A Deep Learning-Based Model for Recognizing Wear Topography of Self-Lubricating Joint Bearings

Abstract

1. Introduction

2. Preliminaries

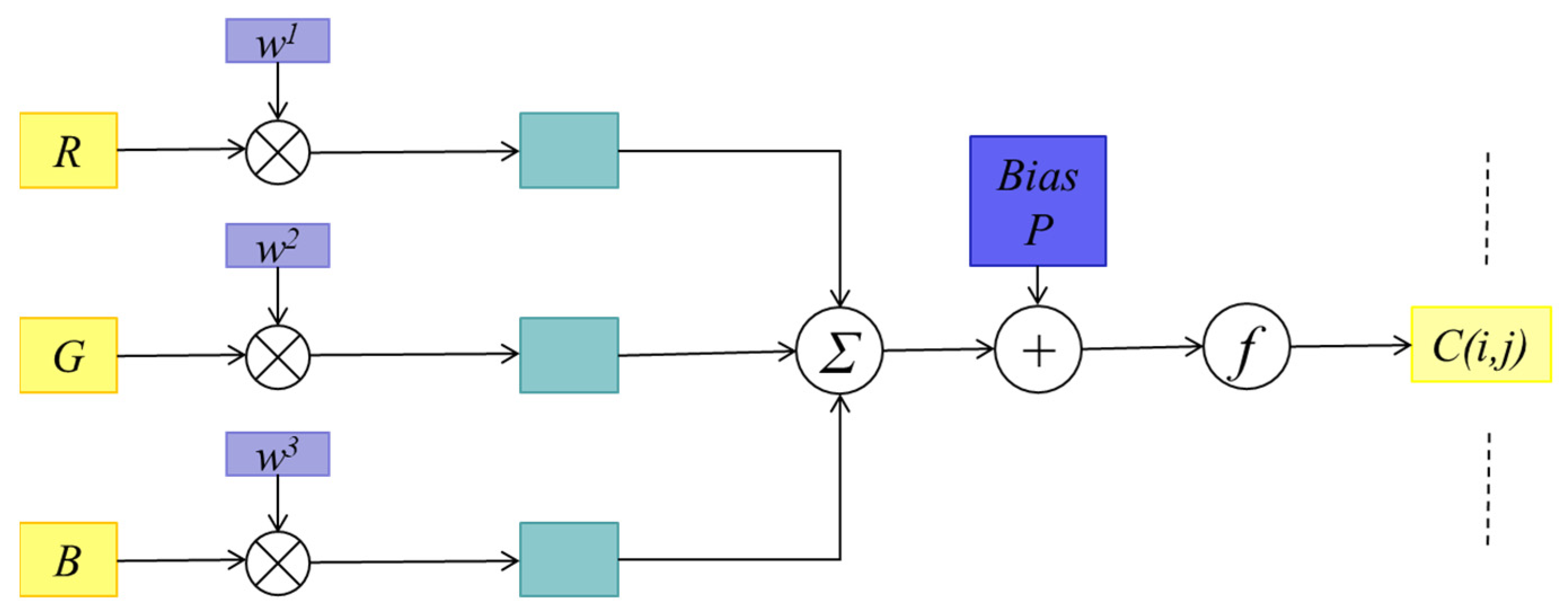

2.1. Convolutional Neural Network Algorithm

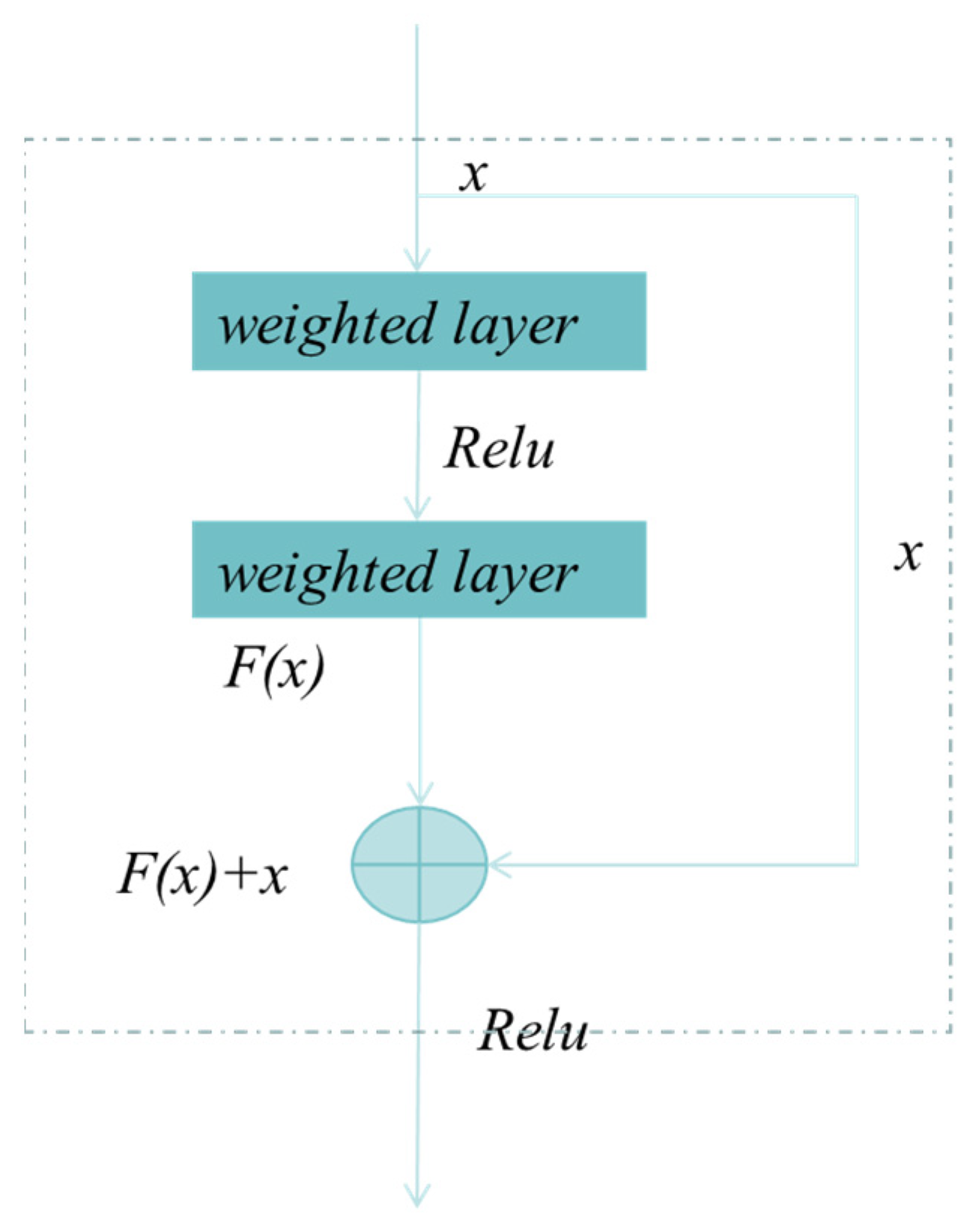

2.2. Residual Neural Network Algorithm and Model

2.3. CNN—Residual Neural Network Algorithm and Model

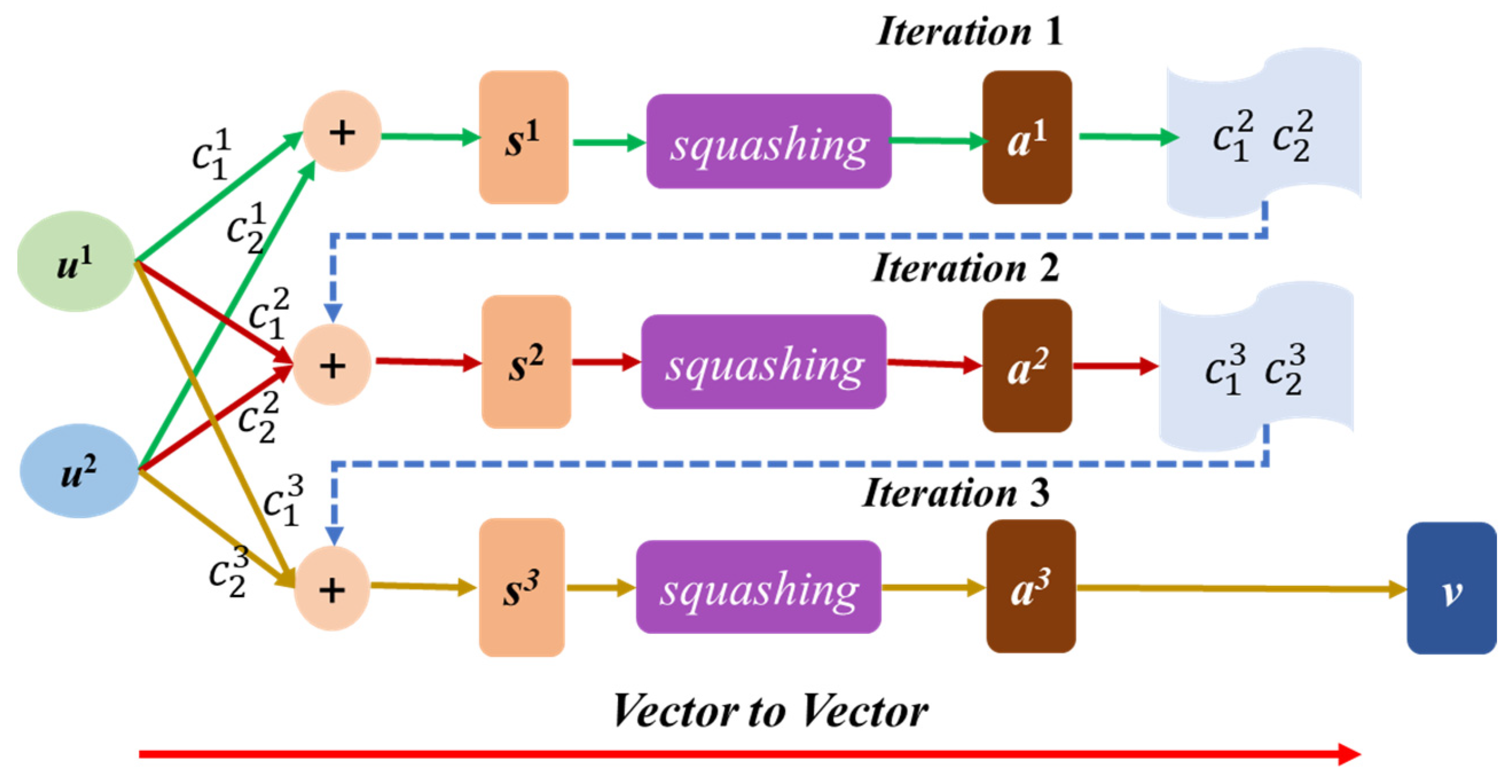

2.4. Capsule Neural Network Algorithm and Model (CapsNet)

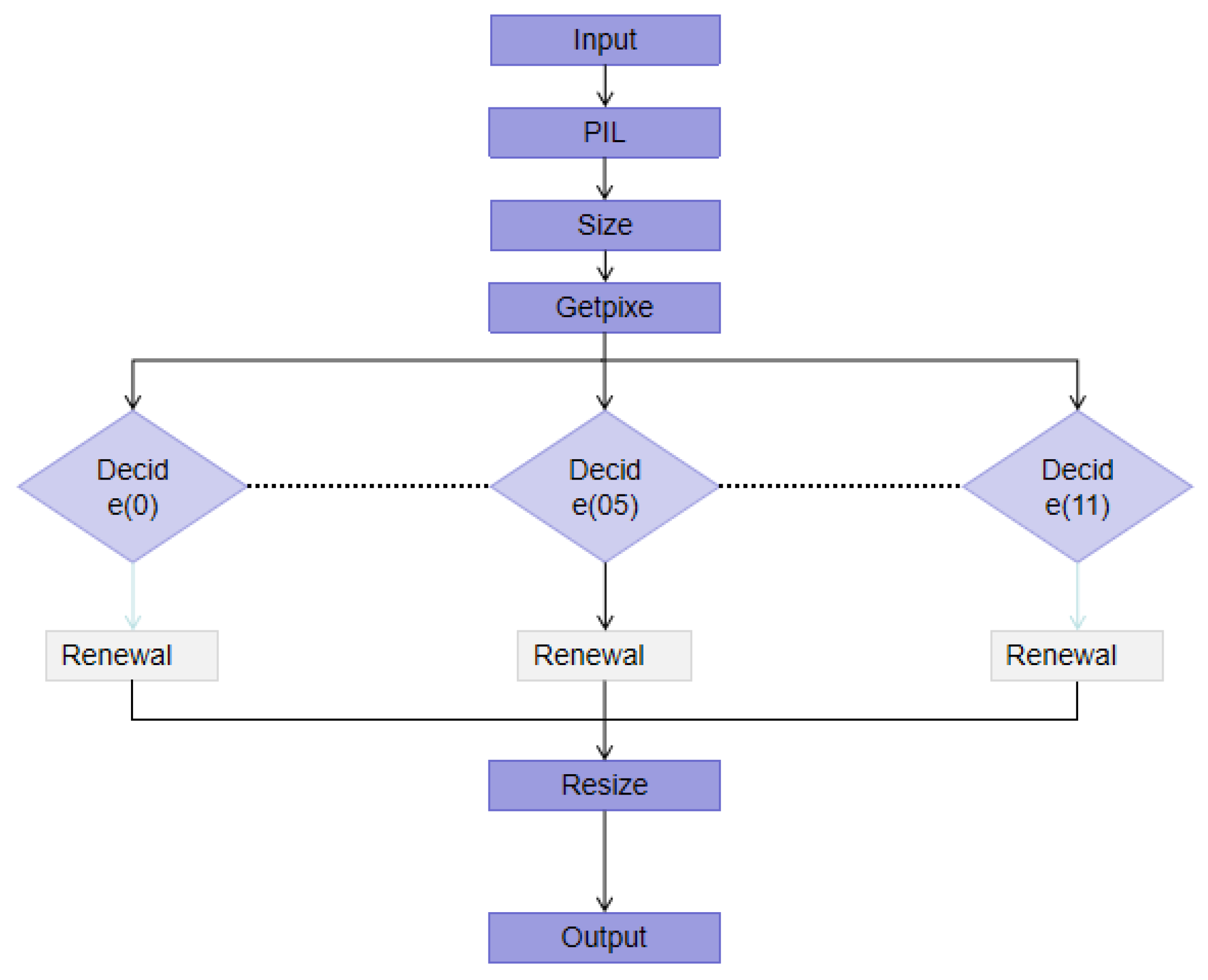

2.5. Image Processing Model

3. Experiment and Analysis

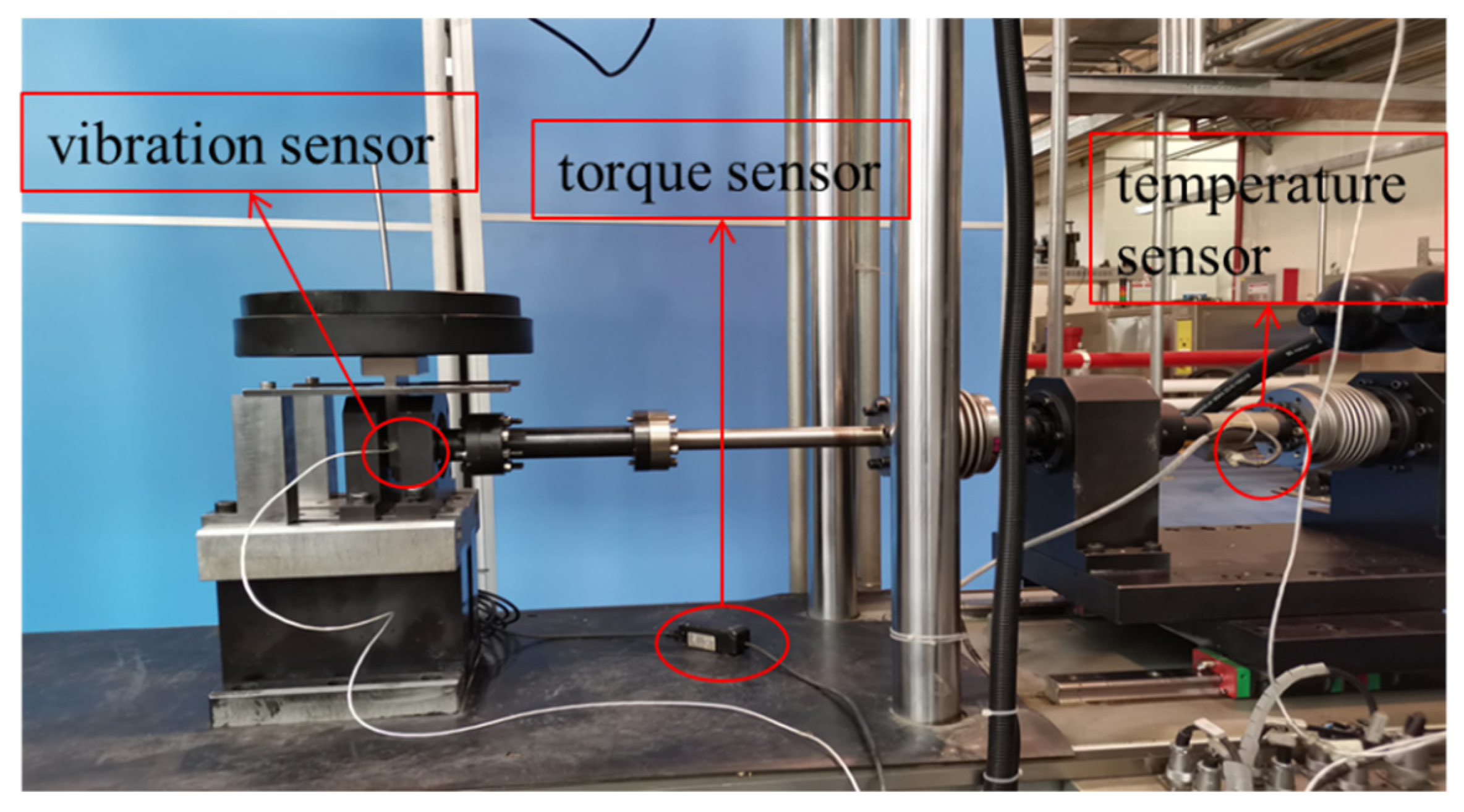

3.1. Bearing Wear Testing

3.2. Image Processing Model of Wear Surface Morphology

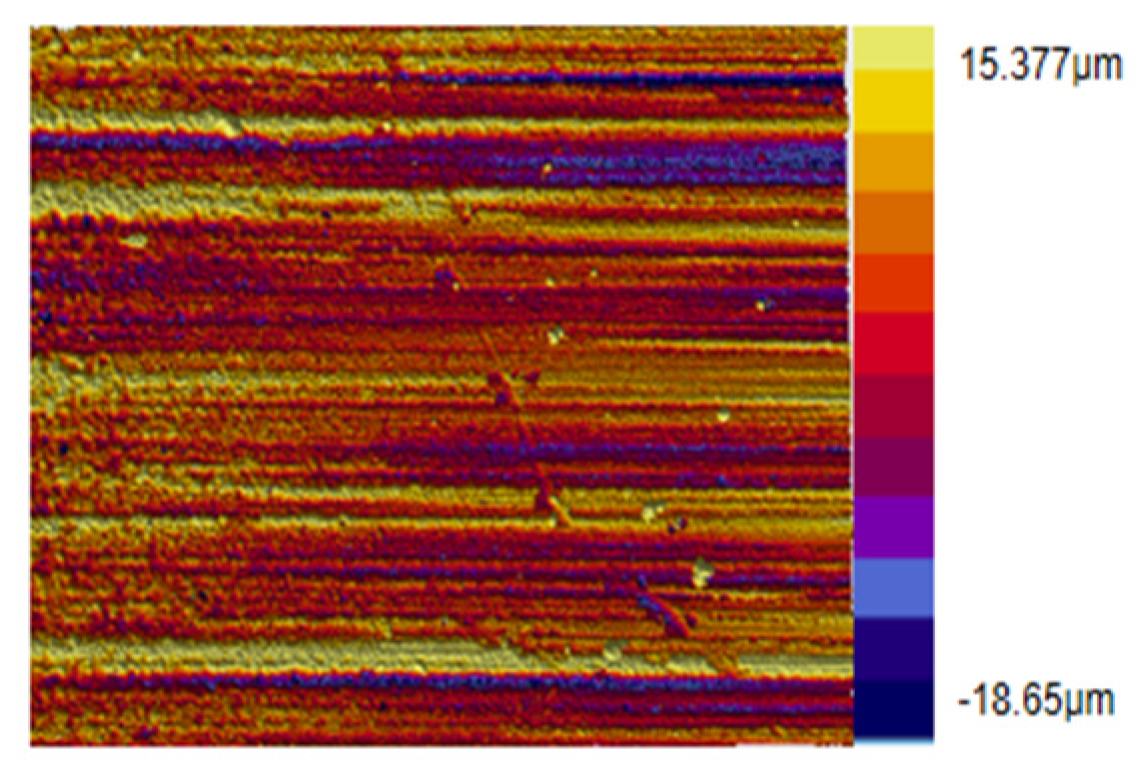

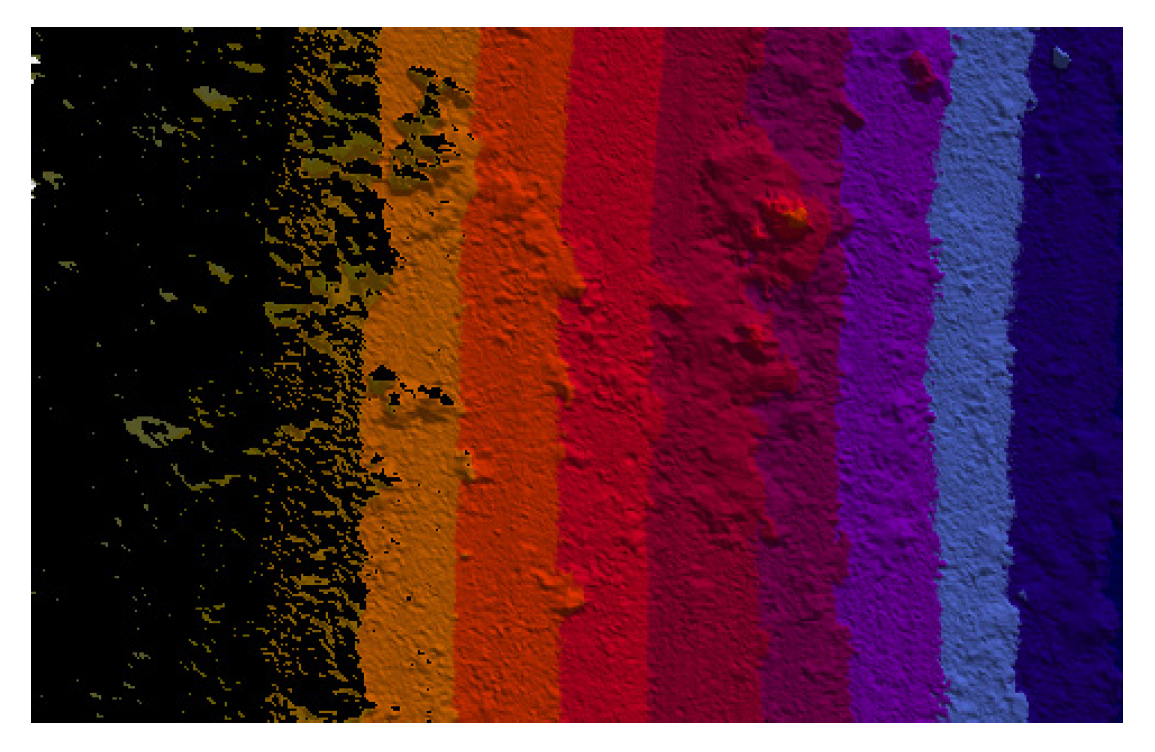

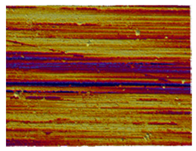

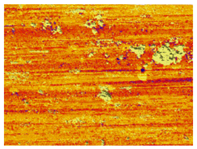

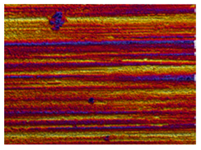

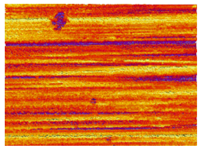

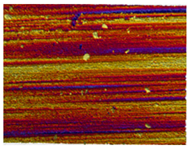

3.2.1. Wear Image Height Color Division

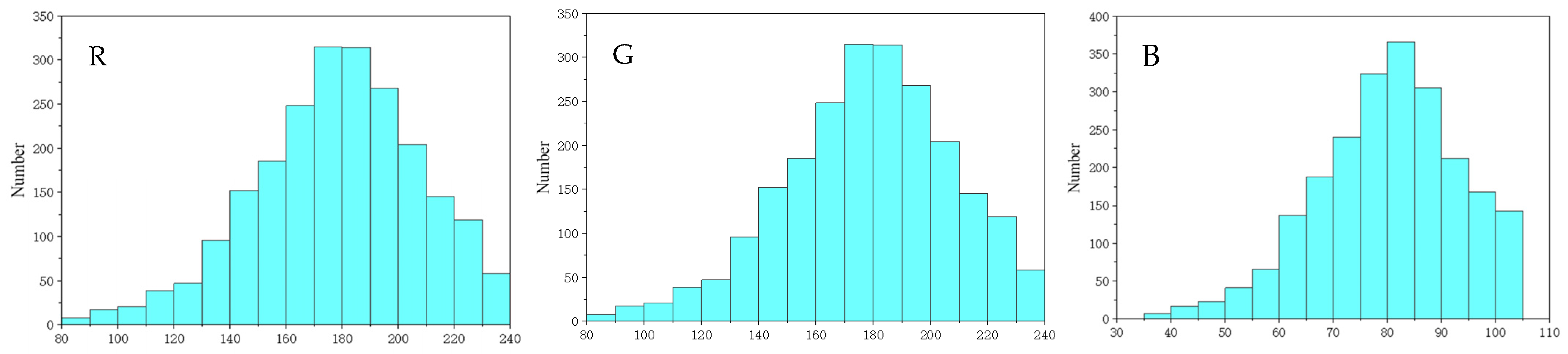

3.2.2. Data Acquisition of Height Color After Fine-Adjustment

3.2.3. Image Dataset of Bearing Worn Surface Morphology

3.3. Comparing the Deep Learning Model

3.4. Analysis

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zhang, Q.; Hao, C.; Wang, Y.; Zhang, K.; Yan, H.; Lv, Z.; Fan, Q.; Xu, C.; Xu, L.; Wen, Z.; et al. Intelligent fault diagnosis of rotating machinery based on improved hybrid dilated convolution network for unbalanced samples. Sci. Rep. 2025, 15, 14127. [Google Scholar] [CrossRef]

- Hakim, M.; Omran, A.A.B.; Ahmed, A.N.; Al-Waily, M.; Abdellatif, A. A systematic review of rolling bearing fault diagnoses based on deep learning and transfer learning: Taxonomy, overview, application, open challenges, weaknesses and recommendations. Ain Shams Eng. J. 2023, 14, 101945. [Google Scholar] [CrossRef]

- Wu, G.; Yan, T.; Yang, G.; Chai, H.; Cao, C. A Review on Rolling Bearing Fault Signal Detection Methods Based on Different Sensors. Sensors 2022, 22, 8330. [Google Scholar] [CrossRef]

- Althubaiti, A.; Elasha, F.; Teixeira, J.A. Fault diagnosis and health management of bearings in rotating equipment based on vibration analysis—A review. J. Vibroeng. 2021, 24, 46–74. [Google Scholar] [CrossRef]

- Xu, J. Research on Bearing Surface Defect Detection and Classification Method Based on Deep Learning. Master’s Thesis, Zhengzhou University, Zhengzhou, China, 2022. (In Chinese). [Google Scholar]

- Roh, Y.; Heo, G.; Whang, S.E. A survey on data collection for machine learning: A big data—AI Integration perspective. IEEE Trans. Knowl. Data Eng. 2021, 33, 1328–1347. [Google Scholar] [CrossRef]

- Whang, S.E.; Roh, Y.; Song, H.; Lee, K. Data collection and quality challenges in deep learning: A data-centric AI perspective. VLDB J. 2023, 32, 791–813. [Google Scholar] [CrossRef]

- Gong, Y.; Liu, G.; Xue, Y.; Li, R.; Meng, L. A survey on dataset quality in machine learning. Inf. Softw. Technol. 2023, 162, 107268. [Google Scholar] [CrossRef]

- Zhou, Y.; Wang, H.; Xu, K. A Survey on data quality dimensions and tools for machine Learning. arXiv 2024, arXiv:2406.19614. [Google Scholar] [CrossRef]

- De, S.; Moss, H.; Johnson, J.; Li, J.; Pereira, H.; Jabbari, S. Engineering a machine learning pipeline for automating metadata extraction from longitudinal survey questionnaires. IASSIST Q. 2022, 46, 1–12. [Google Scholar] [CrossRef]

- Cascales-Fulgencio, D.; Quiles-Cucarella, E.; García-Moreno, E. Computation and statistical analysis of bearings’ time- and frequency-domain features enhanced using cepstrum pre-whitening: A ML- and DL-based classification. Appl. Sci. 2022, 12, 10882. [Google Scholar] [CrossRef]

- Aasi, A.; Tabatabaei, R.; Aasi, E.; Jafari, S.M. Experimental investigation on time-domain features in the diagnosis of rolling element bearings by acoustic emission. J. Vib. Control 2021, 28, 2585–2595. [Google Scholar] [CrossRef]

- Hoang, D.; Kang, H. A survey on Deep Learning based bearing fault diagnosis. Neurocomputing 2019, 335, 327–335. [Google Scholar] [CrossRef]

- Peng, H.; Zhang, H.; Fan, Y.; Shangguan, L.; Yang, Y. A review of research on wind turbine bearings’ failure analysis and fault diagnosis. Lubricants 2023, 11, 14. [Google Scholar] [CrossRef]

- Kumar, P.; Tiwari, R. A review: Multiplicative faults and model-based condition monitoring strategies for fault diagnosis in rotary machines. J. Braz. Soc. Mech. Sci. Eng. 2023, 45, 282. [Google Scholar] [CrossRef]

- Wang, L.; Zhang, X.; Miao, Q. Understanding theories and methods on fault diagnosis for multi-fault detection of planetary gears. In Proceedings of the 2016 Prognostics and System Health Management Conference (PHM-Chengdu), Chengdu, China, 19–21 October 2016; pp. 1–8. [Google Scholar] [CrossRef]

- Chen, C.; Mo, C. A method for intelligent fault diagnosis of rotating machinery. Digit. Signal Process. 2004, 14, 203–217. [Google Scholar] [CrossRef]

- Wang, Y.; Zhao, Y.; Addepalli, S. Remaining useful life prediction using deep learning approaches: A review. Procedia Manuf. 2020, 49, 81–88. [Google Scholar] [CrossRef]

- Chen, Y.; Zhang, T.; Luo, Z.; Sun, K. A Novel Rolling Bearing Fault Diagnosis and Severity Analysis Method. Appl. Sci. 2019, 9, 2356. [Google Scholar] [CrossRef]

- Anwarsha, A.; Babu, T.N. Recent advancements of signal processing and artificial intelligence in the fault detection of rolling element bearings: A review. J. Vibroeng. 2022, 24, 1027–1055. [Google Scholar] [CrossRef]

- Zhang, S.; Zhang, S.; Wang, B.; Habetler, T.G. Deep learning algorithms for bearing fault diagnostics—A comprehensive review. IEEE Access 2020, 8, 29857–29881. [Google Scholar] [CrossRef]

- Sadık Ünlü, B.; Durmuş, H.; Meriç, C. Determination of tribological properties at CuSn10 alloy journal bearings by experimental and means of artificial neural networks method. Ind. Lubr. Tribol. 2012, 64, 258–264. [Google Scholar] [CrossRef]

- Walker, J.; Questa, H.; Raman, A.; Ahmed, M.; Mohammadpour, M.; Bewsher, S.R.; Offner, G. Application of tribological artificial neural networks in machine elements. Tribol. Lett. 2023, 71, 3. [Google Scholar] [CrossRef]

- Gheller, E.; Chatterton, S.; Panara, D.; Turini, G.; Pennacchi, P. Artificial neural network for tilting pad journal bearing characterization. Tribol. Int. 2023, 188, 108833. [Google Scholar] [CrossRef]

- Knežević, I.; Rackov, M.; Kanović, Ž.; Buljević, A.; Antić, A.; Tica, M.; Živković, A. An analysis of the influence of surface roughness and clearance on the dynamic behavior of deep groove ball bearings using artificial neural networks. Materials 2023, 16, 3529. [Google Scholar] [CrossRef]

- Wang, Q.; Wang, X.; Zhang, X. Tribological properties study and prediction of PTFE composites based on experiments and machine learning. Tribol. Int. 2023, 188, 108815. [Google Scholar] [CrossRef]

- Podsiadlo, P.; Stachowiak, G.W. Development of advanced quantitative analysis methods for wear particle characterization and classification to aid tribological system diagnosis. Tribol. Int. 2005, 38, 887–897. [Google Scholar] [CrossRef]

- Wen, S.; Chen, Z.; Li, C. Vision-Based Surface Inspection System for Bearing Rollers Using Convolutional Neural Networks. Appl. Sci. 2018, 8, 2565. [Google Scholar] [CrossRef]

- Que, H.; Liu, X.; Jin, S.; Huo, Y.; Wu, C.; Ding, C.; Zhu, Z. Partial Transfer learning method based on Inter-Class feature transfer for rolling bearing fault diagnosis. Sensors 2024, 24, 5165. [Google Scholar] [CrossRef] [PubMed]

- Guo, P.; Zhang, W.; Cui, B.; Guo, Z.; Zhao, C.; Yin, Z.; Liu, B. Multi-condition fault diagnosis method of rolling bearing based on enhanced deep convolutional neural network. J. Vib. Eng. 2025, 38, 96–108. (In Chinese) [Google Scholar]

- Shao, Y.; Tan, J.; Lu, J. A spatio-temporal fully convolutional recurrent neural network based surface topography Prediction. J. Mech. Eng. 2021, 57, 292–304. (In Chinese) [Google Scholar]

- She, B.; Liang, W.; Qin, F.; Dong, H. Open set domain adaptation method based on adversarial dual classifiers for fault diagnosis. Chin. J. Sci. Instrum. 2023, 44, 325–334. (In Chinese) [Google Scholar]

- Chen, T.; Wang, Z.; Yang, X.; Jiang, K. A deep capsule neural network with stochastic delta rule for bearing fault diagnosis on raw vibration signals. Measurement 2019, 148, 106857. [Google Scholar] [CrossRef]

- Zhu, Z.; Peng, G.; Chen, Y.; Gao, H. A convolutional neural network based on a capsule network with strong generalization for bearing fault diagnosis. Neurocomputing 2019, 323, 62–75. [Google Scholar] [CrossRef]

- Zhao, X.; Chai, J. Adaptive weight-based capsule neural network for bearing fault diagnosis. Meas. Sci. Technol. 2023, 34, 065008. [Google Scholar] [CrossRef]

| Number | Frequency | Angle | Force | Times |

|---|---|---|---|---|

| 1–3 | 2 Hz | ±15° | 100 N | 72,000 |

| 4–6 | 2 Hz | ±15° | 150 N | 72,000 |

| 7–9 | 2 Hz | ±15° | 200 N | 72,000 |

| 9–12 | 2 Hz | ±15° | 250 N | 72,000 |

| Load | Slight Worn Images | Moderate Worn Images | Severe Worn Images |

|---|---|---|---|

| 100 N | −18 μm~18 μm | −36 μm~36 μm | −66 μm~66 μm |

| 150 N | −12 μm~12 μm | −30 μm~30 μm | −60 μm~60 μm |

| 200 N | −12 μm~12 μm | −24 μm~24 μm | −42 μm~42 μm |

| 250 N | −6 μm~6 μm | −24 μm~24 μm | −18 μm~18 μm |

| Number | Color Block | Number | Color Block |

|---|---|---|---|

| 1 |  | 7 |  |

| 2 |  | 8 |  |

| 3 |  | 9 |  |

| 4 |  | 10 |  |

| 5 |  | 11 |  |

| 6 |  | 12 |  |

| Color Block | Value of RGB | Color Block | Value of RGB |

|---|---|---|---|

| R = 232, G = 232, B = 104 |  | R = 160, G = 0, B = 52 |

| R = 240, G = 208, B = 0 |  | R = 128, G = 0, B = 84 |

| R = 228, G = 156, B = 0 |  | R = 120, G = 0, B = 172 |

| R = 216, G = 104, B = 0 |  | R = 80, G = 104, B = 208 |

| R = 224, G = 52, B = 0 |  | R = 32, G = 0, B = 120 |

| R = 208, G = 0, B = 36 |  | R = 0, G = 0, B = 96 |

| Number | Color | Rang Value of RGB | Number | Color | Rang Value of RGB |

|---|---|---|---|---|---|

| 1 |  | 100 ≤ R ≤ 255, 100 ≤ G ≤ 255, 0 ≤ B ≤ 155 | 7 |  | 65 ≤ R ≤ 156, 0 ≤ G ≤ 0, 29 ≤ B ≤ 57 |

| 2 |  | 102 ≤ R ≤ 255, 88 < G < 255, 0 ≤ B ≤ 0 | 8 |  | 1 ≤ R ≤ 141, 0 ≤ G ≤ 0, 0 ≤ B ≤ 100 |

| 3 |  | 34 ≤ R ≤ 222, 55 ≤ G ≤ 155, 0 ≤ B ≤ 0 | 9 |  | 16 ≤ R ≤ 120, 0 ≤ G ≤ 47, 16 ≤ B ≤ 181 |

| 4 |  | 80 ≤ R ≤ 216, 39 ≤ G ≤ 104, 0 ≤ B ≤ 0 | 10 |  | 35 ≤ R ≤ 119, 31 ≤ G ≤ 155, 91 ≤ B < 255 |

| 5 |  | 1 ≤ R ≤ 249, 0 ≤ G ≤ 75, 0 ≤ B ≤ 37 | 11 |  | 12 ≤ R ≤ 47, 0 ≤ G ≤ 0, 45 ≤ B ≤ 179 |

| 6 |  | 0 ≤ R ≤ 208, 0 ≤ G ≤ 0, 0 ≤ B ≤ 57 | 12 |  | 0 ≤ R ≤ 0, 0 ≤ G ≤ 0, 0 ≤ B ≤ 100 |

| Load | Slight Worn Images | Moderate Worn Images | Severe Worn Images | |||

|---|---|---|---|---|---|---|

| BO | AO | BO | AO | BO | AO | |

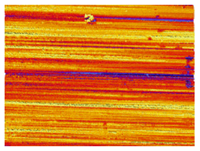

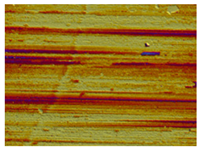

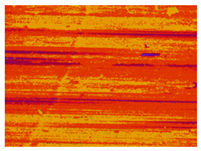

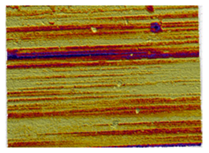

| 100 N |  |  |  |  |  |  |

| 150 N |  |  |  |  |  |  |

| 200 N |  |  |  |  |  |  |

| 250 N |  |  |  |  |  |  |

| Original Labels | Final Labels | Original Labels | Final Labels |

|---|---|---|---|

| 00 | [1,0,0,0,0,0,0,0,0,0,0,0] | 06 | [0,0,0,0,0,0,1,0,0,0,0,0] |

| 01 | [0,1,0,0,0,0,0,0,0,0,0,0] | 07 | [0,0,0,0,0,0,0,1,0,0,0,0] |

| 02 | [0,0,1,0,0,0,0,0,0,0,0,0] | 08 | [0,0,0,0,0,0,0,0,1,0,0,0] |

| 03 | [0,0,0,1,0,0,0,0,0,0,0,0] | 09 | [0,0,0,0,0,0,0,0,0,1,0,0] |

| 04 | [0,0,0,0,1,0,0,0,0,0,0,0] | 10 | [0,0,0,0,0,0,0,0,0,0,1,0] |

| 05 | [0,0,0,0,0,1,0,0,0,0,0,0] | 11 | [0,0,0,0,0,0,0,0,0,0,0,1] |

| CNN | CapsNet | ||

|---|---|---|---|

| Name | Parameters | Name | Parameters |

| Image preprocessing | single-hot coding and data normalization | Image preprocessing | single-hot coding and data normalization |

| Input layer value | (450, 300, 3) | Input layer value | (450, 300, 3) |

| convolution layers | 12 | number of Main capsule and capsule layer | 2,6 |

| convolution kernels | 16 + 2n | convolution kernels | 16 + 2n |

| Convolution kernel size | (3 × 3) | Convolution kernel size | (3 × 3) |

| Model optimizer | Adam | Route iteration times | 5 |

| iterations | 60 | batch samples | 12 |

| batch samples | 6 | iterations | 60 |

| Models | Training Time | R2 | Test-Loss | Test-Acc | Train-Acc | Train-Loss |

|---|---|---|---|---|---|---|

| CNN-ResNet | 8.1 h | 0.77 | 11.65 | 0.99 | 0.66 | 22.19 |

| CNN | 4.1 h | 0.46 | 5.32 | 0.98 | 0.47 | 52.52 |

| CapsNet | 6.3 h | 0.62 | 0.83 | 0.96 | 0.56 | 32.93 |

| ResNet | 7.9 h | 0.56 | 16.73 | 0.92 | 0.54 | 39.24 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Han, C.; Zhou, X.; Qu, Z.; Ma, G.; Li, G. A Deep Learning-Based Model for Recognizing Wear Topography of Self-Lubricating Joint Bearings. Lubricants 2025, 13, 517. https://doi.org/10.3390/lubricants13120517

Han C, Zhou X, Qu Z, Ma G, Li G. A Deep Learning-Based Model for Recognizing Wear Topography of Self-Lubricating Joint Bearings. Lubricants. 2025; 13(12):517. https://doi.org/10.3390/lubricants13120517

Chicago/Turabian StyleHan, Cuihong, Xin Zhou, Zhoude Qu, Guozheng Ma, and Guolu Li. 2025. "A Deep Learning-Based Model for Recognizing Wear Topography of Self-Lubricating Joint Bearings" Lubricants 13, no. 12: 517. https://doi.org/10.3390/lubricants13120517

APA StyleHan, C., Zhou, X., Qu, Z., Ma, G., & Li, G. (2025). A Deep Learning-Based Model for Recognizing Wear Topography of Self-Lubricating Joint Bearings. Lubricants, 13(12), 517. https://doi.org/10.3390/lubricants13120517