Experimental Study on the Tribological Performance of Shark Denticle-Inspired Texture for Roller Cone Bit Bearings

Abstract

1. Introduction

2. Methods

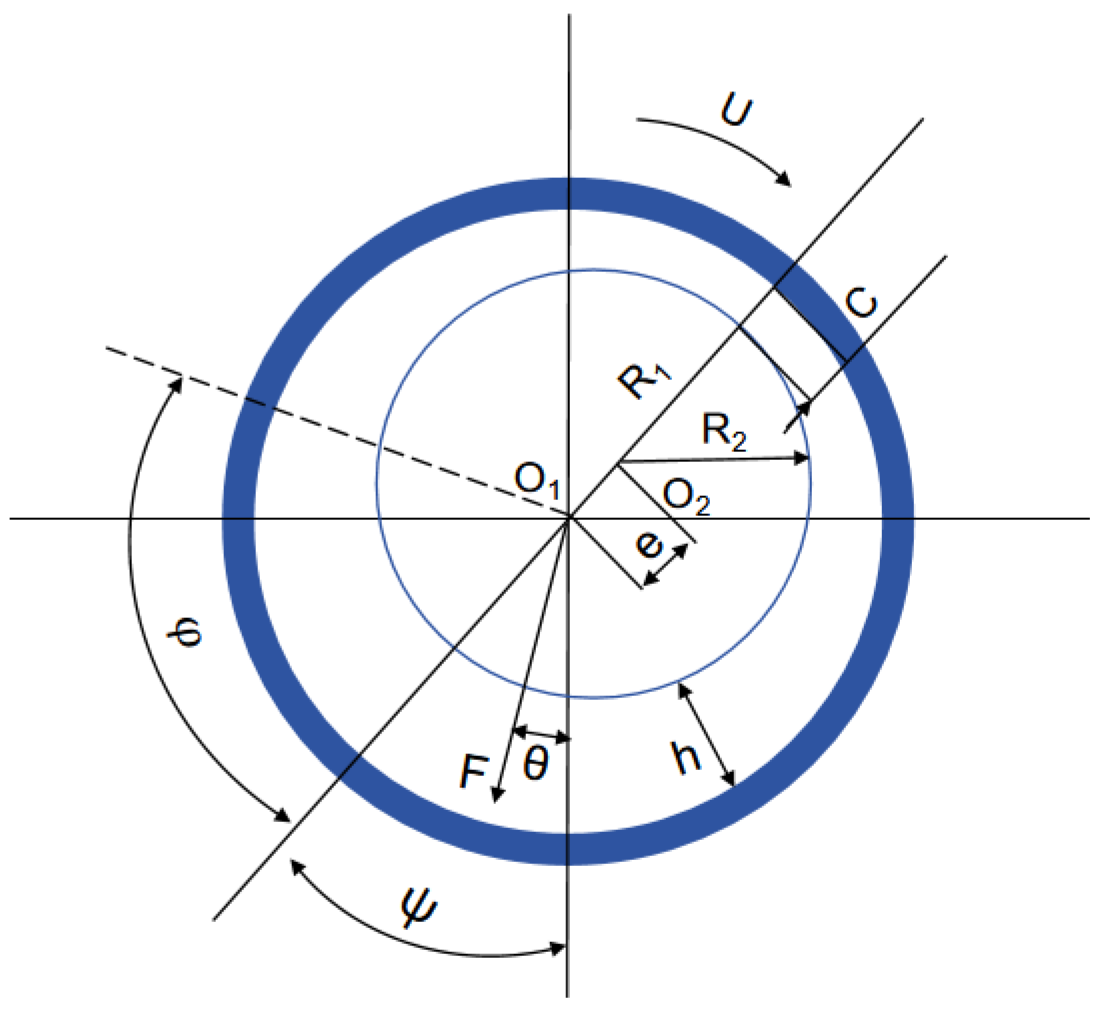

2.1. Equivalent Working Condition Transformation of Roller Cone Bit Bearings

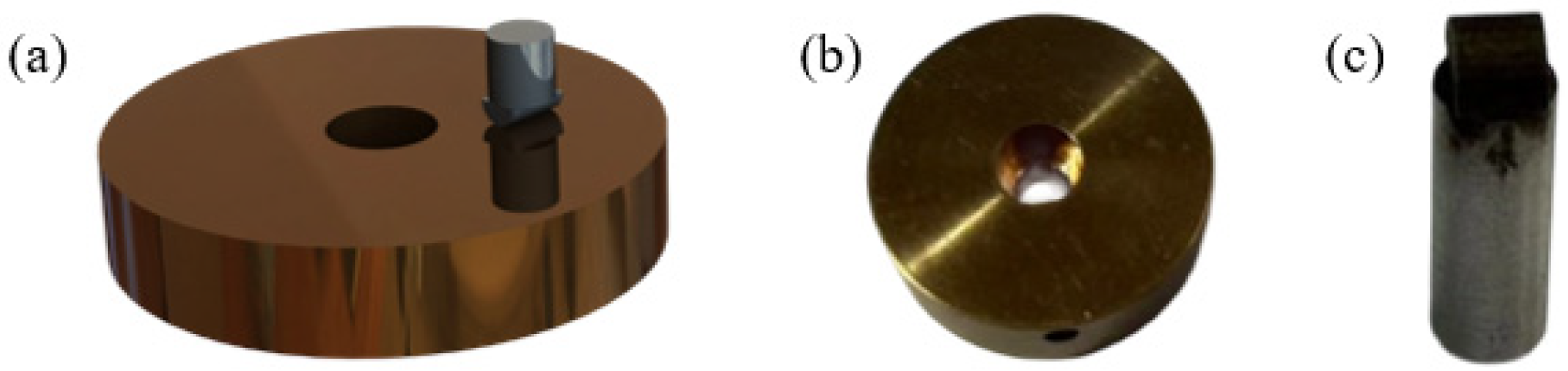

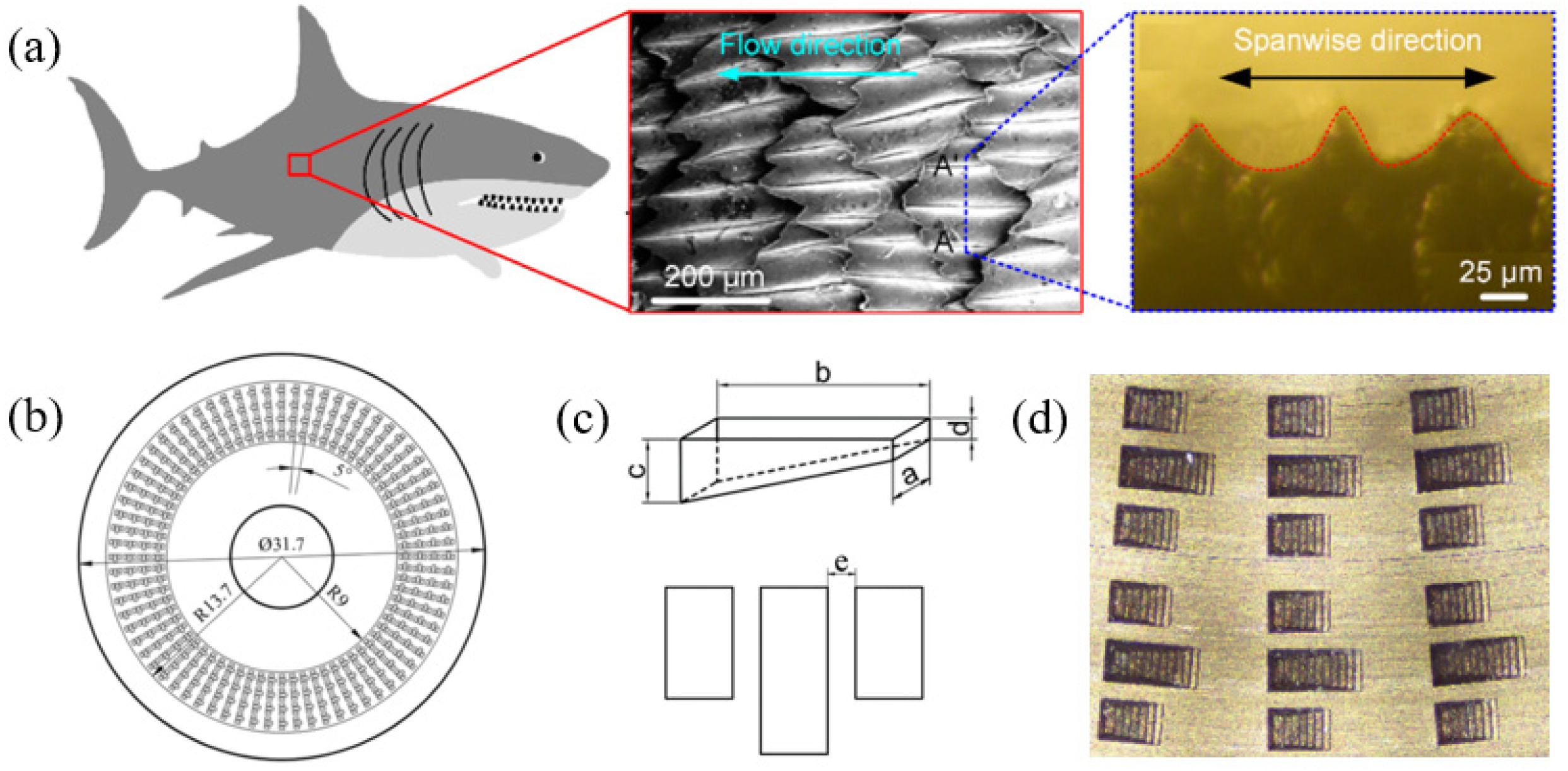

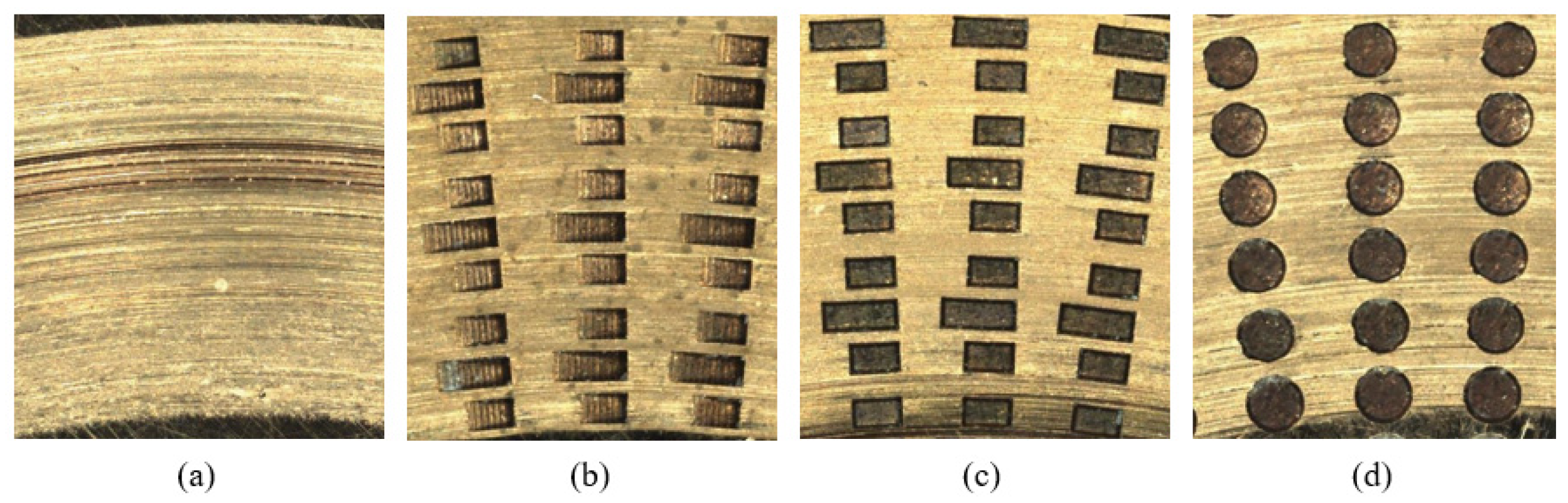

2.2. Surface Texture Design and Fabrication

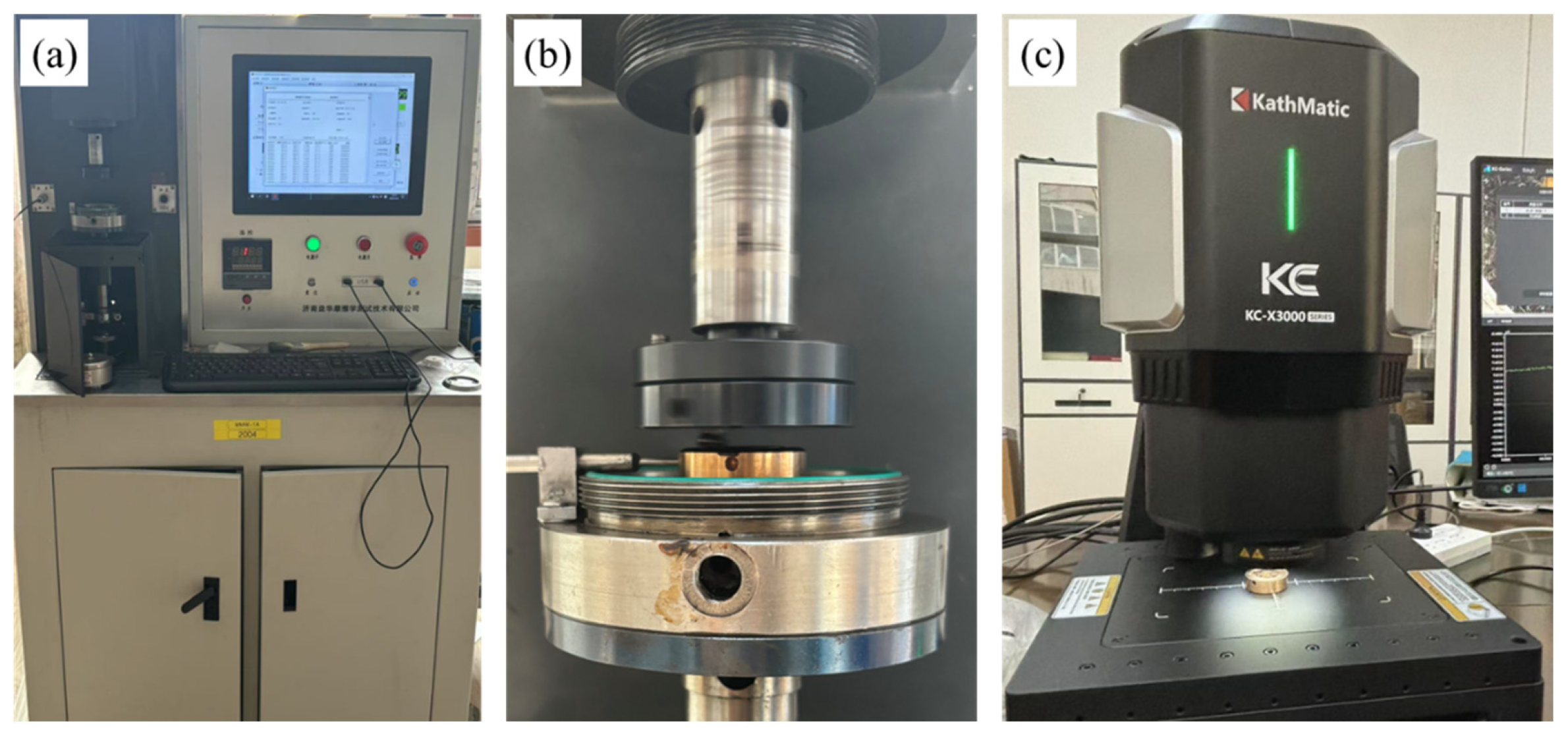

2.3. Equivalent Friction Tests of Roller Cone Bit Bearings

3. Results and Discussion

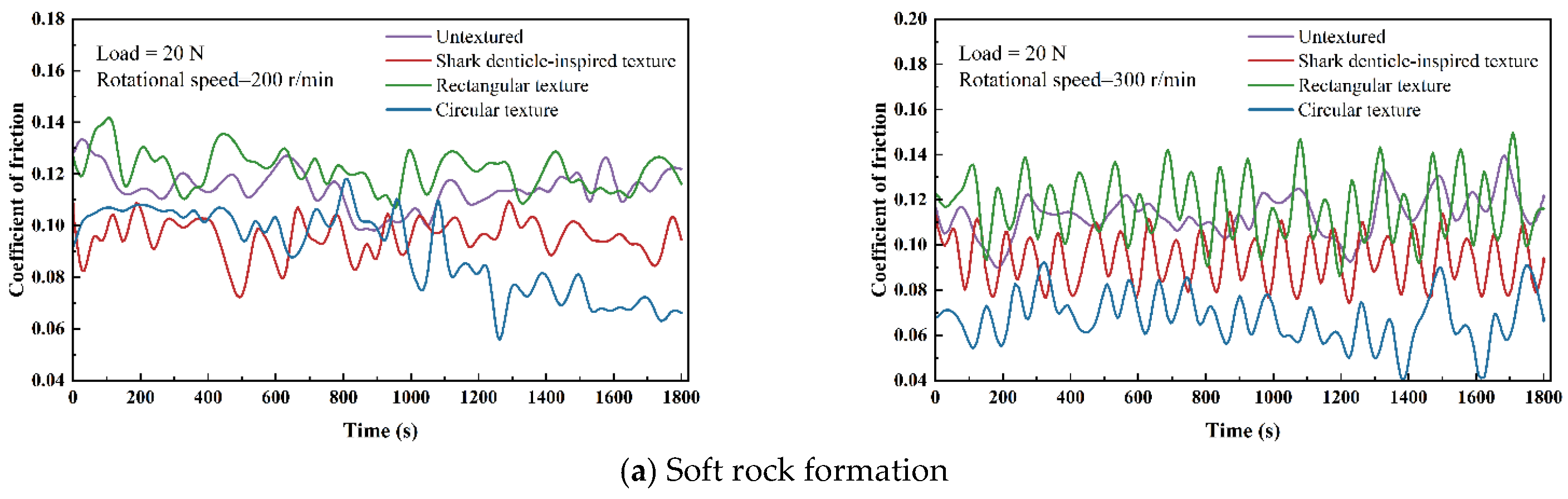

3.1. Effect of Texture on Friction Coefficient

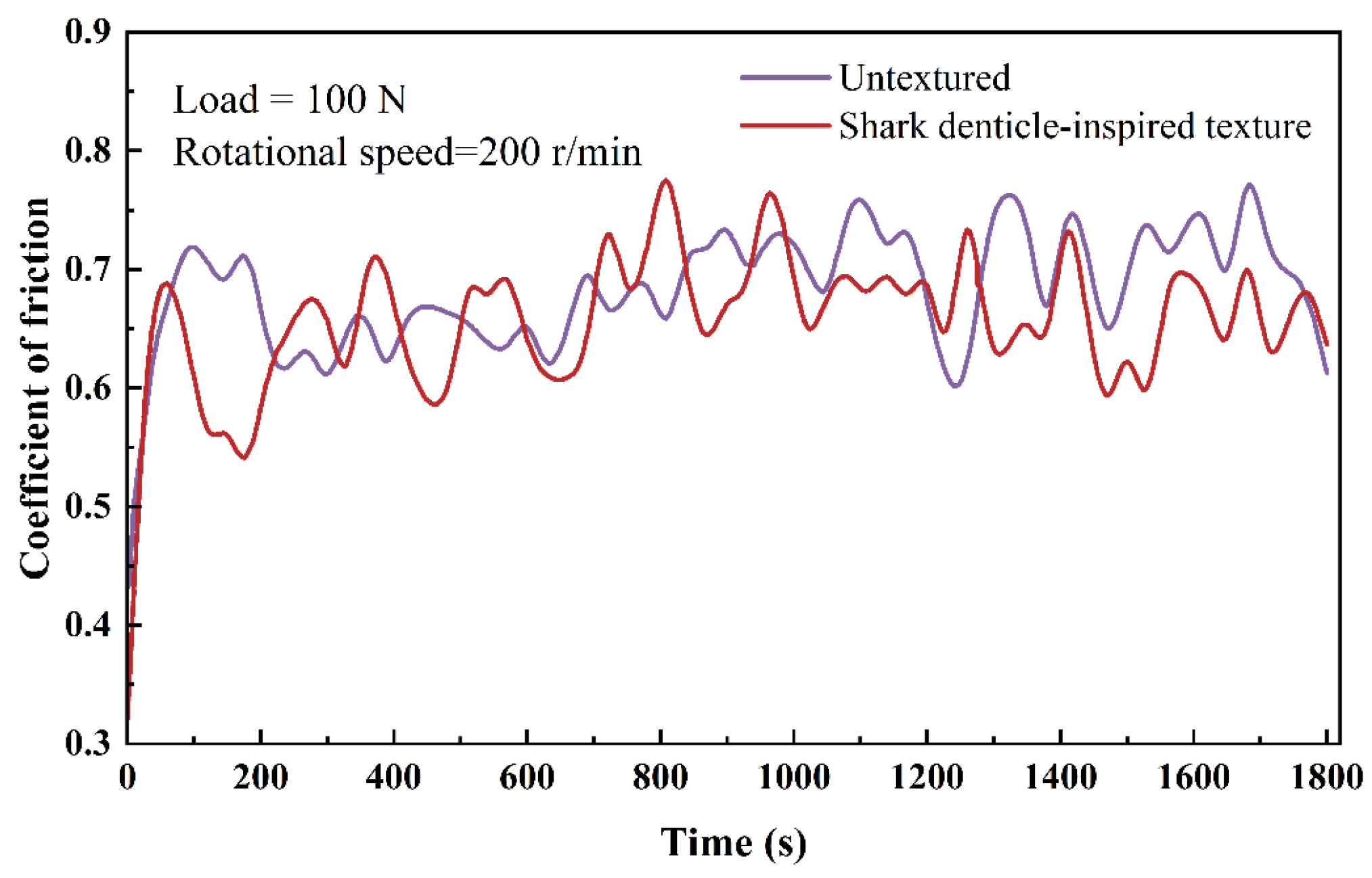

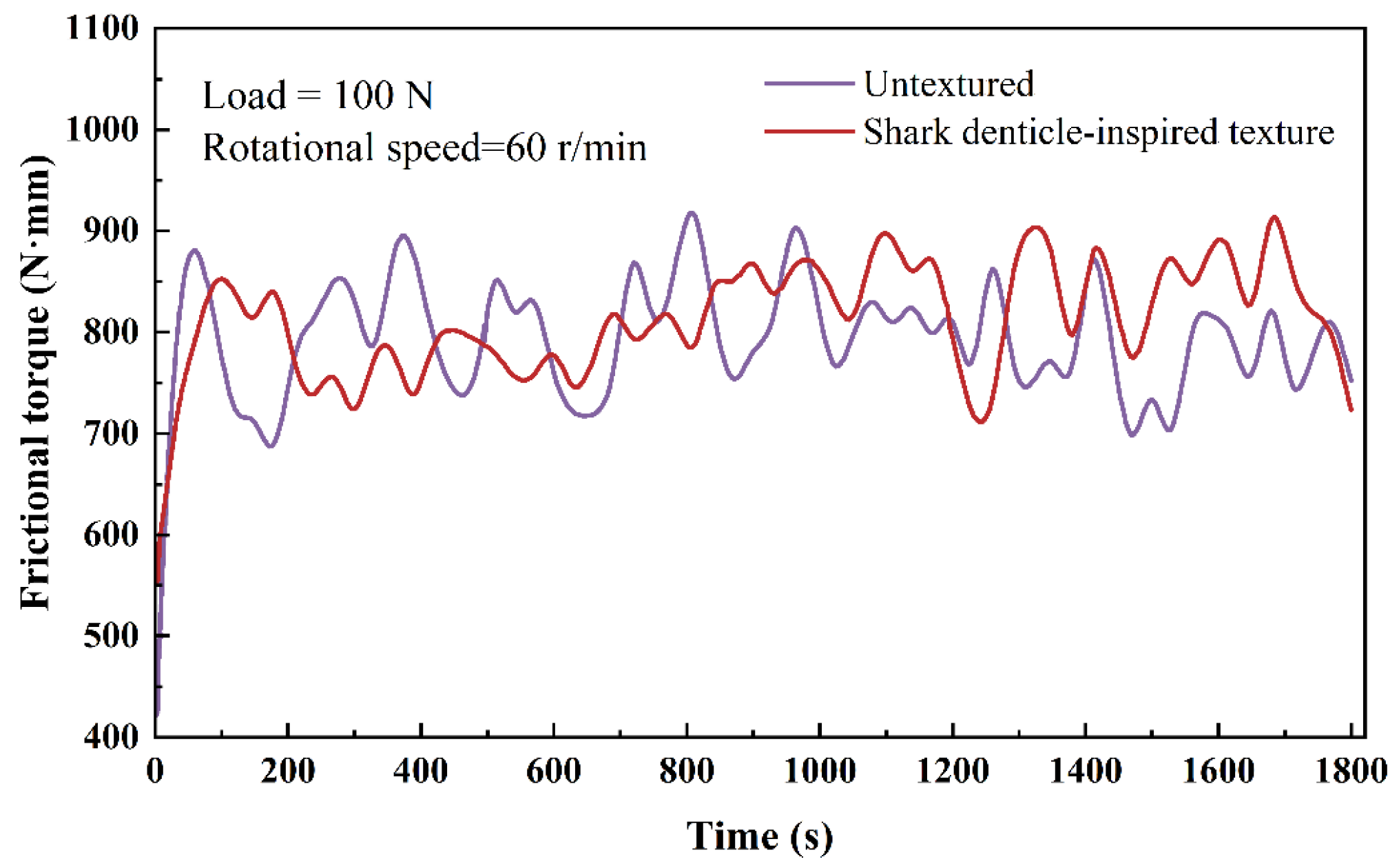

3.2. Effect of Texture on Friction Torque

3.3. Wear Characteristics

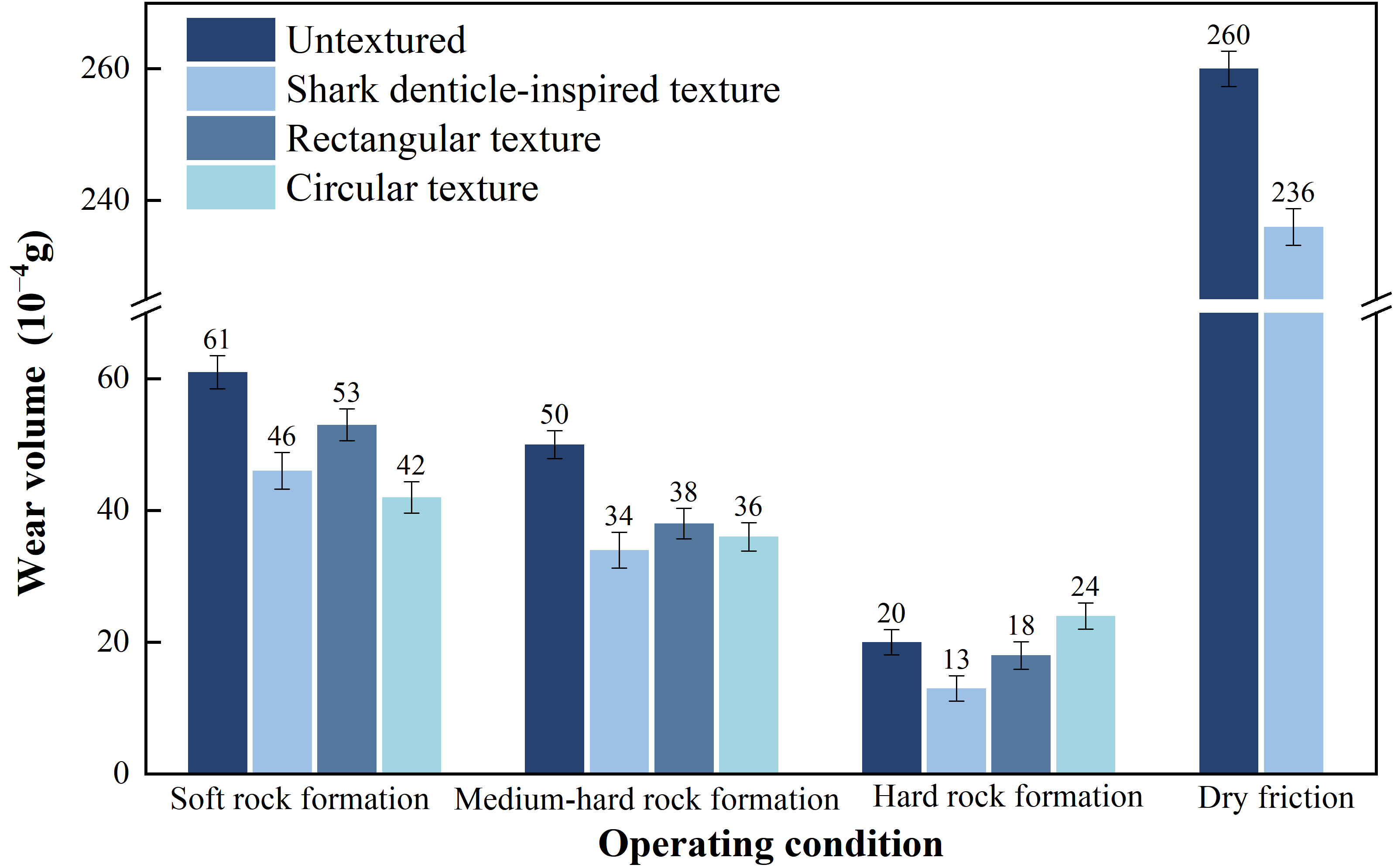

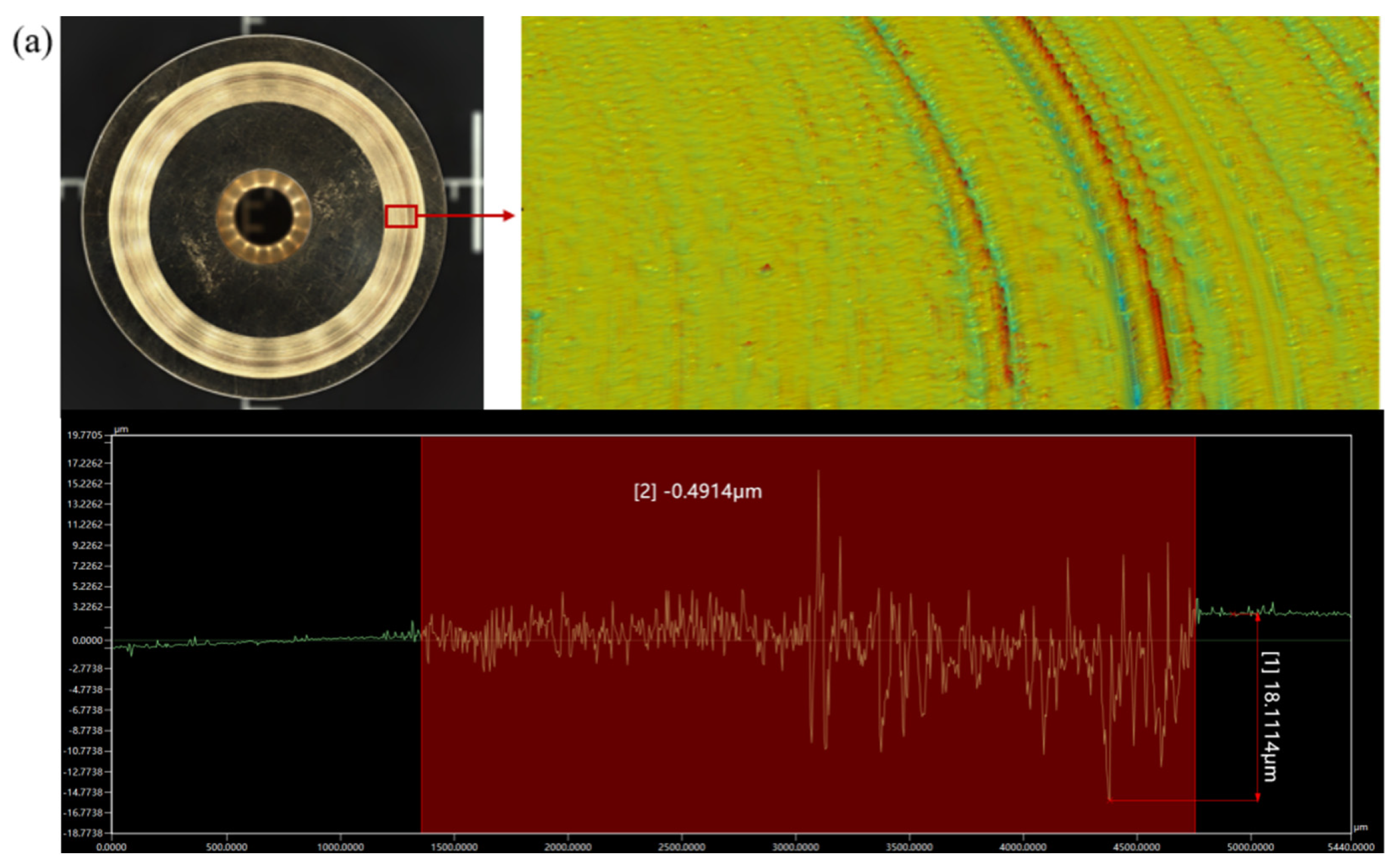

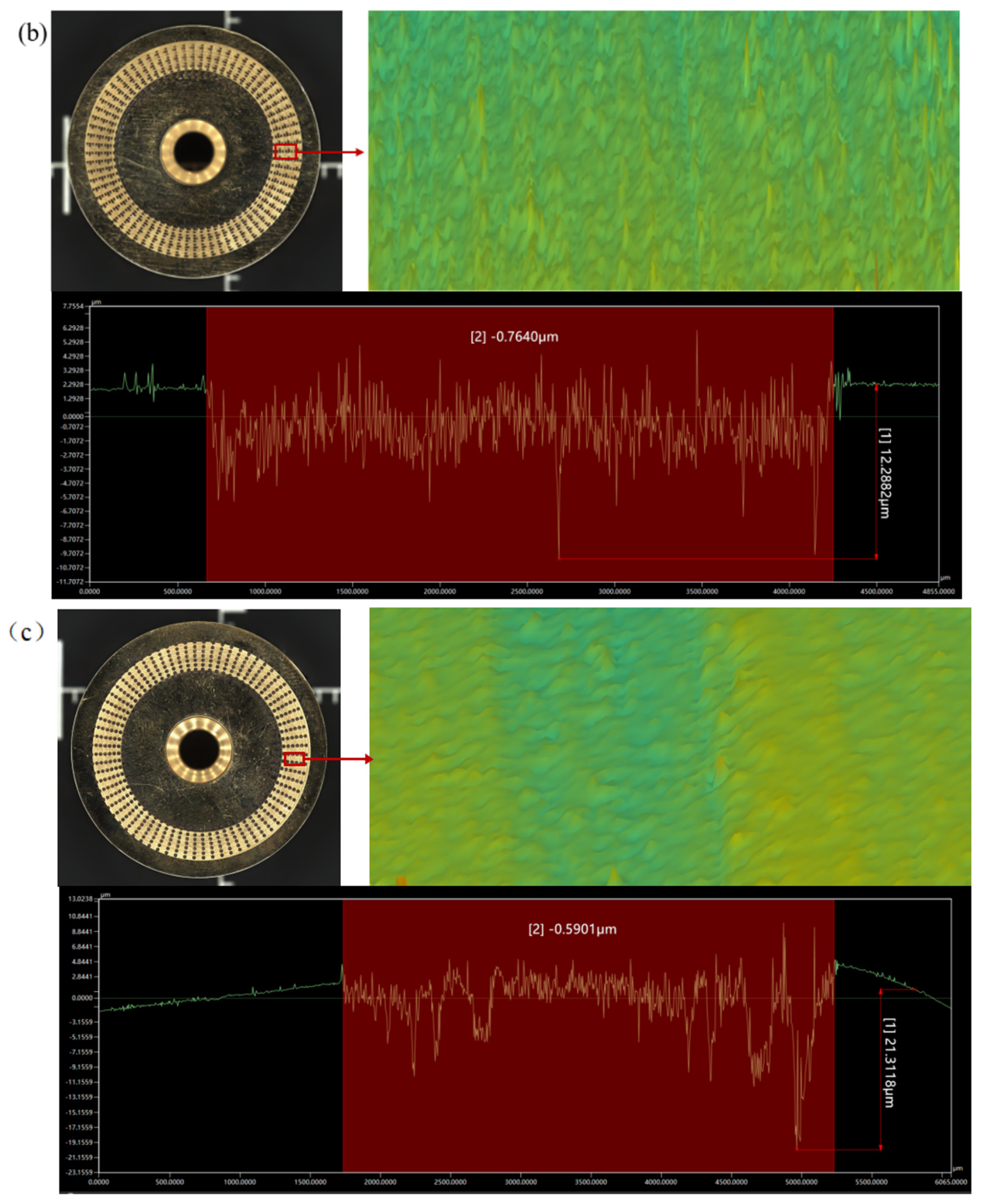

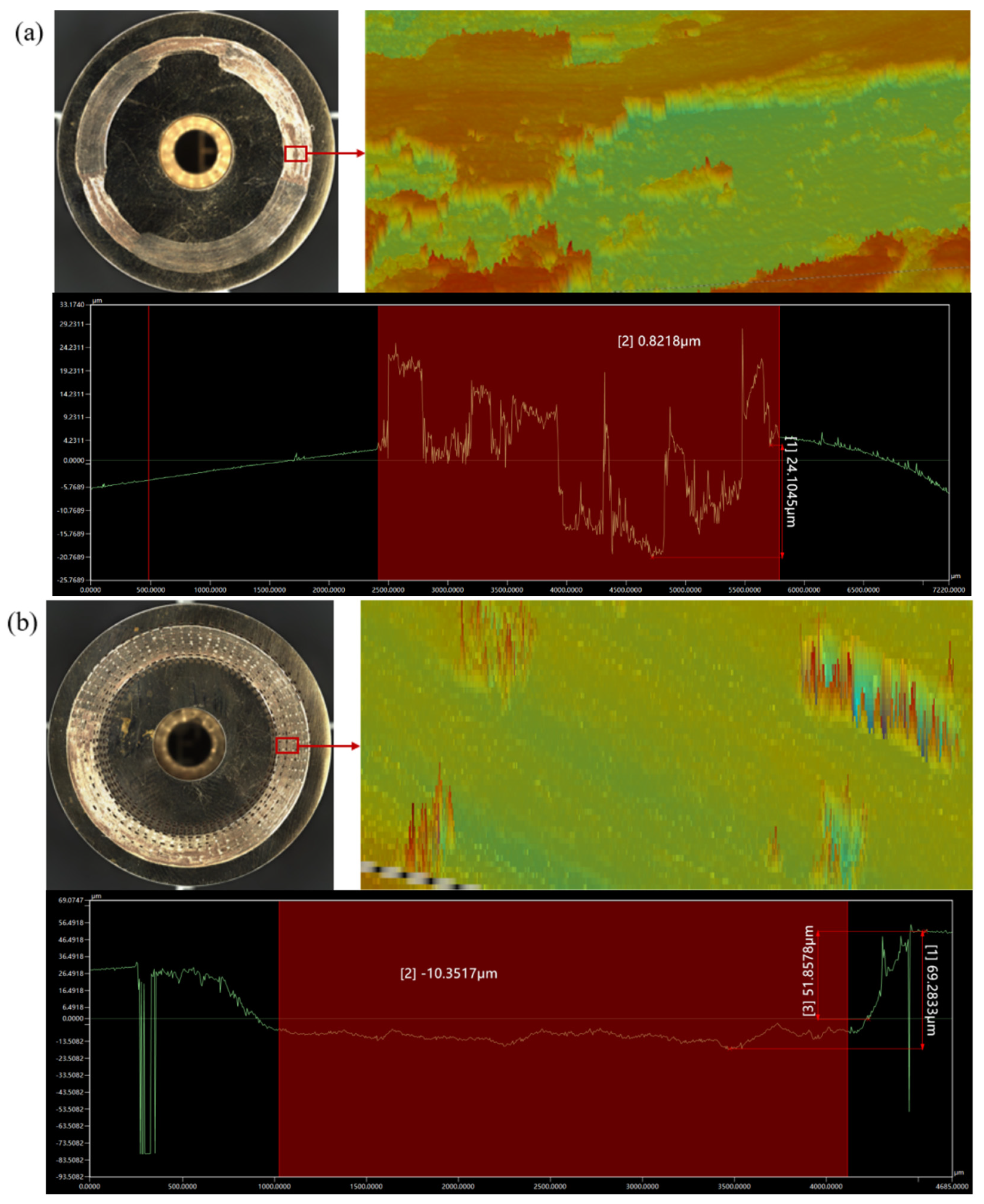

3.3.1. Wear Volume Comparison

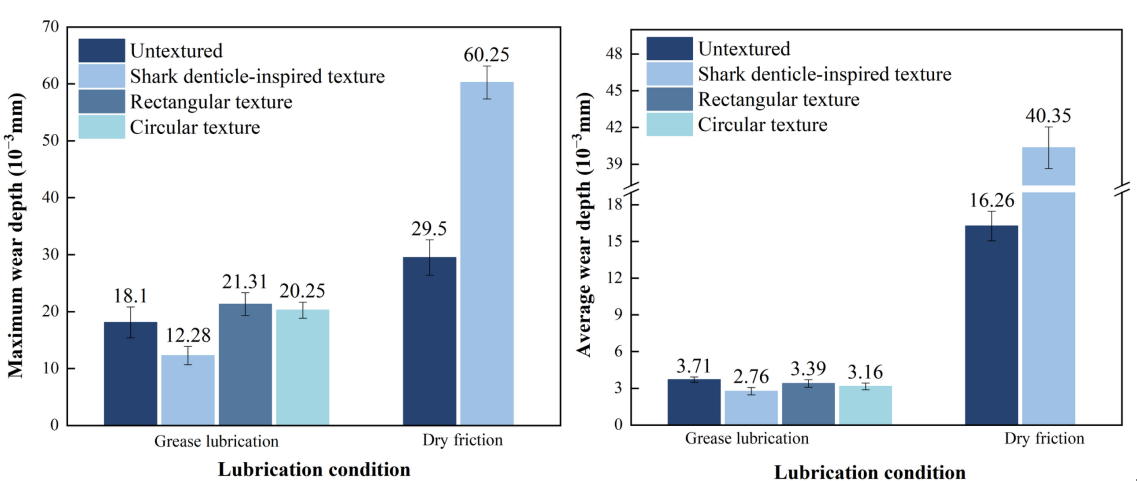

3.3.2. Wear Depth Comparison

3.4. Surface Morphology Analysis

4. Conclusions

- The shark denticle-inspired texture exhibited pronounced friction- and wear-reduction advantages under complex loading conditions. Compared with the untextured specimen, the maximum reductions in friction coefficient, friction torque, and wear volume reached 33.1%, 38.3%, and 35%, respectively. In contrast, the rectangular and circular textures showed poor adaptability, with lubrication instability under some conditions.

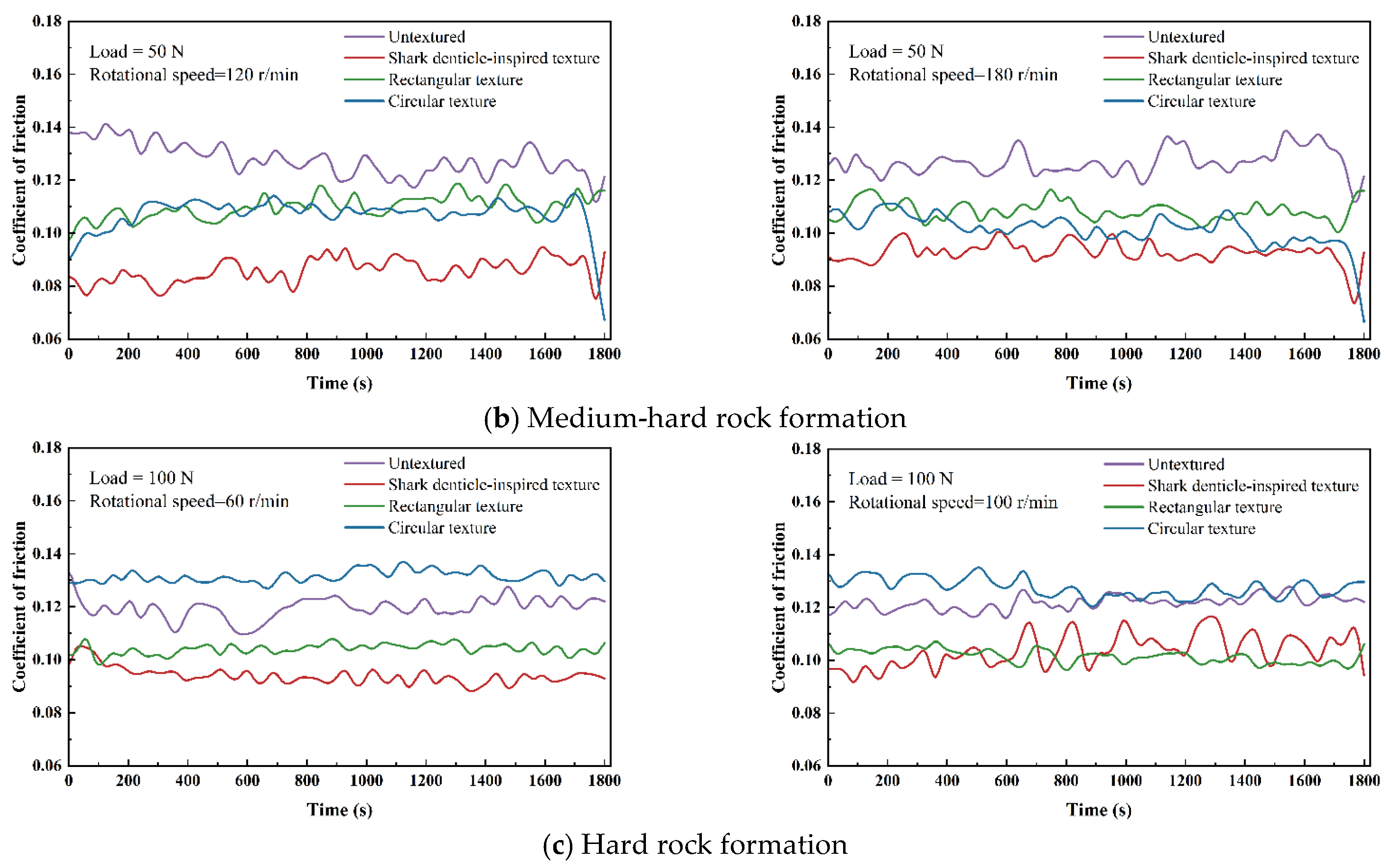

- Under dry friction, the shark denticle-inspired texture still retained a certain degree of friction-reducing capability. Although its wear depth was relatively high, the friction coefficient and torque decreased by 7.6% and 7.9%, respectively, compared with the untextured specimen, and the surface integrity was better preserved in the absence of lubrication.

- The shark denticle-inspired texture provided a degree of surface protection. Under lubricated conditions, it facilitated the formation of a regular lubrication interface, effectively reducing abrasive intrusion and plowing. During lubrication failure, it guided debris away from the contact zone, suppressing adhesive delamination and plastic deformation.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Huang, Z.; Li, Q.; Zhou, Y.; Jing, S.; Ma, Y.; Hu, W.; Fan, Y. Experimental research on the surface strengthening technology of roller cone bit bearing based on the failure analysis. Eng. Fail. Anal. 2013, 29, 12–26. [Google Scholar] [CrossRef]

- Xiao, Q.; Wang, X.; Wang, Y.; Zheng, W.; Xu, J.; Luo, X.; Sun, J.; Zhang, L. Beyond smoothness: The art of surface texturing battling against friction. Int. J. Extrem. Manuf. 2025, 7, 022014. [Google Scholar] [CrossRef]

- Shi, G.; Yu, X.; Meng, H.; Zhao, F.; Wang, J.; Jiao, J.; Jiang, H. Effect of surface modification on friction characteristics of sliding bearings: A review. Tribol. Int. 2023, 177, 107937. [Google Scholar] [CrossRef]

- Saetang, V.; Vengsungnle, P.; Zhu, H.; Qi, H.; Maskong, H.; Daodon, W. Effect of Laser-Textured Groove Patterns on Friction Reduction and Stress Distribution in High-Speed Steel Surfaces. Lubricants 2025, 13, 419. [Google Scholar] [CrossRef]

- Wang, Y.; Luo, S.; Gao, T.; Mo, J.; Wang, D.; Chang, X. Biomimetic Hexagonal Texture with Dual-Orientation Groove Interconnectivity Enhances Lubrication and Tribological Performance of Gear Tooth Surfaces. Lubricants 2025, 13, 420. [Google Scholar] [CrossRef]

- Yu, C.; Cheng, R.; Zhang, H.; Ma, C.; Yu, S. The Influences of Surface Texture Topography and Orientation on Point-Contact Mixed Lubrication. Lubricants 2025, 13, 409. [Google Scholar] [CrossRef]

- Xie, Z.; Zhang, Y.; Zhou, J.; Zhu, W. Theoretical and experimental research on the micro interface lubrication regime of water lubricated bearing. Mech. Syst. Signal Process. 2021, 151, 107422. [Google Scholar] [CrossRef]

- Song, F.; Yang, X.; Dong, W.; Zhu, Y.; Wang, Z.; Wu, M. Research prospect of textured sliding bearing. Int. J. Adv. Manuf. Technol. 2022, 121, 1–25. [Google Scholar] [CrossRef]

- Rao, T.V.V.L.N.; Rani, A.M.A.; Nagarajan, T.; Hashim, F.M. Analysis of slider and journal bearing using partially textured slip surface. Tribol. Int. 2012, 56, 121–128. [Google Scholar] [CrossRef]

- Rao, T.V.V.L.N.; Rani, A.M.A.; Nagarajan, T.; Hashim, F.M. Analysis of couple stress fluid lubricated partially textured slip slider and journal bearing using narrow groove theory. Tribol. Int. 2014, 69, 1–9. [Google Scholar] [CrossRef]

- Etsion, I.; Kligerman, Y.; Halperin, G. Analytical and experimental investigation of laser-textured mechanical seal faces. Tribol. Trans. 1999, 42, 511–516. [Google Scholar] [CrossRef]

- Niu, Y.; Hao, X.; Xia, A.; Wang, L.; Liu, Q.; Li, L.; He, N. Effects of textured surfaces on the properties of hydrodynamic bearing. Int. J. Adv. Manuf. Technol. 2022, 118, 1589–1596. [Google Scholar] [CrossRef]

- Yang, L.; Ma, W.; Gao, F.; Xi, S.; Ma, Z.; Ma, Z. Contact and tribological study of micro/nano groove texture on the surface of gas bearing materials based on nanoscale. Nanomaterials 2023, 13, 152. [Google Scholar] [CrossRef]

- Zhong, L.; Wei, G.; Wang, G.; He, X.; Feng, G.; Dong, Z. Tribological properties of rock bit journal bearings for journal with nanosecond laser surface texture. Tribol. Trans. 2020, 63, 1020–1040. [Google Scholar] [CrossRef]

- Wang, G.; Zhong, L.; Liu, Q.; Wang, Y.; He, X.; Yang, C.; Jiang, L.; Zheng, J.; Huang, S. Effect of microgrooves generated by machining on tribological properties of 20CrNiMo/beryllium bronze tribopairs under low-speed heavy-load conditions. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2016, 230, 783–796. [Google Scholar] [CrossRef]

- Zhong, L.; Kang, G.; Wang, G.; Wei, G.; Wang, Z.; Wu, X.; Chen, L. Tribological properties of rock-bit journal bearings tribo-pair with micro-dimples under contaminated grease lubrication. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2022, 236, 2095–2104. [Google Scholar] [CrossRef]

- Yu, A.; Fu, Y.; Xie, S.; Guo, Z.; Fu, F.; Liu, W. Biomimetic interfaces for drag reduction: From mechanism to applications. Friction 2025, 13, 9440900. [Google Scholar] [CrossRef]

- Hou, Q.; Yang, X.; Cheng, J.; Wang, S.; Duan, D.; Xiao, J.; Li, W. Optimization of performance parameters and mechanism of bionic texture on friction surface. Coatings 2020, 10, 171. [Google Scholar] [CrossRef]

- Li, X.; Guo, Z.; Huang, Q.; Yuan, C. Application of bionic tribology in water-lubricated bearing: A review. J. Bionic Eng. 2022, 19, 902–934. [Google Scholar] [CrossRef]

- Long, R.; Zhao, C.; Zhang, Y.; Wang, Y.; Wang, Y. Effect of vein-bionic surface textures on the tribological behavior of cylindrical roller thrust bearing under starved lubrication. Sci. Rep. 2021, 11, 21238. [Google Scholar] [CrossRef]

- Zhang, P.; Chen, H.; Li, L.; Liu, H.; Liu, G.; Zhang, L.; Zhang, D.; Jiang, L. Bioinspired smart peristome surface for temperature-controlled unidirectional water spreading. ACS Appl. Mater. Interfaces 2017, 9, 5645–5652. [Google Scholar] [CrossRef] [PubMed]

- Gao, T.; Su, B.; Jiang, L.; Cong, Q. Influence of bionic pit structure on friction and sealing performance of reciprocating plunger. Adv. Mater. Sci. Eng. 2020, 2020, 2130341. [Google Scholar] [CrossRef]

- Zhang, F.; Luo, Z.; Zheng, E.; Han, L.; Qian, J.; Yao, H.; Shi, Y.; Wang, X. Imitating pangolin scale structure for reducing adhesion and resistance of rotary tillage in wet-adhesive soil. Soil. Tillage Res. 2025, 245, 106306. [Google Scholar] [CrossRef]

- Ghimire, A.; Dahl, R.B.; Shen, S.; Chen, P. Shark skin denticles: From morphological diversity to multi-functional adaptations and applications. Adv. Funct. Mater. 2024, 34, 2307121. [Google Scholar] [CrossRef]

- Xue, L.; Yan, Z.; Jiang, Y.; Sun, T. Influences of sharkskin texture on lubrication performance of elastic bearing friction pairs. Tribol. Lett. 2024, 72, 103. [Google Scholar] [CrossRef]

- Niu, J.; Luo, T.; Xie, J.; Cai, H.; Zhou, Z.; Chen, J.; Zhang, S. Simulation experimental study on drag reduction anti-adhesion of subsoiler with bionic surface. Int. J. Agric. Biol. Eng. 2022, 15, 57–64. [Google Scholar] [CrossRef]

- Carman, M.L.; Estes, T.G.; Feinberg, A.W.; Schumacher, J.F.; Wilkerson, W.; Wilson, L.H.; Callow, M.E.; Callow, J.A.; Brennan, A.B. Engineered antifouling microtopographies—Correlating wettability with cell attachment. Biofouling 2006, 22, 11–21. [Google Scholar] [CrossRef]

- Johnson, K.L. Contact Mechanics; Cambridge University Press: Cambridge, UK, 1985; ISBN 978-0-521-34796-9. [Google Scholar]

- Wei, M.; Qiu, D.; Yue, T.; Duan, Y.; Wang, H. New method prediction of rock mechanics parameters in drilling process based on machine learning. Pet. Sci. Technol. 2025, 43, 360–383. [Google Scholar] [CrossRef]

- Ekpotu, W.; Akintola, J.; Obialor, M.; Ayoola, A.; Asama, M.; Abdulkareem, Y. Least squares modeling of the depth of cut of reservoir rock from real-time drilling parameters. Pet. Sci. Technol. 2022, 40, 1155–1172. [Google Scholar] [CrossRef]

- Cui, X.; Chen, D.; Chen, H. Multistage gradient bioinspired riblets for synergistic drag reduction and efficient antifouling. ACS Omega 2023, 8, 8569–8581. [Google Scholar] [CrossRef]

| Rock Stratum | Soft Rock Layer | Medium-Hard Rock | Hard Rock Layer | Ultra-Hard Rock |

|---|---|---|---|---|

| Total radial force on bearing (kN) | 7.4~19.8 | 19.8~39.6 | 39.6~59.4 | 59.4~74.2 |

| Large journal radial force (kN) | 6.7~17.4 | 17.4~35.6 | 35.6~53.4 | 53.4~66.8 |

| Small journal radial force (kN) | 0.7~2.4 | 2.4~4.0 | 4.0~6.0 | 6.0~7.4 |

| Name | Sizes |

| Bearing radius R1 (mm) | 41.5 |

| Bearing radius R2 (mm) | 41.25 |

| Bearing width L (mm) | 45 |

| Grease dynamic viscosity μ(Pa·s) | 0.1281 |

| Rock-Breaking Condition | Actual Drilling Pressure (t) | Actual Radial Load (kN) | Actual Linear Velocity (m/s) | Experimental Radial Force (N) | Experimental Rotational Speed (r/min) |

|---|---|---|---|---|---|

| Soft formation | 5 | 20.9 | 0.4346 | 20 | 200/300 |

| Medium-hard formation | 12 | 30 | 0.3477 | 50 | 120/180 |

| Hard formation | 20 | 45.9 | 0.2608 | 100 | 60/100 |

| Parameter | a | b | c | d | e |

|---|---|---|---|---|---|

| Value (mm) | 0.24 | 0.6/0.4 | 0.12/0.08 | 0.01 | 0.1 |

| Loading Conditions | Loading Conditions | RPM Working Conditions | Friction Coefficient Reduction | Friction Torque Reduction | Amount of Wear Reduction | Depth of Wear Reduction |

|---|---|---|---|---|---|---|

| Grease-lubricated condition | Low-load conditions | 200 rpm | 19.2% | 20.4% | 24.6% | 25.6% |

| 300 rpm | 19.6% | 20.1% | ||||

| Medium-load conditions | 120 rpm | 26.7% | 32% | 32% | ||

| 180 rpm | 33.1% | 38% | ||||

| Heavy-duty conditions | 60 rpm | 14.1% | 17.1% | 35% | ||

| 100 rpm | 24.1% | 23.7% | ||||

| Dry friction state | 7.6% | 7.9% | 9.2% | −184.1% | ||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, W.; Li, Y.; Fan, J.; Chen, Z.; Huo, P. Experimental Study on the Tribological Performance of Shark Denticle-Inspired Texture for Roller Cone Bit Bearings. Lubricants 2025, 13, 468. https://doi.org/10.3390/lubricants13110468

Li W, Li Y, Fan J, Chen Z, Huo P. Experimental Study on the Tribological Performance of Shark Denticle-Inspired Texture for Roller Cone Bit Bearings. Lubricants. 2025; 13(11):468. https://doi.org/10.3390/lubricants13110468

Chicago/Turabian StyleLi, Wanzhong, Yapeng Li, Jinlong Fan, Zexiong Chen, and Pengbo Huo. 2025. "Experimental Study on the Tribological Performance of Shark Denticle-Inspired Texture for Roller Cone Bit Bearings" Lubricants 13, no. 11: 468. https://doi.org/10.3390/lubricants13110468

APA StyleLi, W., Li, Y., Fan, J., Chen, Z., & Huo, P. (2025). Experimental Study on the Tribological Performance of Shark Denticle-Inspired Texture for Roller Cone Bit Bearings. Lubricants, 13(11), 468. https://doi.org/10.3390/lubricants13110468