Review and Prospect of Research Status on Sliding Bearing Coatings

Abstract

1. Introduction

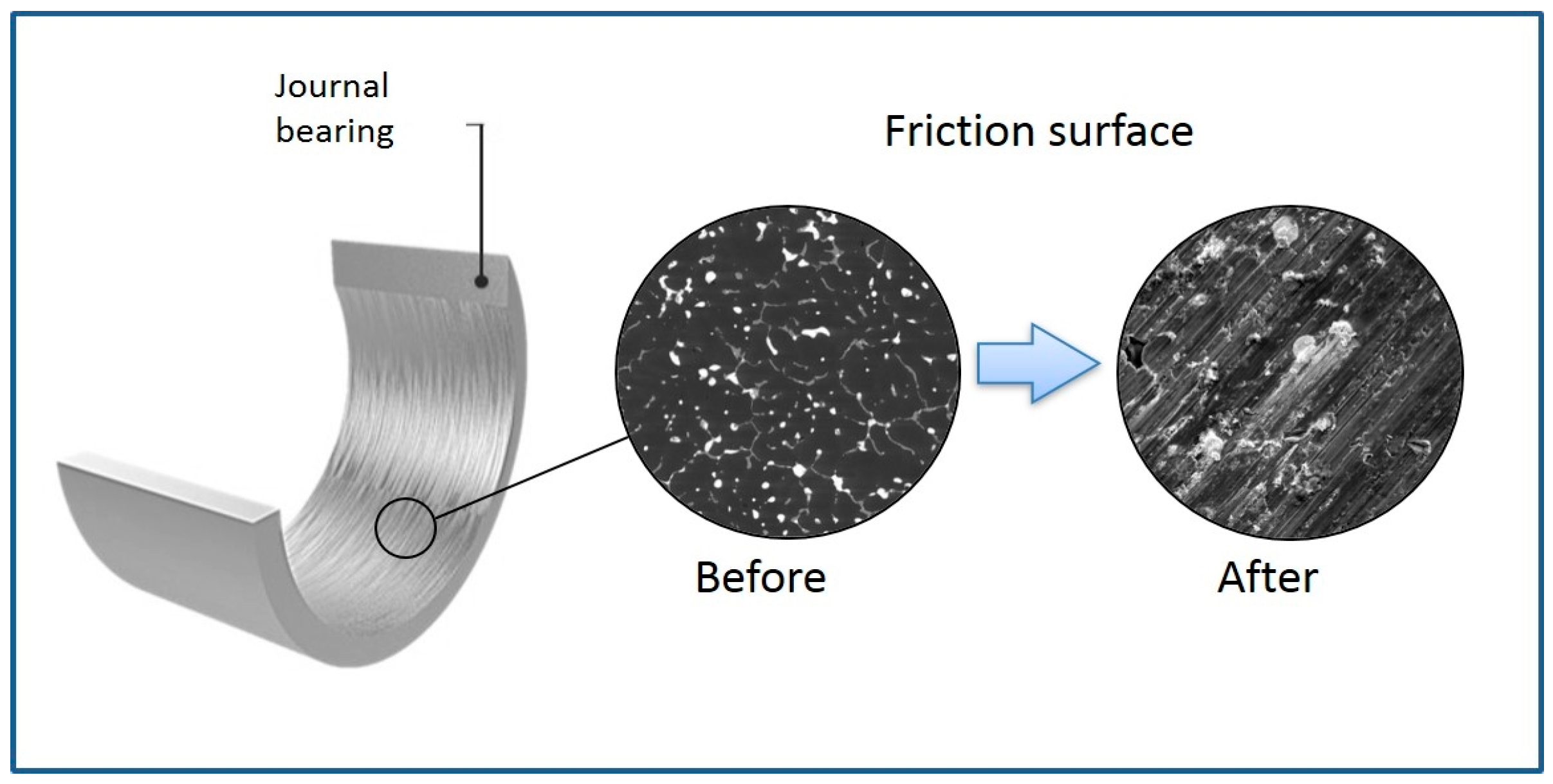

2. Basic Overview of Sliding Bearings

2.1. Structure of Sliding Bearings

- (1)

- Bearing housing.

- (2)

- Bushing (bearing liner).

- (3)

- Lubrication system.

- (4)

- Cooling structure.

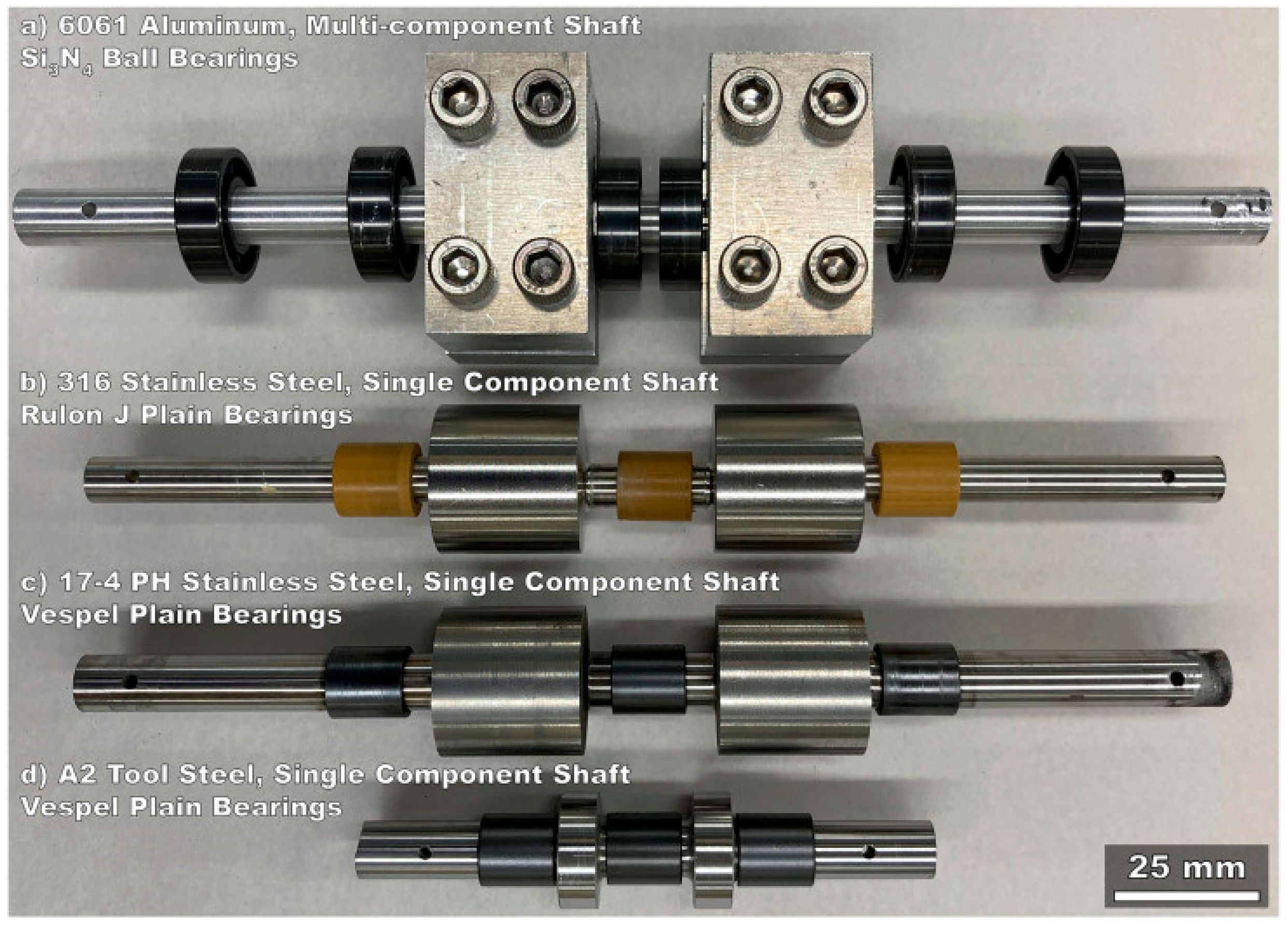

2.2. Classification and Characteristics of Plain Bearings

2.2.1. Classification by Structural Form

2.2.2. Classification by Force-Bearing Direction

2.2.3. Classification by Lubrication State

2.3. Core Materials and Performance Requirements of Plain Bearings

2.3.1. Metal Materials

2.3.2. Non-Metallic Materials

2.3.3. Composite Materials

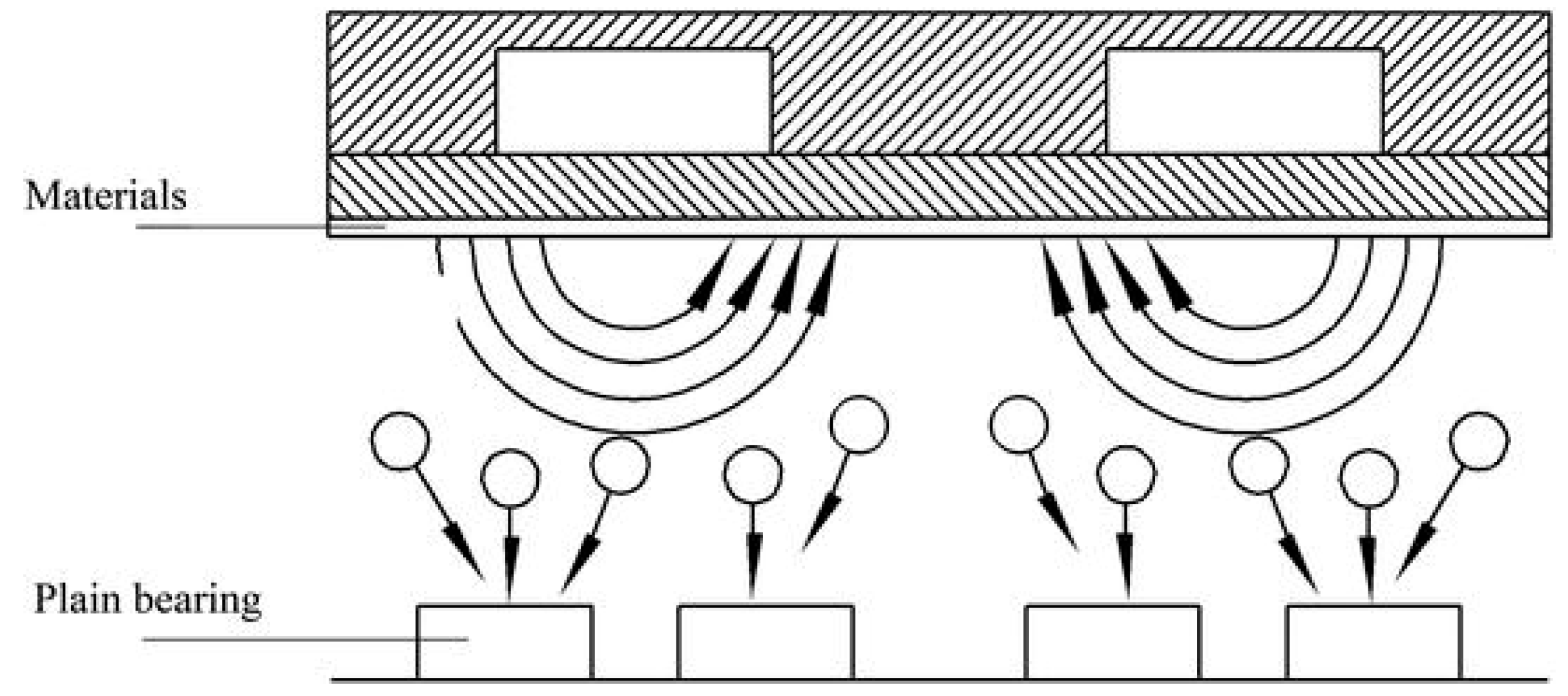

2.4. Working Principle

3. Research Status of Sliding Bearing Coatings

3.1. Coating Materials

3.1.1. Metal-Based Coatings

3.1.2. Ceramic-Based Coatings

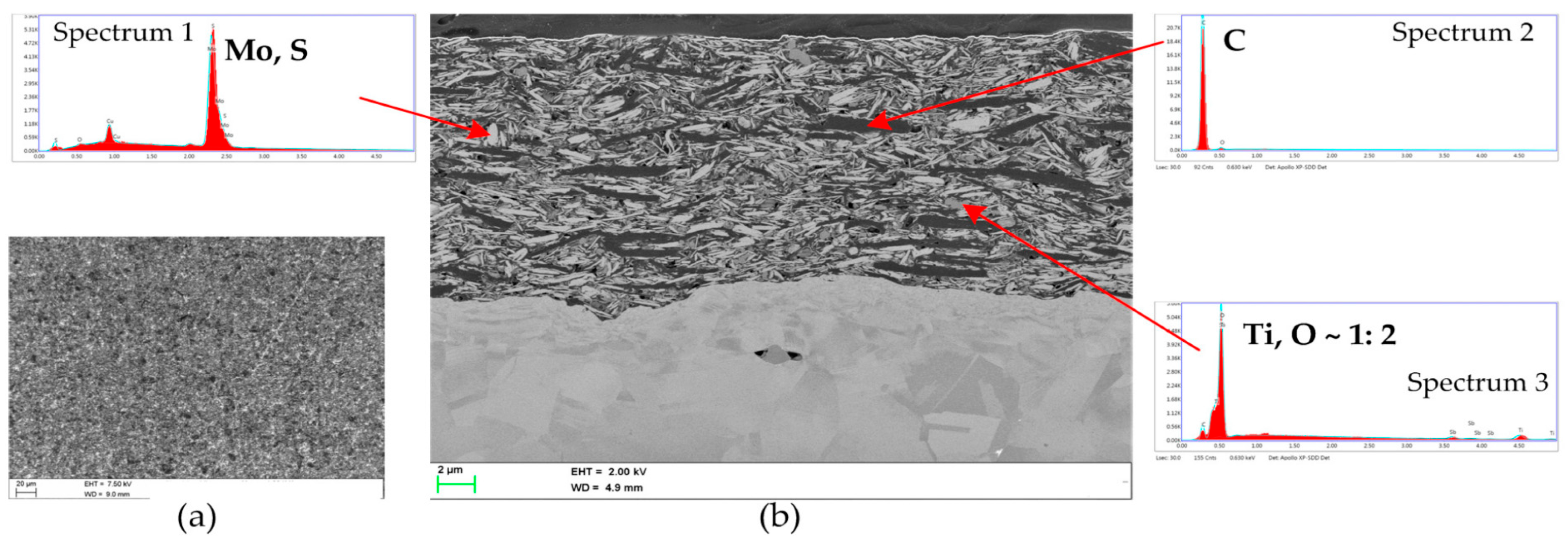

3.1.3. Polymer Coatings

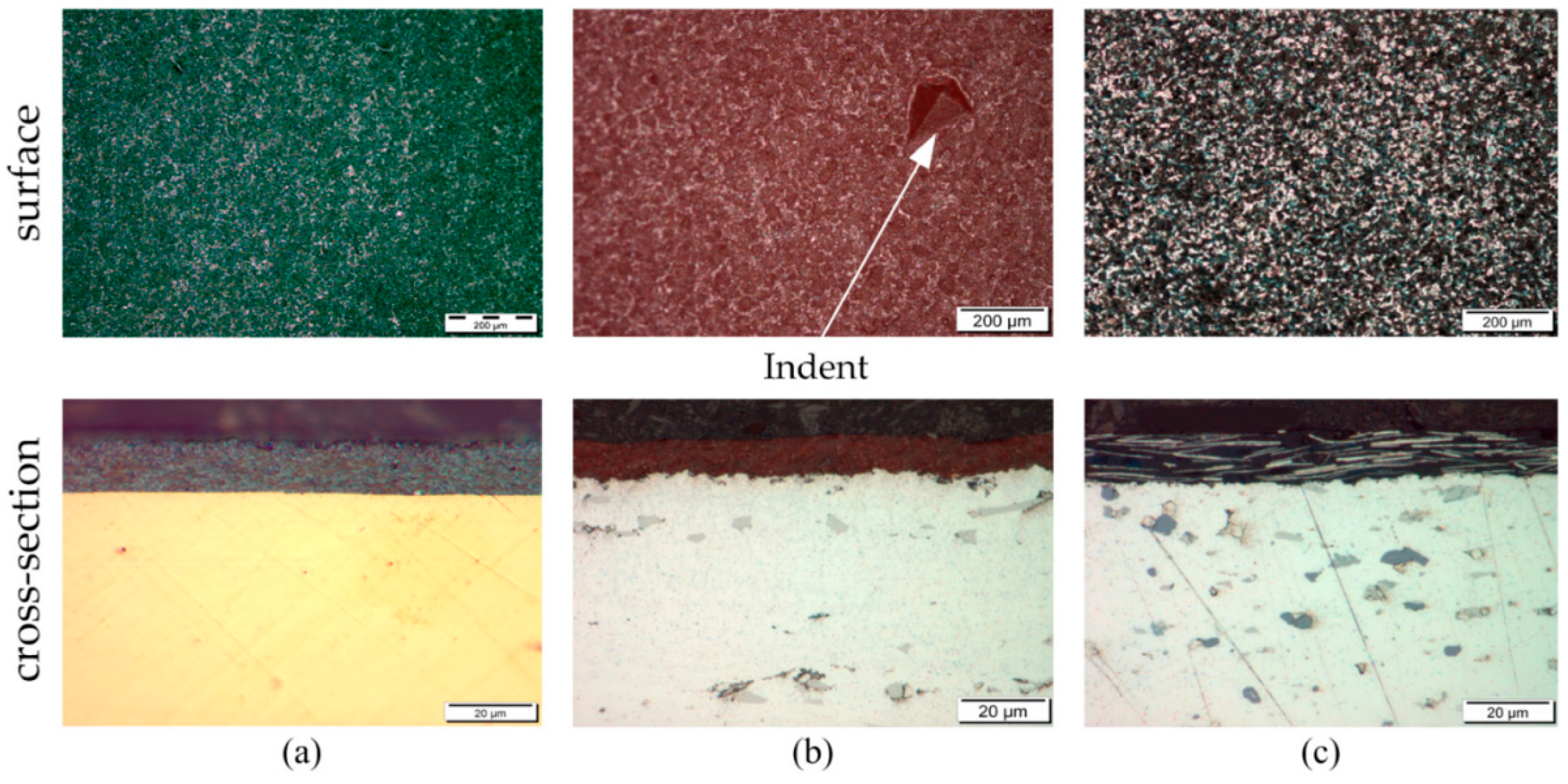

| Analysis Dimension | Polymer Bearing 1 (PB_1) | Polymer Bearing 2 (PB_2) | Polymer Bearing 3 (PB_3) |

|---|---|---|---|

| Top Surface Structure | Fine-grained structure with clearly visible polymer film | Fine-grained structure with clearly visible polymer film | Rough structure with flaky morphology and clearly visible polymer film |

| Surface Roughness | Rough | Rough | Rough |

| Lining Material | Lead-free bronze | Similar matrix to PB_3, with typical aluminum sheen | Similar matrix to PB_2, with typical aluminum sheen |

| Key Phases in Lining | --------- | Intermetallic phases, tin phases | Silicon, intermetallic phases, tin phases |

| Microstructure of Polymer Coating | Fine microstructure with filler particles evenly dispersed in the polymer matrix | Fine microstructure with filler particles evenly dispersed in the polymer matrix | Contains larger phases, which are oriented parallel to the surface |

| Average Coating Thickness | 16 µm | 8 µm | 10 µm |

| Lining-Coating Interface State | Smoother | Slightly rough | Slightly rough |

3.1.4. Horizontal Comparison of Existing Research Results and Extraction of Core Trends

3.2. Preparation Processes

3.2.1. Electroplating

3.2.2. Magnetron Sputtering

3.2.3. Laser Cladding

3.3. Coating Performance Research

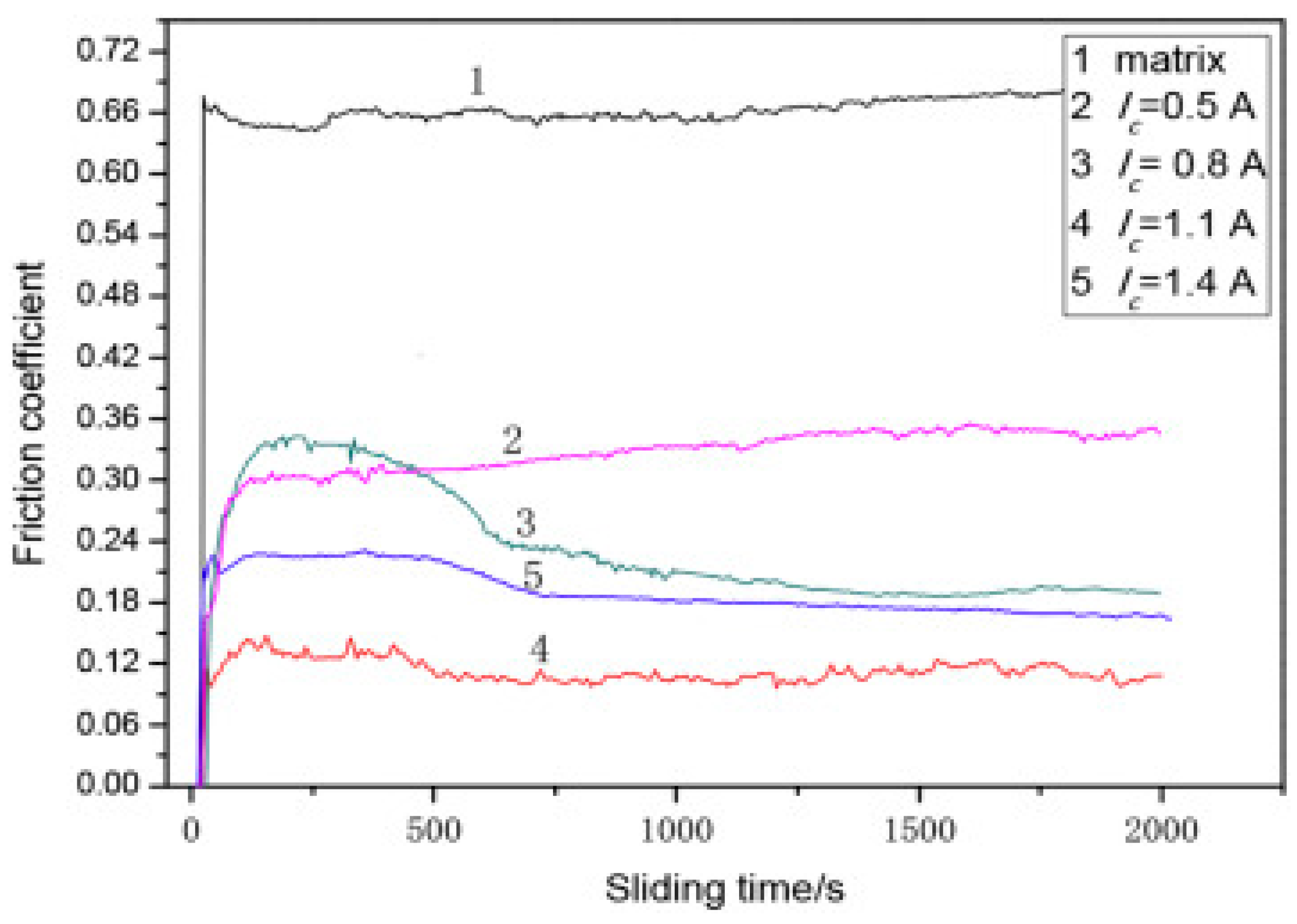

3.3.1. Wear Resistance and Friction Reduction

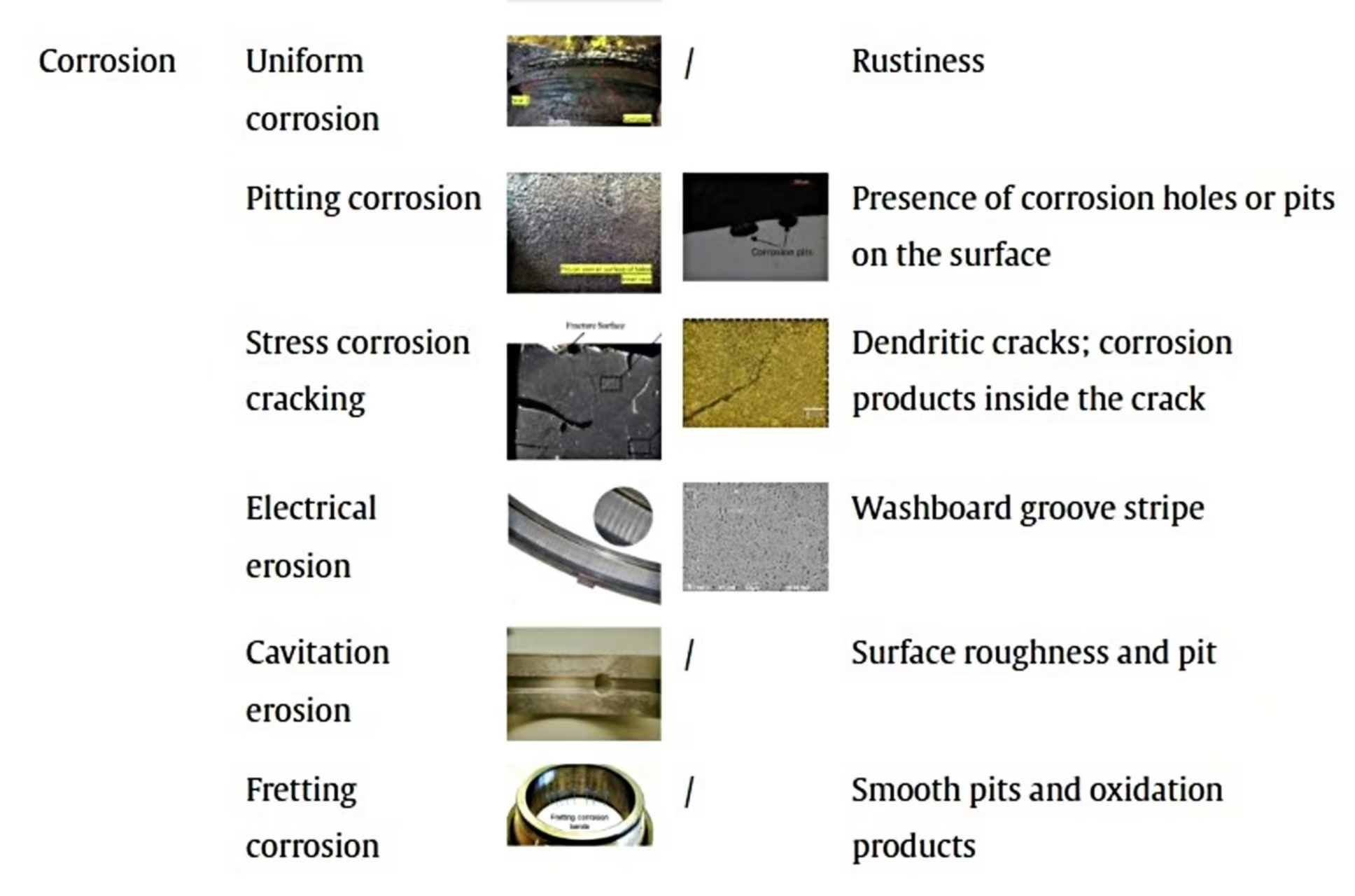

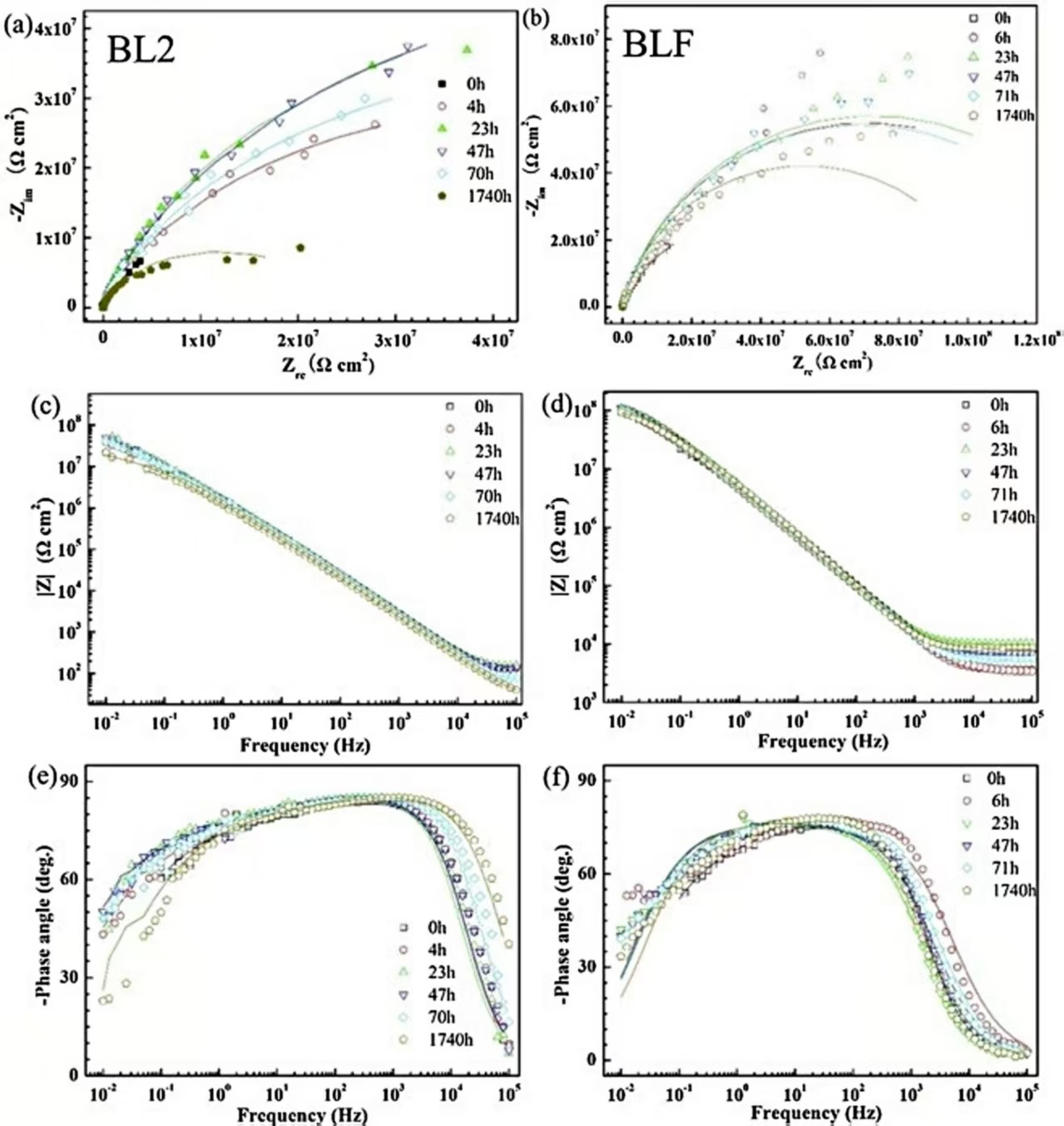

3.3.2. Corrosion Resistance

3.3.3. Fatigue Resistance

3.4. Textured and Engineered Surface Coatings

3.4.1. Design Principles and Tribological Mechanisms

3.4.2. Fabrication Methods for Structured Copper Coatings

3.4.3. Performance Advantages of Textured Copper Coatings

3.4.4. Surface Texture and Coating Hybrid Technology

4. Coating Performance Evaluation System

4.1. Tribological Performance Testing

4.2. Corrosion Behavior Analysis

5. Future Prospects of Sliding Bearing Coatings

5.1. New Material Development

| Coating Type | Thermoplastic Material Coatings | Thermosetting Material Coatings | Nano-Reinforced Coatings |

|---|---|---|---|

| Specific Material/System | PEEK-based (filled with PTFE, MoS2, bronze, glass fiber, carbon fiber, etc.) | Phenolic resin/CF, epoxy resin/CF, phenolic asbestos (before improvement) | PEEK-based (added with brass nanoparticles, MoS2 nanoparticles) |

| Application Field | Mechanical transmission components such as internal combustion engine connecting rod bearings and articulated bearings | Journal bearings that need to bear a certain load, such as some industrial transmission bearings | Internal combustion engine bearings, shafting requiring high damping and stability, 100Cr6 steel substrate components (matched with ionic liquid lubrication) |

| Advantages | 1. Low wear rate, small friction coefficient, and ability to optimize wear parameters; 2. High strength and good stability under different loads and speeds; 3. Excellent performance in indicators such as friction coefficient, wear amount, and temperature rise in tests | 1. Better wear resistance than traditional phenolic asbestos composites; 2. The friction coefficient of phenolic/CF coating is 11.5% lower than that of epoxy/CF coating, and the maximum friction coefficient is 22.4% lower | 1. Improve the bearing load capacity and damping characteristics, and enhance the stability of the shaft at different speeds; 2. A-C:H:W DLC has good compatibility with ionic liquid BMIM-PF6, and its friction coefficient is about 20% lower than that of 100Cr6 steel |

| Disadvantages | 1. Some filled coatings have high requirements for clearance, and the clearance needs to be accurately controlled to ensure performance; 2. They may rely on specific test environments, and the adaptability to actual complex working conditions needs further verification | 1. The temperature resistance of resin-based materials may be inferior to that of metal coatings, so their application in high-temperature working conditions is limited; 2. The preparation process may involve resin curing, resulting in a relatively long process cycle | 1. High requirements for the dispersion uniformity of nanomaterials, resulting in high difficulty in the preparation process; 2. Some nano-coatings rely on specific lubricating media (such as A-C:H:W DLC needs to be matched with ionic liquid), so their application scenarios are limited to a certain extent |

5.2. New Process Application

5.3. Environmental Protection and Sustainable Development

5.4. Knowledge Gaps and Research Challenges

5.4.1. Gaps in Material Design

5.4.2. Challenges in Process Innovation

5.4.3. Gaps in Performance Evaluation and Life Prediction

5.4.4. Challenges in Environmental Protection and Sustainability

5.5. Guiding Significance of Critical Analysis for Future Research

5.6. Evolution of Sliding Bearing Coating

5.6.1. 2000–2010: Single Material Dominance Phase

5.6.2. 2011–2020: The Breakthrough Phase of Composite Modification

5.6.3. 2021–2025: Multi-Functional Integration Phase

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Song, Z.; Peng, Z.; Yan, M.; Li, Z.; Dong, G.; Zhang, L. Microstructures and Mechanical Properties of Tin-Based Babbitt Bearings with Different Fabrication Methods. Xiyou Jinshu/Chin. J. Rare Met. 2021, 45, 378–384. [Google Scholar] [CrossRef]

- Koseki, H.; Shindo, H.; Baba, K.; Fujikawa, T.; Sakai, N.; Sawae, Y.; Murakami, T. Surface-engineered metal-on-metal bearings improve the friction and wear properties of local area contact in total joint arthroplasty. Surf. Coat. Technol. 2008, 202, 4775–4779. [Google Scholar] [CrossRef]

- Pedrizzetti, G.; Genova, V.; Scrinzi, E.; Bottacchiari, R.; Conti, M.; Paglia, L.; Bartuli, C. Slurry Aluminizing Mechanisms of Nickel-Based Superalloy and Applicability for the Manufacturing of Platinum-Modified Aluminide Coatings. Coatings 2025, 15, 822. [Google Scholar] [CrossRef]

- Zhou, Z.; Wu, X.; Wang, Q.; Zhao, G.; Zhou, Z. The Influence of Ni Incorporation on the Surface Porosity and Corrosion Resistance of CrBN Coatings on 45 Steel in Seawater. Coatings 2025, 15, 804. [Google Scholar] [CrossRef]

- Akhverdiev, K.S.; Bolgova, E.A.; Mukutadze, M.A.; Vasilenko, V.V. Mathematical model of a radial sliding bearing with a porous layer on its operating surface with a low-melting metal coating on shaft surface. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1064, 012005. [Google Scholar] [CrossRef]

- Pavlov, A.A.; Soboleva, E.S. Antifriction material based on copper-fluoroplastic coating for shaped surfaces of sliding bearings. Chem. Pet. Eng. 2021, 57, 518–521. [Google Scholar] [CrossRef]

- Chen, S.; Wang, W.; Wang, L.; Bai, Y. Study on the sliding bearing of hot dip galvanized sinking roll. J. Phys. Conf. Ser. 2022, 2419, 012012. [Google Scholar] [CrossRef]

- Wang, L.; Wang, J.; Lu, H.; Du, J.; Qi, X.; Lu, L.; Liu, Z. A Comparative Study on the High-Temperature Oxidation Behavior and Mechanisms of Micro/Nanoparticle Composite-Modified Chromium Carbide Metal Ceramic Coatings. Coatings 2025, 15, 826. [Google Scholar] [CrossRef]

- Mukerji, J.; Prakash, B. Abrasion of nitrogen ceramics and composites in contact with bearing steel under oscillating sliding conditions. Int. Ceram. 1998, 24, 19–24. [Google Scholar] [CrossRef]

- Alisin, V.V.; Roshchin, M.N. Improvement of antifriction properties of sliding bearings with ceramic sleeves made of zirconium dioxide. IOP Conf. Ser. Earth Environ. Sci. 2020, 421, 022020. [Google Scholar] [CrossRef]

- Olszewski, A. Tilting pad journal bearing with ceramic coating. In Proceedings of the 15th International Colloquium on Tribology: Automotive and Industrial Lubrication, Ostfildern, Germany, 17–19 January 2006. [Google Scholar] [CrossRef]

- Wang, J.; Cheng, Y.; Zhang, Y.; Zhang, Y.; Yin, Z.; Hu, X.; Yuan, Q. Friction and wear behavior of microwave sintered Al2O3/TiC/GPLs ceramic sliding against bearing steel and their cutting performance in dry turning of hardened steel. Ceram. Int. 2017, 43, 14827–14835. [Google Scholar] [CrossRef]

- Summer, F.; Grün, F.; Ravenhill, E.R. Friction and wear properties of various polymer coatings of radial bearings when detaining sliding. Lubricants 2020, 8, 1. [Google Scholar] [CrossRef]

- Kusznierewicz, Z.; Michalowski, M.; Luczak, S.; Baginski, K.; Kabzinski, B.; Zams, M. Selection of polymer materials for micro slide bearings with respect to minimization of resistance to motion. IEEE Access 2020, 8, 78622–78629. [Google Scholar] [CrossRef]

- Lawrowski, Z. Polymers in the construction of serviceless sliding bearing. Arch. Civ. Mech. Eng. 2007, 7, 139–150. [Google Scholar] [CrossRef]

- Walczak, M.; Caban, J. Tribological characteristics of polymer materials used for slide bearings. Open Eng. 2021, 11, 624–629. [Google Scholar] [CrossRef]

- Liu, X.; Wang, Y.; Guo, Z.; Liu, X.; Qin, L.; Lu, Z. Ni2O/PTFE Composite Coating Material and the Synergistic Friction Reduction and Wear Resistance Mechanism Under Multiple Working Conditions. Coatings 2025, 15, 830. [Google Scholar] [CrossRef]

- Gorges, R.; Brock, R. High-Performance lead-free electroplated composite bearing overlay for heavy duty application. J. Eng. Gas Turbines Power 2014, 136, 091401. [Google Scholar] [CrossRef]

- Wang, S.; Wei, W. Characterization of electroplated Ni/SiC and Ni/Al2O3 composite coatings bearing nanoparticles. J. Mater. Res. 2003, 18, 1566–1574. [Google Scholar] [CrossRef]

- Jupe, K.; Gorges, R.; Rathod, A.; Carey, J.; Stearns, J.; Rathod, A. Seizure resistance of improved lead-free plating bearing covering system for heavy-duty trucks and off-highway applications. J. Gas Turbine Power Eng. 2018, 140, 112806. [Google Scholar] [CrossRef]

- Cao, J.; Qin, L.; Yu, A.; Huang, H.; Li, G.P.; Yin, Z.W.; Zhou, H.Y. A review of surface treatment for Sliding Bearings used at different temperature. In Friction, Lubrication and Wear; IntechOpen: London, UK, 2019; p. 121. [Google Scholar] [CrossRef]

- Priedeman, J.L.; Thompson, G.B. Conformal coating of powders by magnetron sputtering. Surf. Coat. Technol. 2022, 436, 128242. [Google Scholar] [CrossRef]

- Li, C.S.; Wang, F.; Hu, Z.L.; Sun, J.R.; Tang, H. Preparation and tribological properties of magnetron sputtered Sn-Sb-Cu films. Lubr. Eng. 2013, 38, 1–5+41. [Google Scholar]

- Song, H.; Chen, J.; Liu, Z.; Jiang, N. Preparation of a new multi-layer AlSnCu coating for journal bearings. Surf. Eng. 2022, 38, 244–251. [Google Scholar] [CrossRef]

- Franklin, S.E.; Baranowska, J. Conditions influencing the sliding tribological properties of the selected coating for high vacuum bearing applications. Wear 2007, 263, 1300–1305. [Google Scholar] [CrossRef]

- Guo, Q.; Guo, Y.; Guo, D.; Yang, Z.; Li, J.; Yang, W.; Yang, Y.; Gao, P.; Bai, Y. Microstructure and properties of the Cp/AlSn coatings deposited by magnetron sputtering/multi-arc ion plating. Surf. Coat. Technol. 2020, 384, 125303. [Google Scholar] [CrossRef]

- Kapustynskyi, O.; Golovko, L. Effects of laser cladding and treatment methods on wear resistance in heavy-loaded units. Int. J. Multidiscip. Stud. Update 2024, 7, 17–26. [Google Scholar] [CrossRef]

- Yue, T.M.; Huang, K.J.; Man, H.C. In situ laser cladding of Al2O3 bearing coatings on aluminium alloy 7075 for improvement of wear resistance. Surf. Eng. 2007, 23, 142–146. [Google Scholar] [CrossRef]

- Xu, T.Z.; Zhang, S.; Wang, Z.Y.; Zhang, C.H.; Zhang, D.X.; Wang, M.; Wu, C.L. Wear behavior of graphite self-lubricating Babbitt alloy composite coating on 20 steel prepared by laser cladding. Eng. Fail. Anal. 2022, 141, 106698. [Google Scholar] [CrossRef]

- Kim, C.K.; Choi, S.G.; Kim, J.H.; Jo, H.J.; Jo, Y.C.; Choi, S.; Cho, Y.T. Characterization of surface modification by laser cladding using low melting point metal. J. Ind. Eng. Chem. 2020, 87, 54–59. [Google Scholar] [CrossRef]

- Mironov, A.; Gershman, I.; Gershman, E.; Podrabinnik, P.; Kuznetsova, E.; Peretyagin, P.; Peretyagin, N. Properties of journal bearing materials that determine their wear resistance on the example of aluminum-based alloys. Materials 2021, 14, 535. [Google Scholar] [CrossRef] [PubMed]

- Arkhipov, V.E.; Pugachev, M.S.; Sakhvadze, G.Z. Antifriction wear-resistant coatings process development for sliding bearing friction surfaces of submersible pumps. IOP Conf. Ser. Mater. Sci. Eng. 2020, 747, 012035. [Google Scholar] [CrossRef]

- Gorlenko, A.O.; Davydov, S.V. Coating deposition to improve the wear resistance of the friction surface of spherical plain bearings. Met. Sci. Heat Treat. 2018, 59, 579–583. [Google Scholar] [CrossRef]

- Rodichev, A.; Novikov, A.; Gorin, A.; Tokmakova, M. Analysis of the wear resistance of a hard anti-friction coating, applied to a plain bearing, under the conditions of boundary friction. Transp. Res. Procedia 2021, 57, 573–580. [Google Scholar] [CrossRef]

- Xu, F.; Ding, N.; Li, N.; Li, N.; Liu, L.; Hou, N.; Xu, N.; Guo, W.; Tian, L.; Xu, H.; et al. A review of bearing failure Modes, mechanisms and causes. Eng. Fail. Anal. 2023, 152, 107518. [Google Scholar] [CrossRef]

- Rajaram, G.; Jain, A. Characteristics of alumina coating on SAE 52100 bearing steel with Ni-Cr bond coat. Int. J. Mater. Eng. Innov. 2018, 9, 20–33. [Google Scholar] [CrossRef]

- Xu, J.; Wang, C.; Chen, S.; Zhu, S.; Chen, Z.; Chen, J.; Wang, F. An easy-to-process organic-inorganic self-lubricating composite coating with high corrosion resistance. Adv. Org. Coat. 2019, 137, 105377. [Google Scholar]

- Haedicke, L.; Mergen, R.; Kari, A.; Harreither, L. Improved Tin Based Bearing Alloy for Low Emission Two-Stroke Engines. In Proceedings of the Internal Combustion Engine Division Fall Technical Conference, Vancouver, BC, Canada, 23–26 September 2012; Volume 55096, pp. 61–65. [Google Scholar] [CrossRef]

- Barikin, N.P.; Sadikov, F.A.; Aslanian, I.R. Wear and failure of babbitt bushings in steam turbine plain bearings. J. Mater. Eng. Perform. 2000, 9, 110–115. [Google Scholar] [CrossRef]

- Vinkel, A.; Rac, L. Diesel engine crankshaft journal bearing failure: A case study. Fail. Anal. 2014, 44, 217–228. [Google Scholar] [CrossRef]

- Meruane, V.; Pascual, R. Identification of nonlinear dynamic coefficients in sliding radial bearings. Tribol. Int. 2008, 41, 743754. [Google Scholar] [CrossRef]

- Dhande, D.Y.; Pande, D.W. Multiphase flow analysis of hydrodynamic journal bearing using CFD coupled Fluid Structure Interaction considering cavitation. J. King Saud Univ.—Eng. Sci. 2016, 30, 345–354. [Google Scholar] [CrossRef]

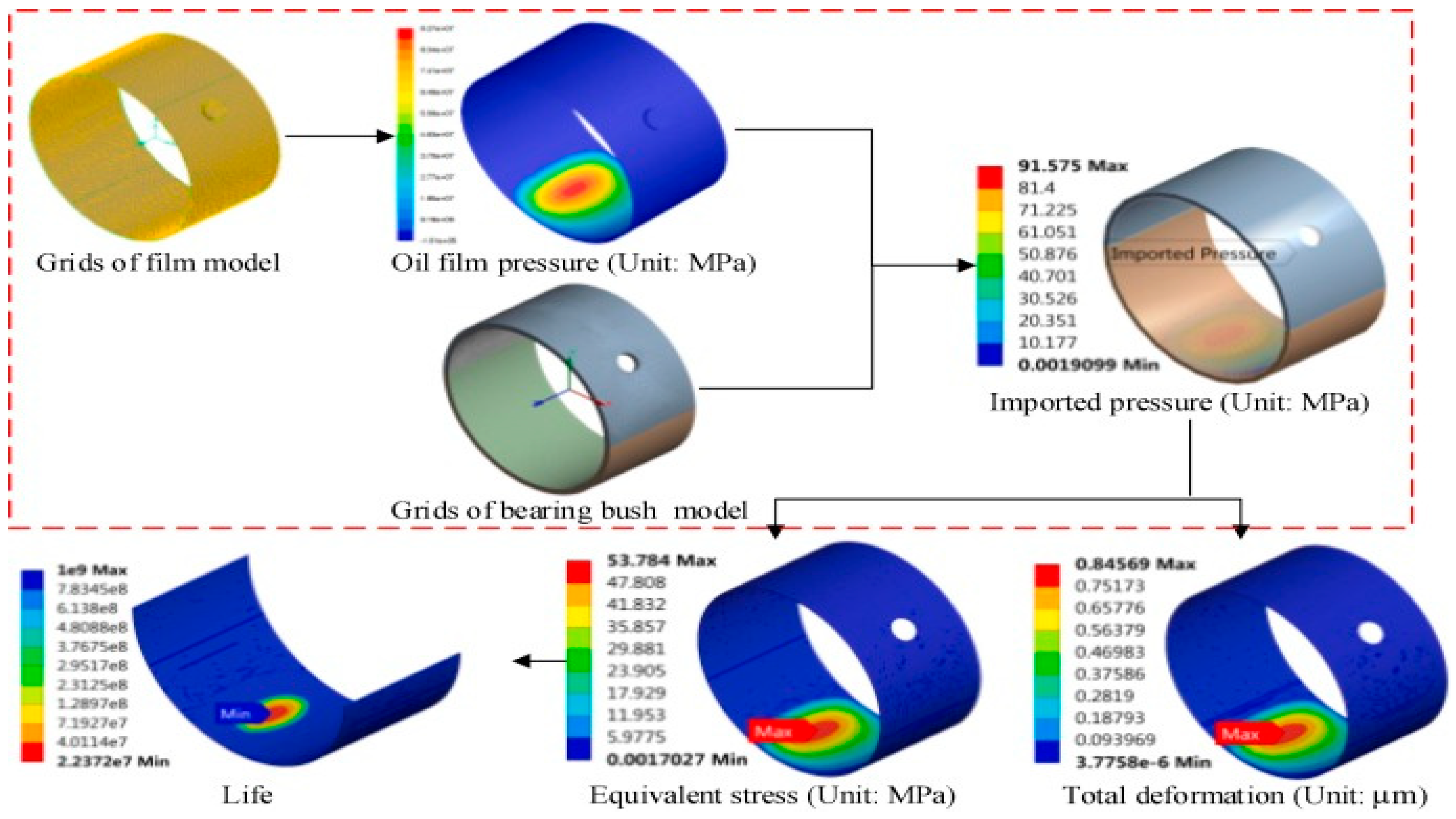

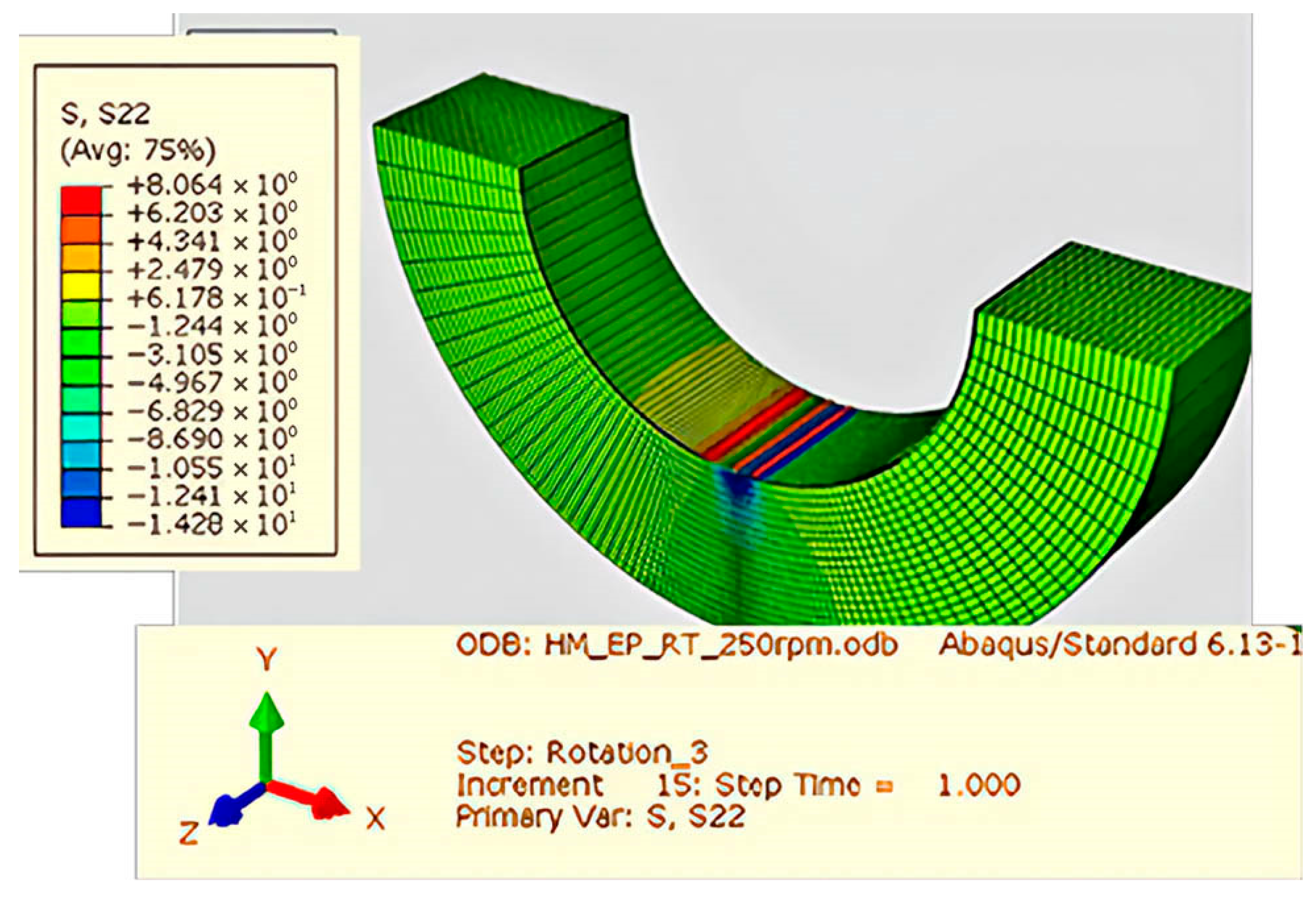

- Dong, Q.; Yin, Z.; Li, H.; Gao, G.; Zhong, N.; Chen, Y. Simulation and experimental validation of fatigue strength assessment of journal bearing bushings. Eng. Fail. Anal. 2020, 109, 104275. [Google Scholar] [CrossRef]

- Chen, G.; Yang, Z.; Huang, J. Laser Texturing of Copper-Based Coatings for Enhanced Lubrication in Sliding Bearings. J. Mater. Process. Technol. 2024, 332, 118876. [Google Scholar]

- Zhao, W.; Sun, X.; Zhou, Y. Multiscale Patterned Copper Coatings: Fabrication and Tribological Performance in Sliding Bearings. Wear 2023, 528–529, 205087. [Google Scholar]

- Li, J.; Wang, Z.; Liu, H. Electrochemical Etching of Textured Copper Coatings for Sliding Bearings: Process Optimization and Tribological Behavior. Electrochim. Acta 2023, 456, 142231. [Google Scholar] [CrossRef]

- Wang, C.; Zhang, D.; Li, S. Mechanical Engraving of Grooved Copper Coatings for Low-Friction Sliding Bearings. J. Manuf. Process. 2022, 81, 654–663. [Google Scholar] [CrossRef]

- Li, X.; Zhang, H.; Liu, J. Advances in Tribological Performance of Sliding Bearing Coatings. Tribol. Int. 2024, 198, 108892. [Google Scholar]

- Wang, Y.; Chen, S.; Zhao, L. Surface Modification Technologies for Sliding Bearings: A Critical Review. Surf. Coat. Technol. 2023, 462, 129235. [Google Scholar] [CrossRef]

- Ashihara, K.; Hashimoto, H. Friction Characteristics of Microgrooved Bearings under Mixed Lubrication. Tribol. Online 2008, 3, 304–309. [Google Scholar] [CrossRef][Green Version]

- Galda, L.; Sep, J.; Olszewski, A.; Zochowski, T. Experimental Investigation into Surface Texture Effect on Journal Bearings Performance. Tribol. Int. 2019, 136, 372–384. [Google Scholar] [CrossRef]

- Rahmani, R.; Mirzaee, I.; Shirvani, A.; Shirvani, H. An Analytical Approach for Analysis and Optimisation of Slider Bearings with Infinite Width Parallel Textures. Tribol. Int. 2010, 43, 1551–1565. [Google Scholar] [CrossRef]

- Manser, B.; Belaidi, I.; Hamrani, A.; Khelladi, S.; Bakir, F. Performance of Hydrodynamic Journal Bearing under the Combined Influence of Textured Surface and Journal Misalignment: A Numerical Survey. Comptes Rendus. Mécanique 2019, 347, 141–165. [Google Scholar] [CrossRef]

- Hou, Q.; Yang, X.; Cheng, J. Optimization of Performance Parameters and Mechanism of Bionic Texture on Friction Surface. Coatings 2020, 10, 171. [Google Scholar] [CrossRef]

- Martin, S.; Bhushan, B. Modeling and Optimization of Shark-Inspired Riblet Geometries for Low Drag Applications. J. Colloid Interface Sci. 2016, 474, 206–215. [Google Scholar] [CrossRef]

- Cheng, X.J.; Ru, S.F.; Sun, Y.W.; Cong, Q. Wear Performance of Bionic Strip-Shaped Mud Pump Pistons. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2017, 231, 4076–4084. [Google Scholar] [CrossRef]

- Wang, L.; Huang, F.; Zhou, Q. Surface Structure Biomimetic Design and Performance Testing of Slippery Trapping Plate Used for Controlling Agricultural Insect. Trans. Chin. Soc. Agric. Eng. 2015, 31, 34–40. [Google Scholar]

- Chang, T.; Guo, Z.; Yuan, C. Study on Influence of Koch Snowflake Surface Texture on Tribological Performance for Marine Water-Lubricated Bearings. Tribol. Int. 2019, 129, 29–37. [Google Scholar] [CrossRef]

- Jiang, H.L.; Jin, J.; Wang, X.J. Static Characteristic Analysis of Sliding Bearings with Sharkskin Texture Under Mixed Flow Regime. Bearing 2023, 3, 11–17. [Google Scholar] [CrossRef]

- Chen, K.; Yang, X.; Zhang, Y.; Yang, H.; Lv, G.; Gao, Y. Research Progress of Improving Surface Friction Properties by Surface Texture Technology. Int. J. Adv. Manuf. Technol. 2021, 116, 2797–2821. [Google Scholar] [CrossRef]

- Kawasegi, N.; Sugimori, H.; Morimoto, H.; Morita, N.; Hori, I. Development of Cutting Tools with Microscale and Nanoscale Textures to Improve Frictional Behavior. Precis. Eng. 2009, 33, 248–254. [Google Scholar] [CrossRef]

- Lu, X.; Khonsari, M.M. An Experimental Investigation of Dimple Effect on the Stribeck Curve of Journal Bearings. Tribol. Lett. 2021, 27, 169–176. [Google Scholar] [CrossRef]

- Kennedy, D.M.; Hashmi, M.S.J. Abrasion test methods for advanced surface coatings and bulk materials. J. Mater. Process. Technol. 1998, 300, 246–253. [Google Scholar] [CrossRef]

- Zhang, Y.; Sun, Z.; Yuan, Z. Analysis of the wear characteristics of the pin pair based on the finite element model. Appl. Mech. Mater. 2012, 148–149, 806–809. [Google Scholar] [CrossRef]

- Ibrahim, K.M.; Havalda, S.S.; Hiryanaya, A.; Keshavamurthy, R. Corrosion characteristics of plasma spray composite coating on bearing steel studied by electrochemical and salt spray tests. J. Biol. Tribocorrosion 2022, 8, 106. [Google Scholar] [CrossRef]

- Chen, T.C.; Zhou, C.C.; Yung, T.Y.; Cai, R.F.; Huang, J.Y.; Yang, Y.C. Comparative study of the tribological behavior of various thermal spray Inconel 625 coatings in saline solution and deionized water. Surf. Coat. Technol. 2020, 385, 125442. [Google Scholar] [CrossRef]

- Jadhav, G.R.; Badgujar, T.Y.; Zoman, D.B.; Jadhav, M.V. Tribological Performance Analysis of Composite Materials for Journal Bearing. Int. J. Mod. Trends Eng. Res. (IJMTER) 2016, 3, 131–138. [Google Scholar] [CrossRef]

- Miler, D.; Škec, S.; Katana, B.; Žeželj, D. An experimental study of composite plain bearings: The influence of clearance on friction coefficient and temperature. Stroj. Vestn./J. Mech. Eng. 2019, 65, 547–556. [Google Scholar] [CrossRef]

- Zhu, J.; Xie, F.; Dwyer-Joyce, R.S. PEEK composites as self-lubricating bush materials for articulating revolute pin joints. Polymers 2020, 12, 665. [Google Scholar] [CrossRef]

- Hintze, M.; Eliasen, N.; Sivebaek, I. Wear and friction of PEEK composites, dry or lubricated. Wear 2023, 534, 205135. [Google Scholar] [CrossRef]

- Kim, S.S.; Park, D.C.; Lee, D.G. Characteristics of carbon fiber phenolic composite for journal bearing materials. Compos. Struct. 2004, 66, 359–366. [Google Scholar] [CrossRef]

- Choe, K.Y.; On, S.Y.; Song, S.A.; Lim, J.W.; You, J.I.; Kim, S.S. Study of the endurance performance of composite journal bearings under the oil cut situation. Compos. Struct. 2015, 134, 772–781. [Google Scholar] [CrossRef]

- Chauhan, N.R.; Khera, A.; Agarwal, S.; Bagri, M.; Aggarwal, A. Effect of nanoparticle on the performance of water lubricated journal bearing. IOP Conf. Ser. Mater. Sci. Eng. 2022, 1228, 012032. [Google Scholar] [CrossRef]

- Venkatesan, M.; Palanikumar, K.; Boopathy, S.R. Experimental investigation and analysis on the wear properties of glass fiber and CNT reinforced hybrid polymer composites. Sci. Eng. Compos. Mater. 2018, 25, 963–974. [Google Scholar] [CrossRef]

- Radoń-Kobus, K.; Madej, M. Properties of Diamond-like Coatings in Tribological Systems Lubricated with Ionic Liquid. Coatings 2025, 15, 799. [Google Scholar] [CrossRef]

- Bobzin, K.; Wietheger, W.; Jacobs, G.; Bosse, D.; Schröder, T.; Rolink, A. Thermally sprayed coatings for highly stressed sliding bearings. Wear 2020, 458, 203415. [Google Scholar] [CrossRef]

- Kim, H.; Park, J.; Lee, S. Evolution of Tribological Coatings for Mechanical Components: A 20-Year Review. Tribol. Lett. 2024, 72, 45. [Google Scholar]

- Zhao, Y.; Li, M.; Wang, Z. Preparation and Performance of Cu-Al2O3 Composite Coatings by Electrodeposition. J. Mater. Sci. Eng. 2018, 36, 456–462. [Google Scholar] [CrossRef]

- Chen, H.; Liu, J.; Zhang, D. Friction Reduction Mechanism of Graphene-Reinforced Copper Composite Coatings. Tribology 2019, 39, 589–598. [Google Scholar]

- Liu, J.; Zhang, D.; Li, H. Development of Copper-Based Coatings for Sliding Bearings: From Traditional Plating to Laser Cladding. J. Mater. Eng. 2023, 51, 123–135. [Google Scholar]

- Zhang, Q.; Li, M.; Wang, H. Bionic Textured Coatings for Sliding Bearings: Design, Fabrication, and Tribological Behavior. Coatings 2025, 15, 2189. [Google Scholar]

- Zhou, Y.; Li, X.; Wang, H. Cu-Ni-PTFE Composite Coatings for Marine Sliding Bearings: Corrosion Resistance and Tribological Behavior. J. Mar. Sci. Eng. 2024, 12, 789. [Google Scholar] [CrossRef]

| Coating Type | Representative Material | Friction Coefficient (μ) | Wear Rate (mm3·N−1·m−1) | Applicable Working Condition | Core Advantage | Key Limitation |

|---|---|---|---|---|---|---|

| Metal-based | Tin-based Babbitt alloy | 0.1–0.25 (dry friction, 4000 rpm) | Cobalt-based coating in [7] reduced by more than 50% compared with 316L steel | High-speed and heavy-load (e.g., steam turbine bearings) | Excellent anti-seizure property and good embeddability | Low fatigue strength and poor high-temperature performance |

| Ceramic-based | Al2O3/TiC/GPLs | Not explicitly mentioned, but cutting life significantly prolonged | Reduced by more than 50% compared with traditional hot-pressed ceramic tools | High-temperature and corrosive environments (e.g., zinc liquid immersion) | High hardness (HV ≥ 1500) and strong chemical stability | Low fracture toughness (<5 MPa·m1/2) and high cost |

| Polymer-based | PEEK + 30% glass fiber | 0.12–0.189 (dry friction) | 3.22 × 10−5 (after composite filling) | Clean environments (food machinery, medical equipment) | Low friction coefficient and light weight | Easy to soften at high temperatures (long-term use ≤250 °C) and strength dependent on reinforcing phases |

| Preparation Process | Representative Application | Coating Adhesion Strength (MPa) | Production Efficiency (m2/h) | Environmental Friendliness | Innovation Direction |

|---|---|---|---|---|---|

| Electroplating | Lead-free composite bearing overlay | 30–50 (traditional electroplating); 50–80 (pulse electroplating) [18] | 5–10 | Poor (contains cyanide and heavy metal wastewater) | Optimization of pulse parameters (frequency 500–1000 Hz) and development of lead-free systems |

| Magnetron sputtering | AlSnCu multi-layer coating | 80–120 [24] | 0.5–2 | Excellent (no wastewater, target utilization rate > 70%) | Multi-target collaborative sputtering and arc-assisted deposition |

| Laser cladding | Nickel-based self-lubricating coating | 150–200 (metallurgical bonding) [28] | 0.1–0.5 | Moderate (high energy consumption but no pollutant emission) | Ultrasonic-assisted grain refinement and precision control of coaxial powder feeding |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Du, F.; Guo, Z.; Mo, R.; Lin, W.; Zhang, S. Review and Prospect of Research Status on Sliding Bearing Coatings. Lubricants 2025, 13, 493. https://doi.org/10.3390/lubricants13110493

Du F, Guo Z, Mo R, Lin W, Zhang S. Review and Prospect of Research Status on Sliding Bearing Coatings. Lubricants. 2025; 13(11):493. https://doi.org/10.3390/lubricants13110493

Chicago/Turabian StyleDu, Fengming, Zhen Guo, Renhao Mo, Wenqing Lin, and Shuai Zhang. 2025. "Review and Prospect of Research Status on Sliding Bearing Coatings" Lubricants 13, no. 11: 493. https://doi.org/10.3390/lubricants13110493

APA StyleDu, F., Guo, Z., Mo, R., Lin, W., & Zhang, S. (2025). Review and Prospect of Research Status on Sliding Bearing Coatings. Lubricants, 13(11), 493. https://doi.org/10.3390/lubricants13110493