Experimental Study of the Service Performance of Full Ceramic Silicon Nitride Ball Bearings

Abstract

1. Introduction

2. Experimental Investigation on the Service Performance of Silicon Nitride Full Ceramic Ball Bearings

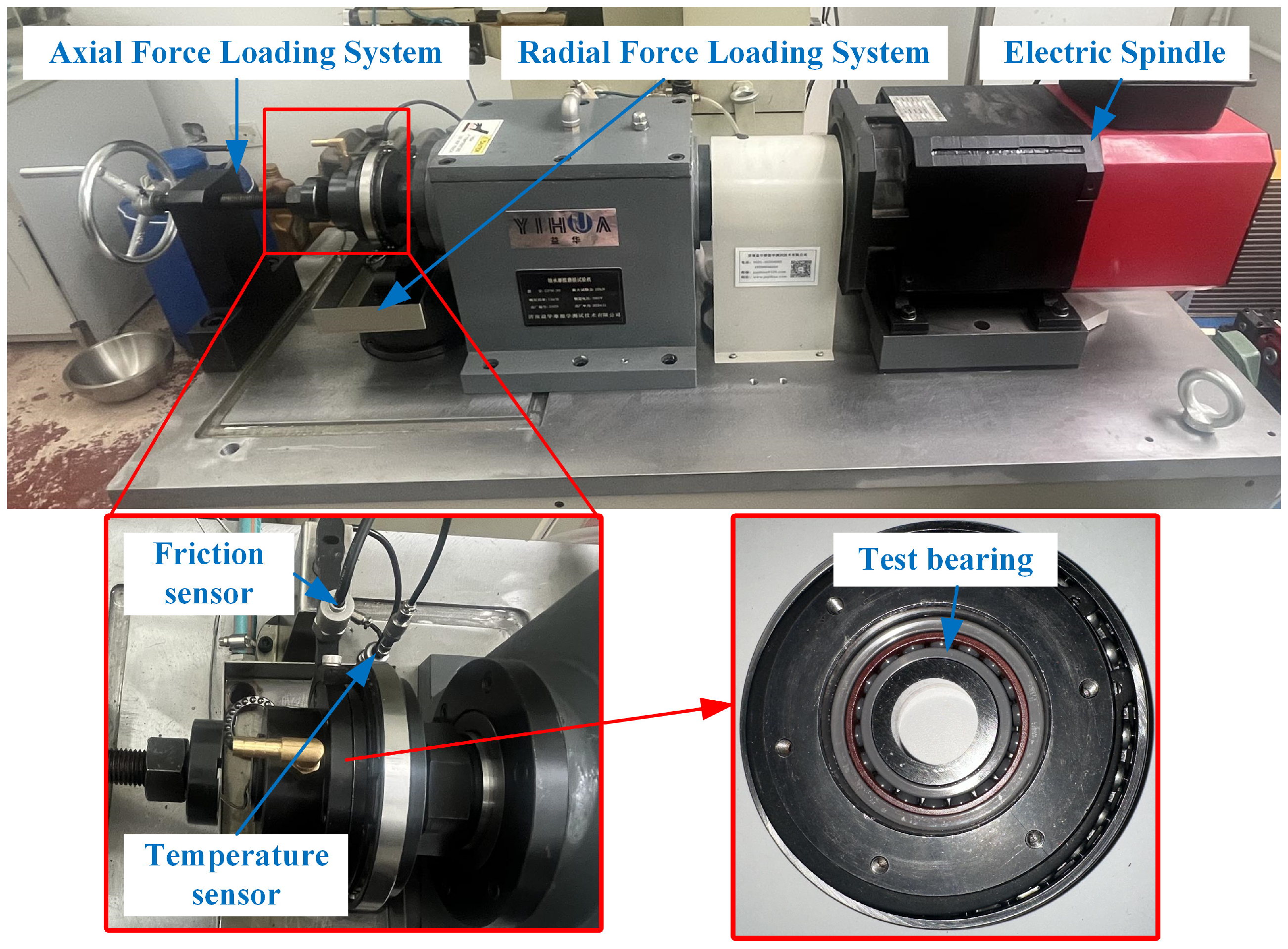

2.1. Experimental Setup

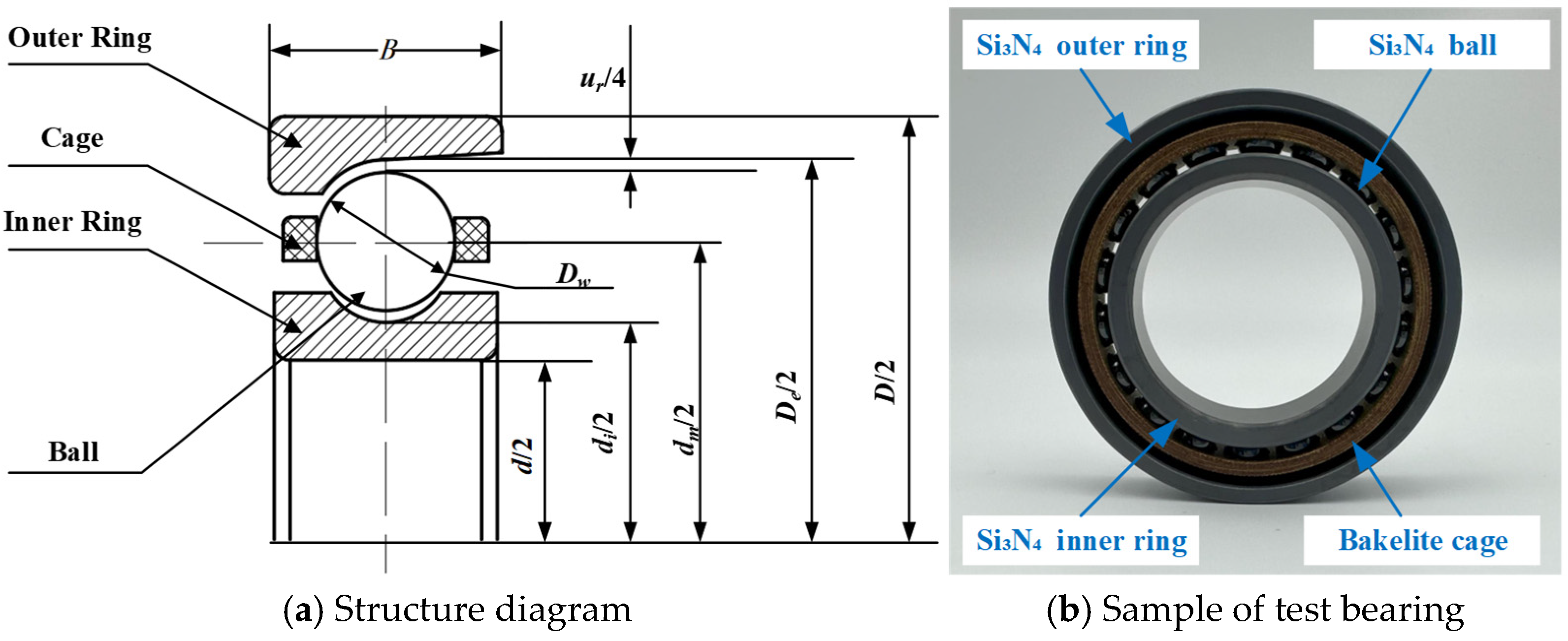

2.2. Experimental Bearings

2.3. Experimental Conditions

3. Experimental Results and Analysis

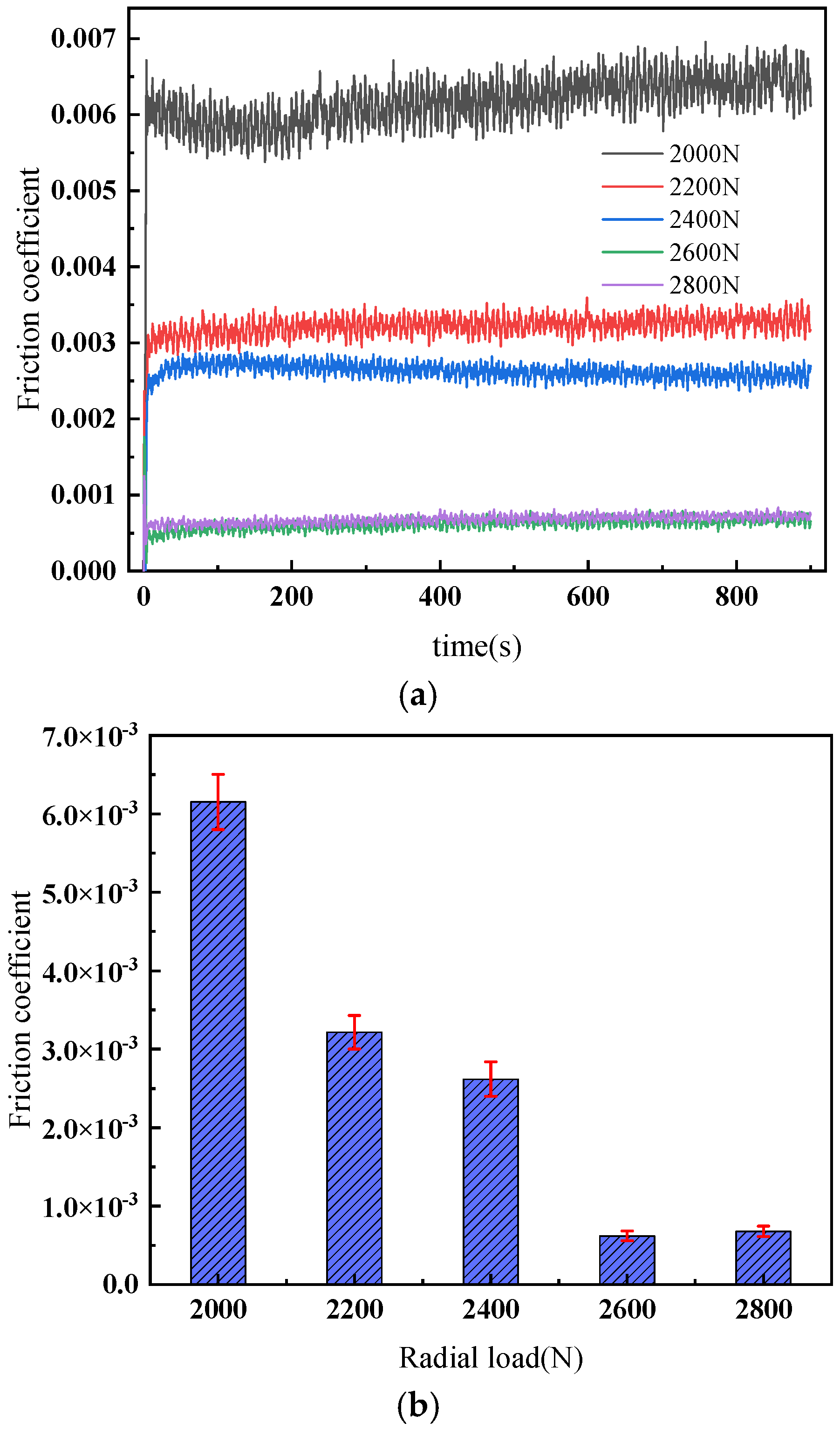

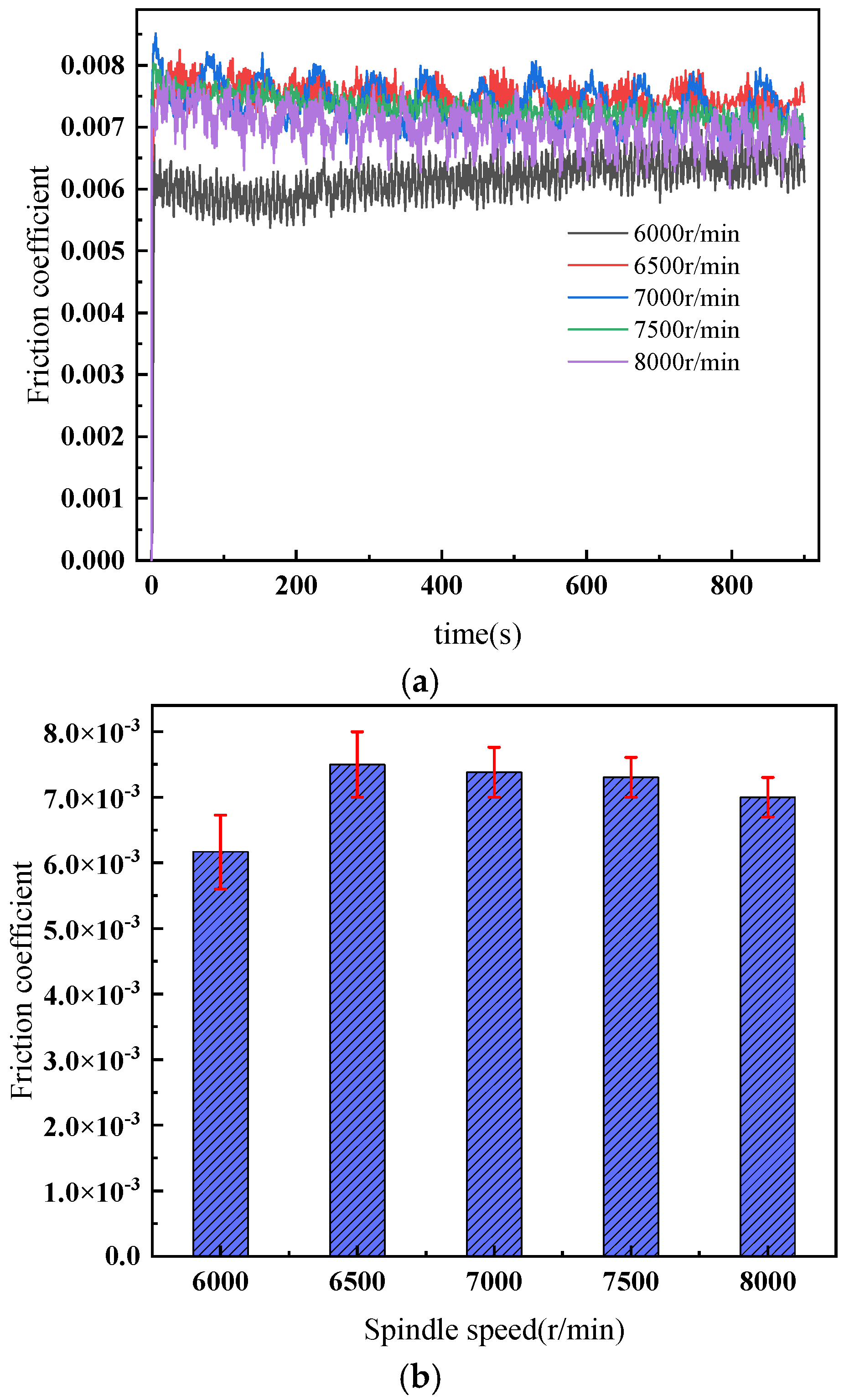

3.1. Overall Friction Coefficient of Silicon Nitride Full Ceramic Ball Bearings

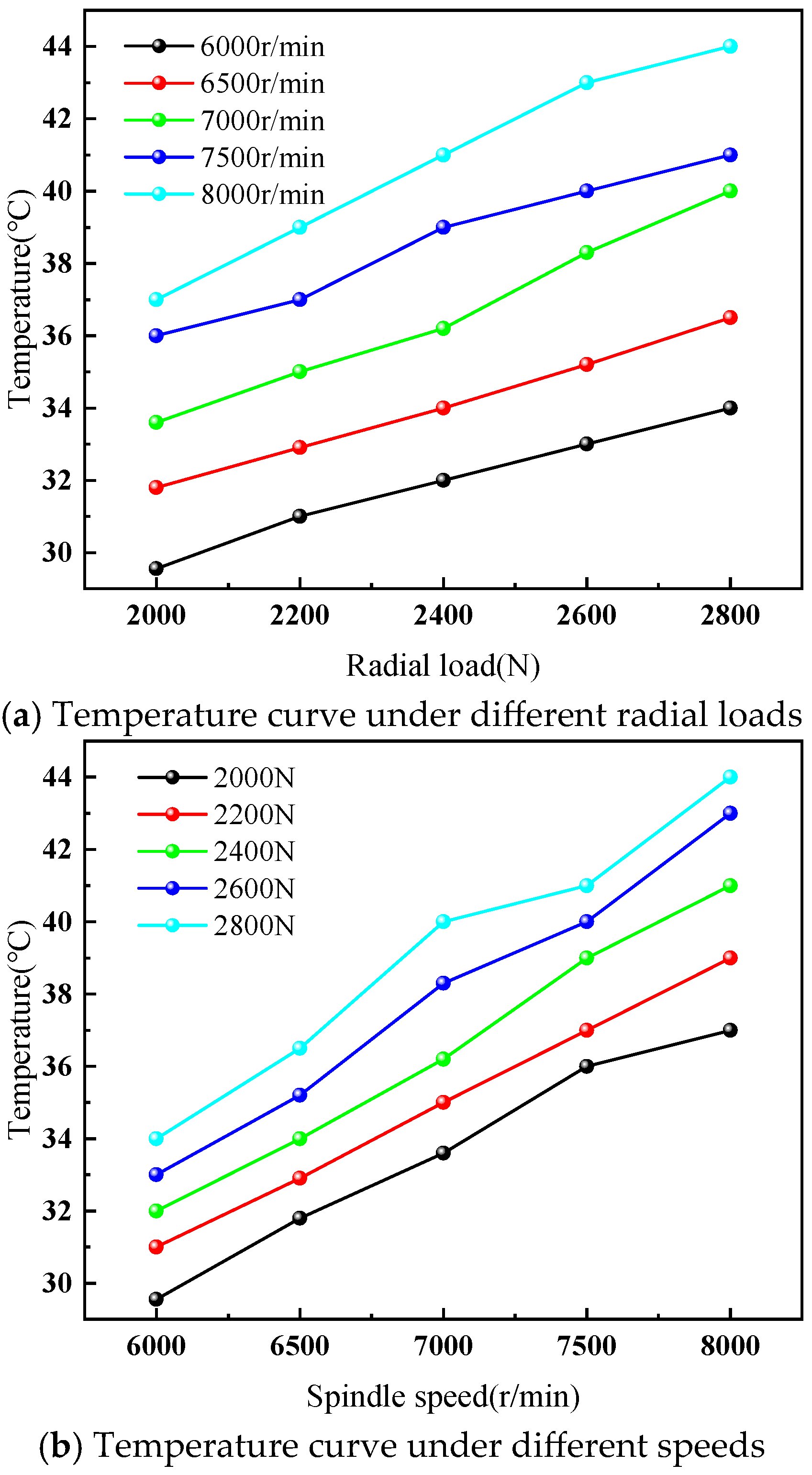

3.2. Service Temperature Range of Silicon Nitride Full Ceramic Ball Bearings

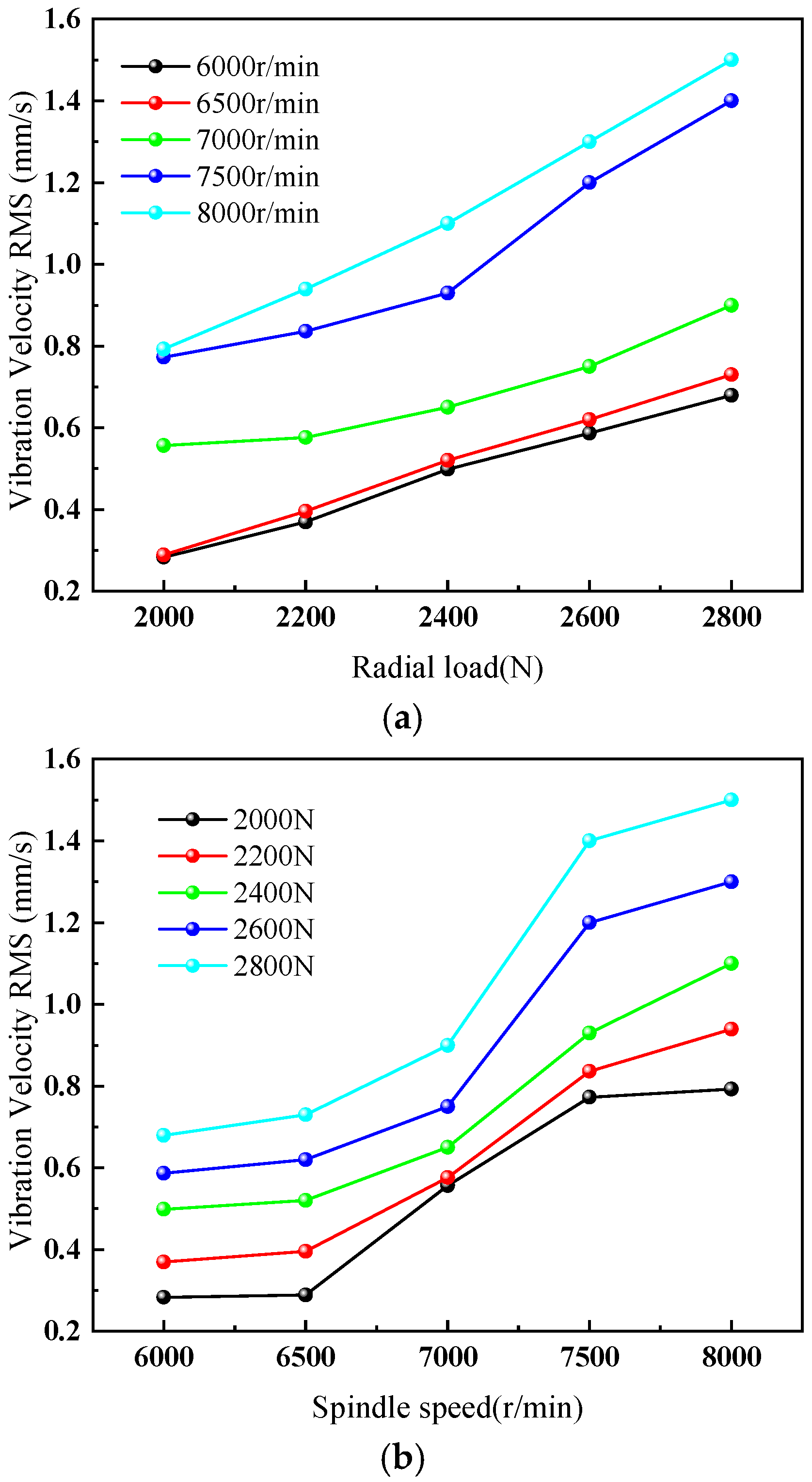

3.3. Service Vibration Range of Silicon Nitride Full Ceramic Ball Bearings

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Kwak, W.; Lee, J.; Lee, Y.-B. Theoretical and experimental approach to ball bearing frictional characteristics compared with cryogenic friction model and dry friction model. Mech. Syst. Signal Process. 2019, 124, 424–438. [Google Scholar] [CrossRef]

- Fan, C.; Wang, P.; Zhang, Y.; Ma, H.; Li, X.; Wang, Q. Digital Twin Assisted Degradation Assessment of Bearing Cage Performance. IEEE Trans. Ind. Inform. 2025, 21, 5171–5181. [Google Scholar] [CrossRef]

- Shi, H.; Li, Y.; Bai, X.; Wang, Z.; Zou, D.; Bao, Z.; Wang, Z. Investigation of the orbit-spinning behaviors of the outer ring in a full ceramic ball bearing-steel pedestal system in wide temperature ranges. Mech. Syst. Signal Process. 2021, 149, 107317. [Google Scholar] [CrossRef]

- Xia, Z.; Wu, Y.; Wei, H.; Ren, K.; Gao, L.; Sun, J.; Li, S. Experimental Research on the Influence of Working Conditions on Vibration and Temperature Rise of Si3N4 Full-Ceramic Bearing Motors. Shock Vib. 2021, 2021, 1176566. [Google Scholar] [CrossRef]

- Wang, M.; Yan, K.; Tang, Q.; Guo, J.; Zhu, Y.; Hong, J. Dynamic modeling and properties analysis for ball bearing driven by structure flexible deformations. Tribol. Int. 2023, 179, 108163. [Google Scholar] [CrossRef]

- Wang, P.; Li, S.; Wu, Y.; Zhao, J. Research on calculation of allowable radial load of silicon nitride full ceramic ball bearing. J. Mech. Sci. Technol. 2024, 38, 6757–6767. [Google Scholar] [CrossRef]

- Vieillard, C.; Brizmer, V.; Kadin, Y.; Morales-Espejel, G.; Gabelli, A. Benefits of hybrid bearings in severe conditions. Evolution 2017, 3, 21–26. [Google Scholar]

- Wang, P.; Li, S.; Wu, Y.; Zhao, J. Initiation of secondary surface crack in the ring raceway of silicon nitride full ceramic bearing. J. Ceram. Process. Res. 2024, 25, 694–703. [Google Scholar] [CrossRef]

- Xia, Z.; Wu, Y.; Bao, Z.; Fan, Y.; Yan, H.; Sun, J. Effects of cage on vibration characteristics of full ceramic ball bearing under cryogenic working condition. J. Vib. Shock 2024, 43, 103–109+130. [Google Scholar]

- Wang, P.; Li, S.; Wu, Y.; Zhang, Y.; Wei, C.; Wang, Y. Research on Crack Propagation Mechanism of Silicon Nitride Ceramic Ball Bearing Channel Surface Based on Rolling Friction Experiment. Appl. Sci. 2024, 14, 674. [Google Scholar] [CrossRef]

- Wu, Y.; Guo, J.; Zhang, X.; Zhang, Y.; Wang, H.; Bai, X.; Sun, J.; Lu, H. Research on vibration characteristics of silicon nitride 6206 full-ceramic bearing with different pre-tightening force and oil supply rate. Int. J. Adv. Manuf. Technol. 2023, 127, 4943–4957. [Google Scholar] [CrossRef]

- Wang, P.; Li, S.; Wu, Y.; Zhang, L.; Wei, C.; Wang, Y.; Lin, G. Research on propagation mechanism of silicon nitride full ceramic ball bearing ring raceway surface crack considering the initial inclination angle. Forsch. Im Ingenieurwesen-Eng. Res. 2025, 89, 73. [Google Scholar] [CrossRef]

- Wu, Y.; Wei, H.; Bao, Z.; Guo, J. Influence of Oil Supply on Vibration and Temperature Rise of Full Ceramic Bearings. Mach. Des. Manuf. 2023, 384, 106–111. [Google Scholar]

- Shi, H.; Guo, J.; Bai, X.; Guo, L.; Liu, Z.; Sun, J. Research on a nonlinear dynamic incipient fault detection method for rolling bearings. Appl. Sci. 2020, 10, 2443. [Google Scholar] [CrossRef]

- Ma, L.; Kang, J.S.; Zhao, C.Y. Research on condition monitoring of bearing health using vibration data. Appl. Mech. Mater. 2012, 226, 340–344. [Google Scholar] [CrossRef]

- Yang, Z.; Yu, T.; Zhang, Y.; Sun, Z. Influence of cage clearance on the heating characteristics of high-speed ball bearings. Tribol. Int. 2017, 105, 125–134. [Google Scholar] [CrossRef]

- Malla, C.; Panigrahi, I. Review of condition monitoring of rolling element bearing using vibration analysis and other techniques. J. Vib. Eng. Technol. 2019, 7, 407–414. [Google Scholar] [CrossRef]

- Cousseau, T.; Graça, B.; Campos, A.; Seabra, J. Friction torque in grease lubricated thrust ball bearings. Tribol. Int. 2011, 44, 523–531. [Google Scholar] [CrossRef]

- Zhang, K.; Wang, Z.; Bai, X.; Shi, H.; Wang, Q. Effect of preload on the dynamic characteristics of ceramic bearings based on a dynamic thermal coupling model. Adv. Mech. Eng. 2020, 12, 1687814020903851. [Google Scholar] [CrossRef]

- Harris, T.A.; Kotzalas, M.N. Rolling Bearing Analysis: Essential Concepts of Bearing Technology; Taylor and Francis: Abingdon, UK, 2007. [Google Scholar]

- Sun, J.; Huang, J.; Tian, Z.; Yao, J.; Zhang, Y.; Wang, L. Effect of oil film stiffness on vibration of full ceramic ball bearing under grease lubrication. Ind. Lubr. Tribol. 2024, 76, 812–821. [Google Scholar] [CrossRef]

- Kannel, J.W.; Barber, S.A. Estimate of surface temperatures during rolling contact. Tribol. Trans. 1989, 32, 305–310. [Google Scholar] [CrossRef]

- Guo, J.; Wu, Y.; Zhang, X.; Zhang, Y.; Wang, H.; Bai, X.; Lu, H. Research on the influence of thermal expansion of steel shaft on dynamic characteristics of full ceramic bearing-rotor system. Adv. Mech. Eng. 2022, 14, 16878132221109349. [Google Scholar] [CrossRef]

- Wu, Y.; Guo, J.; Zhang, X.; Zhou, P.; Meng, W.; Bai, X.; Lu, H. Vibration properties of full ceramic bearing under elastohydrodynamic fluid lubrication based on the energy approach. Case Stud. Therm. Eng. 2024, 64, 105459. [Google Scholar] [CrossRef]

- Guo, J.; Wu, Y.; Zhang, X.; Wang, H.; Bai, X.; Zhang, Y.; Lu, H. Lubrication Characteristics of Silicon Nitride Full Ceramic Bearings Under Different Axial Loads. Lubr. Eng. 2023, 48, 1–8. [Google Scholar]

- Hannon, W.M. Rolling-element bearing heat transfer—Part I: Analytic model. J. Tribol. 2015, 137, 031102. [Google Scholar] [CrossRef]

- Hannon, W.M.; Barr, T.A.; Froelich, S.T. Rolling-element bearing heat transfer—Part iii: Experimental validation. J. Tribol. 2015, 137, 031104. [Google Scholar] [CrossRef]

- Geonea, I.; Dumitru, N.; Dumitru, I. Experimental and theoretical study of friction torque from radial ball bearings. IOP Conf. Ser. Mater. Sci. Eng. 2017, 252, 012048. [Google Scholar] [CrossRef]

- Niizeki, S. Ceramic bearing for special environments. NSK J. Motion Control 2000, 17–22. Available online: https://cnctar.hobbycnc.hu/VarsanyiPeter/THK%20-NSK%20-%20ISEL%20-%20IKO-%20SKF%20-%20Rexroth%20Katalogusok/NSK/TECHNICAL_JOURNAL_Motion_Controll/etj-0008.pdf#page=20 (accessed on 17 October 2025).

- Sun, J.; Zhang, G.; Tian, J.; Zhu, Y. Thermodynamic analysis of hybrid ceramic bearings with metal inner rings. Arch. Thermodyn. 2023, 44, 83–98. [Google Scholar] [CrossRef]

- Wang, L.R.; Snidle, R.W.; Gu, L. Rolling contact silicon nitride bearing technology: A review of recent research. Wear 2000, 246, 159–173. [Google Scholar] [CrossRef]

| Parameter | Taking Values |

|---|---|

| Density g·cm−3 | 3.20–3.30 |

| Elastic modulus GPa | 300–320 |

| thermal expansion coefficient × 10−6 K | 3.1–3.3 |

| Poisson ratio | 0.26 |

| Hardness HV | 1300–1800 |

| bending strength MPa | 800–1000 |

| compressive strength MPa | 2000–3500 |

| Parameter | Taking Values |

|---|---|

| outside diameter D/mm | 68 |

| inside diameter d/mm | 40 |

| bearing width B/mm | 15 |

| Roller diameter Dw/mm | 7.938 |

| Inner channel diameter di/mm | 47 |

| Outer channel diameter De/mm | 61 |

| contact angle/° | 15° |

| Inner raceway curvature coefficient fi | 0.515 |

| Curvature coefficient of outer raceway fo | 0.525 |

| Radial Load Fr (N) | Rotational Speed ni (r/min) | Other |

|---|---|---|

| 2000 | 6000/6500/7000/7500/8000 | Axial load: 200 N |

| 2000/2200/2400/2600/2800 | 6000 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, P.; Zhang, X. Experimental Study of the Service Performance of Full Ceramic Silicon Nitride Ball Bearings. Lubricants 2025, 13, 461. https://doi.org/10.3390/lubricants13100461

Wang P, Zhang X. Experimental Study of the Service Performance of Full Ceramic Silicon Nitride Ball Bearings. Lubricants. 2025; 13(10):461. https://doi.org/10.3390/lubricants13100461

Chicago/Turabian StyleWang, Pengfei, and Xuegang Zhang. 2025. "Experimental Study of the Service Performance of Full Ceramic Silicon Nitride Ball Bearings" Lubricants 13, no. 10: 461. https://doi.org/10.3390/lubricants13100461

APA StyleWang, P., & Zhang, X. (2025). Experimental Study of the Service Performance of Full Ceramic Silicon Nitride Ball Bearings. Lubricants, 13(10), 461. https://doi.org/10.3390/lubricants13100461