Abstract

The properties of lubricating oils are greatly enhanced by the incorporation of additives. With technological advancements, numerous additives have been developed and proven effective for this purpose. Some additives enhance anti-wear and anti-friction characteristics, while others improve the oil’s viscosity index. It has been noted that certain additives influence more than one property of the lubricating oil. In this study, a mixture of TiO2 at 0.2 wt.%, 0.3 wt.%, and 0.4 wt.% and CaCO3 at 0.4 wt.%, 0.6 wt.%, and 0.8 wt.% was used as an additive in gear oil EP140 to prepare the samples. A pin-on-disc test was conducted for the tribological characterization of the various samples. A combination of 0.2 wt.% TiO2 and 0.4 wt.% CaCO3 particles in the gear oil resulted in a remarkable 88.23% reduction in wear compared to the base gear lubricating oil (EP140). The combination of 0.3 wt.% TiO2 and 0.6 wt.% CaCO3 particles in the gear oil led to a significant 36.84% reduction in the coefficient of friction. Field Emission Scanning Electron Microscopy (FESEM) revealed that the pin tested with sample S1 (gear oil containing 0.2 wt.% TiO2 and 0.4 wt.% CaCO3) exhibited a smoother wear surface than the base lubricating oil.

1. Introduction

Lubrication, a vital component of modern engineering, involves strategically introducing substances between moving surfaces to reduce wear and tear. These substances, known as lubricants, include a diverse array of materials from solid forms like graphite to semi-solid greases and liquid lubricating oils, each designed for specific applications and operating conditions [1]. The primary role of a lubricant is to prevent direct metal to metal contact, thereby significantly reducing friction, minimizing wear rates, and averting catastrophic failures, such as seizing. The effectiveness of lubricants, especially liquid lubricating oils, goes beyond merely reducing friction; they also actively maintain surface cleanliness, remove debris, and prevent the buildup of harmful contaminants that could compromise system integrity [2,3,4,5].

With technological progress, the development of high-performance lubricants has advanced significantly. While base oils, traditionally derived from crude oil refining, provide a fundamental lubricating capability, they often fail to meet the demands of modern machinery operating under diverse and often extreme conditions [6,7]. The inherent limitations of base oils necessitate the incorporation of additives that are carefully selected and precisely formulated to enhance their performance characteristics [8,9]. These additives, which include both organic and inorganic compounds, are introduced at concentrations typically ranging from 0.1% to 5% of the total oil volume and meticulously adjusted to meet the specific requirements of the intended application. This customization is crucial because the optimal additive package for a high-speed engine differs substantially from that required for a heavy-duty industrial gear system [9,10]. Additives may exist in solution, fully dissolved within the base oil, or as finely dispersed solid particles, ensuring optimal distribution and performance throughout the lubricated system [11].

The versatility of additive technology lies in its capacity to address numerous performance deficiencies in base oils. Additives are not just enhancements; they are essential components that enable lubricants to achieve performance levels far beyond the capabilities of the base oil [12]. These enhancements span a broad spectrum of crucial properties. For instance, anti-wear additives minimize surface damage and extend the lifespan of components. Anti-friction additives further reduce energy lost to friction, improve efficiency, and lower operating temperatures [13]. Viscosity modifiers ensure that the oil maintains optimal viscosity across a wide range of temperatures, which is vital for maintaining lubrication under both extreme heat and cold conditions. Pour point depressants counteract the tendency of oils to thicken and solidify at low temperatures, ensuring proper lubrication even in subzero environments. Other additives address issues like oxidation stability, corrosion protection, and foam prevention [14]. This complex interplay between the base oil and additives results in a synergistic effect where the combined properties far exceed the sum of their individual components, producing a sophisticated and highly effective lubricating fluid. This introduction lays the groundwork for a deeper exploration of specific types of additives, their mechanisms of action, and their impact on the overall performance of lubricating oils [15,16]. In general, additives perform three basic lubricating roles [15]:

- Enhance the existing properties of the base oil, such as the viscosity index, corrosion resistance, wear, and friction resistance.

- Suppress the undesirable properties of the base oil, such as reducing the pour point of the oil using pour point depressants.

- Impart new properties to base oils, such as high load-carrying capacity, using extreme pressure (EP) additives.

The integration of nanoparticles into lubricants has proven to be a highly effective strategy for enhancing tribological performance. Numerous studies have demonstrated the significant potential of nanoparticles in reducing friction and wear, thereby improving efficiency and extending the lifespan of components across various applications [17]. Research has underscored the positive impact of different types of nanoparticles on lubricant properties. For instance, adding copper nanoparticles to lubricating oil has been shown to effectively reduce both the coefficient of friction and the wear rate on contacting surfaces [18]. Moreover, incorporating 2 wt.% copper oxide (CuO) nanoparticles into polyalphaolefin (POA) base oil resulted in a remarkable 273% increase in load-carrying capacity [19], highlighting the potential of nanoparticles to significantly enhance lubricant performance under heavy loads.

The advantages of these nanoparticles extend beyond those of their metallic counterparts. Incorporating 0.4 vol.% silicon dioxide (SiO2) nanoparticles into R134a refrigerant not only enhanced the refrigerant’s heat transfer properties but also improved the tribological characteristics of polyalkylene glycol (PAG) lubricants used alongside it [11]. Similarly, hybrid nanoparticles made from zinc oxide (ZnO) and multiwalled carbon nanotubes (MWCNTs) yielded promising outcomes. An optimal concentration of 0.25 wt.% of these hybrid nanoparticles, in a 3:1 ZnO:MWCNT ratio, mixed into 10W40 engine oil resulted in significant reductions in both the coefficient of friction (32.30%) and the wear volume (74.48%) compared to the base oil alone [11]. Further studies confirmed the positive effects of ZnO nanoparticles, showing enhancements in the thermophysical and tribological properties of diesel oil. A 0.25 wt.% concentration of ZnO nanoparticles dispersed in oleic acid (ZnO-OA) and added to POA40 base oil led to a 25% reduction in the friction coefficient and an 82% reduction in wear (measured by cross-sectional area) compared to the neat base oil [20,21,22,23,24].

Titanium dioxide (TiO2) nanoparticles have been demonstrated to be effective as lubricant additives. A concentration of 0.3 wt.% of TiO2 nanoparticles in multi-grade engine oil led to an impressive 86% reduction in the coefficient of friction [25]. Moreover, varying concentrations of TiO2 nanoparticles (ranging from 0.005% to 0.025% by volume) in the base oil has been shown to enhance the load-carrying capacity of journal bearings by up to 40% [26]. Further research has investigated the effects of TiO2 nanoparticles at concentrations of 0.1%, 0.5%, and 1% wt. in SAE 10 engine oil, highlighting the range of potential benefits [25]. In some instances, the mechanism behind these improvements is attributed to the formation of boundary lubrication films and adsorption films of oleic acid on rubbing surfaces, as observed with oleic-acid-modified lanthanum titanate (OA/LaTiO2) particles in rapeseed oil [27,28]. These OA/LaTiO2 particles, with an average diameter of 20 nm, enhance both the anti-wear and friction-reducing properties of rapeseed oil.

Calcium carbonate (CaCO3) nanoparticles have demonstrated potential in enhancing the load-carrying capacity, wear resistance, and friction characteristics of polyalphaolefin (PAO) base oils [17]. When combined with cerium oxide (CeO2) nanoparticles, these properties are further improved, particularly in terms of anti-wear and anti-friction capabilities. The optimal anti-wear performance was observed at a 5 wt.% concentration of CaCO3 in an amphiphilic copolymer [17]. Additionally, studies examining the relationship between lubricant chemical structure and friction/wear behavior under boundary conditions have revealed a correlation between increased molecular size and reduced wear and friction [25]. Collectively, these findings highlight the significant potential of nanoparticles to enhance lubricant performance and address critical tribological challenges. All of these references are summarized in Table 1.

Table 1.

Summary of the literature review.

In recent years, extensive research has concentrated on enhancing tribological properties, including, specifically, the reduction of friction and wear of lubricating oils. A substantial portion of this research highlights the effectiveness of incorporating solid particles, particularly metallic oxides and carbonates, to boost lubrication performance. While numerous studies have individually examined the effects of metallic oxides or carbonates, there has been relatively limited exploration of the combined impact of these two additive groups on lubricating oil properties. This study aims to fill this gap by investigating the tribological behavior of gear-lubricating oil modified with a blend of metallic oxides and carbonates. The primary objective is to analyze how these two types of additives collectively influence the key tribological characteristics of the resulting lubricant. This approach facilitates a more comprehensive understanding of the interaction between these additive types and their impact on overall lubrication performance, potentially leading to the development of even more effective lubricant formulations.

2. Materials and Methods

This section provides a detailed account of the materials and methods employed in preparing the lubricating oils for this study. It describes the properties of the chosen base oil and outlines the procedures used to create the various lubricant samples tested in the experiments.

2.1. Base Oil

The developed lubricating oils were intended for use in a gearbox. Consequently, a readily available market oil specifically designed for gearbox lubrication was chosen as the base oil. EP 140 is one such oil, and it has been utilized as the base oil; its characteristics are detailed in Table 2.

Table 2.

Characteristics of the base oil.

2.2. Additives

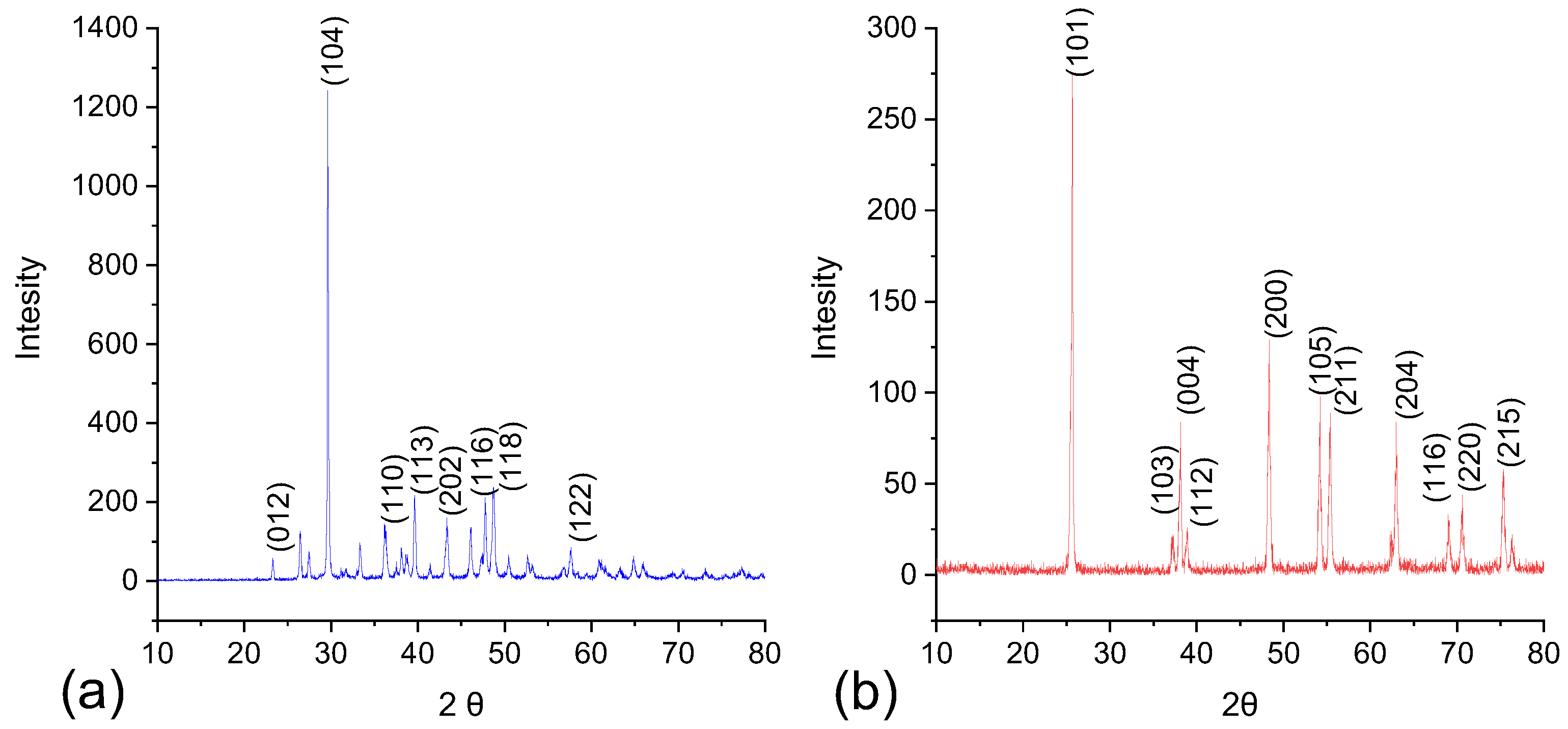

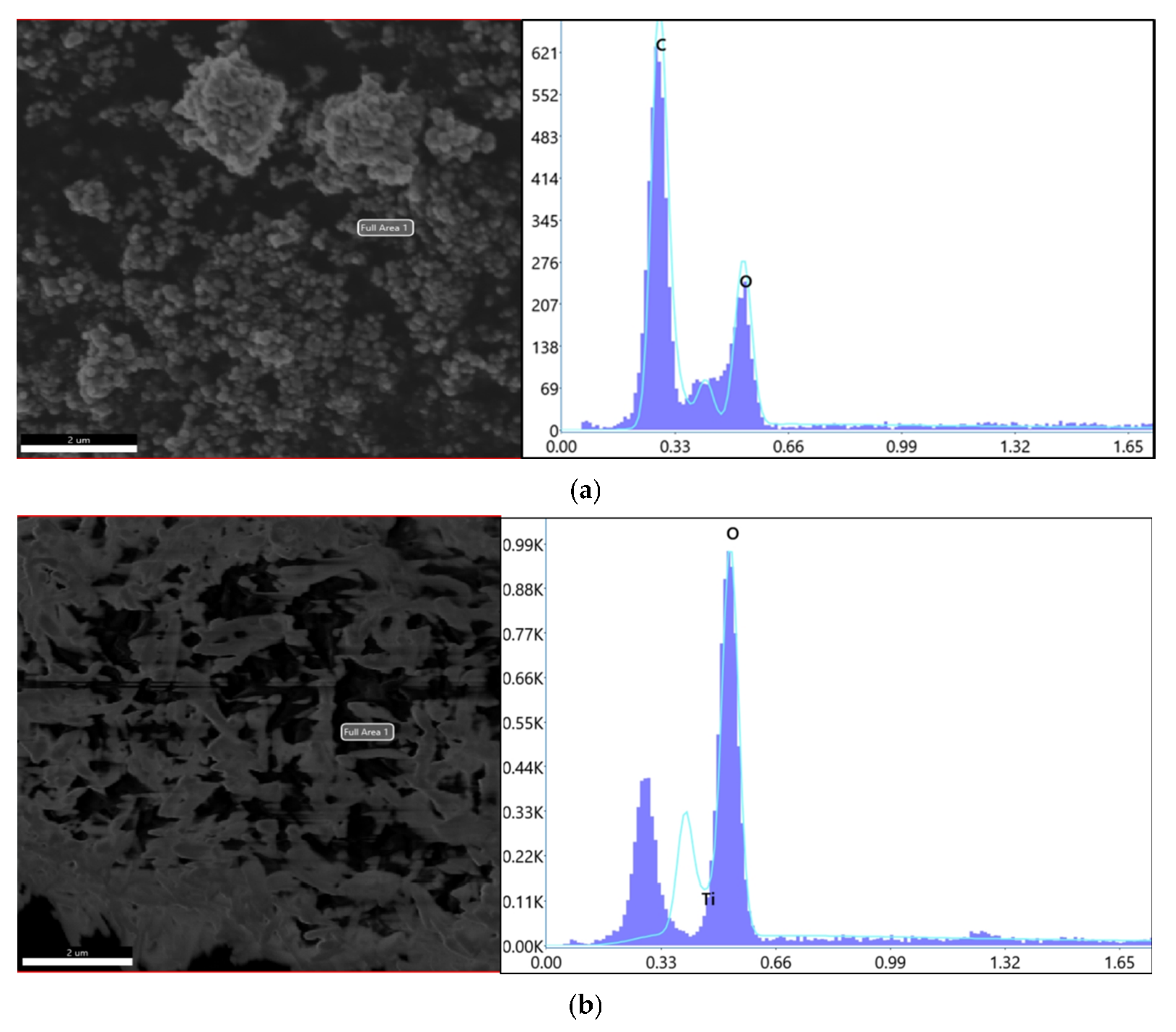

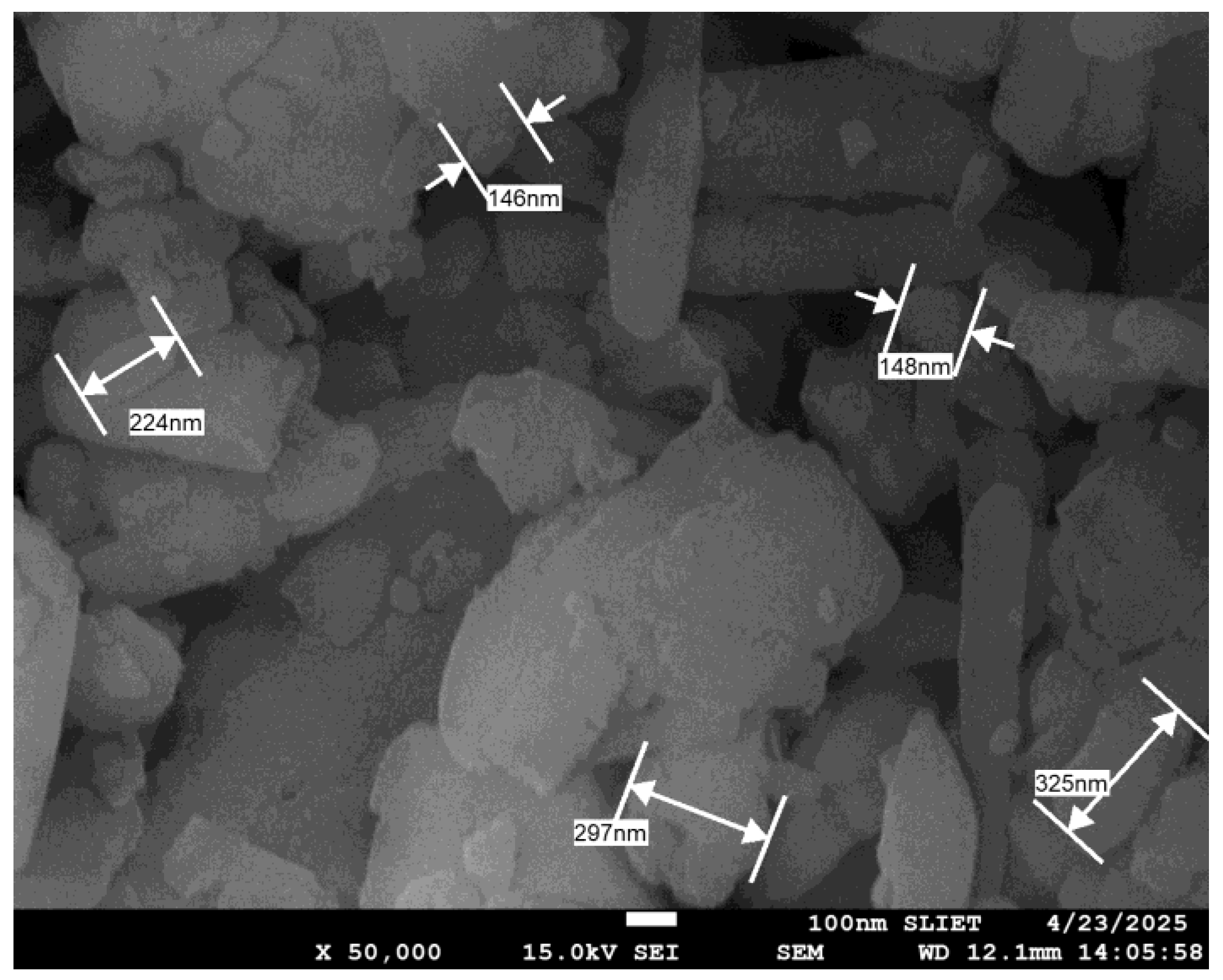

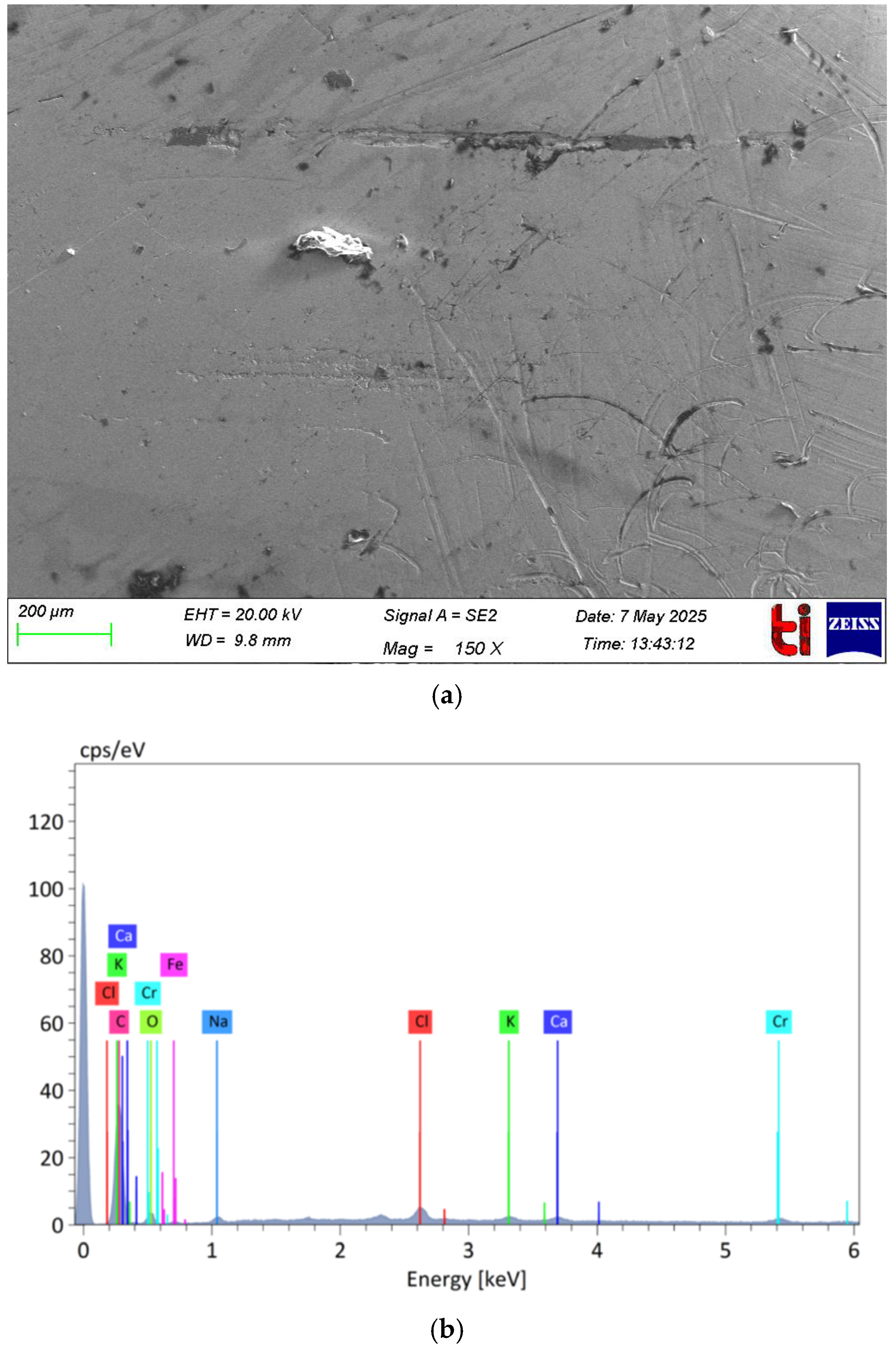

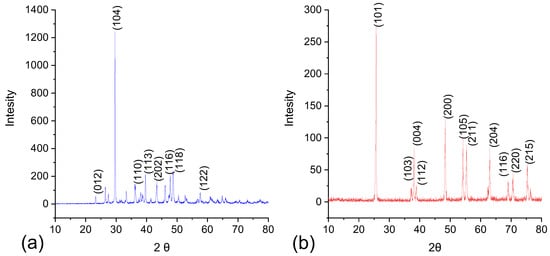

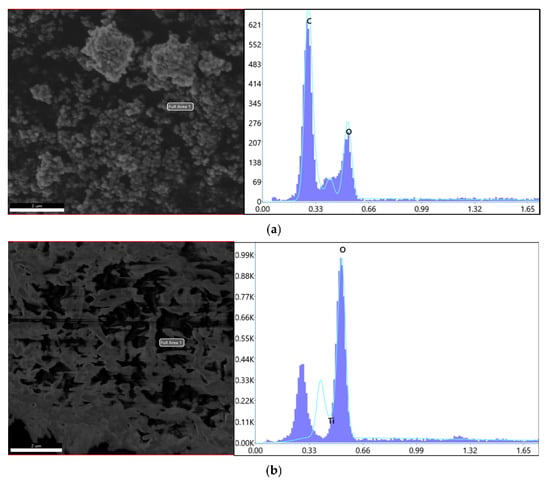

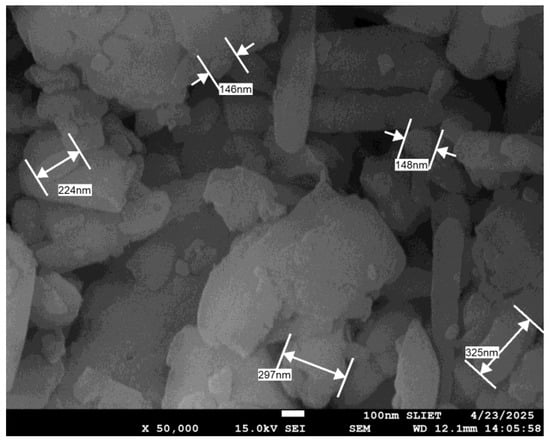

To enhance the properties of lubricants, additives are commonly employed. Among these, nanoparticles have garnered significant interest from researchers investigating their potential as lubricant additives. In this study, titanium oxide (TiO2) and calcium carbonate (CaCO3) powders, in the form of microparticles, were utilized to improve the tribological characteristics of EP 140 gear oil. These powders were procured from the market, and their size, shape, and composition were assessed using X-Ray Diffraction (XRD), Field Emission Scanning Electron Microscopy (FESEM), and Energy Dispersive X-Ray Spectroscopy (EDS), as depicted in Figure 1 and Figure 2, respectively. Additionally, the average size of the additives was determined with the aid of SEM, as illustrated in Figure 3.

Figure 1.

XRD results of (a) CaCO3 powder and (b) TiO2 powder.

Figure 2.

EDX results of (a) CaCO3 powder and (b) TiO2 powder.

Figure 3.

Size of the additives.

2.3. Determination of Concentration of Additives

Previous research has shown that titanium dioxide (TiO2) and calcium carbonate (CaCO3) each independently reduce friction and wear in lubricating oils. This study explores the combined effects of these additives on the lubrication characteristics of base oil. Building on prior research that suggests optimal concentrations of 0.3 wt.% TiO2 and 0.6 wt.% CaCO3, samples were prepared with concentrations both above and below these optimal values, as detailed in Table 3.

Table 3.

Composition of additives in base oil (BS) used for sample preparation.

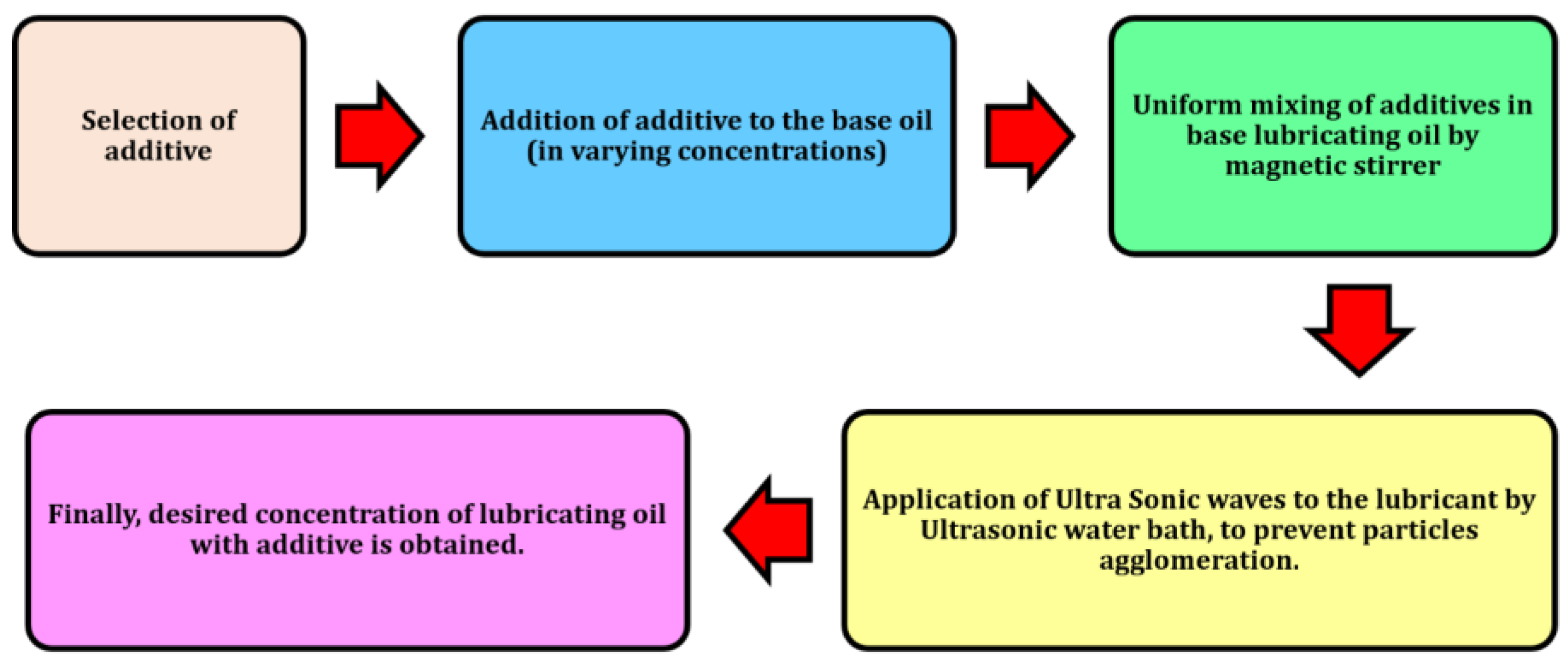

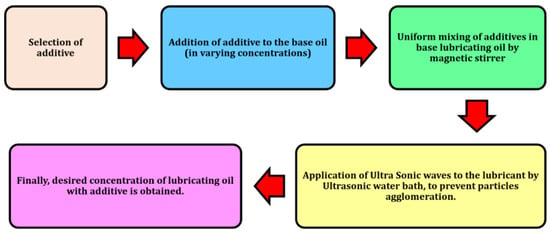

2.4. Methods for Lubricant Synthesis

To prepare lubricant samples, one liter of the base oil was initially weighed. The necessary amounts of titanium dioxide (TiO2) and calcium carbonate (CaCO3) particles, determined as a weight percentage of the base oil, were then measured. These additives were incorporated into the base oil and mixed with a magnetic stirrer for 30 min. To ensure thorough dispersion and minimize particle agglomeration, the mixture was sonicated overnight. The resulting homogeneous lubricant samples are detailed in Table 2. The preparation process is outlined in the flowchart shown in Figure 4.

Figure 4.

Procedure for lubricant synthesis.

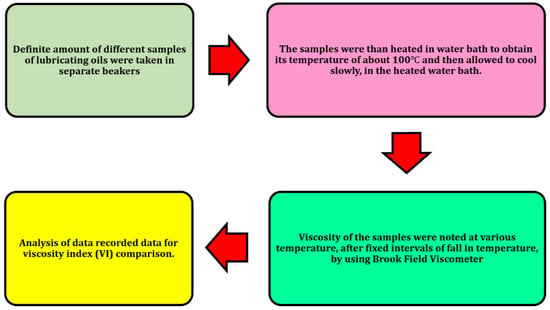

2.5. Viscosity Index Determination

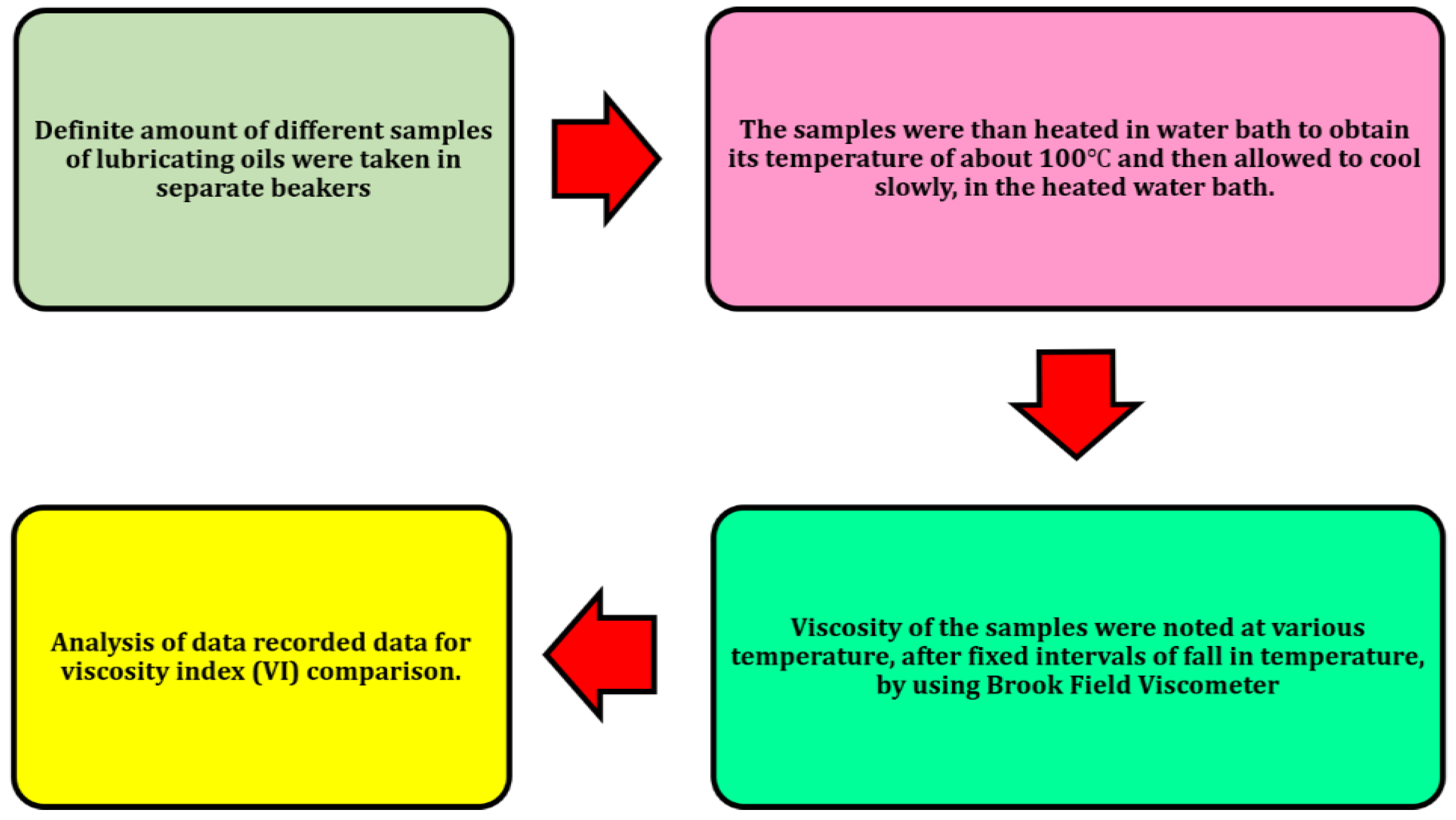

Each 400 mL sample of lubricating oil was placed in a separate beaker, which was then immersed in a temperature-controlled water bath and heated to 70 °C. Viscosity measurements were conducted at various temperatures using a digital Brookfield viscometer. Figure 5 presents a flowchart that illustrates the viscosity–temperature characterization process.

Figure 5.

Procedure for viscosity–temperature relationship evaluation.

3. Tribological Testing of Synthesized Lubricants

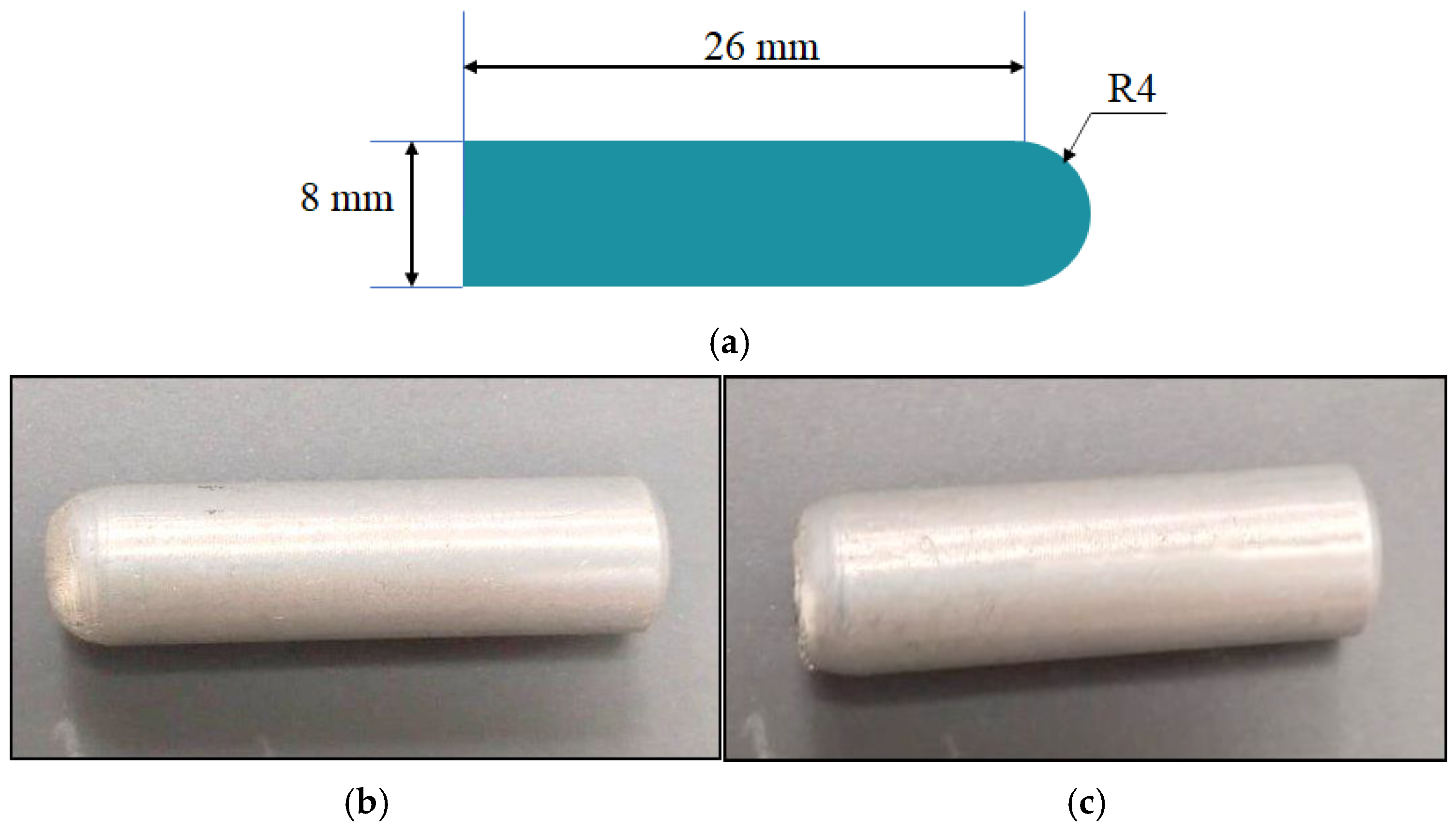

3.1. Test Pin Fabrication

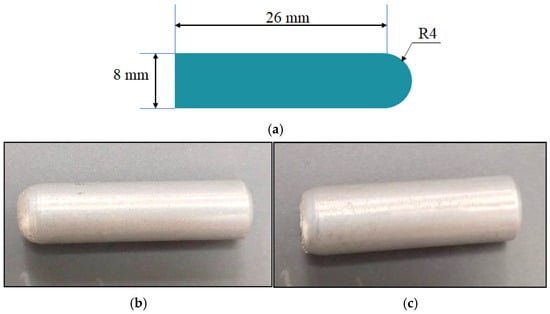

The test specimens, specifically the pins, were crafted from an MS round bar of grade 43A. These pins were machined to meet the specific dimensions required by the tribometer. The pin’s diameter was consistently maintained at 8 mm, with a length of 30 mm, as illustrated in Figure 6.

Figure 6.

(a) Sketch of friction pin, (b) pictorial view of pin before test, and (c) pictorial view of pin after test.

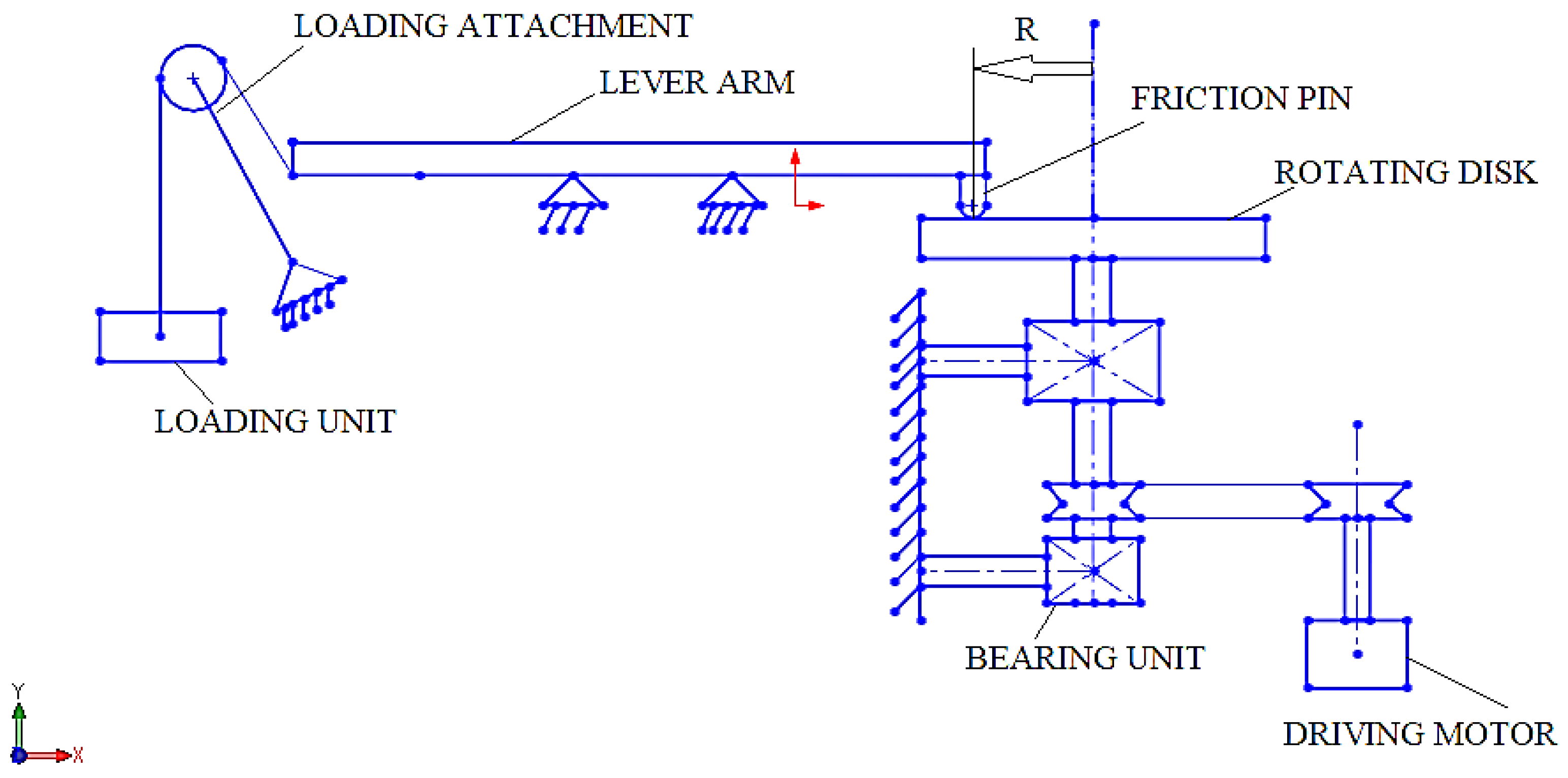

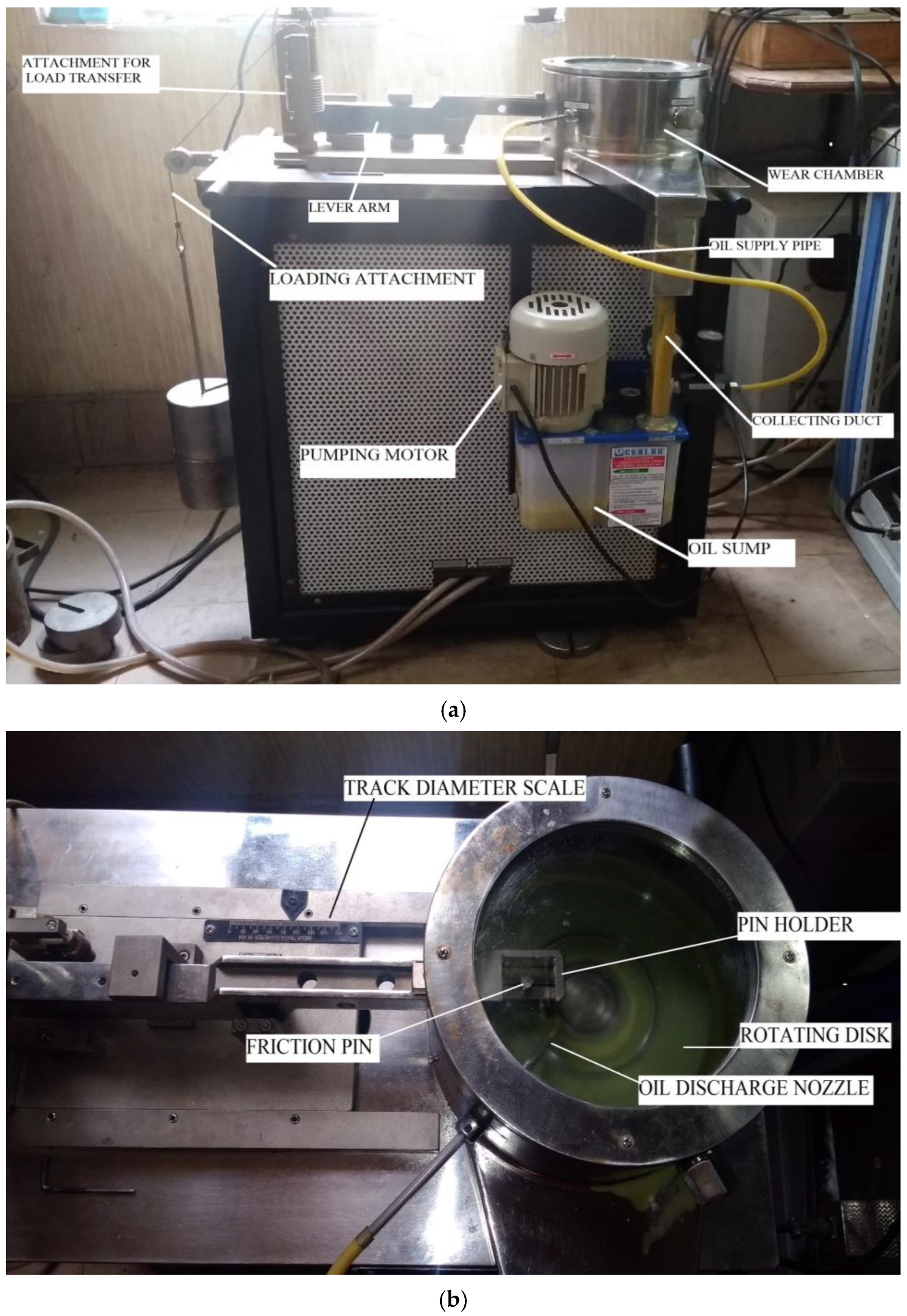

3.2. Pin Disc on Tribometer

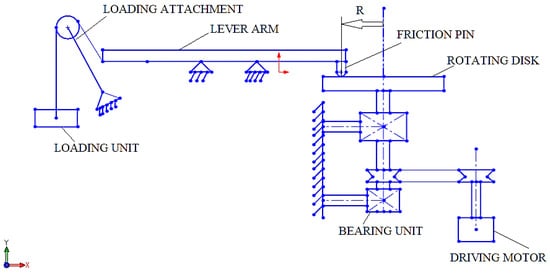

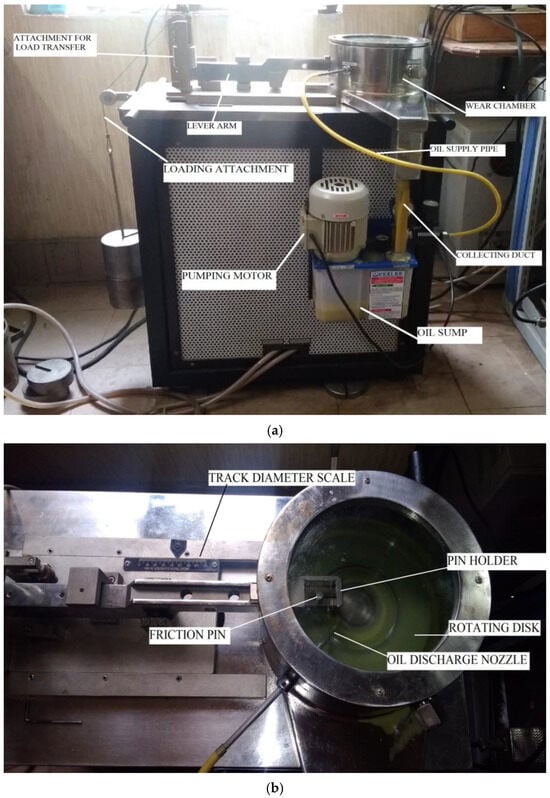

The friction and wear characteristics of the prepared lubricant samples were assessed using a pin-on-disc tribometer integrated with WIN-DUCOM 2010 software. This tribometer featured a motorized spindle and chuck to secure the rotating disc, a lever arm mechanism to hold the test pin, and a loading system that allowed for controlled force application between the pin and the disc, as illustrated in Figure 7. The wear track formed on the disc was circular, accommodating multiple wear passes along the same path. Equipped with a force transducer, the tribometer precisely measured the frictional force, enabling the determination of the coefficient of friction. The complete tribometer setup is depicted in Figure 8a,b. WIN-DUCOM software facilitated data acquisition and analysis of the friction and wear data obtained during testing.

Figure 7.

Schematic sketch of pin-on-disc tribometer.

Figure 8.

(a) Pin-on-disc tribometer; (b) top view of tribometer.

The operating principle of the tribometer is depicted in Figure 7. The test pin was firmly secured in a lever arm assembly and pressed against a rotating disc. This disc was mounted on a rotating chuck, which was directly connected to a constant-speed motor to ensure a uniform rotational speed throughout the test. The opposite end of the lever arm was linked to a loading unit via a loading attachment. A specified load was applied to this loading unit, and it was transferred to the pin through the lever arm, maintaining consistent contact pressure between the pin and the rotating disc for the duration of the experiment. This setup ensured that a constant load was maintained throughout the tests.

Tribological testing using a pin-on-disc apparatus involved the following steps:

- The test pin and disc were thoroughly cleaned and dried to eliminate contaminants or foreign materials that could have affected the results.

- The test pin was securely mounted in its holder to ensure perpendicular alignment with the disc surface to maintain consistent contact conditions.

- The tribometer motor was started, and the rotational speed was adjusted to a predetermined value. At this stage, the pin was not in contact with the rotating disc.

- The lever arm was adjusted to set the desired diameter for the wear track on the rotating disc.

- The required number of disc rotations and total test duration were programmed into the tribometer.

- An appropriate amount of mass was then added to the loading unit. The loading attachment then transferred this force to the test pin via the lever arm, applying the desired normal force to the pin–disc contact zone.

- The lubricant pump was activated to ensure a continuous supply of lubricant to the pin–disc contact zone.

- With the pin in contact with the rotating disc under load, the test commenced and ran until the preset time was reached, automatically stopping the apparatus.

- The test pin and disc were carefully removed from the tribometer, and any wear debris was meticulously removed from the surfaces. Subsequent analysis of the pin and the disc allowed for the determination of the wear volume and the coefficient of friction.

4. Results and Discussion

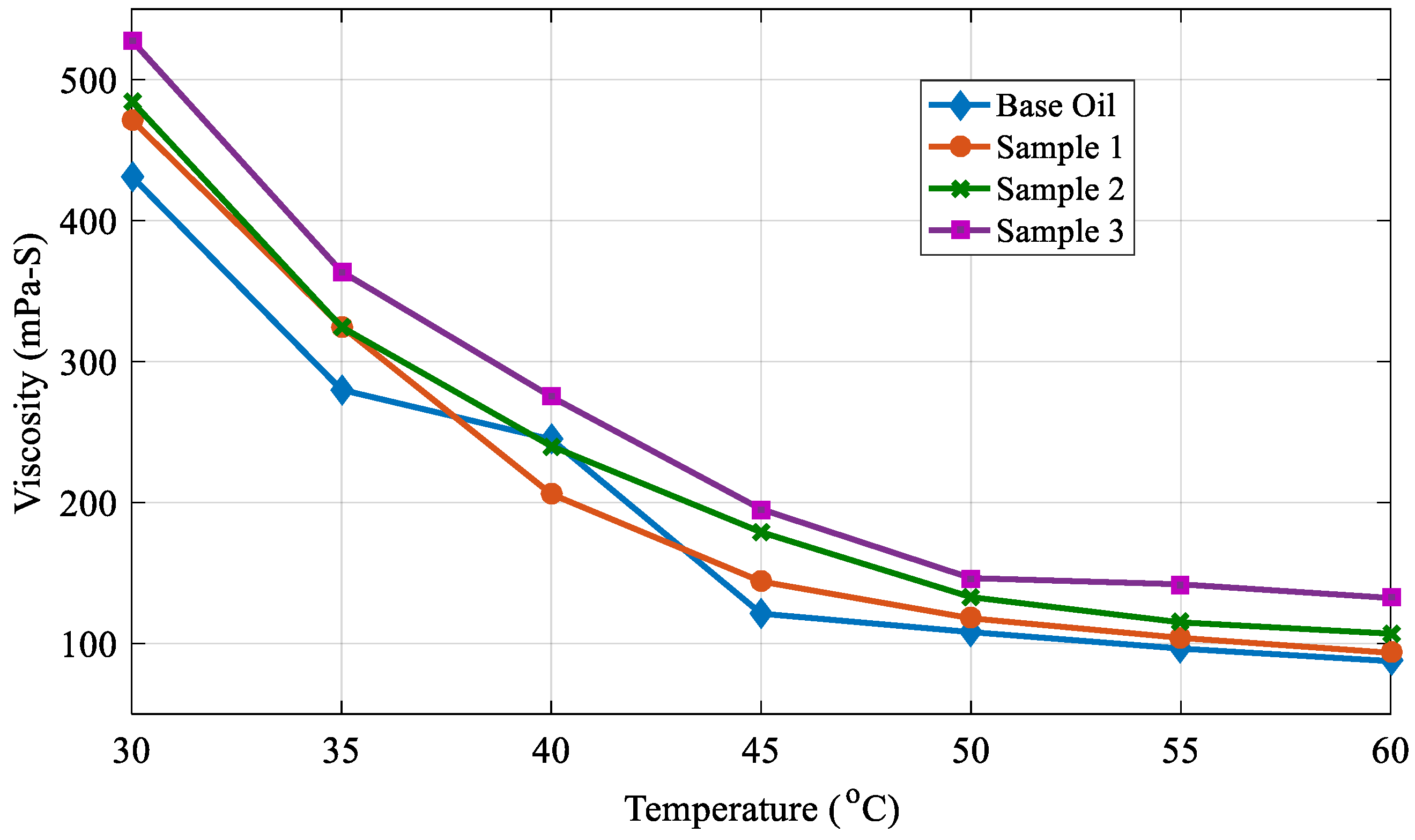

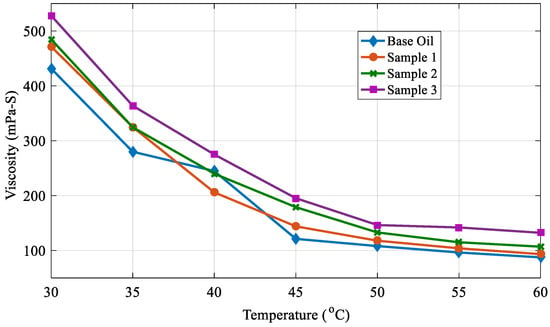

The viscosity of lubricating oils, like most oils, is known to inversely correlate with temperature; as the temperature rises, the viscosity decreases. This reduction in viscosity lessens the oil’s lubricating ability, thereby adversely impacting the overall efficiency of the system. Enhancing the viscosity index (VI) of the oil is a crucial approach to counteracting this temperature-dependent viscosity decline; a higher VI signifies a smaller change in viscosity across a given temperature range. This study examined the effect of titanium dioxide (TiO2) and calcium carbonate (CaCO3) particles on the viscosity and stability of the base oil. Three lubricant samples were prepared, each with different concentrations of additives. The viscosity of each sample, along with that of the base oil, was measured at various temperatures. The resulting viscosity values (in mPa·s) are presented in Table 4, facilitating a comparison of the viscosity–temperature behavior among the different lubricant formulations. This comparison underscores the effectiveness of additives in maintaining viscosity at elevated temperatures.

Table 4.

Viscosity of oils at different temperatures.

The experimental results demonstrated a positive correlation between additive concentration and oil viscosity; as the amount of TiO2 and CaCO3 additives increased, so did the viscosity of the lubricant. This rise in viscosity can be attributed to the formation of agglomerates of additive particles within the oil, which effectively enhances the bulk viscosity. As illustrated in Figure 9, the viscosity of all lubricant samples, including the base oil, decreased with rising temperature, aligning with the typical behavior of lubricating oils. However, at elevated temperatures, samples with higher additive concentrations exhibited greater viscosities than those with lower concentrations. Moreover, the rate at which viscosity decreased with temperature was more pronounced with higher additive concentrations. Lubricants with greater additive concentrations showed a steeper decline in viscosity as the temperature rose. This indicates a complex interplay between additive concentration, temperature, and agglomeration in influencing the overall viscosity of the formulated lubricating oils.

Figure 9.

Viscosity variation of oils with temperature.

4.1. Anti-Friction Test of Lubricating Oils

To assess the impact of various TiO2 and CaCO3 combinations on the anti-friction properties of the base oil, a series of tribological tests were conducted using a pin-on-disc tribometer. Multiple samples of the formulated lubricating oils were tested under different operating conditions to evaluate their anti-friction performance. Specifically, tests were carried out at two rotational speeds and two distinct load levels to thoroughly examine how these parameters influence the lubricating properties of the formulated oils, as detailed in Table 5. The following parameters were kept constant for all tests: a pin revolution track diameter of 90 mm and a total test duration of 10 min. This consistent experimental design ensured that any variations in the measured friction coefficients could be directly attributed to differences in lubricant composition rather than other factors. The results of these tests provided valuable insights into the effectiveness of various additive combinations in reducing friction.

Table 5.

Coefficient of friction of oils at different load and speed conditions.

Table 5 presents the coefficient of friction (COF) results obtained under various test conditions. At low speed and low load, sample S2, which contains 0.3 wt.% TiO2 and 0.6 wt.% CaCO3, exhibited the lowest COF. A general trend emerged, showing that the COF initially decreased to a minimum at intermediate additive concentrations before rising again with further increases in concentration. This suggests the existence of an optimal additive concentration range for minimizing friction under these specific conditions. However, under high load and low speed conditions, S3 (0.4 wt.% TiO2 and 0.8 wt.% CaCO3) demonstrated the lowest COF, as shown in Table 5. This indicates that the optimal additive concentration for reducing friction can be influenced by the applied load. The observed nonlinear relationship between additive concentration and COF suggests a complex interplay between the additives and their interactions within the base oil under various load and speed conditions.

Under conditions of low load and high speed, the lubricant sample with an intermediate additive concentration demonstrated the lowest coefficient of friction (COF), as shown in Table 5. However, a notable change in behavior occurred when the load increased from 4 kg to 10 kg while maintaining high speed. In this high-load scenario, the COF decreased as the additive concentration increased, with the base oil (lacking additives) showing the lowest COF. This unexpected result suggests a breakdown in the tribofilm formation mechanism at higher speeds and loads. Although higher additive concentrations are effective at lower loads and speeds, they may fail to sustain an effective lubricating tribofilm under high loads and speeds, resulting in a higher COF compared to the base oil, which may rely on different lubrication mechanisms under these extreme conditions. The inability to form a stable and effective tribofilm with high additive concentrations at high speeds and loads likely contributed to increased friction.

As shown in Table 5, the reduction in the COF becomes significantly more pronounced at higher speeds, irrespective of the applied load. Among all of the samples, S2 exhibited the greatest reduction in COF, particularly under conditions of low load and high speed, achieving nearly a 90% reduction, as highlighted in Table 5. The base oil and S1 samples performed moderately, with improved results under high-speed conditions. In contrast, S3 demonstrated poor performance under low load and low speed but showed improvement at higher speeds. This pattern indicates that speed exerts a more substantial influence on friction reduction than load. High-speed conditions likely facilitate the formation of a lubricating film or decrease contact resistance, leading to a more effective reduction in COF.

4.2. Anti-Wear Test of Lubricating Oils

To evaluate the anti-wear properties of the formulated lubricating oils, wear tests were conducted alongside friction tests using the same pin-on-disc tribometer. This simultaneous testing ensured consistent experimental conditions, minimizing variations that could result from changes in environmental factors or machine settings between tests. The anti-wear performance of each lubricant sample was assessed, and the results are presented in Table 6. This combined approach facilitates a direct comparison between the anti-friction and anti-wear characteristics of various lubricant formulations.

Table 6.

Wear at different load and speed conditions.

The analysis of the wear test results presented in Table 6 indicates that under conditions of low load and low speed, the lubricant sample containing 0.2 wt.% TiO2 and 0.4 wt.% CaCO3 achieved the lowest wear rate. This formulation demonstrated an impressive 92.23% reduction in wear compared to a no lubrication control test, underscoring the significant anti-wear performance of this specific additive combination under these operating conditions. This finding highlights the potential of this optimized additive mixture to enhance the wear resistance of lubricating oils in low-stress environments.

Under conditions of high load and low speed, a lubricant sample with 0.2 wt.% TiO2 and 0.4 wt.% CaCO3 achieved the lowest wear rate. This formulation resulted in a 50% reduction in wear compared to the base oil without additives. A clear trend was observed, as wear increased as the concentrations of TiO2 and CaCO3 additives rose. Similar findings were noted under low-load, high-speed conditions, where the 0.2 wt.% TiO2 and 0.4 wt.% CaCO3 mixture again achieved the lowest wear rate. In this scenario, wear also increased with higher additive concentrations, as detailed in Table 6. The consistent observation of minimal wear at this specific additive concentration across varying load and speed conditions suggests that this combination provides optimal anti-wear protection, regardless of the operating parameters, within the tested range.

Table 6 presents the percentage of wear reduction (%) across various lubricant samples tested under four distinct combinations of loads and speeds. Sample S1 demonstrates the highest wear reduction under conditions of low load, low speed, high load, and high speed (highlighted with red circles), indicating its exceptional performance in both mild and severe operating conditions. The base oil sample shows moderate performance, but it exhibits lower wear reduction at low loads and high speeds, suggesting reduced effectiveness when only speed is increased. Sample S2 displays a balanced performance across all four conditions, maintaining relatively consistent wear reduction. Sample S4 shows the least wear reduction, particularly under high-speed conditions, indicating its unsuitability for high-speed applications. Figure 10 illustrates that both load and speed influence the wear-reducing performance of the lubricants. However, sample S1 proves to be the most effective across a wide range of conditions, making it a strong candidate for applications involving varying mechanical stresses.

Figure 10.

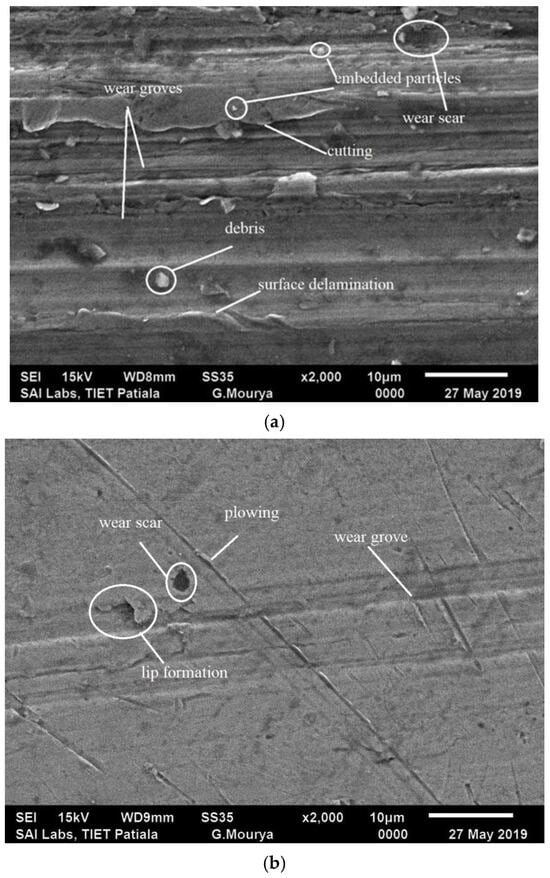

(a) SEM image of specimen base oil (BO) at 10 kg load and 500 rpm speed; (b) SEM image of specimen (S1) tested at 10 kg load and 500 rpm speed.

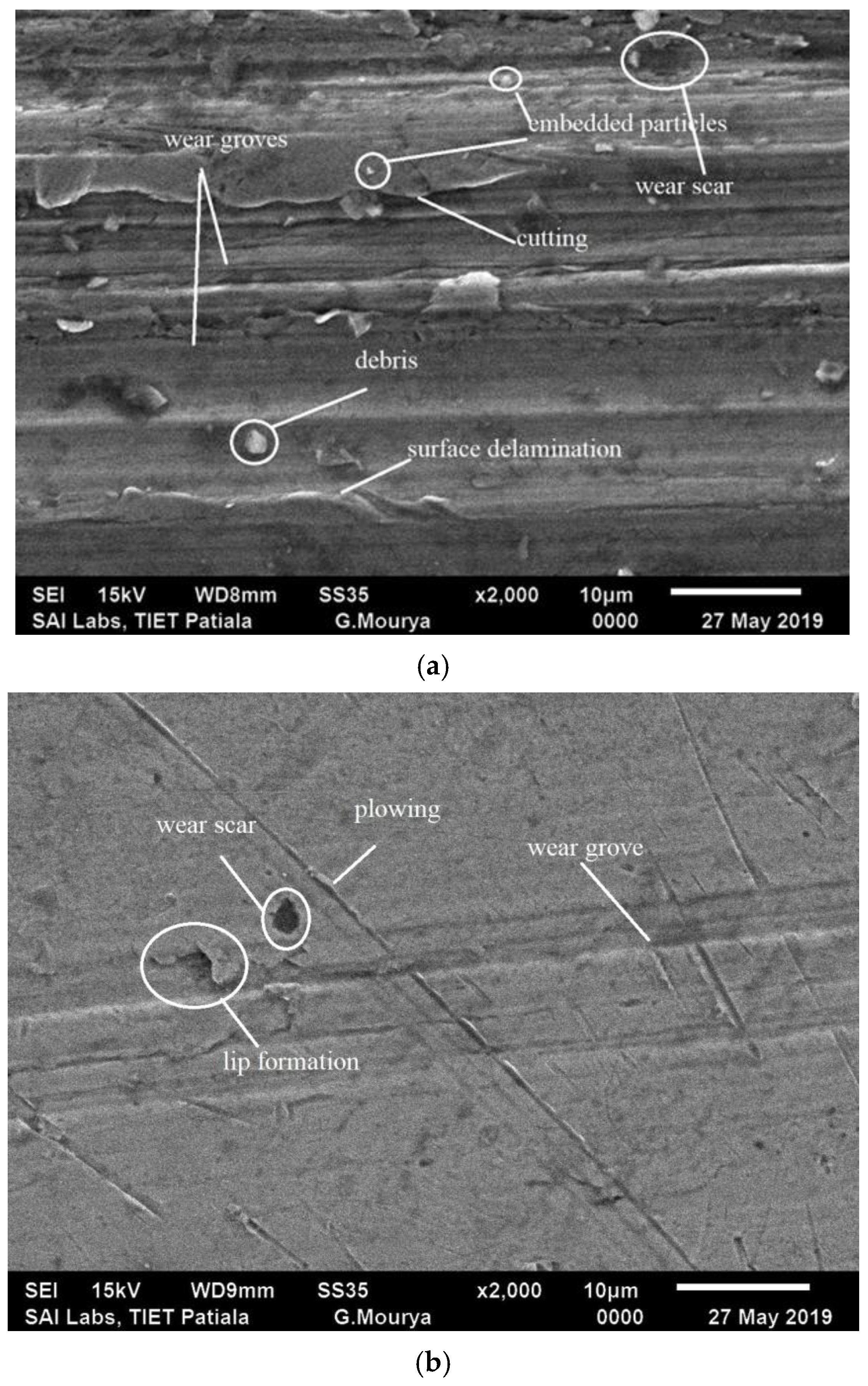

4.3. SEM Testing of Specimen

To explore how rotational speed affects wear patterns, scanning electron microscopy (SEM) was utilized to examine the morphology of the worn test pins. SEM images were captured for two samples tested under a 10 kg load and a speed of 500 rpm, one lubricated with sample S1 (containing additives) and the other with the base oil, as depicted in Figure 10a and Figure 10b, respectively. The specimen lubricated with base oil, shown in Figure 10b, exhibited significant wear damage, including deep grooves, signs of material cutting, and considerable debris accumulation on the worn surface. This severe wear aligned with the higher wear rates observed for the base oil, as indicated in Table 6. Conversely, the inclusion of nanomaterials (TiO2 and CaCO3) in sample S1, as seen in Figure 10a, led to a distinctly different wear pattern. The SEM images showed that the nanomaterials effectively filled the micro-grooves and valleys on the worn surface, forming a protective layer that minimized direct metal to metal contact. This enhanced surface protection mechanism is a crucial factor in the significant reduction in wear observed with additive-containing lubricants, as shown in Table 5. The difference in surface morphology highlights the improved tribological performance resulting from the incorporation of nanomaterials into the base lubricant.

Comparing the SEM images revealed clear differences in wear patterns at various speeds. At low speeds, the wear surface displayed a relatively smooth morphology. However, as the speed increased, the wear pattern shifted to one marked by more material cutting and the formation of lip-like features at the edges of the wear track. This increase in cutting and lip formation resulted directly from the higher shear stresses that developed at elevated speeds. Furthermore, at higher speeds, the presence of embedded particles within the worn surface indicates a more aggressive interaction between the lubricant and the test pin. The presence of wear debris and signs of plowing further contributed to the degradation of the surface texture and an increase in overall wear at higher speeds. The transition from smooth wear at lower speeds to more severe damage characterized by cutting, lip formation, particle embedding, and plowing at higher speeds highlights the significant impact of rotational speed on wear mechanisms in the pin-on-disc test.

The physiochemical interactions between CaCO3, TiO2, and the base oil (EP 140) achieved homogeneous dispersion. This is because the surface energy of the nanoparticles is compatible with the surface tension of the base oil. Also, the nanoparticles naturally attract each other through van der Waals forces, leading to agglomeration. The combination of these factors provides a more robust and durable protective film, improving wear resistance and load-carrying capacity. It can lead to a further reduction in the coefficient of friction, resulting in even better energy efficiency. CaCO3 can help mitigate any potential abrasive effects of TiO2, while TiO2 can compensate for any potential thickening effects of CaCO3, leading to a more balanced and optimized formulation.

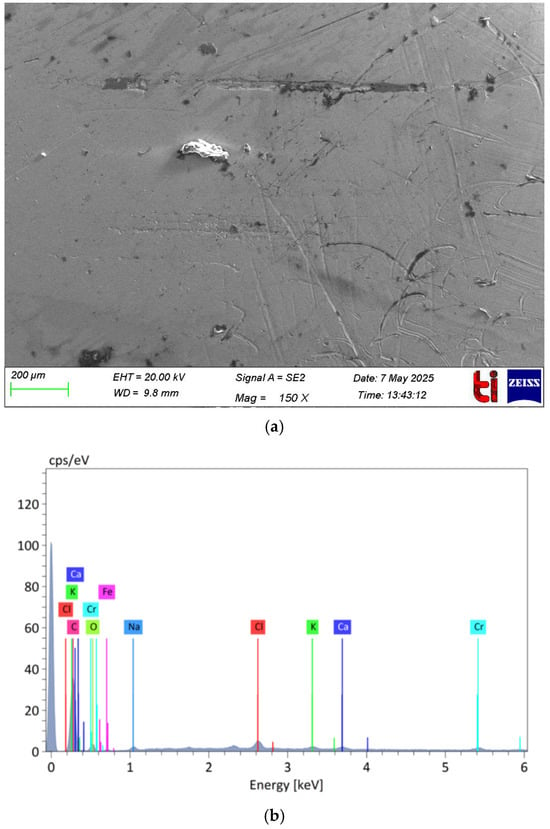

The effect of the developed nanoparticles on the MS round bar (pin) is that it reduces the friction between the pin and the counter surface, which leads to less removal of the material from the pin, extending its lifespan. The surface asperities of the pin have been filled by the developed nanoparticles, providing more contact points and distributing the load more evenly. To validate these findings, the SEM and EDS analyses of the worn-out surface were carried out, as shown in Figure 11. The composition of the elements of the worn-out surface obtained through EDS is tabulated in Table 7. From the results obtained through EDS, it can be easily observed that calcium (Ca) is present on the worn-out surface.

Figure 11.

(a) SEM image of the worn-out surface; (b) EDS of the worn-out surface in the case of sample S1.

Table 7.

Composition of the worn-out surface in the case of sample S1.

5. Conclusions

Viscosity–temperature tests demonstrated that adding titanium dioxide (TiO2) and calcium carbonate (CaCO3) particles increased the base oil’s viscosity without adversely affecting its viscosity index. Moreover, higher concentrations of these additives led to increased viscosities, likely due to particle agglomeration. The combined use of these additives effectively reduced both the coefficient of friction and the wear rate of the gear oil. Although the reduction in the coefficient of friction varied with test conditions, a mixture of 0.2 wt.% TiO2 and 0.4 wt.% CaCO3 notably decreased the wear rate. This improvement is attributed to the formation of a protective tribofilm in the contact zone, which effectively separates the contacting surfaces. However, excessively high additive concentrations may increase the sliding friction and, consequently, the wear rates due to potential interference with effective tribofilm formation. Future research could explore incorporating polymers alongside the TiO2 and CaCO3 additives to further enhance the viscosity index and investigate the impact of compatible extreme-pressure additives on load-carrying capacity. This would broaden the understanding of the synergistic effects of these additive types on the overall tribological performance of gear oil.

Author Contributions

A.S.: data curation, software, writing—original draft, methodology; S.K. (Surinder Kumar): data curation, software, writing—original draft, methodology; S.K. (Sumit Kumar): editing and methodology; H.K.: writing—review and editing, supervision; S.C.: writing—review and editing; G.V.: writing—review and editing, supervision; R.K.: writing—review and editing, supervision. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

Data will be made available upon reasonable request.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Xu, N.; Zhang, M.; Li, W.; Zhao, G.; Wang, X.; Liu, W. Study on the selectivity of calcium carbonate nanoparticles under the boundary lubrication condition. Wear 2013, 307, 35–43. [Google Scholar] [CrossRef]

- Bartz, W.J. Tribology, lubricants and lubrication engineering—A review. Wear 1978, 49, 1–18. [Google Scholar] [CrossRef]

- Blau, P.J. Friction Science and Technology: From Concepts to Applications, Second Edition, 2nd ed.; CRC Press: Boca Raton, FL, USA, 2008. [Google Scholar] [CrossRef]

- Shenoy, B.S.; Binu, K.G.; Pai, R.; Rao, D.S.; Pai, R.S. Effect of nanoparticles additives on the performance of an externally adjustable fluid film bearing. Tribol. Int. 2012, 45, 38–42. [Google Scholar] [CrossRef]

- Wan, S.; Tieu, A.K.; Xia, Y.; Zhu, H.; Tran, B.H.; Cui, S. An overview of inorganic polymer as potential lubricant additive for high temperature tribology. Tribol. Int. 2016, 102, 620–635. [Google Scholar] [CrossRef]

- Chen, L.; Zhu, D. Preparation and tribological properties of unmodified and oleic acid-modified CuS nanorods as lubricating oil additives. Ceram. Int. 2017, 43, 4246–4251. [Google Scholar] [CrossRef]

- Sharma, V.; Timmons, R.B.; Erdemir, A.; Aswath, P.B. Interaction of plasma functionalized TiO2 nanoparticles and ZDDP on friction and wear under boundary lubrication. Appl. Surf. Sci. 2019, 489, 372–383. [Google Scholar] [CrossRef]

- Miao, W.J.; Wang, S.Q.; Wang, Z.H.; Wu, F.B.; Zhang, Y.Z.; Ouyang, J.H.; Wang, Y.M.; Zou, Y.C. Additive Manufacturing of Advanced Structural Ceramics for Tribological Applications: Principles, Techniques, Microstructure and Properties. Lubricants 2025, 13, 112. [Google Scholar] [CrossRef]

- Gupta, R.N.; Harsha, A.P. Synthesis, Characterization, and Tribological Studies of Calcium–Copper–Titanate Nanoparticles as a Biolubricant Additive. J. Tribol. 2016, 139, 021801. [Google Scholar] [CrossRef]

- Abdul Basir, N.F.; Iliya Nor Za’im, S.; Abdul Wahab, Y.; Johan, M.R.; Ghaffari Khaligh, N. Impact Symmetry on Tribology Performance of 2,5-Bis-Cycloalkylsulfenyl[1,3,4]Thiadiazole Derivatives. Tribol. Trans. 2025, 68, 206–223. [Google Scholar] [CrossRef]

- Pendbhaje, G.; Ali, M.; Bajaj, D. Bio-lubricants as viable replacements for mineral oils in automotive engines: A review. Tribol.-Mater. Surf. Interfaces 2025, 19, 24–38. [Google Scholar] [CrossRef]

- Kamel, B.M.; Arafa, E.L.; Mohamed, A. Tribological and rheological properties of the lubricant containing hybrid graphene nanosheets (GNs)/titanium dioxide (TiO2) nanoparticles as an additive on calcium grease. J. Dispers. Sci. Technol. 2023, 44, 2675–2682. [Google Scholar] [CrossRef]

- Alghani, W.; Ab Karim, M.S.; Bagheri, S.; Amran, N.A.M.; Gulzar, M. Enhancing the Tribological Behavior of Lubricating Oil by Adding TiO2, Graphene, and TiO2/Graphene Nanoparticles. Tribol. Trans. 2019, 62, 452–463. [Google Scholar] [CrossRef]

- Sivakumar, B.; Ranjan, N.; Ramaprabhu, S.; Kamaraj, M. Tribological properties of graphite oxide derivative as nano-additive: Synthesized from the waster carbon source. Tribol. Int. 2020, 142, 105990. [Google Scholar] [CrossRef]

- Xia, W.; Zhao, J.; Wu, H.; Zhao, X.; Zhang, X.; Xu, J.; Jiao, S.; Wang, X.; Zhou, C.; Jiang, Z. Effects of oil-in-water based nanolubricant containing TiO2 nanoparticles in hot rolling of 304 stainless steel. J. Mater. Process. Technol. 2018, 262, 149–156. [Google Scholar] [CrossRef]

- Razavi, S.; Sabbaghi, S.; Rasouli, K. Comparative investigation of the influence of CaCO3 and SiO2 nanoparticles on lithium-based grease: Physical, tribological, and rheological properties. Inorg. Chem. Commun. 2022, 142, 109601. [Google Scholar] [CrossRef]

- Tóth, Á.D.; Hargitai, H.; Szabó, Á.I. Tribological Investigation of the Effect of Nanosized Transition Metal Oxides on a Base Oil Containing Overbased Calcium Sulfonate. Lubricants 2023, 11, 337. [Google Scholar] [CrossRef]

- Choi, Y.; Lee, C.; Hwang, Y.; Park, M.; Lee, J.; Choi, C.; Jung, M. Tribological behavior of copper nanoparticles as additives in oil. Curr. Appl. Phys. 2009, 9, e124–e127. [Google Scholar] [CrossRef]

- Peña-Parás, L.; Taha-Tijerina, J.; Garza, L.; Maldonado-Cortés, D.; Michalczewski, R.; Lapray, C. Effect of CuO and Al2O3 nanoparticle additives on the tribological behavior of fully formulated oils. Wear 2015, 332–333, 1256–1261. [Google Scholar] [CrossRef]

- Vardhaman, B.S.A.; Amarnath, M.; Ramkumar, J.; Mondal, K. Enhanced tribological performances of zinc oxide/MWCNTs hybrid nanomaterials as the effective lubricant additive in engine oil. Mater. Chem. Phys. 2020, 253, 123447. [Google Scholar] [CrossRef]

- Mousavi, S.B.; Zeinali Heris, S. Experimental investigation of ZnO nanoparticles effects on thermophysical and tribological properties of diesel oil. Int. J. Hydrog. Energy 2020, 45, 23603–23614. [Google Scholar] [CrossRef]

- Han, X.; Thrush, S.J.; Zhang, Z.; Barber, G.C.; Qu, H. Tribological characterization of ZnO nanofluids as fastener lubricants. Wear 2021, 468–469, 203592. [Google Scholar] [CrossRef]

- Mariño, F.; López, E.R.; Arnosa, Á.; Gómez, M.A.G.; Piñeiro, Y.; Rivas, J.; Alvarez-Lorenzo, C.; Fernández, J. ZnO nanoparticles coated with oleic acid as additives for a polyalphaolefin lubricant. J. Mol. Liq. 2022, 348, 118401. [Google Scholar] [CrossRef]

- Gara, L.; Zou, Q. Friction and Wear Characteristics of Oil-Based ZnO Nanofluids. Tribol. Trans. 2013, 56, 236–244. [Google Scholar] [CrossRef]

- Laad, M.; Jatti, V.K.S. Titanium oxide nanoparticles as additives in engine oil. J. King Saud Univ.-Eng. Sci. 2018, 30, 116–122. [Google Scholar] [CrossRef]

- Binu, K.G.; Shenoy, B.S.; Rao, D.S.; Pai, R. A Variable Viscosity Approach for the Evaluation of Load Carrying Capacity of Oil Lubricated Journal Bearing with TiO2 Nanoparticles as Lubricant Additives. Procedia Mater. Sci. 2014, 6, 1051–1067. [Google Scholar] [CrossRef]

- Ghasemi, R.; Fazlali, A.; Mohammadi, A.H. Effects of TiO2 nanoparticles and oleic acid surfactant on the rheological behavior of engine lubricant oil. J. Mol. Liq. 2018, 268, 925–930. [Google Scholar] [CrossRef]

- Gu, K.; Chen, B.; Chen, Y. Preparation and tribological properties of lanthanum-doped TiO2 nanoparticles in rapeseed oil. J. Rare Earths 2013, 31, 589–594. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).