Potassium Titanate Whisker/Graphene Multi-Dimensional Fillers to Improve the Wear Resistance of Poly(Ether Ether Ketone) Composite

Abstract

1. Introduction

2. Experimental Details

2.1. Materials

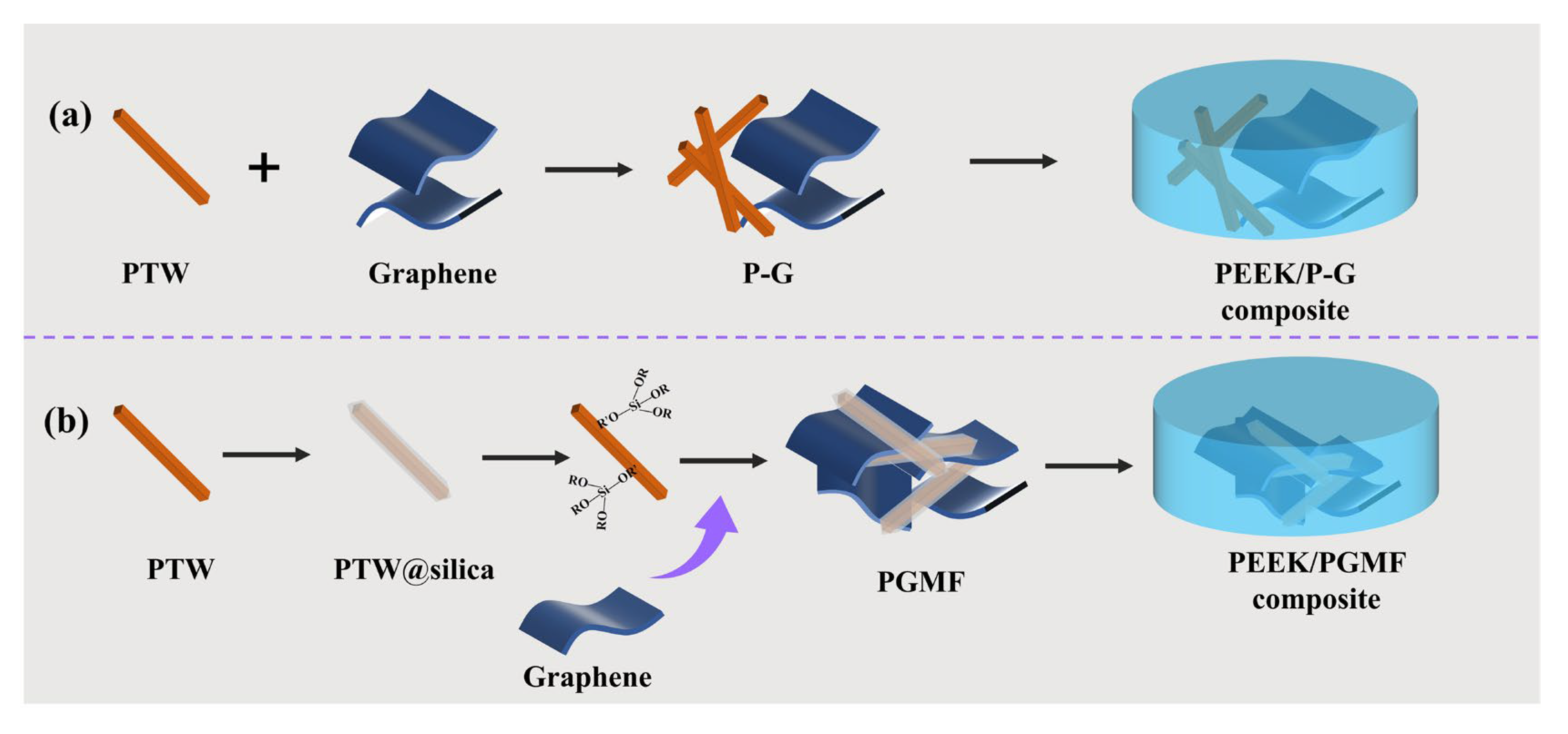

2.2. Synthesis of Multi-Dimensional Fillers

2.2.1. PTW-Graphene Blend Fillers (P-G)

2.2.2. PTW–Graphene Multi-Dimensional Compound Fillers (PGMFs)

2.3. Fabrication of PEEK Composites

2.4. Characterization

3. Results and Discussion

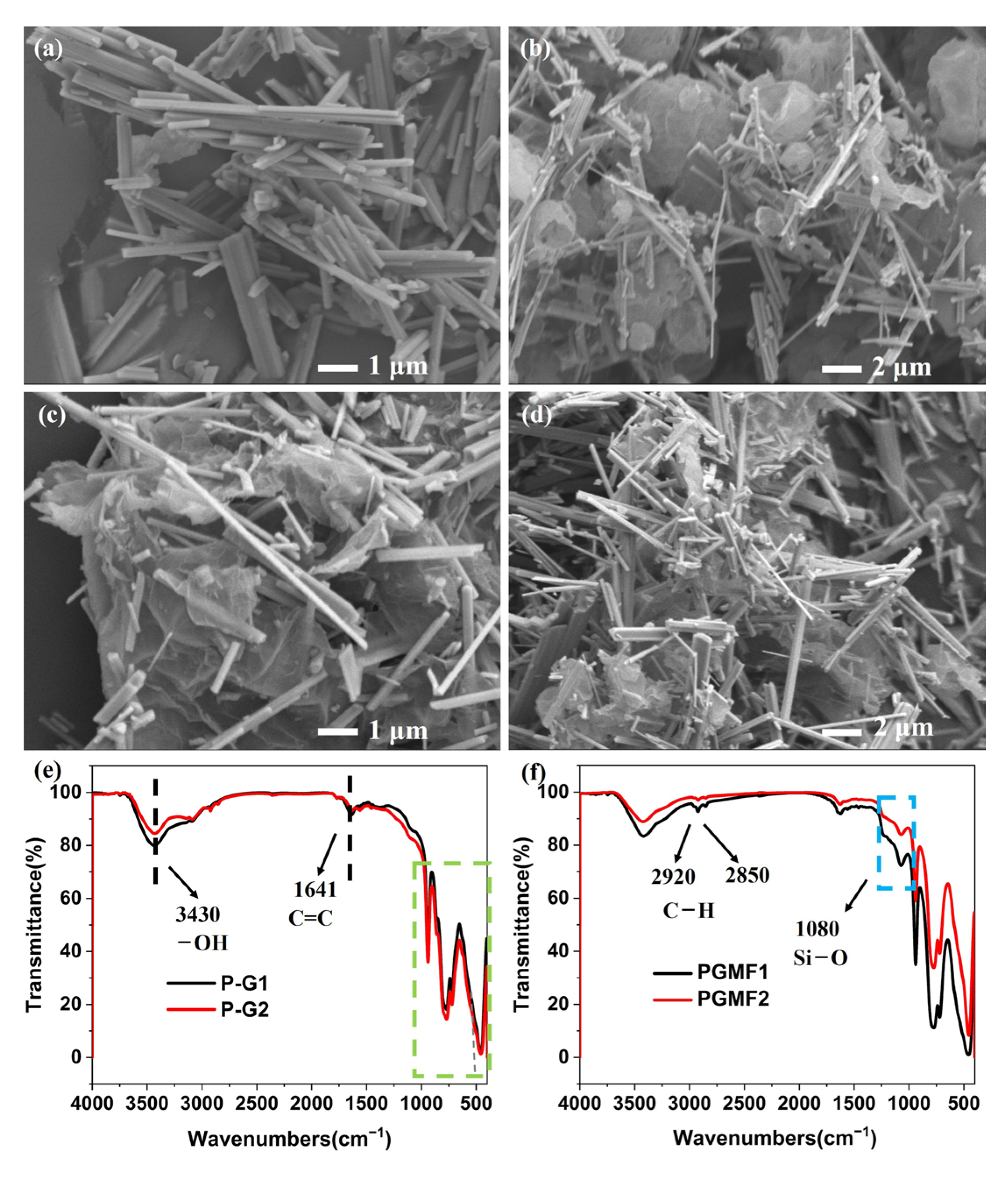

3.1. Microstructure Analysis of the Multi-Dimensional Hybrid Fillers

3.2. Tribological Behaviors

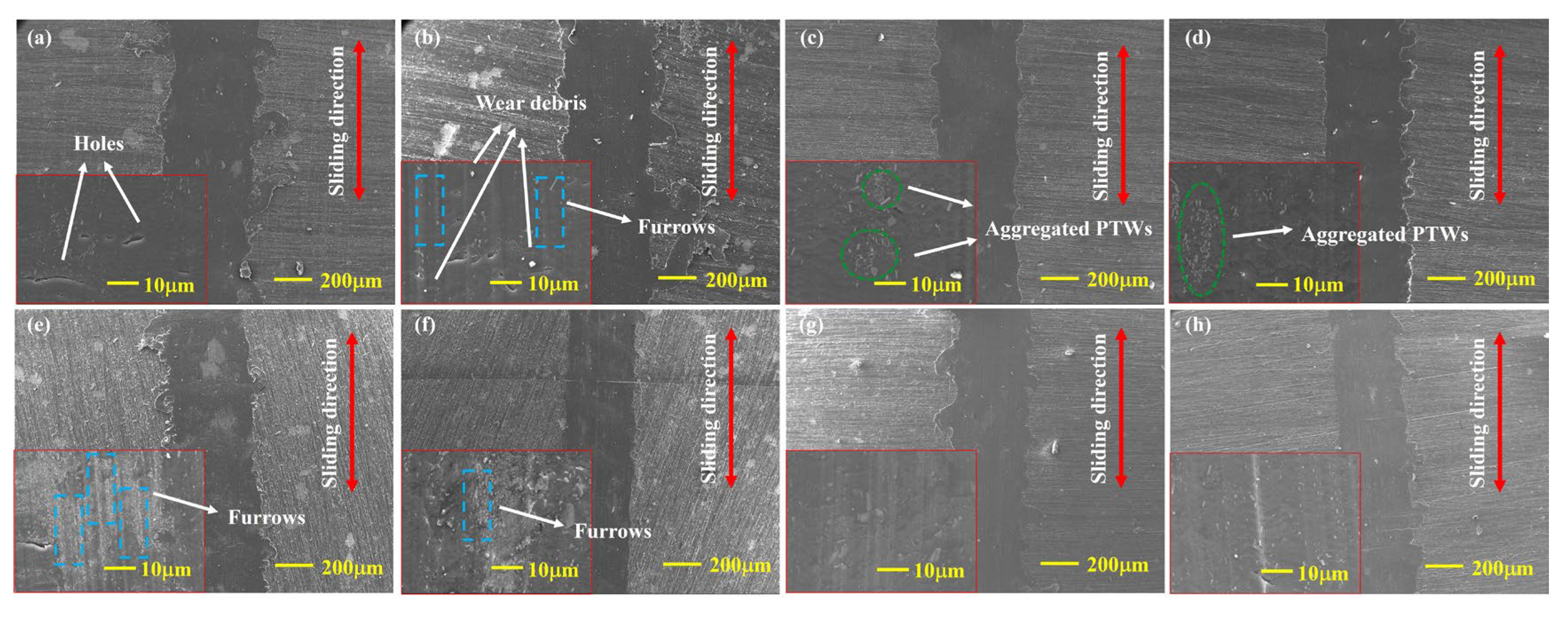

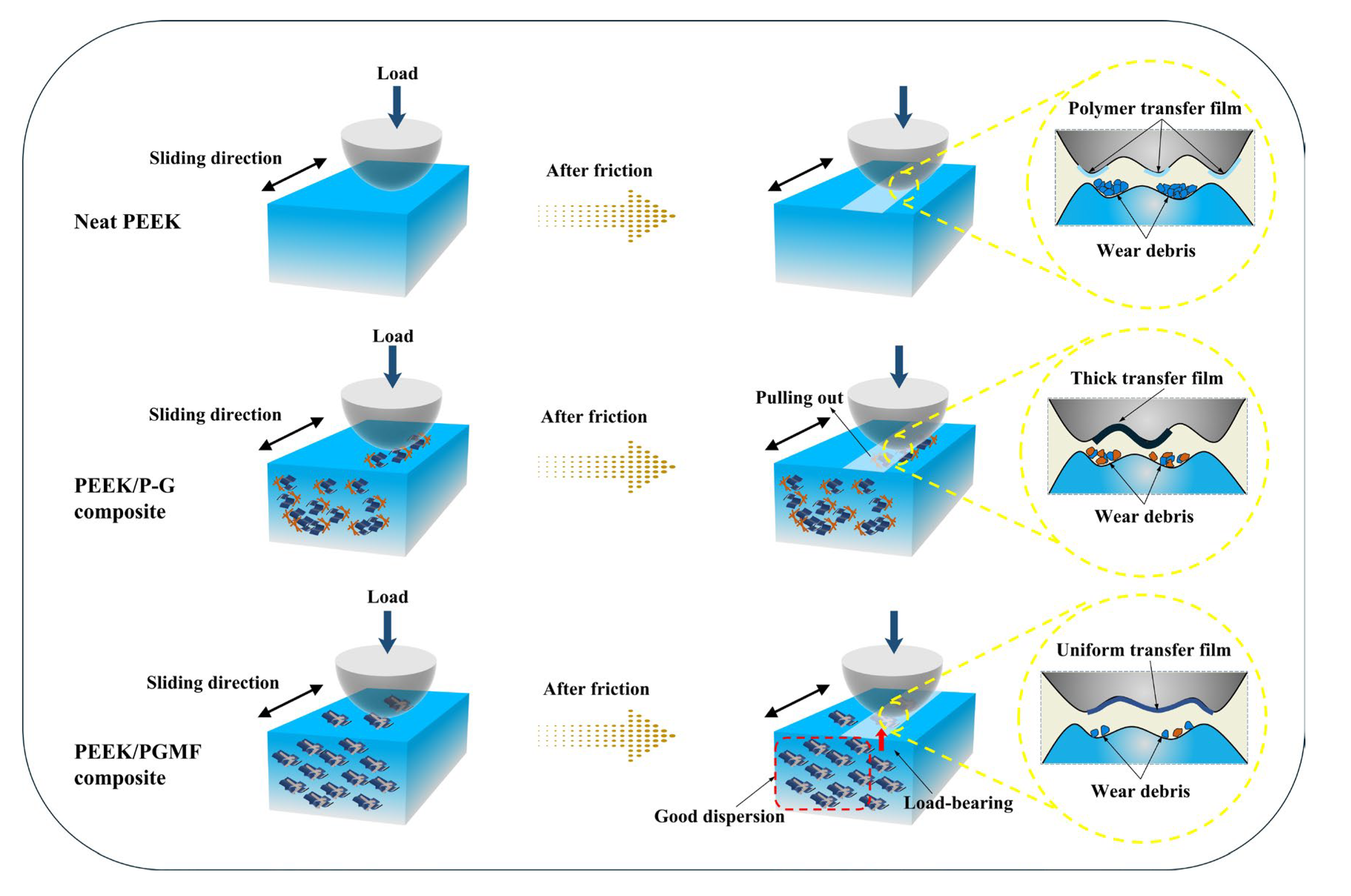

3.3. Wear Mechanism

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Wang, P.; Ma, R.; Wang, Y.; Cao, W.; Liu, C.; Shen, C. Comparative study of fullerenes and graphene nanoplatelets on the mechanical and thermomechanical properties of poly (ether ether ketone). Mater. Lett. 2019, 249, 180–184. [Google Scholar] [CrossRef]

- Maslavi, A.; Unal, H.; Olabi, M.N. Determination of “tribological performance working fields” for pure PEEK and PEEK composites under dry sliding conditions. Wear 2024, 554, 205464. [Google Scholar] [CrossRef]

- Xu, Y.; Zhang, K.; Wu, H.; Yao, L.; Mahapatra, M. Optimization and tribological performance of PEEK based composite coatings reinforced with PTFE for friction pairs of aviation hydraulic pumps. Tribol. Int. 2024, 195, 109661. [Google Scholar] [CrossRef]

- Onodera, T.; Nunoshige, J.; Kawasaki, K.; Adachi, K.; Kurihara, K.; Kubo, M. Structure and function of transfer film formed from PTFE/PEEK polymer blend. J. Phys. Chem. C 2017, 121, 14589–14596. [Google Scholar] [CrossRef]

- McLaughlin, J.W.; Tobin, E.; O’Higgins, R.M. An investigation of Polyether Imide (PEI) toughening of carbon fibre-reinforced Polyether Ether Ketone (PEEK) laminates. Mater. Design. 2021, 212, 110189. [Google Scholar] [CrossRef]

- Yu, S.; Zhu, C.; Wu, H.; Yao, L.; Mahapatra, M.; Xu, Y. Graphite-Enhanced PTFE/PEEK composite coating for improved friction and wear resistance. Appl. Surf. Sci. 2025, 700, 163214. [Google Scholar] [CrossRef]

- Li, Y.; Xu, N.; Lyu, H.; Jiang, N.; Zhang, H.; Zhou, N.; Zhang, D. Enhanced mechanical and tribological properties of carbon fiber/PEEK composites by hydroxylated boron nitride nanosheets and polyetherimide sizing agents. Comp. Sci. Tech. 2023, 232, 109851. [Google Scholar] [CrossRef]

- Li, M.; Yang, J.; Ma, S.; Liu, G.; Yang, H.; Yao, J. Effect of h-BN and Nano-SiO2 Fillers on the High-Temperature Tribological Properties of PEEK/PI-Based Composites. Lubricants 2023, 11, 416. [Google Scholar] [CrossRef]

- Huang, S.; Duan, H.; Zhan, S.; Zhou, Y.; Duan, L.; Ma, L.; Yang, T.; Cheng, B.; Jia, D. Peculiarities of tribological behavior of composites based on polyether ether ketone (PEEK) and whisker carbon nanotubes. Tribol. Int. 2024, 197, 109793. [Google Scholar] [CrossRef]

- Delbé, K.; Doumeng, M.; Denape, J.; Mérian, T.; Berthet, F.; Marsan, O.; Chabert, F. Contribution of Raman analysis on tribological study of PEEK reinforced with micro or nano SiC particles. Wear 2025, 205927. [Google Scholar] [CrossRef]

- Kalin, M.; Zalaznik, M.; Novak, S. Wear and friction behaviour of poly-ether-ether-ketone (PEEK) filled with graphene, WS2 and CNT nanoparticles. Wear 2015, 332, 855–862. [Google Scholar] [CrossRef]

- Puértolas, J.; Castro, M.; Morris, J.; Ríos, R.; Ansón-Casaos, A. Tribological and mechanical properties of graphene nanoplatelet/PEEK composites. Carbon 2019, 141, 107–122. [Google Scholar] [CrossRef]

- Padhan, M.; Marathe, U.; Bijwe, J. Tribology of Poly (etherketone) composites based on nano-particles of solid lubricants. Compos. Part B Eng. 2020, 201, 108323. [Google Scholar] [CrossRef]

- Nikonovich, M.; Ramalho, A.; Emami, N. Cryogenic cyclic aging effect on thermal, mechanical and tribological performance of PEEK-based materials. Wear 2025, 564, 205709. [Google Scholar] [CrossRef]

- Arif, M.F.; Alhashmi, H.; Varadarajan, K.; Koo, J.H.; Hart, A.; Kumar, S. Multifunctional performance of carbon nanotubes and graphene nanoplatelets reinforced PEEK composites enabled via FFF additive manufacturing. Compos. Part B Eng. 2020, 184, 107625. [Google Scholar] [CrossRef]

- Hou, X.; Bai, P.; Li, J.; Li, Y.; Cao, H.; Wen, X.; Meng, Y.; Ma, L.; Tian, Y. MoS2 reinforced PEEK composite for improved aqueous boundary lubrication. Friction 2023, 11, 1660–1672. [Google Scholar] [CrossRef]

- Zhen, J.; Han, Y.; Zhu, L.; Hou, W.; Liu, Y.; Huang, W.; Yang, L.; Yuan, L.; Jia, Z.; Zhang, R. MoS2/CF synergistic enhancement to improve the friction and wear properties of UHMWPE composites. Tribol. Int. 2023, 179, 108097. [Google Scholar] [CrossRef]

- Wu, Y.; Dong, C.; Bai, X.; Yuan, C. Enhancing friction and vibration reduction properties of a polymer using h-BN particles. Wear 2024, 536, 205142. [Google Scholar] [CrossRef]

- Xue, L.; Xu, Q.; Meng, C.; Lei, S.; Zhang, G.; Tang, M.; Zhai, W.; Yu, H.; Liu, X.; Du, C.F. Achieving the ultra-low friction and wear rate of PEEK-PTFE composites by Ti3C2Tx MXene reinforcement. Tribol. Inter. 2024, 199, 110030. [Google Scholar] [CrossRef]

- Gao, Y.; Shu, C.; Zhao, S.; Wang, W. Effect of black phosphorus modified by fullerene C60 on the self-lubricating properties of PEEK-based composite coatings. Surf. Coat. Tech. 2023, 474, 130090. [Google Scholar] [CrossRef]

- Peng, S.; Guo, Y.; Xie, G.; Luo, J. Tribological behavior of polytetrafluoroethylene coating reinforced with black phosphorus nanoparticles. Appl. Surf. Sci. 2018, 441, 670–677. [Google Scholar] [CrossRef]

- Ji, Z.; Zhang, L.; Xie, G.; Xu, W.; Guo, D.; Luo, J.; Prakash, B. Mechanical and tribological properties of nanocomposites incorporated with two-dimensional materials. Friction 2020, 8, 813–846. [Google Scholar] [CrossRef]

- Chen, Z.; Zhou, K.; Ji, Z.; Hou, S.; Jin, H. Study of the Tribological Properties of Modified Potassium Titanate Whisker-Reinforced Resin-Based Friction Composites. Tribol. Trans. 2024, 67, 348–358. [Google Scholar] [CrossRef]

- Azizl, M.J.; Barghamadi, M.; Rezaeeparto, K.; Mokhtary, M.; Parham, S. Graphene oxide and graphene hybrid nanocomposites based on compatibilized PP/PTW/EVA: Effect of nanofiller and compatibilizer on the modeling of viscoplastic behavior. J. Polym. Res. 2021, 28, 1–21. [Google Scholar] [CrossRef]

- Yang, F.; Li, J.; Han, S.; Ma, N.; Li, Q.; Liu, D.; Sui, G. Wear resistant PEEK composites with great mechanical properties and high thermal conductivity synergized with carbon fibers and h-BN nanosheets. Polym. Adv. Tech. 2023, 34, 2224–2234. [Google Scholar] [CrossRef]

- Zhang, K.; Lin, Z.; Ma, S.; Pan, S.; Chen, W.; Wang, D.; Chen, C.; Zhao, X. Silver with tribo-chemistry facilitation synergized with graphite particles for enhancing the tribo-performance of PEEK composites. Compos. Part A Appl. Sci. Manuf. 2024, 187, 108456. [Google Scholar] [CrossRef]

- Hua, Y.; Li, F.; Hu, N.; Fu, S.-Y. Frictional characteristics of graphene oxide-modified continuous glass fiber reinforced epoxy composite. Compos. Sci. Tech. 2022, 223, 109446. [Google Scholar] [CrossRef]

- Feng, C.; Guo, Y.; Yu, Z.; Chen, K.; Wang, D.; Li, X.; Luo, Y.; Wang, Q.; Zhang, D. Tribological properties of PEEK composites reinforced by MoS2 modified carbon fiber and nano SiO2. Tribol. Int. 2023, 181, 108315. [Google Scholar] [CrossRef]

- Xu, N.; Chen, S.; Li, Y.; Jiang, N.; Zheng, T.; Goossens, N.; Vleugels, J.; Zhang, D.; Seveno, D. A hybrid 1D/2D coating strategy with MXene and CNT towards the interfacial reinforcement of carbon fiber/poly (ether ether ketone) composite. Compos. Part B Eng. 2022, 246, 110278. [Google Scholar] [CrossRef]

- Chen, Z.; Zhang, M.; Ren, P.; Lan, Z.; Guo, Z.; Yan, H.; Jin, Y.; Ren, F. Enhanced mechanical and tribological properties of epoxy composites reinforced by novel hyperbranched polysiloxane functionalized graphene/MXene hybrid. Chem. Eng. J. 2023, 466, 143086. [Google Scholar] [CrossRef]

- Wang, Y.; Wu, M.; Wang, J.; Huang, J.; Yang, K.; Miao, X.; Zhang, L. The addition of SiO2-GO hybrid material enhanced the tribological properties of fluorocarbon resin in marine corrosive environments. Mater. Today Commun. 2024, 39, 108676. [Google Scholar] [CrossRef]

- Lan, Z.; Chen, Z.; Zhang, M.; Huang, W.; Ding, D.; Fan, B.; Ren, P. Improved mechanical and tribological properties of epoxy resin with new hyperbranched polysiloxane grafted MXene/Ag hybrids. Tribol. Int. 2025, 204, 110515. [Google Scholar] [CrossRef]

- Badgayan, N.D.; Samanta, S.; Sahu, S.K.; Siva, S.V.; Sadasivuni, K.K.; Sahu, D.; Sreekanth, P.R. Tribological behaviour of 1D and 2D nanofiller based high densitypoly-ethylene hybrid nanocomposites: A run-in and steady state phase analysis. Wear 2017, 376, 1379–1390. [Google Scholar] [CrossRef]

- Lin, Z.; Zhang, K.; Ye, J.; Li, X.; Zhao, X.; Qu, T.; Liu, Q.; Gao, B. The effects of filler type on the friction and wear performance of PEEK and PTFE composites under hybrid wear conditions. Wear 2022, 490, 204178. [Google Scholar] [CrossRef]

- Li, S.; Li, W.; Nie, J.; Liu, D.; Sui, G. Synergistic effect of graphene nanoplate and carbonized loofah fiber on the electromagnetic shielding effectiveness of PEEK-based composites. Carbon 2019, 143, 154–161. [Google Scholar] [CrossRef]

- Mindivan, F.; Dere, H. Wear-resistant layers containing graphene derivatives. Polym. Compos. 2024, 45, 4138–4150. [Google Scholar] [CrossRef]

- Chen, Z.; Zhang, M.; Guo, Z.; Chen, H.; Yan, H.; Ren, F.; Jin, Y.; Sun, Z.; Ren, P. Synergistic effect of novel hyperbranched polysiloxane and Ti3C2Tx MXene/MoS2 hybrid filler towards desirable mechanical and tribological performance of bismaleimide composites. Compos. Part. B Eng. 2023, 248, 110374. [Google Scholar] [CrossRef]

- Wan, C.; Jia, D.; Li, J.; Zhan, S.; Zhang, W.; Yang, T.; Li, Y.; Duan, H. Synergism lubrication of graphene and carbon nanotube in polymeric composites under drying sliding condition. Appl. Surf. Sci. 2023, 630, 157430. [Google Scholar] [CrossRef]

- Karatas, E.; Gul, O.; Karsli, N.G.; Yilmaz, T. Synergetic effect of graphene nanoplatelet, carbon fiber and coupling agent addition on the tribological, mechanical and thermal properties of polyamide 6, 6 composites. Compos. Part B Eng. 2019, 163, 730–739. [Google Scholar] [CrossRef]

| Sample No. | PEEK (wt%) | P-G1 (wt%) | P-G2 (wt%) | PGMF1 (wt%) | PGMF2 (wt%) |

|---|---|---|---|---|---|

| Neat PEEK | 100 | ||||

| PEEK/P-G1–5% | 95 | 5 | |||

| PEEK/P-G1–10% | 90 | 10 | |||

| PEEK/P-G2–5% | 95 | 5 | |||

| PEEK/P-G2–10% | 90 | 10 | |||

| PEEK/PGMF1–5% | 95 | 5 | |||

| PEEK/PGMF1–10% | 90 | 10 | |||

| PEEK/PGMF2–5% | 95 | 5 | |||

| PEEK/PGMF2–10% | 90 | 10 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ji, Z.; Ji, M.; Lv, Q.; Liang, M.; Xu, C. Potassium Titanate Whisker/Graphene Multi-Dimensional Fillers to Improve the Wear Resistance of Poly(Ether Ether Ketone) Composite. Lubricants 2025, 13, 211. https://doi.org/10.3390/lubricants13050211

Ji Z, Ji M, Lv Q, Liang M, Xu C. Potassium Titanate Whisker/Graphene Multi-Dimensional Fillers to Improve the Wear Resistance of Poly(Ether Ether Ketone) Composite. Lubricants. 2025; 13(5):211. https://doi.org/10.3390/lubricants13050211

Chicago/Turabian StyleJi, Zhengjia, Mingliang Ji, Qiuchen Lv, Minggui Liang, and Chao Xu. 2025. "Potassium Titanate Whisker/Graphene Multi-Dimensional Fillers to Improve the Wear Resistance of Poly(Ether Ether Ketone) Composite" Lubricants 13, no. 5: 211. https://doi.org/10.3390/lubricants13050211

APA StyleJi, Z., Ji, M., Lv, Q., Liang, M., & Xu, C. (2025). Potassium Titanate Whisker/Graphene Multi-Dimensional Fillers to Improve the Wear Resistance of Poly(Ether Ether Ketone) Composite. Lubricants, 13(5), 211. https://doi.org/10.3390/lubricants13050211