Influence of Titanium Oxide and Calcium Carbonate Powder as Additives on Tribological Characteristics of Lubricants

Abstract

1. Introduction

- Enhance the existing properties of the base oil, such as the viscosity index, corrosion resistance, wear, and friction resistance.

- Suppress the undesirable properties of the base oil, such as reducing the pour point of the oil using pour point depressants.

- Impart new properties to base oils, such as high load-carrying capacity, using extreme pressure (EP) additives.

2. Materials and Methods

2.1. Base Oil

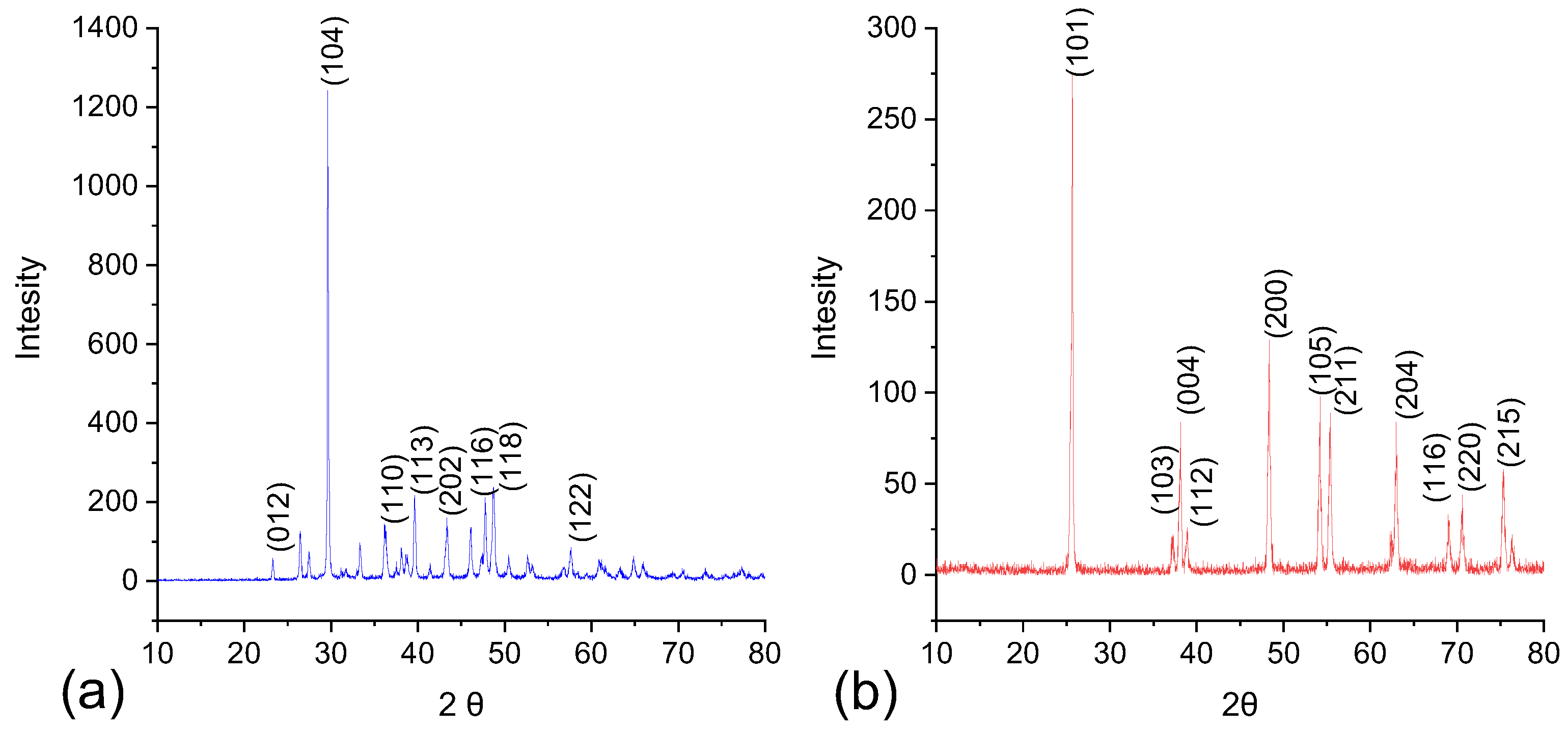

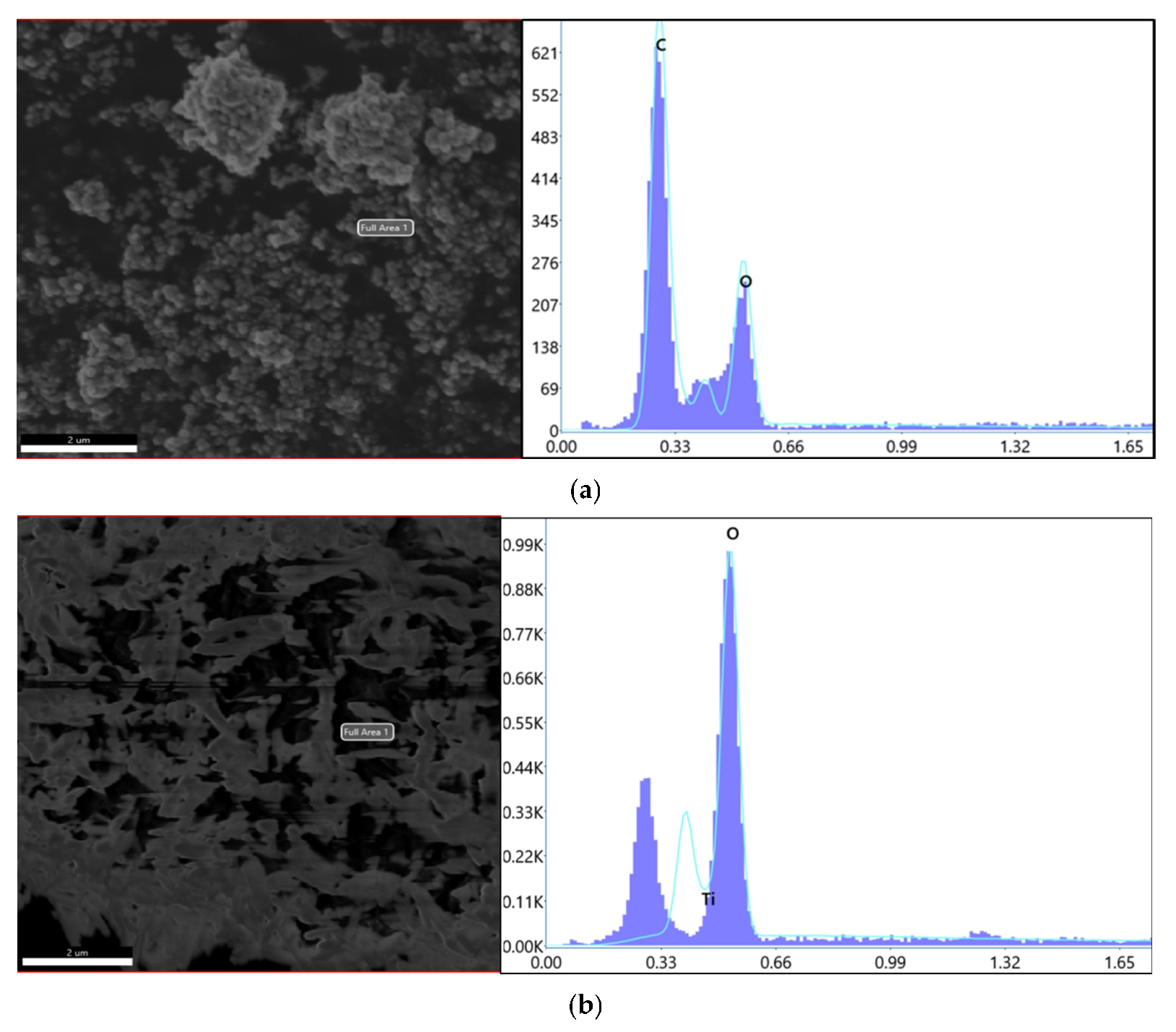

2.2. Additives

2.3. Determination of Concentration of Additives

2.4. Methods for Lubricant Synthesis

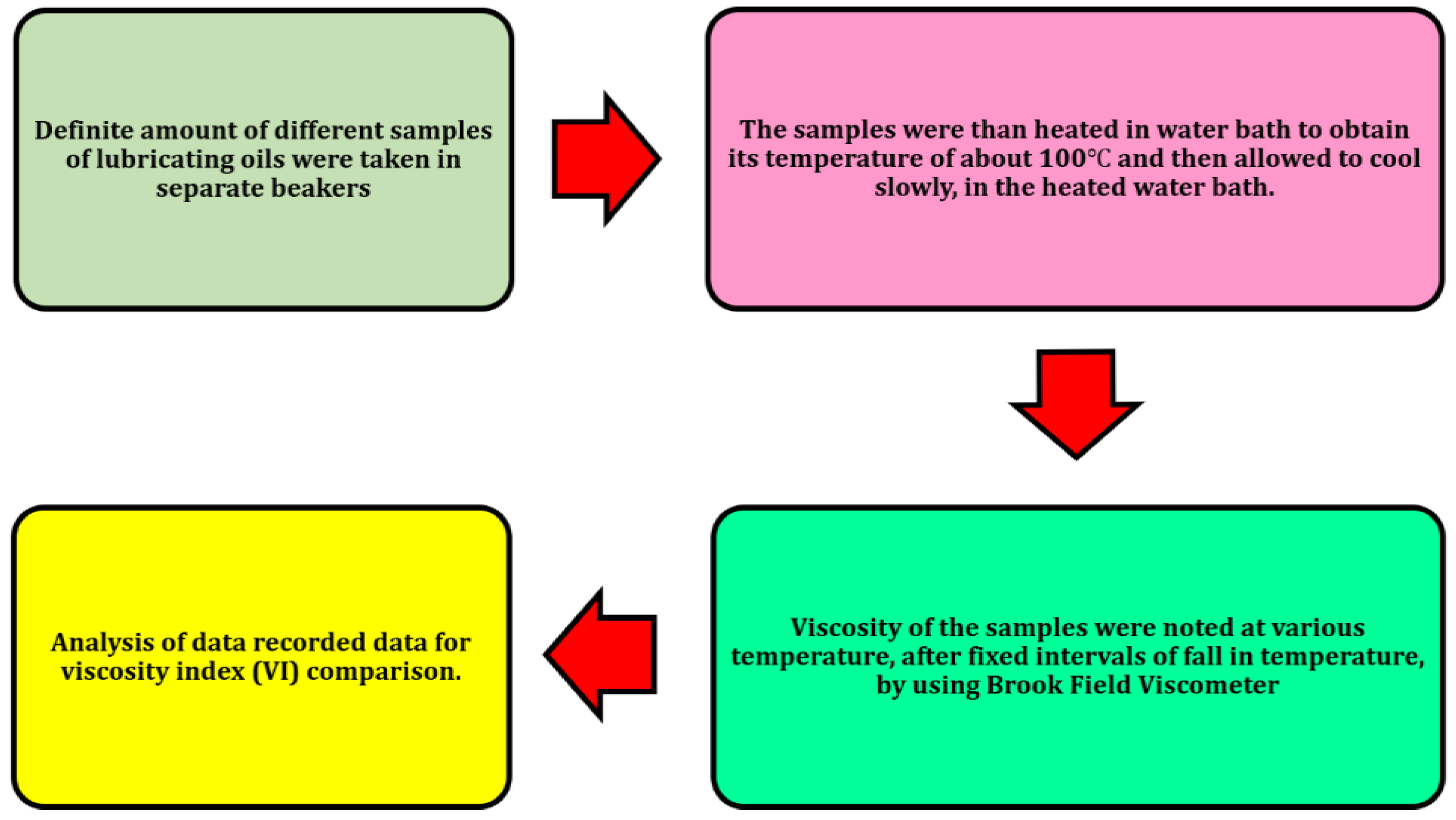

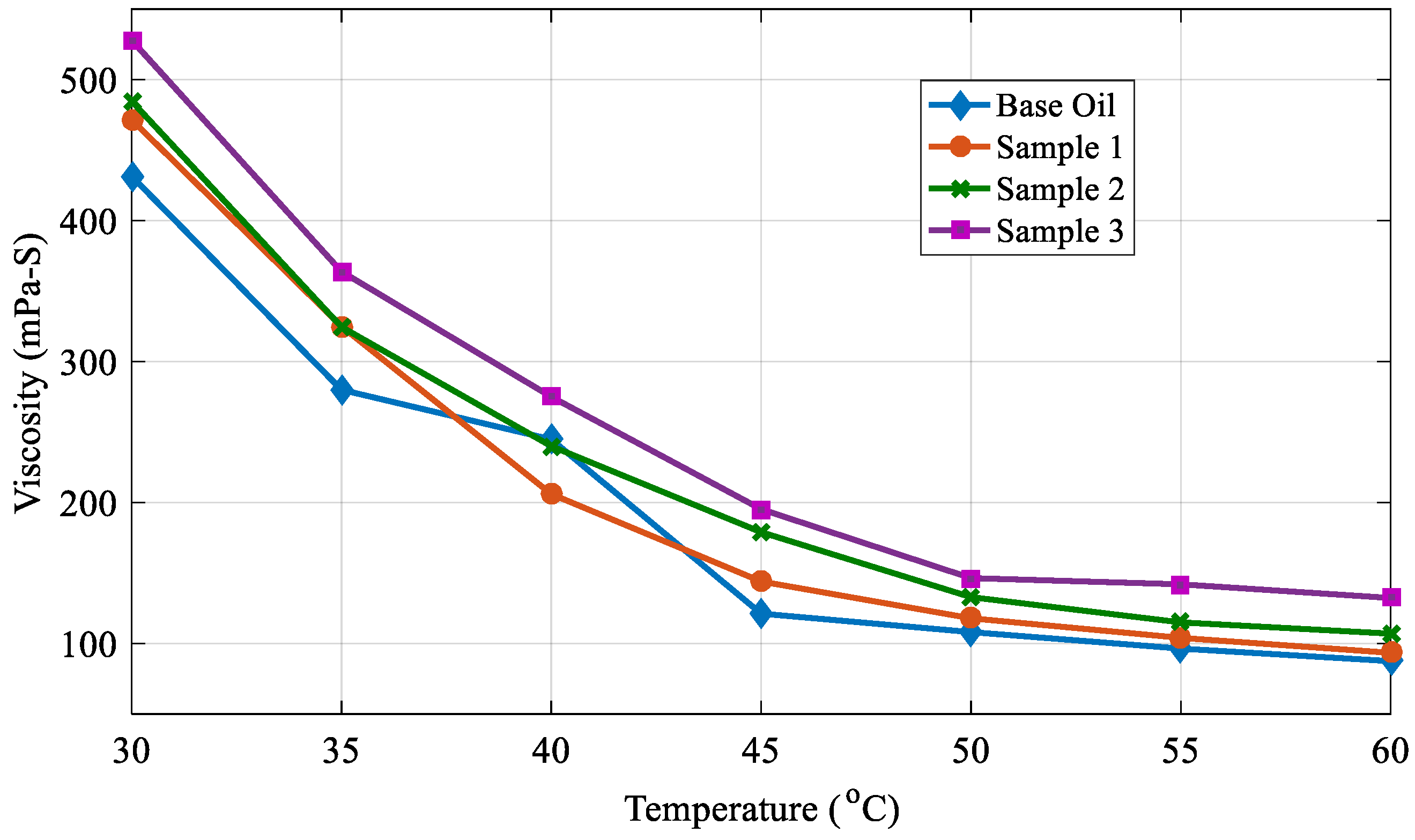

2.5. Viscosity Index Determination

3. Tribological Testing of Synthesized Lubricants

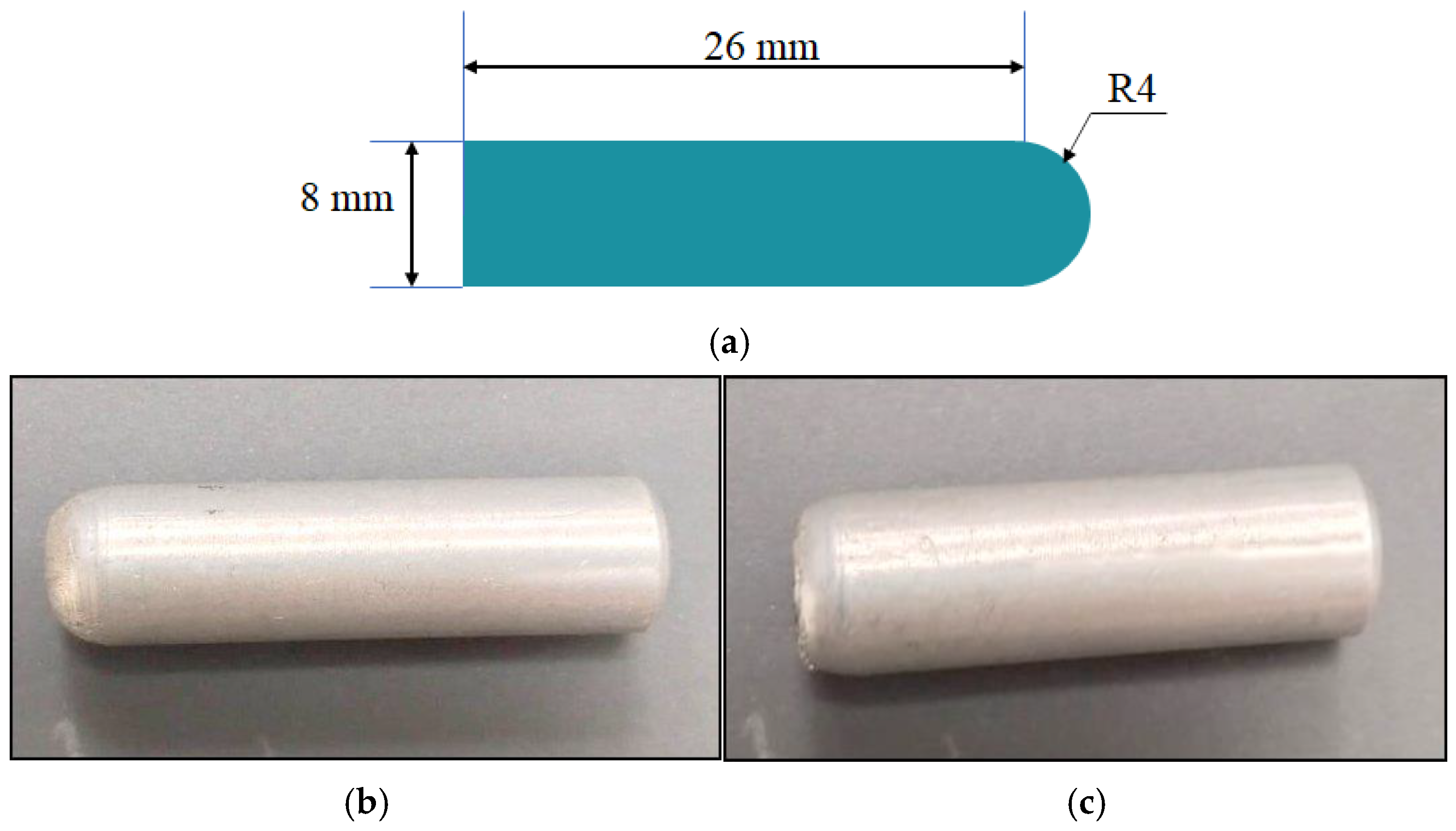

3.1. Test Pin Fabrication

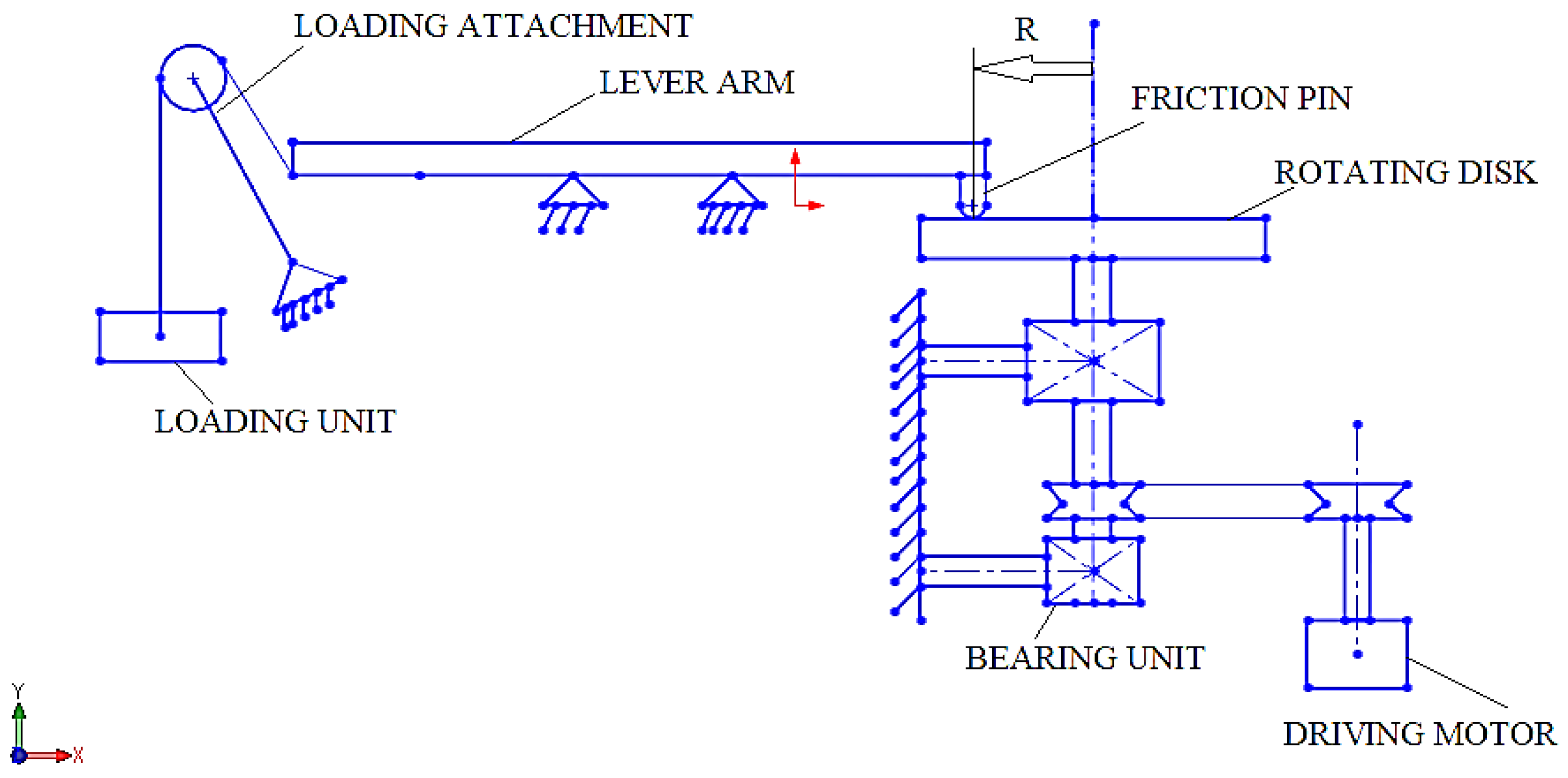

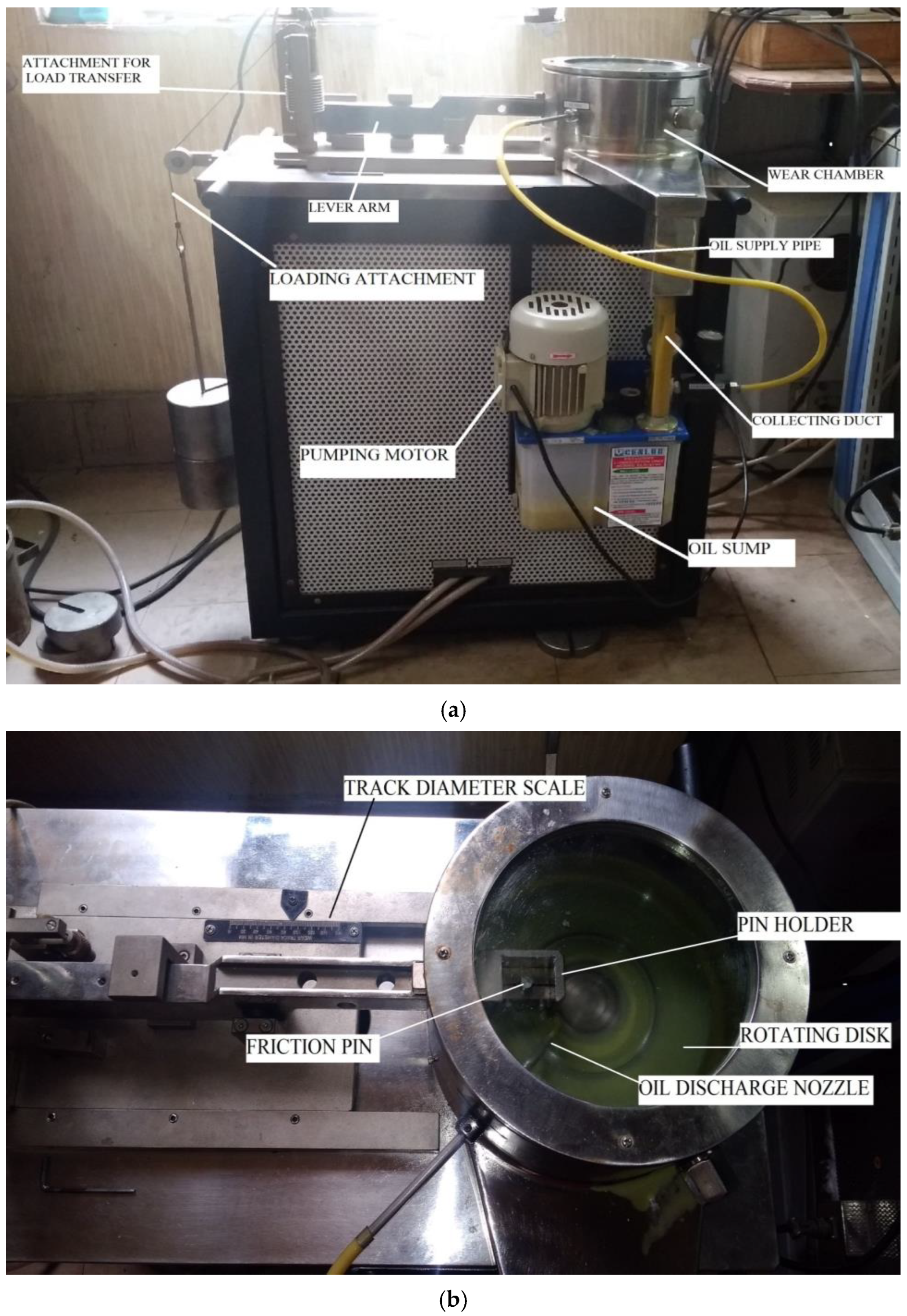

3.2. Pin Disc on Tribometer

- The test pin and disc were thoroughly cleaned and dried to eliminate contaminants or foreign materials that could have affected the results.

- The test pin was securely mounted in its holder to ensure perpendicular alignment with the disc surface to maintain consistent contact conditions.

- The tribometer motor was started, and the rotational speed was adjusted to a predetermined value. At this stage, the pin was not in contact with the rotating disc.

- The lever arm was adjusted to set the desired diameter for the wear track on the rotating disc.

- The required number of disc rotations and total test duration were programmed into the tribometer.

- An appropriate amount of mass was then added to the loading unit. The loading attachment then transferred this force to the test pin via the lever arm, applying the desired normal force to the pin–disc contact zone.

- The lubricant pump was activated to ensure a continuous supply of lubricant to the pin–disc contact zone.

- With the pin in contact with the rotating disc under load, the test commenced and ran until the preset time was reached, automatically stopping the apparatus.

- The test pin and disc were carefully removed from the tribometer, and any wear debris was meticulously removed from the surfaces. Subsequent analysis of the pin and the disc allowed for the determination of the wear volume and the coefficient of friction.

4. Results and Discussion

4.1. Anti-Friction Test of Lubricating Oils

4.2. Anti-Wear Test of Lubricating Oils

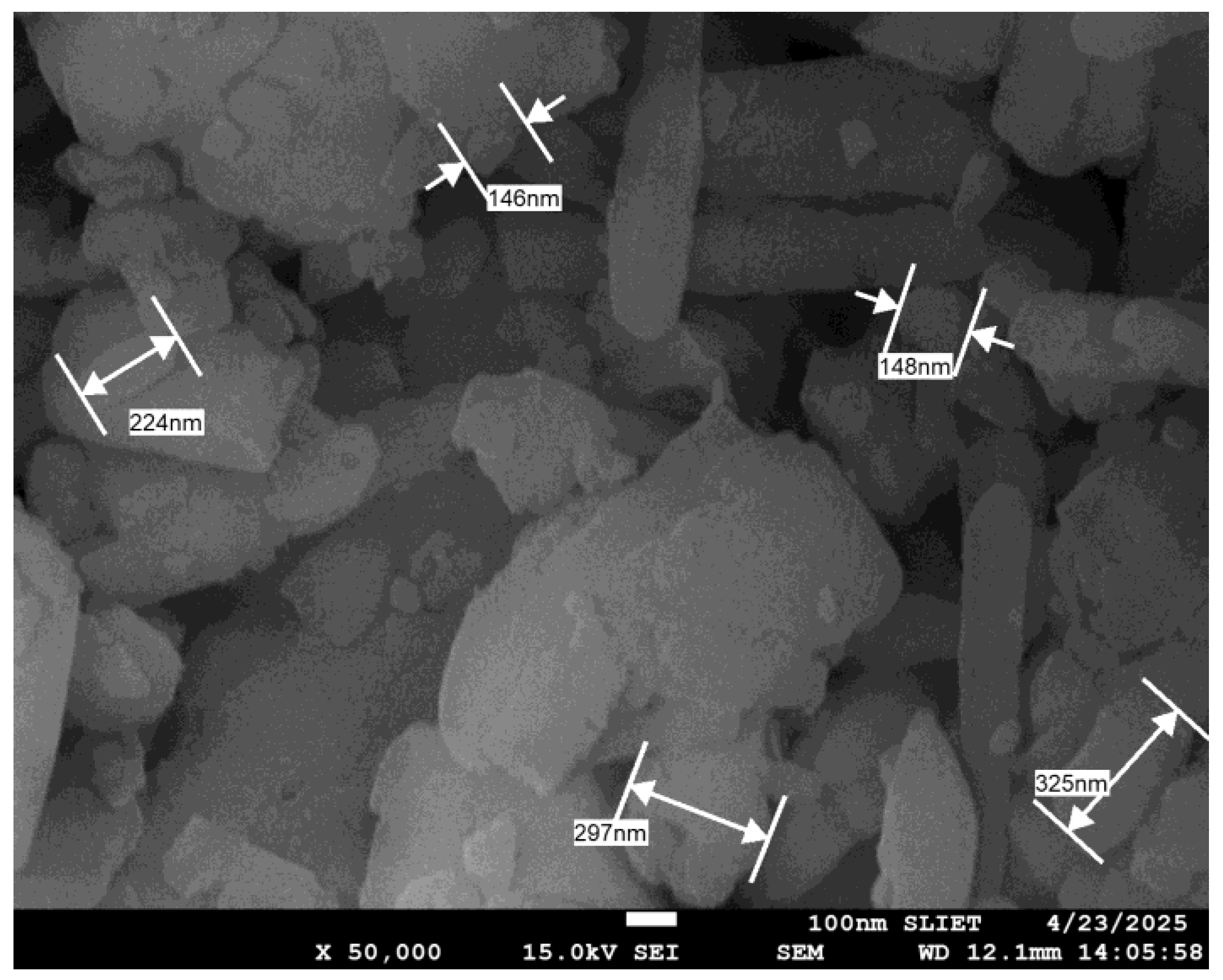

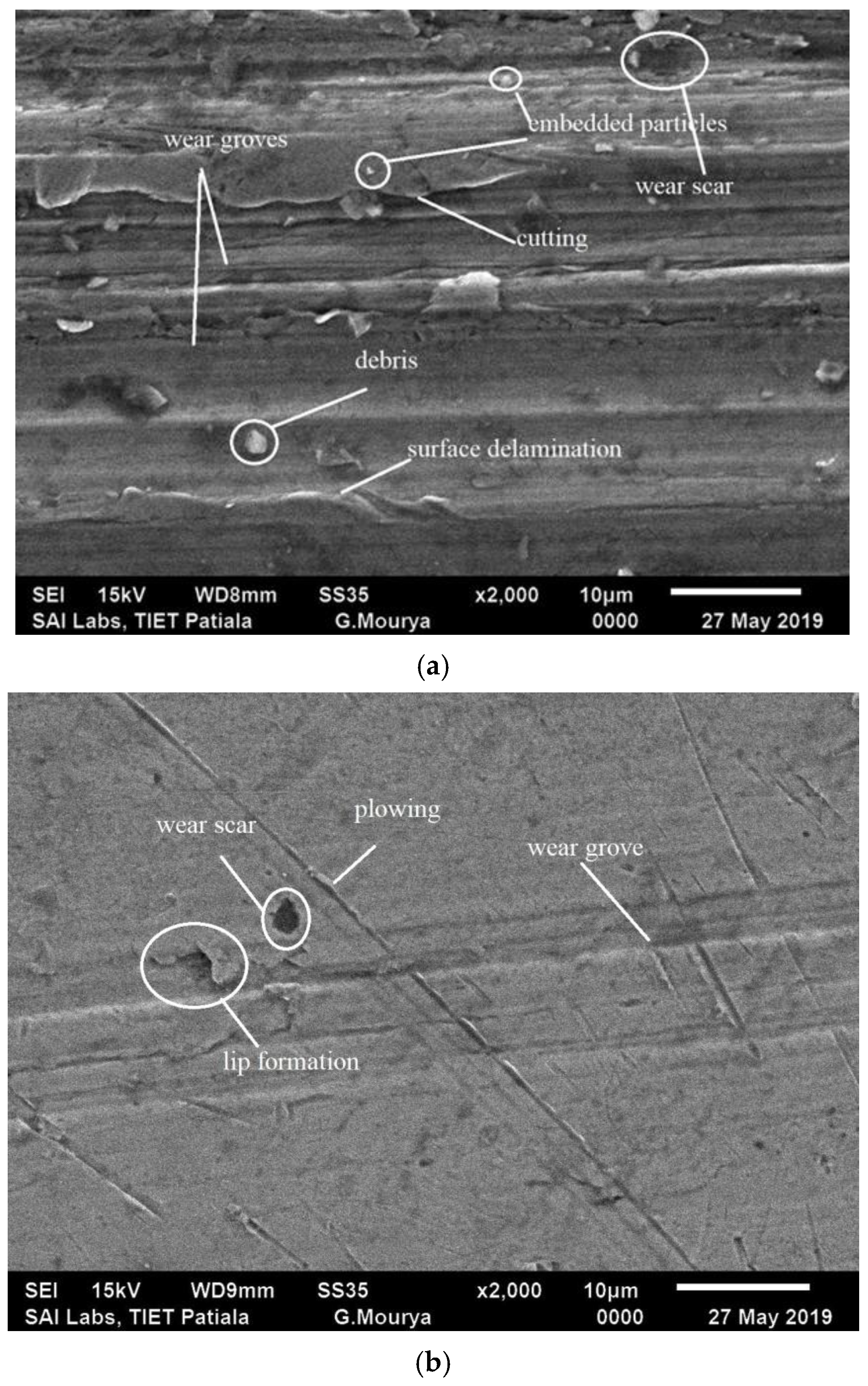

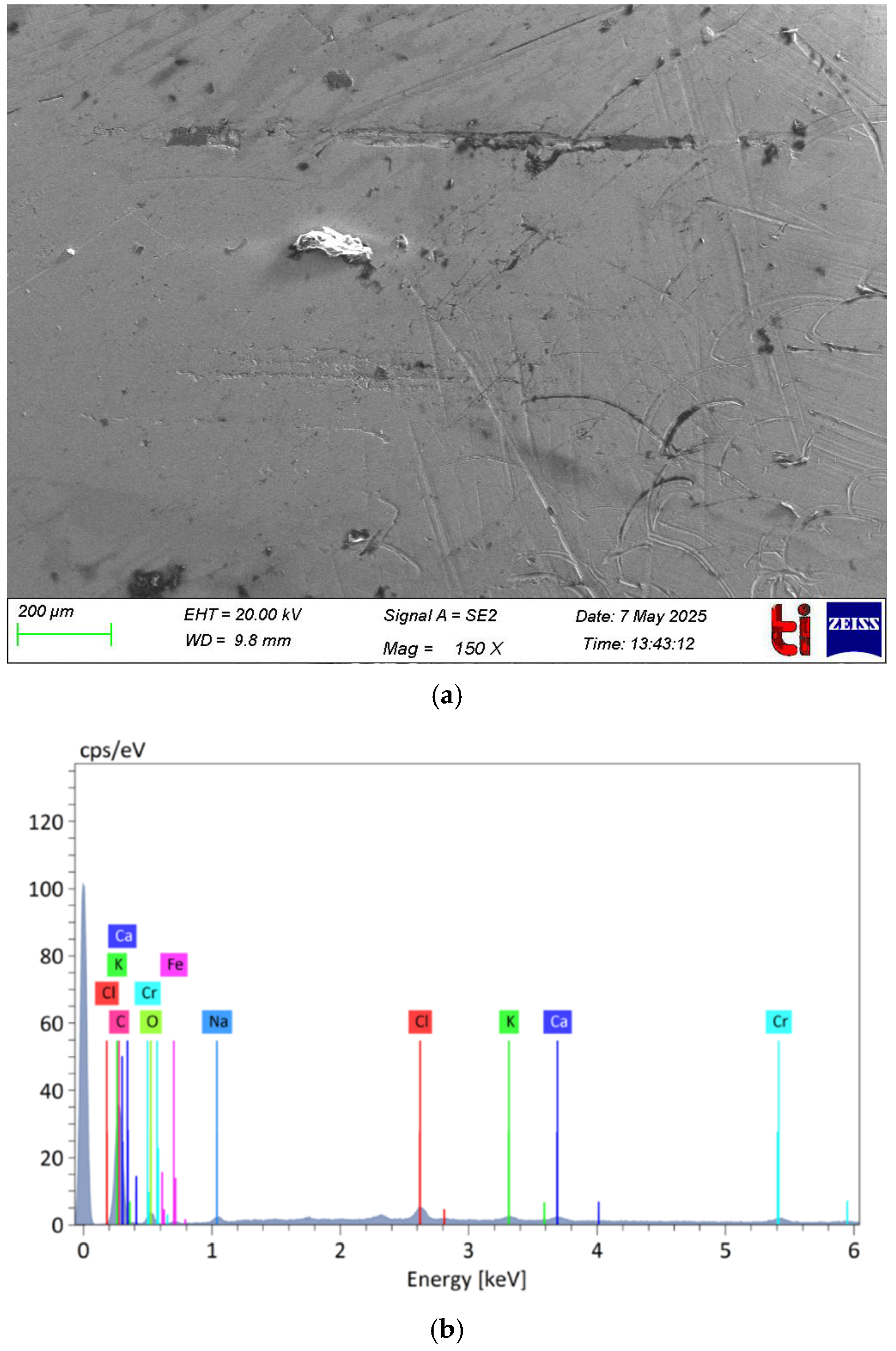

4.3. SEM Testing of Specimen

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Xu, N.; Zhang, M.; Li, W.; Zhao, G.; Wang, X.; Liu, W. Study on the selectivity of calcium carbonate nanoparticles under the boundary lubrication condition. Wear 2013, 307, 35–43. [Google Scholar] [CrossRef]

- Bartz, W.J. Tribology, lubricants and lubrication engineering—A review. Wear 1978, 49, 1–18. [Google Scholar] [CrossRef]

- Blau, P.J. Friction Science and Technology: From Concepts to Applications, Second Edition, 2nd ed.; CRC Press: Boca Raton, FL, USA, 2008. [Google Scholar] [CrossRef]

- Shenoy, B.S.; Binu, K.G.; Pai, R.; Rao, D.S.; Pai, R.S. Effect of nanoparticles additives on the performance of an externally adjustable fluid film bearing. Tribol. Int. 2012, 45, 38–42. [Google Scholar] [CrossRef]

- Wan, S.; Tieu, A.K.; Xia, Y.; Zhu, H.; Tran, B.H.; Cui, S. An overview of inorganic polymer as potential lubricant additive for high temperature tribology. Tribol. Int. 2016, 102, 620–635. [Google Scholar] [CrossRef]

- Chen, L.; Zhu, D. Preparation and tribological properties of unmodified and oleic acid-modified CuS nanorods as lubricating oil additives. Ceram. Int. 2017, 43, 4246–4251. [Google Scholar] [CrossRef]

- Sharma, V.; Timmons, R.B.; Erdemir, A.; Aswath, P.B. Interaction of plasma functionalized TiO2 nanoparticles and ZDDP on friction and wear under boundary lubrication. Appl. Surf. Sci. 2019, 489, 372–383. [Google Scholar] [CrossRef]

- Miao, W.J.; Wang, S.Q.; Wang, Z.H.; Wu, F.B.; Zhang, Y.Z.; Ouyang, J.H.; Wang, Y.M.; Zou, Y.C. Additive Manufacturing of Advanced Structural Ceramics for Tribological Applications: Principles, Techniques, Microstructure and Properties. Lubricants 2025, 13, 112. [Google Scholar] [CrossRef]

- Gupta, R.N.; Harsha, A.P. Synthesis, Characterization, and Tribological Studies of Calcium–Copper–Titanate Nanoparticles as a Biolubricant Additive. J. Tribol. 2016, 139, 021801. [Google Scholar] [CrossRef]

- Abdul Basir, N.F.; Iliya Nor Za’im, S.; Abdul Wahab, Y.; Johan, M.R.; Ghaffari Khaligh, N. Impact Symmetry on Tribology Performance of 2,5-Bis-Cycloalkylsulfenyl[1,3,4]Thiadiazole Derivatives. Tribol. Trans. 2025, 68, 206–223. [Google Scholar] [CrossRef]

- Pendbhaje, G.; Ali, M.; Bajaj, D. Bio-lubricants as viable replacements for mineral oils in automotive engines: A review. Tribol.-Mater. Surf. Interfaces 2025, 19, 24–38. [Google Scholar] [CrossRef]

- Kamel, B.M.; Arafa, E.L.; Mohamed, A. Tribological and rheological properties of the lubricant containing hybrid graphene nanosheets (GNs)/titanium dioxide (TiO2) nanoparticles as an additive on calcium grease. J. Dispers. Sci. Technol. 2023, 44, 2675–2682. [Google Scholar] [CrossRef]

- Alghani, W.; Ab Karim, M.S.; Bagheri, S.; Amran, N.A.M.; Gulzar, M. Enhancing the Tribological Behavior of Lubricating Oil by Adding TiO2, Graphene, and TiO2/Graphene Nanoparticles. Tribol. Trans. 2019, 62, 452–463. [Google Scholar] [CrossRef]

- Sivakumar, B.; Ranjan, N.; Ramaprabhu, S.; Kamaraj, M. Tribological properties of graphite oxide derivative as nano-additive: Synthesized from the waster carbon source. Tribol. Int. 2020, 142, 105990. [Google Scholar] [CrossRef]

- Xia, W.; Zhao, J.; Wu, H.; Zhao, X.; Zhang, X.; Xu, J.; Jiao, S.; Wang, X.; Zhou, C.; Jiang, Z. Effects of oil-in-water based nanolubricant containing TiO2 nanoparticles in hot rolling of 304 stainless steel. J. Mater. Process. Technol. 2018, 262, 149–156. [Google Scholar] [CrossRef]

- Razavi, S.; Sabbaghi, S.; Rasouli, K. Comparative investigation of the influence of CaCO3 and SiO2 nanoparticles on lithium-based grease: Physical, tribological, and rheological properties. Inorg. Chem. Commun. 2022, 142, 109601. [Google Scholar] [CrossRef]

- Tóth, Á.D.; Hargitai, H.; Szabó, Á.I. Tribological Investigation of the Effect of Nanosized Transition Metal Oxides on a Base Oil Containing Overbased Calcium Sulfonate. Lubricants 2023, 11, 337. [Google Scholar] [CrossRef]

- Choi, Y.; Lee, C.; Hwang, Y.; Park, M.; Lee, J.; Choi, C.; Jung, M. Tribological behavior of copper nanoparticles as additives in oil. Curr. Appl. Phys. 2009, 9, e124–e127. [Google Scholar] [CrossRef]

- Peña-Parás, L.; Taha-Tijerina, J.; Garza, L.; Maldonado-Cortés, D.; Michalczewski, R.; Lapray, C. Effect of CuO and Al2O3 nanoparticle additives on the tribological behavior of fully formulated oils. Wear 2015, 332–333, 1256–1261. [Google Scholar] [CrossRef]

- Vardhaman, B.S.A.; Amarnath, M.; Ramkumar, J.; Mondal, K. Enhanced tribological performances of zinc oxide/MWCNTs hybrid nanomaterials as the effective lubricant additive in engine oil. Mater. Chem. Phys. 2020, 253, 123447. [Google Scholar] [CrossRef]

- Mousavi, S.B.; Zeinali Heris, S. Experimental investigation of ZnO nanoparticles effects on thermophysical and tribological properties of diesel oil. Int. J. Hydrog. Energy 2020, 45, 23603–23614. [Google Scholar] [CrossRef]

- Han, X.; Thrush, S.J.; Zhang, Z.; Barber, G.C.; Qu, H. Tribological characterization of ZnO nanofluids as fastener lubricants. Wear 2021, 468–469, 203592. [Google Scholar] [CrossRef]

- Mariño, F.; López, E.R.; Arnosa, Á.; Gómez, M.A.G.; Piñeiro, Y.; Rivas, J.; Alvarez-Lorenzo, C.; Fernández, J. ZnO nanoparticles coated with oleic acid as additives for a polyalphaolefin lubricant. J. Mol. Liq. 2022, 348, 118401. [Google Scholar] [CrossRef]

- Gara, L.; Zou, Q. Friction and Wear Characteristics of Oil-Based ZnO Nanofluids. Tribol. Trans. 2013, 56, 236–244. [Google Scholar] [CrossRef]

- Laad, M.; Jatti, V.K.S. Titanium oxide nanoparticles as additives in engine oil. J. King Saud Univ.-Eng. Sci. 2018, 30, 116–122. [Google Scholar] [CrossRef]

- Binu, K.G.; Shenoy, B.S.; Rao, D.S.; Pai, R. A Variable Viscosity Approach for the Evaluation of Load Carrying Capacity of Oil Lubricated Journal Bearing with TiO2 Nanoparticles as Lubricant Additives. Procedia Mater. Sci. 2014, 6, 1051–1067. [Google Scholar] [CrossRef]

- Ghasemi, R.; Fazlali, A.; Mohammadi, A.H. Effects of TiO2 nanoparticles and oleic acid surfactant on the rheological behavior of engine lubricant oil. J. Mol. Liq. 2018, 268, 925–930. [Google Scholar] [CrossRef]

- Gu, K.; Chen, B.; Chen, Y. Preparation and tribological properties of lanthanum-doped TiO2 nanoparticles in rapeseed oil. J. Rare Earths 2013, 31, 589–594. [Google Scholar] [CrossRef]

| S.No. | Lubricant | Additive | Observation |

|---|---|---|---|

| 1 | General lubricating oils | Anti-wear additives | Minimize surface damage and prolong the lifespan of components. |

| 2 | General lubricating oils | Anti-friction additives | Reduce energy lost to friction, improve efficiency, and reduce operating temperatures. |

| 3 | General lubricating oils | Viscosity modifiers | Maintain optimal viscosity across a wide range of temperatures. |

| 4 | General lubricating oils | Pour point depressants | Counteract the tendency of oils to thicken and solidify at low temperatures. |

| 5 | General lubricating oils | Metallic oxides and carbonates | Improve friction and wear reduction. |

| 6 | Polyalphaolefin (POA) base oil | Copper oxide (CuO) nanoparticles (2 wt.%) | A 273% increase in load-carrying capacity. |

| 7 | R134a refrigerant | Silicon dioxide (SiO2) nanoparticles (0.4 vol.%) | Positive influence on heat transfer properties of the refrigerant and tribological characteristics of polyalkylene glycol (PAG) lubricants. |

| 8 | 10W40 engine oil | Zinc oxide (ZnO) and multiwalled carbon nanotube (MWCNT) hybrid nanoparticles (0.25 wt.%, 3:1 ratio) | A 32.30% reduction in coefficient of friction and a 74.48% reduction in wear volume compared to the base oil alone. |

| 9 | POA40 base oil | Zinc oxide dispersed in oleic acid (ZnO-OA) (0.25 wt.%) | A 25% reduction in the friction coefficient and an 82% reduction in wear (measured by cross-sectional area) compared to the neat base oil. |

| 10 | Multi-grade engine oil | Titanium dioxide (TiO2) nanoparticles (0.3 wt.%) | An 86% reduction in the coefficient of friction. |

| 11 | Base oil | Titanium dioxide (TiO2) nanoparticles (0.005% to 0.025% by volume) | Increased load-carrying capacity of journal bearings by as much as 40%. |

| 12 | SAE 10 engine oil | Titanium dioxide (TiO2) nanoparticles (0.1%, 0.5%, and 1% wt.) | Illustrates the range of potential benefits. |

| 13 | Rapeseed oil | Oleic-acid-modified lanthanum titanate (OA/LaTiO2) particles (20 nm diameter) | Enhances both the anti-wear and friction-reducing properties. Formation of boundary lubrication films and adsorption films of oleic acid on rubbing surfaces. |

| 14 | Polyalphaolefin (PAO) base oils | Calcium carbonate (CaCO3) nanoparticles | Improves load-carrying capacity, wear resistance, and friction characteristics. |

| 15 | Amphiphilic copolymer | Calcium carbonate (CaCO3) nanoparticles (5 wt.%) and cerium oxide (CeO2) nanoparticles | Optimal anti-wear characteristics. |

| S. No. | Property | Value |

|---|---|---|

| 1 | Kinematic viscosity (c-St) at 100 °C | 28–33 |

| 2 | Viscosity index, min | 90 |

| 3 | Flash point (°C) | 190 |

| 4 | Pour point (°C), max | −3 |

| S. No. | Sample Oil | TiO2 (wt.%) | CaCO3 (wt.%) |

|---|---|---|---|

| 1 | Sample 1 (S1) | 0.2 | 0.4 |

| 2 | Sample 2 (S2) | 0.3 | 0.6 |

| 3 | Sample 3 (S3) | 0.4 | 0.8 |

| Oil Sample | Temperature | ||||||

|---|---|---|---|---|---|---|---|

| 30 °C | 35 °C | 40 °C | 45 °C | 50 °C | 55 °C | 60 °C | |

| Base oil | 431.5 | 280.0 | 244.8 | 121.2 | 108.1 | 96.4 | 87.5 |

| Sample 1 | 471.6 | 325.0 | 206.0 | 144.0 | 117.9 | 104.0 | 93.4 |

| Sample 2 | 484.8 | 324.6 | 240.0 | 179.0 | 132.9 | 115.0 | 107.0 |

| Sample 3 | 528.0 | 363.9 | 275.0 | 195.3 | 146.4 | 142.0 | 132.3 |

| Condition | Oil Sample | Load (kg) | Speed (rpm) | Frictional Force (N) | Coefficient of Friction | % Reduction in COF |

|---|---|---|---|---|---|---|

| Low load, low speed | No lubricant | 4 | 350 | 2.9 | 0.068 | - |

| Base oil | 4 | 350 | 1.4 | 0.035 | 48.53 | |

| S1 | 4 | 350 | 1.4 | 0.035 | 48.53 | |

| S2 | 4 | 350 | 1.3 | 0.032 | 52.94 | |

| S3 | 4 | 350 | 2.1 | 0.05 | 26.47 | |

| High load, low speed | No lubricant | 10 | 350 | 12 | 0.105 | - |

| Base oil | 10 | 350 | 6.4 | 0.062 | 40.95 | |

| S1 | 10 | 350 | 5.8 | 0.057 | 45.71 | |

| S2 | 10 | 350 | 6.3 | 0.061 | 41.90 | |

| S3 | 10 | 350 | 5.4 | 0.052 | 50.47 | |

| Low load, high speed | No lubricant | 4 | 500 | 9.2 | 0.212 | - |

| Base oil | 4 | 500 | 1.5 | 0.038 | 82.07 | |

| S1 | 4 | 500 | 1.8 | 0.044 | 79.24 | |

| S2 | 4 | 500 | 1.1 | 0.024 | 88.67 | |

| S3 | 4 | 500 | 2.1 | 0.054 | 74.58 | |

| High load, high speed | No lubricant | 10 | 500 | 33 | 0.31 | - |

| Base oil | 10 | 500 | 5.4 | 0.054 | 82.58 | |

| S1 | 10 | 500 | 5.8 | 0.057 | 81.61 | |

| S2 | 10 | 500 | 7.1 | 0.07 | 77.41 | |

| S3 | 10 | 500 | 7.5 | 0.075 | 75.80 |

| Condition | Oil Sample | Load (kg) | Speed (rpm) | Wear (Micron) | Reduction in Wear (%) |

|---|---|---|---|---|---|

| Low load, low speed | No lubricant | 4 | 350 | 0.013 | - |

| Base oil | 4 | 350 | 0.004 | 69.2 | |

| S1 | 4 | 350 | 0.001 | 92.23 | |

| S2 | 4 | 350 | 0.006 | 53.84 | |

| S3 | 4 | 350 | 0.008 | 38.46 | |

| High load, low speed | No lubricant | 10 | 350 | 0.021 | - |

| Base oil | 10 | 350 | 0.012 | 42.85 | |

| S1 | 10 | 350 | 0.006 | 71.42 | |

| S2 | 10 | 350 | 0.008 | 61.9 | |

| S3 | 10 | 350 | 0.01 | 52.38 | |

| Low load, high speed | No lubricant | 4 | 500 | 0.056 | - |

| Base oil | 4 | 500 | 0.038 | 32.14 | |

| S1 | 4 | 500 | 0.008 | 85.71 | |

| S2 | 4 | 500 | 0.026 | 53.57 | |

| S3 | 4 | 500 | 0.042 | 25.00 | |

| High load, high speed | No lubricant | 10 | 500 | 0.262 | - |

| Base oil | 10 | 500 | 0.153 | 41.6 | |

| S1 | 10 | 500 | 0.018 | 93.13 | |

| S2 | 10 | 500 | 0.096 | 63.35 | |

| S3 | 10 | 500 | 0.171 | 34.73 |

| Element | At. No. | Netto | Mass Norm. [%] | Atom [%] | Abs. Error [%] (3 Sigma) |

|---|---|---|---|---|---|

| C | 6 | 30,245 | 52.25 | 78.89 | 6.89 |

| O | 8 | 3145 | 5.70 | 6.46 | 0.80 |

| Na | 11 | 1660 | 1.29 | 1.02 | 0.28 |

| Cl | 17 | 6023 | 1.20 | 0.61 | 0.11 |

| K | 19 | 2355 | 0.59 | 0.27 | 0.07 |

| Ca | 20 | 2024 | 0.56 | 0.25 | 0.07 |

| Cr | 24 | 2253 | 0.76 | 0.26 | 0.09 |

| Fe | 26 | 68,739 | 37.66 | 12.23 | 2.66 |

| Sum | 100.00 | 100.00 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shrivastava, A.; Kumar, S.; Kumar, S.; Kumar, H.; Chauhan, S.; Vashishtha, G.; Kumar, R. Influence of Titanium Oxide and Calcium Carbonate Powder as Additives on Tribological Characteristics of Lubricants. Lubricants 2025, 13, 229. https://doi.org/10.3390/lubricants13050229

Shrivastava A, Kumar S, Kumar S, Kumar H, Chauhan S, Vashishtha G, Kumar R. Influence of Titanium Oxide and Calcium Carbonate Powder as Additives on Tribological Characteristics of Lubricants. Lubricants. 2025; 13(5):229. https://doi.org/10.3390/lubricants13050229

Chicago/Turabian StyleShrivastava, Abhinit, Surinder Kumar, Sumit Kumar, Hemant Kumar, Sumika Chauhan, Govind Vashishtha, and Rajesh Kumar. 2025. "Influence of Titanium Oxide and Calcium Carbonate Powder as Additives on Tribological Characteristics of Lubricants" Lubricants 13, no. 5: 229. https://doi.org/10.3390/lubricants13050229

APA StyleShrivastava, A., Kumar, S., Kumar, S., Kumar, H., Chauhan, S., Vashishtha, G., & Kumar, R. (2025). Influence of Titanium Oxide and Calcium Carbonate Powder as Additives on Tribological Characteristics of Lubricants. Lubricants, 13(5), 229. https://doi.org/10.3390/lubricants13050229