA1050 aluminum strips and tool surfaces with varying polishing degrees. EDT-textured rolls were used to transfer surface patterns during the skin pass. Strip drawing tests evaluated the tribological behavior. Results showed that increasing the texture level reduced the friction coefficient. This was likely due to better lubricant retention in micro-pockets, linked to a higher void volume parameter (Vvv) as EDT texture increased. Tool roughness played a key role in galling: more polished tools had lower resistance to the phenomenon. The study found that, while sheet texturing improves formability, a minimum texture level is needed to prevent galling. It also highlighted the critical role of die topography in galling prevention.

The influence of roll texturing on sheet metal formability is highly systemic, depending on a complex interaction of factors such as the texturing method, sheet material, tool roughness, lubrication regime, and forming process. There is no single strategy to optimize texture functionality; each system must be analyzed to achieve the best performance. However, a common finding among studies is the key role of lubricant retention in reducing friction and improving formability [82,90,91,92].

In addition, studies indicate that 3D surface texture parameters are more suitable than 2D parameters for analyzing the relationship between surface texture and formability, as they provide a broader understanding of texture, lubrication, and plastic deformability [32,83,93,94].

Therefore, selecting a texturing method should consider not only the desired surface roughness but also its interaction with other elements in the metal forming system. The balance between lubricant retention, friction control, and wear resistance must be adjusted based on sheet material and process conditions to ensure optimal performance [24,91,92].

4.3. Texturing the Sheet or the Die? Insights for Industrial Practices

In most industrial applications, surface texturing is applied to the sheet during the rolling process. In this step, the surface pattern is transferred from the textured work rolls to the sheet, enabling high productivity and consistent roughness across large production volumes [95]. Consequently, the lubrication and friction conditions in subsequent stamping operations are highly dependent on the quality and preservation of the as-rolled surface. Although not the primary focus of this work, it is worth mentioning that another approach involves texturing the forming die surface instead of the sheet surface [60,96,97,98]. The choice between transferring the texture to the sheet during the skin pass and texturing the stamping die depends on various technical and economic factors. For example, textures applied to the sheet via skin pass can be tailored for aesthetic purposes in addition to their tribological functions [3,14]. However, their effectiveness in deep drawing and multi-stage forming is limited, as the patterned sheet surface can wear out quickly [99]. Therefore, die texturing is a viable option for long-term tribological control, provided that it offers sufficient durability [58,99,100,101].

The comparison in Table 2 shows that deciding whether to apply the texture to the sheet surface (via skin-pass rolling) or directly to the forming die has a direct impact on process performance. Skin pass is suitable for high-volume production [95], but its effectiveness may decrease in longer or more complex forming operations, as the textured sheet surface tends to wear over time [99,100]. In these cases, die texturing is a viable alternative, especially when long-term tribological control is needed [58,97,98]. The analysis in Table 2 can help process engineers reconsider their texturing strategies. Choosing a suitable method can improve process predictability and reduce friction-related failures.

Table 2.

Comparison between sheet texturing via skin pass and die texturing in terms of durability and texture control.

5. Surface Texturing and Sustainability

As the science that investigates friction, wear, and lubrication, tribology plays a crucial role in reducing CO2 emissions [102]. According to Holmberg and Erdemir [103], approximately 23% of global energy consumption (119 EJ) is associated with tribological contacts. Of this total, around 20% (103 EJ) is used to overcome friction, while 3% (16 EJ) is allocated to the remanufacturing of components due to wear and related failures. These figures highlight the significance of tribological analyses, which also extend to sheet metal forming processes. Global steel production reaches approximately 2 billion tons annually, representing 8% of the world’s energy consumption and 7% of CO2 emissions in the energy sector [104].

The use of renewable energy sources plays a key role in the transition to a more sustainable world. However, this transition presents structural challenges, as industrial processes are highly dependent on electricity and fossil fuels, making it difficult to immediately replace these sources entirely [105]. For example, the steel industry has been putting great effort and research into the use of green steels to reduce its carbon footprint [106], but the metal forming industry is still responsible for substantial emissions. In this context, the pursuit of technological solutions that reduce energy consumption without compromising productivity becomes essential [61,107]. The adoption of new surface technologies, materials, and lubrication can significantly contribute to reducing friction and degradation in vehicles, machines, and equipment. Holmberg and Erdemir [103] state that these savings could reach 1.4% of global GDP and 8.7% of total energy consumption over 15 years. Among these solutions, surface texturing stands out in the iron and steel industry.

Although it is not a standalone solution for industrial decarbonization, surface texturing helps to reduce friction, optimize lubricant use, and decrease tool wear, leading to energy efficiency gains. Monteiro et al. [7] used friction measurements and topography evaluations from tribological tests, finding that electroless nickel (NiP) coating is a viable alternative to enhance the durability of textures in skin-pass rolling rolls. In addition, the average friction coefficient of textured surfaces coated with NiP was approximately 16% lower than that of uncoated textured surfaces and 19% lower than that of textured surfaces coated with hard chrome, a carcinogenic material. Çolak [108] compared the SBT and EDT methods applied to cold rolling rolls. The work rolls textured using the EDT method exhibited more durable roughness compared to those textured using the SBT method. This means that rolling campaigns with EDT rolls last longer. While SBT rolls lost 53% of their roughness by the end of the campaign, this loss was only 33% for EDT rolls. This also affects the available rolling time, texturing capacity, and process costs. Abe et al. [95] analyzed adhesion resistance in the ironing of stainless steel and aluminum metal cups, comparing TiCN, WC-Co, and tool steel dies. TiCN dies with lubricant pockets exhibited the best adhesion resistance, reducing forming load by 20% and preventing adhesion. Repetitive tests showed that these dies maintained their adhesion resistance for longer periods, which can minimize the need for lubricant resupply. The results highlight the importance of die texturing to enhance efficiency and quality in metal stamping. The previous sections also presented various studies demonstrating that textured surfaces can reduce the coefficient of friction and wear in forming processes.

The adoption of texturing in rolling and stamping serves as a facilitator of the energy transition by reducing energy demand at various points in the production chain. Its main benefits include the following:

- (i)

- Reduction in petroleum-based lubricant use—textured surfaces can optimize lubricant utilization, minimizing waste and enhancing its effectiveness, directly impacting process sustainability [109,110].

- (ii)

- Reduction in CO2 emissions—lower energy demand results in reduced greenhouse gas emissions, especially when electricity comes from non-renewable sources [103,107].

Given these considerations, it is evident that the energy transition presents an inevitable challenge, requiring innovative solutions to reduce energy consumption and minimize environmental impact. In this context, surface texturing emerges as a promising strategy, as it reduces friction, enhances lubrication efficiency, and decreases tool wear, ultimately lowering energy demand and CO2 emissions. To establish this technology as a pillar of sustainability in metallurgy, it is essential to expand investments in research and innovation. Advancements in this field will enable the large-scale application of texturing, ensuring greater production efficiency and competitiveness without compromising environmental responsibility [111,112].

Figure 9 effectively illustrates the role of surface texturing in enhancing the sustainability of metal forming. It presents a clear progression from the environmental challenges of conventional manufacturing to the potential benefits of advanced surface engineering. On the left, it highlights key issues such as reliance on petroleum-based lubricants and CO2 emissions. The central section introduces surface texturing as a technological solution, emphasizing its ability to reduce wear and friction during metal forming processes. Finally, the right section outlines the expected advantages, including improved energy efficiency, lower lubricant consumption, and reduced carbon emissions. This structured representation underscores the importance of innovative surface engineering in promoting greener and more efficient industrial practices.

Figure 9.

The role of surface texturing in enhancing the sustainability of metal forming.

6. Concluding Remarks

Surface texturing is crucial for optimizing metal sheet production, enhancing surface quality, formability, and sustainability. Advances in this field have improved tribological control, increasing efficiency and reducing environmental impact. However, challenges remain, such as texture durability and the economic feasibility of advanced methods. The future of surface texturing relies on new materials, improved techniques, and industry commitment to sustainability. Continued investment in research and innovation will be key to this progress.

Roll texturing is a key technology to achieve the desired surface characteristics of cold-rolled sheets. Traditional methods such as EDT, SBT, EBT, LBT, and ECD offer specific advantages in texture control and durability. Innovative techniques like MECT, LIT, and HSLMI have emerged as promising alternatives to enhance texture durability without relying on hard chrome coatings, which have negative environmental impacts. Alternative coatings like NiP have shown potential to replace hard chrome while offering comparable or superior tribological performance. However, texture durability and the economic feasibility of these new techniques remain challenges that must be overcome for widespread industrial adoption.

The efficiency of texture transfer from the roll to the sheet during the skin pass is influenced by multiple factors, including contact conditions, rolling parameters, and roll wear. Progressive roll wear reduces texture transfer fidelity over time, directly impacting sheet formability. Additionally, the presence of lubricants can affect the roughness transfer rate.

The surface texturing of sheets significantly influences their formability by affecting the lubrication regime and the interaction between the tool and the sheet material. Lubricant retention in closed pockets can promote lubrication micromechanisms (MPHSL and MPHDL), reducing friction and improving sheet drawability. Texturing methods such as EDT and EBT offer different levels of control over texture geometry, leading to distinct tribological performances. As an alternative, die texturing instead of sheet texturing has been explored to enhance texture stability throughout multi-stage forming processes. However, challenges such as texture durability in the die and additional manufacturing costs still need to be overcome.

Moreover, the use of prediction models is essential to avoid the trial-and-error approach, which is highly costly and inefficient. Very few studies have proposed models to predict effects of surface texturing on metal forming. More robust algorithms that can account for complex factors such as processing parameters and roll wear are still in need to advance the field. In particular, the use of machine learning approaches should be promising to accelerate the use of surface texturing in metal forming.

The results presented in this work provide a comparative basis for understanding the technical potential and limitations of LIT, HSLMI, and MECT in the context of tool surface engineering. From an academic standpoint, the findings contribute to the ongoing development of advanced surface modification techniques. From an industrial perspective, the study highlights that, despite recent advances, key challenges such as process standardization, integration into existing production lines, and cost-effectiveness must still be addressed before full-scale industrial implementation becomes viable.

Surface texturing emerges as a key strategy for the sustainability of the metal forming industry, contributing to the reduction in friction, wear, and the consumption of petroleum-based lubricants. This technology can improve energy efficiency and reduce CO2 emissions, playing a significant role in the transition to more sustainable industrial processes. However, to establish this approach on a large scale, continuous investment in research and innovation is essential, ensuring that texturing not only enhances productivity but also strengthens the industry environmental commitment.

Further studies are recommended to investigate the long-term durability of NiP-based textures under industrial operating conditions, as well as to develop predictive models for texture transfer efficiency and wear evolution. Such efforts may support the transition from laboratory-scale feasibility to robust, large-scale application.

Author Contributions

Conceptualization, H.L.C.; methodology, P.L.M.J. and H.L.C.; resources, H.L.C.; writing—original draft preparation, H.L.C.; writing—review and editing, H.L.C.; supervision, H.L.C. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the CNPq/Brazil via INCT CT Trib (grant number 406654/2022-0). PLM received a scholarship from Capes/Brazil.

Data Availability Statement

All relevant data are included in this manuscript.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Labiapari, W.d.S.; de Alcântara, C.M.; Costa, H.L.; De Mello, J.D.B. Wear debris generation during cold rolling of stainless steels. J. Mater. Process. Technol. 2015, 223, 164–170. [Google Scholar] [CrossRef]

- Hilgenberg, K.; Steinhoff, K. Texturing of skin-pass rolls by pulsed laser dispersing. J. Mater. Process. Technol. 2015, 225, 84–92. [Google Scholar] [CrossRef]

- Ogarkov, N.; Zvyagina, E.Y.; Ismagilov, R. Theoretical Analysis of Formation of Automobile Sheet Roughness During Temper Rolling in Shot-Blasted Rolls. Steel Transl. 2019, 49, 499–503. [Google Scholar] [CrossRef]

- Simao, J.; Apinwall, D.; Wise, M.; Subari, K. Surface texture transfer in simulated tandem and temper mill rolling using electrical discharge textured rolls. J. Mater. Process. Technol. 1996, 56, 177–189. [Google Scholar] [CrossRef]

- Kijima, H.; Bay, N. Modelling of skinpass rolling by elasto-plastic analysis of plane strain upsetting. J. Mater. Process. Technol. 2006, 177, 509–512. [Google Scholar] [CrossRef]

- Tang, J. Effects of surface roughness microtopography on formability in cold rolled steel sheet. Adv. Mater. Res. 2013, 690–693, 2232–2235. [Google Scholar] [CrossRef]

- Monteiro, P.L.; Labiapari, W.S.; Da Silva, W.M.; Costa, H.L. Durability of deterministic textures produced by maskless electrochemical texturing (MECT) during Skin pass cold rolling. Wear 2025, 562–563, 205638. [Google Scholar] [CrossRef]

- Ould, C.; Badiche, X.; Montmitonnet, P.; Gachon, Y. PVD coatings for mill rolls for cold rolling of high carbon steel strips—Laboratory tests. Wear 2013, 306, 103–112. [Google Scholar] [CrossRef]

- Simão, J.; Aspinwall, D. Hard chromium plating of EDT mill work rolls. J. Mater. Process. Technol. 1999, 92–93, 281–287. [Google Scholar] [CrossRef]

- Gonçalves, J., Jr.; De Mello, J.; Costa, H. Tribological behaviour of alternative surface modifications for cold rolling mill rolls. Wear 2021, 470–471, 203614. [Google Scholar] [CrossRef]

- Wentink, D.; Matthews, D.; Appelman, N.; Toose, E. A generic model for surface texture development, wear and roughness transfer in skin pass rolling. Wear 2015, 328–329, 167–176. [Google Scholar] [CrossRef]

- Wu, C.; Zhang, L.; Qu, P.; Li, S.; Jiang, Z. A new method for predicting the three-dimensional surface texture transfer in the skin pass rolling of metal strips. Wear 2019, 426–427, 1246–1264. [Google Scholar] [CrossRef]

- Belov, V.; Begletsov, D.; D’yakova, M.; Gorbunov, A. Production of sheet with regulated surface microtopography. Steel Transl. 2014, 44, 298–305. [Google Scholar] [CrossRef]

- Pawelski, O.; Rasp, W.; Zwick, W.; Nettelbeck, H.-J.; Steinhoff, K. The influence of different work-roll texturing systems on the development of surface structure in the temper rolling process of steel sheet used in the automotive industry. J. Mater. Process. Technol. 1994, 45, 215–222. [Google Scholar] [CrossRef]

- Benati, F. Effect of Surface Topography upon the Quality of Autobody Panels. Ph.D. Thesis, Brunel University, London, UK, 2003. [Google Scholar]

- Köhler, K.; Kwiaton, N.; Bretschneider, M. Skin Pass Rolling of High Manganese Steels. Mater. Sci. Forum 2016, 854, 93–98. [Google Scholar] [CrossRef]

- Evin, E.; Tomáš, M.; Kmec, J. Optimization of Electro-Discharge Texturing Parameters for Steel Sheets’ Finishing Rollers. Materials 2020, 13, 1223. [Google Scholar] [CrossRef]

- Gorbunov, A.; Belov, V.; Begletsov, D. Texturing of rollers for the production of auto-industry sheet. Steel Transl. 2009, 39, 696–699. [Google Scholar] [CrossRef]

- De Mello, J.D.B.; Gonçalves, J.L., Jr.; Costa, H.L. Influence of surface texturing and hard chromium coating on the wear of steels used in cold rolling mill rolls. Wear 2013, 302, 1295–1309. [Google Scholar] [CrossRef]

- Aspinwall, D.; Wise, M.; Stout, K.; Goh, T.; Zhao, F.; El-Menshawy, M. Electrical discharge texturing. Int. J. Mach. Tools Manuf. 1992, 32, 183–193. [Google Scholar] [CrossRef]

- McGeough, J.; Rasmussen, H. A model for the surface texturing of steel rolls by electrodischarge machining. Proc. R. Soc. Lond. Ser. A Math. Phys. Sci. 1992, 436, 155–164. [Google Scholar]

- Rodriguez-Vidal, E.; Matthews, D.T.A.; de Viteri, V.S.; Korver, F.; Wentink, D.; Quintana, I. Surface design and texturing of strip steel using nanosecond pulsed lasers for simulated roughness transfer and paint appearance. J. Mater. Process. Technol. 2020, 275, 116365. [Google Scholar] [CrossRef]

- Elkoca, O. A study on the characteristics of electrical discharge textured skin pass mill work roll. Surf. Coat. Technol. 2008, 202, 2765–2774. [Google Scholar] [CrossRef]

- De Mare, C.; Scheers, J.; Lambert, F.; Vermeulen, M.; De Graef, L.; Gadeyne, Y. Development of the SIBETEX sheet having excellent drawability and paint appearance. Rev. Métall. 1997, 94, 827–836. [Google Scholar] [CrossRef]

- Costa, H.L.; Profito, F.J.; Zhang, X.; Thole, K.A. Optimizing the surface of manufactured components for friction, adhesion, and convective heat transfer. MRS Bull. 2022, 47, 1247–1259. [Google Scholar] [CrossRef]

- Yuan, S.; Lin, N.; Zou, J.; Liu, Z.; Wang, Z.; Tian, L.; Qin, L.; Zhang, H.; Wang, Z.; Tang, B.; et al. Effect of laser surface texturing (LST) on tribological behavior of double glow plasma surface zirconizing coating on Ti6Al4V alloy. Surf. Coat. Technol. 2019, 368, 97–109. [Google Scholar] [CrossRef]

- Costa, H.; Hutchings, I.M. Some innovative surface texturing techniques for tribological purposes. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2015, 229, 429–448. [Google Scholar] [CrossRef]

- Simao, J.; Aspinwall, D.; Wise, M.; El-Menshawy, M. Mill roll texturing using EDT. J. Mater. Process. Technol. 1994, 45, 207–214. [Google Scholar] [CrossRef]

- Bünten, R.; Steinhoff, K.; Rasp, W.; Kopp, R.; Pawelski, O. Development of a FEM-model for the simulation of the transfer of surface structure in cold-rolling processes. J. Mater. Process. Technol. 1996, 60, 369–376. [Google Scholar] [CrossRef]

- Šugár, P.; Šugárová, J.; Frnčík, M. Laser surface texturing of tool steel: Textured surfaces quality evaluation. Open Eng. 2016, 6, 90–97. [Google Scholar] [CrossRef]

- Kainz, A.; Paesold, D.; Riha, G.; Keintzel, G.; Krimpelstätter, K.; Zeman, K. Finite Element Simulation of Skin-Pass and Temper Rolling Processes with Special Emphasis on Roughness Transfer. In Proceedings of the NAFEMS World Congress, St. Julians, Malta, 17–20 May 2005; pp. 17–20. [Google Scholar]

- Weidel, S.; Engel, U. Surface characterisation in forming processes by functional 3D parameters. Int. J. Adv. Manuf. Technol. 2007, 33, 130–136. [Google Scholar] [CrossRef]

- Shimizu, I.; Andreasen, J.L.; Bech, J.I.; Bay, N. Influence of workpiece surface topography on the mechanisms of liquid lubrication in strip drawing. J. Trib. 2001, 123, 290–294. [Google Scholar] [CrossRef]