Abstract

Steel wire rope serves as a critical load-bearing and transmission component in the transportation equipment utilized in coal mines. It exhibits various forms of damage during prolonged service, which significantly jeopardizes the safety reliability of the transportation equipment. To investigate the formation process of the surface wear of steel wire rope and its influence on mechanical properties, the tribological evolution and performance degradation of the transmission wire rope under rope–sheave contact and rope–rope contact were studied in this paper. The wire rope’s friction coefficient (COF) is stable between 0.7 and 0.8 under two contact conditions. It is more likely to lead to the accumulation of frictional heat under the condition of rope–sheave contact. The primary wear mechanisms of transmission wire ropes are adhesive wear and fatigue wear. Additionally, the wear evolution leads to the nonlinear degradation of the tensile strength and bending fatigue life of the wire rope, and the wear damage caused by rope–sheave contact is more harmful. As the sliding distance between the wire rope and the sheave increases, the breaking force decreases from approximately 48 kN to 23 kN, and the number of bending fatigues of the wire rope before scrapping is reduced from approximately 6200 times to 200 times.

1. Introduction

Wire rope is a flexible component with excellent mechanical properties. It is widely used in engineering fields such as mine transportation, lifting, bridges, and cableways [1,2,3]. As the core bearing and transmission components of different mechanical equipment, the operational condition of the wire rope plays a crucial role in determining the efficiency and safety reliability of the production system [4]. In order to realize long distances, heavy loads, and a wide range of material transportation, the wire rope is mostly used in the system structure of drum winding traction and sheave support guidance. However, this service condition will lead to extrusion contact between different layers of wire rope on the drum and between wire rope and sheave [5]. Thus, during the service of coal mine transportation wire ropes, there will be cross-contact between ropes (on multilayer wound drums) and arc-shaped contact between wire rope and sheave rope groove. Furthermore, due to the various degrees of vibration and elastic deformation experienced by the wire rope while in operation [6], relative sliding occurs between the rope–rope contact and the rope–sheave contact, respectively, which in turn causes the surface wear of the wire rope [7]. This kind of damage cumulatively changes during the long-term service, causing the degradation of the mechanical properties of the transmission wire rope and seriously threatening its service safety [8]. Therefore, it is essential to explore the tribological evolution mechanism of transmission wire rope under the two sliding friction pairs and examine how different types of wear affect their mechanical properties. This is significant for detecting and maintaining wire rope, improving assessment accuracy, and prolonging its safety service life.

To realize the safe use, efficient operation, and reliable service of wire ropes under different service conditions, scholars have researched the damage mechanism, mechanical properties, and failure behavior of wire ropes. To explore the contact characteristics between steel wires under different load conditions, Chen et al. [9] established a full-state contact mechanics model between steel wires based on contact mechanic theory and the semi-analytical method. The distribution of stress and deformation on the wire surface was revealed. Considering that fretting wear inside the rope stand is common under different application conditions, Argatov et al. [10] established a fretting wear degradation model of steel wire based on the Archard–Kragelsky wear law. The life evaluation of wire rope was discussed by using the experimental results. Cruzado et al. [11] established the fretting wear model of steel wire under different cross angles. Then, the influence of different parameters on the wear scar characteristics was analyzed. Wang et al. [12] conducted an experimental study on the evolution characteristics of wear scars and cracks generated by the fretting wear of steel wires. They discovered that the cracks in the middle of the wear scars were more obvious. Zhang et al. [13] designed a bending fatigue test device for wire ropes and analyzed the wear characteristics of the wire inside the wire rope under bending fatigue load. Furthermore, to explore the external wear characteristics of wire ropes in service, Oksanen et al. [14,15] studied the rolling/sliding wear behavior between the wire rope and the drum groove. The characteristic mechanism of crack propagation and material removal on the drum surface was revealed.

Additionally, the operating environment for wire ropes under real-world service conditions is extremely challenging. This indicates that the wear often occurs under different corrosion conditions. Wang et al. [16,17] simulated the harsh service environment by preparing different corrosive solutions and carried out experimental research on fretting fatigue damage between steel wires. With the increase in pH value of corrosive media, the wear resistance of steel wire is improved. Moreover, the ambient temperature also has a significant effect on the tribological behavior of the wire rope. Under actual working conditions, lubrication serves as a crucial protective measure to mitigate wear and corrosion damage in wire ropes. Its influence on the tribological properties of the wire rope is very important. Zhang et al. [18] studied the impact of various lubricating additives on the tribological behavior of wire ropes and developed a wire rope grease with better protective performance. Using multilayer graphene and graphite as modification additives for the lubricating oil, Sun et al. [19] studied the effects of different additive contents on the fretting wear behavior of steel wires. The results show that the addition of multilayer graphene or micron graphite can improve the wear resistance of the base grease, and the micro-cutting of the wear surface is significantly reduced. By establishing a finite element simulation model, Hakala et al. [20] studied tribological properties between the paste-lubricated wire rope and the pulley rope groove. They explored ways to improve the friction and wear properties. Then, the friction and wear characteristics between steel wire and cast iron material were investigated by a pin-on-disk test.

The failure behavior of steel wire rope in service is directly related to its mechanical characteristics. Exploring the mechanical performance response of wire ropes under different load conditions is helpful to better ensure its safe and reliable service. Therefore, Xiang et al. [21] analyzed the contact stress characteristics of wire ropes under tensile load by establishing an analytical model of elastic–plastic characteristics, which can intuitively predict the elastoplastic response of wire ropes. Onur et al. [22] studied the scrapping life of wire ropes under rope–wheel bending fatigue by theory and experiment. A new theoretical service life prediction model was established by using the least-squares method. The results show that the calculation results of the theoretical model have a strong correlation with the experimental data. To explore the influence of corrosion on the mechanical properties of wire ropes, Chen et al. [23] established a finite element model of the steel wire with pitting damage. Then, the influence of surface pits on the contact and stress–strain characteristics of rope strands was analyzed. Furthermore, the bending of the wire rope will not only lead to fatigue fracture but also cause internal wear, which in turn reduces its fatigue life. Using a homemade wire rope bending fatigue tester, Zhang et al. [24] analyzed the influence of bending fatigue times on the number of broken wires and the internal wear of the wire rope. They found that the main failure modes of the wire rope in the bending fatigue test are wear and steel wire fracture. Because the failure characteristics of wire rope under actual working conditions are related to many factors, Singh et al. [25] systematically analyzed the failure behavior of wire rope for coal mines. They found that the main causes of rope failure are excessive wear and corrosion, and the impact load is the most obvious. Guerra-Fuentes et al. [26] analyzed the fracture failure characteristics of wire ropes for bridge cranes under actual working conditions. Through systematic observation, it was observed that local plastic deformation and wear initially occurred in the service wire ropes, leading to increased stress concentration, which ultimately resulted in fatigue and sudden fractures.

Considering the wire rope’s structure and service condition characteristics, the above-mentioned different damage behaviors are almost inevitable. Consequently, effective detection has emerged as a critical method to ensure the safe and reliable operation of wire ropes. Zhou et al. [27] proposed a damage image recognition method based on texture features for the surface damage of wire ropes, which improved the accuracy of damage feature detection. Battini et al. [28] proposed a bending fatigue life assessment method for wire ropes based on thermal imaging, and the accuracy of the proposed method was verified by the theory of thermal energy dissipation. Additionally, considering the large sample size of the wire rope fatigue life prediction, Zhao et al. [29] proposed a method for predicting the fatigue life of wire rope under small samples based on the grey theory. Then, the accuracy and effectiveness of the prediction method were verified through experimental methods. However, the existing methods of damage identification and life prediction are mostly in the laboratory stage. To guide the safe use of wire ropes in service, it is still necessary to fully grasp the damage characteristics of the wire rope and its influence on the mechanical properties. This is because the damage characteristics and performance degradation laws of wire ropes are quite different under different working conditions.

This study innovatively links the tribological characteristics and mechanisms of coal mine transportation wire ropes to their mechanical performance degradation during service. By incorporating two types of contact wear observed under actual operating conditions, a laboratory simulation test scheme was designed to investigate the wear evolution mechanisms of these wire ropes. This study also analyzes the influence of cumulative damage on mechanical performance degradation throughout the entire service life of the wire ropes. The findings provide essential data and technical guidance for the optimal use and maintenance of wire ropes in real-world applications. Therefore, the two wear behaviors of rope–rope contact and rope–sheave contact of the coal mine transportation wire rope under service conditions were selected as the research objects in this paper. The surface wear evolution characteristics and the mechanical property degradation law of wire rope under two contact states were compared and analyzed. Through homemade tribological testing machines and an infrared thermal imager, the real-time monitoring of the COF evolution and temperature rise due to friction in wire ropes under various sliding contact conditions was conducted. Then, the rope samples’ surface wear scar characteristics and morphology mechanisms were measured and analyzed by an optical microscope (Yongao Precision Instrument Co., Ltd., Shanghai, China) and scanning electron microscope (SEM) (Mocai Materials Science and Technology Co. Ltd., Shanghai, China). Finally, through the breaking tensile test and bending fatigue test of the worn wire rope, the influence of different wear evolution on the mechanical properties of the wire rope is analyzed. This study is of great help to more comprehensively reveal the wear mechanism and performance degradation of coal mine transportation wire ropes. It has important guiding significance for ensuring the safe and efficient service of the wire rope.

2. Materials and Methods

2.1. Samples and Materials

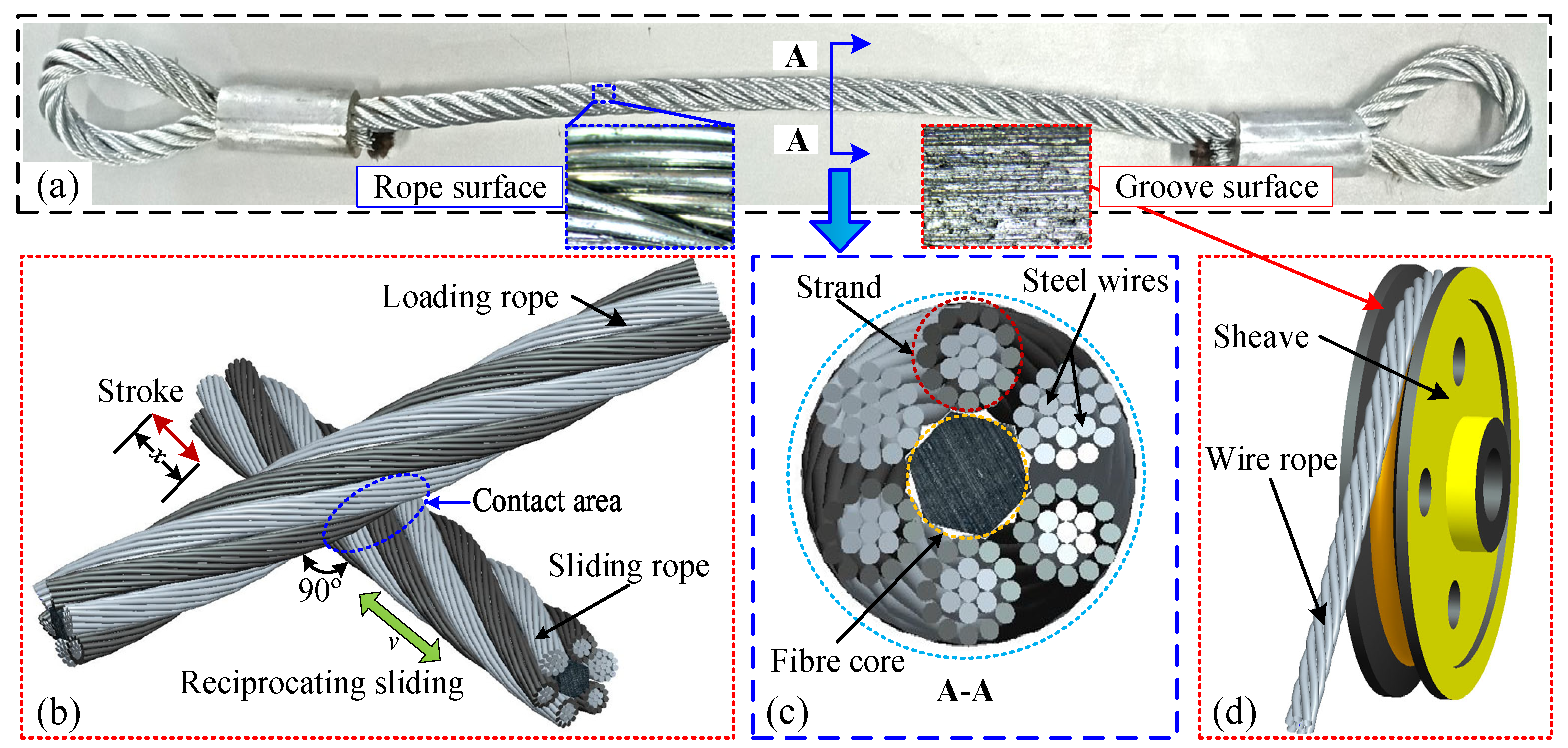

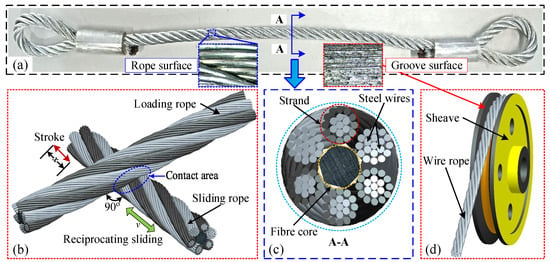

The structures of the rope sample and the sliding friction pairs selected in this study are shown in Figure 1. The steel wire rope (6 × 19 + FC) is made of 6 strands and 1 fiber core. The material of the rope core is a man-made fiber (viscose fiber), which is a regenerative fiber made of natural cellulose and is chemically processed. Its tensile strength is about 0.16–0.27 MPa. Additionally, each strand comprises 19 galvanized steel wires (see Figure 1c). Furthermore, the thickness of the galvanized coating on the steel wires is less than 20 μm. The density of the galvanized steel wire is 7.81 × 103 kg/m3. The Vickers hardness of the rope wires is about 500–550 HV. Moreover, the detailed structure parameters of the wire rope are provided in Table 1, while the chemical composition of the wire material is presented in Table 2. Furthermore, the structures of the rope–rope contact pair and rope–sheave contact pair are shown in Figure 1b,c. The sheave is fabricated from a Q235 steel plate. Its chemical composition (by weight) includes 18% (C), 46% (Mn), 27.5% (Si), 4.5% (S), and 4% (P). The hardness of the sheave groove surface is about 130–140 HV. The sheave has a diameter of 400 mm, with a rope groove diameter of 14 mm.

Figure 1.

Wire rope samples with different contact forms: (a) wire rope sample; (b) rope-rope contact; (c) rope structure; (d) rope-sheave contact.

Table 1.

Structural and mechanical parameters of the rope sample.

Table 2.

Chemical composition of wire rope material.

2.2. Wear and Mechanical Test Procedure

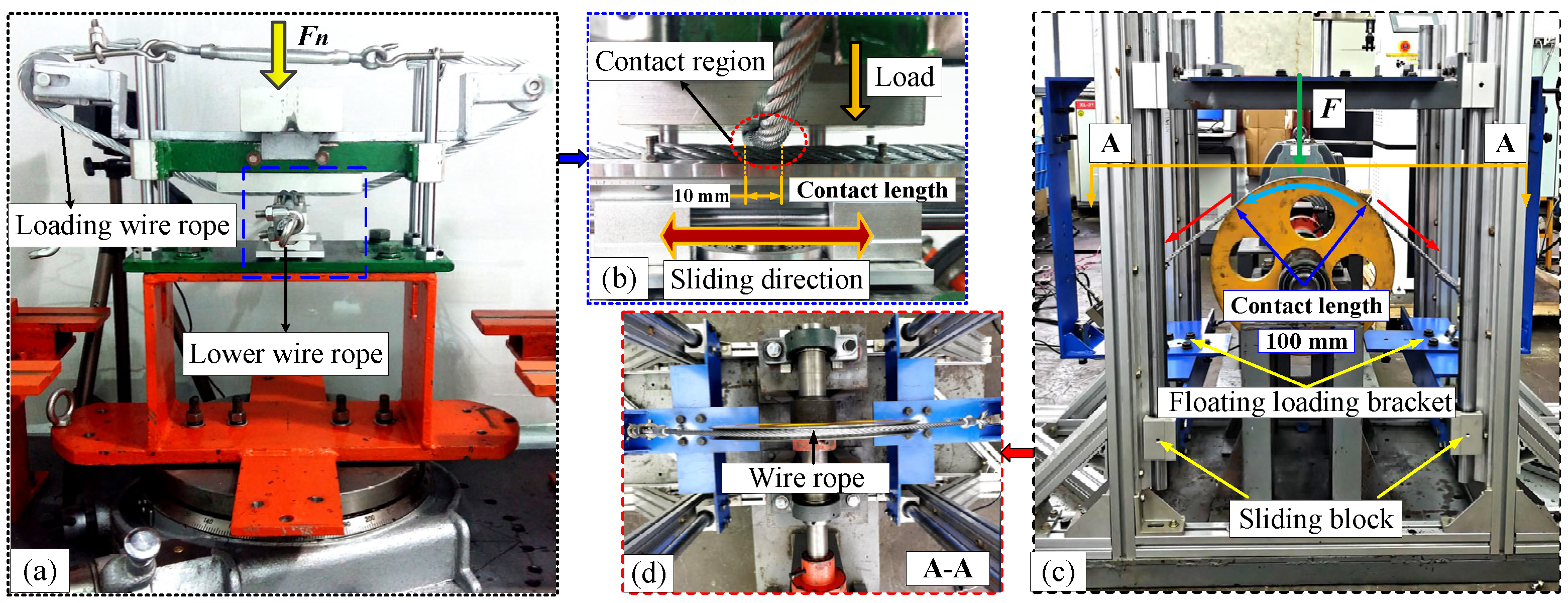

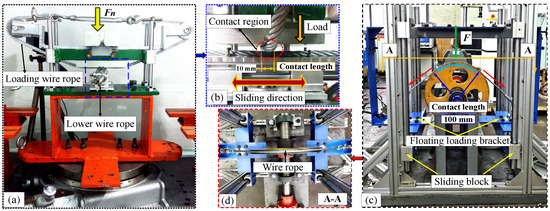

To simulate two typical sliding wear behaviors of coal mine transportation wire rope, two friction and wear test rigs of the wire rope were developed, as shown in Figure 2. The rope–rope sliding wear tester can realize the reciprocating sliding of two wire ropes in the cross-contact state (refer to Figure 2a,b). The contact load, sliding velocity, and cross angle are adjusted by the floating loading device, speed-regulating motor, and rotating platform. The stroke of reciprocating motion is 20 mm, the sliding speed is 12 mm/s, and the experimental frequency under the rope–rope friction pair is approximately 0.3 Hz. The experimental simulation device of the rope–sheave sliding wear behavior is illustrated in Figure 2c,d. Under certain load conditions, the steel wire rope is tensioned in the rope groove of the sheave. During the experiment, the tension of the steel wire rope is approximately 1000 N. Then, driven by the motor, the sheave rotates continuously and the sliding wear of the rope–sheave contact pair is realized. Through the two kinds of damage behavior simulation test devices of the wire rope, the tribological characteristics of the wire rope under different contact conditions can be revealed. Moreover, each test was conducted in triplicate. The final results presented are the average values, and the error bars in this paper represent the range of the three data points obtained from the repeated tests. Then, wire rope samples with varying wear characteristics can be obtained. The detailed parameters of the sliding friction wear test are shown in Table 3. During long-distance transportation in coal mines, the steel wire rope frequently comes in contact with the sheave. Compared with the relative sliding between the steel wire ropes on the drum, the sliding speed, contact load, and sliding distance of the rope–sheave friction pair increase significantly. Therefore, the friction experimental parameters of different contact pairs are different, which is helpful for more accurately comparing and analyzing the different surface wear conditions of the steel wire rope under the same service conditions.

Figure 2.

Friction and wear test rigs: (a,b) sliding wear between wire ropes; (c,d) sliding wear between rope and sheave.

Table 3.

Parameters of sliding friction tests.

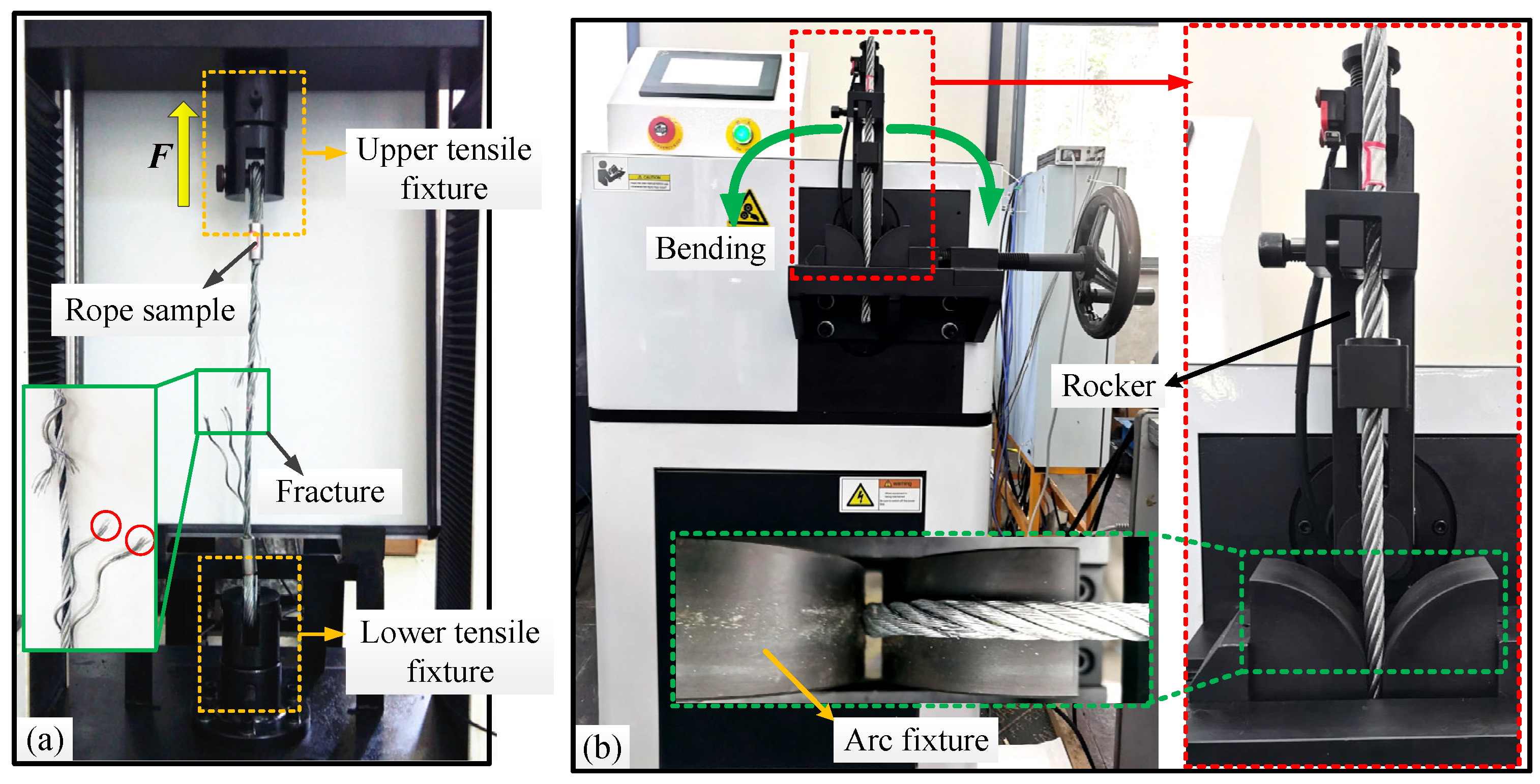

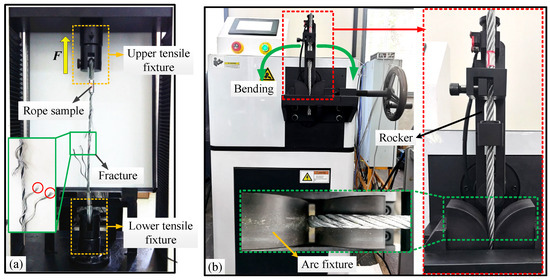

To explore the effects of these two kinds of surface wear on the tensile and bending fatigue properties, the important load forms of service wire ropes, the mechanical tests were carried out by customized mechanical performance testing devices, as shown in Figure 3. Additionally, the differently damaged rope samples were divided into two groups according to the sliding distance and contact form, which are used to carry out the breaking tensile test (see Figure 3a) and bending fatigue test (see Figure 3b), respectively. To accurately evaluate the impact of wear evolution on the mechanical properties of steel wire ropes and to clearly analyze the load variation process, the tensile speed for the breakage tensile test and the bending frequency for the bending fatigue test were standardized. The specific test parameters are outlined in Table 4. Furthermore, the force–elongation curves of different rope samples were studied during the uniform tensile test. The rope samples’ fracture evolution characteristics in the bending fatigue process were also analyzed. Moreover, through the experimental study of mechanical properties, the influence of wear evolution on the service performance degradation of the wire rope under different sliding contact conditions of the worn wire ropes under various contact conditions were revealed, respectively.

Figure 3.

Mechanical performance test machines: (a) breaking tensile test; (b) bending fatigue test.

Table 4.

Parameters of mechanical performance tests.

2.3. Method

In this paper, the variation in the COF of the wire rope during the wear process is explored by the tension pressure sensor and the torque sensor (Bengbu Zhongnuo Sensor Co., Ltd., Bengbu, China) installed in the friction and wear tester. Under the rope–rope contact condition, the tension sensor can measure the frictional resistance of the sliding wire rope during the reciprocating motion. Under the rope–sheave contact condition, the dynamic torque sensor detects the torque caused by friction during the sliding rotation process. Through the parameters measured by the sensors, the COF of the wire rope can be calculated. Moreover, During the reciprocating sliding friction experiment, a hysteresis loop of the friction force is observed. Given the relatively low sliding velocity, both the forward and return strokes exhibit stable phases of friction force. Consequently, the COF analyzed in this study is determined as the average value of the COF during the stable phase of the forward stroke. An infrared thermal imager (ThermoX, Shanghai Juge Electronic Technology Co., Ltd., Shanghai, China) was used to detect the sliding friction area of the wire rope, and the characteristics of temperature increase due to friction under various working conditions were studied. Furthermore, the profile distribution features of wear scars on the rope surface were examined using an electronic measurement microscope. Then, the evolution of wear loss, wear width, and wear rate were statistically analyzed with an electronic balance (measurement accuracy 0.1 mg) and the image measurement software (Digital-Camera 6.0). Finally, the degradation characteristics of the maximum breaking force and bending fatigue life of wire ropes with varying degrees of surface wear were analyzed based on the mechanical property test data.

3. Results and Discussion

3.1. Friction

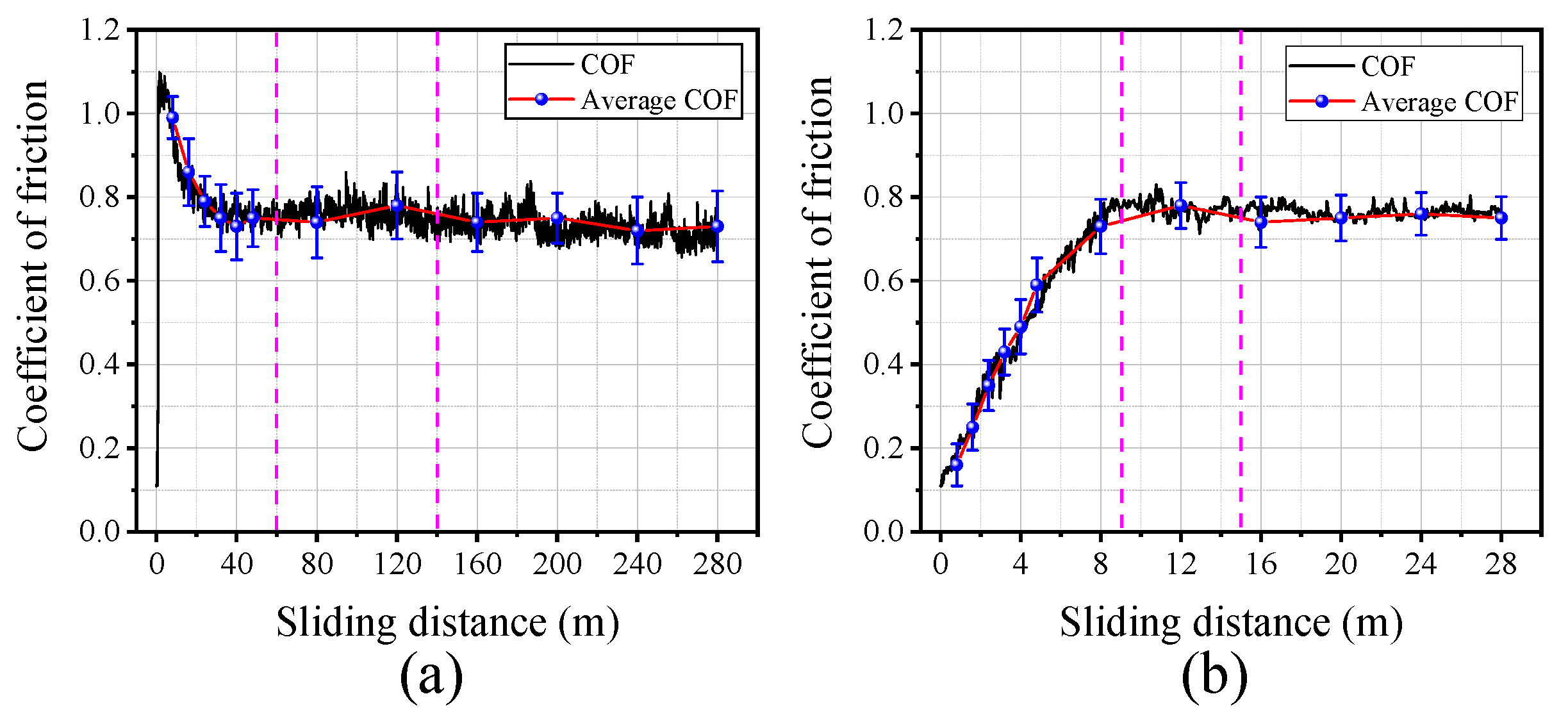

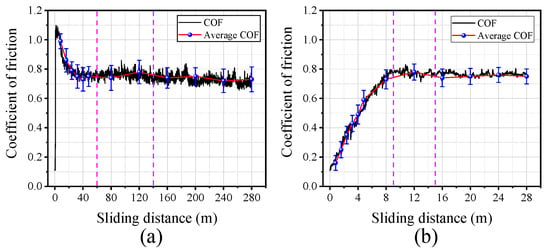

The friction characteristics of wire ropes are intricately linked to the operational stability of the rope transportation system. This study investigates the COF and temperature rise due to friction for the wire rope under various friction pair conditions. Figure 4 shows the variation curve of the COF as a function of sliding distance. Under the condition of rope–sheave sliding contact (see Figure 4a), the COF reaches the maximum at the moment of relative motion of the contact pair and then decreases rapidly. The COF is gradually stable when the sliding distance is more than 60 m. Furthermore, after approximately 140 m of relative sliding, the COF becomes relatively stable. It is approximately 0.72. The higher initial COF observed in the wire rope during the early stages of testing can be attributed to several factors. Firstly, the contact surface being curved increases the complexity of the contact mechanics. Secondly, the relatively high sliding velocity between the friction pair leads to increased dynamic effects. Additionally, the presence of inertial impacts further exacerbates the frictional resistance, resulting in a higher COF at the onset of the test. However, as the friction pair is rope–rope contact, the COF increases rapidly during the experiment (approximately 9 m), reaching a relatively stable state after a short fluctuation. The mean COF during the stable phase is approximately 0.75. In the relevant research literature, Cruzado et al. [30] found that the COF between the wires inside a steel wire rope is stable at around 0.7. Additionally, Wang et al. [31] investigated the bending friction fatigue behavior between the steel wire rope and the sheave groove material in offshore platform winches, revealing that the COF between these components is approximately 0.6. This indicates that the friction coefficients of steel wire ropes exhibit significant variations under different working conditions. Comparing the variation patterns of the COF for the two distinct contact pairs of the wire rope, it can be found that the COF during the stable phase is very close, while there is a big difference in the evolution of the COF during the initial sliding phase. This phenomenon can be attributed to the significant variations in the contact surface characteristics of the wire rope when subjected to two distinct friction pairs. Under the condition of rope–sheave sliding contact (see Figure 4a), the surface of the contact pair is curved. Considering that the relative sliding speed of the friction pair is relatively fast, the friction resistance is large under the influence of inertial impact, resulting in a large COF of the wire rope at the onset of the test. Additionally, the sliding contact area of the rope sample is long. Considering the complex irregular spiral structure of the rope surface, the rope–sheave contact pair is mainly point contact and line contact. As the sliding distance increases, the surface of the wire rope wears at an accelerated rate under the influence of large contact stress, and the real contact area of the rope–sheave contact pair increases quickly. Therefore, the COF decreases quickly in the early stage of the test. Considering the wire rope and its constituent steel wires exhibit a cylindrical geometry, the contact region does not expand rapidly in the process of the sliding wear experiment. The contact surface of the friction pair gradually becomes stable. Consequently, the COF also reaches a relatively stable condition. Moreover, when the friction pair transitions to rope–rope contact (see Figure 4b), the contact area of the wire rope that undergoes sliding motion is relatively limited, and there is direct contact between multiple steel wires. The surface of the friction pair gradually progresses to rough from smooth during sliding wear. Furthermore, the relative sliding speed of the rope–rope contact pair is generally slow. Thus, the COF of wire rope in the running-in wear stage shows an increasing trend. Comparing the COF curves of two kinds of friction contact pairs for the wire rope, it can be found that the impact of contact type on the COF is mainly concentrated in the early stage of the friction experiment.

Figure 4.

The COF curves of the wire rope under different contact pairs: (a) rope–sheave contact; (b) rope–rope contact.

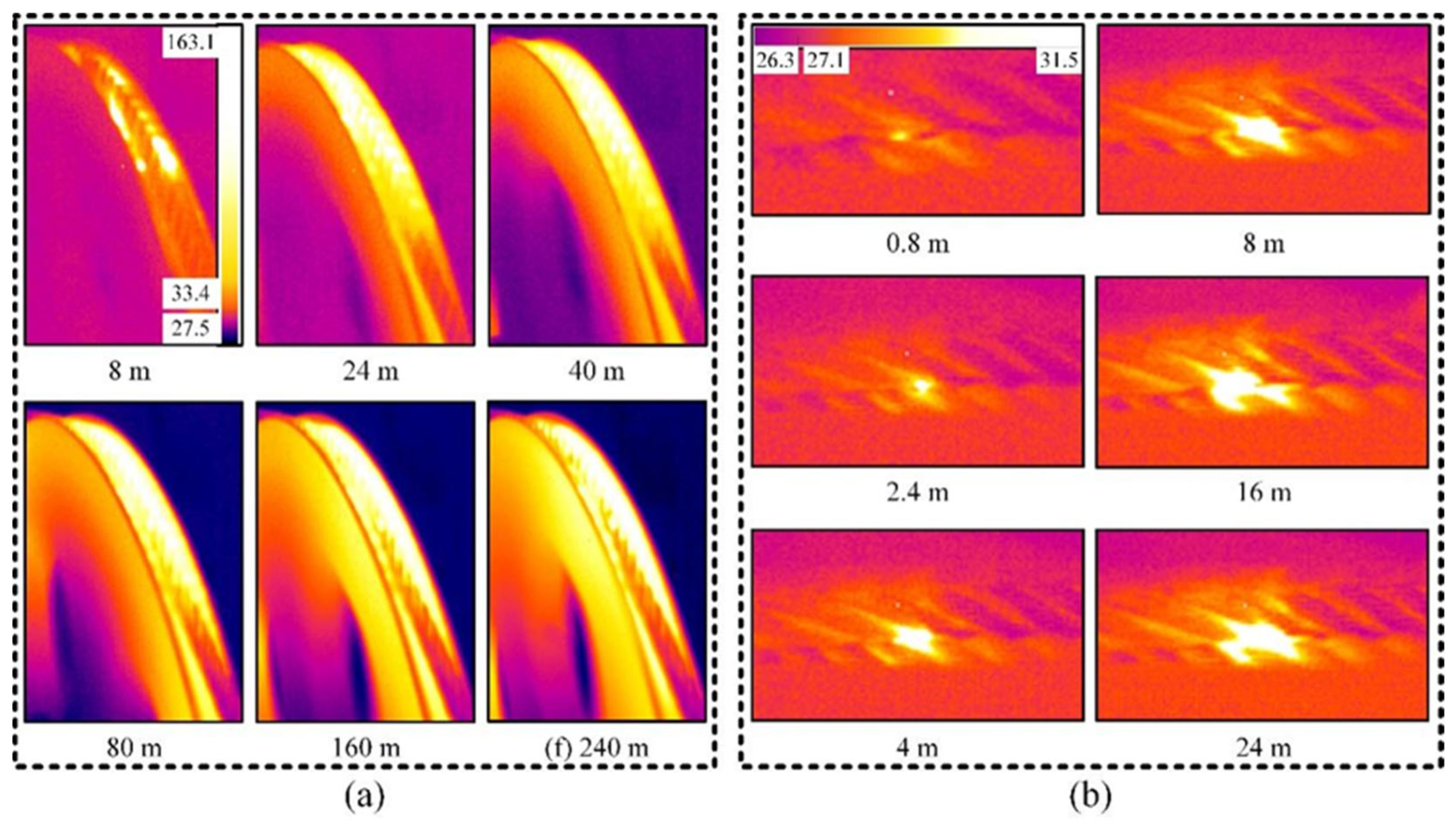

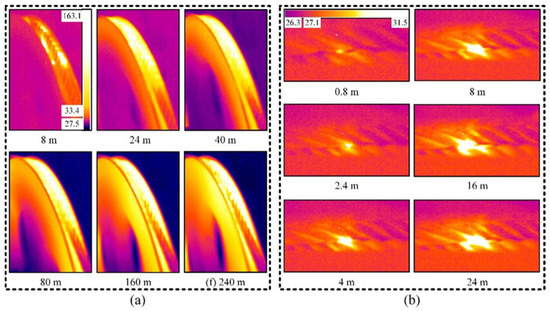

Figure 5 presents the infrared thermal imaging of the friction area for the wire rope under various contact pairs. The infrared thermal imager can visually monitor the dynamic contact characteristics and friction heat changes in different wire rope friction pairs. With the increase in sliding distance, the color intensity in the sliding contact region progressively becomes more pronounced. At the same time, the bright area becomes larger and larger. This indicates that the friction heat continues accumulating during the experiment, and the contact region between the friction pair components expands. Under the condition of rope–sheave contact (Figure 5a), the heat generated is transferred from the contact surface to both the wire rope and the sheave during the friction experiment. The surface temperature increased significantly, but the temperature of the wire rope increased faster. This is because the volume of the sheave is larger. Additionally, it is in a continuous rotation state, and the absorbed heat is transferred outward faster. Compared with the experimental results of the rope–sheave contact pair, the temperature rise in the rope–rope contact pair during the experiment is milder (see Figure 5b). The thermal energy resulting from friction is predominantly localized at the interface of the contact pair, thereby preventing a significant rise in the temperature of the entire wire rope. This is because the sliding speed of the wire rope is slow and the contact area is small, resulting in little temperature rise during the friction experiment. Therefore, the evolution of friction-induced temperature rise in the wire rope exhibits markedly different behaviors when subjected to two distinct contact pair configurations. The temperature rise caused by the rope–sheave contact pair is more intense.

Figure 5.

Infrared thermal images of the friction pairs under different sliding distances: (a) rope–sheave contact; (b) rope–rope contact.

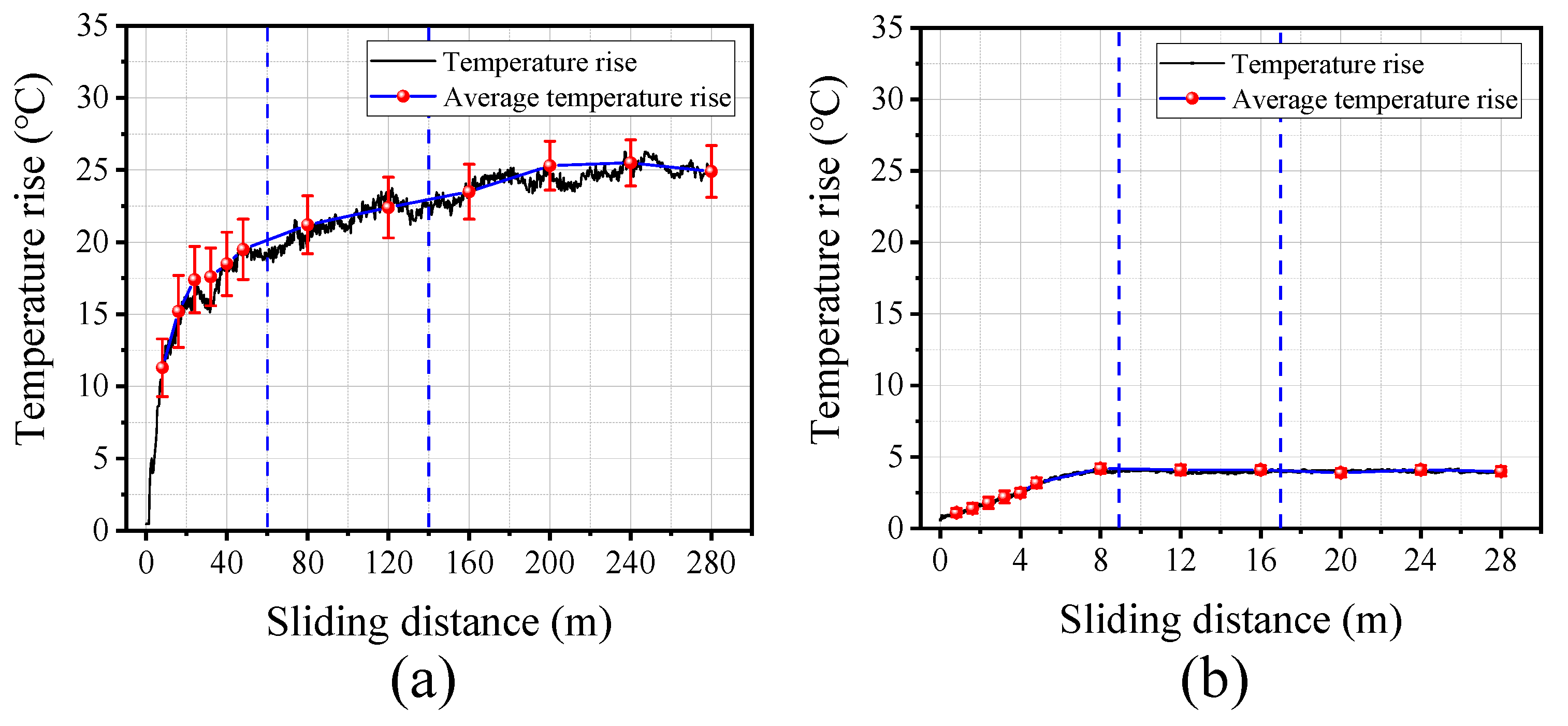

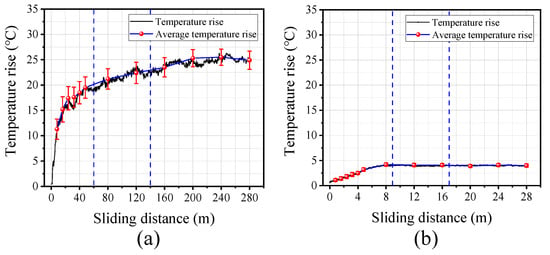

The curves of friction temperature rise under different contact conditions are shown in Figure 6. It is apparent that the temperature rise resulting from friction in the wire rope, when interacting with different sliding contact pairs, demonstrates consistent patterns of variation. The temperature rise increases rapidly during the early phase of the friction experiment, then the curves gradually stabilize and ultimately reach a comparatively stable phase. Additionally, the three stages of change correspond to the evolution of the COF, as shown in Figure 4. However, the influence of different friction pairs on the curve characteristics of various stages is also obvious. Under the condition of rope–sheave contact, the temperature rise rate of the friction pair is faster. When the sliding distance reaches 60 m, the temperature rises to approximately 20 °C. This is because friction heat generation is closely related to friction and wear. During the early phase of the sliding friction experiment, the COF is small but increases rapidly. At the same time, the surface characteristics of the friction contact area also change greatly. Thus, the increased rate of temperature rise is larger in the first 60 m of the sliding process. As the COF and wear state tend to be stable, the thermal energy produced by sliding friction progressively reaches equilibrium with the heat exchange and dissipation characteristics of the contacting surfaces. The friction temperature rise is stable at approximately 25 °C (the actual temperature of the wire rope is about 50 °C). Furthermore, compared with the experimental results in Figure 6a, the rapid increase stage of the temperature curve in the rope–rope contact state is slower, and the stable stage is more stable (see Figure 6b). This is because the heat dissipation conditions of the two wire rope friction pairs are quite different. The sliding contact area of the wire rope is small, and the heat dissipation is mainly through air. Moreover, when the sliding speed is slow and the load is light, the total heat generated by sliding friction is less. The temperature rise finally stabilizes at approximately 4 °C (the actual temperature of the wire rope is about 29 °C). Compared with the braking condition, the temperature rise generated by the friction pair of the transportation wire rope is relatively low. Lu et al. [32] investigated the friction behavior and wear evolution of railway friction blocks under extreme braking conditions. During the test, the temperature of the friction pair gradually increased from approximately 100 °C to 500 °C, and the friction coefficient also changed accordingly. Although the temperature rise in the friction pair studied in this paper was not very obvious during the experiment, it still had an impact on the tribological behavior of the wire ropes. Through this part of the analysis, it is observed that the contact pair between the rope and sheave typically results in a higher temperature rise in the process of engineering application, which can be used as an important parameter for monitoring the friction state of the transmission wire rope.

Figure 6.

Temperature rise curves with different contact pairs: (a) rope–sheave contact; (b) rope–rope contact.

3.2. Wear

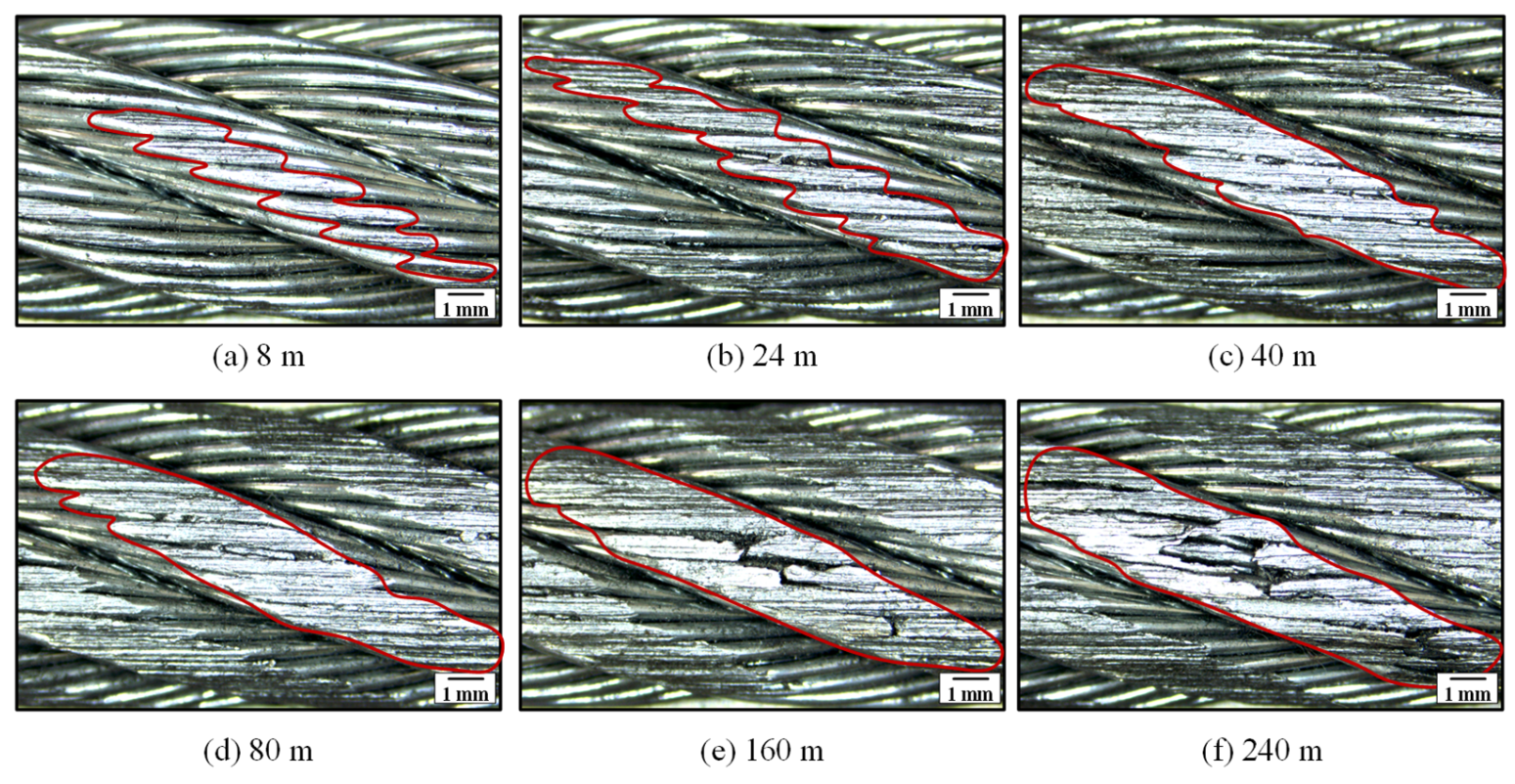

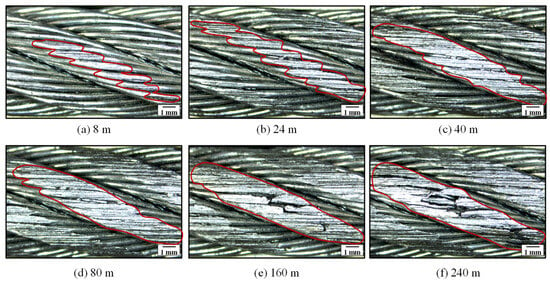

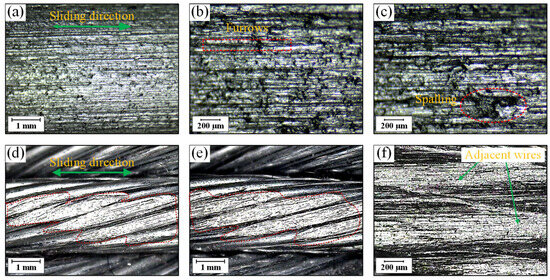

The wear scars of the wire rope subjected to rope–sheave sliding wear are presented in Figure 7. As the sliding wear distance increases, the evolution of surface wear on the wire rope is obtained. The extensive contact surface between the wire rope and the sheave, which is about 100 mm, results in wear scars appearing across several strands on the surface of the wire rope. In this paper, the wear scars on the middle strand of the sliding wear area of the wire rope are selected for comparative analysis. It can be seen that when the distance of sliding is under 40 m, wear scars on the surface of the strand are irregularly oval. Additionally, affected by the twist direction of the rope strand and the steel wire, the wear scars generated by the rope–sheave friction pair are distributed along the axis direction of the surface steel wires. Due to the light wear degree during the preliminary phase of the sliding wear experiment, the wear depth at the wear scar is small, and the distance between the wires is visible, leading to a jagged appearance of the wear scar on the surface of the wire rope. This process corresponds to the rapid change stage of the COF and the temperature rise. This is because the wear area increases while the surface becomes smoother and more complete. Furthermore, as the sliding distance extends from 80 m to 240 m, the contour of the wear scar becomes more regular, and the wear is more severe. Large amounts of wear debris and surface extrusion deformation are generated during the wear process, and the wear depth increases, resulting in the gap between the wires being filled, the surface of the wear scars being more complete, and the contour being smoother (see Figure 7d). However, as the wear distance increases, the surface steel wire has serious material loss, and the bearing capacity degrades greatly. Wang et al. [31] studied similar issues. They found that the center position of the contact area between the steel wire rope and the rope groove was the most severely damaged, and the bending stress and friction coupling effect in this area were the most obvious. In addition, as the number of wear cycles increased, the degree of wear became more and more severe. This is consistent with the wear evolution trend of the steel wire rope under the working conditions studied in this paper. Therefore, the wire, which exhibits significant damage in the central region of the wear scar, experiences failure as a result of frictional forces and dynamic contact stresses.

Figure 7.

Wear scars caused by rope–sheave sliding contact.

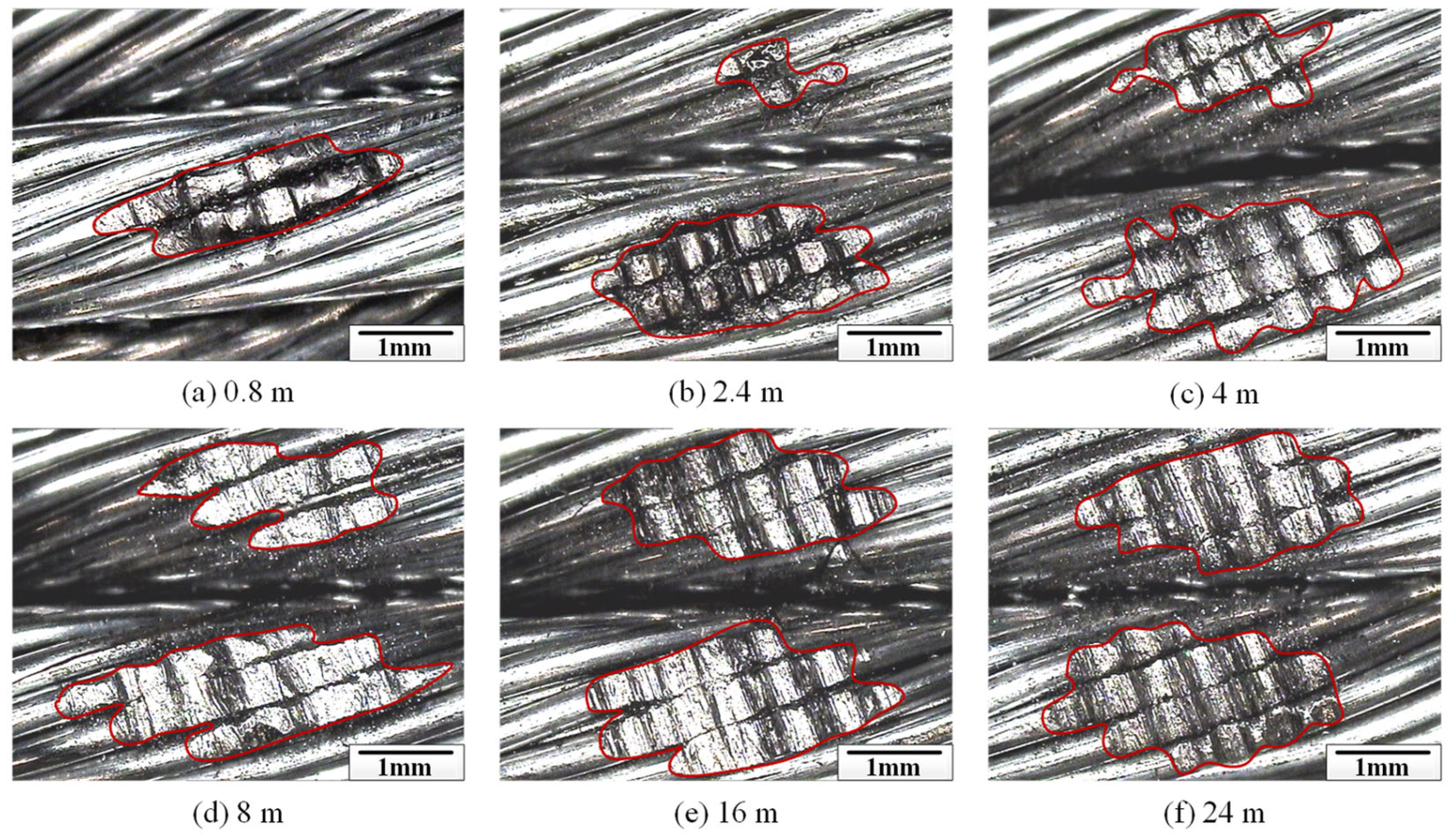

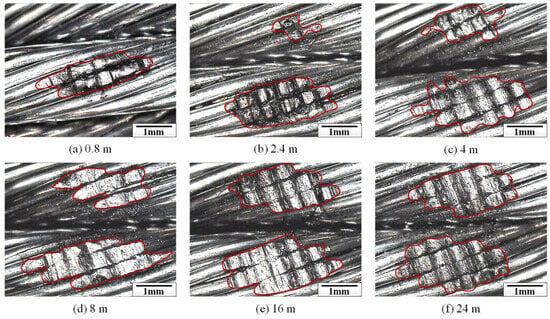

Under the condition of the rope–rope sliding friction test, Figure 8 illustrates how wear scars on the surface of the loading rope develop as the sliding distance increases. The contour characteristics and distribution of the wear scar differ from the experimental results under the condition of rope–sheave contact. Because the length of the sliding contact area is only about 10 mm, the surface wear of the wire rope is very concentrated. Although the profile of the wear scar is still nearly elliptical on the surface of the rope strand, the overall size is significantly smaller. When the sliding distance is short, the wear area is small and concentrated on the rope strand (see Figure 8a). Only two steel wires are damaged. As the sliding distance increases, the wear area gradually distributes across the surfaces of both strands (see Figure 8b,c). This is because the surface structure of the wire rope is complex. The unevenness of the friction pair’s surface is a result of the space between the wires and strands. Additionally, the increasing wear depth during the wear process reduces the influence of irregular surface pairs and increases the contact area of the rope–rope friction pair. As the sliding distance increases, the wear scars become progressively and uniformly spread across the surfaces of both strands due to relative sliding action, as illustrated in Figure 8d–f. Furthermore, due to the multi-wire spiral structure of the friction pair, multiple grooves caused by the sliding wear of the steel wires appear on the wear surface under the condition of the rope–rope contact pair. Moreover, there is also a big difference in the wear degree in the wear scar area. The wear depth in the middle of the wear area is the largest. Thus, the damage is the most serious in the middle position of the ellipse, and the wear observed at both ends is comparatively slight. The primary reason for this is the circular arc configuration of the wire rope friction pair. Compared with the wear evolution between the internal wires of the steel wire rope, the external wear of the steel wire rope is more complex. The damage profile caused by the inter-wire wear is also an irregular ellipse, mainly due to the accumulation of wear debris and plastic flow [12]. Therefore, through the surface damage features of the transport wire ropes, the contact form that causes its damage can be distinguished, and targeted protection and maintenance can be carried out during the use and maintenance process.

Figure 8.

Wear scars caused by rope–rope sliding contact.

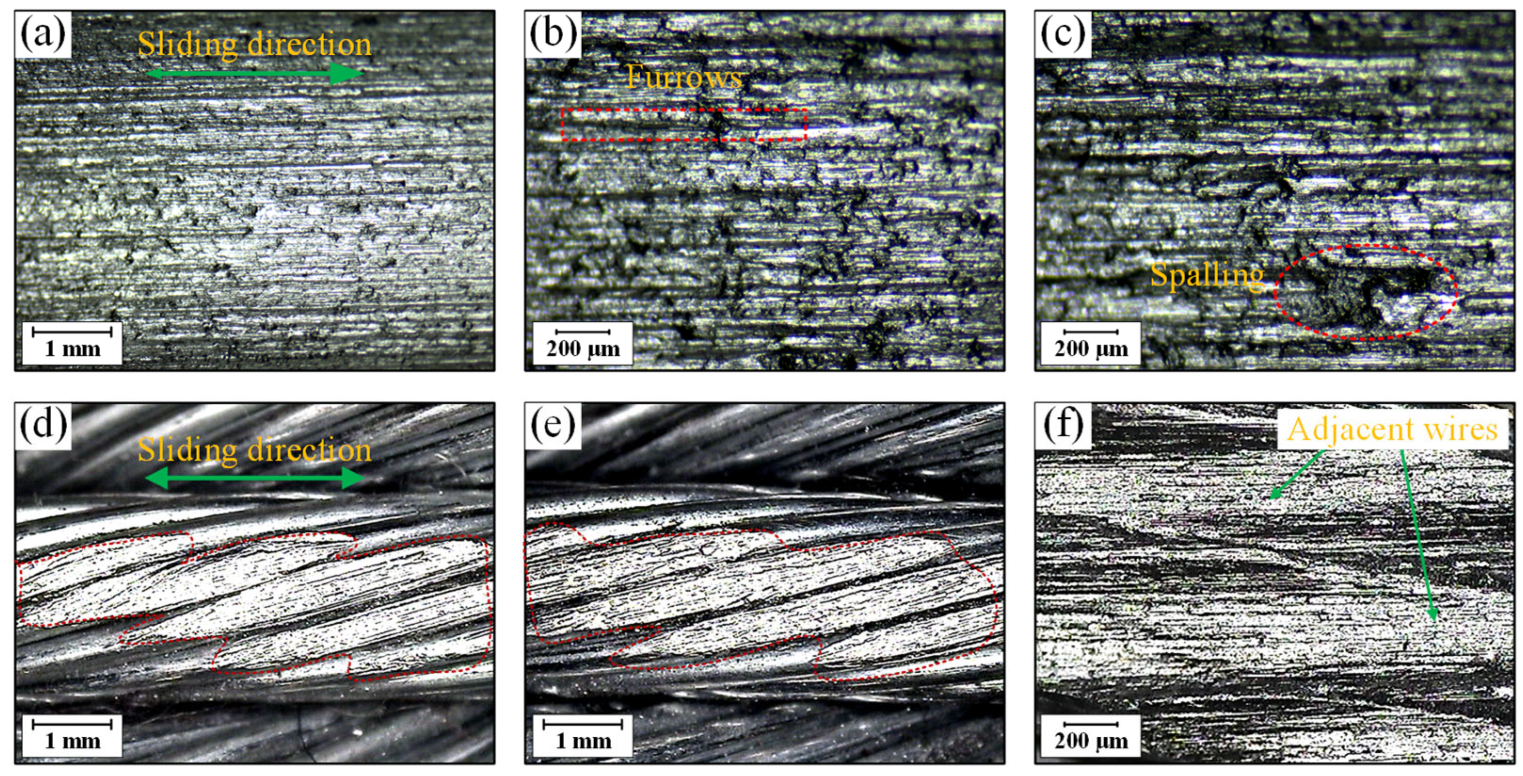

The wear appearances of the counter bodies under different friction pairs are presented in Figure 9. Because the surface characteristics of the counter pair of the wire rope change relatively little in the wear evolution, the typical wear morphology of the moving friction pair was analyzed. In the context of the rope–sheave friction experiment, the wear appearances of the rope groove are shown in Figure 9a–c. The furrows along the sliding direction are distributed on the surface of the rope groove. Additionally, the surface is relatively rough, and obvious plastic deformation and spalling can be seen. This indicates that the wear mechanism of the rope groove is mainly abrasive wear and adhesive wear. Because the surface structure of the loading wire rope is irregular, the surface material of the rope groove easily produces extrusion deformation and adhesion under the influence of friction heat. Moreover, under the condition of the rope–rope friction pair, the wear scars of the sliding wire rope are shown in Figure 9d–f. During the wear test, the wear scars of the sliding wire rope change little and the surface is smooth. The wear morphology is similar to that of the loading wire rope. Due to the obvious gap between adjacent steel wires, different grooves appear in the wear region of the loading rope samples.

Figure 9.

Wear appearances of the counter bodies: (a–c) rope groove of the sheave; (d–f) sliding rope.

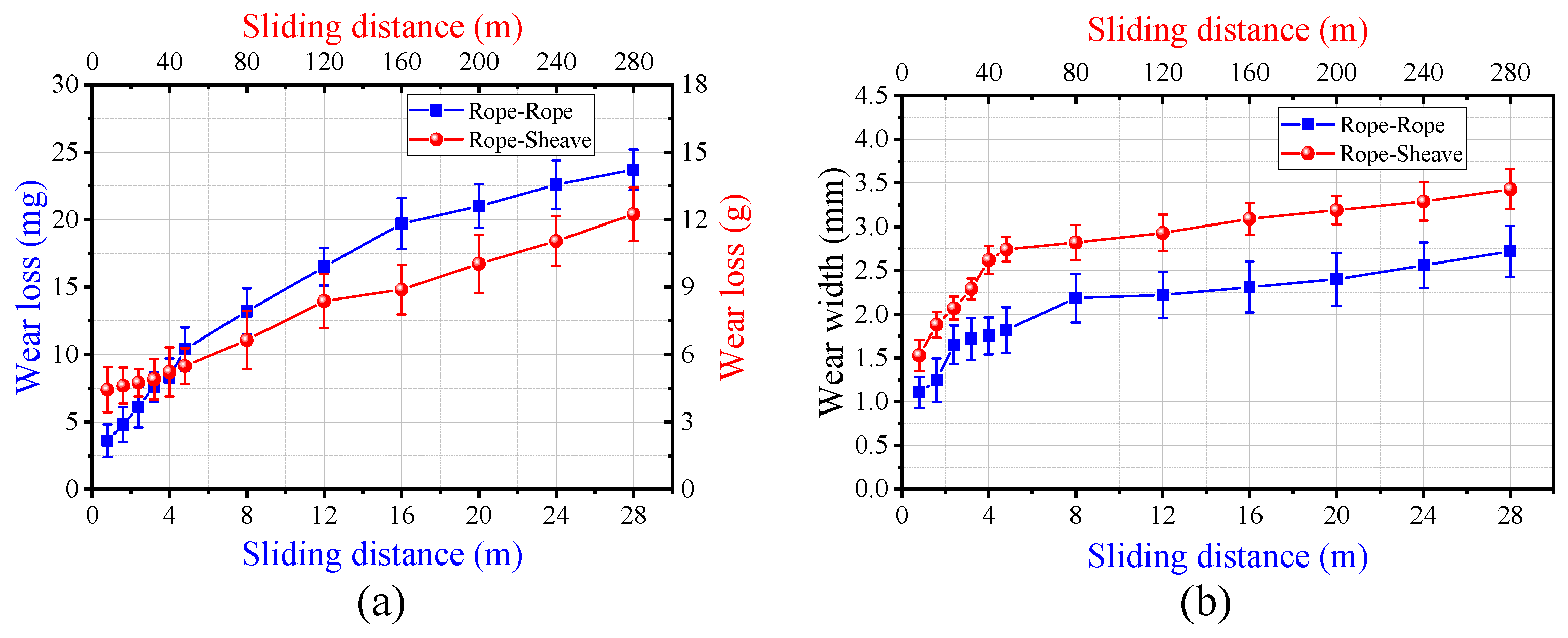

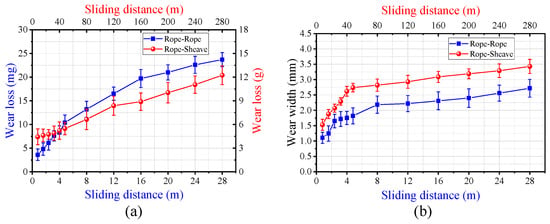

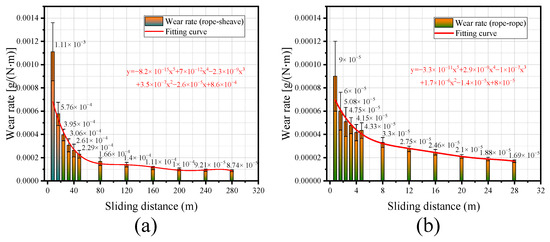

To quantitatively investigate the variation in the wear extent of the wire rope under various contact forms, this study calculates both the wear loss and the width of the wear scar, as depicted in Figure 10. As the sliding distance increases from 8 m to 280 m, the wear loss increases from approximately 4.5 g to 12.2 g, and the wear width increases from approximately 1.5 mm to 3.4 mm under the condition of a rope–sheave contact pair. Moreover, when the contact form changes to a rope–rope friction pair, the wear loss increases from approximately 3.8 mg to 23.7 mg, and as the sliding distance varies from 0.8 m to 28 m, the wear width expands from roughly 1.1 mm to 2.7 mm. The degree of surface wear under the condition of rope–sheave contact is greater than that under the condition of rope–rope contact. In particular, the difference between the two is one order of magnitude for the experimental results of wear loss (see Figure 10a). This occurs due to the surface wear of the wire rope being a cumulative and progressive evolution, and the contact area of the rope–sheave friction pair is larger. The wire rope and the sheave groove will produce large wear debris during the experiment. The wear width analyzed in this paper refers to the maximum wear width observed on a single-strand surface (see Figure 7). However, there is a big difference in the overall wear degree of the wire rope under the two contact states, and the difference in wear width is not as obvious as the result of wear loss (see Figure 10b). Additionally, the wear characteristic parameters showed a rapid growth trend at the beginning of the experiment, and then the growth rate slowed down. This is closely related to the variation in the above-mentioned wear scar distribution. Furthermore, influenced by the intricate circular arc structure of wire ropes, the increase in the wear depth will not lead to the rapid increase in the wear scar area in the later stage of the experiment, but the wear loss still shows a significant growth trend. Therefore, the degree of wear of the rope–sheave contact pair under similar working conditions is more serious. The change in wear loss can better reflect the wear evolution characteristics of the transmission wire rope.

Figure 10.

Damage parameters of rope samples under various contact pairs: (a) wear loss; (b) wear width.

The wear area on the rope surface exhibits significant irregularity, which poses a considerable challenge in accurately quantifying the wear volume. The complexity of these factors complicates the development of a consistent and reliable method for directly measuring wear. Therefore, this paper relies on the observed wear loss in the experiment to estimate the wear rate. Figure 11 provides a detailed illustration of the variation characteristics of the wear rate for both the rope–sheave and rope–rope friction pairs throughout the wear evolution process. As evident from the figure, the wear rate of the rope–sheave friction pair is substantially higher than that of the rope–rope friction pair. This disparity can be attributed to the distinct contact mechanics involved in each type of interaction. Specifically, in rope–sheave contact, the sheave’s surface exerts a more concentrated and localized force on the rope, leading to greater wear per unit area. In contrast, rope–rope contact involves a more distributed load, resulting in less severe wear. Despite the difference in wear rates between the two types of friction pairs, the trend in the change in wear rate as a function of sliding distance remains similar for both. Under rope–sheave contact conditions, the wear rate experiences a rapid decrease in the initial stage of sliding wear. This initial phase is characterized by high levels of surface roughness and microstructural changes, contributing to accelerated wear. However, as the sliding distance exceeds 80 m, the wear rate tends to stabilize. This stabilization can be attributed to the formation of a stable wear layer on the rope surface, which mitigates further material loss.

Figure 11.

Wear rate in various contact pairs: (a) rope–sheave contact; (b) rope–rope contact.

When the friction pair changes to rope–rope contact (as shown in Figure 11b), the wear rate also exhibits a relatively higher value at smaller sliding distances. Initially, the ropes’ surfaces are relatively rough and unconditioned, leading to increased wear. As the sliding distance increases, the wear rate decreases gradually and eventually stabilizes after surpassing 8 m. This behavior can be explained by gradually conditioning the rope surfaces, where the initial roughness is smoothed out, establishing a more uniform wear pattern. This phenomenon can be further understood by examining the expansion process of the wear scars on the rope surface, as depicted in Figure 7 and Figure 8. During the initial stages of sliding wear, the wear scars on the wire rope exhibit a significantly accelerated expansion. This rapid expansion is driven by the high levels of stress and strain experienced by the material at the contact points. Over time, however, the expansion slows down due to the influence of the structural shape of the rope. The inherent geometry and material properties of the rope play a crucial role in determining how the wear scars evolve, ultimately leading to a more predictable and stable wear behavior. In summary, the wear characteristics of wire ropes under different friction scenarios provide valuable insights into the mechanisms governing material loss and surface degradation. Understanding these mechanisms is essential for developing effective maintenance strategies and improving the longevity of wire ropes in various applications.

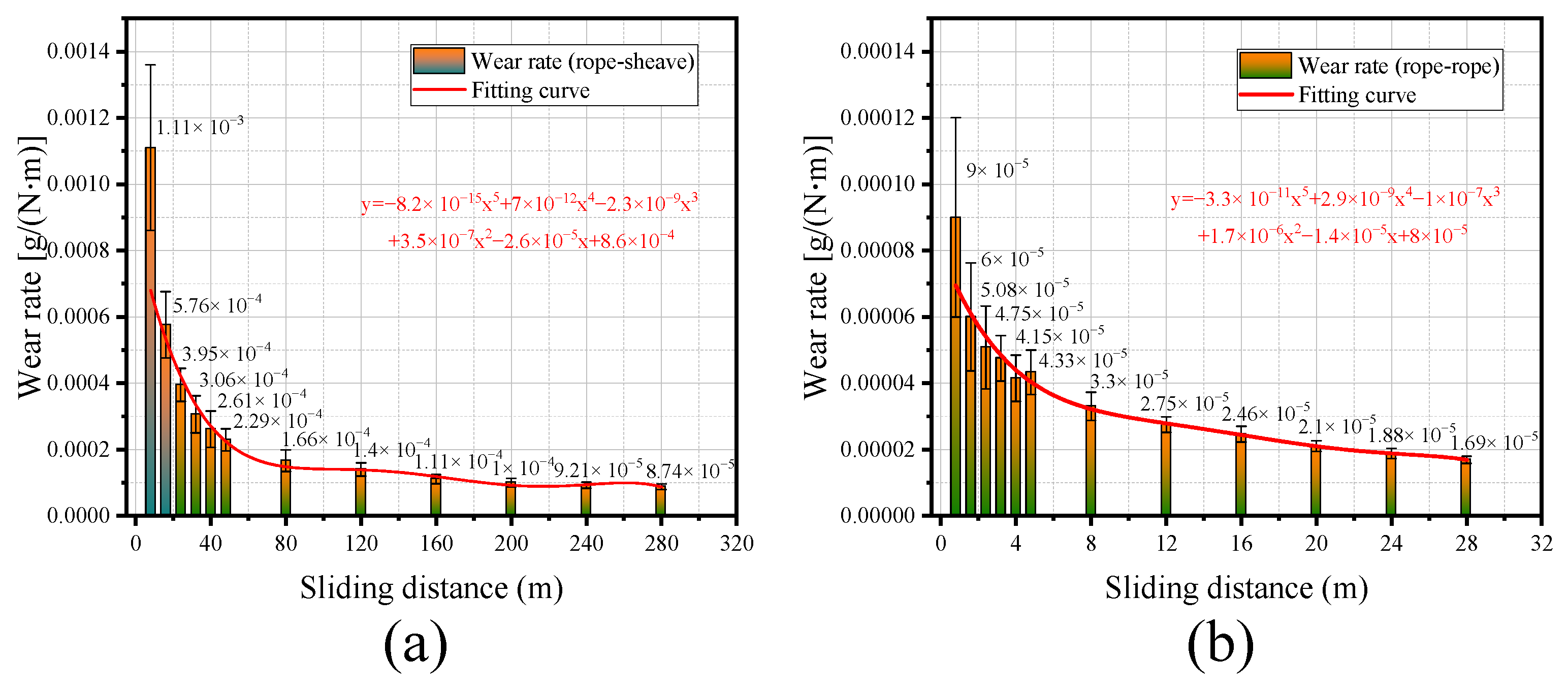

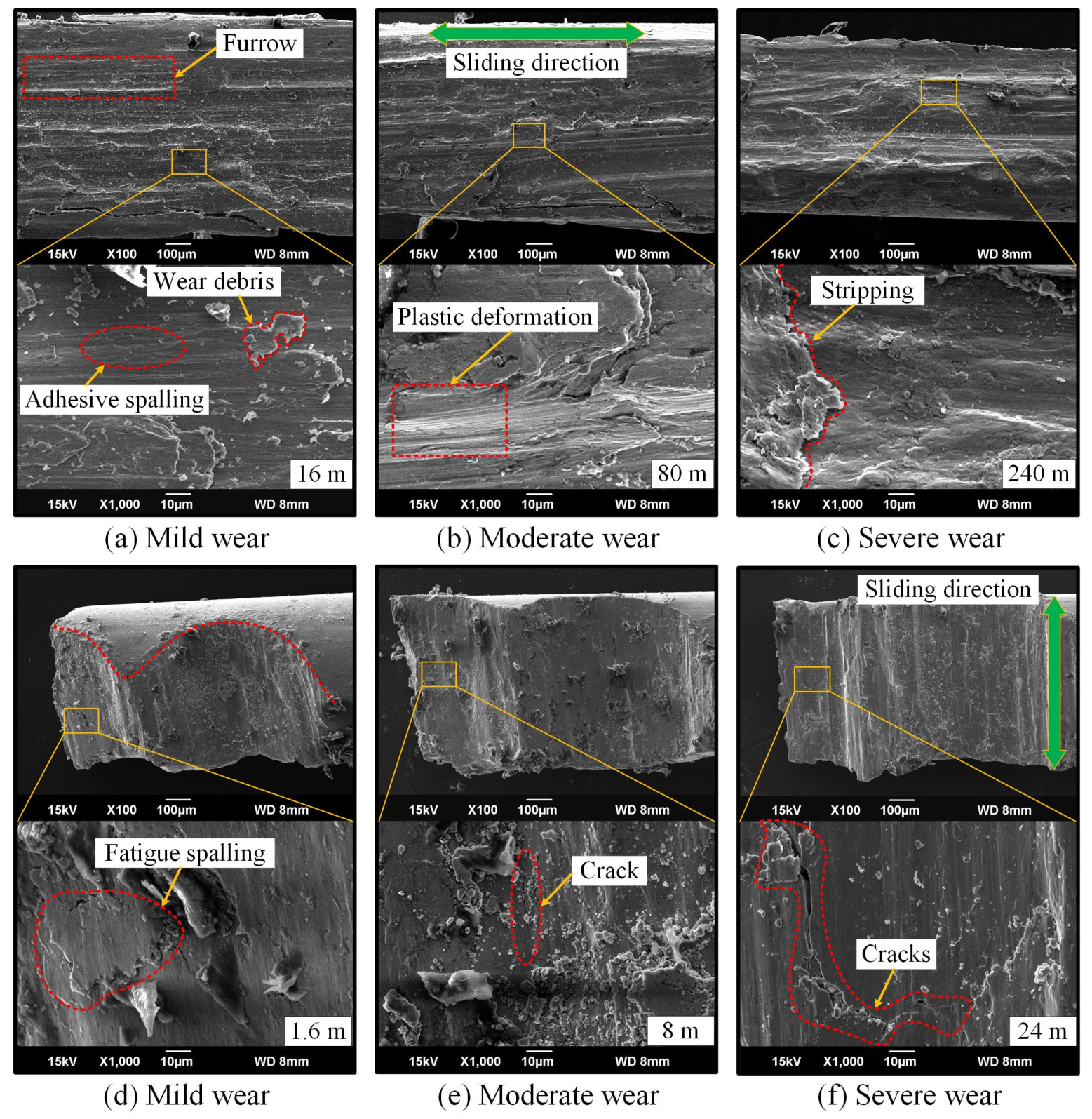

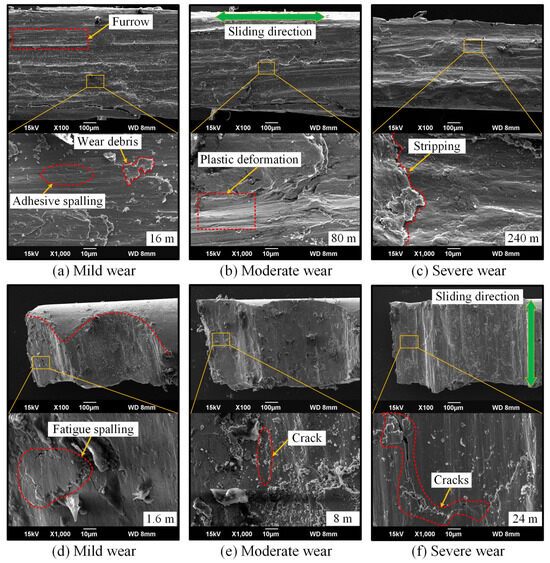

Figure 12 illustrates the representative microstructure of the wire rope’s wear surface under various friction pair conditions. Under the condition of rope–sheave contact, the sliding wear is relatively severe, and the furrows distributed along the sliding wear direction are obvious, accompanied by obvious plastic deformation, as shown in Figure 12a–c. The degree of wear can be roughly divided into three types. When the wear is mild, the furrows are small. The adhesive wear and fatigue wear characteristics are obvious, and the spalling of wear debris in the wear area is mainly caused by adhesion. With the evolution of wear, the surface damage becomes more and more severe (see Figure 12b,c). It can be seen that the number of furrows on the wear surface becomes less, while their size increases, and the features of plastic deformation become more pronounced. This is because the temperature rises rapidly during the friction test, resulting in the softening of the rope–wheel friction pair material. Although the temperature rise due to friction detected by the infrared thermal imager does not reach the melting point of the surface material of the steel wire rope, a relatively high instantaneous high temperature will occur at the sliding contact surface. Under the action of sliding impact load, this high temperature will induce the shear and plastic deformation of the steel wire rope material [33,34]. Additionally, metal materials are more prone to extrusion deformation during plowing. In the wear area of the wire rope, the fatigue spalling of the material is caused by continuous sliding extrusion deformation at the same position. Thus, the typical wear features include furrows and plastic deformation, and the wear mechanism is mainly adhesive wear and fatigue wear under the condition of a rope–sheave friction pair.

Figure 12.

SEM images of the surface morphology under various contact pairs: (a–c) rope–sheave contact; (d–f) rope–rope contact.

When the friction pair is rope–rope sliding contact, the wear characteristics have changed greatly, as illustrated in Figure 12d–f. Because the surfaces of the friction pair are irregular multi-wire spiral structures, the damaged area of the steel wire is mostly an uneven wavy surface. Additionally, the material spalling of the sliding wear surface is mainly caused by micro-cutting and stress fatigue. With the cumulative evolution of surface wear, the damage degree of wire rope becomes more severe. While the worn surface tends to be flat, different degrees of fatigue cracks appear. Therefore, under the condition of a rope–rope friction pair, there is a big difference in the wear degree of steel wire at the same wear region. The primary wear mechanisms involve adhesive wear and fatigue wear. Furthermore, the wear mechanism of steel wire ropes is closely related to influencing factors such as the material of the friction pair, the contact form, and environmental conditions. For the wear mechanism between internal steel wires, it is mainly fretting fatigue wear [17], while the damage of the steel wire rope directly in contact with the drum is mainly rolling fatigue wear, which subsequently induces crack propagation [14,15]. When affected by an acidic environment, the internal friction coefficient of the steel wire rope will decrease, but the wear will intensify, and the corrosion wear mechanism becomes more prominent [35].

3.3. Degradation Characteristics of Mechanical Properties

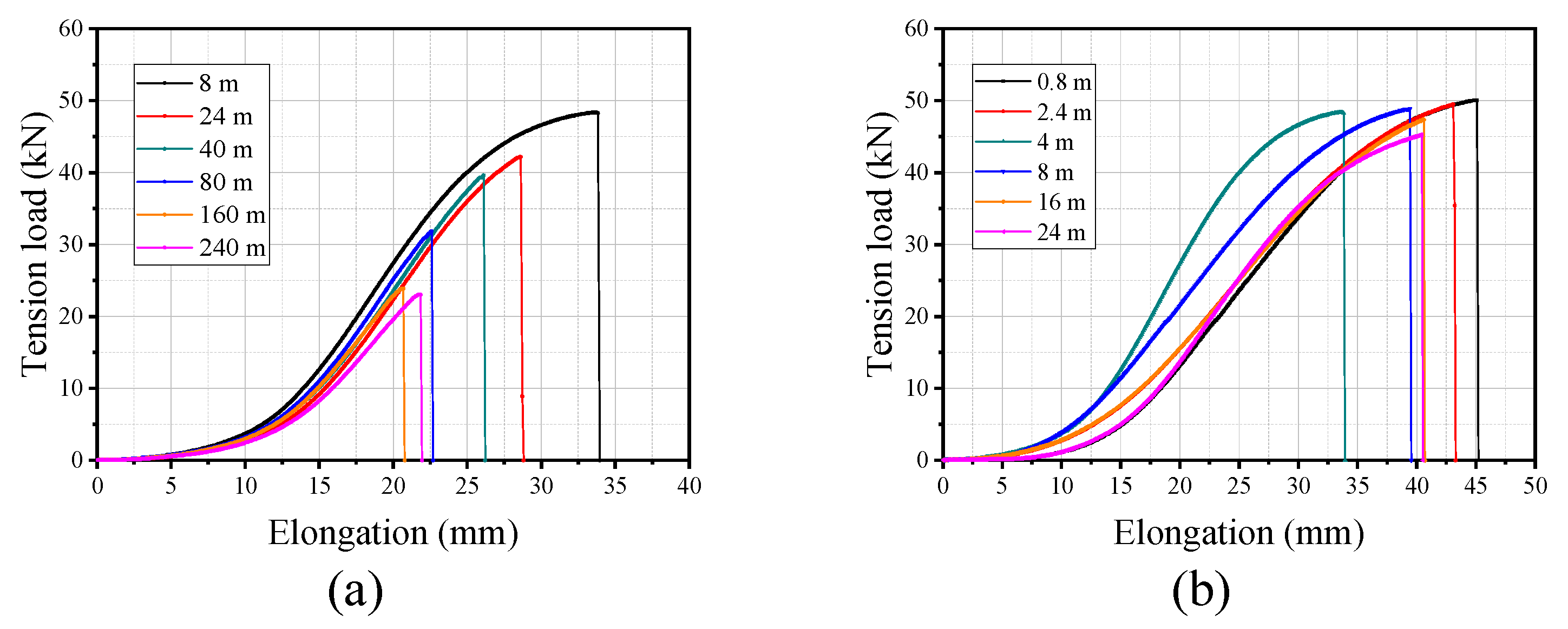

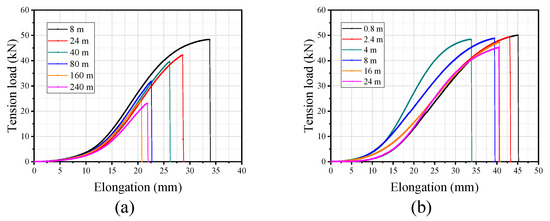

After the wear evolution tests, the force–elongation curves reflecting the degradation of mechanical properties are obtained by breaking the tensile test of different damaged wire ropes, as shown in Figure 13. In the process of uniform tension, the tension increases very slowly at the beginning of the test. After the elongation exceeds approximately 10 mm, the tensile load begins to increase rapidly. This phenomenon can be attributed to the complex structure of the wire rope, which leads to the contraction of internal wires and the elongation of the spiral structure during the tensile test. This stage is caused by the structural deformation of the wire rope, which increases the twist of the rope samples. Thus, the tensile load of the wire rope does not increase linearly with the axial displacement. As the elongation continues to increase, the structural deformation of the rope sample gradually reaches the limit, and the curve then enters the elastic deformation stage. Additionally, the surface wear evolution causes the maximum breaking force and elongation of the wire rope to decrease. This performance decay characteristic of the force–elongation curve is more obvious under the condition of rope–sheave contact friction (see Figure 13a). This indicates that the wear degree of the rope samples is severe and the difference is large. Because of the large damaged area of the wire rope in the rope–sheave contact state, a steel wire has multiple damages in different twist pitches, and the strength is greatly reduced. In the rope–rope contact state, the surface wear is local damage, and the quantity of damaged steel wires is minimal. Therefore, the maximum breaking force and elongation of the corresponding force–elongation curve change little, as shown in Figure 13b. Moreover, under rope–rope contact conditions, the change stage of the damaged rope samples in the tensile process is more complete, and the yield change before breaking is more obvious. This indicates that local damage has a relatively small effect on the tensile mechanical properties of the wire rope.

Figure 13.

The force–elongation curves of the damaged wire rope caused by different contact forms: (a) rope–sheave contact, (b) rope–rope contact.

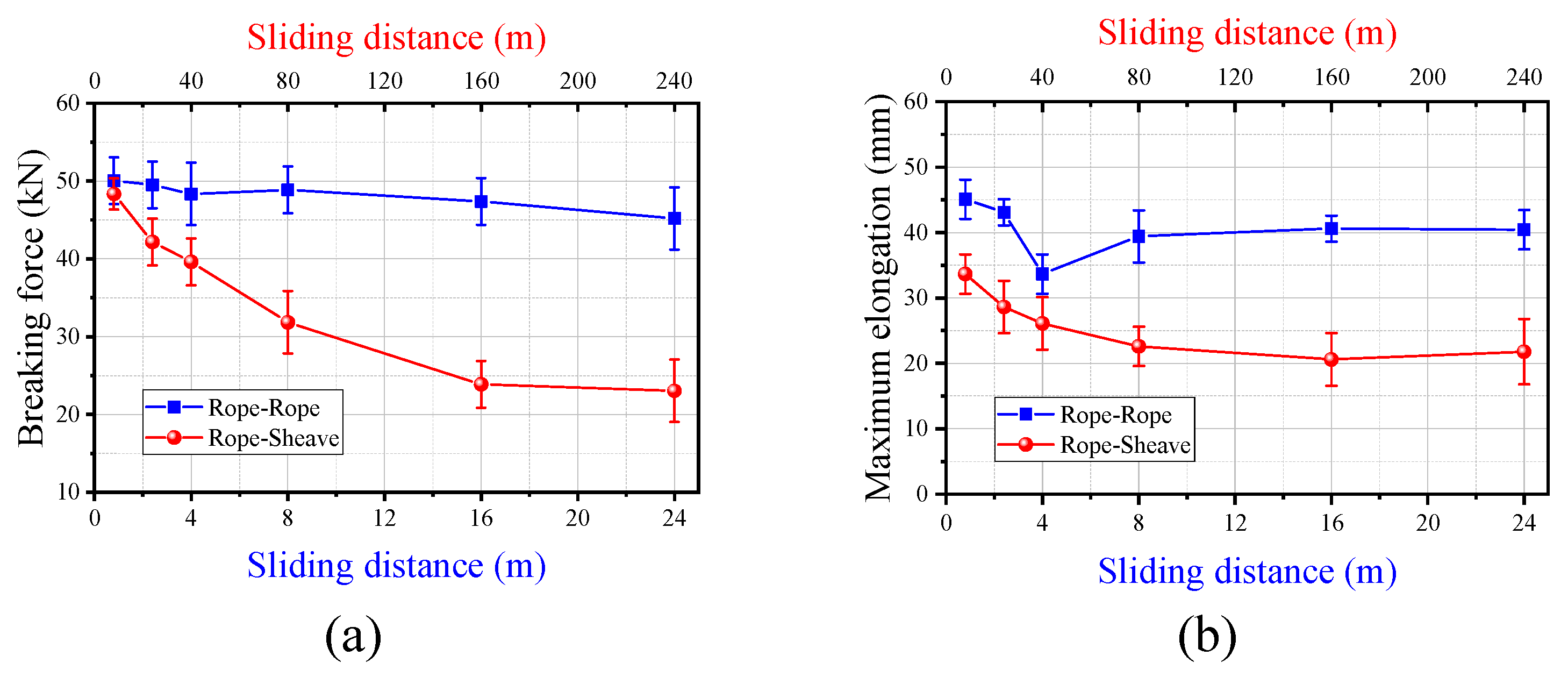

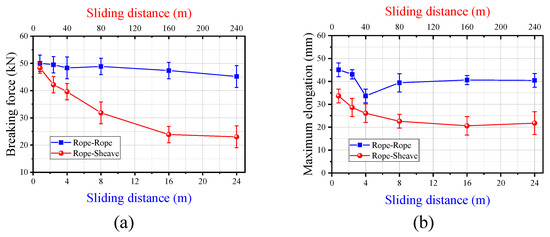

To quantitatively evaluate the influence of wear evolution on tensile strength degradation under two contact friction pairs, the maximum breaking force and elongation of the rope samples are further analyzed, as shown in Figure 14. With the increase in wear loss and wear width, the maximum breaking force of the damaged rope samples decreases from approximately 50 kN to 46 kN under the condition of rope–rope contact. However, when the contact form is a rope–sheave friction pair, the breaking force decreases from approximately 48 kN to 23 kN. Thus, the rope–sheave sliding friction pair has a greater influence on the tensile strength of the transmission wire rope, and the harm is more serious. Additionally, when the sliding distance is below 80 m, the degradation rate of the breaking force is the fastest, and the decrease is about 17 kN. This corresponds to the variation law of wear scar distribution and the wear characteristic parameters of the wire rope. Moreover, the maximum elongation of the damaged wire rope decreases from approximately 45 mm to 34 mm under the condition of rope–rope contact. In comparison, it decreases from approximately 33 mm to 21 mm when the friction pair is rope–sheave contact (see Figure 14b). The tensile strength of the steel wire rope decreases obviously under this condition, and the fracture of the steel wire rope happens earlier in the experimental process. Thus, all the elongations of the rope sample are relatively smaller.

Figure 14.

Variation curves of the maximum breaking force and elongation of damaged rope samples: (a) rope–sheave contact; (b) rope–rope contact.

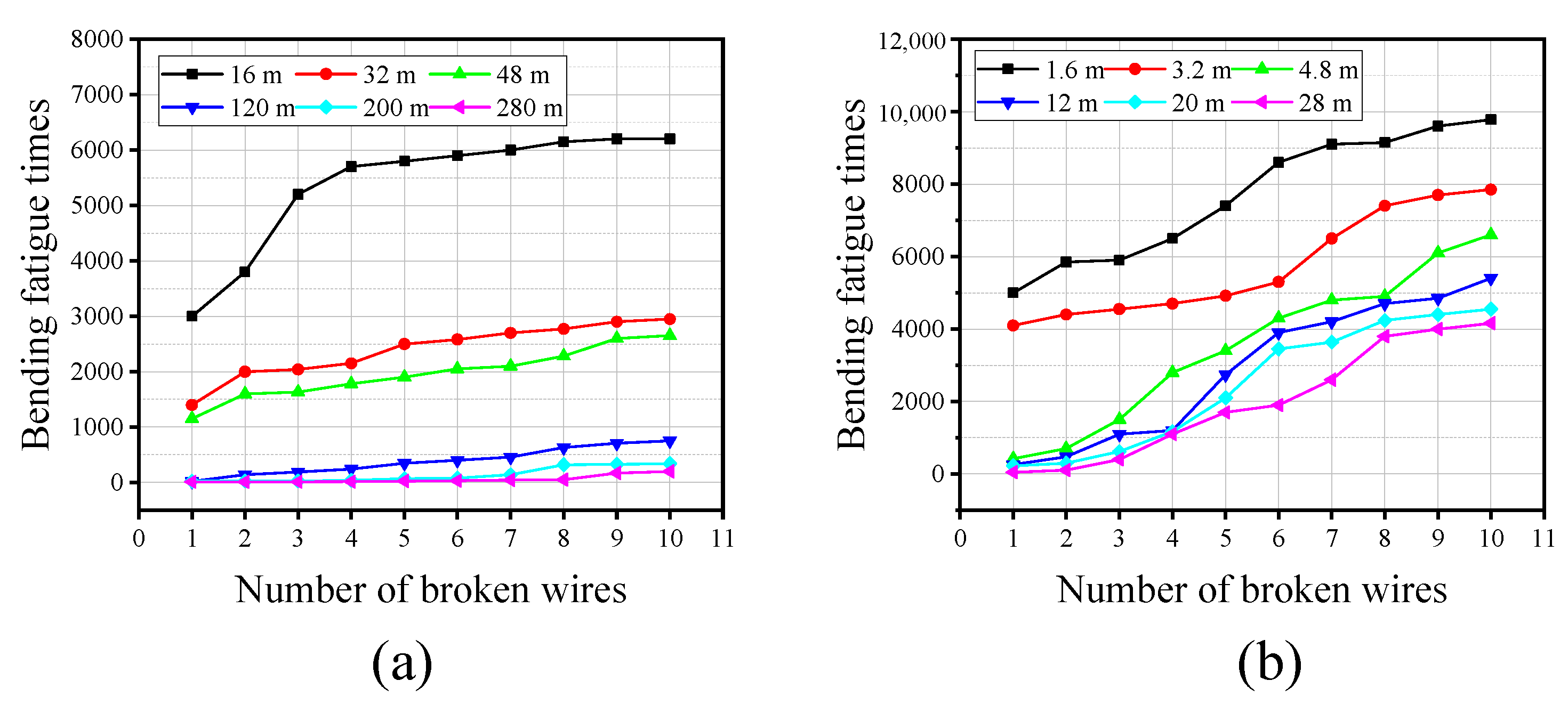

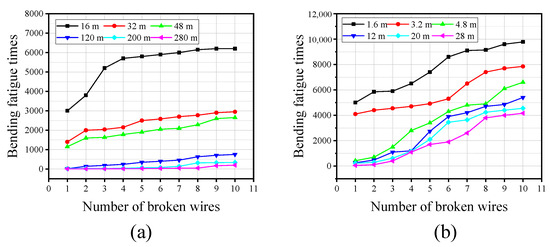

The bending fatigue test outcomes of the wire rope with varying damages are presented in Figure 15. In the bending fatigue test, as the number of bending cycles increases, the number of broken wires in the steel wire rope gradually increases. The bending fatigue testing machine records the number of bending cycles for each test and simultaneously observes and records the broken wire situation of the steel wire rope, thereby establishing the corresponding relationship between the number of bending cycles and the number of broken wires. Additionally, when broken wires reach 10, the steel wire rope is considered scrapped. Therefore, the termination criterion for a single fatigue test is the appearance of 10 broken wires in the steel wire rope. By examining the correlation between the number of broken wires and the bending fatigue cycles, it can be found that there are great differences in bending fatigue performance at different stages of the wear evolution. As shown in Figure 15a, under the condition of the rope–sheave friction pair, the first four broken wires of the wire rope sample often require more bending fatigue times when the surface wear is mild. It is about 3000 to 5700 times. As the number of broken wires increases from 5 to 10, the change in bending fatigue times is relatively small. The bending times concentrate around 6000. This is because the number of steel wires with severe damage inside the wire rope is small, and the steel wires with relatively severe surface wear are first broken during the test. The fracture occurs almost simultaneously for the steel wires with uniform and mild wear, and the number of bending fatigue times required to achieve a fracture is also more. Moreover, with the increase in sliding distance, the number of severely worn steel wires becomes higher, and its bending fatigue resistance decreases. Less bending fatigue times will lead to the fracture of the steel wire. Especially when the sliding distance exceeds 120 m, the number of broken wires in the rope samples reaches 10 after approximately 500 times of experiencing bending fatigue. However, the bending fatigue test results of rope samples with local wear caused by rope–sheave friction pairs are quite different, as shown in Figure 15b. As the number of broken wires increases, the bending fatigue cycles of the rope samples initially rise rapidly and subsequently stabilize gradually. This is because the damage degree of the worn steel wires on the rope surface is quite different under this condition, but the overall damage is not severe, and the number of worn steel wires is small. In bending fatigue, the severely worn steel wire breaks first. With the decrease in the wear degree of the steel wire, the number of bending fatigues increases gradually. Therefore, the most important impact of wear on the bending fatigue performance of transmission wire ropes is the steel wires with more severe damage. Furthermore, the larger wear area on the rope surface will greatly reduce its bending fatigue resistance.

Figure 15.

The bending fatigue curves of damaged rope samples caused by different contact forms: (a) rope–sheave contact; (b) rope–rope contact.

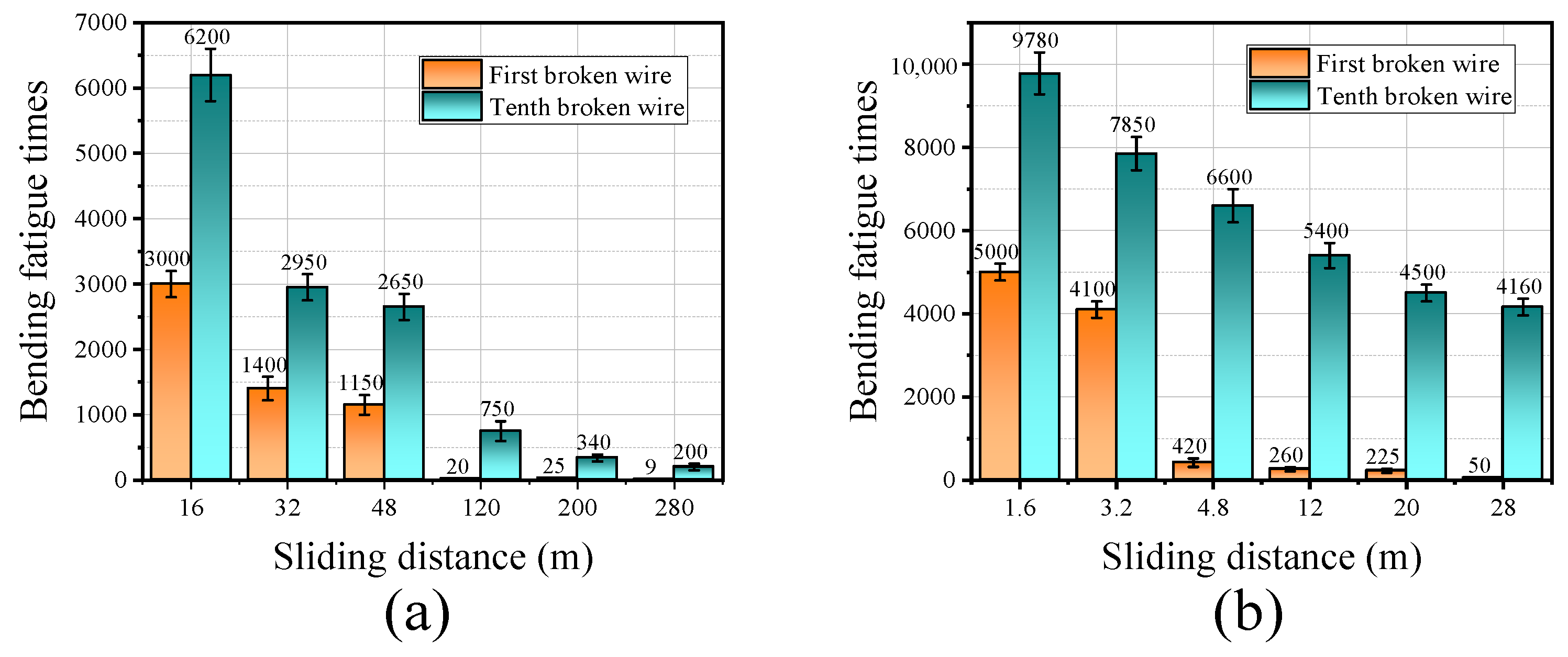

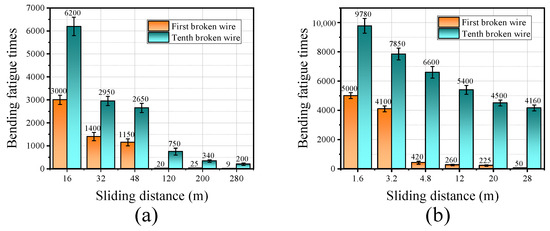

The variation pattern of bending fatigue cycles corresponding to the first and tenth broken wires in a damaged wire rope under various contact forms is illustrated in Figure 16. As the wire rope undergoes wear progression, the bending fatigue cycles associated with the first broken wire decrease from approximately 3000 times to 9 times (rope–sheave contact), and from approximately 5000 times to 50 times (rope–rope contact). This suggests that the fatigue life of the severely worn wires is progressively diminishing, and the wear caused by the rope–sheave friction pair is more harmful to the fracture of wires. Because the first broken wire in the bending fatigue process is the most seriously worn steel wire, the impact of the two contact forms on the experimental outcomes is not significant. However, when the number of broken wires accumulates to 10, the difference in the influence of wear evolution on bending fatigue life under the two friction pairs is relatively large. It decreases from approximately 6200 times to 200 times (rope–sheave contact), and from approximately 9780 times to 4160 times (rope–rope contact). The wear evolution caused by the rope–sheave contact condition leads to a rapid decrease in the bending fatigue life of the wire rope (Figure 16a). The surface wear under the condition of rope–rope contact also decreases bending fatigue life, but the decrease is smaller. The whole rope still has good bending fatigue resistance (Figure 16b). Furthermore, fatigue damage is a cumulative evolution process, and the location of the broken wire often has a certain randomness. The surface wear greatly reduces this randomness. Once the first broken wire appears in the wear area, it is easy to trigger the rapid fracture of other steel wires. Therefore, in the process of the safety inspection and maintenance of the transmission wire rope, more attention should be paid to the degradation of mechanical characteristics in the wear area, especially the surface wear caused by rope–sheave contact.

Figure 16.

Bending fatigue life of damaged rope samples: (a) rope–sheave contact; (b) rope–rope contact.

The friction and wear of steel wire ropes used in coal mine transportation and their hazards constitute a complex and multi-dimensional systemic issue. Current research is still in its infancy, and further in-depth studies are needed on the variation laws of the tribological properties of steel wire ropes under different lubrication states, harsh environments, and corrosive conditions. Additionally, the effects of different damages on the strength, service life, and multi-axial fatigue fracture failure mechanism of steel wire ropes also require more thorough exploration. In the next step, we will conduct systematic research on the above-mentioned related issues, aiming to fully understand the friction and wear characteristics and failure mechanisms of steel wire ropes to ensure their safe and reliable operation.

4. Conclusions

In this study, the friction characteristics and wear mechanism of the transmission wire rope under different contact forms (rope–sheave contact and rope–rope contact) were revealed, and the influence of varying damage on the degradation of the mechanical properties of the wire rope was analyzed. The main conclusions are as follows:

1. Different contact forms affect the evolution law of the COF and friction temperature rise. Under the condition of rope–sheave contact, the COF decreases first before entering the stable stage and shows an increasing trend under the condition of rope–rope contact. The stable COF is not much different between the two contact situations, from approximately 0.7 to 0.8. It is easy to produce greater temperature rise under rope–sheave contact, and the sliding distance to reach the stable stage is longer.

2. The surface wear of the wire rope is a nonlinear cumulative expansion process. The contact area between the wire rope and the sheave is large. The wear extends on the surface of multiple rope strands simultaneously, and the surface is flat. However, the wear scar is more concentrated under rope–rope contact, mainly expanding along the longitudinal direction, and the surface is uneven.

3. The wear characteristics of the wire rope under the rope–sheave contact condition are mainly furrows and plastic deformation, and they are fatigue spalling and cracks under the rope–rope contact condition. The wear mechanisms of the transmission wire rope under two friction pairs are mainly adhesive wear and fatigue wear. Additionally, with the evolution of damage, the adhesion and fatigue damage characteristics become more obvious.

4. The wear evolution leads to the nonlinear decrease in tensile strength and bending fatigue life of the wire rope. Under the condition of rope–sheave contact, the breaking force is reduced from approximately 48 kN to 23 kN, and the maximum elongation is reduced from approximately 33 mm to 21 mm. Furthermore, during the bending fatigue test, the rate of increase in the number of broken wires initially increases slowly and then accelerates.

Author Contributions

Conceptualization, X.C. (Xiangdong Chang), F.S. and X.C. (Xiao Chen); methodology, X.C. (Xiangdong Chang) and X.C. (Xiao Chen); validation, Y.P. and Y.T.; investigation, X.C. (Xiangdong Chang), W.X. and R.H.; resources, F.S. and X.C. (Xiao Chen); data curation, W.X. and R.H.; writing—original draft preparation, X.C. (Xiangdong Chang), F.S., X.C. (Xiao Chen), and Y.P.; writing—review and editing, F.S., Y.T., W.X. and R.H.; visualization, F.S., W.X. and R.H.; supervision, Y.P. and Y.T.; project administration, X.C. (Xiangdong Chang); funding acquisition, X.C. (Xiangdong Chang). All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the National Natural Science Foundation of China (Grant No. 52475234 and 52475174). This project is also partly supported by the Coal Mine Safety Mining Equipment Manufacturing Industry Innovation Center of Anhui Province (CMSMEICAP2023004), the Priority Academic Program Development of Jiangsu Higher Education Institutions (PAPD), and the Top-notch Academic Programs Project of Jiangsu Higher Education Institutions (TAPP).

Data Availability Statement

The data presented in this study are available on request from the corresponding author.

Conflicts of Interest

Author Fahui Shi was employed by the company Changzhou Scientific Research Trial Center Co., Ltd. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

References

- Zhou, P.; Zhou, G.; Li, Y.; He, Z.; Liu, Y. A Hybrid Data-Driven Method for Wire Rope Surface Defect Detection. IEEE Sens. J. 2020, 20, 8297–8306. [Google Scholar] [CrossRef]

- Pal, U.; Mukhopadhyay, G.; Sharma, A.; Bhattacharya, S. Failure analysis of wire rope of ladle crane in steel making shop. Int. J. Fatigue 2018, 116, 149–155. [Google Scholar] [CrossRef]

- Bruski, D. Determination of the Bending Properties of Wire Rope Used in Cable Barrier Systems. Materials 2020, 13, 3842. [Google Scholar] [CrossRef] [PubMed]

- Zhang, D.; Yang, X.; Chen, K.; Zhang, Z. Fretting fatigue behavior of steel wires contact interface under different crossing angles. Wear 2018, 400–401, 52–61. [Google Scholar] [CrossRef]

- Onur, Y.A.; İmrak, C.E.; Onur, T.Ö. Discarding lifetime investigation of a rotation resistant rope subjected to bending over sheave fatigue. Measurement 2019, 142, 163–169. [Google Scholar] [CrossRef]

- Emrani, A.; Berrada, A.; Bakhouya, M. Modeling and Performance Evaluation of the Dynamic Behavior of Gravity Energy Storage with a Wire Rope Hoisting System. J. Energy Storage 2021, 33, 102154. [Google Scholar] [CrossRef]

- Zhang, Q.; Peng, Y.; Zhu, Z.; Tang, W.; Chen, G.; Zhao, X.; Wang, F. Studies on friction and wear characteristics of wire rope used in multi-layer winding hoist during inter-circle transition under dry friction, Proceedings of the Institution of Mechanical Engineers. Part J J. Eng. Tribol. 2022, 236, 90–104. [Google Scholar] [CrossRef]

- Wang, D.; Zhang, D.; Ge, S. Finite element analysis of fretting fatigue behavior of steel wires and crack initiation characteristics. Eng. Fail. Anal. 2013, 28, 47–62. [Google Scholar] [CrossRef]

- Chen, Y.; Meng, F.; Gong, X. Full contact analysis of wire rope strand subjected to varying loads based on semi-analytical method. Int. J. Solids Struct. 2017, 117, 51–66. [Google Scholar] [CrossRef]

- Argatov, I.I.; Gómez, X.; Tato, W.; Urchegui, M.A. Wear evolution in a stranded rope under cyclic bending: Implications to fatigue life estimation. Wear 2011, 271, 2857–2867. [Google Scholar] [CrossRef]

- Cruzado, A.; Urchegui, M.A.; Gómez, X. Finite element modeling of fretting wear scars in the thin steel wires: Application in crossed cylinder arrangements. Wear 2014, 318, 98–105. [Google Scholar] [CrossRef]

- Wang, D.; Li, X.; Wang, X.; Zhang, D.; Wang, D.A. Dynamic wear evolution and crack propagation behaviors of steel wires during fretting-fatigue. Tribol. Int. 2016, 101, 348–355. [Google Scholar] [CrossRef]

- Zhang, J.; Wang, D.; Song, D.; Zhang, D.; Zhang, C.; Wang, D.A.; Araújo, J.A. Tribo-fatigue behaviors of steel wire rope under bending fatigue with the variable tension. Wear 2019, 428–429, 154–161. [Google Scholar] [CrossRef]

- Oksanen, V.; Andersson, P.; Valtonen, K.; Holmberg, K.; Kuokkala, V.T. Characterization of the wear of nodular cast iron rollers in contact with wire ropes. Wear 2013, 308, 199–205. [Google Scholar] [CrossRef]

- Oksanen, V.; Valtonen, K.; Andersson, P.; Vaajoki, A.; Laukkanen, A.; Holmberg, K.; Kuokkala, V.T. Comparison of laboratory rolling–sliding wear tests with in-service wear of nodular cast iron rollers against wire ropes. Wear 2015, 340–341, 73–81. [Google Scholar] [CrossRef]

- Wang, D.; Song, D.; Wahab, M.A. Effects of Contact Load and Torsion Angle on Crack Propagation Behaviors of Inclined Crossed Steel Wires during Tension–Torsion Fretting Fatigue in Acid Solution. Appl. Sci. 2021, 11, 10529. [Google Scholar] [CrossRef]

- Wang, D.; Zhang, D.; Zhao, W.; Ge, S. Quantitative analyses of fretting fatigue damages of mine rope wires in different corrosive media. Mater. Sci. Eng. A 2014, 596, 80–88. [Google Scholar] [CrossRef]

- Zhang, Q.; Peng, Y.; Chang, X.; Zhou, X.; Zhang, Y.; Chen, G.; Lu, H. Tribological performances of α-Zrp as the additive of the grease used for mine hoisting wire rope. Wear 2022, 504–505, 204428. [Google Scholar] [CrossRef]

- Sun, Z.; Xu, C.; Peng, Y.; Shi, Y.; Zhang, Y. Fretting tribological behaviors of steel wires under lubricating grease with compound additives of graphene and graphite. Wear 2020, 454–455, 203333. [Google Scholar] [CrossRef]

- Hakala, T.J.; Laukkanen, A.; Suhonen, T.; Holmberg, K. A finite-element model for a paste lubricated steel wire vs cast iron contact. Tribol. Int. 2020, 150, 106362. [Google Scholar] [CrossRef]

- Xiang, L.; Wang, H.Y.; Chen, Y.; Guan, Y.J.; Dai, L.H. Elastic-plastic modeling of metallic strands and wire ropes under axial tension and torsion loads. Int. J. Solids Struct. 2017, 129, 103–118. [Google Scholar] [CrossRef]

- Onur, Y.A.; İmrak, C.E. Discard fatigue life of stranded steel wire rope subjected to bending over sheave fatigue. Mech. Ind. 2017, 18, 223. [Google Scholar] [CrossRef]

- Chen, Y.; Wang, Q.; Qin, W.; Xiang, J. Study on the mechanical performance of a three-layered wire rope strand with a surface pit in varied corrosion direction into the wire. Eng. Fail. Anal. 2022, 136, 106181. [Google Scholar] [CrossRef]

- Zhang, D.; Chen, K.; Jia, X.; Wang, D.; Wang, S.; Luo, Y.; Ge, S. Bending fatigue behaviour of bearing ropes working around pulleys of different materials. Eng. Fail. Anal. 2013, 33, 37–47. [Google Scholar] [CrossRef]

- Singh, R.P.; Mallick, M.; Verma, M.K. Studies on failure behaviour of wire rope used in underground coal mines. Eng. Fail. Anal. 2016, 70, 290–304. [Google Scholar] [CrossRef]

- Guerra-Fuentes, L.; Torres-López, M.; Hernandez-Rodriguez, M.A.L.; Garcia-Sanchez, E. Failure analysis of steel wire rope used in overhead crane system. Eng. Fail. Anal. 2020, 118, 104893. [Google Scholar] [CrossRef]

- Zhou, P.; Zhou, G.; He, Z.; Tang, C.; Zhu, Z.; Li, W. A novel texture-based damage detection method for wire ropes. Measurement 2019, 148, 106954. [Google Scholar] [CrossRef]

- Battini, D.; Solazzi, L.; Lezzi, A.M.; Clerici, F.; Donzella, G. Prediction of steel wire rope fatigue life based on thermal measurements. Int. J. Mech. Sci. 2020, 182, 105761. [Google Scholar] [CrossRef]

- Zhao, D.; Gao, C.; Zhou, Z.; Liu, S.; Chen, B.; Gao, J. Fatigue life prediction of the wire rope based on grey theory under small sample condition. Eng. Fail. Anal. 2020, 107, 104237. [Google Scholar] [CrossRef]

- Cruzado, A.; Hartelt, M.; Wäsche, R.; Urchegui, M.A.; Gómez, X. Fretting wear of thin steel wires. Part 2: Influence of crossing angle. Wear 2011, 273, 60–69. [Google Scholar] [CrossRef]

- Wang, D.; Chong, H.; Ge, S.; Wu, K.; Wang, B.; Li, C.; Ji, W.; Zhang, J.; Chen, J.; Deng, H.; et al. Bending tribo-fatigue behaviors between steel wire rope and rope groove material of offshore rig winch drum. Tribol. Int. 2025, 204, 110477. [Google Scholar] [CrossRef]

- Lu, C.; Jiang, X.; Chen, X.; Mo, J. Experimental study on the evolution of friction and wear behaviours of railway friction block during temperature rise under extreme braking conditions. Eng. Fail. Anal. 2022, 141, 106621. [Google Scholar] [CrossRef]

- Heldin, M.; Heinrichs, J.; Jacobson, S. On the critical roles of initial plastic deformation and material transfer on the sliding friction between metals. Wear 2021, 477, 203853. [Google Scholar] [CrossRef]

- Hanke, S.; Santos, J.F. Comparative study of severe plastic deformation at elevated temperatures of two aluminium alloys during friction surfacing. J. Mater. Process. Tech. 2017, 247, 257–267. [Google Scholar] [CrossRef]

- Xu, L.; Zhang, D.; Yin, Y.; Wang, S.; Wang, D. Fretting wear behaviors of hoisting rope wires in acid medium. Mater. Des. 2014, 55, 50–57. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).