Stability and Tribological Performance of Water-Emulsified Engine Oils for Hydrogen-Fuelled Internal Combustion Engines

Abstract

1. Introduction

2. Methodology

2.1. Materials and Sample Preparation

2.2. Viscosity Measurement and Vogel–Fulcher–Tammann (VFT) Analysis

2.3. Copper Strip Corrosion Test

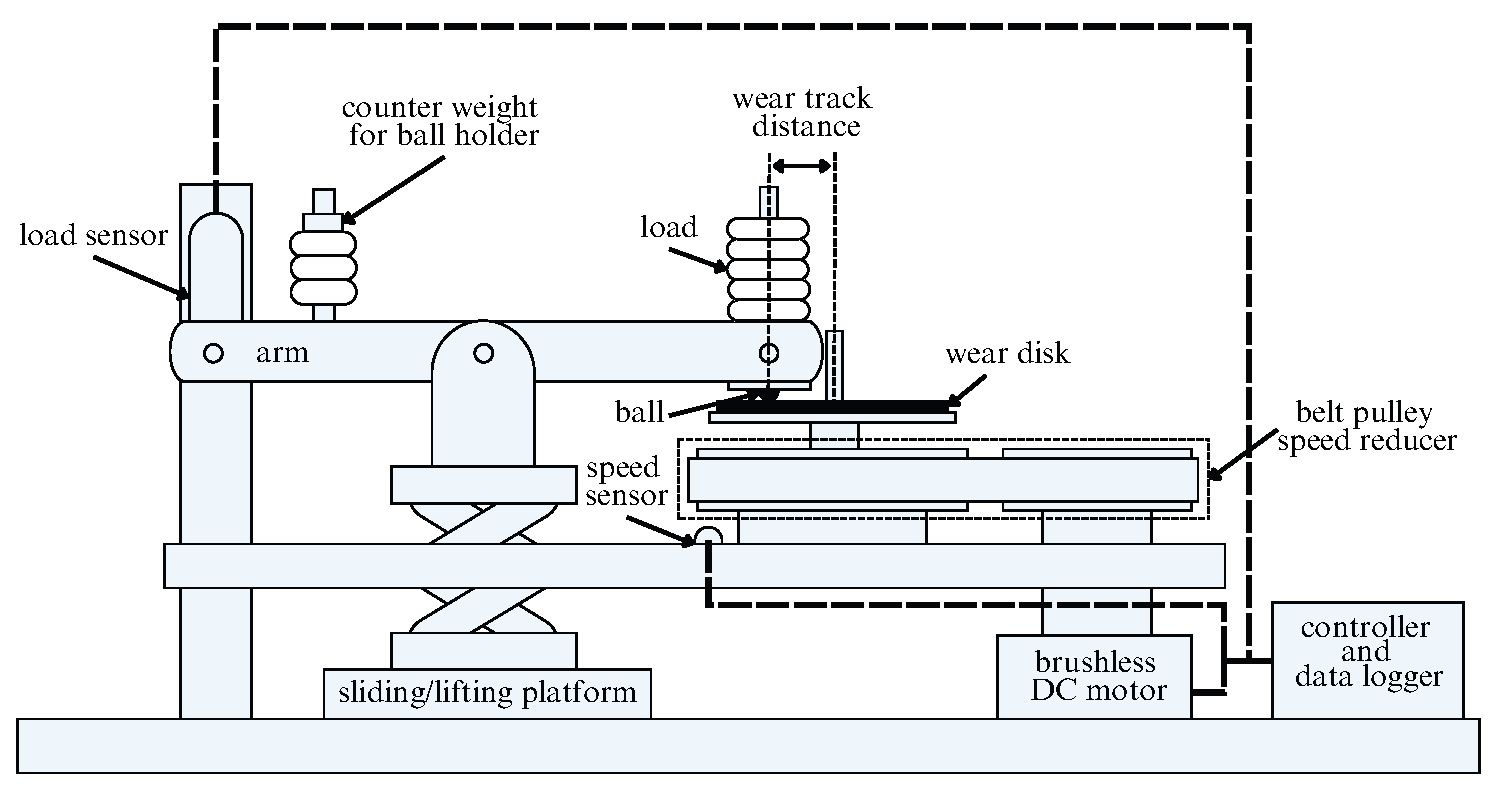

2.4. Boundary Friction Testing

3. Results and Discussion

3.1. Emulsified Engine Oil

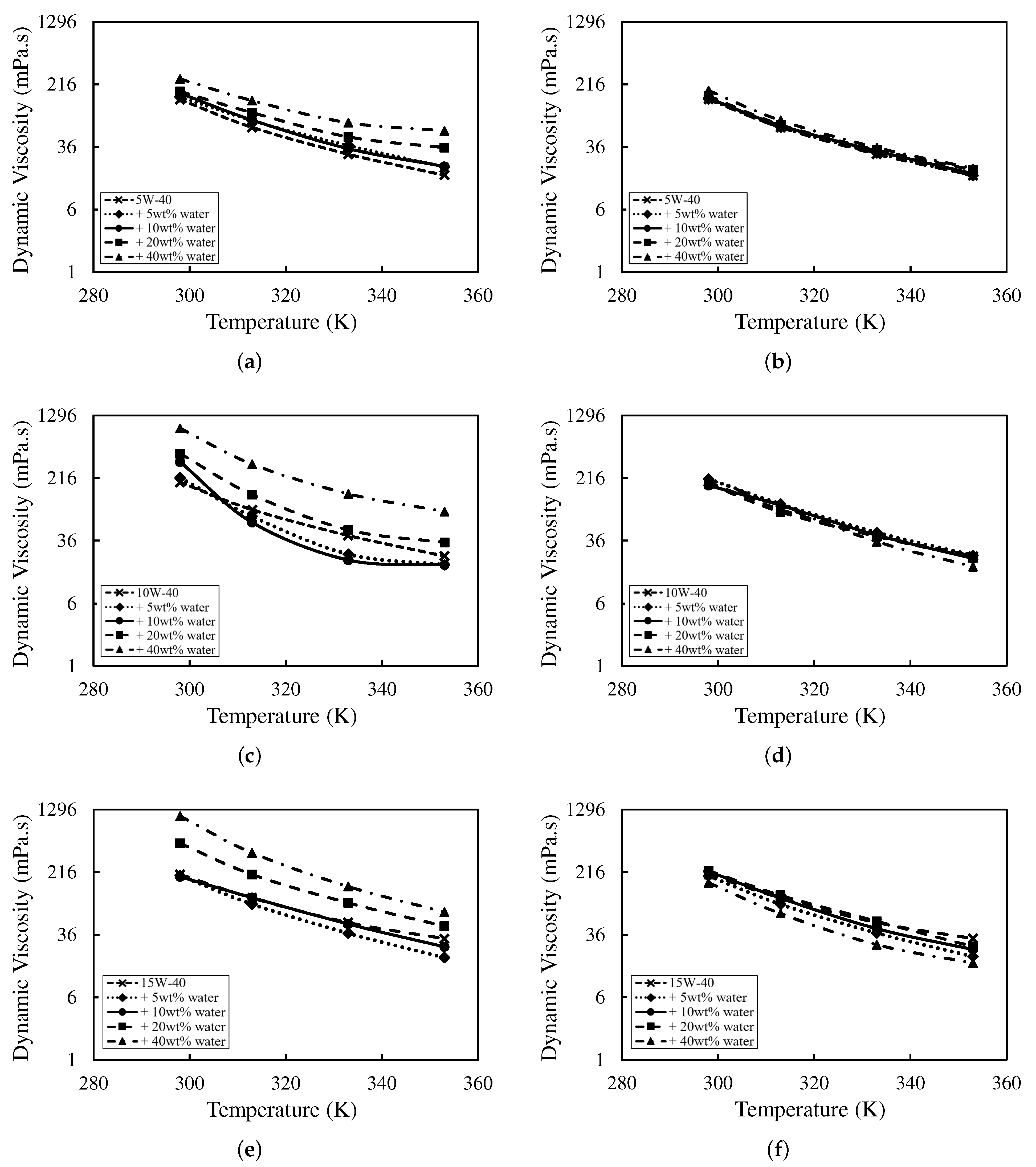

3.2. Viscosity–Temperature Variation

3.3. Corrosion Rating

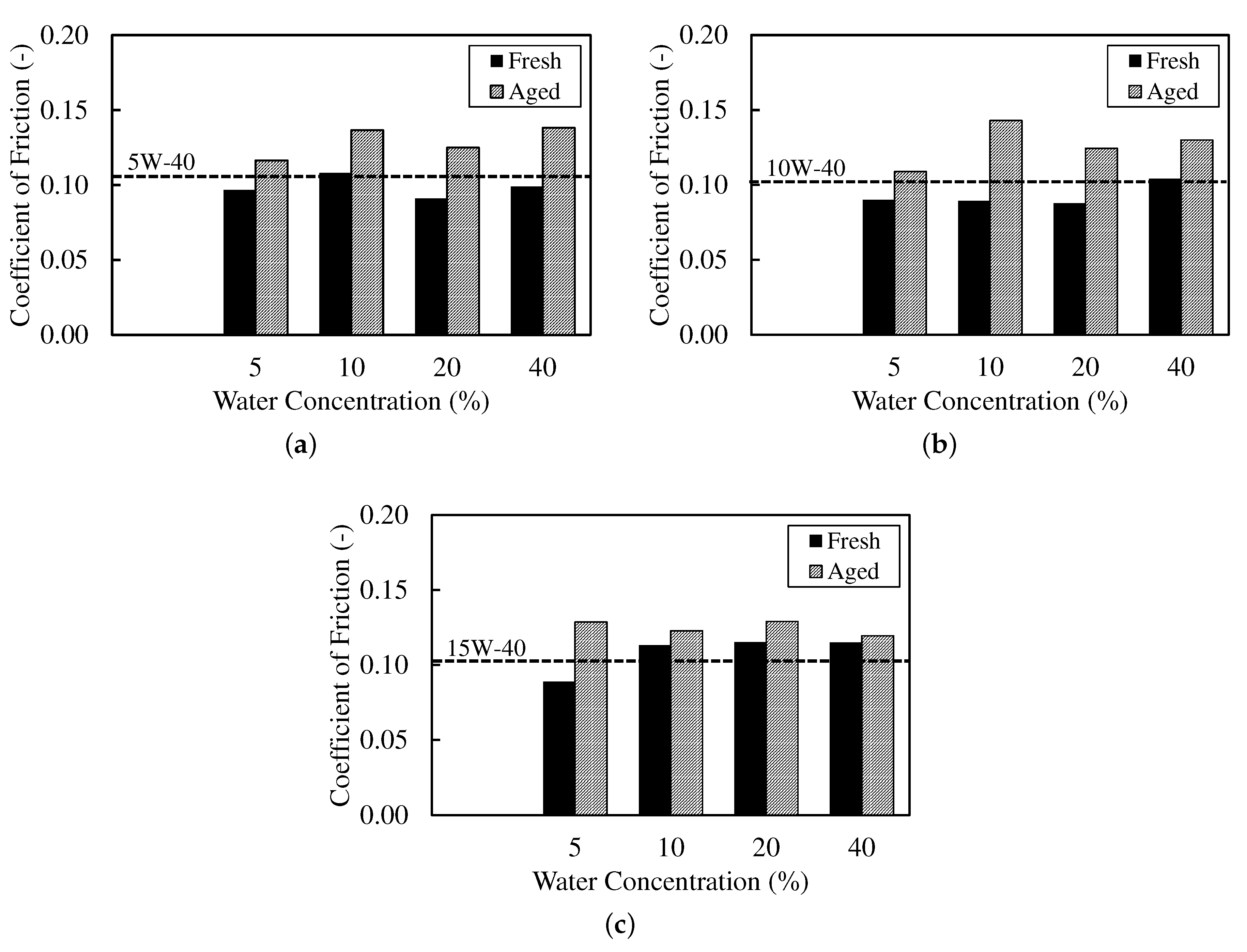

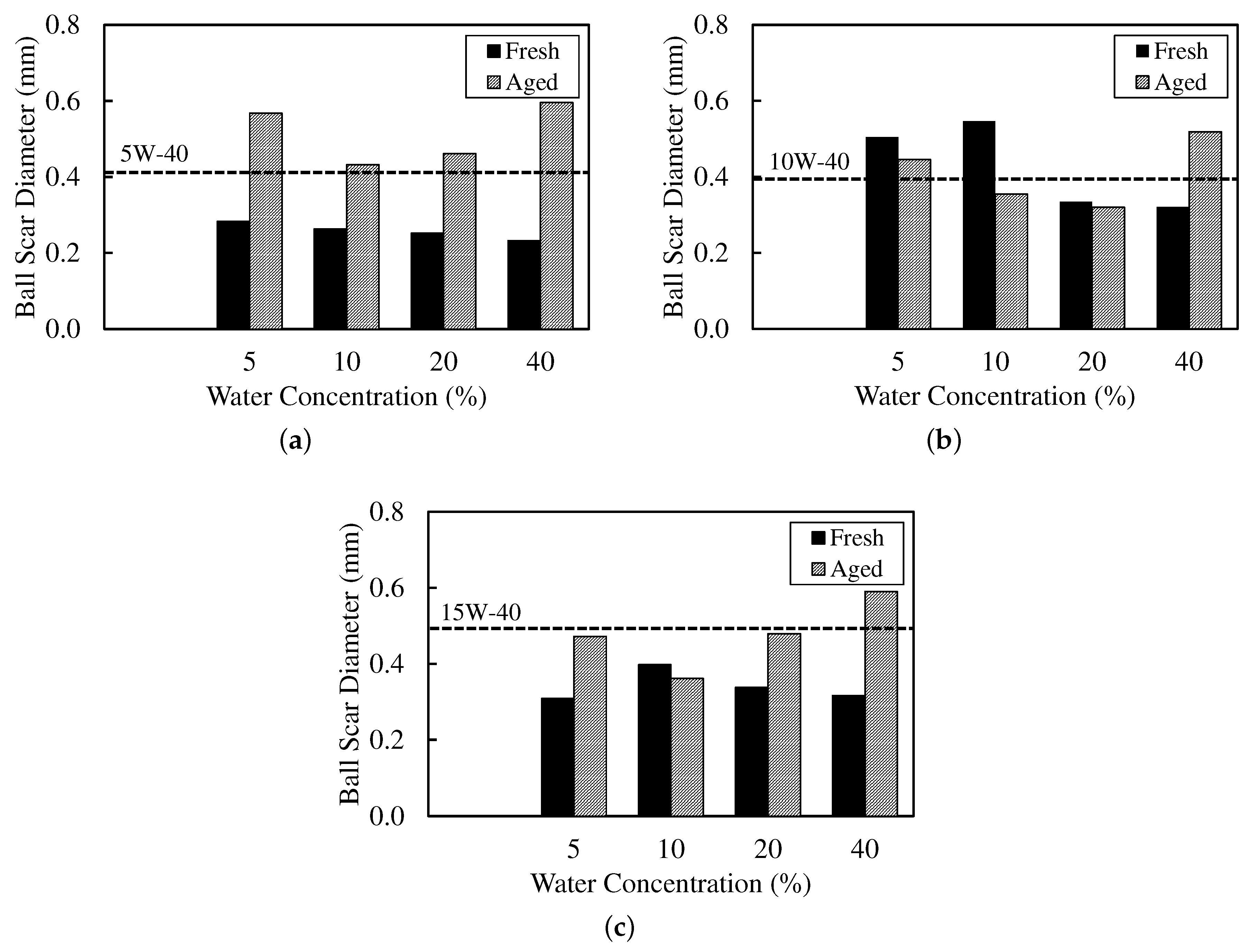

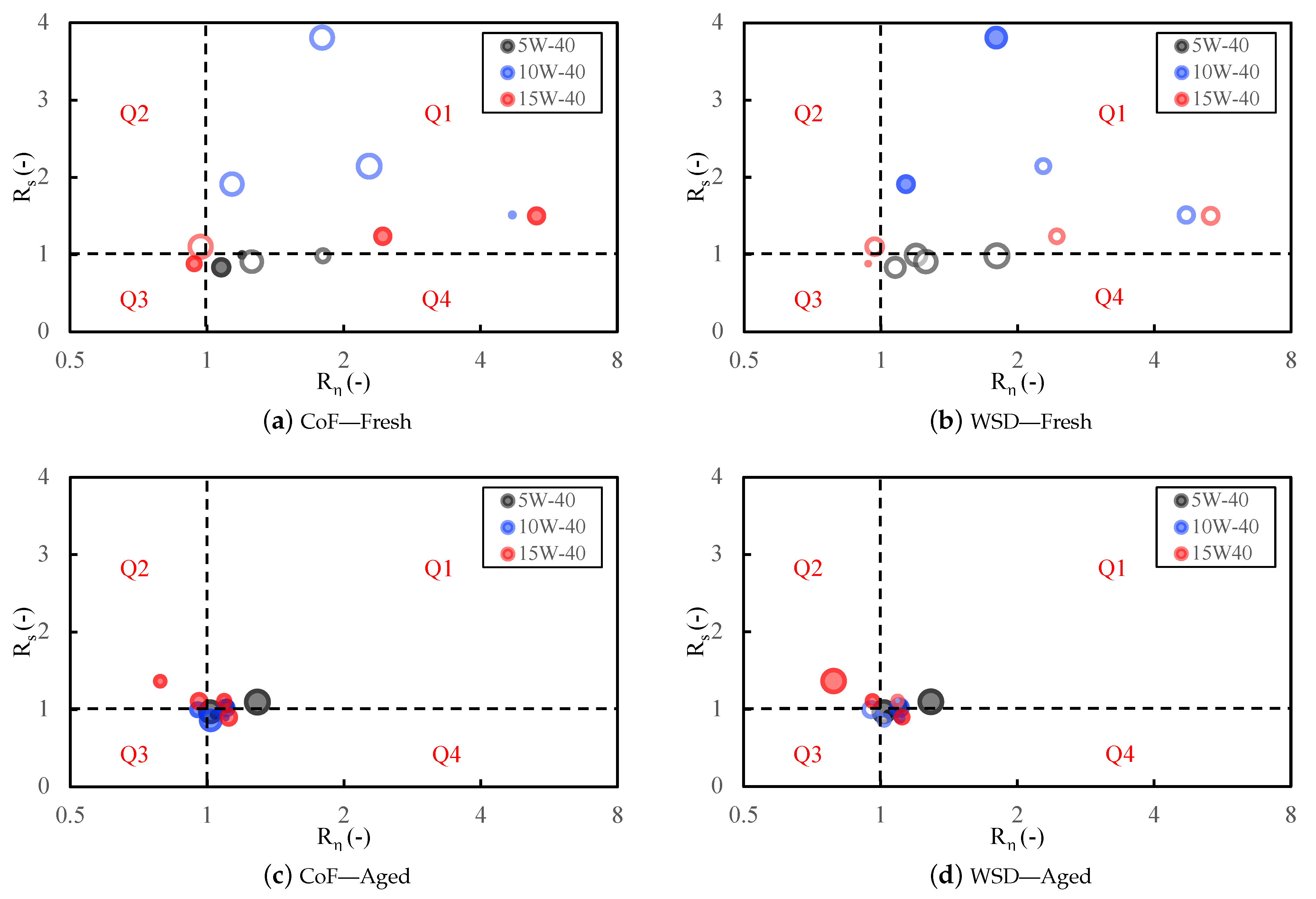

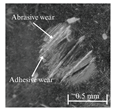

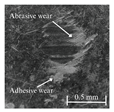

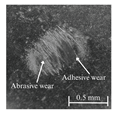

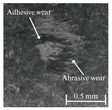

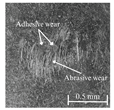

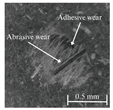

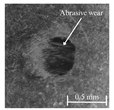

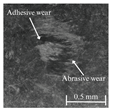

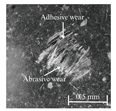

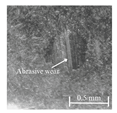

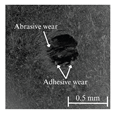

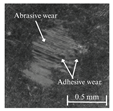

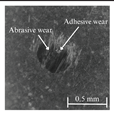

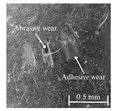

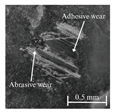

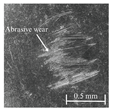

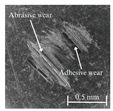

3.4. Friction and Wear Properties

3.5. Integrated Interpretation: VFT Rheology, Friction/Wear, and Copper Corrosivity

- Rheology-dominated protection (Q4, , ): Copper 1a (typical of fresh synthetic oil), lower WSD, and neutral-to-lower CoF because thicker, thermally resilient films limit junction shear and real contact area.

- Additive weakening/flash-thinning (Q1, , ): Often lower CoF but higher WSD; initially thick films thin rapidly under flash heating while functional additives are partially compromised.

- Thin and sensitive (Q2, , ): Limited CoF benefit and larger WSD due to both low baseline thickness and high thinning propensity.

- Thin and stable (Q3, , ): Thermally stable but too thin; CoF is typically neutral or slightly higher and WSD reduction is modest at best, so protection is limited.

3.6. Limitations and Future Work

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Lieuwen, T.; Emerson, B.; Acharya, V.; Gupta, I. Roles for combustion in a net-zero CO2 society. Proc. Combust. Inst. 2024, 40, 105753. [Google Scholar] [CrossRef]

- Link, S.; Stephan, A.; Speth, D.; Plötz, P. Rapidly declining costs of truck batteries and fuel cells enable large-scale road freight electrification. Nat. Energy 2024, 9, 1032–1039. [Google Scholar] [CrossRef]

- Wallington, T.J.; Woody, M.; Lewis, G.M.; Keoleian, G.A.; Adler, E.J.; Martins, J.R.; Collette, M.D. Green hydrogen pathways, energy efficiencies, and intensities for ground, air, and marine transportation. Joule 2024, 8, 2190–2207. [Google Scholar] [CrossRef]

- Wallington, T.; Woody, M.; Lewis, G.; Keoleian, G.; Adler, E.; Martins, J.; Collette, M. Hydrogen as a sustainable transportation fuel. Renew. Sustain. Energy Rev. 2025, 217, 115725. [Google Scholar] [CrossRef]

- Chong, W.W.F.; Howell-Smith, S.; Teodorescu, M.; Vaughan, N. The influence of inter-ring pressures on piston-ring/liner tribological conjunction. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2013, 227, 154–167. [Google Scholar] [CrossRef]

- Rahmani, R.; Dolatabadi, N.; Rahnejat, H. Multiphysics performance assessment of hydrogen fuelled engines. Int. J. Engine Res. 2023, 24, 4169–4189. [Google Scholar] [CrossRef]

- Butcher, R.; Bradley, N.; Powell, T. Real Time Observations of Water Entering and Leaving Internal Combustion Engine Oil, Over Both Standard Engine, ICE and Plug-in Hybrid, PHEV Dynamic Drive-Cycles. SAE Int. J. Adv. Curr. Pract. Mobil. 2023, 6, 133–144. [Google Scholar] [CrossRef]

- Zhou, Z.; Zhou, X.; Huang, Q.; Liu, X.; Wang, L.; Xing, S. Impact of oil-water emulsions on lubrication performance of ship stern bearings. Sci. Rep. 2024, 14, 31478. [Google Scholar] [CrossRef] [PubMed]

- Liu, H.; Pape, F.; Zhao, Y.; Ellersiek, L.; Denkena, B.; Poll, G. On the elastohydrodynamic film-forming properties of metalworking fluids and oil-in-water emulsions. Tribol. Lett. 2023, 71, 10. [Google Scholar] [CrossRef]

- Al Sheikh Omar, A.; Salehi, F.M.; Farooq, U.; Morina, A. Additives depletion by water contamination and its influences on engine oil performance. Tribol. Lett. 2024, 72, 74. [Google Scholar] [CrossRef]

- Su, R.; Cao, W.; Jin, Z.; Wang, Y.; Ding, L.; Maqsood, M.; Wang, D. Deterioration Mechanism and Status Prediction of Hydrocarbon Lubricants under High Temperatures and Humid Environments. Lubricants 2024, 12, 116. [Google Scholar] [CrossRef]

- Dobrenizki, L.; Tremmel, S.; Wartzack, S.; Hoffmann, D.C.; Brögelmann, T.; Bobzin, K.; Bagcivan, N.; Musayev, Y.; Hosenfeldt, T. Efficiency improvement in automobile bucket tappet/camshaft contacts by DLC coatings–Influence of engine oil, temperature and camshaft speed. Surf. Coatings Technol. 2016, 308, 360–373. [Google Scholar] [CrossRef]

- Apicella, B.; Catapano, F.; Di Iorio, S.; Magno, A.; Russo, C.; Sementa, P.; Tregrossi, A.; Vaglieco, B.M. Impact of fuel and lubricant oil on particulate emissions in direct injection spark ignition engines: A comparative study of methane and hydrogen. Fuel Process. Technol. 2024, 265, 108144. [Google Scholar] [CrossRef]

- ASTM D130-20; Standard Test Method for Corrosiveness to Copper from Petroleum Products by Copper Strip Test. ASTM International: West Conshohocken, PA, USA, 2020. [CrossRef]

- Dorgham, A.; Azam, A.; Parsaeian, P.; Khan, T.; Sleiman, M.; Wang, C.; Morina, A.; Neville, A. Understanding the effect of water on the transient decomposition of zinc dialkyldithiophosphate (ZDDP). Tribol. Int. 2021, 157, 106855. [Google Scholar] [CrossRef]

- Costa, A.; Ferreira, F.; Colaux, J.; Vahidi, A.; Serra, R.; Oliveira, J. Effect of hydrogen incorporation on the mechanical properties of DLC films deposited by HiPIMS in DOMS mode. Surf. Coatings Technol. 2023, 473, 129980. [Google Scholar] [CrossRef]

- Vogel, H. The law of the relation between the viscosity of liquids and the temperature. Phys. Z. 1921, 22, 645–646. [Google Scholar]

- Fulcher, G.S. Analysis of recent measurements of the viscosity of glasses. J. Am. Ceram. Soc. 1925, 8, 339–355. [Google Scholar] [CrossRef]

- Tammann, G.; Hesse, W. Die Abhängigkeit der Viscosität von der Temperatur bie unterkühlten Flüssigkeiten. Z. Anorg. Allg. Chem. 1926, 156, 245–257. [Google Scholar] [CrossRef]

- MacLaren, A.; Kadiric, A. Elastohydrodynamic traction and film thickness at high speeds. Tribol. Lett. 2024, 72, 92. [Google Scholar] [CrossRef]

- Nikolopoulou, V.I.; Zavos, A.; Nikolakopoulos, P. A Comparative Analysis of Friction and Energy Losses in Hydrogen and CNG Fueled Engines: Implications on the Top Compression Ring Design Using Steel, Cast Iron, and Silicon Nitride Materials. Materials 2024, 17, 3806. [Google Scholar] [CrossRef]

- Michelberger, B.; Schell, F.; Jaitner, D.; Götze, A.; Leupolt, B.; Wetzel, F.J.; Leson, A.; Lasagni, A.F. Positive Effect of Periodic Micropatterns on Compression Ring Friction. Adv. Eng. Mater. 2023, 25, 2201708. [Google Scholar] [CrossRef]

- Ravera, F.; Dziza, K.; Santini, E.; Cristofolini, L.; Liggieri, L. Emulsification and emulsion stability: The role of the interfacial properties. Adv. Colloid Interface Sci. 2021, 288, 102344. [Google Scholar] [CrossRef]

- Shi, Y.; Larsson, R. Non-corrosive and biomaterials protic ionic liquids with high lubricating performance. Tribol. Lett. 2016, 63, 1. [Google Scholar] [CrossRef]

- Puthillam, U.; Selvam, R.E. Tribocorrosion in biomaterials and control techniques: A review. Corros. Rev. 2024, 42, 37–56. [Google Scholar] [CrossRef]

- Mohamed Ariffin, N.A.A.; Foong, S.Y.; Chong, W.W.F.; Lam, S.S.; Ng, J.H.; Zhang, H. Ionic liquid lubricity enhancement with bio-oil derived from microwave pyrolysis of bamboo. Ind. Crops Prod. 2024, 214, 118543. [Google Scholar] [CrossRef]

- Greenwood, J.A.; Williamson, J.P. Contact of nominally flat surfaces. Proc. R. Soc. Lond. Ser. A Math. Phys. Sci. 1966, 295, 300–319. [Google Scholar] [CrossRef]

- Kupikowska-Stobba, B.; Domagała, J.; Kasprzak, M.M. Critical review of techniques for food emulsion characterization. Appl. Sci. 2024, 14, 1069. [Google Scholar] [CrossRef]

- Zhou, K.; Che, X.; Wei, C.; Tang, Z.; Yu, H.; Wang, D.; Wang, J.; Zhang, L. The Molecular Modeling, Simulation, and Design of Base Oils and Additives in Lubricating Oils: A Review. Processes 2024, 12, 2407. [Google Scholar] [CrossRef]

- Cyriac, F.; Yi, T.X.; Poornachary, S.K.; Chow, P.S. Influence of base oil polarity on the tribological performance of surface-active engine oil additives. Tribol. Lett. 2021, 69, 87. [Google Scholar] [CrossRef]

- Cañellas, G.; Emeric, A.; Combarros, M.; Navarro, A.; Beltran, L.; Vilaseca, M.; Vives, J. Tribological performance of esters, friction modifier and antiwear additives for electric vehicle applications. Lubricants 2023, 11, 109. [Google Scholar] [CrossRef]

- McClements, D.J.; Lu, J.; Grossmann, L. Proposed methods for testing and comparing the emulsifying properties of proteins from animal, plant, and alternative sources. Colloids Interfaces 2022, 6, 19. [Google Scholar] [CrossRef]

- Pessanha, T.M.; Varade, S.; Salonen, A.; Langevin, D. Coalescence Frequency in O/W Emulsions: Comparisons of Experiments with Models. Langmuir 2024, 40, 23695–23705. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Qiu, Q.; Zhang, P.; Gao, X.; Zhang, Z.; Huang, P. Correlation between lubricating oil characteristic parameters and friction characteristics. Coatings 2023, 13, 881. [Google Scholar] [CrossRef]

- Bantchev, G.B.; Cermak, S.C. Correlating viscosity of 2-ethylhexyl oleic estolide esters to their molecular weight. Fuel 2022, 309, 122190. [Google Scholar] [CrossRef]

- Chen, Y.Y.; Horng, J.H. Investigation of lubricant viscosity and third-particle contribution to contact behavior in dry and lubricated three-body contact conditions. Front. Mech. Eng. 2024, 10, 1390335. [Google Scholar] [CrossRef]

- Manjunath, M.; De Baets, P.; Fauconnier, D. In Situ Measurement and Mapping of Lubricant Film Temperature in Cylindrical Roller Thrust Bearings Using Thin-Film Sensors. Machines 2025, 13, 297. [Google Scholar] [CrossRef]

- Chong, W.W.F.; De la Cruz, M. Elastoplastic contact of rough surfaces: A line contact model for boundary regime of lubrication. Meccanica 2014, 49, 1177–1191. [Google Scholar] [CrossRef]

- Simpson, M.; Rahmani, R.; Dolatabadi, N.; Morris, N.; Jones, D.; Craig, C. An analytical friction model for point contacts subject to boundary and mixed elastohydrodynamic lubrication. Tribol. Int. 2024, 196, 109699. [Google Scholar] [CrossRef]

| Parameter | Test Condition/Value |

|---|---|

| Speed (rpm) | 500 |

| Load (g) | 60–200 (20 g increments) |

| Duration per load (s) | 255 |

| Young’s modulus, E (ball/disk) | 210 GPa/210 GPa |

| Poisson’s ratio, (ball/disk) | 0.30/0.30 |

| Sphere radius, R | 3 mm |

| Maximum Hertzian pressure (range) | 535–800 MPa |

| Sample | Water Fraction (wt%) | ||||

|---|---|---|---|---|---|

| 0 | 5 | 10 | 20 | 40 | |

| Synthetic (5W-40) |  |  |  |  |  |

| Semi-synthetic (10W-40) |  |  |  |  |  |

| Mineral (15W-40) |  |  |  |  |  |

| Sample | Day | ||||

|---|---|---|---|---|---|

| 1 | 3 | 5 | 7 | 90 | |

| Synthetic (5W-40), 20 wt% |  |  |  |  |  |

| Semi-synthetic (10W-40), 20 wt% |  |  |  |  |  |

| Mineral (15W-40), 20 wt% |  |  |  |  |  |

| Sample | (mPa·s) | B (K) | (K) | |||

|---|---|---|---|---|---|---|

| Fresh | Aged | Fresh | Aged | Fresh | Aged | |

| Synthetic (5W-40) | ||||||

| Neat (0 wt%) | 0.261 | 0.262 | 657 | 657 | 193 | 193 |

| + 5 wt% | 0.116 | 0.160 | 1030 | 790 | 155 | 182 |

| + 10 wt% | 0.420 | 0.133 | 600 | 870 | 198 | 174 |

| + 20 wt% | 4.56 | 0.730 | 246 | 455 | 231 | 213 |

| + 40 wt% | 14.1 | 0.591 | 141 | 497 | 249 | 211 |

| Semi-synthetic (10W-40) | ||||||

| Neat (0 wt%) | 0.467 | 0.467 | 614 | 614 | 196 | 196 |

| + 5 wt% | 2.58 | 0.0237 | 176 | 1570 | 258 | 125 |

| + 10 wt% | 6.67 | 0.00405 | 69.4 | 2300 | 280 | 84.7 |

| + 20 wt% | 7.05 | 0.480 | 135 | 599 | 265 | 197 |

| + 40 wt% | 8.41 | 0.00361 | 245 | 2010 | 245 | 115 |

| Mineral (15W-40) | ||||||

| Neat (0 wt%) | 1.48 | 1.48 | 449 | 450 | 207 | 207 |

| + 5 wt% | 0.0506 | 0.0877 | 1150 | 992 | 159 | 169 |

| + 10 wt% | 0.0181 | 0.174 | 1810 | 854 | 103 | 179 |

| + 20 wt% | 0.672 | 0.00289 | 652 | 2610 | 199 | 65.9 |

| + 40 wt% | 0.874 | 0.699 | 625 | 401 | 210 | 224 |

| Sample | Condition | Water Concentrations (wt%) | ||||

|---|---|---|---|---|---|---|

| 0 | 5 | 10 | 20 | 40 | ||

| Freshly polished |  | |||||

| 5W-40 | Fresh |  |  |  |  |  |

| 1a | 1a | 1a | 2a | 2b | ||

| Aged |  |  |  |  |  | |

| 1a | 1a | 1a | 2a | 2a | ||

| 10W-40 | Fresh |  |  |  |  |  |

| 1a | 1a | 1a | 1a | 2c | ||

| Aged |  |  |  |  |  | |

| 1a | 1a | 1a | 1b | 2b | ||

| 15W-40 | Fresh |  |  |  |  |  |

| 1a | 1a | 1a | 2a | 2c | ||

| Aged |  |  |  |  |  | |

| 1a | 1a | 1a | 1a | 2b | ||

| Sample | Condition | Water Concentrations (wt%) | ||||

|---|---|---|---|---|---|---|

| 0 | 5 | 10 | 20 | 40 | ||

| Synthetic (5W-40) | Fresh |  |  |  |  |  |

| Aged |  |  |  |  |  | |

| Semi-synthetic (10W-40) | Fresh |  |  |  |  |  |

| Aged |  |  |  |  |  | |

| Mineral (15W-40) | Freshl |  |  |  |  |  |

| Aged |  |  |  |  |  | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mohamed Ariffin, N.A.A.; Poy, J.; Wong, K.J.; Ng, J.-H.; Chong, W.W.F. Stability and Tribological Performance of Water-Emulsified Engine Oils for Hydrogen-Fuelled Internal Combustion Engines. Lubricants 2025, 13, 464. https://doi.org/10.3390/lubricants13100464

Mohamed Ariffin NAA, Poy J, Wong KJ, Ng J-H, Chong WWF. Stability and Tribological Performance of Water-Emulsified Engine Oils for Hydrogen-Fuelled Internal Combustion Engines. Lubricants. 2025; 13(10):464. https://doi.org/10.3390/lubricants13100464

Chicago/Turabian StyleMohamed Ariffin, Nur Aisya Affrina, Jiahe Poy, King Jye Wong, Jo-Han Ng, and William Woei Fong Chong. 2025. "Stability and Tribological Performance of Water-Emulsified Engine Oils for Hydrogen-Fuelled Internal Combustion Engines" Lubricants 13, no. 10: 464. https://doi.org/10.3390/lubricants13100464

APA StyleMohamed Ariffin, N. A. A., Poy, J., Wong, K. J., Ng, J.-H., & Chong, W. W. F. (2025). Stability and Tribological Performance of Water-Emulsified Engine Oils for Hydrogen-Fuelled Internal Combustion Engines. Lubricants, 13(10), 464. https://doi.org/10.3390/lubricants13100464