1. Introduction

The engine friction reduction through low viscosity lubricants, viscous modifiers (VM), anti-wear (AW), and friction modifier (FM) additives is a significant way to improve fuel efficiency of the vehicles equipped with internal combustion engines (ICE), both in a conventional and hybrid topology.

Friction losses are a significant share on car fuel consumption. On urban conditions, ICE friction losses are around 10% of fuel energy. As the losses occur after combustion, they represent as much as 25% of fuel consumption and CO

2 emissions [

1,

2]. The ICE friction losses are composed of different tribological systems in which the lubrication regime: boundary, mixed or hydrodynamic, depends on lubricant film thickness and combined surface roughness ratio. Lower lubricant viscosity reduces hydrodynamic but increases boundary and, in lower magnitude, mixed regime friction of moving surfaces [

2,

3,

4,

5,

6]. The higher engine friction with low viscosity lubricant in boundary and mixed regimes can be reduced by FM additives. Taylor et al. [

3] investigated the effect of two 0W12 oils, with and without FM, in comparison to a baseline 15W40 in motored test, see

Figure 1. Due to the lower viscosity, the 0W12 without FM (

Figure 1a) caused more boundary friction than 15W40, represented by an increase on the engine friction mean effective pressure (FMEP) in lower engine speeds, values in red in

Figure 1. The use of a FM in the 0W12 oil practically annulated the lower viscosity disadvantage below 1000 rpm (

Figure 1b).

Devlin [

7] points vehicle mileage and test procedure as significant variables that difficulties to measure the improvement of low viscosity lubricants in fuel economy. In addition, the lubricant impact on fuel economy cannot be defined simply by lubricant viscosity but by FM and AW additives that, respectively, improve lubricant behavior in boundary and mixed lubrication regimes and influences on friction coefficient in low film thickness.

De Carvalho et al. [

8] measured the lubricant viscosity impact in a dyno bench with the efficiency of a single-cylinder diesel engine. The 0W20 lubricant resulted in about 0.8% improvement in engine brake specific fuel consumption (BSFC) compared to a 5W40 lubricant in three steady speed and load conditions.

According to Cui et al. [

9] vehicle fuel economy improvement is closely related to engine oil viscosity and FM. They investigated the impact of drive cycle, vehicle type and VM chemistry on vehicle fuel economy in three different standard drive cycles [

10]. The proposed 0W20 lubricant reduced fuel consumption in about 2.6 and 2.7% on NEDC and on FTP75, respectively, compared to a 15W40 baseline lubricant. Three different spark ignition (SI) vehicles were compared in NEDC resulting in 1.6 to 3.2% better fuel economy with the proposed lubricant with about 1% variation between vehicles with the same naturally aspirated engine displacement. The better results were observed in a vehicle equipped with a 1.4 L turbocharged engine.

Macián et al. [

11] simulated a NEDC [

10] in a dyno bench with a light-duty diesel engine and observed 1.7% enhancement in engine efficiency with a 5W20 lubricant compared to a baseline 5W30. The lubricant low viscosity advantage was more pronounced in urban conditions, with lower engine load and speed, reaching 2.7% better fuel economy while 0.5% in extra urban use.

Tormos et al. [

12] studied the fuel economy impact of lubricant specs: viscosity, FM and sulphated ash, phosphorus and sulfur (SAPS) content that is important for diesel (DPF) or gasoline (GPF) particulate filter compatibility. The lubricant impact in fuel economy was estimated for a medium-duty diesel engine in steady-state conditions and simulated real drive emissions (RDE), two urban and one rural, in a dyno bench. The 5W20 resulted in up to 5.3%, and kept around 4% at low loads, lower fuel consumption compared to a baseline 10W30, both lubricants without FM. RDE enhanced the fuel economy improvement up to 8.84% in urban use and to 5.19% in rural route. Other 5W30 lubricants with molybdenum-based FM and different SAPS content resulted in opposite and unexpected results.

Blanco-Rodríguez et al. [

13] proposed a mathematical model to estimate the impact of lubricant viscosity on fuel economy of a passenger car. A semi-predictive model based on lubricant experimental characterization: viscosity, shear rate and heat transfer, was implemented on GT-SUITE platform. The replacement of a 5W40 by a 0W20 lubricant was simulated for a spark ignition sport-utility vehicle (SUV), important to notice quite like the vehicle analyzed and tested in this article. The simulations resulted 3.5% fuel savings in WLTC [

10] and confirmed the more pronounced advantage of low viscosity lubricant in urban conditions.

The clear low viscosity lubricant frictional losses reduction in the hydrodynamic regime must be balanced with the concern of its potential higher engine wear in mixed and boundary lubrication regimes affected by asperity friction, as pointed by Blanco-Rodríguez et al. [

13], Cui et al. [

9], Zhang et al. [

14], Lee and Zhmud [

15] and Barnhill et al. [

16].

Zhang et al. [

14] performed simulation based on input data from six-cylinder diesel engine dynamometer bench test, e.g., measured cylinder pressure, to conclude the replacement of a baseline 15W40 oil by a low viscosity 0W20 could reduce 24% the hydrodynamic friction losses at 2150 rpm, and higher engine speeds are benefited by hydrodynamic phenomenon. The asperity friction increases with low viscosity lubricant in lower engine speeds which could lead to heavy wear, risk of engine failure, and fully neutralize the low viscosity hydrodynamic advantages.

According to Lee and Zhmud [

15] the ultralow viscosity lubricants stress the engine beyond the limits considered in the engineering design, leading to wear problems, more pronounced in low engine speeds and high engine loads. Engine friction losses, from lubricant viscous and frictional losses due to boundary contact, can be reduced with low viscosity oils, FM and anti-friction coatings on critical parts. The 0W16 with FM and 1000 ppm Mo significantly reduces engine friction at low engine speeds, below 2000 rpm. Experimental tests on ASTM dynamometer procedures, which correlate with in-vehicle tests, indicated up to 3.8% better fuel economy with 5W20 in VIE procedure [

17], and up to 4.1% with 0W16 in VIF procedure [

18] compared to a 20W30 baseline mineral oil. Vehicle tests can result in average 3 to 4% better fuel economy with 0W20 instead of 15W40 in NEDC. The more aggressive WLTC results reduce the advantages in NEDC in about 0.3 to 0.6% but the less aggressive cycle JC08 [

10] can improve the low viscosity advantage to 5%. The NEDC results are improved in 2 to 3% more fuel economy with 0W8 lubricant viscosity index.

The challenge of low-viscosity lubricants for engine wear protection were investigated by Barnhill et al. [

16] in terms of anti-wear additives (AW) that allow the low viscosity benefits while remaining engine durability. The combination of an oil-miscible phosphorous-organophosphate ionic liquid (IL) and zinc diakyl dithiophosphate (ZDDP) provided effective wear protection through boundary lubrication of ball-on-flat reciprocation wear tests, and 2.12% improvement in fuel economy in VIE test, ASTM dynamometer procedure [

17] that correlated with in-vehicle results.

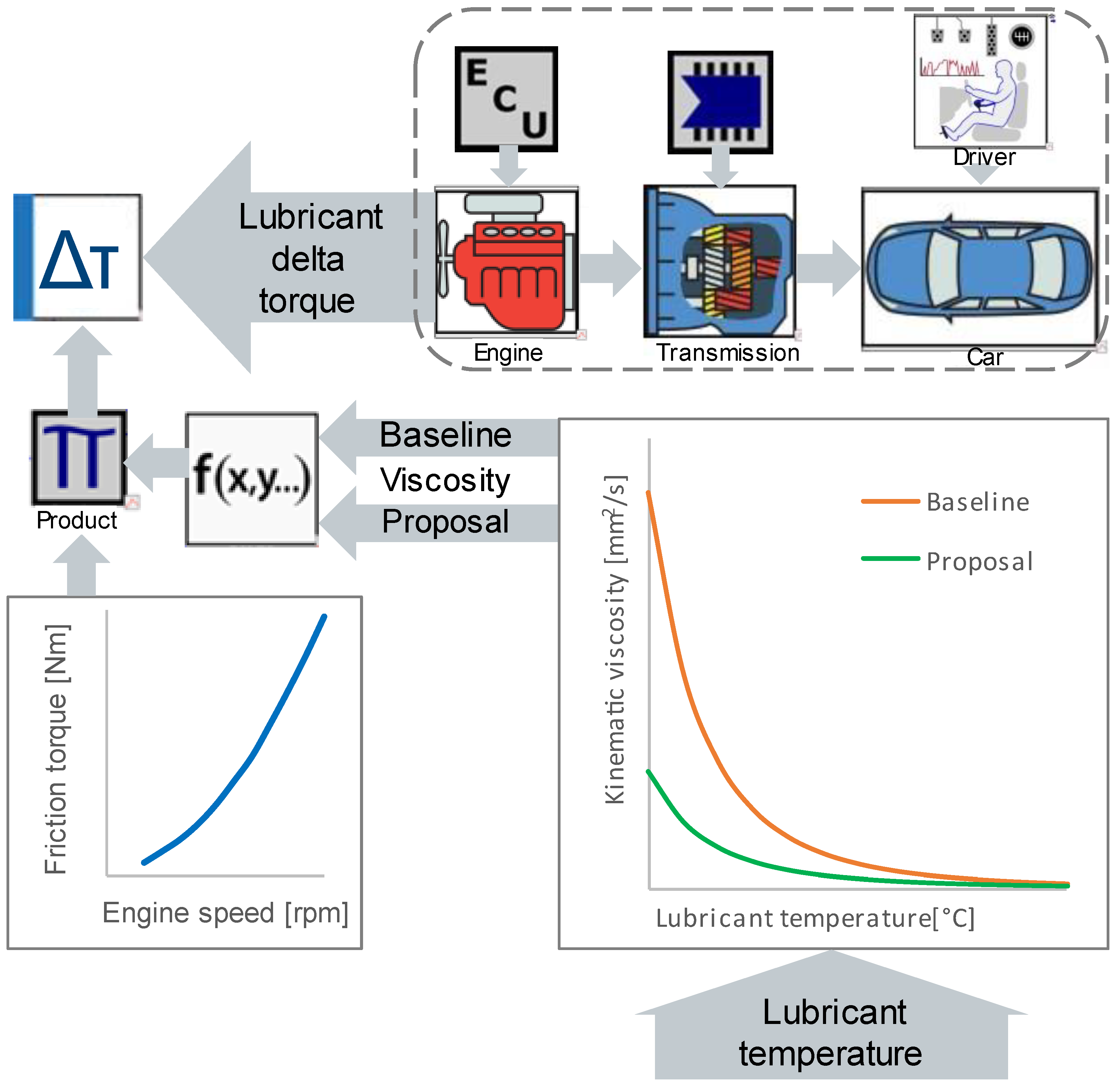

The experimental challenge to measure and confirm the effective lubricant impact on vehicle’s fuel economy can be made plausible by comparing the experimental with vehicle numerical simulation results.

The lubricant’s impact on engine friction can be mathematically estimated by a viscosity ratio powered by an engine specific index that accounts for the lubricant viscosity influence on the lubrication regime of each engine tribological system (Equation (1), in

Section 2.3). This method was adopted by Shayler et al. [

19], Taylor [

20], Sandoval and Heywood [

21].

The lubricant higher viscosity in low temperatures, studied by Seeton [

22], and its influence on engine friction and consequently on higher fuel consumption during cold conditions, e.g., cold start and warm-up, were also investigated by Roberts, Brooks and Shipway [

23], Liu et al. [

24], Lim et al. [

25] and Rovai and Mady [

26]. Jehlik and Rask [

27] adjusted the engine efficiency map for engine cold conditions to be interpolated with the stabilized map through the vehicle test cycle.

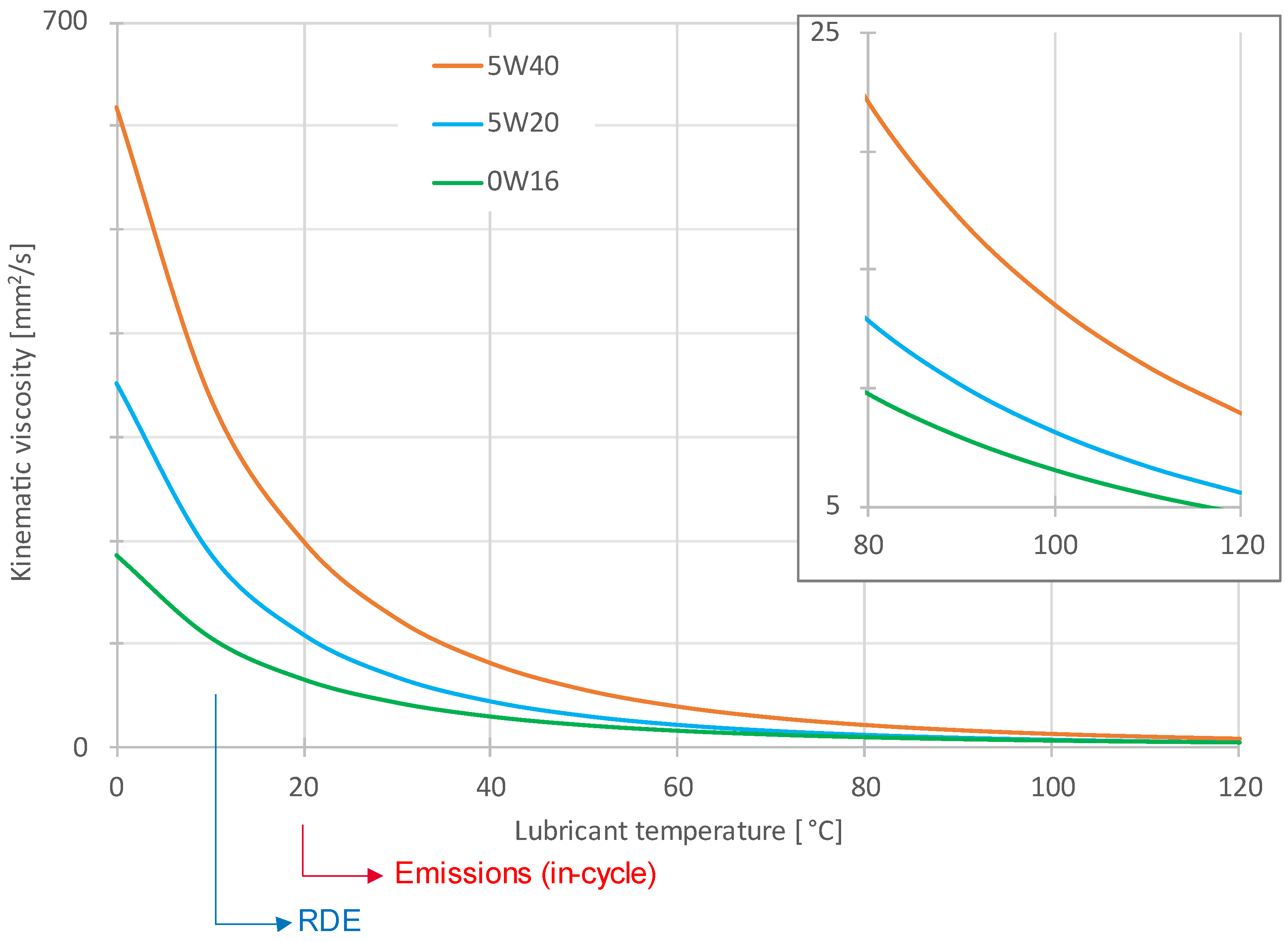

This study investigates the effect of a lower viscosity engine oil and FM additive on engine friction reduction and vehicle fuel economy. A baseline 5W40 was compared with two low viscosity engine oil proposals, 5W20 without FM and 0W16 with FM [

28]. The experimental in-cycle tests were performed on a chassis dyno in an OEM certified emissions laboratory. A numerical simulation model based on lubricant viscosity impact in engine friction was built and compared with experimental results.

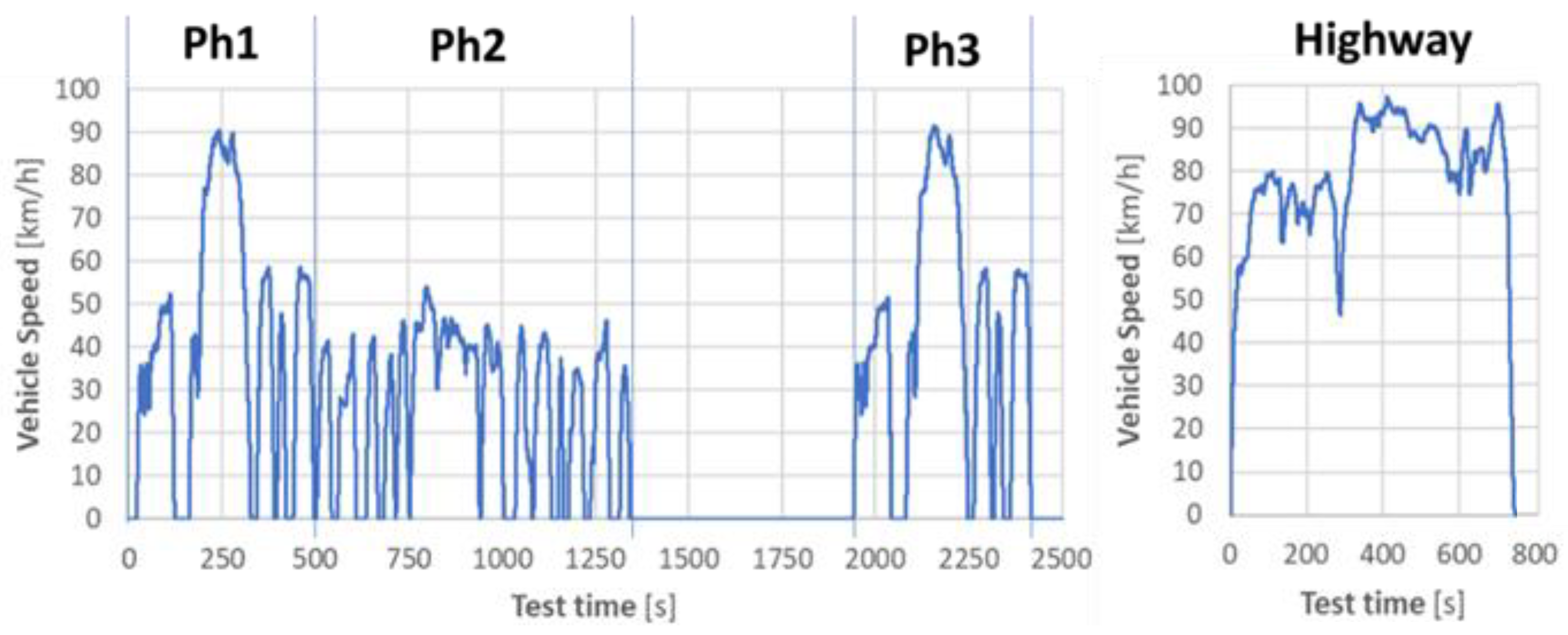

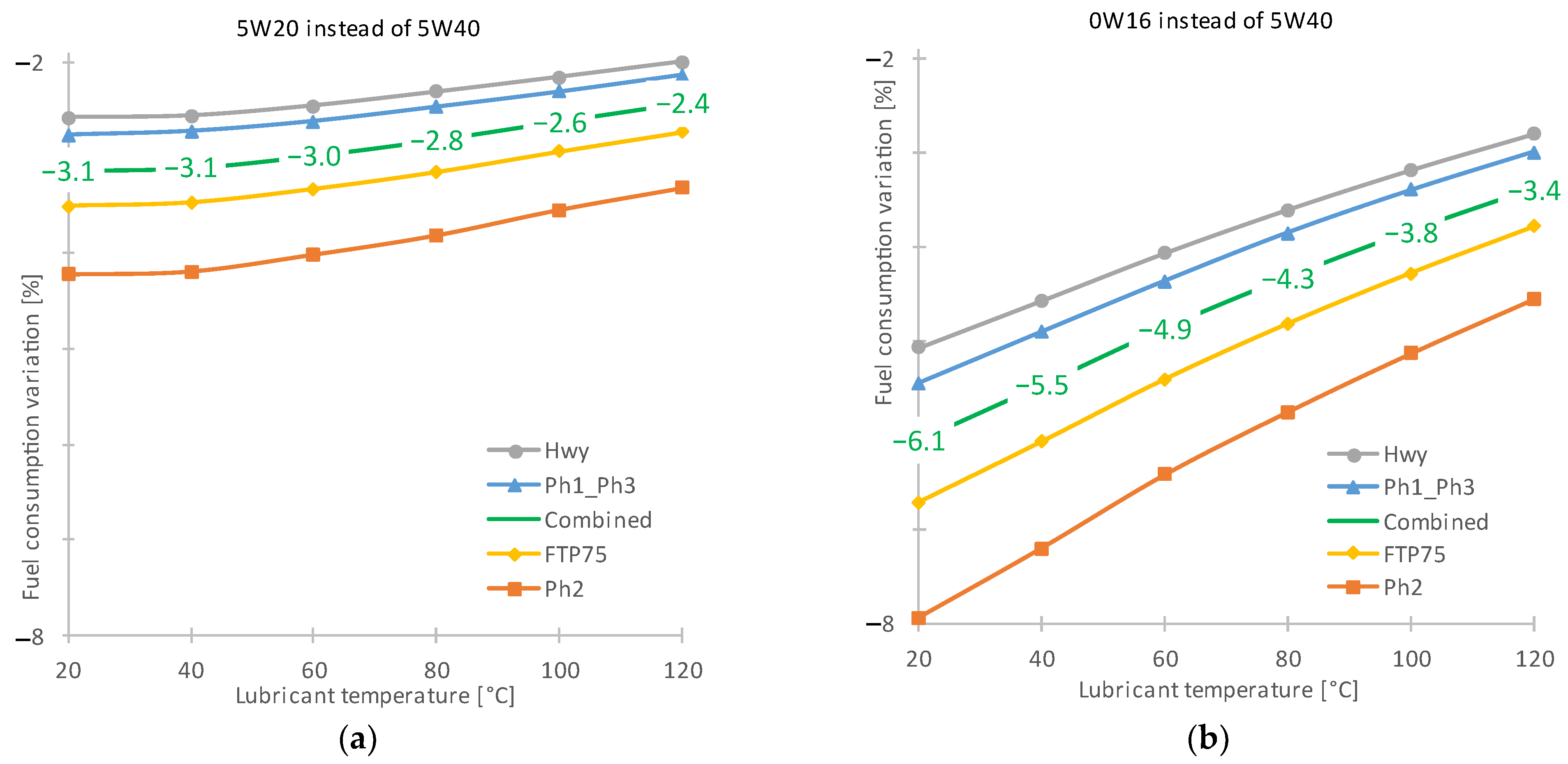

4. Discussion

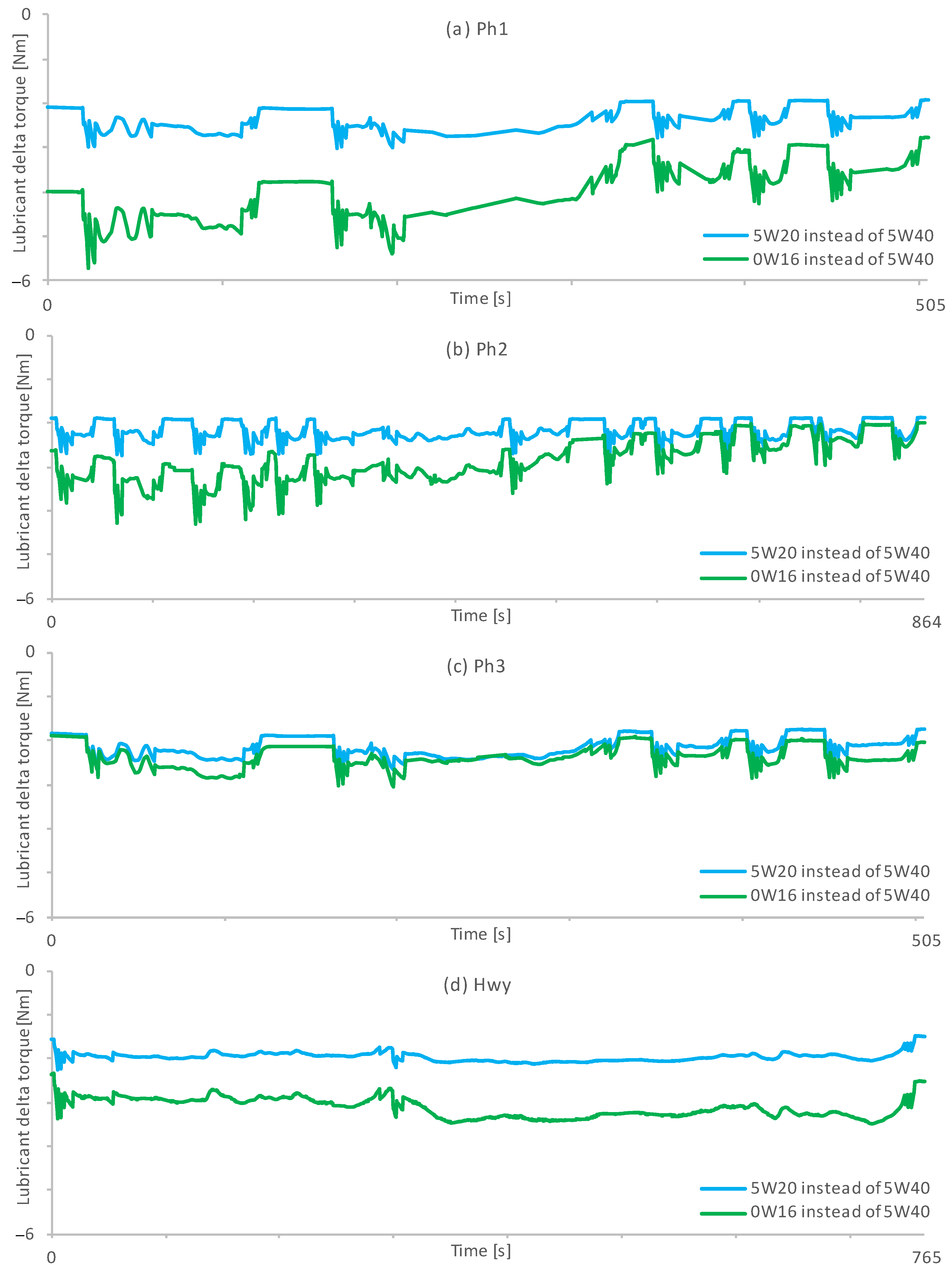

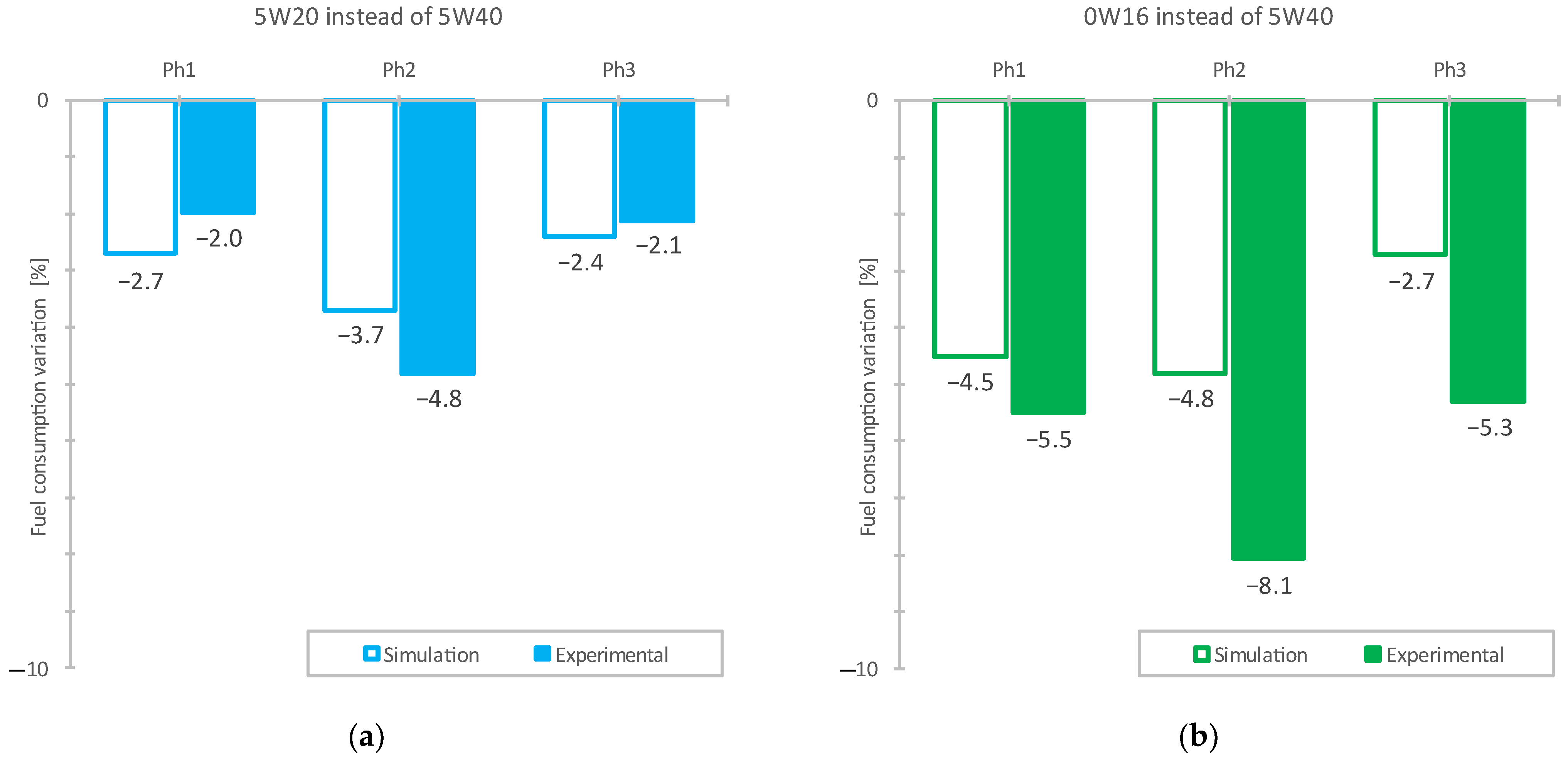

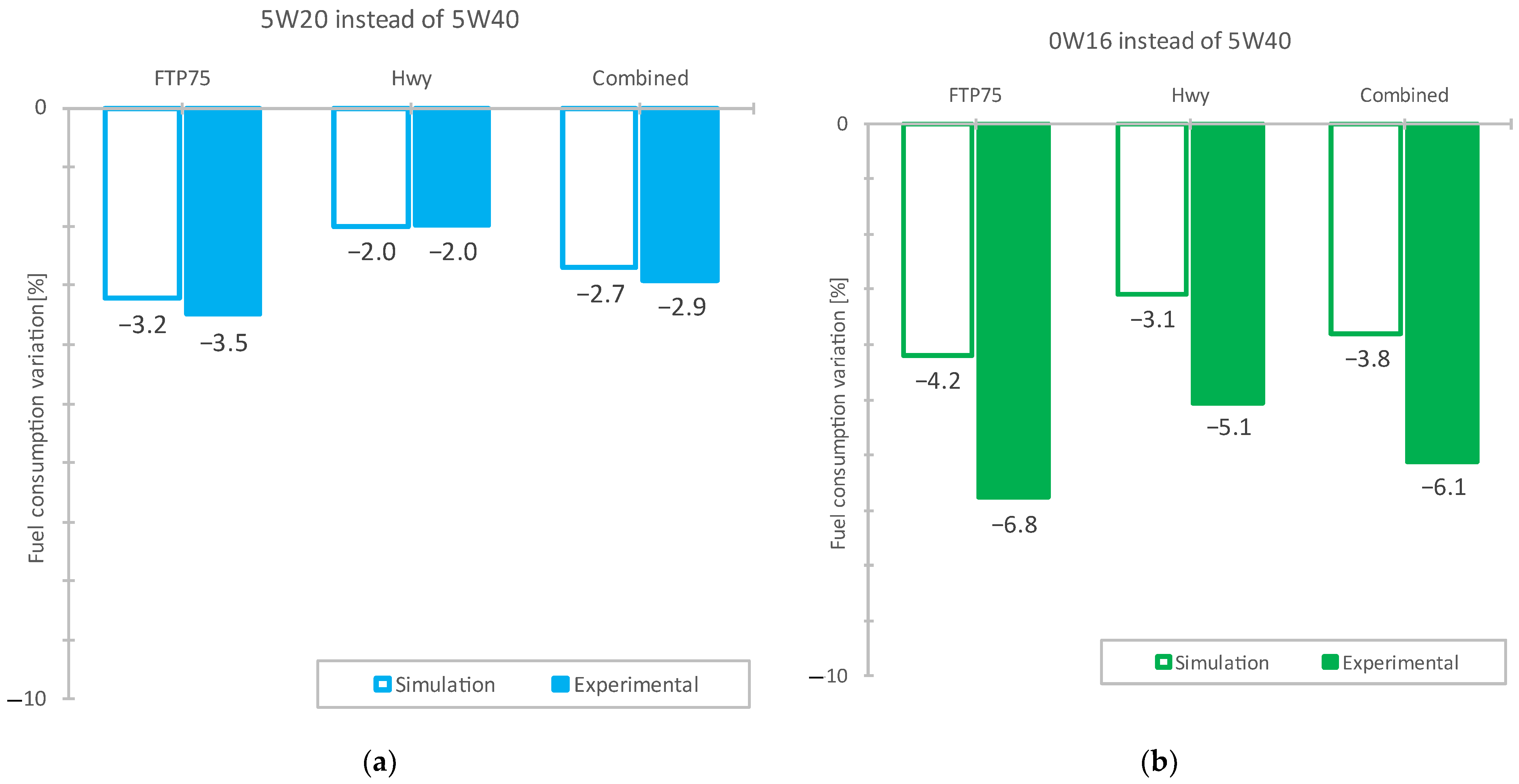

The fuel consumption variation with 5W20 or 0W16 lubricants instead of the baseline 5W40 expected by 1D numerical simulation (

Table 6) are plotted with experimental results (

Table 2) for the three FTP75 phases, Ph1, Ph2 and Ph3, in

Figure 8 and

Figure 9, showing the results for FTP75 (urban cycle), highway (road cycle) and combined [

31] cycle that comprises 55% of urban and 45% of road cycles.

In general, the results in

Figure 8 and

Figure 9 shows clear reduction tendency in fuel consumption with lower viscosity lubricants, expressed by negative fuel consumption variation values. The measured fuel savings, between 2.0 and 4.8% with 5W20, and between 5.1 and 8.1% with 0W16, are significant to be compared with other technologies, e.g., engine downsizing or low voltage electrification. In addition, engine friction reduction by low viscosity lubricants can be implemented in parallel with these technologies, potentializing its results.

The simulation results with 5W20 conservatively follows the experimental results, with the higher deviation observed in Ph2. Simulation results for 0W16 are significantly lower than the experimental keeping the same tendency of fuel consumption reduction in each phase, with Ph2 with higher deviations. The higher fuel economy in cold phase (Ph1) compared to hot phase (Ph3), numerically calculated from lubricant viscosity variation with temperature (

Figure 2), was experimentally confirmed.

The delta fuel consumption deviation between simulation and experimental results (DFC) when replacing the baseline lubricant (5W40) with the proposed low viscosity lubricants (5W20 or 0W16), plotted in

Figure 8 and

Figure 9, is calculated in absolute values (DFC

abs_dev) by Equation (4), and in percentual values (DFC

pct_dev) by Equation (5), in which DFC

sim is the simulated fuel consumption reduction and DFC

exp is the experimental result.

The results obtained by Equations (4) and (5) for phases 1, 2 and 3, FTP75, highway and combined cycles are shown in

Table 7, in which positive values mean the simulation is optimistic and resulted in higher fuel consumption reduction than the experimentally observed, and vice versa.

The absolute deviation results are the uncertainty to be expected in vehicle fuel economy, and the percentual deviation values are helpful to understand the simulation model consistency within test conditions.

Table 7 shows the simulation results are close to experimental validation for FTP75, highway and combined cycles, with less than 0.3% absolute deviation (DFC

abs_dev) and percentual deviation (DFC

pct_dev) below 8%. Closer simulation results for 5W20 demonstrates good correlation between the mathematical model, based on lubricant viscosity, and the experimental results. It is important to emphasize that both 5W40 (baseline) and 5W20 proposal do not have FM.

Simulation results for 0W16 with FM instead of 5W40 resulted in more pronounced deviations from experimental measurements. For FTP75, highway and combined cycles, the absolute deviation (DFC

abs_dev) was around 2%, and the percentual deviation (DFC

pct_dev) was about 38% lower for fuel economy than experimentally observed, concluding the simulation results are very conservative for 0W16. The lower fuel consumption reduction from simulations with 0W16 against 5W40 probably cover the impact of lubricant lower viscosity but do not account for FM additional improvements. The tested 0W16 has 900 ppm of Molybdenum, in

Table 1. The mathematical model improvement to consider FM is an important next step, which could be performed with a 0W16 sample without FM, not available in this study. Additionally, motoring FMEP and power index (i), from Equation (3), were experimentally determined only for 5W40 and should be investigated with low viscosity lubricant, desirable with and without FM.

Even conservative simulation results indicated at least 1% additional fuel saving with 0W16 compared to 5W20, except in Ph3, value that rises to about 3% based on experimental tests, see

Figure 8 and

Figure 9.

The NMOG measurements in

Table 3 do not indicate higher lubricant consumption with lower viscosity tested proposals. Even though the lubricant temperature profiles (

Figure 6) did not show lubricant temperature increase with low viscosity tested proposals, which could eventually be an indicative of poor lubricant efficiency and higher friction, the reliable engine durability should demand additional bench tests or a durability test in vehicle. Also, a concern should be applied to potentially higher low viscosity lubricants with a sensitivity to fuel dilution, observed by Taylor et al. [

3]. Lubricant dilution is a relevant condition for flex fuel vehicles, especially running on ethanol in cold conditions.

5. Conclusions

Two low viscosity lubricant proposals resulted in significant in-cycle fuel economy measured on a large sport-utility SI vehicle.

The inherent experimental uncertainties, most of the time close to the fuel consumption reduction expected from low viscosity lubricant, were reduced by well-controlled experimental variables. Besides experimental validation, a 1D mathematical model of the tested vehicle were built, based on lubricant temperature and viscosity, to simulate the delta engine friction with low viscosity lubricants and its impact on fuel economy. The simulated and experimental results were compared and considered plausible.

The use of a 5W20 lubricant instead of baseline 5W40 resulted in 2.9% fuel economy measured in combined cycle, while simulation predicted 2.7%. The 5W20 good correlation between experimental and simulation results points this methodology is appropriate to predict lubricant viscosity impact in fuel economy.

The replacement of the baseline 5W40 by a 0W16 lubricant with FM resulted in 6.1% fuel economy measured in combined cycle, with 3.8% fuel economy expected by simulation. The simulation with 0W16 considered only the lubricant viscosity impact but the FM additive in this lubricant can explain the considerably higher simulation deviation, which demand mathematical model improvement to be performed in the future.

Despite these in-cycle tests performed without abnormal engine noise or irregular engine running, a deep investigation is required, in all of the vehicle environmental boundary conditions, regarding engine wear and durability, especially with 0W16.