Abstract

The development of green lubrication requires nano-lubricants to possess more environmentally friendly fabrication modes and materials with superior tribological properties. This study investigates the tribological properties of nano-biochar in PAO6 base oil and in combination with different additives. The effect of adsorption on friction reduction and anti-wear performance is demonstrated by replacing the friction sub-materials in the four-ball friction test. Based on the comparison of wear region characterization, the incorporation of nano-biochar improves the friction reduction performance of detergent and dispersant base oils with a reduction in coefficient of friction (COF) by 16.7% and 19.0%, respectively, and produces a synergistic effect on the anti-wear performance. When nano-biochar is compounded with anti-wear agents and friction reducer, there is a synergistic effect on friction reduction performance, and COF decreases by 9.4% and 4.5% compared with anti-wear agents and friction reducer base oils, respectively. A method to analyze the friction reduction and anti-wear mechanism of nano-additives in complex lubrication system is proposed, which reveals in depth the interaction law and synergistic lubrication mechanism between NBC and additives in the friction process.

1. Introduction

Friction and wear are one of the main causative factors for failure of components such as engines, gears, and bearings [1]. Lubrication serves as an effective means of protecting the components. Commercial lubricants utilized in automotive and aerospace engines contain base oils and various additives, among which friction-reducing and anti-wear agents play an important role in improving lubrication performance [2]. In recent years, nanomaterials have demonstrated excellent tribological properties due to size effect [3]. Nanomaterials routinely incorporated into lubricants include metals [4,5,6,7], metal oxides [8,9], sulfides [10,11,12,13], carbon materials [14,15,16,17], etc. Conventional lubricant additives are doped with elements such as sulfur, phosphorus, and heavy metals. Despite possessing prominent tribological properties [18], the application of the related additives is harmful to the environment and organisms, making it difficult to meet the requirements of environmental protection [19].

With the development of green lubrication, biochar, relying on the advantages of low production cost, wide sources, tunable properties and green environmental friendliness, has gradually become an alternative to other carbon materials and has also been applied to the field of friction. Biochar is a carbonaceous material produced by pyrolysis or carbonization of organic biomass, such as agricultural residues, wood or crop wastes [20]. Further nanosizing biochar, i.e., less than 100 nm in one dimension, by physical ball milling for top-down fabrication of nanomaterials [21], could solve the problem of dispersion stability. Factors such as ball diameter, ball-to-biochar mass ratio, running speed, milling time and grinding aid affect the size of nano-biochar during ball milling [22]. As a renewable material, nano-biochar exhibits superior physicochemical properties with minor size, larger surface area, higher mobility, and more abundant surface oxygen-containing functional groups such as hydroxyl, aldehyde/ketone, and carboxyl groups [23]. Nano-biochar has been employed as an additive in various fields, including engine fuels, rubber, and coolants. Prabhu et al. [24] added 7.0 wt% of biochar to the resin, which resulted in a 41.6% enhancement in thermal conductivity, 44.4% reduction in COF, and 61.5% decrease in wear rate. Wang et al. [25] used sesame straw as raw materials for the preparation of nano-biochar, which was incorporated into PAO6. Four-ball tribological tests were conducted using steel and ceramic balls as friction pairs, and XPS was applied to analyze the wear surface. The results showed that the maximum wear volume of the lubricant containing 0.2 wt% nano-biochar was reduced by 46% and the coefficient of friction of the ceramic ball was reduced by 34.6% compared to PAO6. Xiao et al. [26] prepared biochar from bovine bone meal and reduced micron-sized lump biochar to below 220 nm by ball milling plus centrifugation. In addition, homogenization and ultrasonication were also applied to fabricate nano-biochar [27]. Gui et al. [28] found that the presence of oxygen-containing functional groups heightens the wettability of carbon materials on steel surfaces. Increased wettability corresponds to better friction and wear properties [29], which inferred that nano-biochar as an additive would improve the tribological properties of engine lubricants. Regarding the lubrication mechanism of nanomaterials to enhance the friction reduction and anti-wear performance of lubricants, it is mainly divided into two aspects. On the one hand, it comes from the lubrication mechanisms generated by nanomaterials themselves, such as ball bearing effect [30,31,32,33], interlayer shear [34,35,36], adsorption [37,38,39], and friction film formation [18,40]. On the other hand, nanomaterials improve tribological properties by enhancing friction surface effects, such as polishing and self-repair [41,42,43,44].

Modern commercial lubricants are complex chemical systems consisting of base oils and a variety of carefully screened additives, the combination of which produces diverse mutual reactions. Synergistic effect occurs when two additives perform better in combination than alone [45]. Conversely, it is called an antagonistic effect [46,47]. The major additives in commercial engine lubricants are categorized into the following four types. Dispersants are applied to disperse suspended solids and detergents inhibit high-temperature deposits. Anti-wear and extreme pressure additives form a chemical friction film on the friction surface, while friction modifiers generate a thinner oil film by adsorption to achieve engine friction reduction. Syed et al. [48] investigated the interaction of SiO2 nanoparticles with ZDDP during friction. At room temperature, COF fell by 60.0% and wear decreased by 70.0% compared to the base oil, suggesting that the introduction of nano-SiO2 into the lubricant can reduce the amount of ZDDP. Jia et al. [49] presented the synergistic effect of CeO2 nanoparticles and organic molybdenum friction-reducing additives in grease. The combination of CeO2 nanoparticles and organic molybdenum reduced the COF by 33.9% and increased the load carrying capacity of the grease from 900 N to 1400 N compared to the grease with only organic molybdenum.

The above research demonstrates that nano-biochar is provided with considerable application prospects in the field of lubrication, but the current exploration on liquid lubrication is still insufficient, and there is the problem of the ambiguous relationship between the complex chemical system of commercial lubricants and the role of nano-additives in the friction process. In order to develop green, efficient, and low-cost nano-lubricant additives, biochar, a renewable and environmentally friendly material, is selected in this study. The biochar is transformed into nano-biochar by freezing and ball milling, and dispersed into PAO6 base oil as an additive. The tribological properties of the nano-biochar lubricant are examined with a four-ball friction test. Meanwhile, the tribological performance and interaction mechanisms of different lubricant additives, such as detergents, dispersants, anti-wear agents, and friction reducers, when compounded with nano-biochar are further explored. The innovation is to propose a method to analyze the friction reduction and anti-wear mechanism of nano-additives in complex lubrication systems. Variable load condition experiments are designed and the effect of lubricant adsorption on the friction and wear performance is illustrated by replacing the ZrO2 friction sub-material. Combined with the elemental distribution comparison of EDS characterization on the wear surface, the in-depth lubrication mechanism of the lubricant compounded with nano-biochar and additives is specifically revealed, which lays the foundation for the analysis of lubrication mechanism and application of nano-biochar in the system of refined oil. It is of great significance to the development of environmental protection, agricultural waste recycling, green lubrication, and the achievement of the dual-carbon goal.

2. Experimental Section

2.1. Materials and Devices Employed

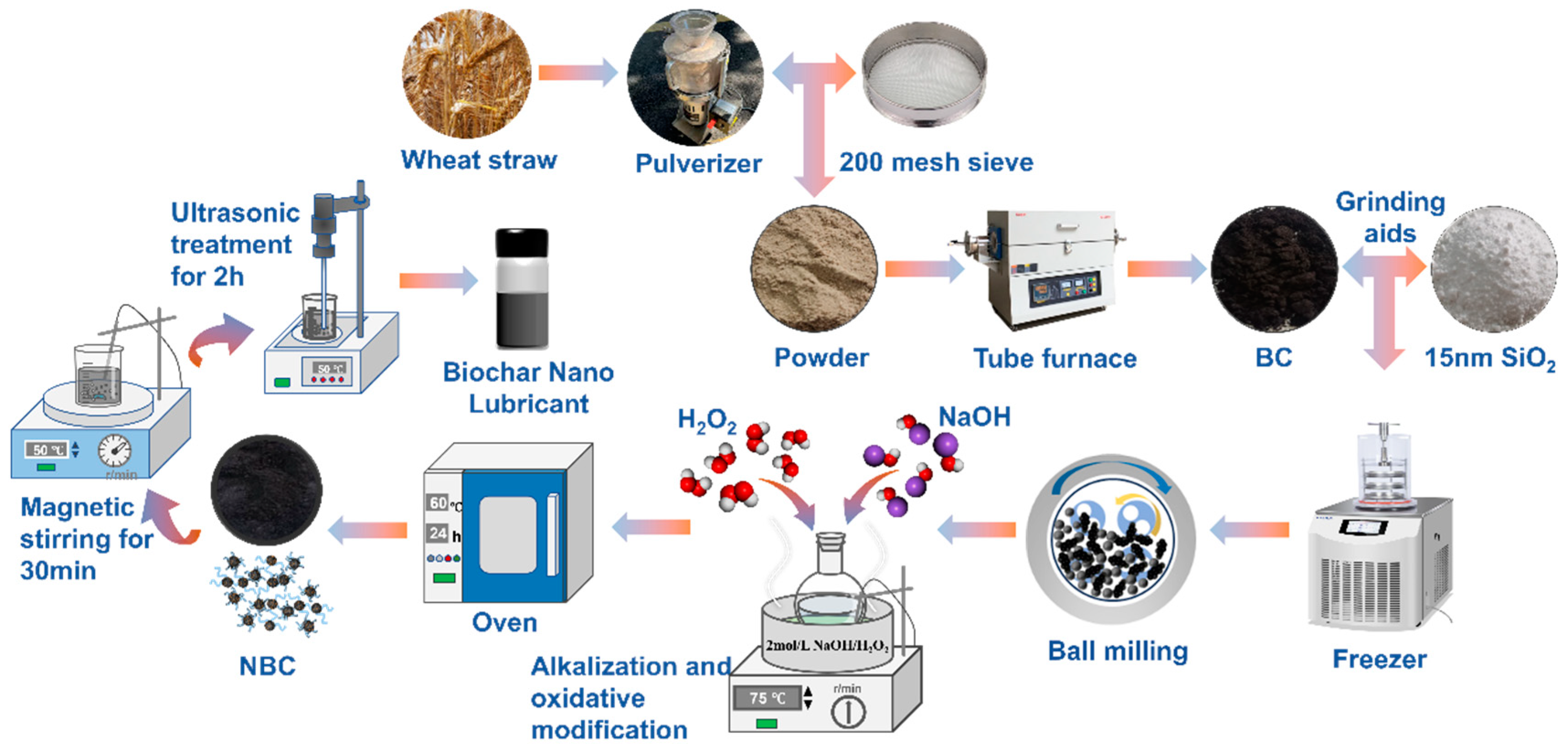

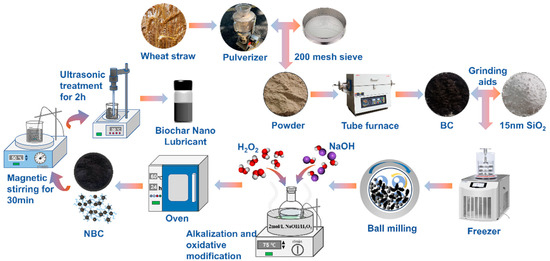

Wheat straw, a common agricultural waste in Hubei, was selected as the raw material for the fabrication of biochar in the experiment. The raw materials were cleaned and dried, then crushed into biomass powder by a powder mill, and the large biomass particles were separated by a 200-mesh sieve. The pyrolysis temperature of the obtained biomass powder was set at 500 °C, which was carried out in a tube furnace by passing argon gas. The product was virgin biochar, named biochar (BC). The prepared BC was frozen in a freeze-drying oven at −70 °C for 24 h. The purpose was to make the BC more brittle at low temperatures, which would be favorable for subsequent ball milling. The frozen BC and nano-SiO2 were put into a ball mill at a mass ratio of 1:2 for grinding. The ratio of onyx balls to mixed powders applied in the ball milling process was 10:1 and the rotational speed was 350 r/min. The ball milling process lasted for 4 h and was stopped at 5 min intervals for a few minutes to prevent BC agglomeration due to high temperature. After ball milling, the BC and SiO2 powder mixture was placed into 1 mol/L NaOH solution (200 mL) with continuous stirring at 80 °C for 1 h for alkalization modification process. The grinding aid nano-SiO2 was also eliminated during the alkalization process. Subsequently, the alkalization mixture solution was vacuum filtered, washed with deionized water and dried at a constant temperature to isolate the alkalized biochar powder. The alkalized biochar was added into 7 wt% H2O2 solution and kept stirring at 60 °C for 1 h for oxidative modification. The mixture was filtered and dried at 80 °C for 12 h to gain the final product, modified nano-biochar, which was recorded as Nano-Biochar (NBC). The fabrication process of NBC was demonstrated in Figure 1. For the characterization of the NBC, the surface morphology and particle size of the samples were analyzed by SEM, the three-dimensional structure was observed by AFM, and the surface functional groups and chemical composition were resolved by FTIR. Four additives commonly utilized in lubricants were chosen for four-ball friction test, including cleaner ultra-high alkali value magnesium sulfonate T107, dispersant T155, sulfur-phosphorus zinc salt T205 in the anti-wear agent ZDDP and friction improvement agent organic molybdenum dialkyl dithiocarbamate (Molybdenum Dithiocarbamate, MoDTC). Prior to the friction test, 1 wt% of the additive was weighed and added to the PAO6 base oil with magnetic stirring in a water bath at 60 °C for 20 min to ensure that the additive was homogeneously blended in the base oil, and the mass fraction of NBC added was 0.2%.

Figure 1.

Fabrication process of NBC and nano-lubricants.

The deionized water used in the experiments was produced by a water purifier, and its impedance was greater than 18.25 MΩ. Analytical-grade chemical reagents such as NaOH and H2O2 were obtained from Aladdin Biochemical Science and Technology Co., Ltd. in Shanghai, China, and nano-SiO2 was purchased from Xianfeng Nanomaterials Technology Co., Ltd. in Nanjing, China. The above four lubricant additives were provided by Jinzhou Kangtai Lubricant Additives Co., Ltd. in Jinzhou, China, and the PAO6 base oil was supplied by Shanghai Daopu Chemical Co., Ltd. in Shanghai, China. Information on the apparatus employed for the biochar preparation and friction tests is shown in Table 1.

Table 1.

The models and manufacturers of the experimental apparatus.

2.2. Tribological Tests

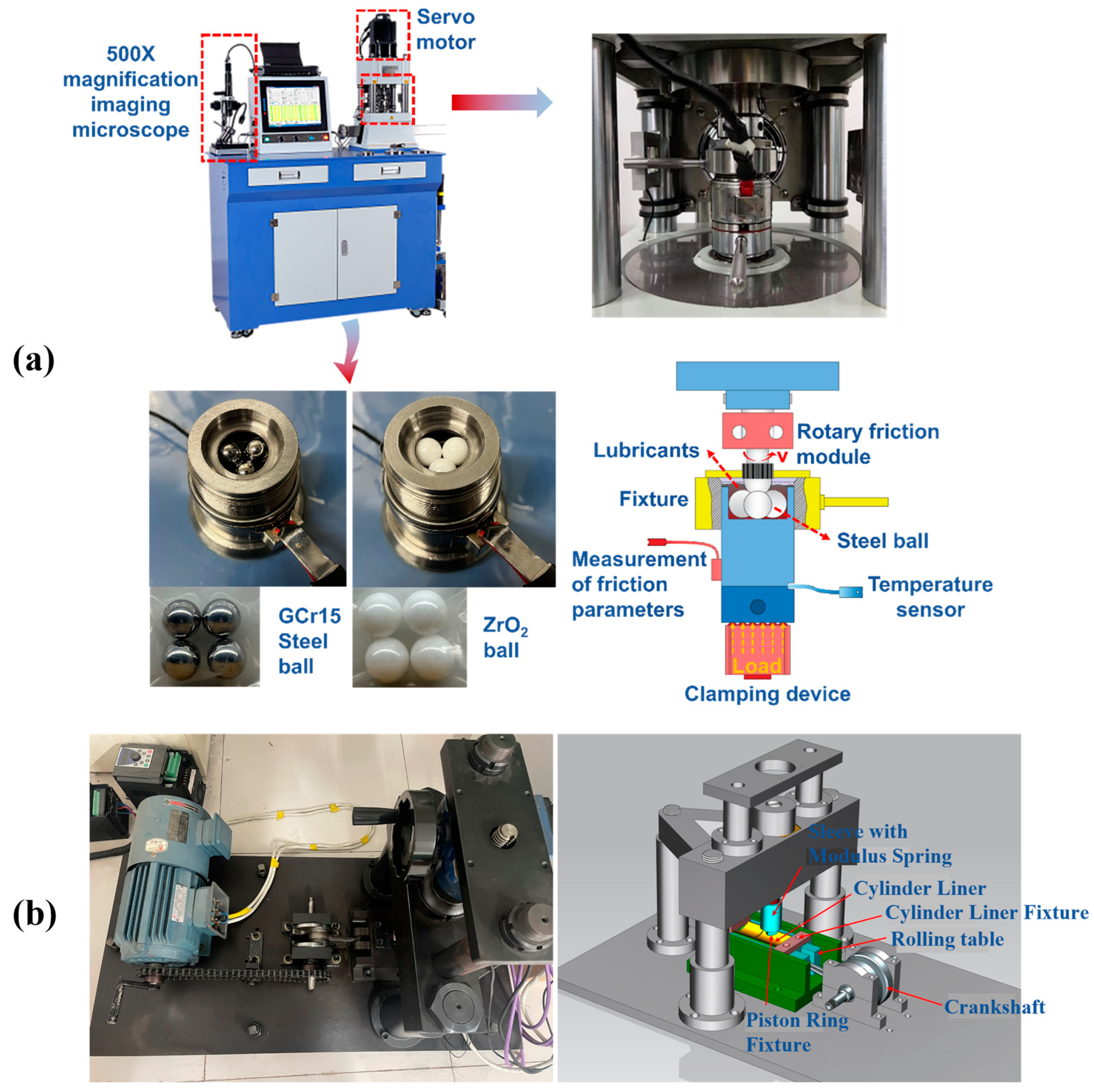

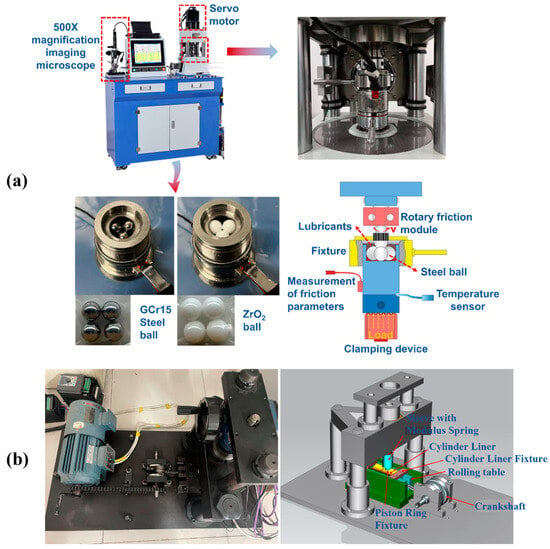

A four-ball friction test was utilized to investigate the effect of NBC complexed with different lubricant additives on the friction reduction and anti-wear properties of PAO6 base oil, as exhibited in Figure 2a. The centers of the four steel balls formed a positive tetrahedron. The upper ball was entirely fixed and rotated along the Z-axis driven by a servomotor. The three lower balls were anchored in the oil cup and were in contact with the upper ball under the gravitational load of the weights, creating an equilibrium of forces. The operating conditions were 1200 r/min, 98 N and 1200 r/min, 196 N. The duration of the test was 30 min. The lubricant temperature was kept at 75 °C and the relative humidity was not more than 80% during the test. The diameter of the GCr15 steel balls was 12.7 mm and the hardness was HRC 63.5. The friction reduction performance was evaluated by testing the COF of different lubricants through a four-ball friction machine, and the average value of COF was taken for each measurement. The WSD of the steel balls was measured with a 500× optical microscope to evaluate the anti-wear performance. Each test was repeated 5 times. The maximum and minimum values were removed, and the average value was calculated for the remaining 3 sets of data to make the final value. At the end of the four-ball friction test, the steel balls were ultrasonically cleaned with petroleum ether to remove oil stains, and EDS was applied to analyze the elemental distribution in the wear areas of the balls. In order to investigate the relationship between the adsorption effect and the tribological properties of lubricants, ceramic material ZrO2 balls were utilized in the four-ball friction experiments instead of GCr15 steel balls. ZrO2 was a stable chemical substance that did not react with the oxygenated groups in NBC by chemisorption. By replacing the friction sub-materials, the adsorption effect of NBC base oil was eliminated, so as to investigate the mechanism of friction reduction and anti-wear. The ZrO2 balls used in the test were 12.7 mm in diameter with a hardness of HRC70. Since the ZrO2 balls possessed stronger hardness but lower toughness than the steel balls, they are prone to oil film rupture at higher speeds and heavier loads. After several measurements, the final experimental conditions were set to 300 r/min and 98 N.

Figure 2.

(a) Schematic diagram of four-ball friction machine; (b) cylinder liner-piston ring reciprocating friction tester.

During the real engine operation, the loads on the cylinder liner-piston ring, cam-valve tappet and crankshaft-shaft tile friction groups were always in a variable state, while the loads were fixed in the conventional four-ball long-wear test. In order to analyze the tribological performance of different additives at variable loads, experiments under variable load conditions were designed. Similarly, the rotational speed was set to 1200 r/min, the lubricant temperature was kept at 75 °C and the relative humidity was maintained less than 80% during the test. The load was 98 N for the first 15 min and the WSD was recorded at 15 min of operation. The load was raised to 294 N by adding weights after 15 min and the WSD was logged at 16, 25, 35, and 45 min for different base oils. In order to more accurately simulate the kinematic properties between the piston ring and cylinder liner friction pair in a real engine, the results of the four-ball friction experimental study can be strengthened by the additional validation of the reciprocating tribometer test. In this study, a cylinder liner-piston ring reciprocating motion device is designed to evaluate the tribological properties of the lubricant, as shown in Figure 2b. During the reciprocating friction test, the piston ring is fixed on a specific fixture, and the movement of the piston ring on the Z-axis is controlled by a mold spring and sleeve device. When the piston ring is in contact with the cylinder sleeve, positive pressure is generated by the elastic deformation of the spring. At the same time, a worm gear reducer is applied to lock the position of the piston ring. The motor drags the crankshaft and drives the rolling table and the cylinder liner to carry out the motion, forming the reciprocating motion of the cylinder liner-piston ring. For data acquisition, a piezoelectric biaxial force sensor and charge amplifier are installed above the piston ring. The signals produced are transmitted to a PC-based host computer program through the data acquisition system to record the positive pressure and friction force between the friction pairs during the friction process in real time.

3. Results and Discussion

3.1. Characterization of Nano-Biochar

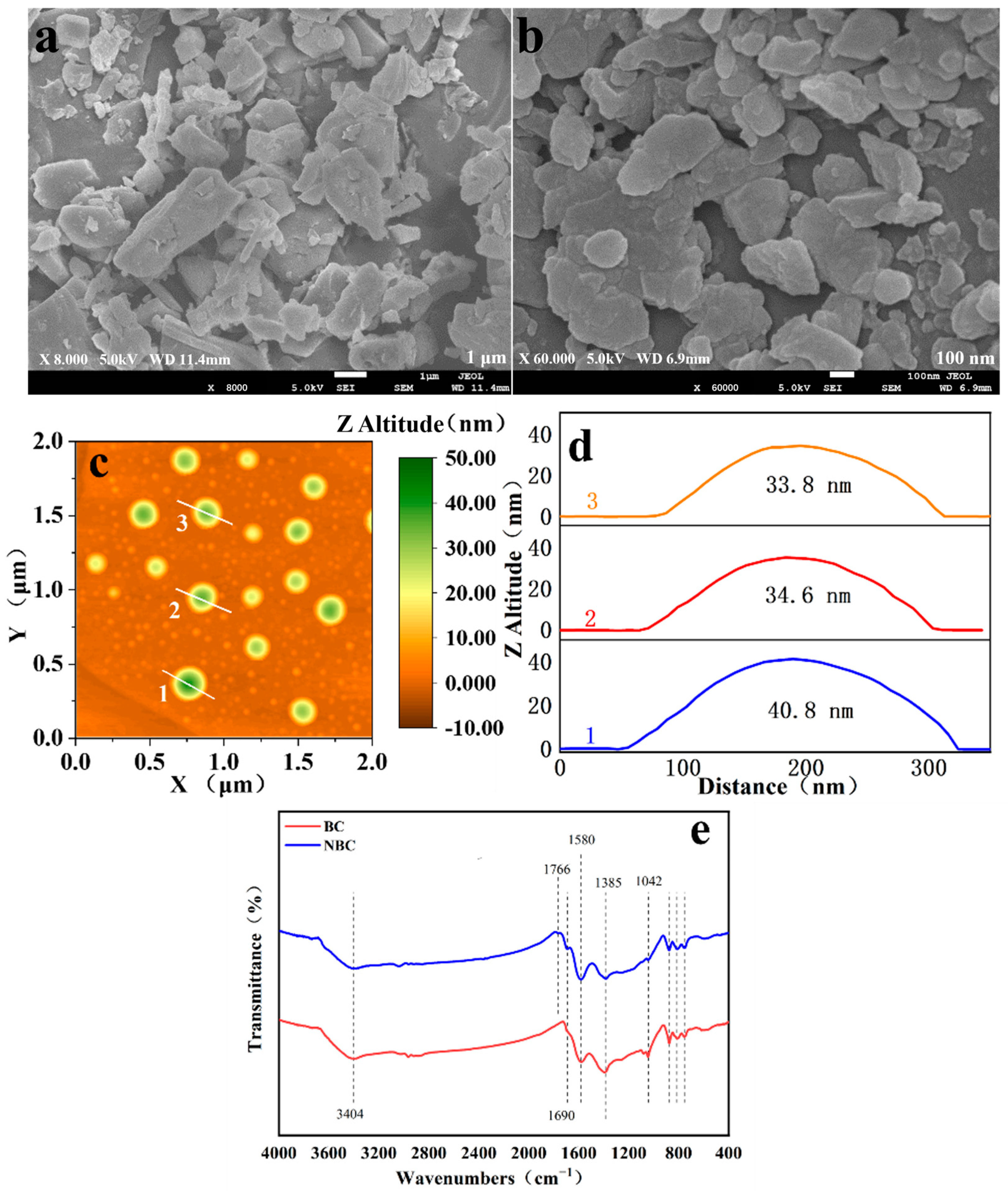

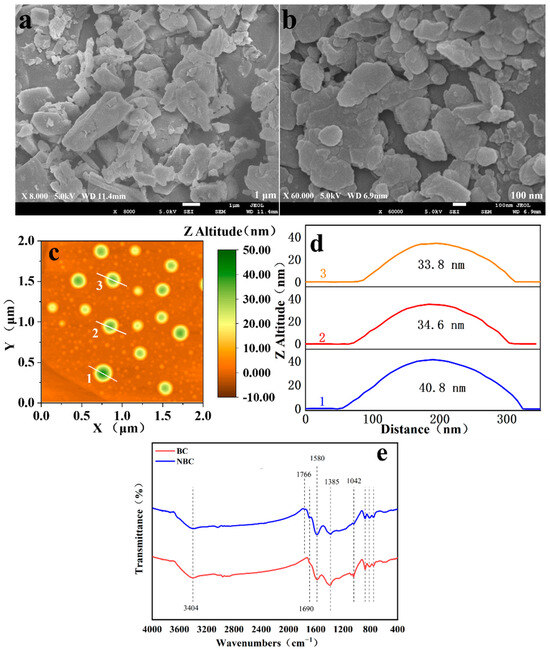

The SEM of BC and NBC is shown in Figure 3a,b. BC presents a lamellar structure and a rough surface, which mainly consists of large flakes interspersed with many small round particles. The particle size is in the micrometer level. After ball milling, most of the NBCs show elliptical lamellar structure with smoother edges, and their sizes ranged from 100 to 450 nm. The overall structure of BC becomes brittle after cryogenic treatment, which is favorable for destroying its structure by mechanical force during ball milling. The grinding aid of high hardness SiO2 nanoparticles facilitates the disruption of the BC structure and acts as a polishing agent, resulting in a smaller size and a smoother surface. This is consistent with the findings of Mitra et al. [50] that freezing plus ball milling treatment can effectively reduce the size of BC.

Figure 3.

SEM characterization of biochar: (a) BC; (b) NBC. AFM map of NBC: (c) contour map of NBC nanosheets; (d) height map along tangents; (e) FTIR characterization of biochar.

Only the surface morphology of the biochar samples is observed by SEM inspection, which could not demonstrate the three-dimensional characterization. AFM is applied to depict the 3D morphology of NBC. The contour map is shown in Figure 3c. The projection of NBC on the XY plane is circular, and its diameter is in the range of 200–300 nm. In the Z-axis direction, the thickness is less than 45 nm. Three larger particles are selected in the contour map and the cross section along the tangent direction is exhibited in Figure 3d. The maximum heights of the three NBC nanosheets in the Z-axis direction are 40.8 nm, 34.6 nm, and 33.8 nm, respectively, corresponding to diameters of 275 nm, 240 nm, and 235 nm in the XY plane. The ratio of diameter to height is approximately 7:1, confirming that the actual NBC possesses a lamellar structure. According to the connotation of nanomaterials, substances less than 100 nm in a certain spatial dimension are defined as nanomaterials. Combined with SEM and AFM analyses, the NBC presents a sheet-like nanostructure with a thickness of just a few tens of nanometers.

The compositions of the different samples are further resolved by FTIR detection, as shown in Figure 3e. For biochar, the peak near 3400 cm−1 corresponds to the OH stretching vibration, whereas the peak around 3000 cm−1 corresponds to the CHn stretching vibration. The peaks appearing at wave numbers 1766 cm−1 and 1690 cm−1 are associated with the stretching vibrations of the carboxyl group and C=O, respectively. The peak adjacent to 1580 cm−1 corresponds to the stretching vibration of C=C on the aromatic benzene ring [51]. In the fingerprint region, the peak at 1385 cm−1 corresponds to the CHn bending vibration, while 1042 cm−1 corresponds to the C-O stretching vibration. The peaks at 876 cm−1, 813 cm−1 and 753 cm−1 correspond to the CHn bending vibration outside the benzene ring [52]. Comparing the results of FTIR, it can be found that most of the peak positions of both BC and NBC biochars are the same, and the characteristic peak of 1110 cm−1 corresponding to the Si-O-Si stretching vibration does not appear, which indicates that SiO2 nanoparticles as grinding aids have been completely removed after alkalization and filtration treatments. The C=O absorption peak at 1690 cm−1 is enhanced in the alkalized NBC sample compared to BC, reflecting that alkalization increased the C=O bond content [53]. In addition, a new peak at 1766 cm−1 appears in NBC, demonstrating that both C=O and carboxyl content have been elevated in oxidized NBC compared to BC. The results indicate that H2O2 modification effectively increases the content of carboxyl functional groups on the surface of nanoparticles [54].

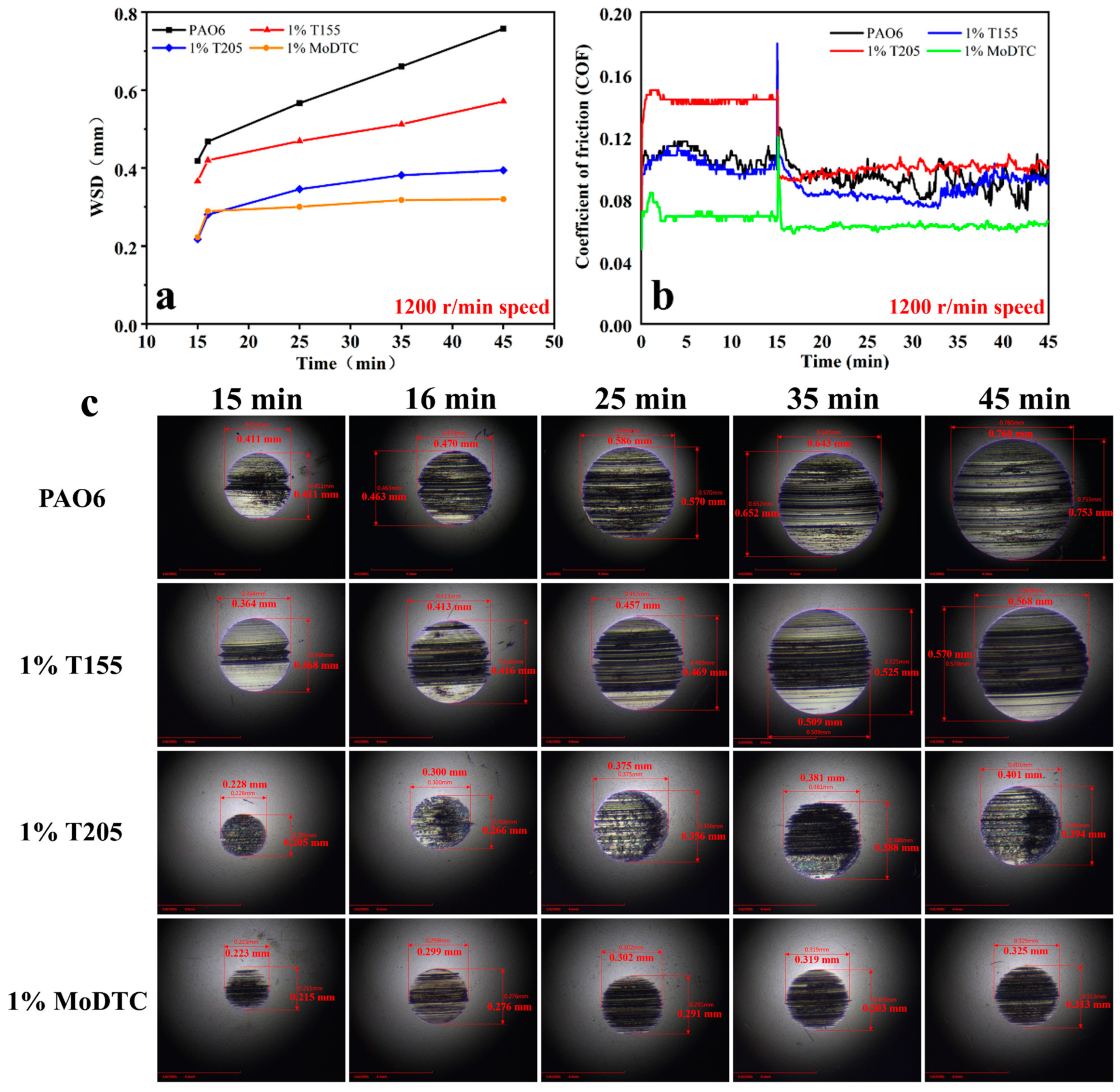

3.2. Tribological Properties of Lubricant Additives Under Variable Load Conditions

The wear spots of steel balls lubricated with PAO6 and other additive base oils at different moments during the variable load condition test are exhibited in Figure 4c. After 15 min of operation at low load in PAO6 base oil, the WSD has reached 0.42 mm. According to the morphology of the wear spots, it can be observed that the middle part of the wear area is highlighted with black color and deep grooves, which is subjected to high pressure and oxidation reaction of iron elements on the surface. The bright metallic luster of the upper and lower sections of the wear spot confirms that the adsorption of PAO6 base oil on the surface of the steel ball is weak. The surface of the friction film is continuously abraded. At sudden rise in load to 294 N, the WSD ascends to 0.47 mm and most of the wear area is black. The rise in load causes the temperature in the friction zone to ascend dramatically, resulting in areas of metallic luster darkening under intense oxidation. As the friction time advances, the iron oxide and metal on the wear surface are continuously ground and the WSD keeps increasing. The WSD of the steel ball under PAO6 base oil lubrication is directly proportional to the friction time after load elevation.

Figure 4.

(a) WSD; (b) COF; (c) wear spots of base oils with different additives under variable load conditions.

Experiments on four-ball friction at a lower load of 98 N were carried out normally by adding 1 wt% T107 to PAO6 base oil. However, when the load surged from 98 N to 294 N, the lubricant film ruptured, leading directly to the occurrence of dry friction. The COF instantly exceeded 0.2 and the balls were severely worn. Even when the heavy load was reduced from 294 N to 196 N, the oil film rupture was still manifested. Therefore, T107 detergent is not suitable for variable load condition test. The addition of 1 wt% dispersant T155 to PAO6 base oil produced a certain degree of decrease in WSD compared to PAO6 base oil at 15 min, which was 0.37 mm. The metal was oxidized in the middle portion, while the top and bottom portions reflect a metallic luster. The photos of the wear spots were similar to the PAO6 base oil. With the sharp ascent in load, the oxidized area in the wear region of the T155 base oil was significantly enlarged, and the WSD ascended linearly with the continuation of friction. The WSD of T155 base oil under variable load conditions and the morphology of wear spots at different moments were relatively similar to that of PAO6 base oil, which confirmed that the lubrication mechanisms of T155 and PAO6 base oils were basically the same. T155 consisted of amino and long-chain oily groups. The presence of amino groups enhanced the adsorption ability on the steel balls, thus expanding the coverage of the lubricant film and improving the tribological properties of the base oil.

In the variable load test of the anti-wear agent T205, the WSD for the first 15 min decreased evidently to only 0.22 mm, with a Hertzian diameter of 0.19 mm at the corresponding load. It was found that the WSD barely ascended by 0.03 mm in the 30 min long wear period, which proved that the addition of T205 significantly improved the anti-wear performance of the base oils. Based on the morphology of the wear spots, it was observed that the surface of the wear area under the lubrication of T205 base oil was covered with a friction film and no metal wear marks appeared. This morphology was drastically different from the wear spots of PAO6 and T155 base oils. At light loads, the involvement of T205 formed a friction film on the wear surface. When the load surged to 294 N, the COF of the T205 base oil rose abruptly and oil film rupture subsequently occurred. In order to ensure the integrity of the oil film in the friction experiments, the heavy load was adjusted to 196 N. The WSD of the T205 base oil was 0.28 mm after 1 min of operation under this condition. As the friction time continued, the WSD augmented slowly in a non-linear relationship. The wear spot morphology also differed from that of PAO6 and T155 base oils. There were obvious traces of friction film in the wear area of T205 base oil, and no abrasion marks were found, indicating that the lubrication mechanism of T205 base oil was different from that of T155 and PAO6 base oil. Under the variable load condition, the wear spots of T205 base oil at 15, 16, and 25 min were distinctly elliptical with a longer length along the friction direction. The WSD of MoDTC base oil was just 0.22 mm after 15 min of operation under light load, indicating better wear resistance. Wear spots were observed with deeper furrows in the middle part of the area and shallow wear marks on the top and bottom. When the load reached 294 N, the WSD expanded to 0.29 mm and the wear spot images showed deeper furrows in the majority of the area. The WSD of the organic molybdenum base oil ascended gently with time. Even after 45 min of operation under variable load conditions, the WSD was merely 0.32 mm, which demonstrated that the friction film produced by the organic molybdenum additives on the surface provided great protection for the friction pair. With excellent lubrication, the duration of friction had little effect on WSD. Unlike the T205 base oil, the wear spots under organic molybdenum base oil lubrication are rounded.

The COF for variable load exploration with different additives was consistent with the above wear analysis as shown in Figure 4b. The COF of T155 base oil descended compared to PAO6 base oil due to adsorption of dispersant. The COF ascended at the moment of load rise and then fell gradually. After 20 min it was slightly less than the COF value before loading. T205 base oil was provided with an apparently higher COF than PAO6 base oil at minor loads, mainly due to the narrower WSD of T205 base oil and the more concentrated pressure in the wear region. Meanwhile, the irregular shape of the ZDDP friction film generated by T205 led to a rise in COF. The COF remained stable during the transient of load increase. COF also descended significantly after loading. Organic molybdenum base oil displayed excellent friction reduction performance, with smaller COF under both light and heavy load conditions. However, a sudden rise in COF also occurred at the moment of load boost.

In summary, the oil film under the lubrication of the detergent T107 was susceptible to fragmentation under the variable load experiments, causing severe wear. The participation of dispersant T155 improved the tribological performance of PAO6 base oils, benefiting from the adsorption properties of T155. The addition of T205 greatly heightened the anti-wear performance of PAO6 base oils, but it was prone to oil film rupture under variable load conditions. T205 demonstrated excellent anti-wear properties when heavy loads were reduced, while its COF was ascended over PAO6 base oils. MoDTC exhibited optimal tribological performance, with enhancements in both friction reduction and anti-wear.

3.3. Tribological Properties of NBC in Combination with Lubricant Additives

3.3.1. Tribological Properties of NBC

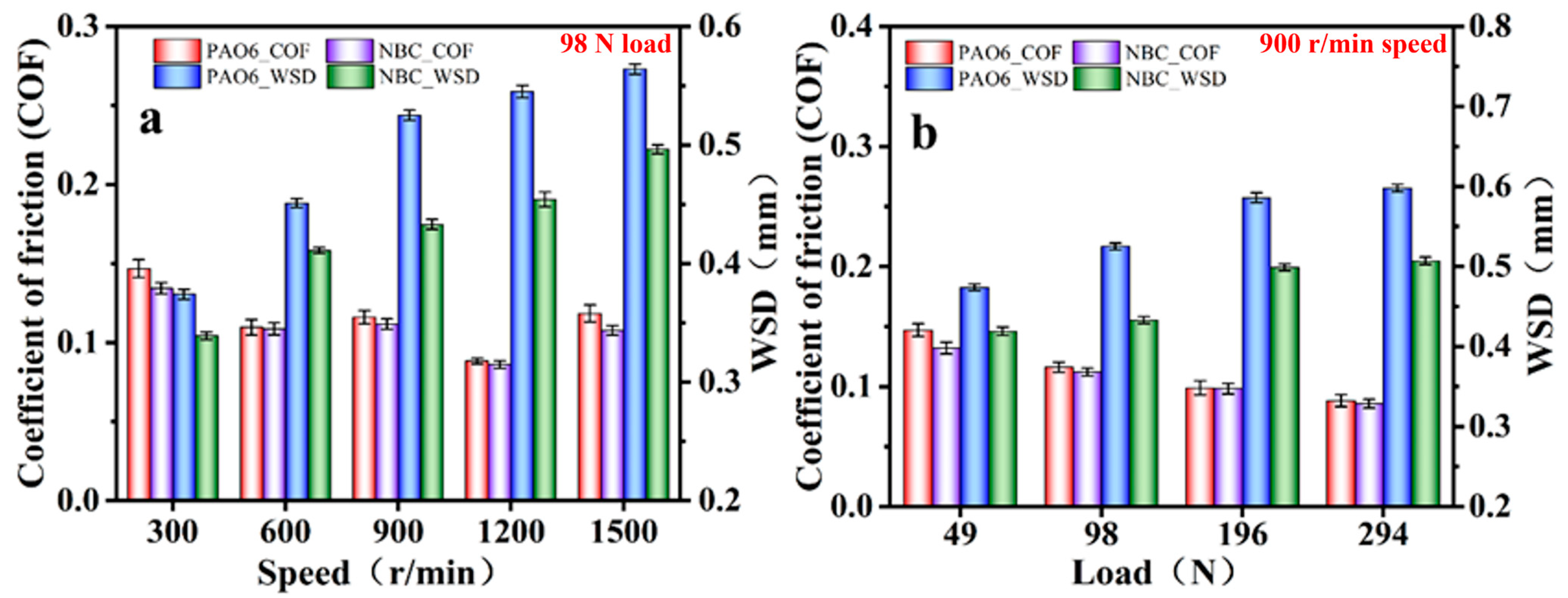

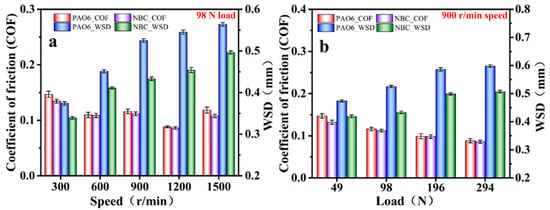

The tribological performances of PAO6 and 0.2 wt% NBC base oils at a load of 98 N and different rotational speeds are shown in Figure 5a. In terms of friction reduction, the COFs of the two base oils were basically the same. When the rotational speed was less than 1200 r/min, the system was in the stage of boundary lubrication. As the rotational speed was raised, the lubricant film became thicker and the coverage expanded. The contact area of dry friction between the moving parts shrank by degrees, contributing to a decrease in COF. When the rotational speed exceeded 1200 r/min, the COF gradually ascended. The principle was that higher transient temperatures on the surface of the friction pair led to a thinning of the lubrication film, which in turn enlarged the dry friction area. In terms of wear, the WSD of both base oils was directly proportional to the rotational speed. As the rotational speed accelerated, the friction distance increased and hence the wear volume and WSD grew accordingly. Compared to PAO6 base oils, NBC base oils provided a significant reduction in WSD, which was more pronounced at high rpm. In particular, at 900 r/min, the WSD declined by 17.5%, while the corresponding wear volume fell by 46.0%. Compared to PAO6 base oils, NBC base oils provided superior anti-wear performance at constant loads, especially at higher speeds. However, the addition of NBC had little effect in improving the friction reduction capability of PAO6 base oil. The tribological properties of PAO6 and 0.2 wt% NBC base oils are shown in Figure 5b for different loads at a speed of 900 r/min. The COF of both base oils decreased gradually with rising load, which was explained by the binomial theorem of tribology, i.e., the rate of increase in friction was less than that of load under boundary and mixed lubrication conditions [55]. With the addition of NBC, COF was reduced by an average of 4.3% compared to PAO6 lubricants. In terms of wear, the WSD of both base oils became larger as the load ascended. The WSD of NBC base oil descended by 11.6% to 17.5% compared with PAO6 base oil, corresponding to a descent of 38.2% to 46.0% in wear volume. At a certain speed, NBC base oils possessed more excellent anti-wear performance.

Figure 5.

Friction reduction and anti-wear properties of NBC base oils under different operating conditions: (a) 98 N load, different speeds; (b) 900 r/min speed, different loads.

The maximum non-seize load PB of PAO6 and NBC base oils are measured by a four-ball friction machine for evaluating the extreme pressure performance of the lubricants. The PB value indicates the maximum load at which the lubricant will not seize under the test conditions. The PB value represents the strength of the oil film, i.e., the load carrying capacity of the lubricant. The higher the PB value, the better the lubricating performance of the lubricant and the stronger the load carrying capacity. This is important to ensure stable operation under extreme conditions. During the monitoring of PB, the test time is 10 s, the rotational speed is set as 1450 r/min, and the temperature is controlled at 25 ± 5 °C. If the WSD of the steel ball in the lubricant under a given load is less than or equal to the WSD specified in the GB/T3142-2019 standard, which is routinely 1.05 times the diameter of the Hertz [56], then it is considered that no seizure had occurred. The maximum load without seizure is the PB value of the lubricant. The experimental results reflected that the PB of PAO6 base oil is 598 N and that of NBC base oil is 697 N, indicating that the addition of NBC enhanced the extreme pressure performance of PAO6 base oil. The sintering load PD of the lubricant is the working limit of the lubricant. Beyond the sintering load, the lubricant entirely lost its lubricating function, and the friction surface is sintered or severely scuffed. Normally, when the applied load caused a WSD of the lubricant greater than 4 mm, it is confirmed that the load had breached the sintering load of the lubricant [57]. The maximum load at which no sintering occurred is the sintering load PD of the lubricant. The measurement conditions of sintering load are consistent with those of maximum non-seize load. The results demonstrated that the PD of both PAO6 and NBC base oils are 1568 N. The addition of NBC contributed a negligible amount to improving the sintering load PD of the PAO6 base oil.

A comparison of the tribological properties of PAO6 and NBC base oils under different working conditions reveals that NBC base oils are strikingly superior to PAO6 base oils in terms of anti-wear. However, the friction reduction performance of NBC base oils is basically the same as that of PAO6 base oils, which does not mean that the friction reduction performance is kept intact. Under the same operating conditions, the WSD of NBC base oil is smaller, and the contact area between the friction parts is also narrower, leading to an ascent in the load carried by the oil film per unit area. According to the Stribeck curve, an increase in the load bearing pressure per unit area triggers a decrease in the film thickness and a rise in COF during the boundary and mixing lubrication stages. However, the COF of NBC and PAO6 base oils are essentially equal. This suggests that the unfavorable factor of COF increase brought about by the decrease in WSD is offset by the excellent friction reduction performance of NBC. In addition, the participation of NBC heightens the extreme pressure capability of PAO6 base oils as well as the load-bearing capacity of the oil film.

NBC possesses more oxygen-containing functional groups, which boosts the adsorption on the iron base surface. With the addition of NBC, the adsorption effect of PAO6 base oil on the surface of GCr15 steel balls is strengthened. Meanwhile, due to the diminutive size, NBC is apt to enter the narrow contact area and acts as a physical separator to avoid dry friction between solid surfaces, thus achieving friction reduction and anti-wear performance [58]. The high degree of graphitization of NBC provides a laminar self-lubricating structure, which creates favorable conditions for interlayer shear between the friction pairs. In addition, NBC deposits and fills pits on the contact surface, and the filling effect greatly reduces abrasive wear. Eventually, NBC adsorbs on the metal surface and forms a stable and powerful physical adsorption film. In the subsequent grinding chemical reaction, a friction film containing Fe3O4 is generated on the wear surface, which further improves the friction reduction and anti-wear ability of the base oil.

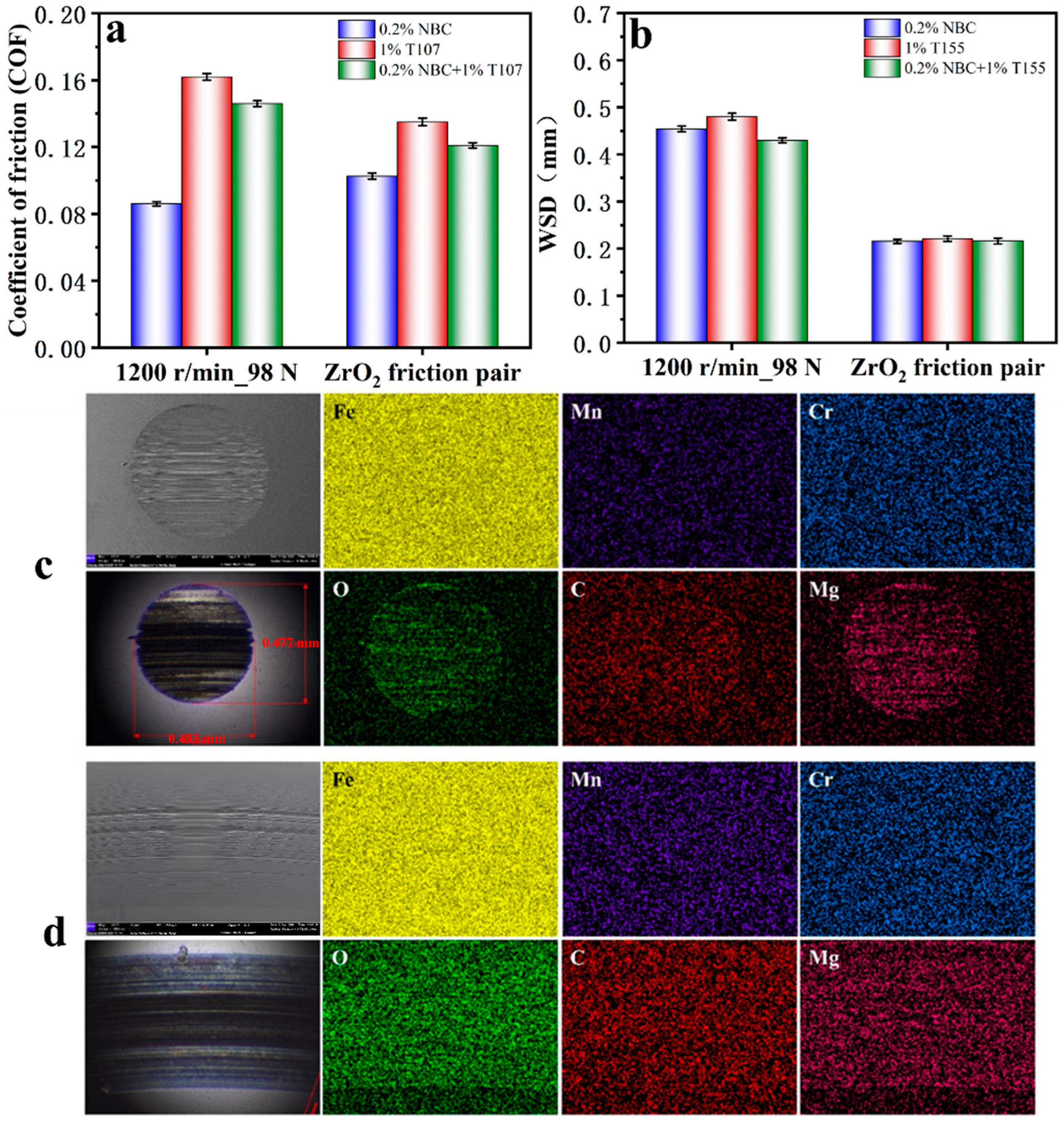

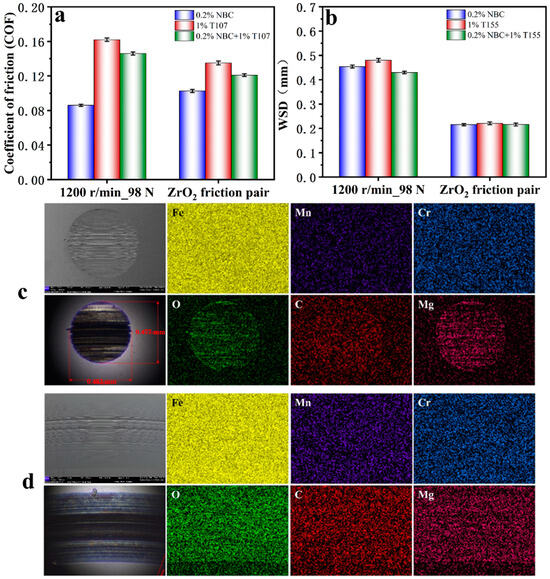

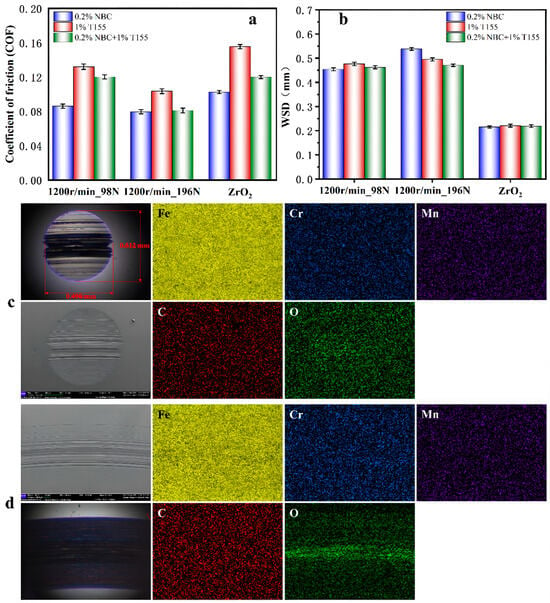

3.3.2. NBC Composite with Detergents

After the addition of 1 wt% T107 to PAO6 base oil, the frictional wear increased dramatically at 196 N operating conditions when the oil film was damaged. Therefore, the tribological properties of NBC, T107, and their hybrid base oils were analyzed when steel and ZrO2 balls were served as friction pairs at 1200 r/min, 98 N. The results are exhibited in Figure 6a,b. When T107 was added to PAO6 base oil, the COF rose sharply to 0.162, which was 86.0% higher than that of NBC base oil. The WSD was enlarged compared to NBC base oil but narrowed compared to PAO6 base oil, confirming that the T107 additive possessed some anti-wear effect. When T107 was compounded with NBC, the COF was reduced by 16.7% compared to T107 base oil. In terms of anti-wear, T107 and NBC synergized with each other, and WSD further descended by 5.3% and 10.4% compared to NBC and T107 single base oil, respectively. In the application of ZrO2 balls as friction pairs, the COF of T107 fell compared with pure PAO6 base oil, but still worse than that of NBC base oil. After excluding the adsorption effect of lubricant, the WSD of T107 compounded with NBC was basically equal to that of NBC base oil. The introduction of NBC strengthened the friction-reducing properties of T107 base oils with less impact on anti-wear performance.

Figure 6.

Tribological performance of NBC, T107, and compound base oils: (a) COF; (b) WSD. EDS face sweep of T107 base oil wear surface: (c) lower ball; (d) upper ball.

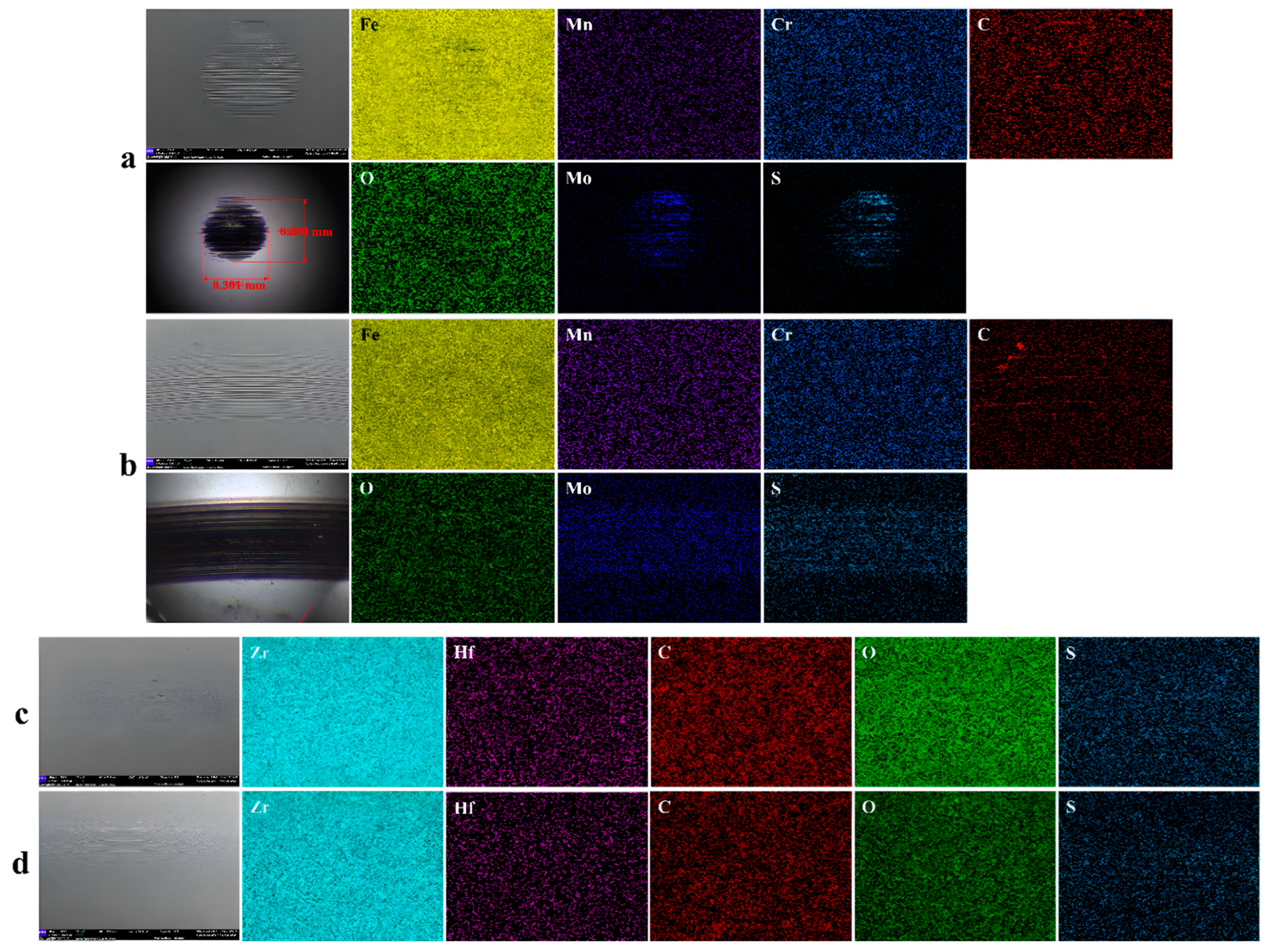

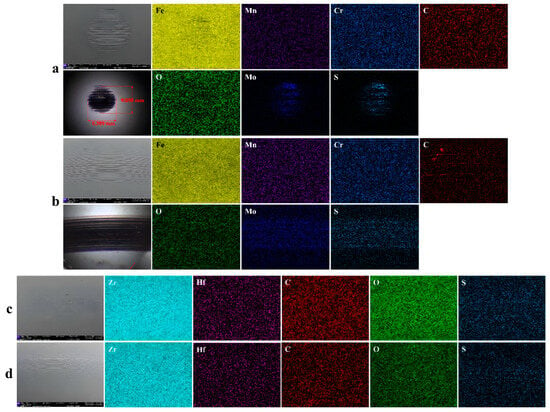

In order to investigate the lubrication mechanism of the T107 base oil, EDS characterization of the worn lower ball surface of the T107 base oil was performed as shown in Figure 6c. Six elements were detected in the wear region of the lower ball, of which Fe, Mn and Cr were the basic elements of the ball. These elements were uniformly distributed throughout the plane. There was a prominent difference in the content of the elements Mg and O between the worn and unworn areas, while the distribution of the C element differed to a slight degree. Element S was not measured on the worn surface of the steel balls, probably due to insufficient adsorption of the oil film it formed. Element S was removed during ultrasonic cleaning with petroleum ether. Post-wear EDS confirmed that the addition of PAO6 base oil to T107 constructed a powerful and robust friction film in the wear region, which remained adsorbed on the steel ball surface even after ultrasonic cleaning. According to Zhao et al. [59], the introduction of the scavenger calcium high-alkalinity sulfonate into the base oil produced a friction film containing CaO and CaCO3 within the wear spots. In contrast, the addition of high alkali value magnesium sulfonate T107 to the base oil might generate friction films containing MgO and MgCO3 on the surface of the wear region in this study. EDS characterization indicated that the distribution of Mg elements overlapped with that of O elements in a wide range. Therefore, it was inferred that the friction film contained a large amount of MgO. Due to the hard texture of MgO, localized oil shortage was induced, which boosted the probability of dry friction and led to deterioration of COF and wear. When the load was up to 196 N, the MgO formed on the friction surface tended to puncture the oil film and eventually the lubrication failed. The EDS surface sweep within the wear region of the upper ball of T107 base oil is shown in Figure 6d. The elemental distribution was consistent with that of the lower ball, and only Mg and O elements were obviously present in the annular wear region. Moreover, the width of the wear marks was large, and the middle section was black with deeper scratches. The upper and lower portions of the ring wear area exhibited lighter, bluish wear marks.

With the addition of 0.2 wt% NBC, the friction performance of T107 base oil was improved at 1200 r/min, 96 N operating condition. The results of the EDS surface scans in the lower and upper ball wear regions are shown in Figure 7a,b, respectively. The elemental distribution was basically the same as that in T107 base oil, except for a remarkable difference in the C element. It was inferred that the composition of MgCO3 in the friction film might be augmented after the addition of NBC, which was provided with a lower hardness than MgO and produced less damage to the friction surface. Due to the adsorption and filling effect of NBC, the formation of an oil film containing NBC was beneficial to further heightening the friction reduction and anti-wear properties of the base oil. From the EDS surface scan of the upper ball, it could be seen that there was also a signal difference in the distribution of C elements between the worn and unworn areas, which confirmed that the intervention of NBC enhanced the tribological performance of T107 base oil.

Figure 7.

EDS surface sweep of the wear area of T107 + NBC base oil: (a) lower ball; (b) upper ball. EDS surface sweep of the wear area of ZrO2 upper ball: (c) T107 base oil; (d) T107 + NBC base oil.

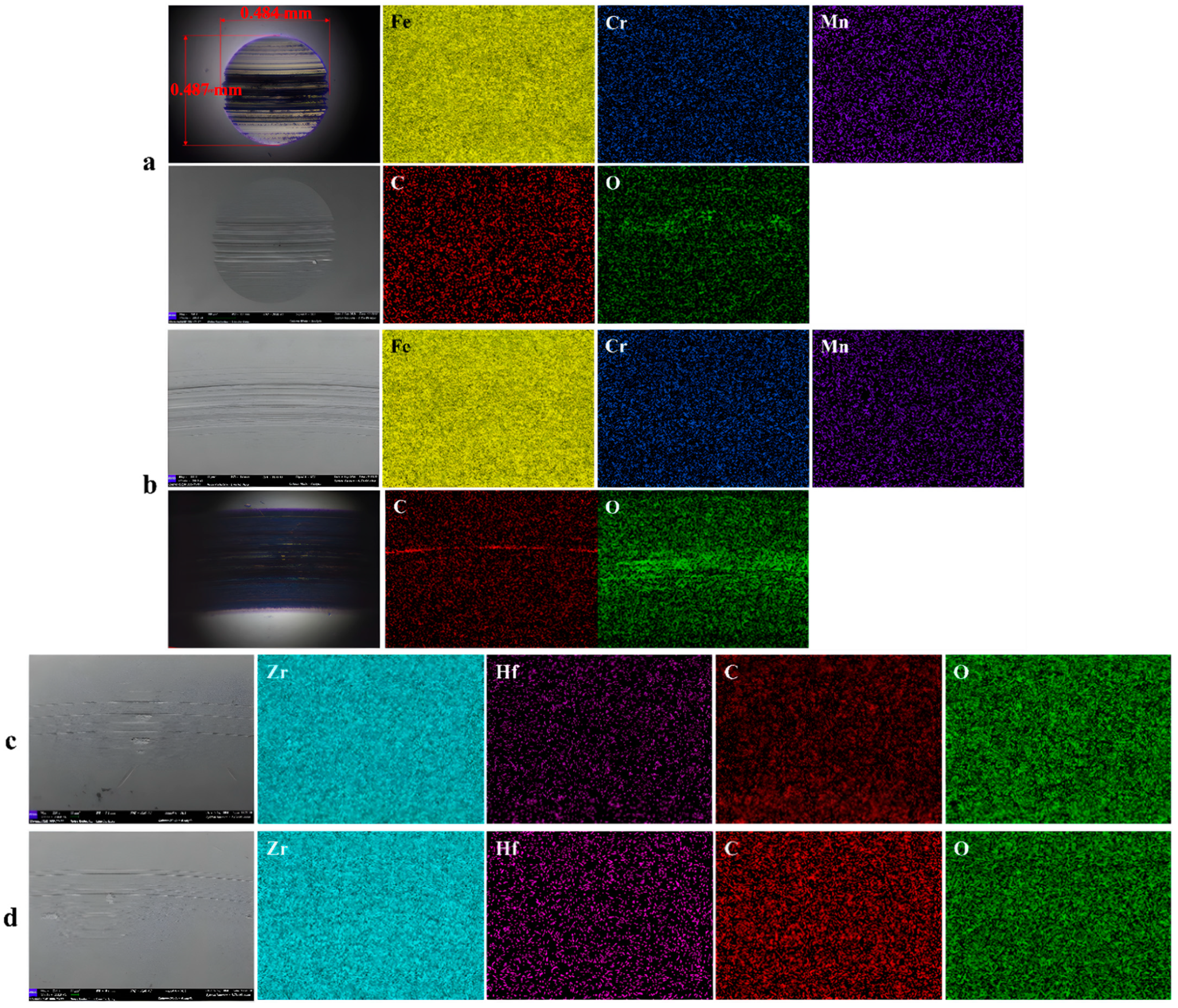

In addition, the tribological properties of T107 base oil were investigated when ZrO2 balls were employed as the friction pair. The ZrO2 balls were white in color and the area of the lower ball wear spot was tiny, making it difficult to measure during EDS face sweep testing. Therefore, only the annular wear area of the ZrO2 upper ball was characterized, as shown in Figure 7c. The elements Zr, O, Hf and C were detected on the friction surface, where Zr and O were the constituent elements of ZrO2 spheres, Hf was a doping element during the preparation of ZrO2 spheres, and the source of C was relatively complex. All four elements were uniformly dispersed in the detection area, balanced between the worn and non-worn areas, indicating that no friction film with potent adsorption was present in the worn area. In the case of steel balls as friction pairs, Mg was detected in the wear zone of the T107 base oil. Physical and weaker chemical adsorption was excluded when the ZrO2 ball was utilized as the friction pair, so no Mg and S elements were measured in the wear region. For NBC added to T107 base oil, the EDS results of the upper ball are exhibited in Figure 7d. The Zr, O, Hf and C elements were evenly distributed, which was consistent with the EDS characterization of T107 base oil, and the absence of Mg and S elements was also detected.

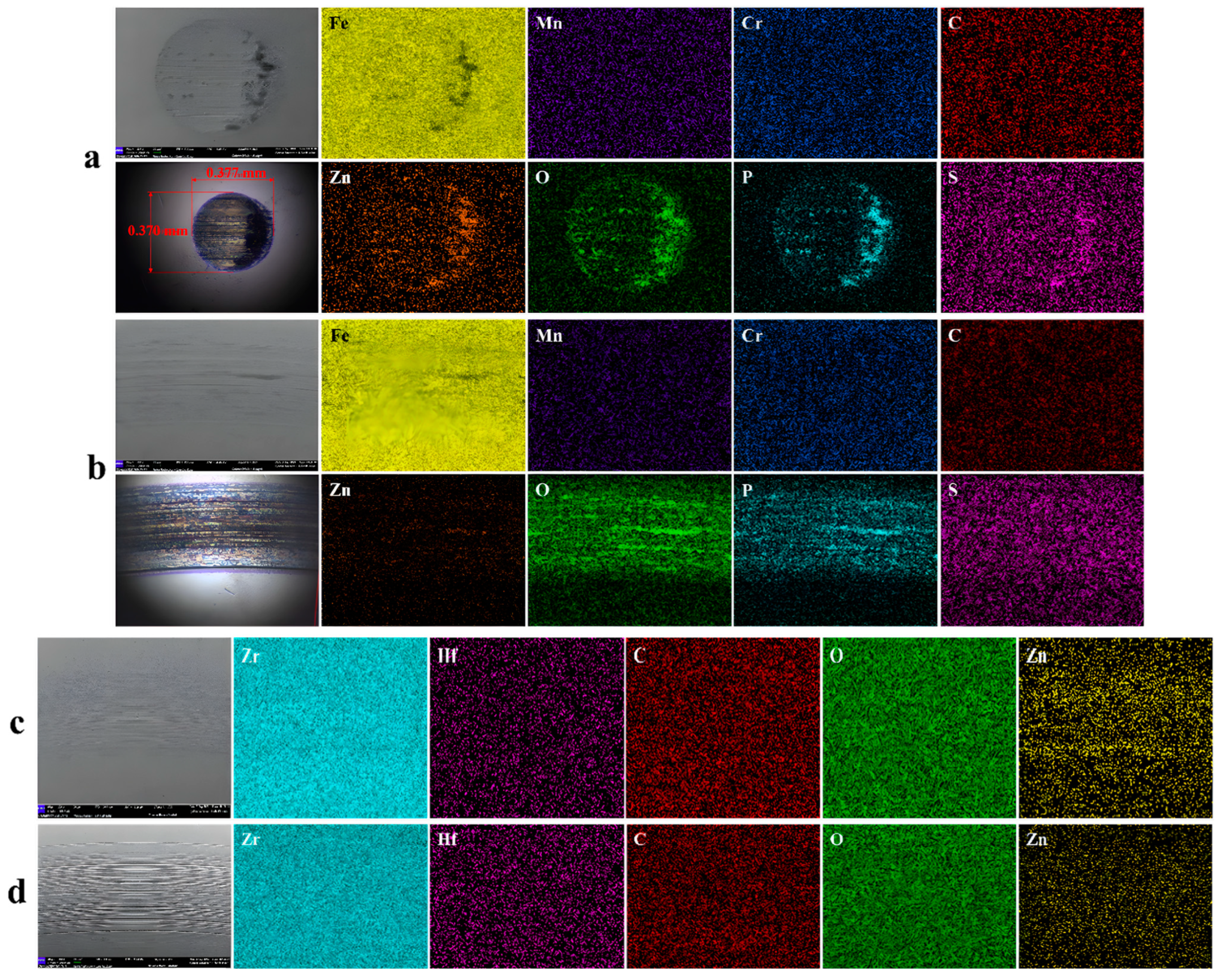

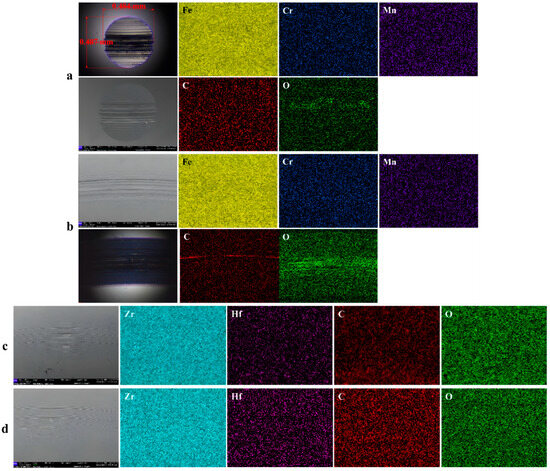

3.3.3. NBC Composite with Dispersant

The dispersant T155 plays a crucial role in the improvement of the dispersion stability performance of NBC in PAO6 base oil. It is necessary to study the tribological properties of T155 when compounded with NBC. Except for T107 additive at 1200 r/min, 196 N where the oil film was ruptured, all the additives were capable of completing the 30 min long wear test properly. The tribological performance of T155 at different operating conditions with steel balls and ZrO2 as the friction pairs is shown in Figure 8a,b. At 1200 r/min and 98 N, the WSD of T155 base oil was basically the same as that of NBC base oil, but its friction reduction performance was not as good as that of NBC base oil. When NBC was added to T155 base oil, the WSD and COF were reduced by 3.0% and 9.0%, respectively. When the load was raised to 196 N, the WSD of T155 base oil declined by 8.2% and the COF ascended by 30.0% compared to NBC base oil. T155 contained polar groups, which realized certain adsorption on the surface of steel balls and played a protective role, thus strengthening the anti-wear ability of the base oil, but the friction reduction performance was poor. After adding NBC into T155 base oil, the COF and WSD of the composite base oil were reduced by 19.0% and 4.8%, respectively, compared with T155 base oil. In terms of friction reduction, NBC decreased the COF of T155 base oil due to its interlayer shear effect. In terms of anti-wear, NBC and T155 interacted synergistically with each other, and the WSD of the composite base oils decreased by 4.8% and 12.5%, respectively, compared to that of T155 and NBC base oils. This was mainly attributed to the filling effect of NBC, which enhanced the anti-wear properties of the base oil. In addition, T155 acted as a dispersant and efficiently helped NBC to disperse in the base oil in a more uniform and orderly manner. When ZrO2 spheres were applied as the friction vice, excluding the adsorption capacity of T155, the tribological performance of T155 base oil was basically similar to that of PAO6 lubricant, with huge COF and small WSD. After the addition of NBC, benefiting from the excellent friction reduction performance of NBC, the value of COF declined. However, the anti-wear ability of NBC, T155 and the corresponding composite base oils was basically the same as that of PAO base oil, which confirmed that the lubrication mechanism of T155 base oil was adsorption and film formation.

Figure 8.

Tribological performance of NBC, T155 and compound base oils: (a) COF; (b) WSD. EDS surface sweep in the wear region of T155 base oil: (c) lower ball; (d) upper ball.

The wear surface of T155 base oil at 1200 r/min, 196 N was characterized by EDS, and the face sweep of the lower ball is exhibited in Figure 8c. After adding T155 to PAO6 base oil, only Fe, Cr, Mn, C and O elements appeared in the wear area, and the five elements were uniformly distributed, indicating that no firm and forceful friction film was generated at the wear spots of T155 base oil. It was demonstrated that the lubrication mechanism of T155 was the physical adsorption of amino groups on the surface of steel balls. Compared to friction films created by chemical reactions, physically adsorbed lubricant films were readily eliminated during friction and sonication. Therefore, element N, representing the dispersant T155, was not detected in the wear area. From the photographs of the wear spots on the lower ball, it was observed that the middle portion was black with iron oxides, while the upper and lower portions reflected a metallic luster. The EDS surface sweep of T155 base oil in the upper ball wear region is shown in Figure 8d. The elemental fractions of the upper and lower balls were generally consistent, with Fe, Cr, Mn and C elements evenly spread out. Only the element O was significantly more abundant in the severe wear region, where the surface was black, than in the other wear regions, which had a blue color. The enrichment of element O originated from the iron oxides on the friction surface, which can alleviate the wear to some extent. In contrast, there was no distinct difference in the distribution of O elements in the lower ball, which was due to the inconsistent frictional stress on the lower ball and the upper ball. The circular wear spots of the lower ball were continuously stressed during friction, while the annular wear areas of the upper ball were in a state of intermittent pressure. The lower ball was subjected to much harsher forces and even protective layers of iron oxides such as Fe3O4 are ground.

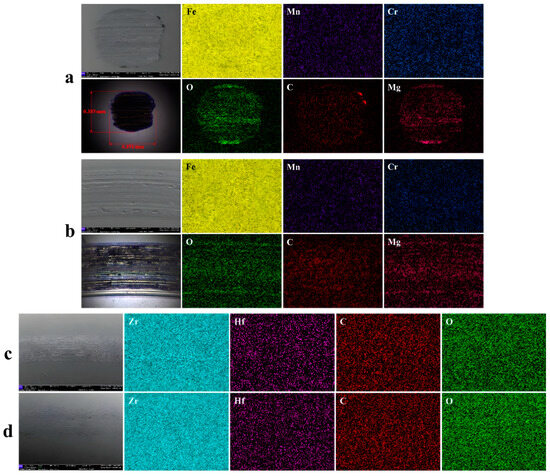

The face-scan EDS of the wear region after the addition of NBC to the T155 base oil were indicated in Figure 9a,b. On the lower ball, the elements Fe, Cr, Mn and C were evenly dispersed in the detection area, while there was aggregation of O elements in localized areas. With the addition of NBC, a small amount of protective layer formed by iron oxides was retained on the wear surface. The face-scan results for the upper ball were consistent with the T155 base oil, with the most plentiful oxygen content in the severe wear region, mainly from iron oxides. In the face sweep of the C element, there was clearly more C element in the linear area. After ultrasonic cleaning with petroleum ether, the C element remained on the surface of the steel ball. This was attributed to the repairing and filling effect of NBC, which optimized the pressure resistance of T155 base oil, and at the same time strengthened the anti-wear performance of the base oil. In addition, T155 also contributed to a more homogeneous dispersion of NBC in the PAO6 base oil, allowing T155 and NBC to exhibit further synergies in anti-wear performance. When ZrO2 balls were employed as the friction pairs, the EDS surface sweeps of the upper balls of T155 base oil and T155 + NBC composite base oil are shown in Figure 9c,d. Similar to the characterization of T107 base oil, only the elements Zr, O, Hf and C were measured on the wear surfaces and all four elements were evenly distributed in the detection area, indicating that no friction film was formed on the friction surface by T155 base oil. The tribological properties of T155 base oil were consistent with those of PAO6 base oil when ZrO2 was the friction pair, which also demonstrated that the lubrication mechanism of T155 base oil was physisorption.

Figure 9.

EDS surface sweep in the wear region of T155 + NBC base oil: (a) lower ball; (b) upper ball. EDS surface sweep in the wear region of ZrO2 upper ball: (c) T155 base oil; (d) T155 + NBC base oil.

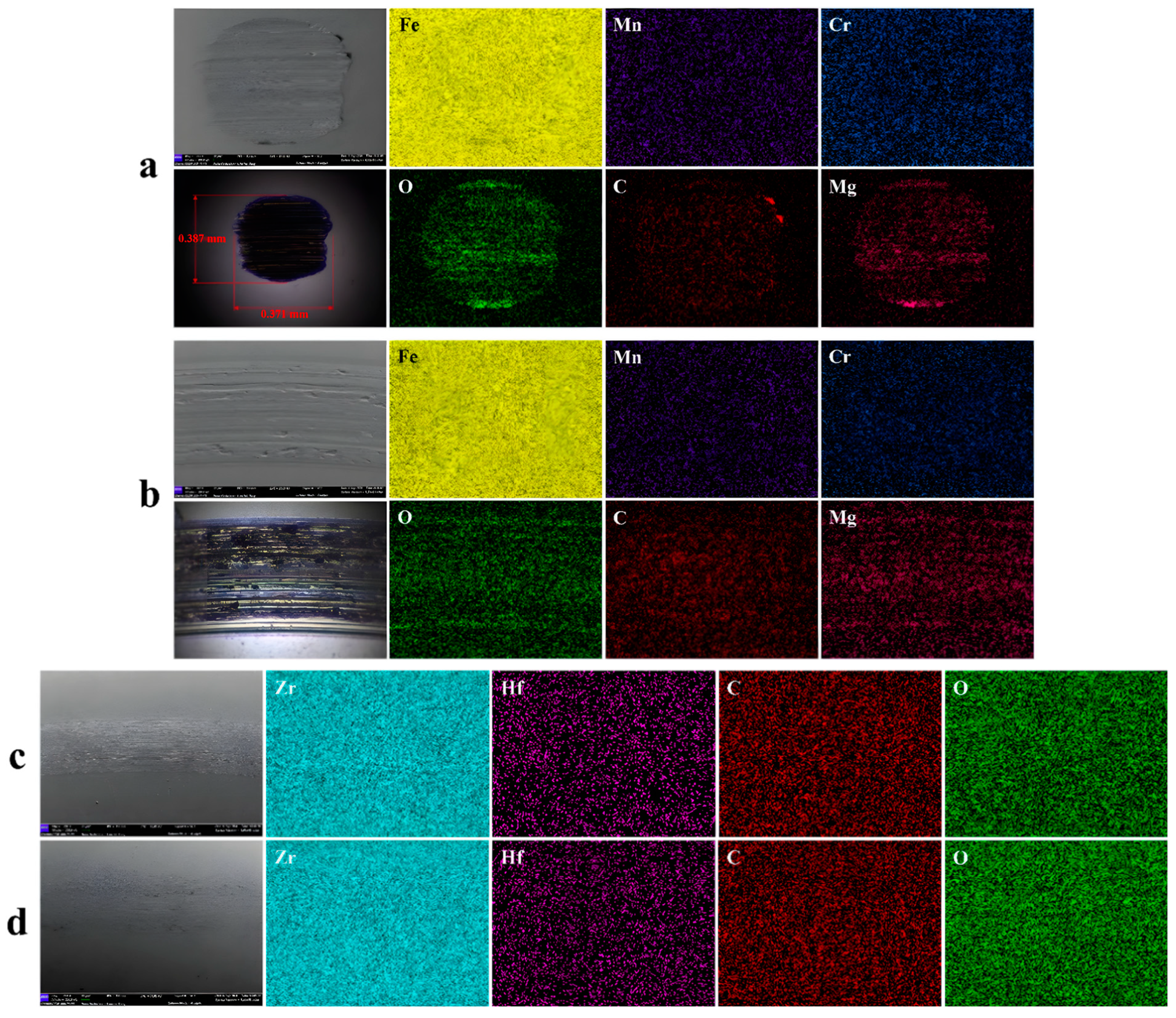

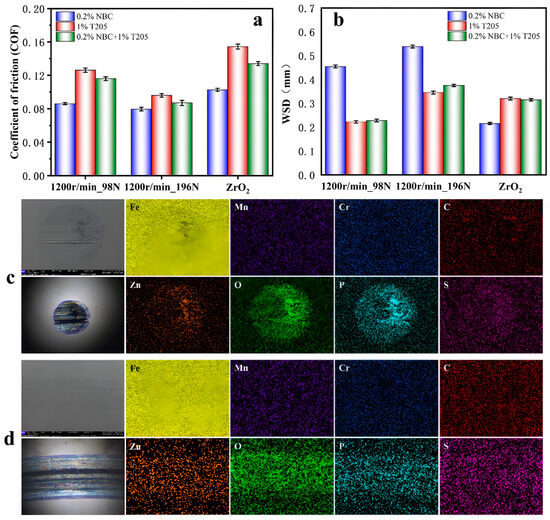

3.3.4. NBC Composite with Anti-Wear Agents

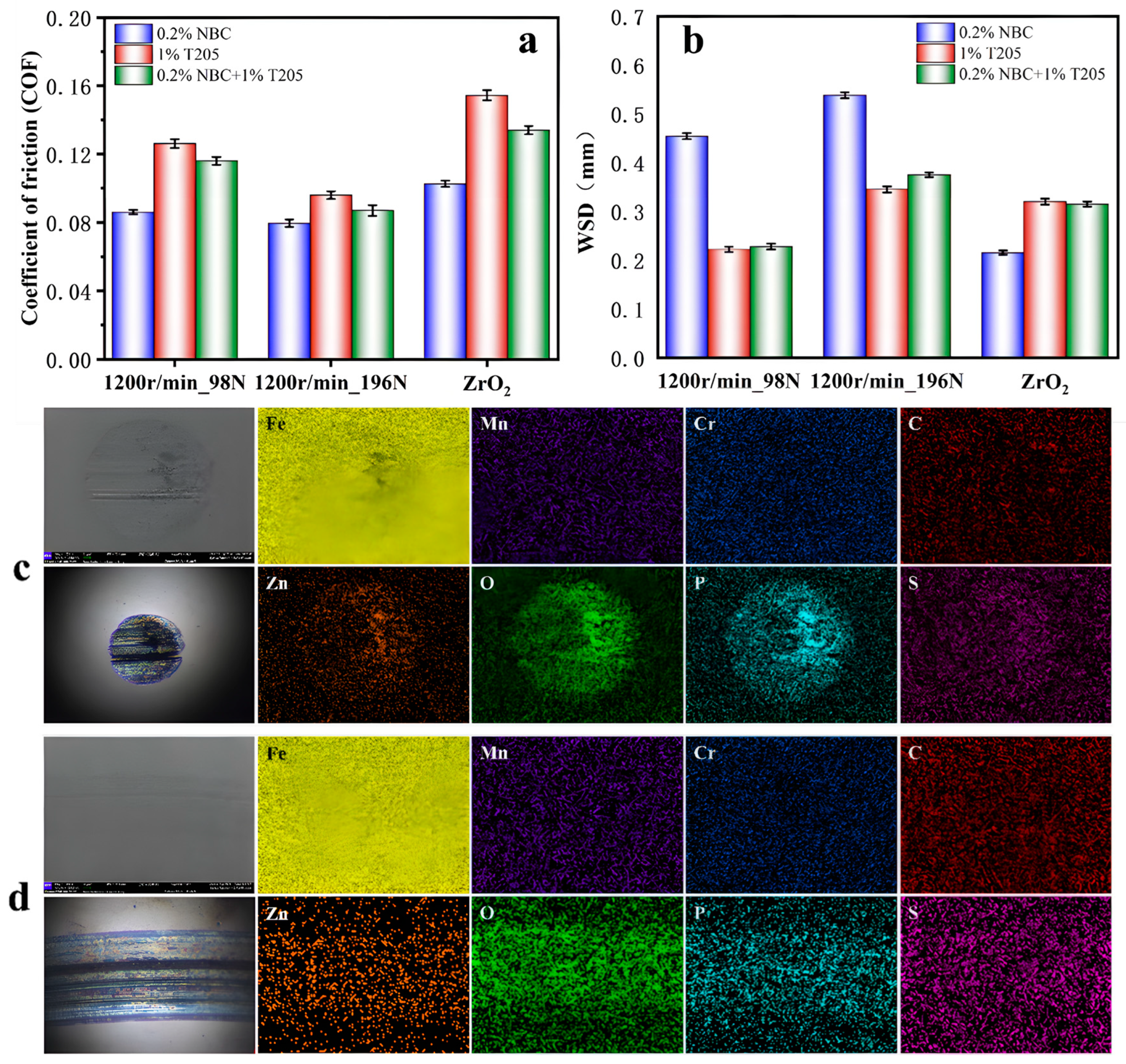

ZDDP is widely used in lubrication as a vital anti-wear agent. The research of the tribological properties of NBC compounded with ZDDP is crucial for the application of NBC in lubricants. The tribological performance of T205, NBC and composite base oils at different operating conditions as well as ZrO2 ball friction sub are shown in Figure 10a,b. In terms of anti-wear, the addition of T205 to PAO6 base oil greatly improved the anti-wear performance of PAO6 base oil due to its chemical film-forming mechanism. In terms of friction reduction, the ascent in load per unit area due to the reduction in WSD resulted in a larger COF than that of NBC base oil. With the addition of NBC, the WSD was essentially unchanged and the COF decreased by 8.0% at 1200 r/min and 98 N operating conditions. When the load was raised to 196 N, the wear deteriorated, with WSD ascending by 8.7% and COF falling by 9.4%. In the case of ZrO2 balls as the friction pair, the addition of T205 exacerbated the wear. In contrast, when NBC was utilized in combination with T205, both COF and WSD were reduced compared to T205 base oil.

Figure 10.

Tribological performance of NBC, T205 and compound base oils: (a) COF; (b) WSD. EDS surface sweep in the wear region of T205 base oil: (c) lower ball; (d) upper ball.

In order to investigate the lubrication mechanism of T205, the wear surfaces were characterized at 1200 r/min, 196 N. The EDS surface sweeps of the lower and upper balls were represented in Figure 10c,d. Prominent traces of oil film coverage were noted in the upper ball ring wear area of the T205 base oil. Most of the area possessed shallow abrasion marks and only localized furrows are deeper. In the EDS results of the lower ball, a total of eight elements were detected, with Mn, Cr and C elements evenly distributed in the measurement range. The Fe element in some areas of the wear surface was less than the rest of the region, indicating that it was covered by the friction film. Meanwhile, the content of Zn, P and O elements in this region was evidently higher, and S element was also more abundant than the rest, but the variation of S element was bland. It was known that a large amount of ZDDP friction film was generated in the region. The bottom part of the ZDDP film consisted of metal sulfides, the middle layer contained iron or zinc polyphosphate in a glassy state, and the top layer consisted of zinc phosphate and other organic materials [60]. After petroleum ether cleaning, the black friction film in the wear area was mainly composed of zinc polyphosphate and included a few metal sulfides. According to Zhang et al. [61], in the case of an instantaneous ascent in load, the temperature and pressure of the friction surface subsequently rose rapidly, and ZDDP decomposed and generated a large number of friction films. Due to the irregular shape of the friction film formed by ZDDP, accompanied by the larger thickness and harder texture of the oil film, it led to localized oil shortage in the wear region, which in turn triggered oil film rupture and wear deterioration. This also illustrated the principle of oil film breakage of T205 base oil under variable load conditions.

The EDS surface sweeps within the lower and upper ball wear regions after the addition of NBC to the T205 base oil are exhibited in Figure 11a,b. The elemental composition was mostly similar to that characterized in the T205 base oil. However, the inclusion of NBC narrowed the coverage of Zn, P and O elements in the wear region. According to Kontou et al. [62], there was a corrosion–wear mechanism between ZDDP and nanomaterials in terms of wear. ZDDP reacted chemically with the steel ball substrate to construct a friction film, which was removed during the grinding process. Nanomaterials played the role of abrasive particles in the friction process exacerbating the depletion of the friction film, while ZDDP produced a new friction film on the surface of the steel ball after wear. The friction film continued to be generated and removed, and the steel ball substrate was corroded by chemical reactions, eventually leading to severe wear. NBC, as a nanomaterial, also caused increased wear. In addition, at a load of 98 N, the wear caused by NBC was subtle. When the load ascended to 196 N, the wear was more intense. However, the filling and repairing effects of NBC itself improved the anti-wear performance of the base oil to a certain extent. The addition of NBC to the T205 base oil induced shallower ball wear marks, in contrast to the deeper furrows in the T205 base oil.

Figure 11.

EDS surface sweep in the wear region of T205 + NBC base oil: (a) lower ball; (b) upper ball. EDS surface sweep in the wear region of ZrO2 upper ball: (c) T205 base oil; (d) T205 + NBC base oil.

The EDS characterization of the upper ball wear region in T205 and T205 + NBC base oil when ZrO2 balls were utilized as the friction pair is shown in Figure 11c,d. A total of five elements were detected in the measurements, in which Zr, Hf, O and C elements were uniformly distributed. Unlike the results of the EDS surface sweeps in detergent T107 and dispersant T155, the enrichment of elemental Zn was observed in the wear region of T205 base oil. This suggested that even on the ZrO2 surface, ZDDP still underwent a chemical film-forming reaction. According to Kontou et al., ZDDP built up a friction film under high temperature and shear, and the film became thicker with the rise in temperature and shear. During the friction process of high temperature and shear, ZDDP reacted with the ZrO2 surface matrix to generate a friction film. Since the ZrO2 material was hard, the WSD was minor and the load per unit area became greater. As a result, the ZDDP friction film generated on the surface was harder and more irregular in shape, which might act as abrasive particles to accelerate wear. This also led to insufficient oil supply in certain areas, which caused dry friction and resulted in elevated COF. The above evidence elucidated the principle of harsh wear of T205 base oil when ZrO2 balls are employed as a friction pair. With the addition of NBC, the abundance of Zn elements was diminished. Although NBC had no adsorption effect on ZrO2, NBC possessed the advantage of laminar shear and still contributed to reducing friction.

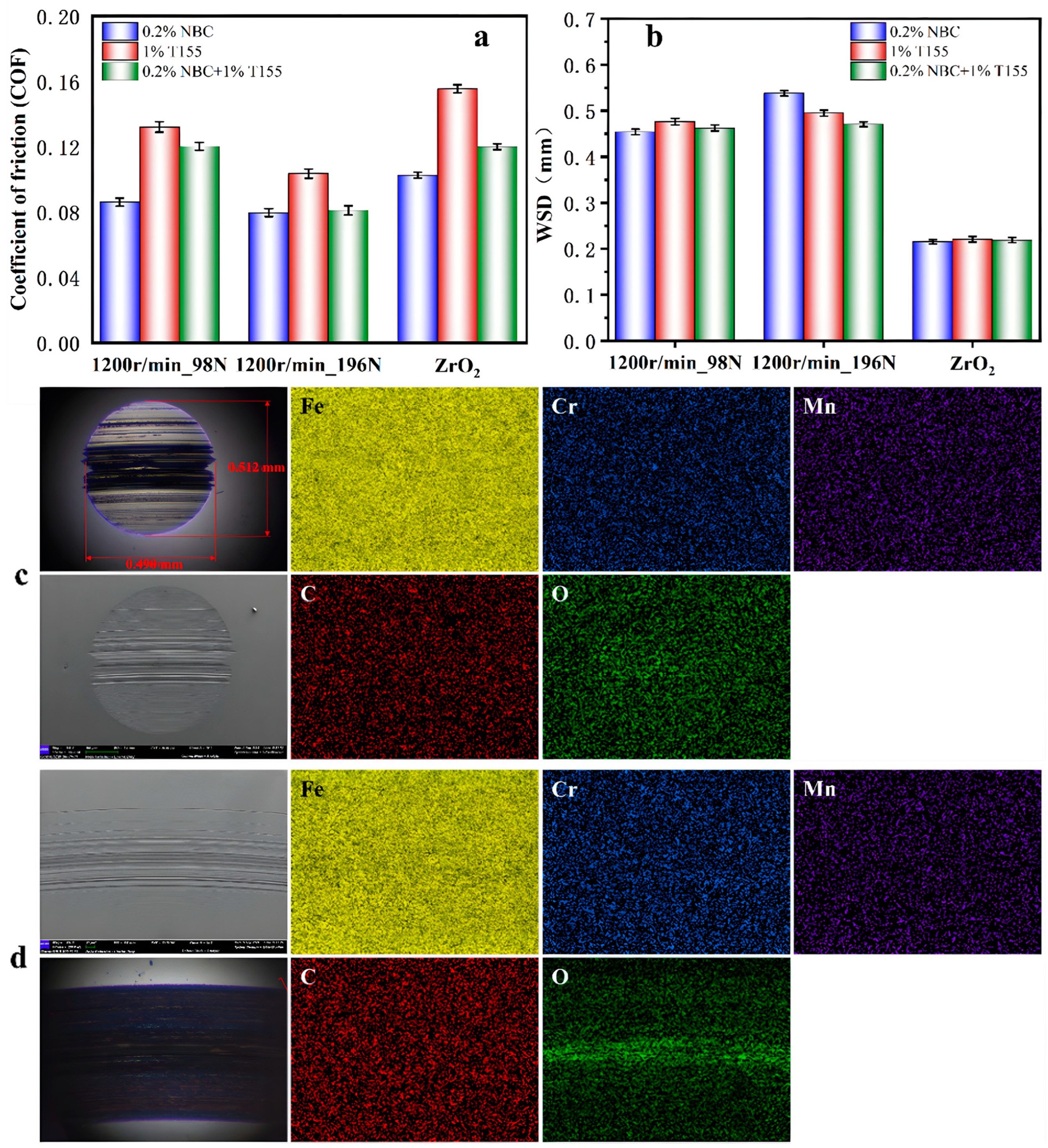

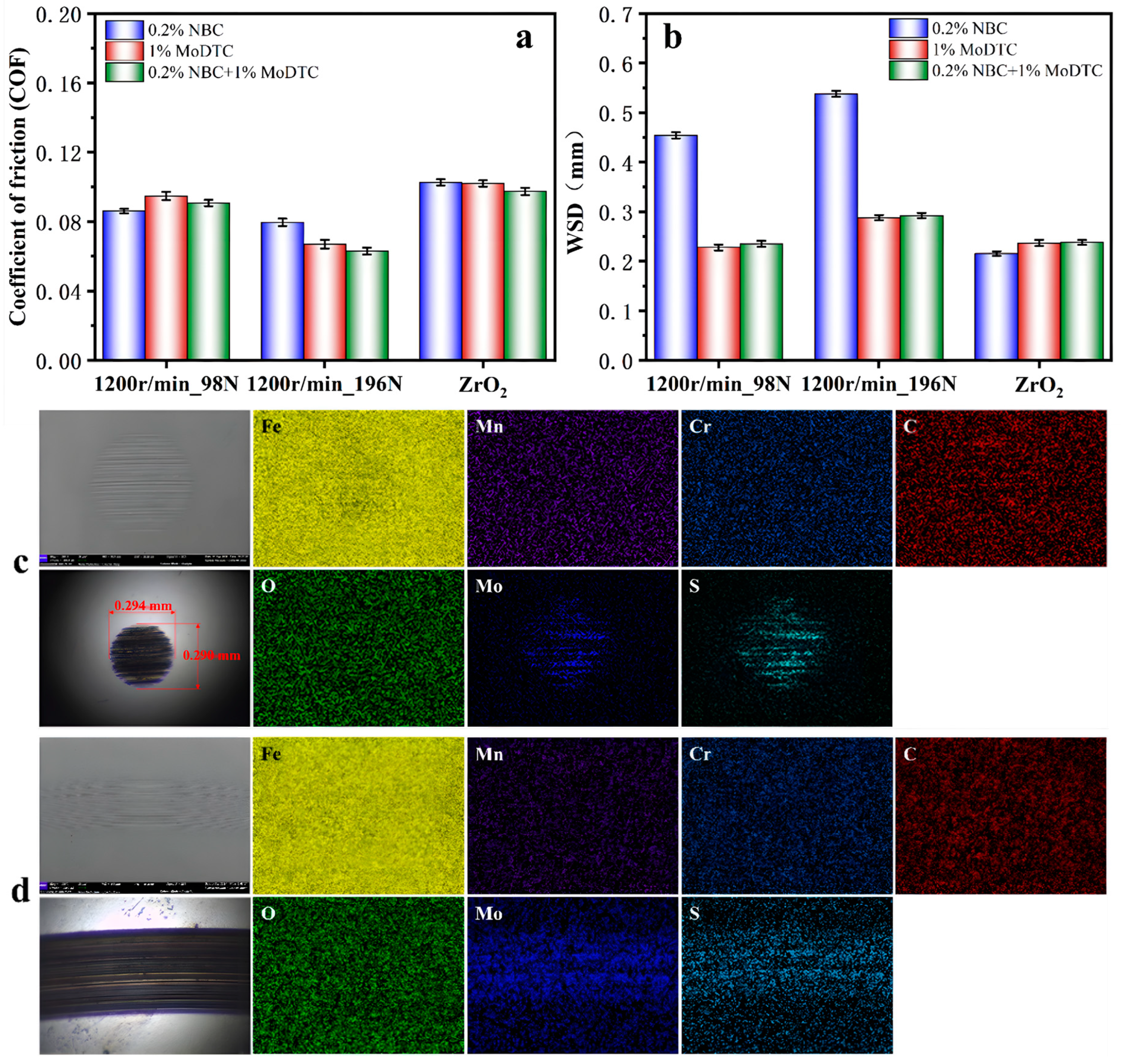

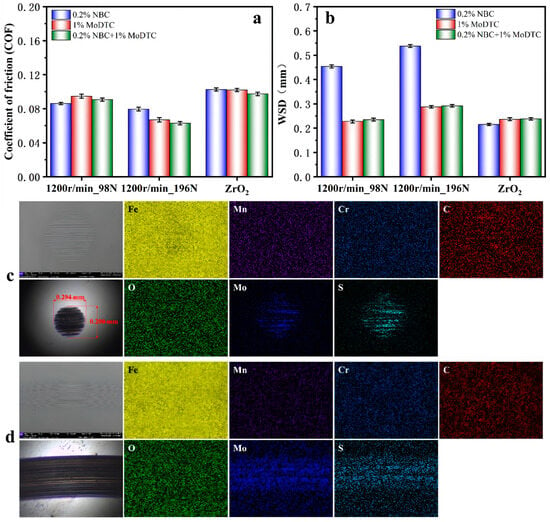

3.3.5. NBC Composite with Organic Molybdenum

Organic molybdenum has received more and more attention as an excellent friction-reducing agent in recent years. Among them, MoDTC produces MoS2 by chemical reaction on the friction surface under high temperature and shear environment, which reflects remarkable tribological properties. The tribological performance of MoDTC, NBC and composite base oils under different working conditions and friction vice is exhibited in Figure 12a,b. The WSD of MoDTC base oil was just 0.23 mm at 1200 r/min and 98 N operating conditions, suggesting brilliant anti-wear performance. The Hertzian diameter at this load was 0.19 mm, indicating that the WSD of MoDTC base oil grew by merely 0.04 mm during the friction process in 30 min. Meanwhile, the COF was maintained at a low level due to the prominent friction reduction properties of MoS2 with its two-dimensional layered structure. MoDTC base oils were capable of maintaining a low COF even with a diminutive WSD, confirming the outstanding tribological properties of MoDTC. When the load was raised to 196 N, the WSD was 0.29 mm, which increased only 20.8% compared with the Hertzian diameter of 0.24 mm at this load. It was conceivable that MoDTC formed a relatively complete lubricant film on the friction surface, which provided perfect protection. At the same time, the COF of MoDTC base oil further decreased with the ascent of load, which was 15.8% lower than that of NBC base oil. When NBC was compounded with MoDTC, the synergistic effect in terms of friction reduction was demonstrated, with a COF decline of 6.0% compared to the MoDTC base oil and 21.0% compared to the NBC base oil at 1200 r/min, 196 N operating conditions. The addition of NBC reduced the COF of the MoDTC base oil by 4.2% at 1200 r/min and 98 N. In terms of anti-wear, the addition of NBC contributed to a rise of 4.4% and 1.3% in WSD over MoDTC base oils at 98 N and 196 N, respectively. When ZrO2 was applied as the friction pair, the COF of both NBC and MoDTC base oils were kept at a low level, and when they were compounded, a synergistic effect was reflected in the friction reduction performance, with a 4.5% decrease in COF compared to MoDTC base oil. The WSD of the MoDTC base oil was enlarged by 9.7% over the NBC base oil in terms of anti-wear properties, and the mechanism of wear intensification was similar to that of T205. With the addition of NBC, the WSD was essentially equal to that of MoDTC base oil.

Figure 12.

Tribological performance of NBC, MoDTC and compound base oils: (a) COF; (b) WSD. EDS surface sweep of MoDTC base oil wear region: (c) lower ball; (d) upper ball.

The lower and upper ball wear regions of the MoDTC base oil at 1200 r/min, 196 N were characterized by EDS surface scanning, as shown in Figure 12c,d. Seven elements were measured in the lower ball wear region, with Mn, Cr, C and O elements evenly dispersed. The Fe element was apparently under-represented in the specific region, while the corresponding S and Mo elements were relatively plentiful, indicating the formation of a MoS2 friction film. The same situation existed in the annular wear region of the upper ball. The decomposition of MoDTC generated oxides of molybdenum with different valences in addition to MoS2. The complex origin of the O element made it difficult to identify such oxides by EDS characterization. MoDTC and T205 were both chemical reaction film-forming mechanisms in the friction process. However, according to the comparison of the wear spots, there were differences between the two friction films. In the wear spots of MoDTC base oil, furrows along the friction direction were observed and the traces of the oil film were indistinct, inferring that MoDTC built a thinner friction film than ZDDP. After the addition of NBC to MoDTC base oil, the EDS surface sweeps in the wear regions of the lower and upper balls at 1200 r/min and 196 N were demonstrated in Figure 13a,b. The elemental distribution in the wear region of the composite lubricant was basically the same as that of the MoDTC base oil. The difference between the content of Mo and S elements in the worn and unworn regions was more significant.

Figure 13.

EDS surface sweep of MoDTC + NBC base oil wear region: (a) lower ball; (b) upper ball. EDS surface sweep of wear area of ZrO2 upper ball: (c) MoDTC base oil; (d) MoDTC + NBC base oil.

The EDS surface sweeps within the annular wear region of the upper ball in MoDTC and MoDTC + NBC base oils when ZrO2 balls were utilized as the friction pair are shown in Figure 13c,d. Five elements were detected within the wear area, and element S was measured in addition to Zr, Hf, C and O elements. It was suggested that MoDTC chemically reacted on the surface of the ZrO2 ball and a friction film was generated. However, the produced MoS2 possessed weak adsorption on the ZrO2 friction sub-surface, which was eliminated during ultrasonic cleaning, resulting in the absence of Mo elements in the face-scan inspection. The wear aggravation mechanism of MoDTC base oils on the ZrO2 friction surface was similar to that of ZDDP. The organic molybdenum reacted with the ZrO2 during the generation of the friction film, which was subsequently continuously removed and created. The ZrO2 substrate was also consumed and eventually the wear deteriorated. After the addition of NBC, the elemental composition in the wear region was basically consistent with that of the MoDTC base oil.

3.3.6. Verification of Cylinder Liner-Piston Ring Reciprocating Friction Test with Compound Lubricants

The effect of NBC and various lubricant additives on the tribological properties of base oils was verified by the cylinder liner-piston ring reciprocating friction experiment. Prior to the friction test, 0.2 wt% NBC was added to the base oil containing 1% of the above four lubricant additives (refined oil), and ultrasonic treatment was performed for 20 min to ensure that the NBC was uniformly distributed in the refined oil, i.e., NBC refined oil. The lubricant consumption for a single test was 5 g. The running time was 2 h and the temperature was set at 25 °C. The load was 100 N. The crankshaft speed was 300 r/min. At the end of the experiments, the piston rings and cylinder liner were ultrasonically cleaned using petroleum ether to facilitate the subsequent characterization tests. The quality of the piston rings and cylinder liner before and after the reciprocating friction test for both refined oil and NBC refined oil is demonstrated in Table 2. The mass difference analysis based on weighing shows that the difference in mass loss of piston ring between refined oil and NBC refined oil is relatively slight, only 0.0001 g, while there is a large difference in mass loss on the cylinder liner material. The wear mass of the cylinder liner of NBC refined oil before and after the test is reduced by 41.1% compared with that of the refined oil, suggesting that the NBC refined oil possesses superior anti-wear performance in reciprocating friction movement.

Table 2.

Piston ring and cylinder liner quality variables for refined oil and NBC refined oil before and after the test.

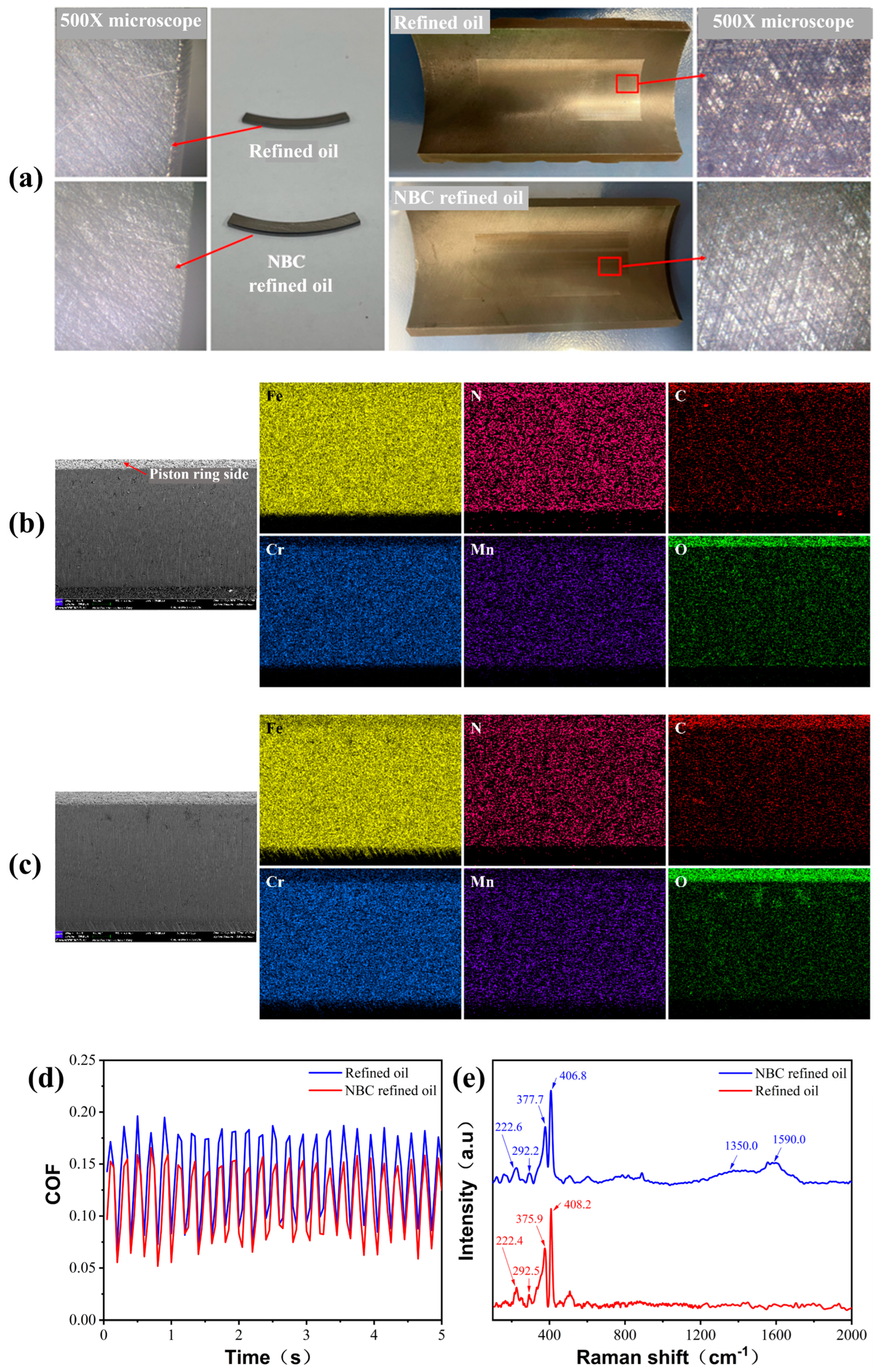

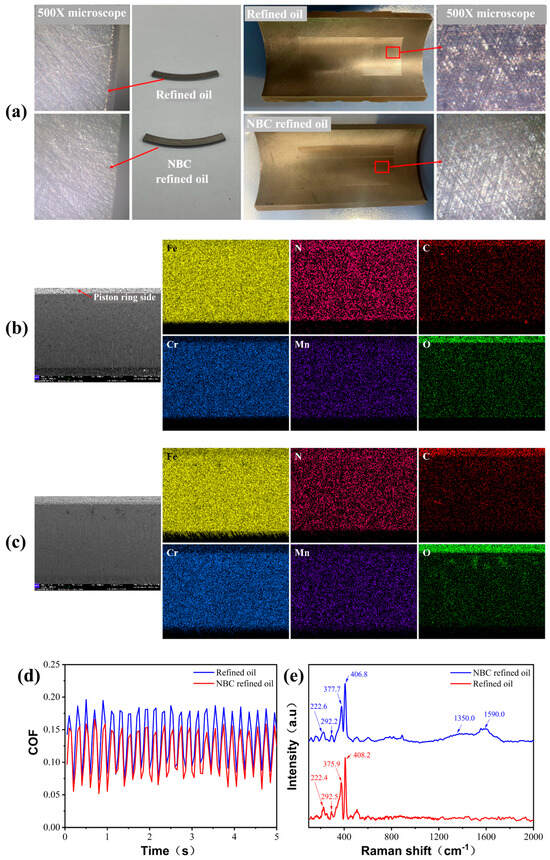

The piston ring and cylinder liner after friction are exhibited in Figure 14a. There are more grid-like lines on the worn surface of the cylinder liner, and such lines enhance the adsorption strength of the lubricant. The wear marks on the cylinder liner surface of the refined oil are deeper and more obvious, while the wear marks on the surface of the NBC refined oil are lighter and thinner. Due to the filling effect of NBC, its nanosheets are attached to the grid pattern. A lubricant film of NBC is formed on the worn surface, thus providing an anti-wear effect. The COF of the lubricant is measured after the cylinder liner-piston ring reciprocating motion has entered the stabilization phase, as shown in Figure 14d. In terms of friction reduction, the average COF of NBC refined oil and refined oil were 0.114 and 0.138, respectively. The reduction in COF of NBC refined oil is 17.4%. The presence of the reticulated structure on the cylinder liner surface ensures the stable adsorption of the lubricant, while the addition of NBC increases the adsorption capacity of the refined oil. Under the effect of NBC interlayer shear, the friction reduction performance is improved. In addition, NBC adheres to the mesh pattern and reduces the roughness of the friction surface, which is conducive to enhancing the friction reduction performance of the lubricant.

Figure 14.

(a) Worn cylinder liner and piston ring; (b) EDS surface swept characterization of the piston ring wear region in refined oil; (c) EDS surface swept characterization of the piston ring wear region in NBC refined oil; (d) COF of the cylinder liner-piston ring reciprocating motion; (e) Raman characterization of the cylinder liner wear surface.

At the end of the test, the piston rings were characterized by EDS. Due to the large size of the cylinder liner, only the worn surface of the liner was analyzed by Raman. The EDS characterization of the piston ring wear area is shown in Figure 14. Both refined oil friction pairs exhibit shallow wear marks. The surface is relatively smooth. According to the EDS results, only elements Fe, Cr, Mn, N, C and O are detected on the piston ring surface. The uppermost part of the detected area is the side area of the piston ring. The six elements are evenly distributed in the wear area. The presence of friction films such as ZDDP and MoS2 is not detected on the friction surface. It may be due to the fact that the piston ring surface is smoother and harder. The friction film is poorly adsorbed on the surface and is removed during the ultrasonic cleaning process.

The Raman characterization results of the cylinder liner wear region are shown in Figure 14e. The peaks at 222.4 cm−1 and 292.5 cm−1 for the refined oil correspond to the eigenvalues of Fe2O3 [63]. There are two distinct peaks near 375.9 cm−1 and 408.2 cm−1, which correspond to the in-plane (E2g) and interlayer (A1g) modes of vibration of the MoS2 laminar structure [64]. In NBC refined oil, the peaks at 222.6 cm−1 and 292.9 cm−1 correspond to the characteristic peaks of Fe2O3. The characteristic E2g and A1g peaks of MoS2 are observed at 377.7 cm−1 and 406.8 cm−1. The difference in wave number between E2g and A1g of MoS2 increases with the thickening of the MoS2 layer [65]. The frequency differences of the cylinder liner wear surfaces in refined oil and NBC refined oil are 32.3 cm−1 and 29.1 cm−1, respectively, confirming that the wear surfaces are all typical multilayer MoS2 structures. In contrast, the NBC refined oil has fewer MoS2 layers and produces a thinner MoS2 friction film, leading to superior friction reduction performance. In the Raman characterization of the wear region of the NBC refined oil cylinder liner, there are peaks around 1350 cm−1 and 1590 cm−1, which correspond to the D and G peaks of C atoms. The presence of these characteristic peaks was not detected on the surface of the cylinder liner in the refined oil, indicating the formation of a carbon film on the surface of the cylinder liner in the NBC refined oil. This is attributed to the self-healing effect of NBC on the reticulated surface of the cylinder liner. In the reciprocating friction pair, the refined oil forms a friction film of MoS2 on the surface of the cylinder liner. With the addition of NBC, the NBC lubricant film is generated in the reticulation region of the cylinder liner due to the repair effect, which enhances the friction reduction and anti-wear performance of the refined oil. Meanwhile, the laminar shear effect of NBC further strengthens the friction reduction performance of the lubricant.

3.4. Lubrication Mechanism of NBC in Combination with Additives

The tribological properties of four lubricant additives were investigated by designing variable load condition tests. The lubricant additives were compounded with NBC, and their tribological performances were measured by four-ball friction experiments under different loads and friction sub-materials. Combined with the morphology and EDS characterization of the wear region, the lubrication mechanism of different additives when compounded with NBC was vividly revealed. The adsorption capacity of the base oil was closely related to the anti-wear performance. The detergent T107 base oil formed MgO friction film on the wear surface, and the presence of MgO was prone to oil film rupture, which in turn caused severe wear. There was a synergistic effect between NBC and T107 in terms of anti-wear. The addition of NBC improved the oil film composition of T107 base oil, transforming the MgO-dominated lubricant film into a MgCO3 and NBC lubricant film. The COF and WSD of the composite lubricant were reduced by 19.0% and 10.4%, respectively, compared with T107 base oil. When NBC was compounded with dispersant T155, the laminar shear effect of NBC enhanced the friction reduction performance of T155 base oil, and the COF declined by a maximum of 19.0% compared with T155 base oil. In terms of anti-wear, NBC and T155 were provided with a synergistic effect, with WSD reduced by 12.5% and 4.8% compared to NBC and T155 base oils, respectively. This was mainly attributed to the self-healing of NBC and the uniform dispersion of NBC by T155. When NBC was compounded with T205, in terms of friction reduction properties, the addition of NBC decreased the COF of T205 base oil by up to 9.4%. In terms of wear, due to the chemical film formation of T205, a corrosion–wear mechanism was generated with NBC, leading to wear deterioration. The lubrication mechanism of MoDTC was to construct a friction film of MoS2 on the friction surface. When NBC was compounded with MoDTC, both demonstrated a synergistic effect in friction reduction, with a 4.5% fall in COF over MoDTC base oil. However, the addition of NBC had little effect on the anti-wear performance of MoDTC base oil.

The oil film on the friction surface remains intact under light load conditions. The addition of NBC reduces the COF, which is attributed to the better adsorption effect of NBC. NBC is able to enter the friction region, and the self-lubricating layered graphitized structure induces interlayer shearing of NBC. When the friction pair is replaced with ZrO2 material, the friction reduction performance is weakened due to the loss of adsorption effect. Under heavy load conditions, NBC smoothly slides into the friction area due to its excellent adsorption and nanoscale size, and deposits on the surface of the steel ball by adsorbing lubricant to form an oil film. In addition, the filling effect of NBC effectively alleviates the abrasive wear and heightens the carrying capacity of the lubricant film. Thus, the oxidation rate of Fe2+ and Mo4+ in the friction area is decreased under high temperature and high pressure, and the content of the film of MoS2 and Fe3O4 on the friction surface is multiplied. MoS2 presents a lamellar shape and has superior friction reduction and anti-wear performance compared to MoO3 and ZDDP. After the ZrO2 ball as friction vice excludes the physical adsorption, only the chemical reaction film-forming mechanism exists. The incorporation of NBC moderates the high localized load caused by micro-convex body contact and improves the anti-friction performance by slowing down the chemical reaction rate between ZDDP and ZrO2 matrix. The laminar shear effect possessed by NBC also enhances the friction-reducing properties.

4. Conclusions

In response to green lubrication, this study investigates the environmentally friendly material NBC, which is applied as an additive in lubrication. The tribological properties of NBC in PAO6 base oil and additive base oil were thoroughly explored, and a method to analyze the friction reduction and anti-wear mechanism of nano-additives in complex lubrication system was proposed. The main conclusions are as follows:

- Wheat straw biomass is selected as the raw material, and NBC is successfully fabricated by the freezing plus ball milling method to reach the definition of nanomaterials. Meanwhile, the surface modification is carried out to meet the lubrication requirements, and the NBCs possess diminutive size, higher degree of graphitization and more oxygen-containing functional groups.

- The maximum reduction in wear volume of steel balls in NBC base oils was 46.0% compared to PAO6 base oils. The friction reduction and anti-wear mechanism of NBC consists of adsorption, self-repair, interlayer shear and film-forming effects.

- The addition of NBC enhanced the friction-reducing properties of the detergent and dispersant base oils with COF decrease of 16.7% and 19.0%, respectively, and improved the composition of the friction film, resulting in a synergistic effect on the anti-wear performance. NBC, when compounded with anti-wear agents and friction reducers, generates a synergistic effect in friction reduction performance, with COF reductions of 9.4% and 4.5%, respectively.

- A method to analyze the friction reduction and anti-wear mechanism of nano-additives in complex lubrication systems is proposed. The tribological performance of the lubricant is compared under different friction sub-conditions by replacing the friction sub-materials to exclude the lubricant adsorption. Combined with the characterization of wear surfaces, the friction reduction and anti-wear mechanisms of nano-lubricants are demonstrated. This approach is applicable to nanomaterials with multiple lubrication mechanisms as well as complex lubrication systems in the presence of diverse additives.

Author Contributions

Methodology, Y.W.; Software, C.C.; Validation, Y.W.; Formal analysis, W.G.; Data curation, W.G.; Writing—original draft, W.G.; Writing—review & editing, M.K.A.A.; Visualization, C.C.; Supervision, Y.W. and M.K.A.A.; Project administration, X.H.; Funding acquisition, X.H. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

The original contributions presented in this study are included in the article. Further inquiries can be directed to the corresponding author.

Conflicts of Interest

The authors declare no conflict of interest.

Abbreviations

| BC | Biochar |

| NBC | Nano-Biochar |

| COF | Coefficient of friction |

| WSD | Wear scar diameter |

| FESEM | Field emission scanning electron microscopy |

| FTIR | Fourier Transform Infrared Spectrometry |

| AFM | Atomic Force Microscope |

| EDS | Energy Dispersive Spectrometer |

| T107 | Synthetic magnesium sulfonate with super alkali value (Detergent) |

| T155 | Polyisobutylene Succinimide (Dispersant) |

| T205 | Dialkylzinc phosphorothioate (Anti-wear agent) |

| ZDDP | Zinc Dialkyl Dithiophosphate (Anti-wear agent) |

| MoDTC | Molybdenum dialkyl dithiocarbamate (Friction modifier) |

References

- Zhou, Y.; Tang, X.; Zuo, X.; Zhu, H.; Ma, C. Incipient wear fault diagnosis using a modified change detection method. Tribol. Int. 2019, 137, 164–172. [Google Scholar] [CrossRef]

- Meng, Y.; Su, F.; Chen, Y. Synthesis of nano-Cu/graphene oxide composites by supercritical CO2-assisted deposition as a novel material for reducing friction and wear. Chem. Eng. J. 2015, 281, 11–19. [Google Scholar] [CrossRef]

- Meng, Y.; Xu, J.; Jin, Z.; Prakash, B.; Hu, Y. A review of recent advances in tribology. Friction 2020, 8, 221–300. [Google Scholar]

- Chen, Y.; Zhang, Y.; Zhang, S.; Yu, L.; Zhang, P.; Zhang, Z. Preparation of Nickel-Based Nanolubricants via a Facile In Situ One-Step Route and Investigation of Their Tribological Properties. Tribol. Lett. 2013, 51, 73–83. [Google Scholar] [CrossRef]

- Hisakado, T.; Tsukizoe, T.; Yoshikawa, H. Lubrication Mechanism of Solid Lubricants in Oils. J. Lubr. Technol. 1983, 105, 245–252. [Google Scholar] [CrossRef]

- Uflyand, I.E.; Zhinzhilo, V.A.; Burlakova, V.E. Metal-containing nanomaterials as lubricant additives: State-of-the-art and future development. Friction 2019, 7, 93–116. [Google Scholar] [CrossRef]

- Zhu, N.; Shan, W.; Shan, Y.; Du, J.; Lian, Z.; Zhang, Y.; He, H. Effects of alkali and alkaline earth metals on Cu-SSZ-39 catalyst for the selective catalytic reduction of NOx with NH3. Chem. Eng. J. 2020, 388, 124250. [Google Scholar] [CrossRef]

- Hernández Battez, A.; González, R.; Viesca, J.L.; Fernández, J.E.; Díaz Fernández, J.M.; Machado, A.; Chou, R.; Riba, J. CuO, ZrO2 and ZnO nanoparticles as antiwear additive in oil lubricants. Wear 2008, 265, 422–428. [Google Scholar] [CrossRef]

- Wu, J.; Huang, X.; Berglund, K.; Lu, X.; Feng, X.; Larsson, R.; Shi, Y. CuO nanosheets produced in graphene oxide solution: An excellent anti-wear additive for self-lubricating polymer composites. Compos. Sci. Technol. 2018, 162, 86–92. [Google Scholar] [CrossRef]

- Chen, Z.; Liu, X.; Liu, Y.; Gunsel, S.; Luo, J. Ultrathin MoS2 Nanosheets with Superior Extreme Pressure Property as Boundary Lubricants. Sci. Rep. 2015, 5, 12869. [Google Scholar] [CrossRef]

- Desanker, M.; He, X.; Lu, J.; Liu, P.; Pickens, D.B.; Delferro, M.; Marks, T.J.; Chung, Y.; Wang, Q.J. Alkyl-Cyclens as Effective Sulfur- and Phosphorus-Free Friction Modifiers for Boundary Lubrication. ACS Appl. Mater. Interfaces 2017, 9, 9118–9125. [Google Scholar] [CrossRef]

- Farhanah Azman, N.; Samion, S.; Paiman, Z.; Kameil Abdul Hamid, M. Tribological performance and mechanism of graphite, hBN and MoS2 as nano-additives in palm kernel oil-based lubricants: A comparative study. J. Mol. Liq. 2024, 410, 125616. [Google Scholar] [CrossRef]

- Uğur, A.; Avan, İ. Investigation of 1-octanethiol capped ZnS nanoparticles as lubricant additives and tribological behavior of oil-based nanolubricant. Wear 2023, 530, 205029. [Google Scholar] [CrossRef]

- Berman, D.; Erdemir, A.; Sumant, A.V. Few layer graphene to reduce wear and friction on sliding steel surfaces. Carbon 2013, 54, 454–459. [Google Scholar] [CrossRef]

- Liu, J.; Chen, B.; Guo, P.; Yu, Z.; Sheng, W.; Zhang, K.; Liu, X. Fabrication of 3D porous graphene materials for oil-based lubrication: Tribological and wear performance. Carbon 2024, 221, 118892. [Google Scholar] [CrossRef]

- Ouyang, T.; Sun, X.; Tang, W.; Li, Y.; Tian, Z.Q.; Li, Y. Anti-wear and vibration-noise control of nitrogen-doped graphene/C60 nano additives. Wear 2024, 536–537, 205173. [Google Scholar] [CrossRef]

- Yoo, M.J.; Park, H.B. Effect of hydrogen peroxide on properties of graphene oxide in Hummers method. Carbon 2019, 141, 515–522. [Google Scholar] [CrossRef]

- Gulzar, M.; Masjuki, H.H.; Kalam, M.A.; Varman, M.; Zulkifli, N.W.M.; Mufti, R.A.; Zahid, R. Tribological performance of nanoparticles as lubricating oil additives. J. Nanopart. Res. 2016, 18, 223. [Google Scholar] [CrossRef]

- Erdemir, A.; Ramirez, G.; Eryilmaz, O.L.; Narayanan, B.; Liao, Y.; Kamath, G.; Sankaranarayanan, S.K. Carbon-based tribofilms from lubricating oils. Nature 2016, 536, 67–71. [Google Scholar] [CrossRef] [PubMed]

- Ravindiran, G.; Rajamanickam, S.; Janardhan, G.; Hayder, G.; Alagumalai, A.; Mahian, O.; Lam, S.S.; Sonne, C. Production and modifications of biochar to engineered materials and its application for environmental sustainability: A review. Biochar 2024, 6, 62. [Google Scholar] [CrossRef]

- Song, B.; Cao, X.; Gao, W.; Aziz, S.; Gao, S.; Lam, C.-H.; Lin, R. Preparation of nano-biochar from conventional biorefineries for high-value applications. Renew. Sustain. Energy Rev. 2022, 157, 112057. [Google Scholar] [CrossRef]

- Lyu, H.; Gao, B.; He, F.; Zimmerman, A.R.; Ding, C.; Huang, H.; Tang, J. Effects of ball milling on the physicochemical and sorptive properties of biochar: Experimental observations and governing mechanisms. Environ. Pollut. 2018, 233, 54–63. [Google Scholar] [CrossRef] [PubMed]

- Sultan, H.; Li, Y.; Ahmed, W.; Mu, Y.; Shah, A.; Faizan, M.; Ahmad, A.; Abbas, H.M.M.; Nie, L.; Khan, M.N. Biochar and nano biochar: Enhancing salt resilience in plants and soil while mitigating greenhouse gas emissions: A comprehensive review. J. Environ. Manag. 2024, 355, 120448. [Google Scholar] [CrossRef] [PubMed]

- Prabhu, P.; Jayabalakrishnan, D.; Balaji, V.; Bhaskar, K.; Maridurai, T.; Prakash, V.R.A. Mechanical, tribology, dielectric, thermal conductivity, and water absorption behaviour of Caryota urens woven fibre-reinforced coconut husk biochar toughened wood-plastic composite. Biomass Convers. Biorefin. 2024, 14, 109–116. [Google Scholar] [CrossRef]

- Wang, Y.; Hou, X.; Zhang, L.; Ali, M.K.A.; Jiang, H.; Ma, Y. Development of nano biochar as a lubricating oil additive for tribological applications. J. Clean. Prod. 2023, 421, 138519. [Google Scholar] [CrossRef]

- Xiao, J.; Hu, R.; Chen, G. Micro-nano-engineered nitrogenous bone biochar developed with a ball-milling technique for high-efficiency removal of aquatic Cd(II), Cu(II) and Pb(II). J. Hazard. Mater. 2020, 387, 121980. [Google Scholar] [CrossRef] [PubMed]

- Aziz, S.; Uzair, B.; Ali, M.I.; Anbreen, S.; Umber, F.; Khalid, M.; Aljabali, A.A.; Mishra, Y.; Mishra, V.; Serrano-Aroca, A.; et al. Synthesis and characterization of nanobiochar from rice husk biochar for the removal of safranin and malachite green from water. Environ. Res. 2023, 238, 116909. [Google Scholar] [CrossRef]