Investigation of Performance Degradation in Calcium-Based Grease Under Combined SiO2 Particle and Water Contamination

Abstract

1. Introduction

2. Materials and Methods

2.1. Tested Lubricants

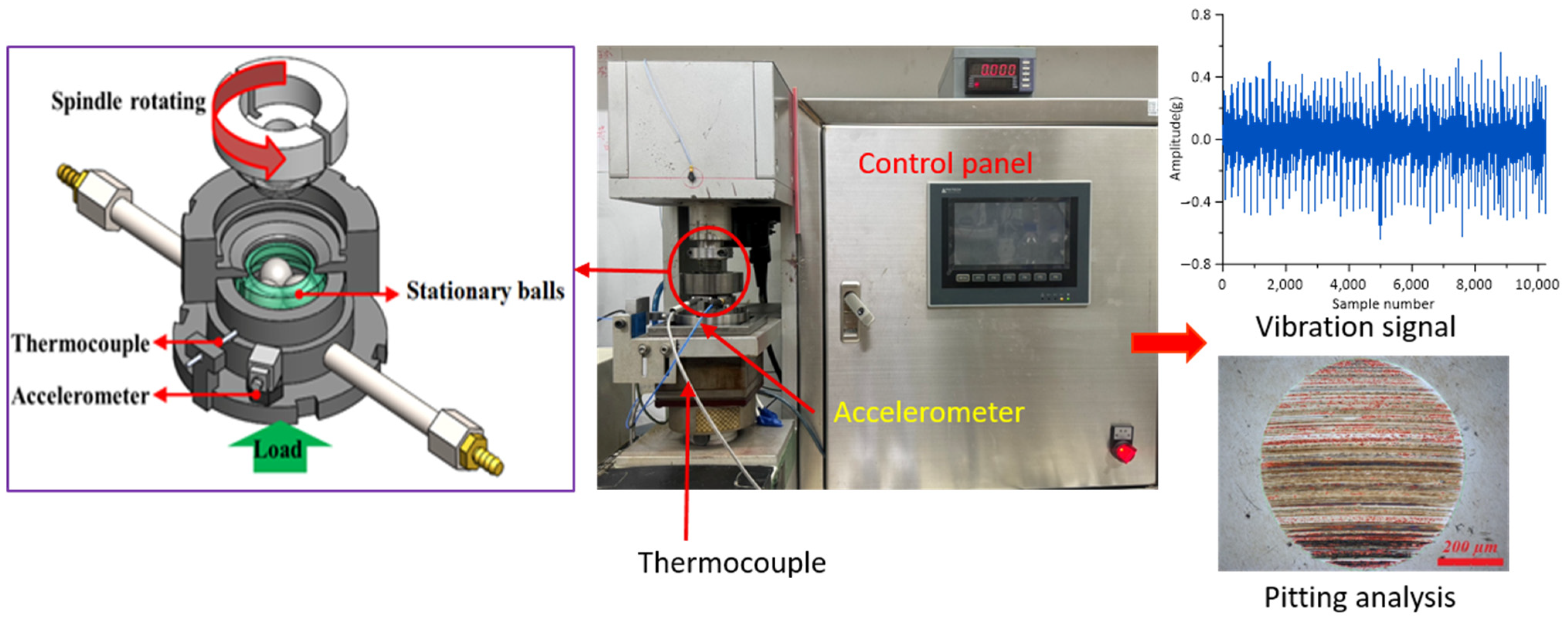

2.2. Tribological Test

3. Experimental Results and Discussion

3.1. Lubricant Properties

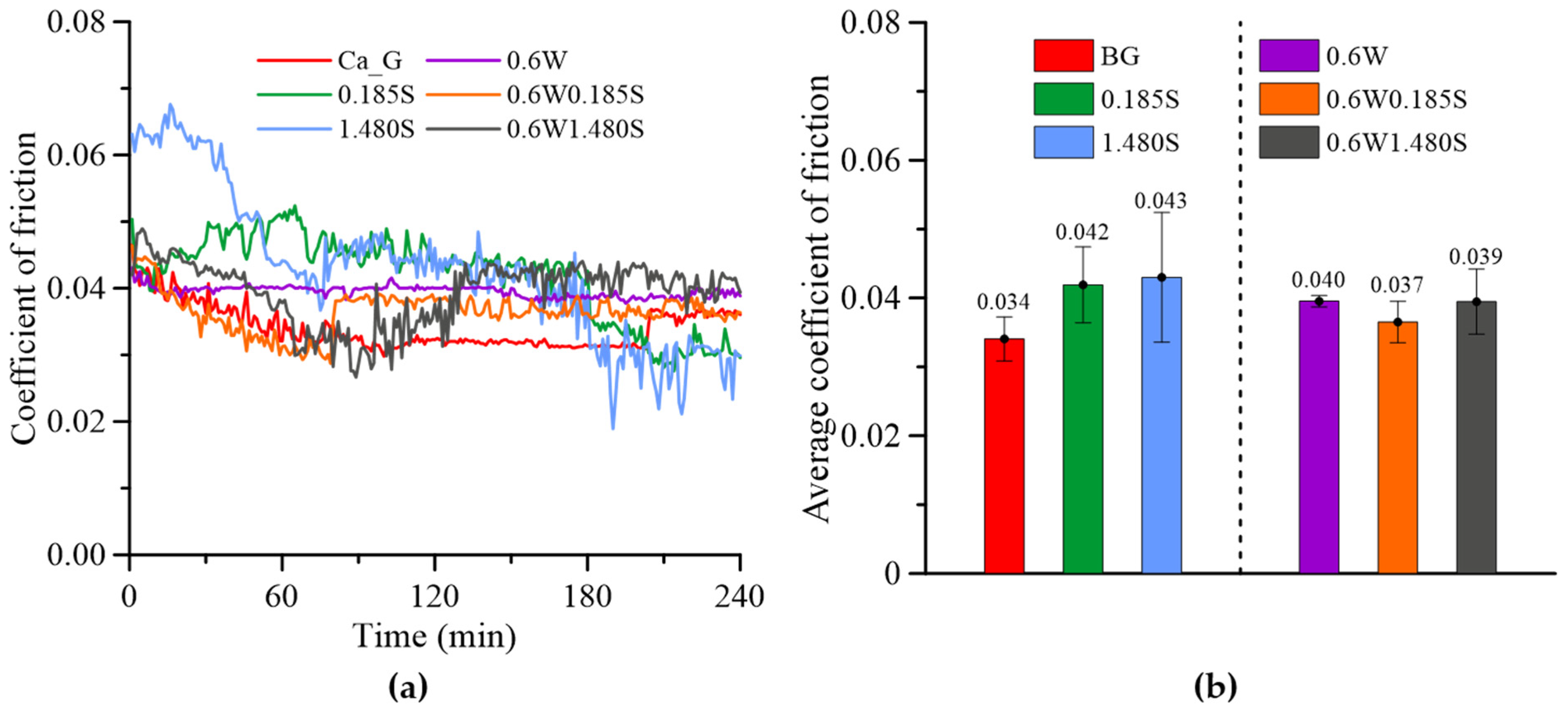

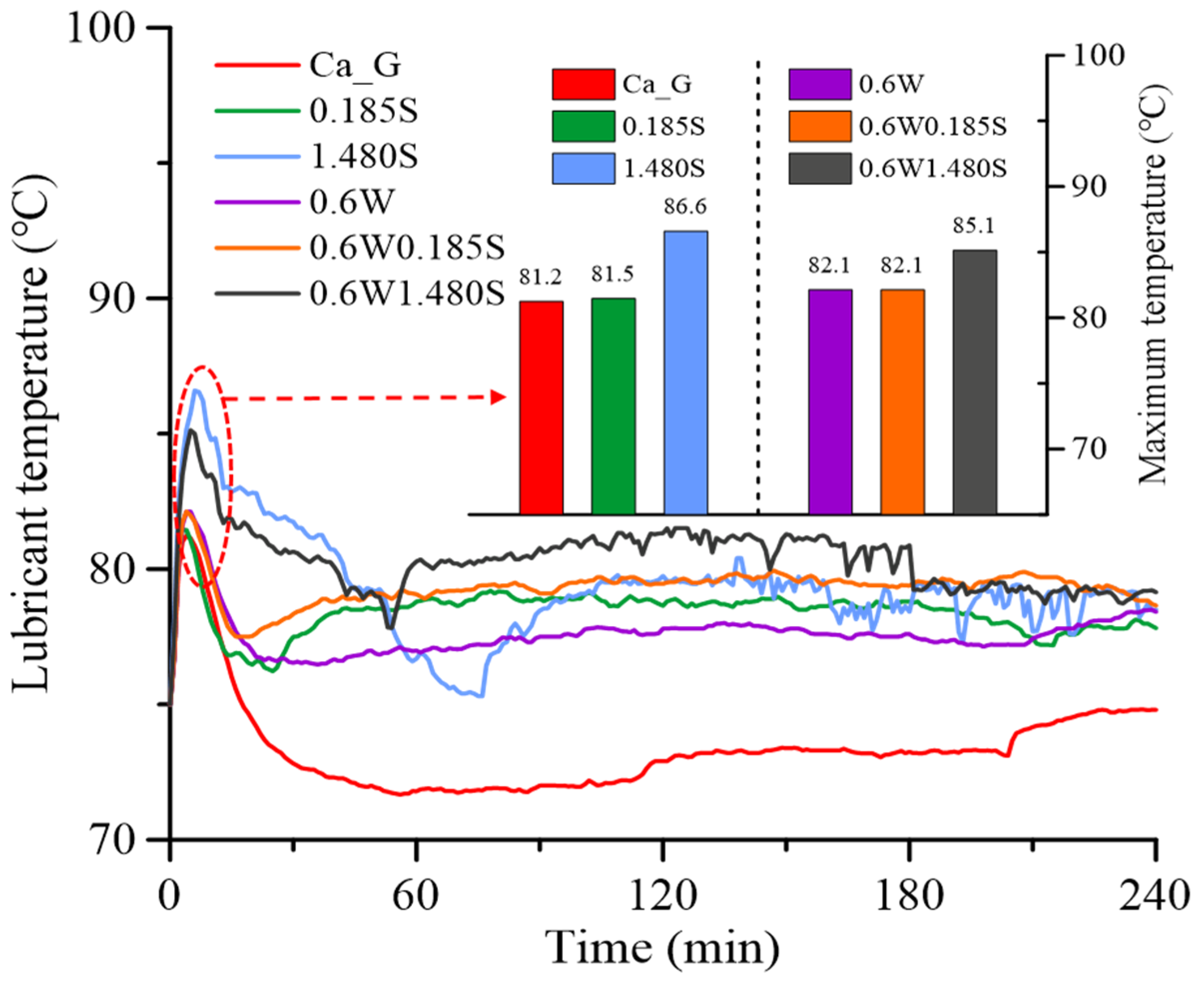

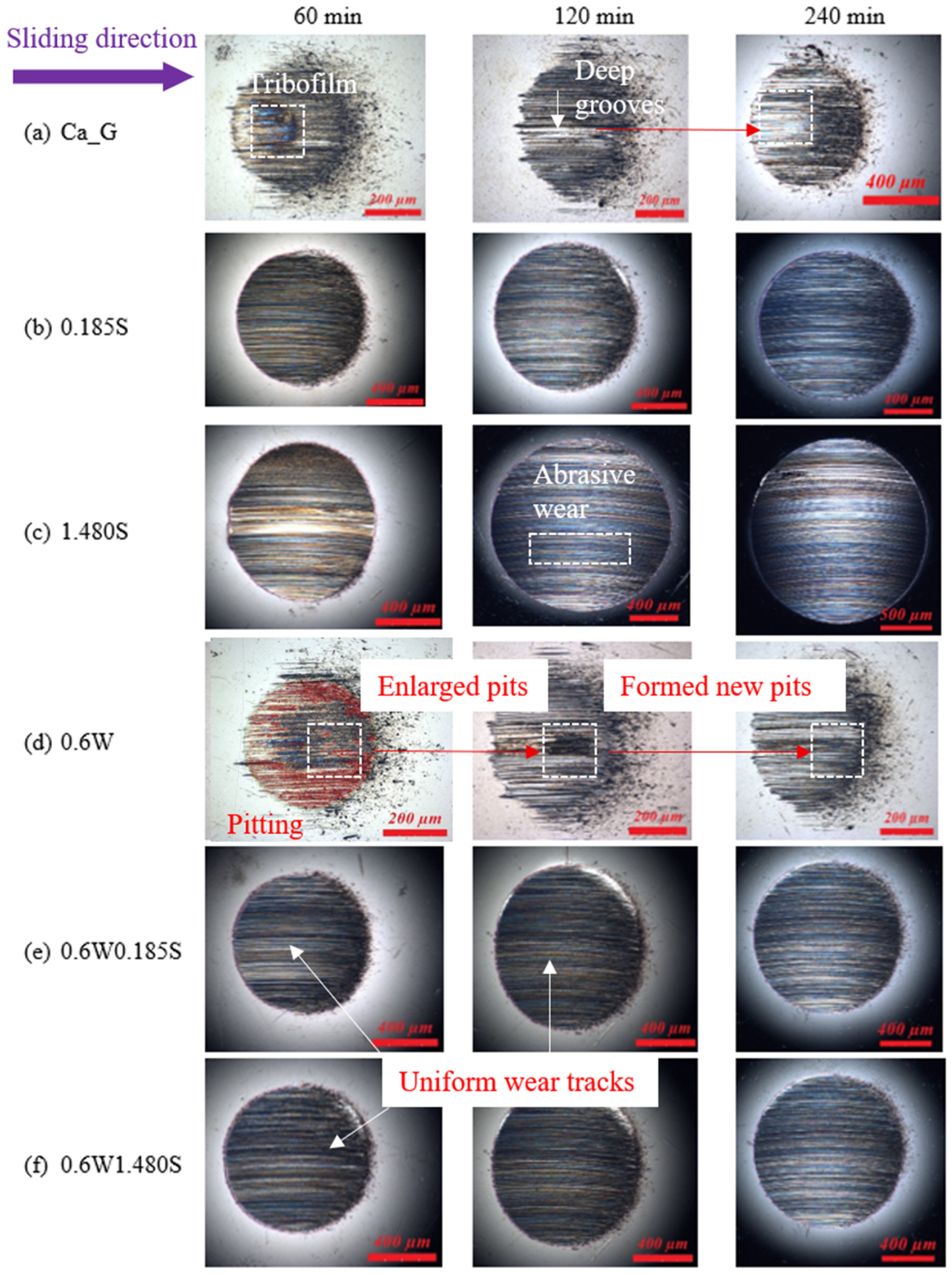

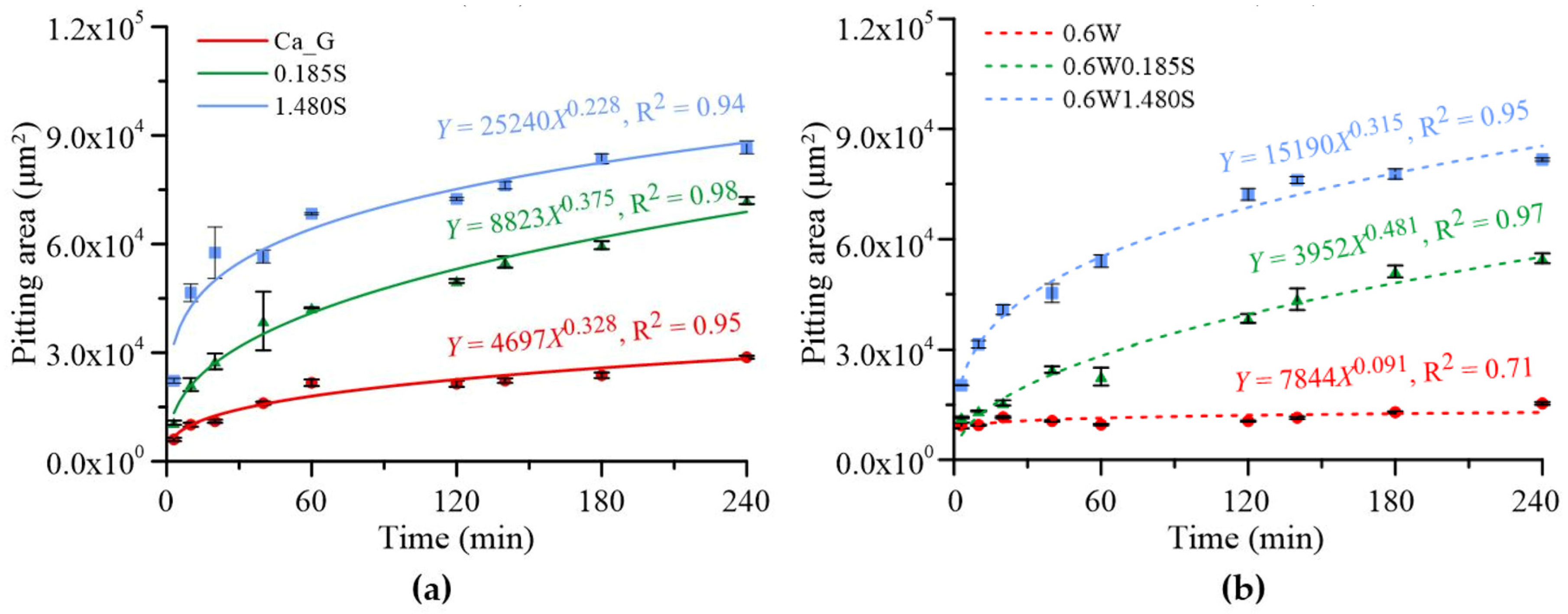

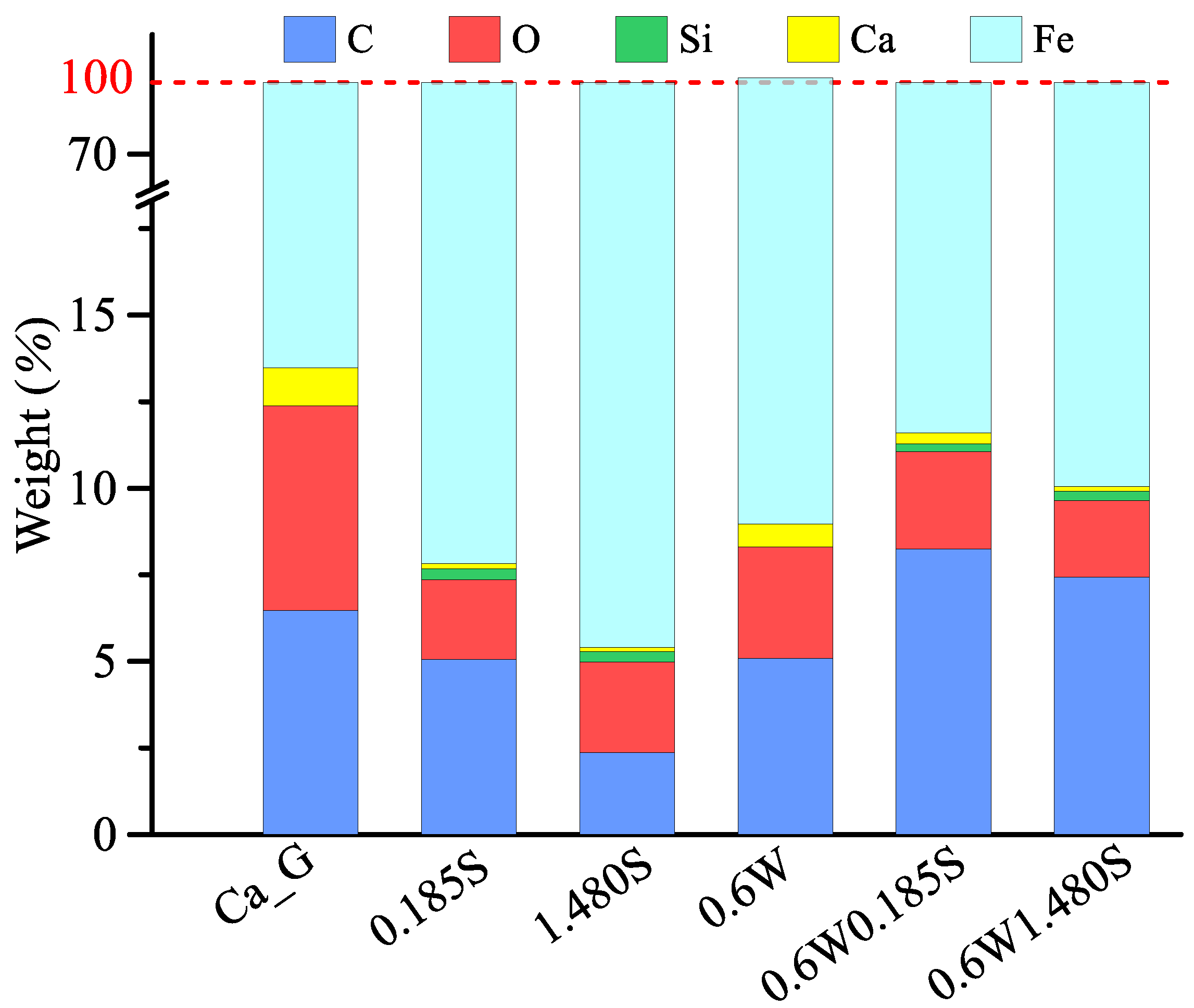

3.2. Tribological Behaviors

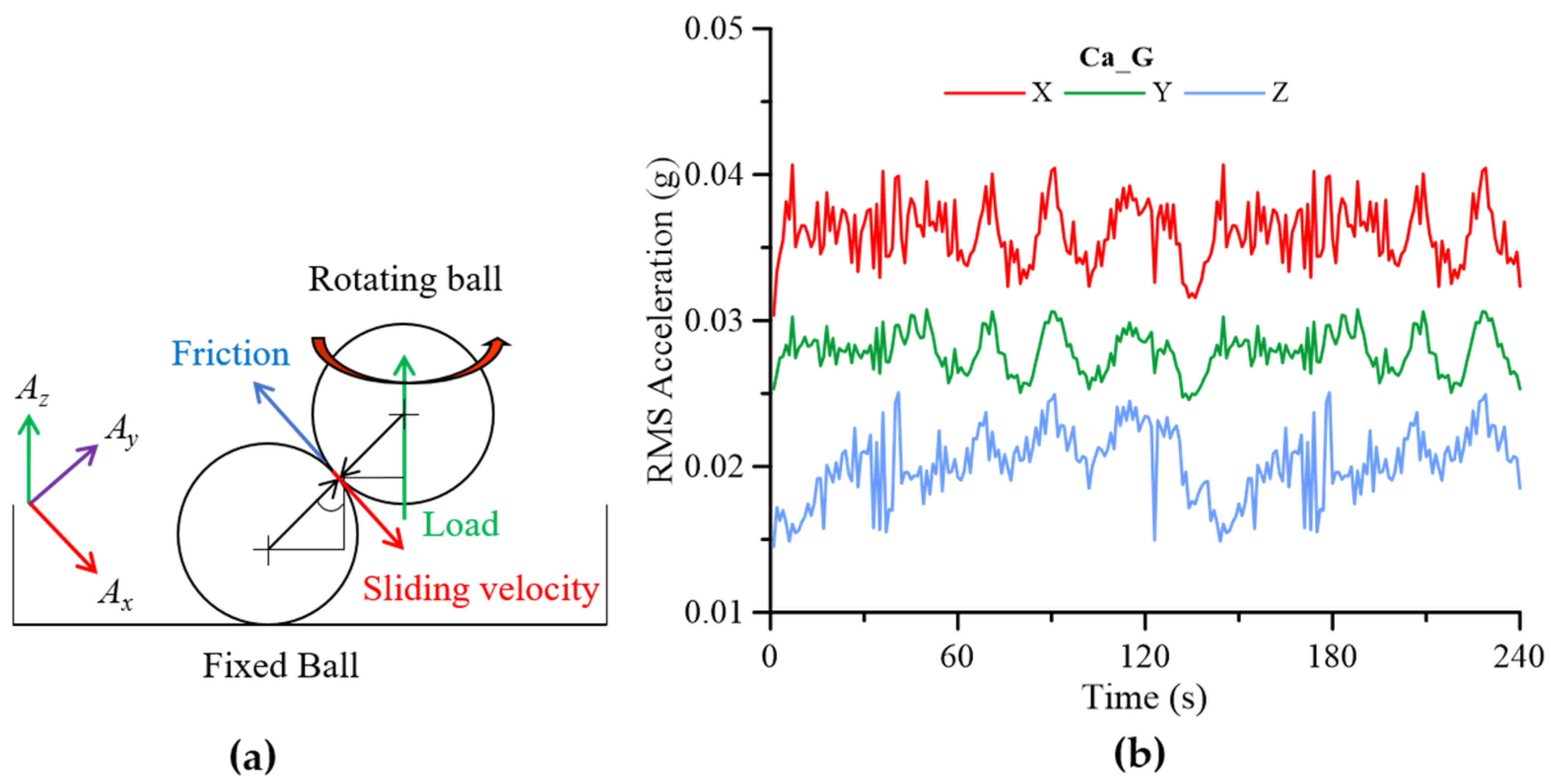

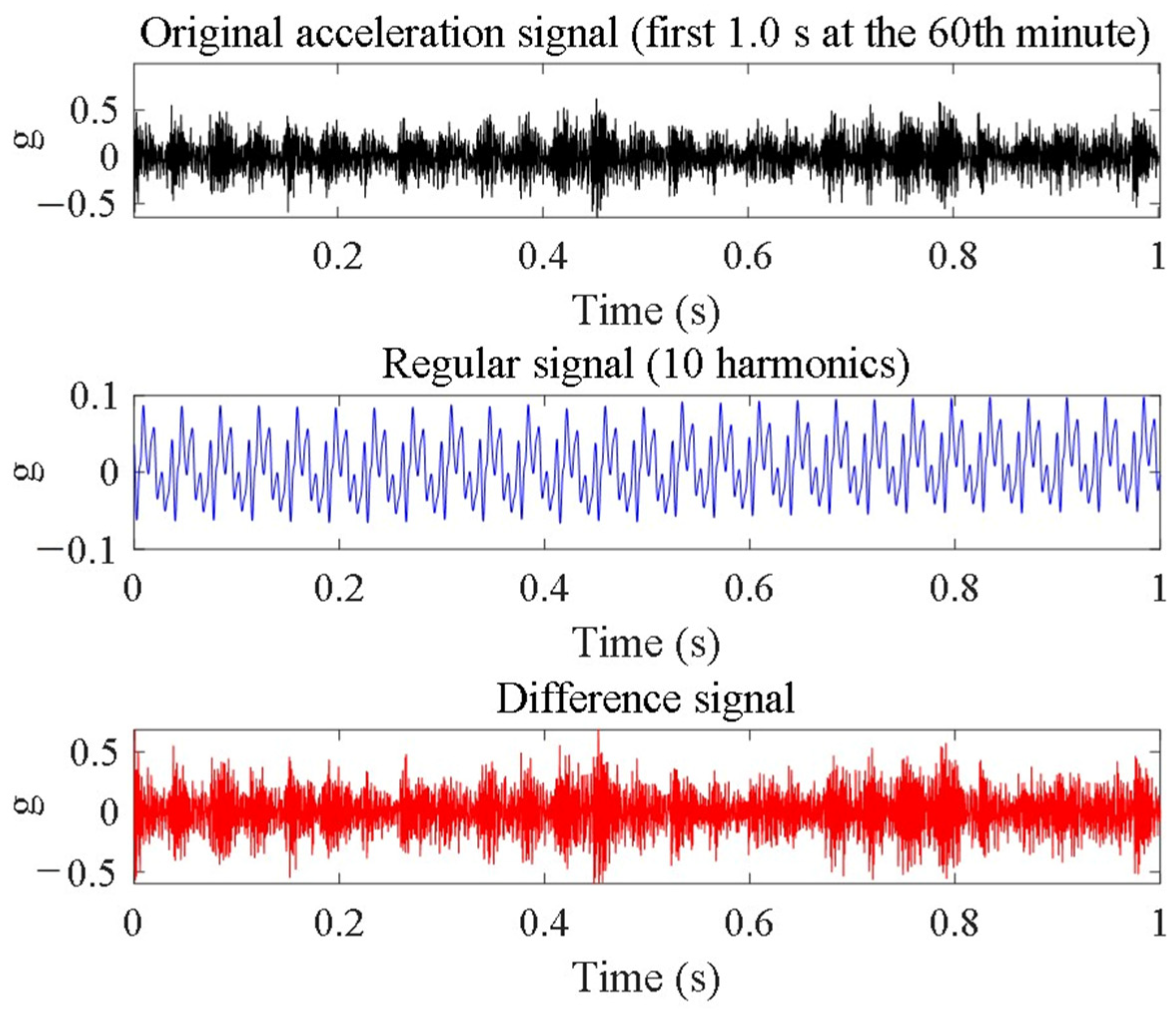

4. Vibration Indicator for Monitoring Surface Damage

5. Conclusions

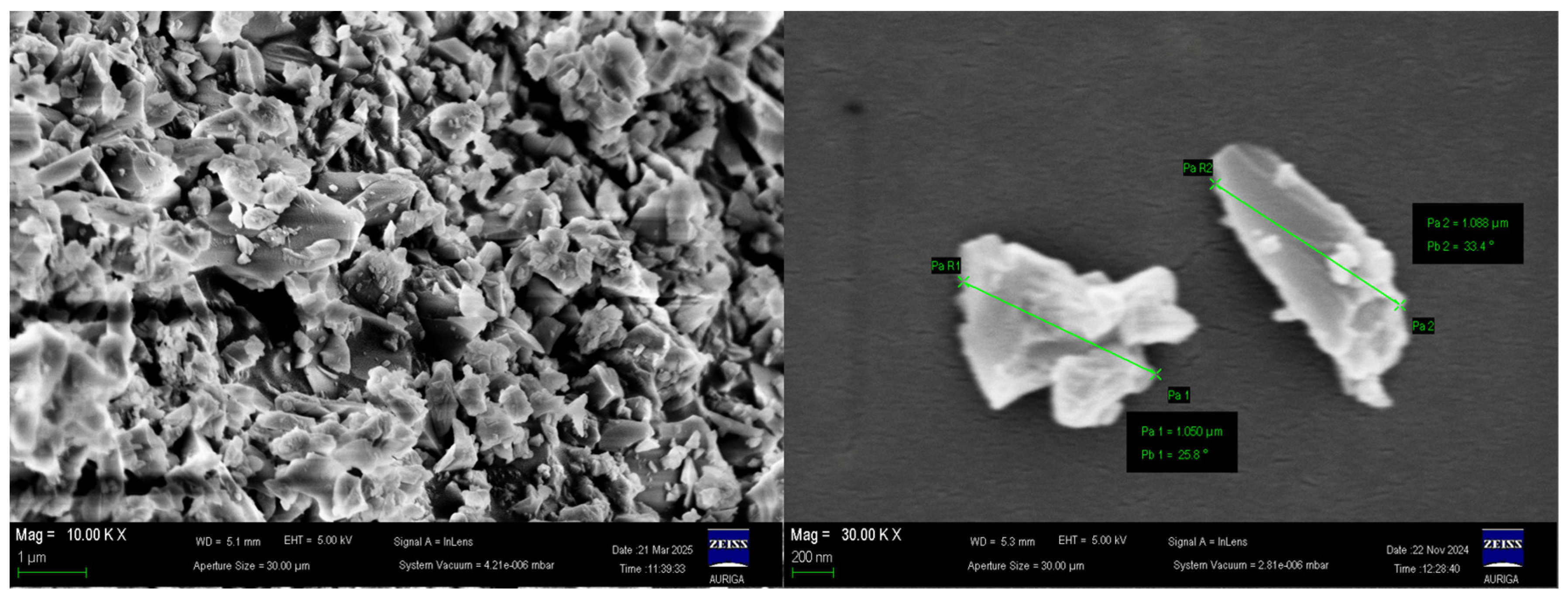

- The influence of SiO2 contamination exhibited a concentration-dependent behavior. However, unlike the nanoscale spherical silica previously reported to promote mild polishing or tribofilm repair at low concentrations, the relatively large (~1 µm) and irregularly shaped SiO2 particles used in this work did not produce a beneficial polishing effect. Instead, even at 0.185 wt%, the particles introduced intermittent three-body contacts and local micro-abrasion, and further increasing the concentration to 1.480 wt% resulted in pronounced abrasive wear, higher frictional heating, and accelerated surface fatigue.

- The introduction of 0.6 wt% water reduced temperature and friction variability, primarily due to enhanced heat dissipation and transient softening of the grease microstructure. However, when water coexisted with a high SiO2 concentration, lubricant degradation was intensified due to weakened thickener integrity and more severe abrasive interaction, resulting in accelerated pitting and wear progression.

- The energy ratio vibration indicator corresponded well with the progression of pitting, suggesting it can serve as an important parameter for monitoring pitting evolution.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Jin, X. The Effect of Contamination Particles on Lithium Grease Deterioration in Sealed Ball Bearings. Lubr. Sci. 1995, 7, 233–245. [Google Scholar] [CrossRef]

- Schnabel, S.; Marklund, P.; Larsson, R. Study of the Short-term Effect of Fe3O4 Particles in Rolling Element Bearings: Observation of Vibration, Friction and Change of Surface Topography of Contaminated Angular Contact Ball Bearings. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2014, 228, 1063–1070. [Google Scholar] [CrossRef]

- Koulocheris, D.; Stathis, A.; Costopoulos, T.h.; Gyparakis, G. Comparative Study of the Impact of Corundum Particle Contaminants Size on Wear and Fatigue Life of Grease Lubricated Ball Bearings. Mod. Mech. Eng. 2013, 3, 161–170. [Google Scholar] [CrossRef]

- Koulocheris, D.; Stathis, A.; Costopoulos, T.h.; Tsantiotis, D. Experimental Study of the Impact of Grease Particle Contaminants on Wear and Fatigue Life of Ball Bearings. Eng. Fail. Anal. 2014, 39, 164–180. [Google Scholar] [CrossRef]

- Lin, C.L.; Meehan, P.A. Morphological and Elemental Analysis of Wear Debris Naturally Formed in Grease Lubricated Railway Axle Bearings. Wear 2021, 484–485, 203994. [Google Scholar] [CrossRef]

- Mir, A.H. Improved Concrete Properties using Quarry Dust as Replacement for Natural Sand. Int. J. Eng. Res. Dev. 2015, 11, 46–52. [Google Scholar] [CrossRef]

- Razavi, S.; Sabbaghi, S.; Rasouli, K. Comparative Investigation of the Influence of CaCO3 and SiO2 Nanoparticles on Lithium-based Grease: Physical, Tribological, and Rheological Properties. Inorg. Chem. Commun. 2022, 142, 109601. [Google Scholar] [CrossRef]

- Singh, Y.; Rahim, E.A.; Singh, N.K.; Sharma, A.; Singla, A.; Palamanit, A. Friction and Wear Characteristics of Chemically Modified Mahua (madhuca indica) Oil Based Lubricant with SiO2 Nanoparticles as Additives. Wear 2022, 508–509, 204463. [Google Scholar] [CrossRef]

- Szwajka, K.; Trzepieciński, T.; Szewczyk, M.; Zielińska-Szwajka, J. Effect of SiO2 and MoS2 Particles as Lubricant Additives on Lubrication Performance in Sheet Metal Forming. Materials 2025, 18, 4605. [Google Scholar] [CrossRef]

- Qin, C.; He, S.; Zhou, X.; Li, Q.; Li, Q.; Yang, Z. Research on the Effect of Nano/micron SiO2 Particles on Actual Wear of the Main Gear Box of Large-scale Mechanical Equipment. Tribol. Lett. 2024, 72, 12. [Google Scholar] [CrossRef]

- Kamaya, M. Environmental Effect on Fatigue Strength of Stainless Steel in PWR Primary Water–Role of Crack Growth Acceleration in Fatigue Life Reduction. Int. J. Fatigue 2013, 55, 102–111. [Google Scholar] [CrossRef]

- Chopra, O.K.; Stevens, G.L.; Tregoning, R.A.; Rao, S. Effect of Light Water Reactor Water Environments on the Fatigue Life of Reactor Materials. J. Press. Vessel. Technol. 2017, 139, 060801. [Google Scholar] [CrossRef]

- ASTM D1264; Standard Test Method for Determining the Water Washout Characteristics of Lubricating Greases. ASTM International: West Conshohocken, PA, USA, 2020.

- Hudedagaddi, C.B.; Raghav, A.G.; Tortora, A.M.; Veeregowda, D.H. Water Molecules Influence the Lubricity of Greases and Fuel. Wear 2017, 376–377, 831–835. [Google Scholar] [CrossRef]

- Dittes, N. Mixing Grease with Water. In Proceedings of the 1st European Conference on Improvement in Bearing Technology Through European Research Collaboration (iBETTER), Utrecht, The Netherlands, 23–24 February 2015; SKF Engineering and Research Center: Nieuwegein, The Netherlands, 2015. [Google Scholar]

- Lijesh, K.P.; Khonsari, M.M.; Miller, R.A. Assessment of Water Contamination on Grease using the Contact Angle Approach. Tribol. Lett. 2020, 68, 103. [Google Scholar] [CrossRef]

- Lijesh, K.P.; Miller, R.A.; Shah, R.; Shirvani, K.; Khonsari, M.M. The Standard for Assessing Water Resistance Properties of Lubricating Grease Using Contact Angle Measurements. Lubricants 2023, 11, 440. [Google Scholar] [CrossRef]

- Blaine, S.; Savage, P.E.P. Reaction Pathways in Lubricant Degradation. Reaction Model for n-hexadecane Autoxidation. Ind. Eng. Chem. Res. 1992, 31, 69–75. [Google Scholar] [CrossRef]

- Soltanahmadi, S.; Morina, A.; Eijk, M.C.P.V.; Nedelcu, I.; Neville, A. Tribochemical Study of Micropitting in Tribocorrosive Lubricated Contacts: The Influence of Water and Relative Humidity. Tribol. Int. 2017, 107, 184–198. [Google Scholar] [CrossRef]

- Lancaster, J.K. A Review of the Influence of Environmental Humidity and Water on Friction, Lubrication and Wear. Tribol. Int. 1990, 23, 371–389. [Google Scholar] [CrossRef]

- Druet, K.; Olszewski, O.; Romanowski, P. Viscosity and Influence on Pitting of Laboratory-aged Gear Oil. Wear 1991, 141, 321–333. [Google Scholar] [CrossRef]

- Tuszynski, W.; Michalczewski, R.; Piekoszewski, W.; Szczerek, M. Effect of Ageing Automotive Gear Oils on Scuffing and Pitting. Tribol. Int. 2008, 41, 875–888. [Google Scholar] [CrossRef]

- Engelhardt, C.; Witzig, J.; Tobie, T.; Stahl, K. Influence of Water Contamination in Gear Lubricants on Wear and Micro-pitting Performance of Case Carburized Gears. Ind. Lubr. Tribol. 2017, 69, 612–619. [Google Scholar] [CrossRef]

- Yazid, I.I.M.; Komata, H.; Hashimoto, S.; Ueda, K. An Experimental Study of Surface Damage on Rolling Bearings in Low Lambda Conditions. Tribol. Online 2023, 18, 1–9. [Google Scholar] [CrossRef]

- Kundu, P.; Darpe, A.K.; Kulkarni, M.S. A Correlation Coefficient Based Vibration Indicator for Detecting Natural Pitting Progression in Spur Gears. Mech. Syst. Signal Process. 2019, 129, 741–763. [Google Scholar] [CrossRef]

- Sonawane, P.R.; Chandrasekaran, M. Investigation of Gear Pitting Defect Using Vibration Characteristics in a Single-stage Gearbox. Int. J. Electr. Eng. Educ. 2020, 57, 272–278. [Google Scholar] [CrossRef]

- Cao, W.; Han, Z.; Yang, Z.Z.; Wang, N.; Qu, J.X.; Wang, D. Deterioration State Diagnosis and Wear Evolution Evaluation of Planetary Gearbox Using Vibration and Wear Debris Analysis. Measurement 2022, 193, 110978. [Google Scholar] [CrossRef]

- Dittes, N.; Sjödahl, M.; Pettersson, A.; Lang, D. Corrosion Sensor for Water-contaminated Grease. Tribol. Trans. 2020, 63, 891–896. [Google Scholar] [CrossRef]

- Zhao, Y.; Chang, L. A Micro-contact and Wear Model for Chemical–mechanical Polishing of Silicon Wafers. Wear 2002, 252, 220–226. [Google Scholar] [CrossRef]

- Horng, J.H.; Yu, C.C.; Chen, Y.Y. Tribological Characteristics and Load-Sharing of Point-Contact Interface in Three-Body Mixed Lubrication. J. Tribol. 2022, 144, 052201. [Google Scholar] [CrossRef]

- Grease Data Sheets. Available online: https://www.bechem.de/de_en/products/lubricating-greases/berulub-fg-h-2-ep.html (accessed on 29 October 2025).

- ASTM D2266-01; Standard Test Method for Wear Preventive Characteristics of Lubricating Grease (Four-Ball Method). ASTM International: West Conshohocken, PA, USA, 2015.

- Horng, J.H.; Ta, T.N.; Jheng, R.Y.; Huang, M.W.; Zhang, K.S.; Torskaya, E. Effect of Liquid Contaminants on Tribological Performance of Greases. Wear 2023, 530–531, 205054. [Google Scholar] [CrossRef]

- Hirani, H.; Jangra, D.; Sidh, K.N. Experimental Analysis of Chemically Degraded Lubricant’s Impact on Spur Gear Wear. Lubricants 2023, 11, 201. [Google Scholar] [CrossRef]

- Cyriac, F.; Lugt, P.M.; Bosman, R. Impact of Water on the Rheology of Lubricating Greases. Tribol. Trans. 2016, 59, 679–689. [Google Scholar] [CrossRef]

- Acar, N.; Franco, J.M.; Kuhn, E.; Gonçalves, D.E.P.; Seabra, J.H.O. Tribological Investigation on the Friction and Wear Behaviors of Biogenic Lubricating Greases in Steel-steel Contact. Appl. Sci. 2020, 10, 1477. [Google Scholar] [CrossRef]

- Larsson, E.; Westbroek, R.; Leckner, J.; Jacobson, S.; Rudolphi, A.K. Grease-lubricated Tribological Contacts–Influence of Graphite, Graphene Oxide and Reduced Graphene Oxide as Lubricating Additives in Lithium Complex (LiX)-and Polypropylene (PP)-thickened Greases. Wear 2021, 486–487, 204107. [Google Scholar] [CrossRef]

- Singh, J.; Kumar, D.; Tandon, T. Tribological and Vibration Studies on Newly Developed Nanocomposite Greases Under Boundary Lubrication Regime. J. Triobol. 2018, 140, 032001. [Google Scholar] [CrossRef]

- Ta, T.N.; Horng, J.H.; Hwang, Y.L. Correlation Between Tribological and Vibraiton Behaviors in Sliding Lubricated Contacts. J. Tribol. 2022, 144, 111603. [Google Scholar] [CrossRef]

- Ciprari, S.; Ripard, V.; Saulot, A.; Massi, F. Investigation of Third Body Role in Dry Contacts: Experimental Procedure to Dissociate the Effects of Substrate and Interface Layer on the Contact Pair Frictional Response. Tribol. Int. 2023, 190, 109047. [Google Scholar] [CrossRef]

- Pawar, A.A.; Patil, K.A.; Mohite, D.D. Impact of CuO Nanoparticles on the Viscosity and Vibration Damping Characteristics of Shock Absorber Oil. Discov. Nano 2024, 19, 131. [Google Scholar] [CrossRef] [PubMed]

- Ikhsan, A.; Gasni, D.; Rusli, M. Wear Patterns on Ball Bearings Lubricated by Grease Contaminated with Several Large Solid Particles. Tribol. Ind. 2025, 47, 202–216. [Google Scholar] [CrossRef]

| Grease | Calcium Soap-Based Grease |

|---|---|

| Temperature range (°C) | −40 to 160 |

| Thickener | Calcium complex soap |

| Base oil type | Polyalphaolefin (PAO) |

| Base oil kinematic viscosity @40 °C, mm2/s | 150 |

| Worked penetration (0.1 mm) | 285–320 |

| NLGI grade | 1–2 |

| Dropping point (°C) | ≥240 |

| Test Number | Symbol | Lubricant |

|---|---|---|

| 1 | Ca_G | Calcium complex based grease |

| 2 | 0.185S | CaG + 0.185 wt% SiO2 |

| 3 | 1.480S | CaG + 1.480 wt% SiO2 |

| 4 | 0.6W | CaG + 0.6 wt% water |

| 5 | 0.6W0.185S | CaG + 0.6 wt% water + 0.185 wt% SiO2 |

| 6 | 0.6W1.480S | CaG + 0.6 wt% water + 1.480 wt% SiO2 |

| Test No. | Water Content (wt%) | TAN (mg KOH/g) | Consistency (NLGI) | |||

|---|---|---|---|---|---|---|

| Before | After | Before | After | Before | After | |

| Ca_G | 0.223 | 0.266 | 4.361 | 3.457 | 2.000 | 2.142 |

| 0.185S | 0.241 | 0.250 | 2.930 | 3.197 | 2.042 | 2.125 |

| 1.480S | 0.372 | 0.304 | 3.264 | 4.143 | 2.250 | 2.000 |

| 0.6W | 0.541 | 0.328 | 3.858 | 4.121 | 2.117 | 1.925 |

| 0.6W0.185S | 0.657 | 0.407 | 4.843 | 4.058 | 2.192 | 2.125 |

| 0.6W1.480S | 0.675 | 0.386 | 3.406 | 4.663 | 2.217 | 1.908 |

| Test | Acceleration (m/s2) |

|---|---|

| Ca_G | 0.35 |

| 0.185S | 0.66 |

| 1.480S | 0.52 |

| 0.6W | 0.41 |

| 0.6W0.185S | 0.62 |

| 0.6W1.480S | 0.45 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ta, T.-N.; Chern, S.-Y.; Horng, J.-H.; Kuo, C.-W.; Liao, S.-J. Investigation of Performance Degradation in Calcium-Based Grease Under Combined SiO2 Particle and Water Contamination. Lubricants 2025, 13, 499. https://doi.org/10.3390/lubricants13110499

Ta T-N, Chern S-Y, Horng J-H, Kuo C-W, Liao S-J. Investigation of Performance Degradation in Calcium-Based Grease Under Combined SiO2 Particle and Water Contamination. Lubricants. 2025; 13(11):499. https://doi.org/10.3390/lubricants13110499

Chicago/Turabian StyleTa, Thi-Na, Shin-Yuh Chern, Jeng-Haur Horng, Chun-Wei Kuo, and Sheng-Jie Liao. 2025. "Investigation of Performance Degradation in Calcium-Based Grease Under Combined SiO2 Particle and Water Contamination" Lubricants 13, no. 11: 499. https://doi.org/10.3390/lubricants13110499

APA StyleTa, T.-N., Chern, S.-Y., Horng, J.-H., Kuo, C.-W., & Liao, S.-J. (2025). Investigation of Performance Degradation in Calcium-Based Grease Under Combined SiO2 Particle and Water Contamination. Lubricants, 13(11), 499. https://doi.org/10.3390/lubricants13110499