Modeling and Analysis of the Eccentric-Load Resistance of Single Rectangular Hydrostatic Oil Pad Units

Abstract

1. Introduction

2. Materials and Methods

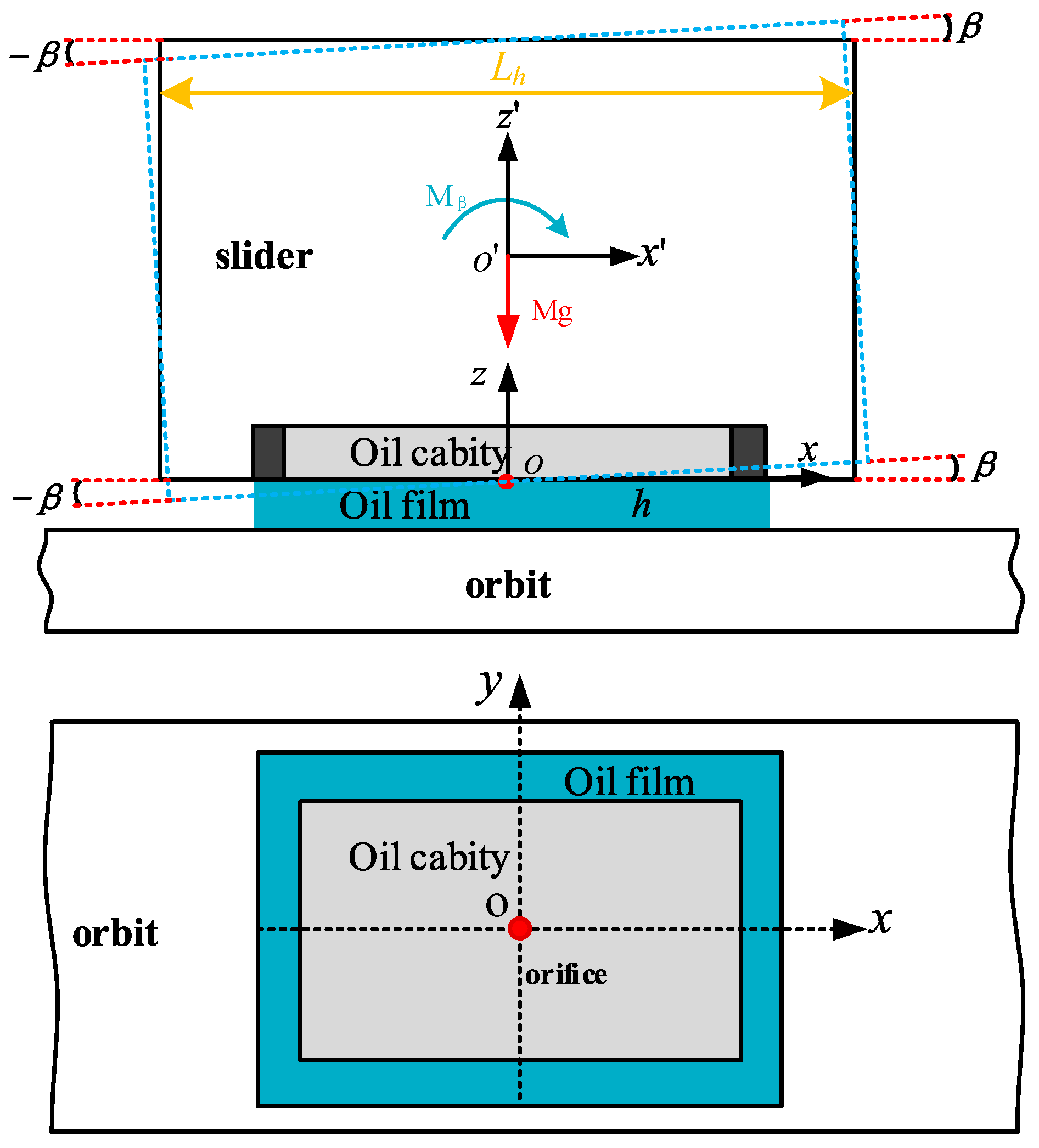

2.1. Principles and Assumptions

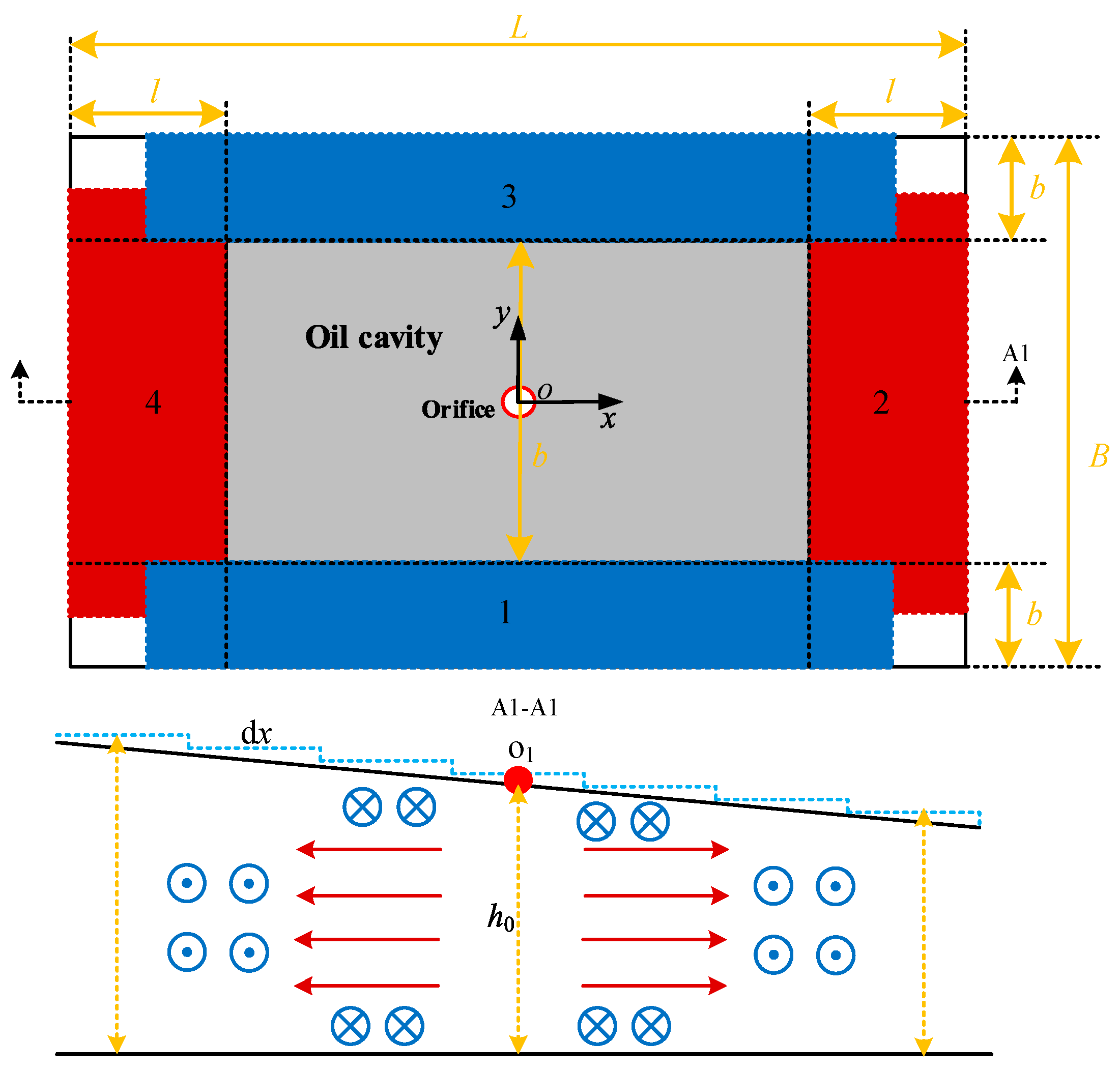

2.2. Calculation of the Load-Bearing Characteristics of the Rectangular Oil Pad

- Calculation of normal bearing characteristics

- 2.

- Calculation of deflection load resistance

3. Algorithm Validation

3.1. Verification of Normal Characteristic Calculations

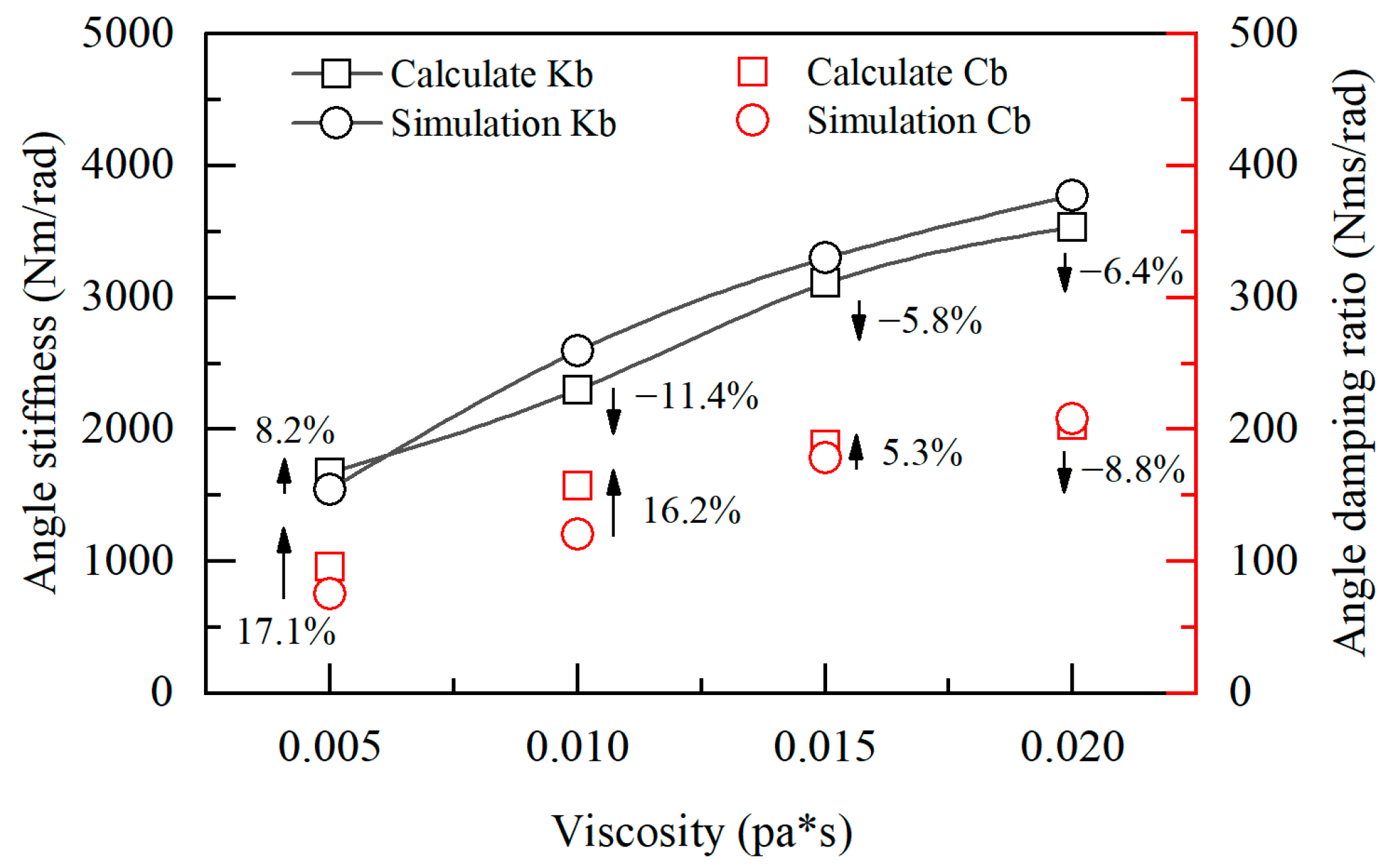

3.2. Calculation and Validation of Deflection Load Resistance

4. Results and Discussion

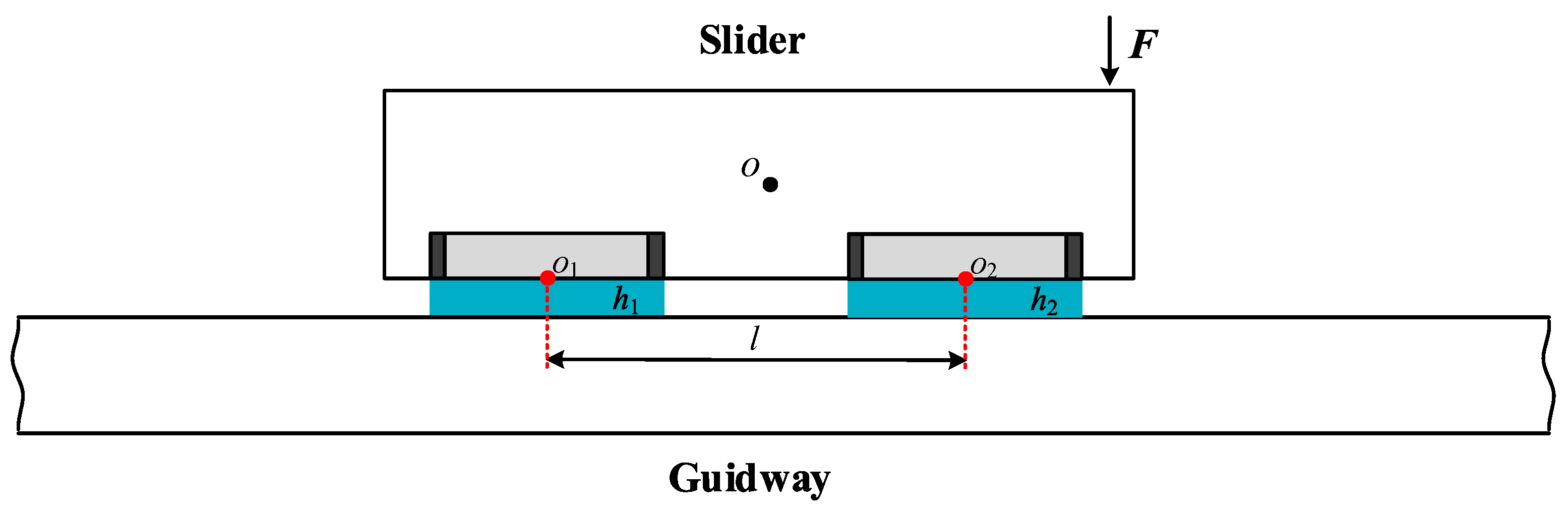

4.1. Analysis of the Anti-Deviation Load Capability of Single Oil Pad

- Anti-deviation load torque of single oil pad

- Support torque of each oil pad relative to the center of mass of the slider

4.2. Analysis of Factors Influencing the Anti-Deflective Load Characteristics

4.2.1. Feed Pressure

4.2.2. The Diameter of Orifice

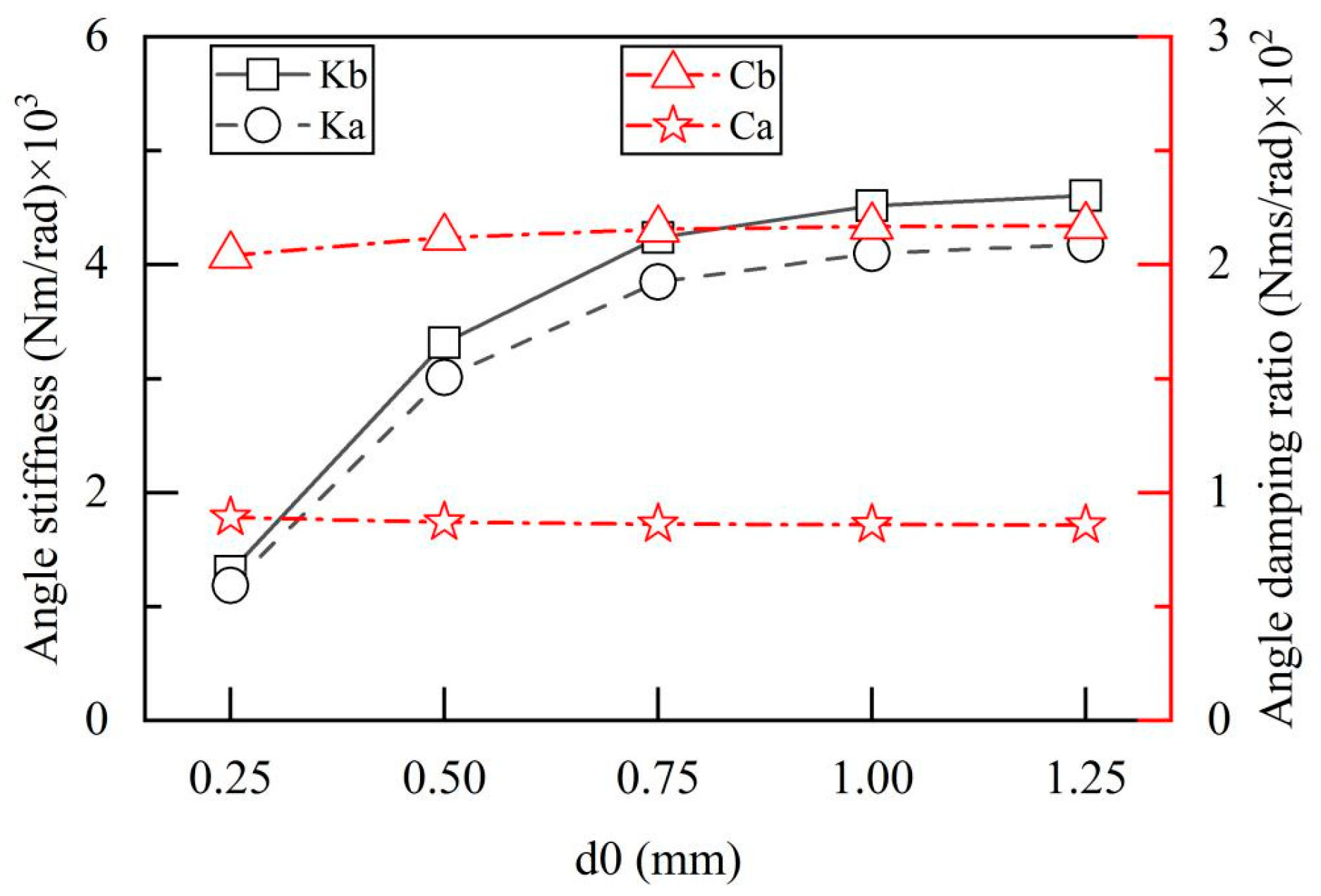

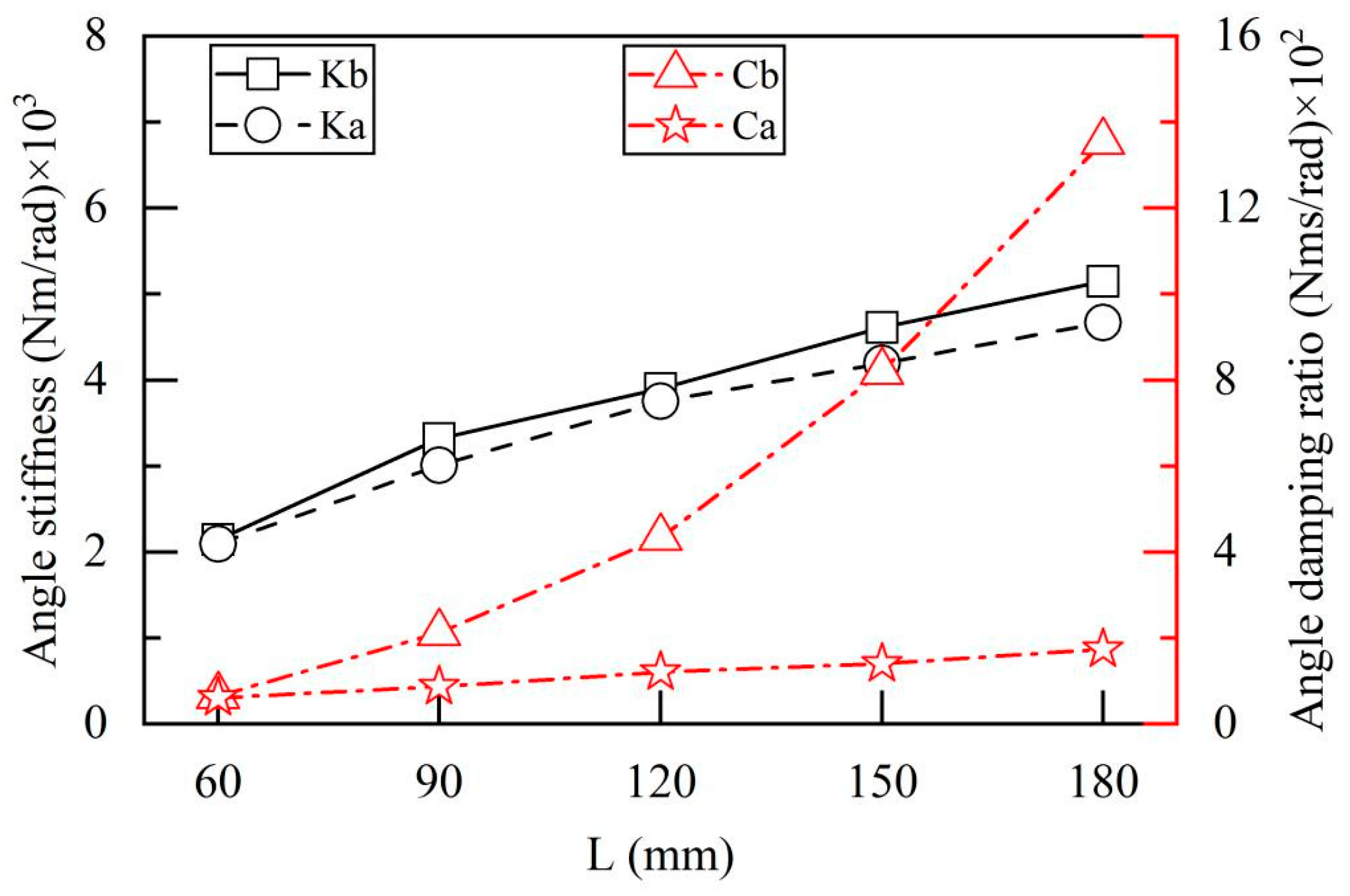

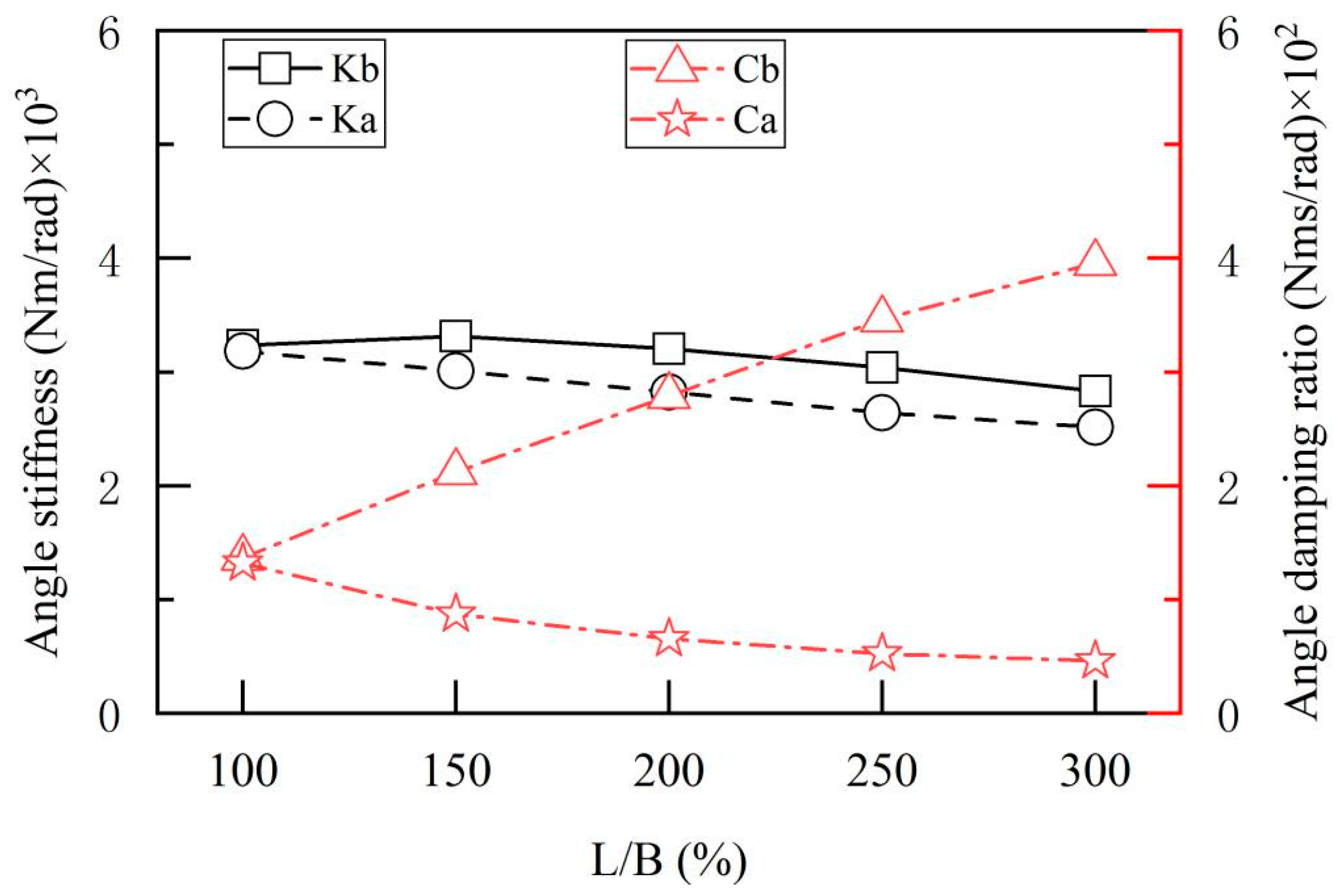

4.2.3. Oil Pad Dimensions and Aspect Ratio

5. Conclusions

- The calculated values of angular stiffness and angular damping for a single oil pad are in good agreement with the simulation results, verifying the accuracy of the proposed mathematical model. However, due to the idealization of the complex flow behavior at the four corners of the rectangular oil pad, high-order nonlinear terms in the flow balance equation were neglected, which introduces a minor deviation in the model.

- For a support system with multiple oil pads, when the center-to-center distance between adjacent oil pads is small, the anti-eccentric load capacity of individual oil pads within the system is substantial, and their contribution cannot be overlooked. Therefore, when designing the normal load-carrying capacity of a hydrostatic oil pad system, its eccentric load-carrying capacity must be taken into account simultaneously.

- The anti-eccentric load capacity of the rectangular oil pad can be significantly enhanced by increasing the oil supply pressure and optimizing the orifice diameter. In contrast, adjustments to the oil pad diameter, oil pad dimensions, and length-to-diameter ratio affect both the normal load-carrying capacity of the oil pad and its eccentric load-carrying capacity in specific directions. Specifically, increasing the oil supply pressure to above 3 MPa is beneficial for improving its eccentric load-carrying capacity; under the premise of ensuring static load-carrying capacity, a moderate increase in the orifice diameter also contributes to enhancing anti-eccentric load performance. Thus, during the design of rectangular oil pads, parameter optimization should be conducted based on specific application scenarios to improve the comprehensive load-carrying characteristics of the rectangular oil pad.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Glossary

| h(x) | The oil film gap |

| P | The pressure value at the calculated position |

| P0 | The internal pressure in the oil chamber and the oil viscosity |

| The oil viscosity | |

| β | Pitch angle in X direction |

| Pitch angle in y direction | |

| normal stiffness | |

| normal damping value | |

| y-direction angular stiffness component | |

| x-direction angular stiffness component | |

| y-direction angular damping value component | |

| x-direction angular damping value component |

References

- Nguyen, M.T.; Pham, V.H.; Tran, V.T.; Bui, T.A. Displacement Analysis of a Hydrostatic Spindle: An Experimental Investigation. Eng. Technol. Appl. Sci. Res. 2024, 14, 16962–16969. [Google Scholar] [CrossRef]

- Nguyen, M.T.; Tran, T.H.; Le, D.D.; Tran, D.T.; Bui, D.T.; Anh, B.T. The Influence of Capillary Geometry on the Stiffness of Hydrostatic Bearings in MediumSized Cylindrical Grinding Machines: A Simulation Analysis. Eng. Technol. Appl. Sci. Res. 2024, 14, 15993–15999. [Google Scholar] [CrossRef]

- Guo, M.H.; Rong, Y.M.; Huang, Y.; Feng, X.L.; Hu, H.D.; Wu, C.Y.; Zhang, G.J. Ultrafast laser-chemical modification hybrid fabrication of hydrostatic bearings with a superhydrophobicity solid-liquid interface. Sci. China (Technol. Sci.) 2024, 67, 696–708. [Google Scholar] [CrossRef]

- Marov, A.; Bokova, T.; Bokov, P.; Volkov, N. Experimental correction of the known procedure for calculating hydrostatic bearings operating in a heavy liquid-metal coolant. AIP Conf. Proc. 2023, 2697, 6. [Google Scholar] [CrossRef]

- Liu, H.; Wang, G.; Ke, J.; Yu, L. Research on the anti-sticking characteristics of water hydraulic piston friction pairs with hydrostatic bearing. Lubr. Sci. 2013, 25, 453–462. [Google Scholar] [CrossRef]

- Yu, X.; Du, B.; Meng, X.; Qiao, W.; Sun, Y.; Ma, W.; Sun, K.; Dai, R.; Jia, W.; Jiao, J.; et al. Dynamic Characteristics of Hydrostatic Thrust Bearing With Tilting Oil Pad Under Eccentric Load. J. Tribol. 2025, 147, 91104. [Google Scholar] [CrossRef]

- Bambhania, M.P.; Doshi, N. Optimization of Film Thickness for Hydrostatic Circular Pad Bearing Used in V-25 vertical Turning Machine. Int. J. Mech. Eng. Robot. 2013, 1, 118–121. [Google Scholar] [CrossRef]

- Zhang, Y.; Wu, Y.; Li, J.; Wang, M.; Quan, Z. Thermal Characteristics of Oil Film in Critical Lubrication State of Heavy Hydrostatic Bearing. Recent Pat. Mech. Eng. 2024, 17, 304–311. [Google Scholar]

- Liu, T.; Bei, Z.; Wang, H.; Duan, R.; Chen, F.; Zhang, J. Study on microgroove working surface in hydrostatic bearing for oil film heat suppression. Appl. Therm. Eng. 2025, 266, 125618. [Google Scholar] [CrossRef]

- Zhang, Y.; Li, J.; Wu, Y.; Wang, M.; Kong, P. Study of the Lubricity of Oil Film at Constant Cutting Speed Under Different Loads of a Hydrostatic Turntable. Tribol. Trans. 2023, 66, 135–143. [Google Scholar] [CrossRef]

- Zhang, Y.; Tao, J.; Ni, S.; Zhao, R. Mechanical Performance Analysis of Hydrostatic Thrust Bearing under Microbevel Parameters. Recent Pat. Eng. 2023, 19, e240223214025. [Google Scholar] [CrossRef]

- Tian, Z.; Cao, H.; Huang, Y. Static characteristics of hydrostatic thrust bearing considering the inertia effect on the region of supply hole. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2019, 233, 188–193. [Google Scholar] [CrossRef]

- Zhang, W.; Han, L.; Qian, L. Application of anti-eccentric open hydrostatic guideway in vertical lathe. Int. Conf. Adv. Compos. Mater. Manuf. Eng. 2020, 612, 32073. [Google Scholar] [CrossRef]

- Poole, W.; Chetta, G. Eccentric end wear in cylindrical roller bearings can be predicted and prevented. In Proceedings of the 19th Joint Propulsion Conference, Seattle, WA, USA, 27–29 June 1983. [Google Scholar] [CrossRef]

- Huang, H.C.; Yang, S.H. Thrust-Bearing Layout Design of a Large-Sized Hydrostatic Rotary Table to Withstand Eccentric Loads for Horizontal Boring Machine Applications. Lubricants 2022, 10, 49. [Google Scholar] [CrossRef]

- Foltýn, J.; Maccioni, L.; Michalec, M.; Concli, F.; Svoboda, P. Uncertainty analysis of hydrostatic bearing working conditions with experimental, CFD, and analytical approach. Forsch. Im Ingenieurwesen 2025, 89, 67. [Google Scholar] [CrossRef]

- Abdullah, R.; Trimulyono, A.; Samuel; Adietya, B.A. Numerical simulation of sloshing with floating baffles using smoothed particle hydrodynamics. IOP Conf. Ser. Earth Environ. Sci. 2025, 1461, 12007. [Google Scholar] [CrossRef]

- Michalec, M.; Foltn, J.; Svoboda, P.; Křupka, I.; Hartl, M. Experimental Comparison of Hydrostatic Bearing Pad Geometry Optimization Approaches Under Static Conditions; International Symposium on Industrial Engineering and Automation; Springer: Cham, Switzerland, 2024. [Google Scholar] [CrossRef]

- Gao, W.; Yu, X.; Wang, P.; Jiang, H. Deformation behavior prediction and structural optimization of vertical hydrostatic guideway ram in vertical lathe. J. Braz. Soc. Mech. Sci. Eng. 2025, 47, 352. [Google Scholar] [CrossRef]

- Yu, X.; Sun, F.; Zhou, D.; Huang, D.; Zhan, S.; Han, F.; Jiao, J.; Jiang, H. Research on influencing factors of oil film temperature field characteristics for adaptive hydrostatic thrust bearing. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2024, 238, 1727–1735. [Google Scholar] [CrossRef]

- Guo, C.S.; Cui, Y. Study on the Hydrostatic Slide Film Temperature Field and Bearing Capacity of Precision Grinding Machine; Springer: Berlin/Heidelberg, Germany, 2016. [Google Scholar] [CrossRef]

- Yu, X.; Li, S.; Chen, M.; Wang, S.; Han, Z.; Tang, B.; Wang, J.; Jiang, H.; Jia, W. Prediction and improvement on anti-eccentric load characteristics of high-speed and heavy-type hydrostatic bearing. J. Braz. Soc. Mech. Sci. Eng. 2022, 44, 558. [Google Scholar] [CrossRef]

- Yu, X.; Shao, M.; Yang, X.; Li, L.; Lin, Y.; Lan, Z.; Li, E.; Dai, R.; Jia, W.; Wang, J.; et al. Investigation on lubrication characteristics and deformation control of hydrostatic bearing workbench. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2025, 239, 133–150. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhao, R.; Tao, J.; Wang, M.; Kong, P. Effect of cutting and feed speed on lubrication performance of large hydrostatic turntable with constant linear velocity. Lubr. Sci. 2024, 36, 330–340. [Google Scholar] [CrossRef]

- Liu, Z.; Guo, J.; Wang, Y.; Xiangmin, D.; Wu, Y.; Yan, Z.; Jinlong, G. Influence of rotational speed of a heavy-duty hydrostatic turret on bearing performance under tilt. Ind. Lubr. Tribol. 2020, 72, 575–579. [Google Scholar] [CrossRef]

- Du, Y.; Mao, K.; Liu, H.; Mao, X.; Li, Z. A simplified analytical method for the pressure of tilt hydrostatic journal bearing. Ind. Lubr. Tribol. 2018, 70, 993–1001. [Google Scholar] [CrossRef]

- Tripkewitz, F.A.; Fritz, M.; Weigold, M. Experimental study on tilting stiffness of oil hydrostatic shallow recess thrust bearings. MM Sci. J. 2021, 2021, 5000–5007. [Google Scholar] [CrossRef]

- Chen, Y. Principle and Design of Hydrostatic Bearing; National Defense Industry Press: Beijing, China, 1980. [Google Scholar]

- Qi, E. Modelling on Static & Dynamic Performance And Geometric Error Analysis Of Ultra Precision Vertical Linear Motion System. Ph.D. Thesis, Harbin Institute of Technology, Harbin, China, 2016. [Google Scholar]

- Pu, Y.; Zhang, X.; Zhang, F. Research on the Static and Dynamic Characteristics of Liquid Static Pressure Guides for Ultra Precision Machine Tools. Comb. Mach. Tool Autom. Process. Technol. 2020. [Google Scholar]

- Li, M.; Hu, Q. Research on rapid modeling and analysis method of hydrostatic bearing based on COMSOL Multiphysics. Hydraul. Pneum. 2020, 44, 95–100. [Google Scholar]

| Parameters | Numerical Values |

|---|---|

| L (mm) | 90 |

| B (mm) | 60 |

| l (mm) | 15 |

| b (mm) | 15 |

| h0 (me) | 40 |

| d0 (mm) | 0.5 |

| Ps (MPa) | 1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, M.; Ding, Y.; Wu, J. Modeling and Analysis of the Eccentric-Load Resistance of Single Rectangular Hydrostatic Oil Pad Units. Lubricants 2025, 13, 471. https://doi.org/10.3390/lubricants13110471

Li M, Ding Y, Wu J. Modeling and Analysis of the Eccentric-Load Resistance of Single Rectangular Hydrostatic Oil Pad Units. Lubricants. 2025; 13(11):471. https://doi.org/10.3390/lubricants13110471

Chicago/Turabian StyleLi, Mengyang, Ye Ding, and Jie Wu. 2025. "Modeling and Analysis of the Eccentric-Load Resistance of Single Rectangular Hydrostatic Oil Pad Units" Lubricants 13, no. 11: 471. https://doi.org/10.3390/lubricants13110471

APA StyleLi, M., Ding, Y., & Wu, J. (2025). Modeling and Analysis of the Eccentric-Load Resistance of Single Rectangular Hydrostatic Oil Pad Units. Lubricants, 13(11), 471. https://doi.org/10.3390/lubricants13110471