A Preliminary Study on Wear Resistance and High-Temperature Steam Oxidation of AlCrFeMoZr High-Entropy Alloy Coatings for Accident-Tolerant Fuel

Abstract

1. Introduction

2. Materials and Methods

2.1. Coating Preparation

2.2. Microstructure Characterization

2.3. Microhardness and Tribological Properties Tests

2.4. Water Vapor Corrosion Test

3. Results and Discussion

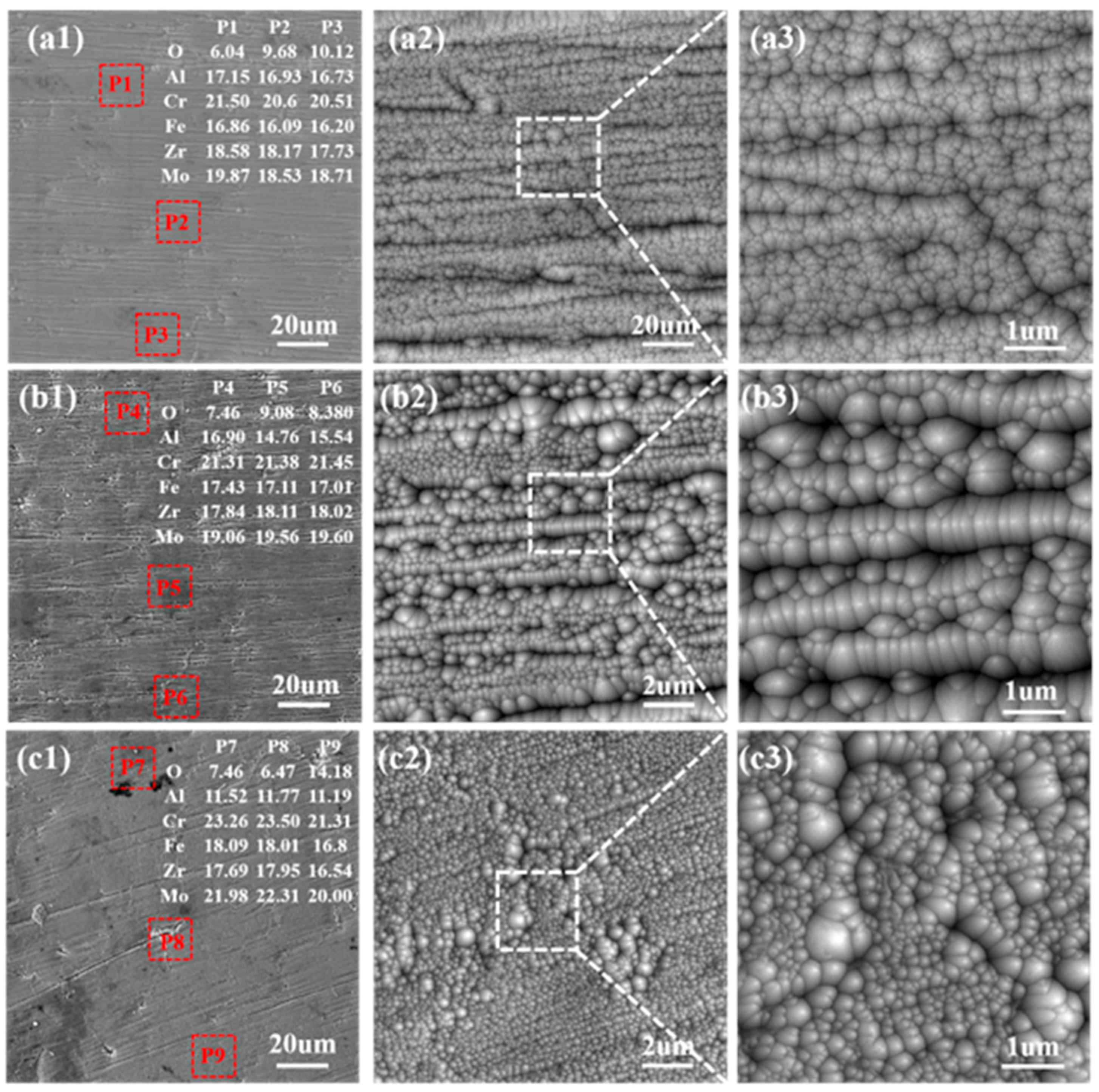

3.1. Coating Morphology and Microstructure

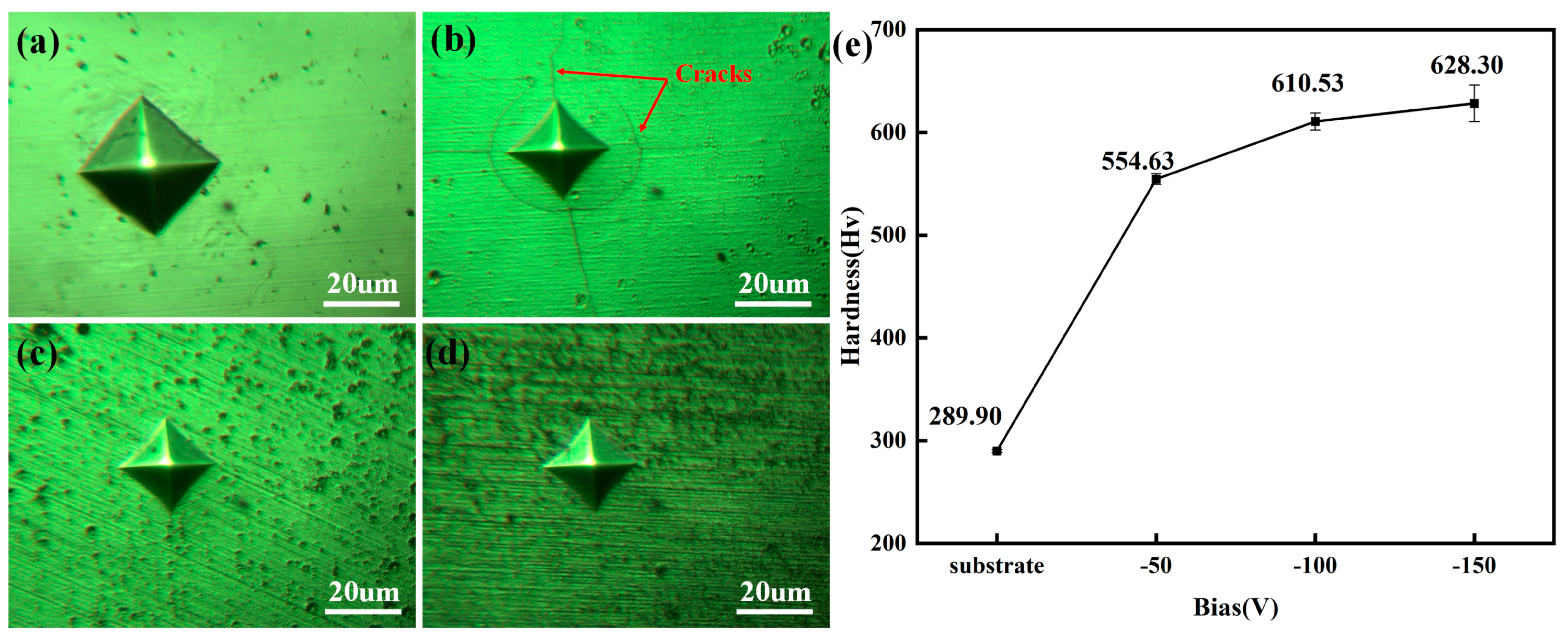

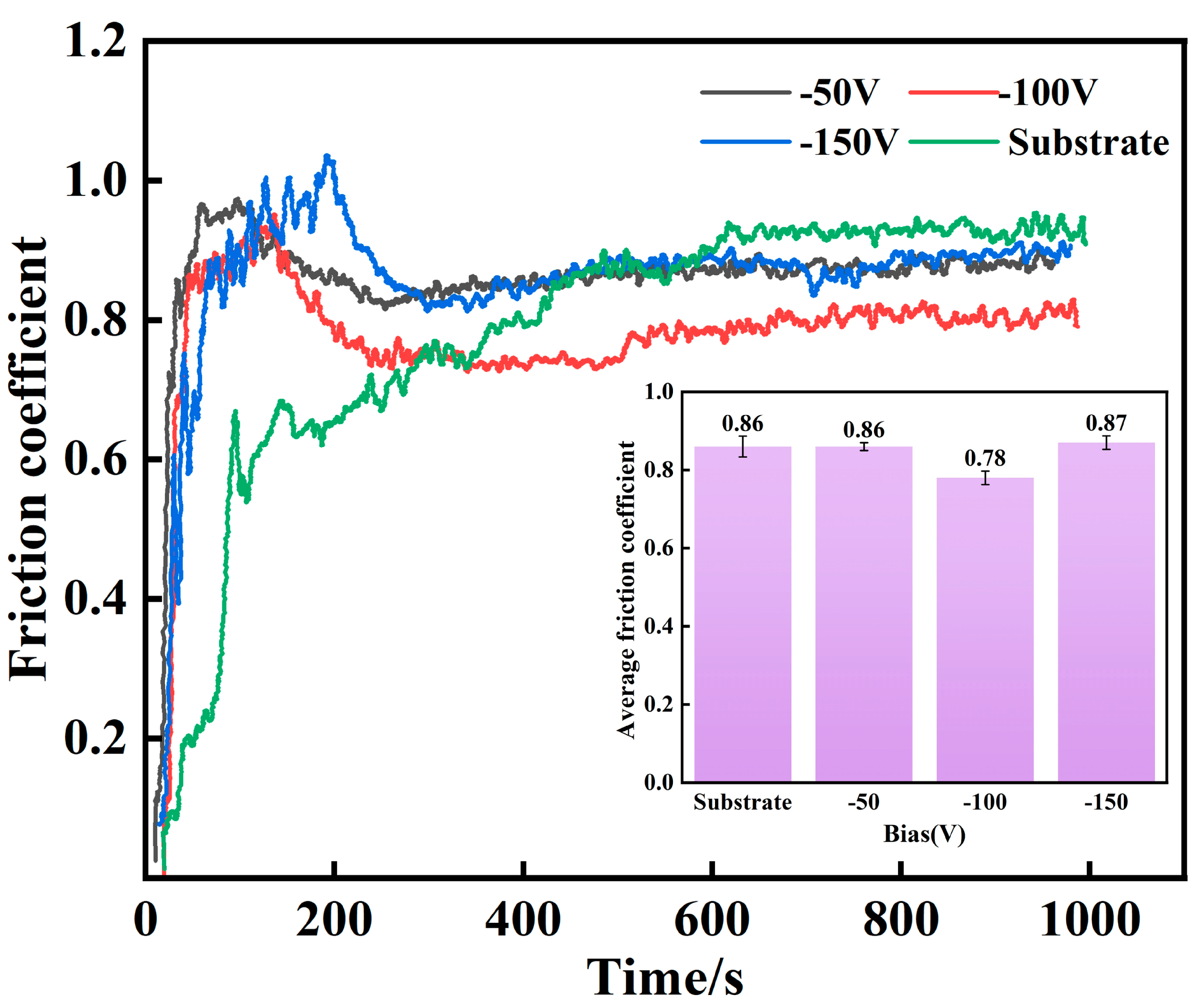

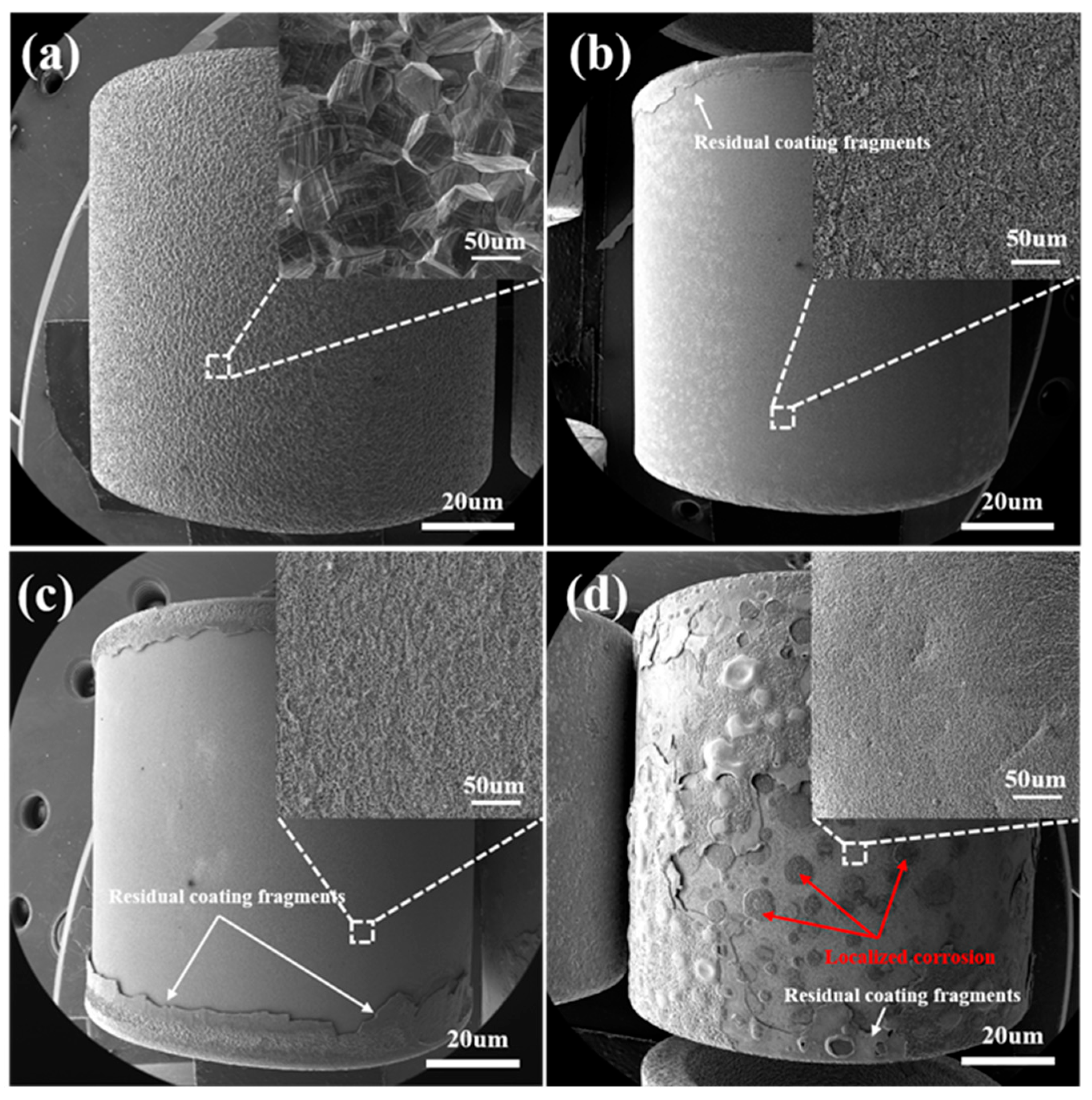

3.2. Coating Microhardness and Tribological Properties

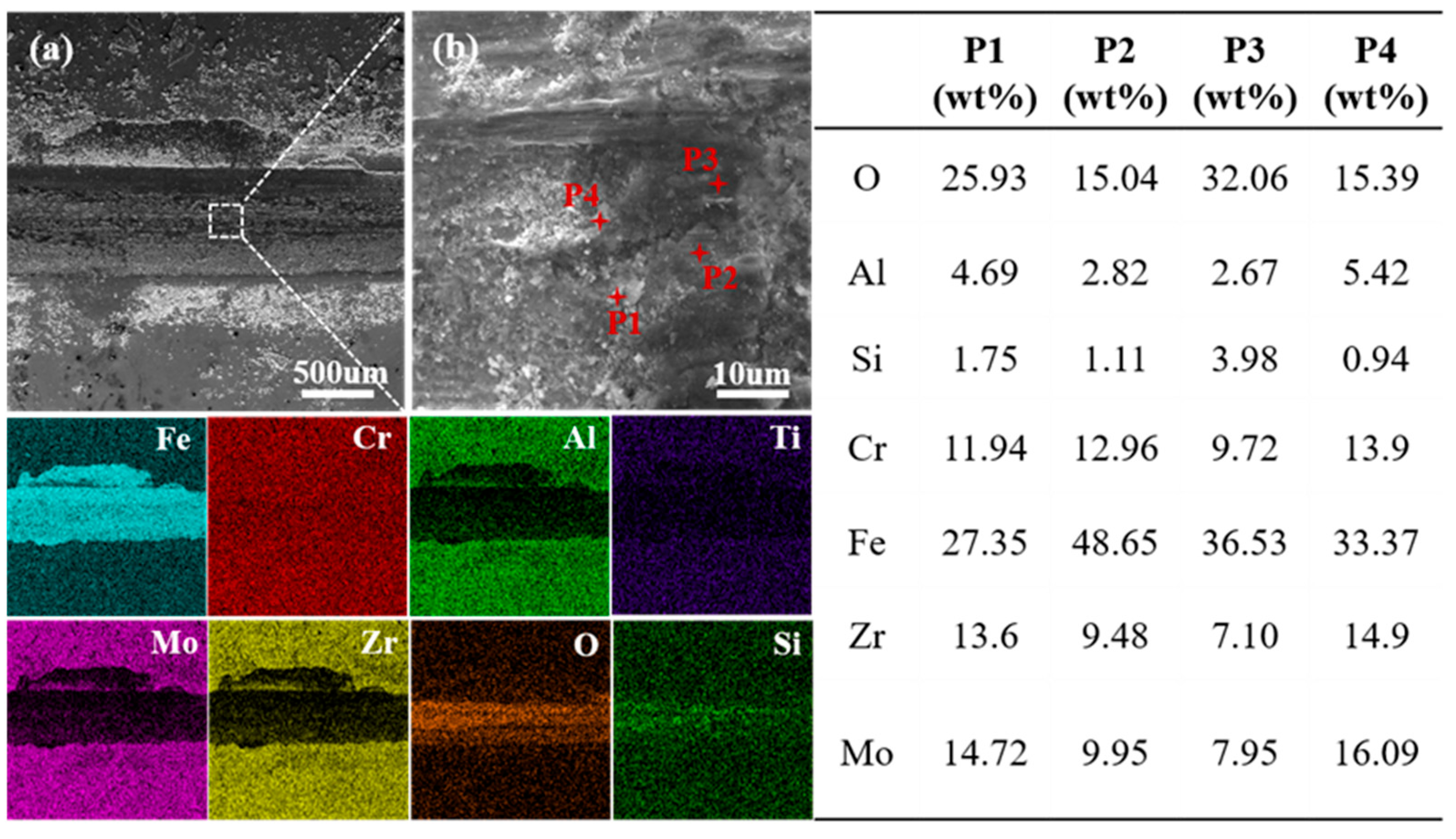

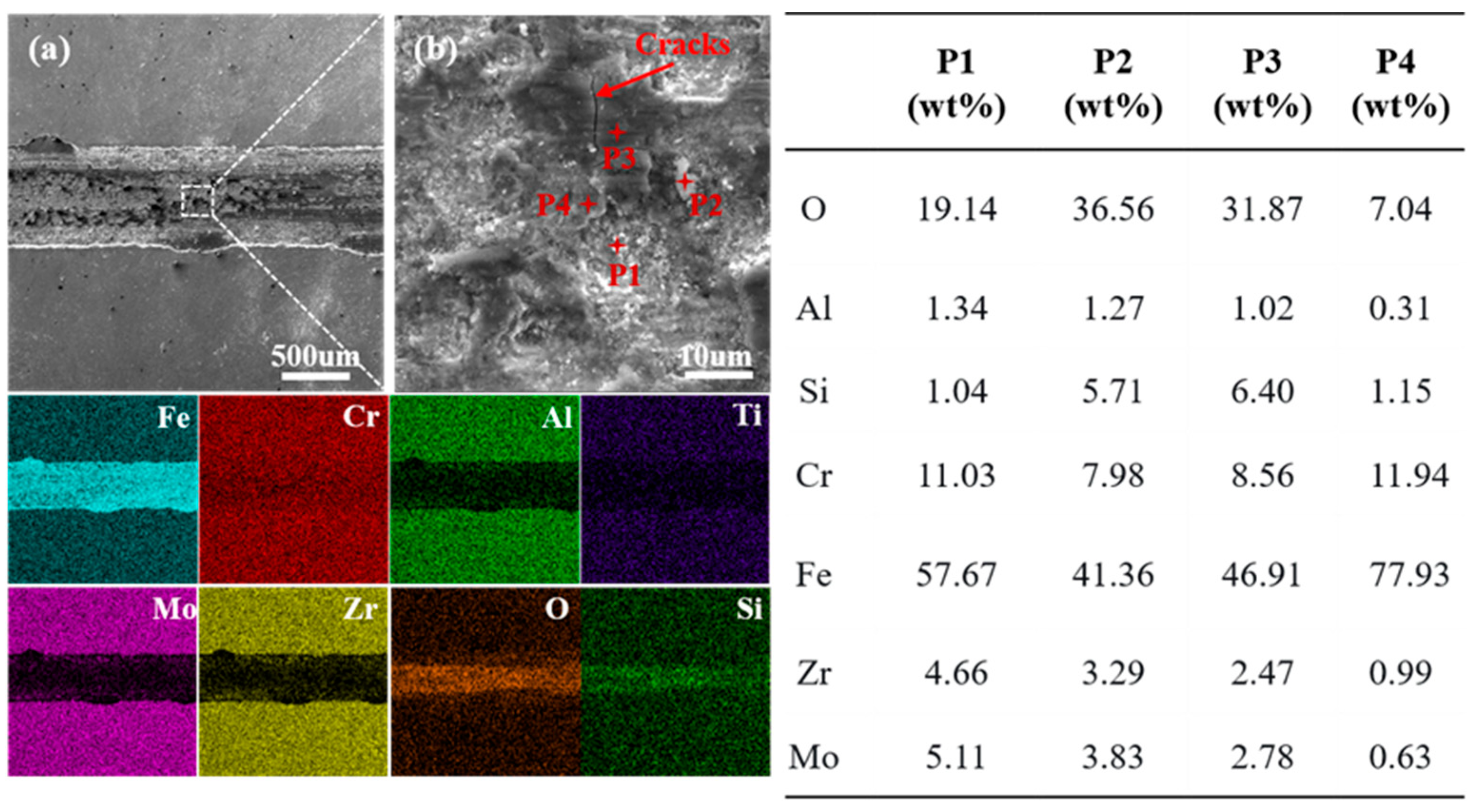

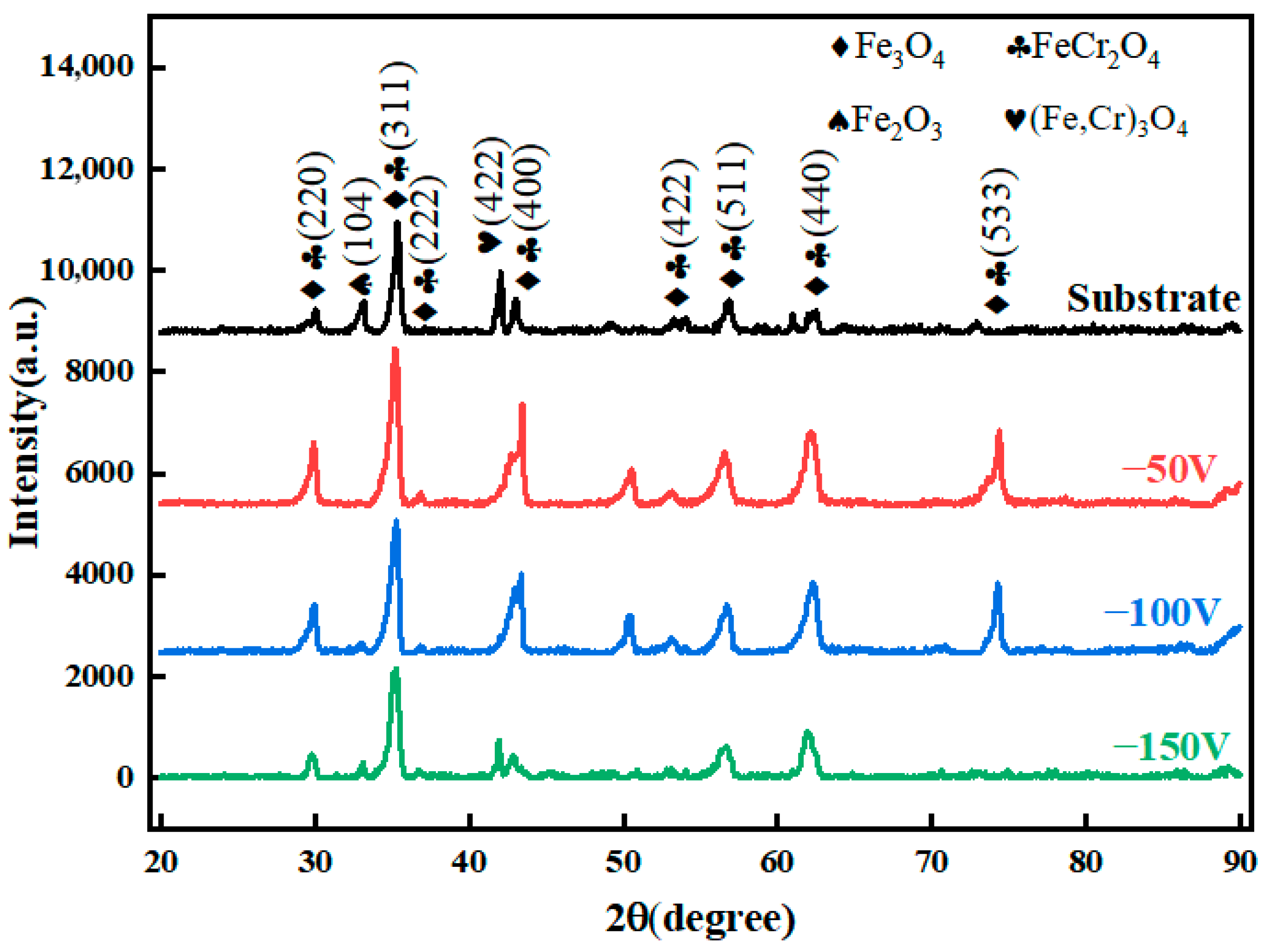

3.3. Coating Water Vapor Corrosion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| HEA | High entropy alloy |

| ATF | Accident fault-tolerant fuel |

| LOCA | Loss-of-coolant accident |

| XRD | X-ray diffractometer |

| SEM | Scanning electron microscope |

| EDS | X-ray energy dispersive spectrometer |

| HV | Micro-hardness |

| BV | Bias voltage |

| COF | Coefficient of friction |

References

- Zinkle, S.J.; Was, G.S. Materials challenges in nuclear energy. Acta Mater. 2013, 61, 735–758. [Google Scholar] [CrossRef]

- Pint, B.A.; Terrani, K.A.; Brady, M.P.; Cheng, T.; Keiser, J.R. High temperature oxidation of fuel cladding candidate materials in steam–hydrogen environments. J. Nucl. Mater. 2013, 440, 420–427. [Google Scholar] [CrossRef]

- Singh, G.; Jayaganthan, R.; Arora, U.K.; Vishnu Narayanan, K.I.; Srivastava, D. Texture analysis and fracture behavior of zircaloy-4 processed through swaging. Metall. Microstruct. Anal. 2020, 9, 273–284. [Google Scholar] [CrossRef]

- Wang, X.; Li, J.; Zhao, Z.; Yu, Y.; Shi, H. Corrosion behaviors of Zr-Sn-Nb alloys: Influence of different concentration dissolved oxygen environment and trace V element on the anti-corrosion properties. J. Nucl. Mater. 2024, 595, 155068. [Google Scholar] [CrossRef]

- Massey, C.P.; Terrani, K.A.; Dryepondt, S.N.; Pint, B.A. Cladding burst behavior of Fe-based alloys under LOCA. J. Nucl. Mater. 2016, 470, 128–138. [Google Scholar] [CrossRef]

- Younker, I.; Fratoni, M. Neutronic evaluation of coating and cladding materials for accident tolerant fuels. Prog. Nucl. Energy 2016, 88, 10–18. [Google Scholar] [CrossRef]

- Yeom, H.; Dabney, T.; Johnson, G.; Maier, B.; Lenling, M.; Sridharan, K. Improving deposition efficiency in cold spraying chromium coatings by powder annealing. Int. J. Adv. Manuf. Technol. 2019, 100, 1373–1382. [Google Scholar] [CrossRef]

- Liu, K.; Li, Y.; Wang, J.; Ma, Q. In-situ synthesized Ni–Zr intermetallic/ceramic reinforced composite coatings on zirconium substrate by high power diode laser. J. Alloys Compd. 2015, 624, 234–240. [Google Scholar] [CrossRef]

- Bragg-Sitton, S. Development of advanced accident tolerant fuels for commercial light water reactors. Nucl. News 2014, 57, 83–91. [Google Scholar]

- Tallman, D.J.; Yang, J.; Pan, L.; Anasori, B.; Barsoum, M.W. Reactivity of Zircaloy-4 with Ti3SiC2 and Ti2AlC in the 1100–1300 °C temperature range. J. Nucl. Mater. 2015, 460, 122–129. [Google Scholar] [CrossRef]

- Chen, Q.S.; Liu, C.H.; Zhang, R.Q.; Yang, H.Y.; Wei, T.G.; Wang, Y.; Li, Z.; He, L.X.; Wang, J.; Wang, L.; et al. Microstructure and high-temperature steam oxidation properties of thick Cr coatings prepared by magnetron sputtering for accident tolerant fuel claddings: The role of bias in the deposition process. Corros. Sci. 2020, 165, 108378. [Google Scholar] [CrossRef]

- Syrtanov, M.; Kashkarov, E.; Abdulmenova, A.; Gusev, K.; Sidelev, D. High-Temperature Steam Oxidation of Accident-Tolerant Cr/Mo-Coated Zr Alloy at 1200–1400 °C. Coatings 2023, 13, 191. [Google Scholar] [CrossRef]

- Yeh, J.W.; Chen, S.K.; Lin, S.J.; Gan, J.Y.; Chin, T.S.; Shun, T.T.; Tsau, C.H.; Chang, S.Y. Nanostructured High-Entropy Alloys with Multiple Principal Elements: Novel Alloy Design Concepts and Outcomes. Adv. Eng. Mater. 2004, 6, 299–303. [Google Scholar] [CrossRef]

- Li, D.; Zheng, S.; Gu, J.; Liu, S.; Si, J. Effect of Sc/Y Co-Doping on Microstructure and High-Temperature Oxidation Properties of FeCoNiCrAl High-Entropy Alloys. Mater. Prot. 2025, 58, 65–73. [Google Scholar] [CrossRef]

- Yang, J.; Shi, K.; Chen, Q.; Zhang, W.; Zhu, C.; Ning, Z.; Liao, J.; Yang, Y.; Liu, N.; Zhang, W.; et al. Effect of Au-ion irradiation on the surface morphology, microstructure and mechanical properties of amorphous AlCrFeMoTi HEA coating. Surf. Coat. Technol. 2021, 418, 127252. [Google Scholar] [CrossRef]

- Yang, J.; Zhao, K.; Wang, G.; Deng, C.; Liu, N.; Zhang, W.; Yang, J. Influence of coating thickness on microstructure, mechanical and LBE corrosion performance of amorphous AlCrFeTiNb high-entropy alloy coatings. Surf. Coat. Technol. 2022, 441, 128502. [Google Scholar] [CrossRef]

- Jiang, X.; Zeng, X.K.; Xie, W.; Liu, M.; Leng, Y.X. Optimizing substrate bias voltage to improve mechanical and tribological properties of ductile FeCoNiCu high entropy alloy coatings with FCC structure. J. Alloys Compd. 2024, 1004, 175972. [Google Scholar] [CrossRef]

- Xiao, W.; Xu, S.; Hu, X.; Huang, J.; Liu, S.; Zou, S. Microstructure, oxidation kinetics and hydrogen absorption of Cr-coated Zr-Sn-Nb alloy cladding tubes after single-sided oxidation at 1000–1200 °C followed by fast reflood. J. Nucl. Mater. 2025, 608, 155718. [Google Scholar] [CrossRef]

- Xiao, W.; Ren, Z.; Hu, X.; Huang, J.; Deng, X.; Zou, S.; Liu, S.; Wu, Y. Comparative study on high-temperature air and steam oxidation of Cr-coated Zr-4 alloy through experimental and DFT calculation. J. Nucl. Mater. 2025, 603, 155382. [Google Scholar] [CrossRef]

- ASTM E384-22; Standard Test Method for Microindentation Hardness of Materials. ASTM International: West Conshohocken, PA, USA, 2022.

- ASTM G99-17; Standard Test Method for Wear Testing with a Pin-on-Disk Apparatus. ASTM International: West Conshohocken, PA, USA, 2017.

- Yang, J.; Shi, K.; Zhang, W.; Chen, Q.; Ning, Z.; Zhu, C.; Liao, J.; Yang, Y.; Liu, N.; Zhang, W.; et al. A novel AlCrFeMoTi high-entropy alloy coating with a high corrosion-resistance in lead-bismuth eutectic alloy. Corros. Sci. 2021, 187, 109524. [Google Scholar] [CrossRef]

- Zhang, X.; Pelenovich, V.; Zeng, X.; Wan, Q.; Liu, J.; Pogrebnjak, A.; Guo, Y.; Liu, Y.; Lei, Y.; Yang, B. Unravel hardening mechanism of AlCrNbSiTi high-entropy alloy coatings. J. Alloys Compd. 2023, 965, 171222. [Google Scholar] [CrossRef]

- Zhang, W.; Tang, R.; Yang, Z.B.; Liu, C.H.; Chang, H.; Yang, J.J.; Liao, J.L.; Yang, Y.Y.; Liu, N. Preparation, structure, and properties of an AlCrMoNbZr high-entropy alloy coating for accident-tolerant fuel cladding. Surf. Coat. Technol. 2018, 347, 13–19. [Google Scholar] [CrossRef]

- Guo, M.; Chen, C.; Song, B.; Guo, J.; Hu, J.; Cao, G. Effect of Al on the oxidation behavior of TiCrZrNbTa high-entropy coatings on Zr alloy. Materials 2025, 18, 1997. [Google Scholar] [CrossRef]

- Zhu, Y.; Tao, Z.; Gu, X.; Wang, C.; Lan, R. Enhanced accident tolerance properties of AlCrCuFeMoNbx high entropy coating for nuclear fuel cladding. J. Alloys Compd. 2025, 1010, 177206. [Google Scholar] [CrossRef]

- Zak, A.K.; Majid, W.A.; Abrishami, M.E.; Yousefi, R. X-ray analysis of ZnO nanoparticles by Williamson–Hall and size–strain plot methods. Solid State Sci. 2011, 13, 251–256. [Google Scholar] [CrossRef]

- He, L.; Liu, C.; Zhao, S.; Shu, C.; Yang, J.; Liu, H.; Zhang, W.; Lin, J.; Long, J.; Chang, H. Microstructure, mechanical and corrosion properties of high hardness TiVZrCrAl HEA coatings prepared by magnetron sputtering. Surf. Coat. Technol. 2022, 441, 128532. [Google Scholar] [CrossRef]

- Xin, H.; Yang, J.; Mao, J.; Chen, Q.; Yang, J.; Zhang, W.; Ning, Z.; Teng, C.; Ma, C.; Wu, L.; et al. Effect of Al Concentration on Microstructure and Properties of AlNbTiZr Medium-Entropy Alloy Coatings. Materials 2021, 14, 7661. [Google Scholar] [CrossRef] [PubMed]

- Kang, X.D.; Zhang, G.H.; Chou, K.C. Synergistic enhancement of hardness-toughness-strength in TiC-based cermets prepared by ultrafine TiC with WC addition. Int. J. Appl. Ceram. Technol. 2025, e70115. [Google Scholar] [CrossRef]

- Cantor, B.; Chang, I.T.H.; Knight, P.; Vincent, A.J.B. Microstructural development in equiatomic multicomponent alloys. Mater. Sci. Eng. A 2004, 375–377, 213–218. [Google Scholar] [CrossRef]

- Liu, L.; Zhu, J.B.; Hou, C.; Li, J.C.; Jiang, Q. Dense and smooth amorphous films of multicomponent FeCoNiCuVZrAl high-entropy alloy deposited by direct current magnetron sputtering. Mater. Des. 2013, 46, 675–679. [Google Scholar] [CrossRef]

- He, M.; Kang, H.; Hou, G.; Lian, Z.; Lu, S.; Li, Y.; Qin, W.; Wu, X. Fabrication of eutectic FeCrCoNiV1. 5 high entropy alloy coating with excellent high-temperature wear resistance. Surf. Coat. Technol. 2024, 476, 130232. [Google Scholar] [CrossRef]

- Zhou, Q.; Xia, Q.; Li, Q.; Luo, D.; Huang, Z.; Wang, C.; Chen, Z.; Wang, H. Microstructure, mechanical and tribological properties of NbMoWTaAg refractory high entropy films with nano-layered self-organization. Tribol. Int. 2024, 198, 109888. [Google Scholar] [CrossRef]

- Liu, H.Y.; Gong, Y.L.; Ma, D.L.; Jing, P.P.; You, L.N.; Wei, L.J.; Leng, Y.X. The adhesion strength and stability of TiN films deposited on magnesium substrate with different substrate roughness. Ceram. Int. 2024, 50, 21658–21666. [Google Scholar] [CrossRef]

- Mahade, S.; Awe, S.A.; Björklund, S.; Lukáč, F.; Mušálek, R.; Joshi, S. Sliding wear behavior of a sustainable Fe-based coating and its damage mechanisms. Wear 2022, 500, 204375. [Google Scholar] [CrossRef]

- Luo, D.; Zhou, Q.; Huang, Z.; Li, Y.; Liu, Y.; Li, Q.; He, Y.; Wang, H. Tribological Behavior of High Entropy Alloy Coatings: A Review. Coatings 2022, 12, 1428. [Google Scholar] [CrossRef]

- Nair, R.B.; Ngan, S.; McDonald, A. Dry abrasive wear and solid particle erosion assessments of high entropy alloy coatings fabricated by cold spraying. Mater. Today Commun. 2023, 34, 105527. [Google Scholar] [CrossRef]

- Oppong Boakye, G.; Geambazu, L.E.; Ormsdottir, A.M.; Gunnarsson, B.G.; Csaki, I.; Fanicchia, F.; Kovalov, D.; Karlsdottir, S.N. Microstructural Properties and Wear Resistance of Fe-Cr-Co-Ni-Mo-Based High Entropy Alloy Coatings Deposited with Different Coating Techniques. Appl. Sci. 2022, 12, 3156. [Google Scholar] [CrossRef]

- Vallimanalan, A.; Babu, S.P.K.; Muthukumaran, S.; Murali, M.; Mahendran, R.; Gaurav, V.; Manivannan, S. Synthesis, characterisation and erosion behaviour of AlCoCrMoNi high entropy alloy coating. Mater. Res. Express 2019, 6, 116543. [Google Scholar] [CrossRef]

- Hao, X.; Liu, H.; Zhang, X.; Chen, L.; Wang, Y.; Yang, C.; Liu, Y. Friction–wear behaviors and microstructure of AlTiVCrNb lightweight refractory high-entropy alloy coating prepared by laser cladding on Ti–6Al–4V substrate. J. Mater. Res. Technol. 2024, 29, 1–11. [Google Scholar] [CrossRef]

- Wang, J.; Zhang, B.; Yu, Y.; Zhang, Z.; Zhu, S.; Lou, X.; Wang, Z. Study of high temperature friction and wear performance of (CoCrFeMnNi)85Ti15 high-entropy alloy coating prepared by plasma cladding. Surf. Coat. Technol. 2020, 384, 125337. [Google Scholar] [CrossRef]

- Wu, J.-M.; Lin, S.-J.; Yeh, J.-W.; Chen, S.-K.; Huang, Y.-S.; Chen, H.-C. Adhesive wear behavior of AlxCoCrCuFeNi high-entropy alloys as a function of aluminum content. Wear 2006, 261, 513–519. [Google Scholar] [CrossRef]

- Jurasz, Z.; Adamaszek, K.; Janik, R.; Grzesik, Z.; Mrowec, S. High temperature corrosion of valve steels in atmosphere containing water vapor. J. Solid State Electrochem. 2009, 13, 1709–1714. [Google Scholar] [CrossRef]

- Liu, G.; Wang, C.; Yu, F.; Tian, J. Evolution of Oxide Film of T91 Steel in Water Vapor Atmosphere at 750 °C. Oxid. Met. 2014, 81, 383–392. [Google Scholar] [CrossRef]

| Bias | Lattice Parameters (Å) |

|---|---|

| −50 V | 3.177 |

| −100 V | 3.161 |

| −150 V | 3.138 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, Y.; Liu, Y.; Yan, P.; Huang, J. A Preliminary Study on Wear Resistance and High-Temperature Steam Oxidation of AlCrFeMoZr High-Entropy Alloy Coatings for Accident-Tolerant Fuel. Lubricants 2025, 13, 511. https://doi.org/10.3390/lubricants13120511

Wu Y, Liu Y, Yan P, Huang J. A Preliminary Study on Wear Resistance and High-Temperature Steam Oxidation of AlCrFeMoZr High-Entropy Alloy Coatings for Accident-Tolerant Fuel. Lubricants. 2025; 13(12):511. https://doi.org/10.3390/lubricants13120511

Chicago/Turabian StyleWu, Yunyun, Yilong Liu, Ping Yan, and Jinghao Huang. 2025. "A Preliminary Study on Wear Resistance and High-Temperature Steam Oxidation of AlCrFeMoZr High-Entropy Alloy Coatings for Accident-Tolerant Fuel" Lubricants 13, no. 12: 511. https://doi.org/10.3390/lubricants13120511

APA StyleWu, Y., Liu, Y., Yan, P., & Huang, J. (2025). A Preliminary Study on Wear Resistance and High-Temperature Steam Oxidation of AlCrFeMoZr High-Entropy Alloy Coatings for Accident-Tolerant Fuel. Lubricants, 13(12), 511. https://doi.org/10.3390/lubricants13120511