Abstract

Enhancing the durability and tribological performance of babbitt alloys is critical for high-stress applications in automotive, marine, and industrial machinery. The present study explores the electrodeposition of chromium coatings on SnSb11Cu6 alloys to improve their microstructural, mechanical, and tribological properties. The coatings were applied through an electrolytic process and systematically characterized using scanning electron microscopy and energy-dispersive X-ray spectroscopy to evaluate their morphology, composition, and wear performance. The chromium coating exhibited a uniform thickness of 20.2 µm and significantly improved the surface hardness to 715.2 HV, far surpassing the matrix and intermetallic phases of the uncoated alloy. Tribological testing under dry sliding conditions demonstrated a 44% reduction in the coefficient of friction (COF) and a 54% decrease in mass wear for the coated alloy, highlighting the protective role of the chromium layer against abrasive and adhesive wear. To further analyze the frictional behavior, a deep learning model based on a one-dimensional convolutional neural network was employed to predict COF trends over time, achieving excellent accuracy with R2 values of 0.9971 for validation and 0.9968 for testing. Feature importance analysis identified coating hardness as the most critical factor influencing COF and wear resistance, followed by matrix hardness near the coating. These findings underscore the effectiveness of chromium coatings in mitigating wear damage and improving the operational lifespan of SnSb11Cu6 alloys in high-stress applications. This study not only advances the understanding of chromium coatings for babbitt materials but also demonstrates the potential of machine learning in optimizing tribological performance.

1. Introduction

Babbitt materials, traditionally composed of tin, antimony, and copper, have long been the preferred choice for bearing applications in automotive, marine, and industrial machinery. These materials are valued for their excellent conformability, embeddability, and anti-friction properties, making them ideal for reducing wear and ensuring smooth operation in high-load, high-speed environments. The unique microstructure of babbitt alloys, consisting of a soft matrix embedded with hard phases, allows for effective load distribution and self-lubrication, extending the service life of bearing components [1,2,3,4]. Among these, tin-based babbitt alloys exhibit superior mechanical and tribological performance compared to lead-based alternatives, particularly in applications requiring high thermal and load resistance. A widely used tin-based babbitt alloy is SnSb11Cu6, which consists of 11 wt.% antimony and 6 wt.% copper in a tin-rich matrix [5,6,7]. This alloy is known for its excellent balance of strength, wear resistance, and thermal stability, making it particularly well suited for heavy-duty bearing applications. The microstructure of babbitt materials typically consists of a soft tin-rich matrix with dispersed hard intermetallic phases, such as Cu₆Sn5 and SbSn. These intermetallics enhance wear resistance by forming a robust load-bearing framework, while the soft matrix facilitates lubrication [8,9].

Despite these advantages, conventional babbitt materials exhibit limitations, particularly in terms of wear resistance and mechanical strength. Under high-stress and high-temperature conditions, babbitt bearings are susceptible to fatigue, deformation, and accelerated wear, which can lead to premature failure [10,11,12]. For instance, Sn-Sb-Cu bearings may fail prematurely when subjected to insufficient load-carrying capacity under rising temperatures. Dong et al. [13] demonstrated that the hardness and strength of SnSb11Cu6 alloys decrease significantly as operating temperatures increase, limiting their overall service life. These challenges underscore the need to develop novel strategies to enhance the durability and performance of babbitt materials, particularly in demanding applications where extended service life and reliability are essential. Over the years, various strategies have been explored to enhance the mechanical strength, wear resistance, and tribological performance of tin-based babbitt alloys, particularly in high-speed and heavy-load applications. Reinforcing the matrix with ceramic particles such as SiC has yielded improvements of up to 80% in hardness, compressive strength, and wear resistance over unmodified Sn-Sb-Cu alloys [14]. Similarly, the addition of rare-earth elements, such as yttrium, has been demonstrated to refine the microstructure, enhance the tensile strength, and improve the wear properties of Sn-based babbitt alloys, particularly SnSb11Cu6 [11]. Micro-alloying with elements like Ag and Co has also proven effective in strengthening the matrix, modifying intermetallic phases, and enhancing bonding strength with steel substrates, further optimizing the load-bearing capabilities of SnSb11Cu6-based alloys [6,13,15]. Beyond bulk modifications, surface engineering techniques such as ultrasonic nanocrystalline surface modification, laser remelting, and high-velocity oxygen fuel spraying have been employed to refine grain structure, reduce porosity, and extend service life in bearing applications [16,17]. Additionally, electrodeposited SnSbCu coatings on bronze and copper substrates have demonstrated better tribological performance by reducing wear rates [18].

In addition to experimental approaches, computational modeling has played a crucial role in understanding and predicting the behavior of Sn-based alloys, including babbitt materials, under various operating conditions. Finite element analysis (FEA) and molecular dynamics (MD) simulations have been widely employed to investigate the stress distribution, deformation mechanisms, and wear characteristics of Sn-Sb-Cu alloys in tribological applications. For instance, Sous et al. [19] conducted FE simulations alongside nano-indentation experiments to characterize the elastic–plastic properties of key microstructural phases in tin-based bearing alloys, revealing the impact of Cu₆Sn5 and SbSn intermetallics on load-bearing capacity. Similarly, Etesami et al. [20] developed a MD-based thermodynamic model to accurately predict phase behavior and mechanical properties of Sn-based alloys, allowing for better control over their solidification and stability. Recent advances in dislocation density-based modeling have also enabled researchers to simulate microstructural evolution during deformation, providing insights into strengthening mechanisms such as twinning and dislocation pile-up, as demonstrated by Vafaeenezhad et al. [21]. Furthermore, high-throughput thermodynamic modeling techniques, such as those employed by Yang et al. [22], have been used to design optimized Sn-based alloys with enhanced mechanical properties by systematically screening thousands of compositions. Beyond these classical computational methods, recent years have witnessed the rapid adoption of machine learning (ML) techniques to enhance predictive accuracy and efficiently analyze complex tribological phenomena. Various algorithms such as Random Forest (RF), K-Nearest Neighbors (KNN), Extreme Gradient Boosting (XGB), and Support Vector Machine (SVM) have demonstrated high predictive accuracy for wear phenomena. For instance, in ball-on-disk wear experiments, XGB has consistently provided superior predictions for wear depth, highlighting the significance of input parameters like sliding speed, load, and lubrication conditions [23]. Similarly, the comparative performance of ML models has been extensively analyzed for magnesium matrix composites, demonstrating the impact of meticulous hyperparameter tuning on prediction outcomes even with limited datasets [24]. A comprehensive review by Khan et al. further consolidates these findings, illustrating how algorithms such as artificial neural networks, Bayesian modeling, logistic regression, and transfer learning have consistently achieved accuracy scores exceeding 93% in predicting lubrication film thickness, friction, and wear under varying operational conditions [25]. Recent studies have increasingly employed deep learning techniques that combine convolutional neural networks (CNNs) and sequential models like Informer encoders and Bidirectional Long Short-Term Memory (BiLSTM) networks to monitor tool wear, achieving accuracy levels up to 99% by effectively capturing complex temporal dependencies [26]. Additionally, sophisticated multi-sensor fusion techniques employing ResNet-LSTM architectures have been shown to significantly enhance tool wear prediction accuracy, yielding minimal average errors (0.0085 mm) and robust noise reduction capabilities [27]. Furthermore, hyperparameter optimization techniques such as grid-search have been leveraged to further enhance the predictive performance of classical ML models (RF, SVM, KNN, Gaussian Process Regression, and Linear Regression), reinforcing their reliability and accuracy in wear-rate estimation [28]. Recent hybrid deep learning approaches, such as the PSD-CVT model, combining power spectral density analysis with CNN and Vision Transformer (ViT), have also set new benchmarks by outperforming conventional CNN or ViT approaches individually in predicting progressive tool wear [29]. By complementing experimental studies with advanced computational modeling, researchers can accelerate the development of next-generation babbitt materials with improved mechanical strength, wear resistance, and service life.

In addition to bulk alloy modifications and predictive modeling, surface engineering techniques such as coatings offer another viable strategy for enhancing material performance, particularly in tribological applications. Among various surface coatings, chromium (Cr) coatings have emerged as a highly effective solution for enhancing the hardness, wear resistance, and corrosion protection of bearing materials [30,31]. Chromium coatings are widely used in tribological applications due to their exceptional surface hardness, which significantly reduces material loss under high-contact stress conditions [32,33]. Their low friction coefficient and superior adhesion properties contribute to improved lubrication and reduced surface fatigue, extending the operational lifespan of coated components [34]. Furthermore, Cr coatings exhibit excellent corrosion resistance, preventing oxidation and degradation in harsh environments, making them a preferred choice for demanding applications in automotive, marine, and industrial machinery [35].

However, while chromium coatings have been extensively applied to improve the performance of various alloys, their effect on SnSb11Cu6 babbitt alloys remains largely unexplored. In particular, there is a lack of research on the microstructural characterization, hardness, and tribological performance of Cr-coated SnSb11Cu6 alloys. Furthermore, predictive modeling techniques, such as machine learning and time-series forecasting, have not been widely explored to assess the tribological behavior of these coatings under dynamic loading conditions. Moreover, despite significant advancements in applying ML methods to tribology, as demonstrated by numerous recent studies employing algorithms like Random Forest, Extreme Gradient Boosting, and convolutional neural networks, such approaches have yet to be applied extensively to coated babbitt materials. In particular, the capability of deep learning architectures such as convolutional neural networks [36], which have proven effective in capturing complex temporal dependencies and accurately predicting wear and friction behaviors, has not been evaluated for chromium-coated SnSb11Cu6 alloys. Addressing this specific knowledge gap by employing one-dimensional convolutional neural networks (Conv1D), predictive models could lead to a deeper understanding of frictional and wear dynamics, enabling more effective optimization of surface engineering strategies aimed at enhancing bearing performance and longevity.

To address this knowledge gap, the present study investigates the electrodeposition of chromium coatings directly on SnSb11Cu6 and evaluates their microstructural, mechanical, and tribological properties. The coatings were systematically characterized using scanning electron microscopy (SEM) and energy-dispersive X-ray spectroscopy (EDS) to analyze their morphology and composition. Microhardness tests and wear evaluations were then conducted to quantify improvements in mechanical strength and durability improvements. Additionally, an advanced deep learning model, specifically a Conv1D architecture, was employed to predict COF trends over time. This approach enables a deeper understanding of frictional behavior and wear progression, facilitating more precise optimization of coating parameters. Furthermore, feature importance plots for the COF and mass wear were generated to determine which parameters most significantly influence these tribological outcomes. Chromium coatings were selected due to their well-established industrial use in bearing applications, offering superior hardness, excellent wear resistance, and the ability to form dense, protective layers. Building on previous research on chromium coatings applied to aluminum alloys [37], this work further explores the potential of chromium coatings to enhance wear resistance and extend the operational lifespan of babbitt bearing materials.

2. Materials and Methods

2.1. Fabrication

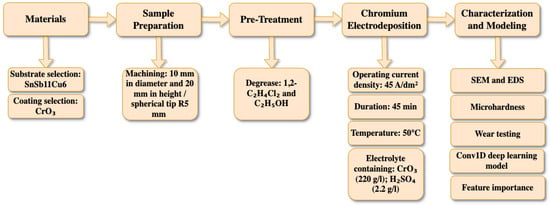

The substrate material used was SnSb11Cu6 alloy, commonly utilized in bearing applications due to its excellent wear resistance and load-bearing capacity. The samples were cylindrical in shape, with dimensions of 10 mm in diameter, 20 mm in height, and a spherical tip of radius R5. The initial preparation involved degreasing the samples successively in 1,2-dichloroethane (C2H4Cl2) and ethanol (C2H5OH), followed by weighing and measuring to ensure dimensional accuracy. Before electrodeposition, the samples underwent an etching process using acidic mixtures containing sulfuric acid (H2SO4). A systematic cleaning process was developed to achieve reproducibility and ensure clean and uniform surfaces. The fabrication and analysis process is summarized in Figure 1, which outlines the steps from material preparation to chromium electrodeposition and characterization. Chromium deposition on the surface of the SnSb11Cu6 samples was carried out through an electrolytic process using a traditional acidic electrolyte containing CrO3 at a concentration of 220 g/L and sulfuric acid (H2SO4) at 2.2 g/L. The electrolytic process was conducted under controlled parameters, including a current density of 45 A/dm2, a process duration of 45 min, and an electrolyte temperature of 50 °C. A semi-circular lead electrode as an anode (12 × 6 cm) was used during the electrodeposition process. The electrolyte solution was agitated using an electromagnetic stirrer to ensure uniform deposition, and the pH was maintained between 5.3 and 5.5 throughout the process. The resulting coatings were uniform, continuous, and dense, conforming to the surface of the sample. However, due to the spherical tip of the substrate material, slight variations in coating thickness were observed. The chromium yield was 11.03 mg/cm2, with a mass difference of 0.104 g before and after the chroming process of the babbitt alloy sample. The selection of these deposition parameters was based on our previous work [37] on chromium coatings.

Figure 1.

Fabrication and analysis scheme for chromium-coated SnSb11Cu₆ alloy.

2.2. Characterization

SEM and EDS analyses were carried out using a HIROX SH-5500P SEM (Hirox Japan Co., Ltd., Tokyo, Japan) equipped with a ‘QUANTAX 100 Advanced’ EDS system (Bruker, Billerica, MA, USA) to examine the surface morphology and elemental composition of the materials. The tribological performance was evaluated using a pin-on-disk dry sliding wear test, conducted at room temperature on a TR-20 model Ducom Rotary tribometer (Ducom Instruments, Bangalore, India). The test parameters included a load of 10 N, a sliding velocity of 0.85 m/s, and a total sliding distance of 418 m. Chromium-coated SnSb11Cu6 alloy and uncoated SnSb11Cu6 alloy were tested against an EN-31 steel counter-disk to assess wear resistance and frictional behavior. The tribological tests were conducted on multiple samples following consistent experimental procedures to ensure the reliability and reproducibility of the results. Representative tests were selected based on stable and repeatable friction behavior under the specified conditions. The specimens used for the tribological tests were cylindrical with a length of 25 mm, a diameter of 10 mm, and a spherical tip with a radius of 5 mm. The tests were carried out under a normal load of 10 N, at room temperature, and ambient humidity. The wear mass loss was determined by measuring the initial and final mass of each sample using a Boeco BAS 32 Plus (Hamburg, Germany) analytical balance with a precision of 0.1 mg (d = 0.1 mg). Samples were thoroughly cleaned and dried before each measurement to ensure accuracy. Prior to microhardness measurements, the samples were prepared following a standard metallographic procedure. Cross-sections were embedded in acrylic resin, ground with silicon carbide papers up to grit #1200, and mechanically polished using diamond suspensions. The samples were then etched by immersion in a solution of 2 mL HCl, 5 mL HNO3, and 93 mL methanol to reveal the microstructure. The microhardness of the coated material was analyzed using a Polyvar Met light microscope (Reichert Jung, Vienna, Austria) equipped with a semi-automated micro-Vickers hardness measurement system (Micro-Duromat 5000 computer control, Reichert Jung, Vienna, Austria). The microhardness measurements were performed using a standardized Vickers indenter with a diamond pyramid tip at a 136° angle at the vertex. A load of 0.05 kgf was applied for a duration of 10 s, with the pressure maintained for an additional 10 s to ensure accurate measurements. Microhardness measurements were performed on multiple indentations under consistent experimental conditions to ensure the reliability and reproducibility of the results. To capture the hardness distribution across the coating and substrate, indentations were systematically performed in four distinct regions: (i) within the matrix of the SnSb11Cu6 alloy, (ii) in the matrix close to the coating, (iii) within the SnSb intermetallic phase, and (iv) within the chromium coating layer. Multiple measurements were taken at each region to ensure repeatability and assess the hardness gradient. Data are presented as the mean with the standard deviation to represent both the average values and the variability observed across measurements. These methods provided comprehensive insights into the microstructural, tribological, and mechanical properties of the materials under investigation.

2.3. Deep Learning-Based Predictive Modeling and Feature Importance Analysis

To predict the COF trends over time for chromium-coated and uncoated SnSb11Cu6 alloys, a deep learning model based on a one-dimensional Conv1D was implemented using TensorFlow and Keras. The Conv1D architecture was chosen for its ability to extract local temporal dependencies from time-series data, making it well-suited for tribological analysis [38,39]. The model was designed with an initial Conv1D layer containing 32 filters and a kernel size of 2, activated using the ReLU function to introduce non-linearity. This was followed by a Flatten layer, which transformed the feature maps into a one-dimensional vector. The fully connected layers included 16 neurons with ReLU activation, followed by a single output neuron with linear activation to predict COF values. The model was compiled using the Adam optimizer and trained with a mean squared error (MSE) loss function for regression. Training was conducted over 200 epochs with a batch size of 16, and validation was performed at each epoch to monitor performance and prevent overfitting. To prepare the data, experimental COF measurements were collected from separate datasets for chromium-coated and uncoated alloys. The data were preprocessed by scaling the COF values to a [0, 1] range using the MinMaxScaler function to improve training efficiency. A look-back window of three time steps was applied to construct time-series sequences, ensuring that the model captured past COF values to predict future trends. The dataset was then split into 70% training, 15% validation, and 15% testing, maintaining a balanced representation across different COF ranges. The model’s performance was assessed using key evaluation metrics, including mean squared error (MSE), root mean squared error (RMSE), mean absolute error (MAE), and the R2 score (coefficient of determination). These metrics quantified the model’s predictive accuracy, and results were stored in a text file for documentation.

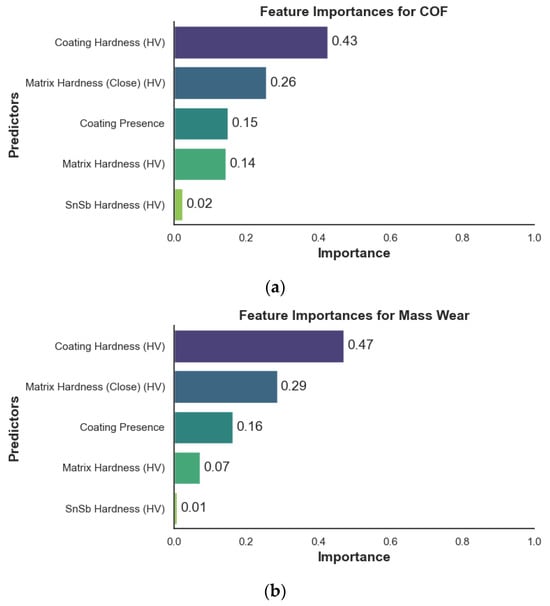

In addition to deep learning-based COF prediction, a feature importance analysis was conducted using a Random Forest Regressor to evaluate the influence of different material properties on COF and mass wear. This robust ensemble learning method is known for its ability to handle non-linearity, feature interactions, and high-dimensional datasets, making it well suited for identifying key factors affecting tribological performance [40]. The model considered several key predictors, including coating presence (binary: 1 = coated; 0 = uncoated), matrix hardness, matrix hardness near the coating, SnSb hardness, and coating hardness. Two separate regression models were trained: one for COF prediction and another for mass wear estimation. The importance of each feature was extracted from the trained models and visualized using Seaborn bar plots, ranking the most influential parameters for each target variable.

3. Results and Discussion

3.1. Microstructural Analysis

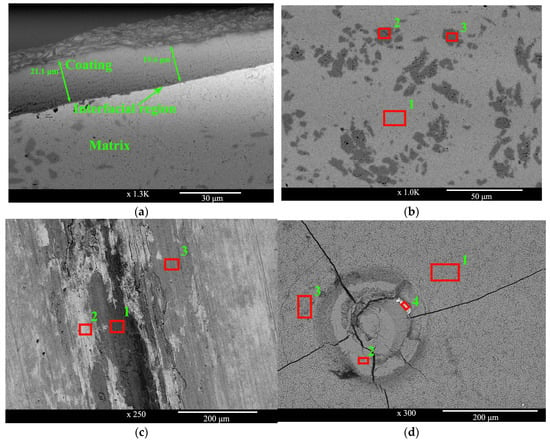

The microstructural analysis of the chromium-coated SnSb11Cu6 alloy and uncoated SnSb11Cu6 alloy was conducted to evaluate their surface morphology and chemical composition before and after the wear test. The thickness of the chromium coating was measured to assess its uniformity and its contribution to wear resistance. SEM micrographs and EDS analysis results (Figure 2, Table 1) were used to examine the structural integrity and wear behavior of these materials under different conditions. Table 1 presents the elemental composition of the SnSb11Cu6 alloy for (i) the uncoated alloy before the wear test (Figure 2b), (ii) the uncoated alloy after the wear test (Figure 2c), and (iii) the chromium-coated alloy after the wear test (Figure 2d). Key elements analyzed include Sn, Sb, Cu, Cr, O, and Fe, highlighting wear-induced changes and the protective effects of the chromium coating. The chromium coating on the SnSb11Cu6 alloy, as shown in Figure 2a, was measured to have a mean thickness of 20.2 µm, with a clearly defined interfacial region separating the coating from the alloy matrix. The SnSb11Cu6 substrate material features a spherical tip on the contact surface side, where the wear test is conducted. Due to this geometry, a slight variation in coating thickness was observed, with the thickest part measuring 21.1 µm and the thinner regions measuring 19.4 µm. This consistent yet slightly variable coating thickness indicates a well-applied protective layer, which is crucial for enhancing wear resistance. The surface morphology of the uncoated SnSb11Cu₆ alloy before the wear test (Figure 2b) shows a relatively homogeneous distribution of elements. EDS results indicate that Zone 1 primarily represents the matrix of the alloy, with a high concentration of Sn (92.11%) and Sb (7.89%), characteristic of the Sn-rich base material. In contrast, Zones 3 and 2 correspond to intermetallic phases, with compositions of Sn (65.21%, 64.63%) and Cu (34.79%, 35.37%), suggesting the presence of intermetallic compounds. These intermetallic phases provide structural reinforcement, improving the wear resistance and load-bearing capacity of the alloy. After the wear test, the surface morphology of the uncoated alloy (Figure 2c) demonstrates significant changes, with wear-induced alterations visible in the EDS analysis. Zone 1 exhibits a notable presence of Fe (26.72%), alongside reduced amounts of Sn (62.22%), Sb (8.62%), and Cu (2.45%). The introduction of Fe suggests material transfer from the counterbody during the wear process, indicative of adhesive wear. Zone 2, in contrast, remains dominated by Sn (88.97%) and Sb (11.03%), indicating areas less affected by wear. Zone 3 shows a mixture of Sn (75.34%), Sb (10.16%), Cu (5.21%), and Fe (9.28%), highlighting a combination of the original matrix material and tribolayer formation from wear debris, characteristic of third-body wear. The grooved and plowed surface morphology observed in the SEM image further supports the presence of abrasive wear. In comparison, the chromium-coated SnSb11Cu6 alloy after the wear test (Figure 2d) demonstrates a more intact and stable surface morphology. EDS analysis reveals that the chromium coating effectively preserved the surface integrity of the SnSb11Cu6 alloy, by minimizing material loss and mitigating wear-induced compositional changes. In Zones 1, 2, and 3, the EDS results show a dominant presence of chromium (95.20–95.80%), along with minor oxygen content (4.20–4.80%), originating from the chromium coating itself. The absence of Sn, Sb, Cu, and Fe in these zones indicates that the chromium layer successfully shielded the underlying alloy from direct contact and wear, acting as an effective barrier against both mechanical abrasion and chemical interaction. However, Zone 4 presents a deviation from this protective pattern. Here, the Cr content drops to 79.85%, accompanied by the appearance of Sn (15.75%) and oxygen (4.40%). Detailed SEM image analysis shows that this exposed area measures approximately 11 µm in width and 39 µm in length. This confirms that the coating degradation is highly localized and limited in size, without compromising the overall protective function of the chromium layer. Such confined exposure did not trigger crack propagation or delamination. This is validated by SEM observations showing that microcracks remained shallow and non-propagating, and EDS analysis confirmed stable chromium content with no substrate exposure or material transfer. Additionally, the significant reduction in COF and wear mass supports that the overall protective function of the chromium layer remained intact under the test conditions. The SEM image reveals five microcracks radiating from the wear track, all of which are confined primarily to the surface layer. Detailed measurements show that the largest microcrack width is approximately 4 µm, further confirming that these cracks remain shallow and do not penetrate deeply enough to compromise the coating’s integrity. Importantly, no material transfer or significant degradation was detected, underscoring the stability of the chromium layer. Overall, the limited size of the exposed area and the stable microstructure indicate that the coating effectively withstood the wear process, maintaining excellent resistance to wear with minimal vulnerability under standard operating conditions.

Figure 2.

SEM micrographs illustrating the structural features of the coated and uncoated materials: (a) Cross-sectional view of the chromium-coated SnSb11Cu6 alloy; (b) Surface morphology of the SnSb11Cu6 alloy before the wear test, with red square zones indicating the locations (1–3) where EDS analysis was performed; (c) Surface morphology of the SnSb11Cu6 alloy after the wear test, with red square zones indicating the locations (1–3) where EDS analysis was performed; (d) Surface morphology of the chromium-coated SnSb11Cu6 alloy after the wear test, with red square zones indicating the locations (1–4) where EDS analysis was performed.

Table 1.

EDS analysis results (in mass norm. %) for the zones highlighted in SEM micrographs (Figure 2).

The wear behavior observed in the chromium-coated sample differs markedly from that of the uncoated alloy. While the uncoated SnSb11Cu6 alloy (Figure 2c) exhibited significant Fe transfer from the counterbody and clear signs of abrasive and adhesive wear, the chromium-coated surface maintained an intact structure with no evidence of material transfer. The coating effectively minimized adhesive wear and limited wear debris formation. Overall, the chromium layer exhibited resilience across most zones, with abrasive wear significantly mitigated and adhesive wear occurring only in the minor localized breach at Zone 4. These results demonstrate the superior wear resistance of the chromium-coated SnSb11Cu6 alloy, highlighting its effectiveness in protecting the substrate.

3.2. Microhardness and Wear Behavior

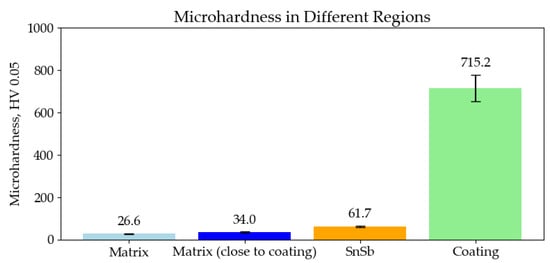

The microhardness distribution of the Chromium-coated SnSb11Cu6 alloy exhibits significant variation across the analyzed regions, as illustrated in Figure 3. The matrix region displays the lowest microhardness value, measuring 26.6 HV, indicative of the soft and ductile nature of the SnSb11Cu6 alloy’s base material. However, a moderate increase in microhardness is observed in the matrix region close to the coating, where the value rises to 34.0 HV, likely due to the influence of the coating process. The SnSb phase, known to provide structural reinforcement, demonstrates a microhardness of 61.7 HV, reflecting the presence of intermetallic phases that contribute to higher hardness compared to the unreinforced matrix. This intermediate hardness value highlights the strengthening effect of the SnSb phase on the alloy, albeit still significantly lower than the surface-coating hardness. The chromium coating region exhibits an exceptionally high microhardness of 715.2 HV, far surpassing all other regions. This significant increase is attributed to the inherent hardness of the chromium layer, which forms a wear-resistant surface with enhanced mechanical properties. The difference in hardness between the coating and the other regions underscores the efficiency of the coating in imparting superior surface strength and durability to the alloy.

Figure 3.

Microhardness distribution in different regions of Chromium-coated SnSb11Cu6 alloy.

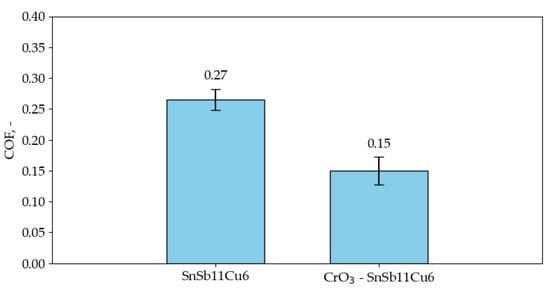

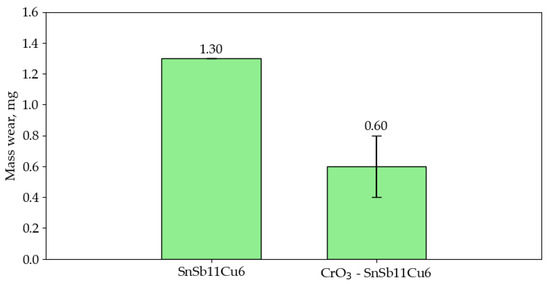

The materials tested included the chromium-coated SnSb11Cu6 alloy and the uncoated SnSb11Cu6 alloy. COF (Figure 4) and mass wear (Figure 5) were analyzed to assess the effectiveness of the coating in improving the tribological properties. The uncoated SnSb11Cu6 alloy exhibited a higher COF of 0.27 and a mass loss of 1.30 mg, indicating significant material removal and higher resistance during sliding. These results align with the microstructural observations, where abrasive and adhesive wear mechanisms dominated the wear process. The EDS analysis of the worn surface (Figure 2c) revealed notable Fe transfer from the counterbody, a hallmark of adhesive wear, alongside clear signs of abrasive wear characterized by grooves and plowed regions. The relatively soft Sn-rich matrix in the uncoated alloy, though reinforced by intermetallic phases, lacks sufficient surface hardness to withstand high sliding stresses, leading to increased material detachment and wear debris formation. In contrast, the chromium-coated SnSb11Cu6 alloy demonstrated superior tribological performance, as evidenced by the reduced COF of 0.15—a 44% decrease—and a significantly lower mass loss of 0.60 mg, representing a 54% improvement in wear resistance. This enhancement directly reflects the microstructural integrity of the chromium coating observed in Figure 2d. The hard chromium layer effectively served as a barrier, minimizing direct contact between the softer SnSb11Cu6 substrate and the counterbody, thereby reducing both friction and wear. Similar to Zeng et al. [41], our results confirm that the hardness of the chromium layer significantly dictates the wear behavior under dry sliding conditions. The findings align with previous research [37], where uniform chromium coatings doped with nanodiamond particles significantly enhanced microhardness and wear performance on aluminum alloys. Notably, even without nanodiamond reinforcement, our electrodeposited pure chromium coating demonstrated a similarly protective role, effectively improving wear resistance and reducing friction. The uniform chromium distribution across the worn surface, as shown in Table 1 for Figure 2d (Zones 1–3), contributed to consistent wear resistance as well as enhanced hardness and chemical stability. The presence of microcracks in the chromium-coated alloy, though observed in the SEM analysis, did not compromise the protective function of the coating. These microcracks were shallow, with no visible phases detected within them, indicating that they did not facilitate material transfer or significant degradation. Even in Zone 4, where a minor 39 µm exposed phase was identified, the disruption was localized and had minimal impact on the overall wear performance. This highlights the coating’s robustness, ensuring that adhesive wear mechanisms were effectively suppressed, and abrasive wear was significantly minimized.

Figure 4.

COF comparison between Chromium-coated SnSb11Cu6 alloy and uncoated SnSb11Cu6 alloy.

Figure 5.

Mass wear (mg) comparison between Chromium-coated SnSb11Cu6 alloy and uncoated SnSb11Cu6 alloy.

3.3. Modeling and Feature Importance Analysis

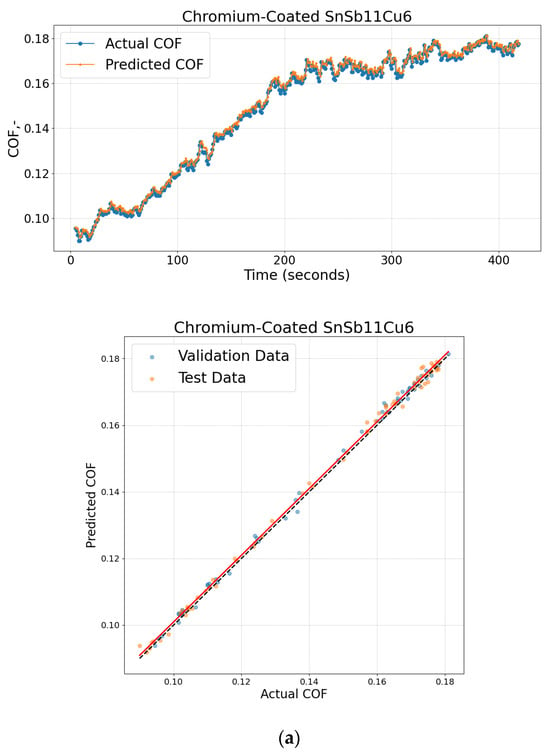

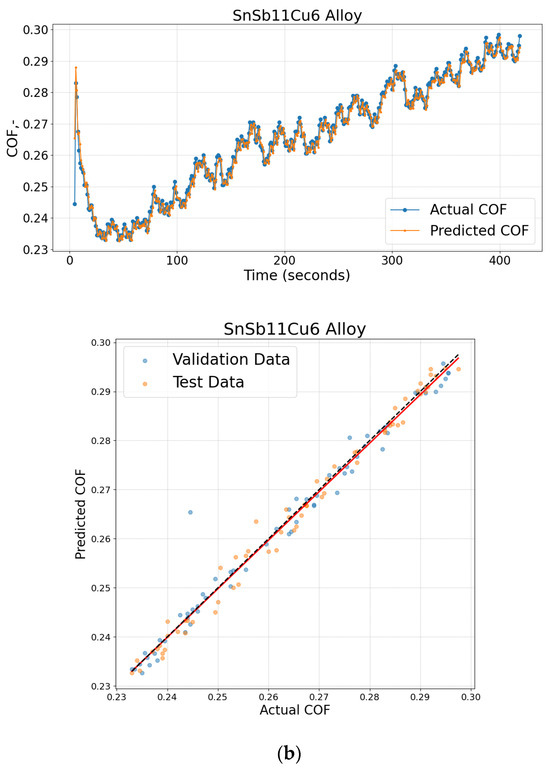

To predict the COF trends over time for chromium-coated (Figure 6a) and uncoated SnSb11Cu6 alloys (Figure 6b), a deep learning approach based on a one-dimensional Conv1D model was implemented using TensorFlow (https://www.tensorflow.org) and Keras (https://keras.io/). The Conv1D architecture was selected for its ability to capture local temporal dependencies in time-series data, making it suitable for tribological analysis. The model featured a Conv1D layer with 32 filters (kernel size: 2), ReLU activation, and a fully connected layer for regression, optimized using the Adam optimizer and MSE loss function. Experimental COF data were scaled to [0, 1] with MinMaxScaler and prepared using a three-step look-back window. The dataset was split into 70% training, 15% validation, and 15% testing, and performance was evaluated using MSE, RMSE, MAE, and R2 (Table 2). A key finding of this computational analysis is the high predictive accuracy achieved by the Conv1D model, particularly for the coated alloy. This result is significant as it demonstrates the potential of advanced computational approaches to reliably predict wear behavior, thereby supporting more efficient material optimization and component lifespan prediction. Specifically, the model for the chromium-coated SnSb11Cu6 alloy attained a validation R2 of 0.9971 and a test R2 of 0.9968, confirming its superior predictive capability under the tested conditions. In comparison, the model for the uncoated SnSb11Cu6 alloy yielded a slightly lower validation R2 of 0.9742 and test R2 of 0.9887, reflecting marginally reduced prediction accuracy. The lower MSE and RMSE values for the chromium-coated alloy model further confirm its superior predictive capability. The results presented in Table 2 highlight the performance of the Conv1D model in predicting the COF for chromium-coated and uncoated SnSb11Cu6 alloys. The validation R2 for the chromium-coated alloy is 0.9971, higher than the 0.9742 observed for the uncoated alloy, demonstrating a stronger ability to explain the variance in the coated alloy’s COF. Similarly, the test R2 is slightly higher for the coated alloy (0.9968) compared to the uncoated alloy (0.9887), further reinforcing the superior model performance for the coated material. The error metrics, including MSE, RMSE, and MAE, are consistently lower for the coated alloy, indicating more accurate predictions. For example, the test RMSE for the coated alloy is 0.0018, compared to 0.0021 for the uncoated alloy. The deviation in COF measurements was inherently addressed during model training by applying the MSE loss function, which penalizes larger prediction errors more strongly and enables the model to generalize across local fluctuations in the experimental data. Although the uncoated alloy exhibited a visually more stable COF trend, the coated sample provided better prediction accuracy because the chromium layer induced a more consistent wear mechanism dominated by abrasion. In contrast, the uncoated alloy involved random micro-adhesive events that, while subtle in amplitude, introduced irregularities that were difficult for the model to generalize. This suggests that the wear process for the coated alloy, while dynamic, is fundamentally more predictable than the complex adhesive and abrasive interactions occurring on the uncoated surface.

Figure 6.

Prediction of COF and assessment of model performance: (a) chromium-coated SnSb11Cu6; (b) SnSb11Cu6 materials.

Table 2.

Evaluation metrics for COF prediction models.

To further understand the factors driving the observed tribological behavior and to quantitatively validate the experimental findings, a Random Forest Regressor was employed to assess the feature importance of material properties like coating presence, coating hardness, and matrix hardness on COF and mass wear. The feature importance results were visualized using bar plots to identify key predictors influencing tribological performance. The importance of various features in predicting COF and mass wear is depicted in Figure 7a,b. For COF, the most influential predictor is coating hardness, contributing 43% to the model’s accuracy. This is followed by matrix hardness (close to coating) at 26%, and coating presence at 15%, highlighting the critical role of the chromium coating in reducing friction. The base matrix and SnSb phase hardness contribute less significantly, with 14% and 2%, respectively. Similarly, for mass wear, coating hardness is the dominant predictor, accounting for 47% of the importance. The matrix hardness (close to coating) contributes 29%, while coating presence adds 16%. The minimal contributions from matrix hardness (7%) and SnSb hardness (1%) underscore the decisive impact of the chromium coating in enhancing wear resistance. These findings align with the experimental results, reinforcing the superior performance of the chromium-coated SnSb11Cu6 alloy in both friction and wear resistance. Crucially, these feature importance results provide strong, data-driven confirmation of the experimental observations discussed in Section 3.2. The analysis highlights the primary role of coating hardness and the proximity of the matrix to the coating in determining the alloy’s overall tribological behavior. The high importance attributed to coating hardness directly reflects its physical role in providing a robust barrier against the abrasive and adhesive wear mechanisms that were prevalent in the uncoated alloy. While this study demonstrates the effectiveness of the coating under specific dry sliding conditions and the utility of the modeling approach, further investigation could explore performance under lubricated conditions or varying loads and speeds, potentially leveraging similar predictive models to optimize for different operational scenarios.

Figure 7.

Feature importance analysis of microhardness in different regions of chromium-coated SnSb11Cu6 alloy, highlighting key factors influencing tribological performance: (a) COF and (b) mass wear.

The results presented herein confirm and extend recent findings in ML applications within tribology. Consistent with previously published works, our Conv1D model achieved excellent predictive performance, comparable to advanced deep learning frameworks recently proposed in the literature. For instance, previous studies using convolutional neural networks combined with recurrent or attention-based architectures (Informer, BiLSTM, and ResNet-LSTM) reported high predictive accuracies (up to 99%) in tool-wear monitoring scenarios by effectively capturing temporal dependencies from sensor data [26,27]. Our Conv1D model aligns with these results, obtaining high R2 values (validation R2 = 0.9971; testing R2 = 0.9968) for predicting COF in chromium-coated SnSb11Cu6 alloys, reinforcing the suitability of CNN-based deep learning methods for tribological data.

However, this study introduces notable novelty and superior aspects. Unlike previous studies, which predominantly focused on tool wear prediction or lubrication regimes in steels and composites, our work uniquely explores tribological predictions specifically for chromium-coated SnSb11Cu6 alloys—materials of critical importance in high-stress bearing applications. To our knowledge, this represents the first application of a deep learning Conv1D model for the prediction of COF in electrodeposited chromium-coated SnSb11Cu6 babbitt alloys. Furthermore, the incorporation of feature importance analysis using a Random Forest Regressor further distinguishes our approach, quantitatively validating experimental insights and clearly identifying coating hardness as the paramount feature influencing frictional and wear outcomes. This combined predictive and interpretive methodology offers deeper mechanistic insights by specifically applying predictive and feature importance models to chromium-coated SnSb11Cu6 alloys, whose frictional and wear properties have not previously been predicted using ML techniques [23,24,28]. Consequently, our integrated experimental ML framework not only achieves predictive accuracy comparable to the most sophisticated models in the recent literature but also demonstrates a uniquely comprehensive understanding of the factors driving tribological performance in coated babbitt alloys. This methodological advancement paves the way for more targeted optimization of coating processes, facilitating improved reliability and longevity in industrial applications.

4. Conclusions

This study aimed to investigate the electrodeposition of chromium coatings on SnSb11Cu6 alloys and evaluate their microstructural, mechanical, and tribological properties, complemented by advanced predictive modeling of frictional behavior. The chromium coatings were found to form a uniform and robust layer with a mean thickness of 20.2 µm, significantly enhancing the surface hardness of the alloy to 715.2 HV. This improvement in mechanical properties contributed to the superior wear resistance observed during dry sliding tests. The coated alloy exhibited a 44% reduction in the COF and a 54% improvement in wear resistance compared to the uncoated alloy. These tribological benefits were attributed to the formation of a stable chromium layer, which acted as an effective barrier against abrasive and adhesive wear. The uncoated alloy, by contrast, showed substantial wear-induced damage, including material transfer from the counterbody and compositional redistribution, which were absent in the coated samples. SEM and EDS analyses revealed that the chromium coating effectively protected the substrate from wear damage, with only minimal localized penetration of the coating layer.

The predictive modeling approach, utilizing a Conv1D architecture, accurately captured COF trends over time, achieving R2 values of 0.9971 for validation and 0.9968 for testing in the coated alloy. The feature importance analysis identified coating hardness as the most significant parameter influencing COF and wear resistance, followed by matrix hardness near the coating, underscoring the decisive role of the chromium layer in enhancing the alloy’s tribological performance.

This investigation demonstrates that chromium coatings significantly enhance the mechanical strength, wear resistance, and durability of SnSb11Cu6 alloys, thereby increasing their suitability for high-stress applications. By integrating an advanced deep learning model specifically designed to predict wear properties, this work provides a comprehensive framework for optimizing coating parameters and gaining deeper insights into the complex tribological behavior of coated babbitt materials. It is important to note that this study was limited to dry sliding conditions. The coating’s performance under varying unit pressures or extended test durations will be considered in future research to further evaluate its long-term durability and performance.

Author Contributions

Conceptualization, M.K. and V.P. (Vladimir Petkov); methodology, M.K., V.P.(Vladimir Petkov), V.P. (Veselin Petkov), R.D., S.U. and B.K; software, M.K., V.P.(Vladimir Petkov), V.P. (Veselin Petkov), R.D. and S.U; validation, M.K, V.P.(Vladimir Petkov), V.P. (Veselin Petkov), R.D. and S.U; formal analysis, M.K and V.P. (Vladimir Petkov); in-vestigation, M.K, V.P.(Vladimir Petkov), V.P. (Veselin Petkov), R.D., S.U. and B.K.; resources, M.K. and V.P. (Vladimir Petkov); data curation, M.K, V.P. (Vladimir Petkov), R.D. and S.U.; writing—original draft preparation, M.K. and V.P. (Vladimir Petkov); writing—review and editing, M.K. and V.P. (Vladimir Petkov); visualization, M.K., V.P.(Vladimir Petkov), V.P. (Veselin Petkov), and R.D; supervision, M.K. and V.P. (Vladimir Petkov); project administration, M.K; funding acquisition, M.K. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Bulgarian National Science Fund, Project KΠ-06-H57/20 ‘Fabrication of new type of self-lubricating antifriction metal matrix composite materials with improved mechanical and tribological properties’.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The raw data supporting the conclusions of this article will be made available by the authors on request.

Acknowledgments

We acknowledge the support of the European Regional Development Fund within the OP Science and Education for Smart Growth 2014–2020, Project CoE, National Center of Mechatronics and Clean Technologies, BG05M2OP001-1.001-0008, in providing the necessary equipment for conducting the SEM and EDS analyses in this work.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Zhang, X.; Wu, S.; Liu, W.; Chu, X.; Xie, Y.; Zhang, F. High Performance Tin-Based Babbitt Coatings Deposited by High-Pressure Cold Spraying. Surf. Coat. Technol. 2023, 473, 130048. [Google Scholar] [CrossRef]

- Ramadan, M.; Alghamdi, A.S.; Subhani, T.; Halim, K.S.A. Fabrication and Characterization of Sn-Based Babbitt Alloy Nanocomposite Reinforced with Al2O3 Nanoparticles/Carbon Steel Bimetallic Material. Materials 2020, 13, 2759. [Google Scholar] [CrossRef] [PubMed]

- Luo, W.; Lin, D.; Xi, X.; Wang, Y.; Liu, Y.; Liu, D.; Chen, B.; Bian, H.; Song, Y.; Liu, F.; et al. High-Strength and Wear-Resistant Babbitt Alloy Coatings Prepared through in-Situ Alloying. Surf. Coat. Technol. 2024, 494, 131416. [Google Scholar] [CrossRef]

- Ribeiro, R.M.; Câmara, M.A. Estudo Do Comportamento Tribológico Do Par Liga Babbitt—Aço ABNT 1045 Quando Variadas a Espessura e a Rugosidade Do Revestimento. Matéria 2020, 25, e-12661. [Google Scholar] [CrossRef]

- Wang, J.; Xue, Y.; Zhang, Y.; Wang, S. Creep Mechanical Properties of Babbitt SnSb11Cu6. Xiyou Jinshu Cailiao Yu Gongcheng/Rare Met. Mater. Eng. 2015, 44, 1432–1438. [Google Scholar]

- Cheng, Z.; Wang, M.; Wang, B.; Zhang, L.; Zhu, T.; Li, N.; Zhou, J.; Jia, F. Effect of Co Addition on the Microstructure and Mechanical Properties of Sn-11Sb-6Cu Babbitt Alloy. Materials 2024, 17, 5494. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Z.; Konoplianchenko, I.; Tarelnyk, V.; Liu, G.; Du, X.; Yu, H. The Characterization of Soft Antifriction Coating on the Tin Bronze by Electro-Spark Alloying. Mater. Sci. 2022, 29, 40–47. [Google Scholar] [CrossRef]

- Chen, R.; Wei, Y.; Jia, Q.; Xu, J.; Zhang, F.; Yuan, X. Effect of Increasing Cu Content on Mechanical Properties of Tin-Based Babbitt. Rare Met. Mater. Eng. 2018, 47, 1854–1859. [Google Scholar]

- Kolev, M.; Drenchev, L.; Petkov, V. Wear Analysis of an Advanced Al–Al2O3 Composite Infiltrated with a Tin-Based Alloy. Metals 2021, 11, 1692. [Google Scholar] [CrossRef]

- Флегентoв, И.А.; Старшинoв, Д.М.; Михеев, Ю.Б.; Рябцев, Е.А. Improving reliability of main pumping unit by improving bearing units. Sci. Technol. Oil Oil Prod. Pipeline Transp. 2023, 12, 569–575. [Google Scholar] [CrossRef]

- Ren, X.R.X.; Chang, Y.C.Y.; Chen, S.C.S.; Chen, N.C.N.; Shi, Z.S.Z.; Zhang, Y.Z.Y.; Chen, H.C.H.; Guo, Z.G.Z.; Hu, J.H.J.; Zhang, G.Z.G.; et al. Effect of Rare Earth Y on the Microstructure, Mechanical Properties and Friction of Sn-Babbitt Alloy. Coatings 2024, 14, 1325. [Google Scholar] [CrossRef]

- Ganiev, I.N.; Khodjanazarov, K.M.; Khodzhaev, F.K.; Ashov, B.B. Temperature Dependence of the Heat Capacity and Changes in the Thermodynamic Functions of BLi (PbSb15Sn10Li) Lead Babbitt Doped with Lithium. Metallurgist 2023, 67, 240–248. [Google Scholar] [CrossRef]

- Dong, Q.; Yin, Z.; Li, H.; Zhang, X.; Jiang, D.; Zhong, N. Effects of Ag Micro-Addition on Structure and Mechanical Properties of Sn-11Sb-6Cu Babbitt. Mater. Sci. Eng. A Struct. Mater. 2018, 722, 225–230. [Google Scholar] [CrossRef]

- Abioye, T.E.; Zuhailawati, H.; Azlan, M.A.I.; Anasyida, A.S. Effects of SiC Additions on the Microstructure, Compressive Strength and Wear Resistance of Sn-Sb-Cu Bearing Alloy Formed via Powder Metallurgy. J. Mater. Res. Technol. 2020, 9, 13196–13205. [Google Scholar] [CrossRef]

- Amanov, A.; Ahn, B.; Lee, M.G.; Jeon, Y.; Pyun, Y.-S. Friction and Wear Reduction of Eccentric Journal Bearing Made of Sn-Based Babbitt for Ore Cone Crusher. Materials 2016, 9, 950. [Google Scholar] [CrossRef]

- Nascimento, A.R.C.; Ettouil, F.B.; Moreau, C.; Savoie, S.; Schulz, R. Production of Babbitt Coatings by High Velocity Oxygen Fuel (HVOF) Spraying. J. Therm. Spray Technol. 2017, 26, 1732–1740. [Google Scholar] [CrossRef]

- Deng, D.; Wang, J.; Meng, F.; Wan, H.; Sun, Q.; Zhang, Y. Laser Remelting Effect on Casting and CMT Surfacing Babbitt Metal Microstructure. Laser Optoelectron. Prog. 2023, 60, 1514010. [Google Scholar] [CrossRef]

- Valeeva, A.K.; Valeev, I.S. Investigation of SnSbCu Coatings, Electrodeposited on Bronze and Copper. Lett. Mater. 2016, 6, 122–125. [Google Scholar] [CrossRef][Green Version]

- Sous, C.; Jacobs, G.; Lutz, T. Characterisation of Elastic-Plastic Material Characteristics of Sn Solid Solution, SbSn and Cu6Sn5 in the Tin-Based Sliding Bearing Alloy SnSb12Cu6ZnAg. Mater. Sci. Eng. A Struct. Mater. 2018, 724, 566–575. [Google Scholar] [CrossRef]

- Etesami, S.A.; Baskes, M.I.; Laradji, M.; Asadi, E. Thermodynamics of Solid Sn and Pb Sn Liquid Mixtures Using Molecular Dynamics Simulations. Acta Mater. 2018, 161, 320–330. [Google Scholar] [CrossRef]

- Vafaeenezhad, H.; Aliakbari-Sani, S.; Seyedein, S.H.; Aboutalebi, M.R.; Eivani, A.R. Dislocation Density and Twinning-Related Constitutive Modeling of Substructural Evolution in Sn-5Sb-0.5(Ag/Cu) Alloys under Monotonic Deformation. J. Alloys Compd. 2023, 938, 168516. [Google Scholar] [CrossRef]

- Yang, C.-H.; Liu, Y.-C.; Hirata, Y.; Nishikawa, H.; Lin, S.-K. High-Strength Sn–Bi-Based Low-Temperature Solders with High Toughness Designed via High-Throughput Thermodynamic Modelling1. Sci. Technol. Weld. Join. 2022, 27, 572–578. [Google Scholar] [CrossRef]

- Zhu, C.; Jin, L.; Li, W.; Han, S.; Yan, J. The Prediction of Wear Depth Based on Machine Learning Algorithms. Lubricants 2024, 12, 34. [Google Scholar] [CrossRef]

- Aydin, F.; Durgut, R.; Mustu, M.; Demir, B. Prediction of Wear Performance of ZK60/CeO2 Composites Using Machine Learning Models. Tribol. Int. 2023, 177, 107945. [Google Scholar] [CrossRef]

- Rahman, M.H.; Shahriar, S.; Menezes, P.L. Recent Progress of Machine Learning Algorithms for the Oil and Lubricant Industry. Lubricants 2023, 11, 289. [Google Scholar] [CrossRef]

- Xie, X.; Huang, M.; Sun, W.; Li, Y.; Liu, Y. Intelligent Tool Wear Monitoring Method Using a Convolutional Neural Network and an Informer. Lubricants 2023, 11, 389. [Google Scholar] [CrossRef]

- Wang, K.; Wang, A.; Wu, L.; Xie, G. Machine Tool Wear Prediction Technology Based on Multi-Sensor Information Fusion. Sensors 2024, 24, 2652. [Google Scholar] [CrossRef]

- Hulipalled, P.; Lokesha, V. Optimized Machine Learning Algorithms to Predict Wear Behavior of Tribo-Informatics. Res. Sq. 2022, preprint. [Google Scholar]

- Si, S.; Mu, D.; Si, Z. Intelligent Tool Wear Prediction Based on Deep Learning PSD-CVT Model. Sci. Rep. 2024, 14, 20754. [Google Scholar] [CrossRef]

- Gidikova, N.; Sulowski, M.; Madej, M.; Valov, R.; Petkov, V. Mechanical Properties of Composite Coatings of Chromium and Nanodiamonds on Aluminum. MATEC Web Conf. 2018, 145, 05012. [Google Scholar] [CrossRef]

- Zhang, Q.; Wang, J.; Shen, W.; Huang, F.; Zhao, Y. Failure Analysis of Chromium Plating Layer on the Surface of the Piston Rod of the Hydraulic Jack. Coatings 2022, 12, 774. [Google Scholar] [CrossRef]

- Imam Khan, K.; Minhas, B.; Tauqir, A.; Malik, R.A.; Baluch, A.H.; Alrobei, H.; Al Baijan, I.; Atiq ur Rehman, M. Wear and Corrosion Properties of Laser Treated Cr2O3 on Stainless Steel. Mater. Lett. 2024, 368, 136679. [Google Scholar] [CrossRef]

- Bolelli, G.; Steduto, D.; Kiilakoski, J.; Varis, T.; Lusvarghi, L.; Vuoristo, P. Tribological Properties of Plasma Sprayed Cr2O3, Cr2O3–TiO2, Cr2O3–Al2O3 and Cr2O3–ZrO2 Coatings. Wear 2021, 480–481, 203931. [Google Scholar] [CrossRef]

- Rhaiem, S.; Nasri, F.; Kharrat, M.; Dammak, M. Characterization of the Tribological Behavior of Chromium and Zinc Coatings Electrodeposited on the Steel Substrate. Mater. Sci. 2014, 50, 135–140. [Google Scholar] [CrossRef][Green Version]

- Nuñez Celis, H.; Rincón Ortiz, M.; González Hern’ández, A. Corrosion Behavior of Flame Sprayed Cr2O3 Coatings on Carbon Steel in Chloride Solutions. Rev. Ing. Univ. Medellín 2022, 21, 143–162. [Google Scholar] [CrossRef]

- Brili, N.; Ficko, M.; Klančnik, S. Automatic Identification of Tool Wear Based on Thermography and a Convolutional Neural Network during the Turning Process. Sensors 2021, 21, 1917. [Google Scholar] [CrossRef]

- Gidikova, N.; Valov, R.; Petkov, V.; Sułowski, M.; Witkowska, M.; Cempura, G. Nanocomposite Chromium Coatings on Aluminum Alloys. Pr. Inst. Odlew. 2017, 57, 241–244. [Google Scholar] [CrossRef]

- DeMille, K.J.; Hall, R.; Leigh, J.R.; Guven, I.; Spear, A.D. Materials Design Using Genetic Algorithms Informed by Convolutional Neural Networks: Application to Carbon Nanotube Bundles. Compos. B Eng. 2024, 286, 111751. [Google Scholar] [CrossRef]

- Yin, B.; Huang, J.; Sun, W. Peridynamics-Fueled Convolutional Neural Network for Predicting Mechanical Constitutive Behaviors of Fiber Reinforced Composites. Comput. Methods Appl. Mech. Eng. 2024, 431, 117309. [Google Scholar] [CrossRef]

- Hasan, M.S.; Kordijazi, A.; Rohatgi, P.K.; Nosonovsky, M. Triboinformatic Modeling of Dry Friction and Wear of Aluminum Base Alloys Using Machine Learning Algorithms. Tribol. Int. 2021, 161, 107065. [Google Scholar] [CrossRef]

- Zeng, Z.; Wang, L.; Chen, L.; Zhang, J. The Correlation between the Hardness and Tribological Behaviour of Electroplated Chromium Coatings Sliding against Ceramic and Steel Counterparts. Surf. Coat. Technol. 2006, 201, 2282–2288. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).