Investigation of Thermo-Mechanical Characteristics in Friction Stir Processing of AZ91 Surface Composite: Novel Study Through SPH Analysis

Abstract

1. Introduction

| Ref. | BM | Approach | Software | Objective | Outcomes | Merits/Demerits |

|---|---|---|---|---|---|---|

| [45] | AZ91 | Lagrangian | DEFORM 3D | Temperature & material flow predictions | Major flow occurs on the AS, with the SZ stretching towards it. The peak temperature for recrystallization was determined. Material deformation and temperature are linked to microstructure. | Automatic re-meshing & point tracking. Distortion in networks & elements. |

| [46] | AZ91 | Lagrangian | ABAQUS Explicit | Small hole drilling analysis on FSP and Friction Stir Vibration Processing (FSVP) | Higher deformation in the stir zone (SZ) of FSVP compared to FSP. Chip formation and its morphology: Discontinuous chips in FSVP have higher hardness than the FSP. Cutting force is reduced in FSP. | JC law was applied, & only the impact of vibration on drilling was modelled. |

| [47] | Mg alloy; Tool-H13 | Lagrangian | ANSYS | FSP tool design and simulation for Mg alloy. | Low stress, long fatigue life, and slight deformation resulted from the tool’s structural and fatigue examination. Maximum force occurs at the tool shoulder and pin tip during plunging and on the pin side during travelling. | Tool designed with 20 mm SD & 4 mm PD must be used for safety operations in Mg alloy. |

| [48] | SS304L | Eulerian | Forge | Prediction of grains from flow stresses, strain rate, and temperature. | Estimated the recrystallized grains in the SZ using simulated temperatures. Model is favourable for hardness, exhibiting minimal variation of 10%. | Predicted grain size differed by up to 39%. Difficulty was encountered in analyzing material flow at free boundary surfaces. |

| [49] | AA2024 | – | ABAQUS Fluent | Temperature field and plastic material flow in crack repair. | Crack healing occurred in the solid phase, as indicated by the measured temperature. Strength of the repaired zone was restored through grain refinement. Material flow was chaotic in the RS & regular in the AS. | Different FEM tools were used for temperature & material flow predictions. |

| [50] | Al-12% Si | CEL | – | Effect of process parameters on a temperature gradient | Temperature and plastic strain were directly proportional to TRS. Temperature decreases from the surface through thickness; Less heat is generated & increased dissipation to the backing plate. | Impact of used parameters on material flow was not reported. |

| [31] | AA6061-T6 | SPH | LS-Dyna | Develop an AFSP model using the meshfree technique. | Entire HAZ had a dome shape, with the Tmax. at the filler rod-substrate contact surface reached about 79% of Tmelt. High hardness & stress were observed at the top deposition layer. | JC material law was applied. SPH-SPH contact not defined. |

| Ref. | BM/Reinf. | Approach | Software | Objective | Outcomes | Merits/Demerits |

|---|---|---|---|---|---|---|

| [51] | A356/ZrO2, B4C, TiC & SiC | – | DEFORM 3D | Material flow simulation for different pin profiles | Material revolution around the threaded pin, a vertical material motion was observed. Vertical motion discontinued the transverse bands formed in the cylindrical pin profile. TiC achieved an increase in hardness due to excellent bonding. | Non-uniform and automatic remeshing. Reinforcing particles are not accounted in the numerical analysis; instead, pointers are assumed. |

| [18] | A356/B4C | Lagrangian | DEFORM 3D | Impact of tool pin profile on reinforcement distribution | Particle distribution was nearly uniform in threaded pin profiles compared to square, hexagonal, and cylindrical profiles. Material flow patterns closely matched SZ shapes from simulation and experiment. | Reinforcement distribution requires point-tracking adjustment at specific intervals for complex deformations. Network and element distortions necessitate severe re-meshing. |

| [19] | LM13/Gr | Lagrangian incremental | DEFORM 3D | Simulate the material flow and its behaviour. | Material flow, prediction of SZ shape, and temperature matched the experimental data well. Powder agglomeration and tunnel defects were observed at AS. Moving the FSP tool towards RS, leads to a more even powder distribution. | Reinforcing particles are excluded from the numerical modelling; markers or tracers are assumed. |

| [39] | Polyamide 6/MWCNT | ALE | DEFORM 3D | Temperature distribution, material flow & plastic strain | Peak Temperature (Tp) is observed at the shoulder/workpiece interface, and the temperature distribution is asymmetric at the surface. Plastic strain shows higher shearing on the AS than the Retreating Side (RS) and decreases towards the edge of the SZ. | Point tracing depicts the concave cross-section of the SZ. Point tracing required adjustment & pre-assumed specific intervals. |

| [52] | AA6061/SiC | CEL | ABAQUS | Impact of tool pin profile on temperature distribution | Minor temperature variations were observed due to the same shoulder size serving as the primary heat source. Cylindrical tool exhibited higher temperatures in the pin-affected region due to its larger surface area. In contrast, the triangular tool sample experienced lower temperatures in this area due to its smaller surface area. | Reinforcing particles are excluded from the model. Backing plate is not considered. |

2. Methodology

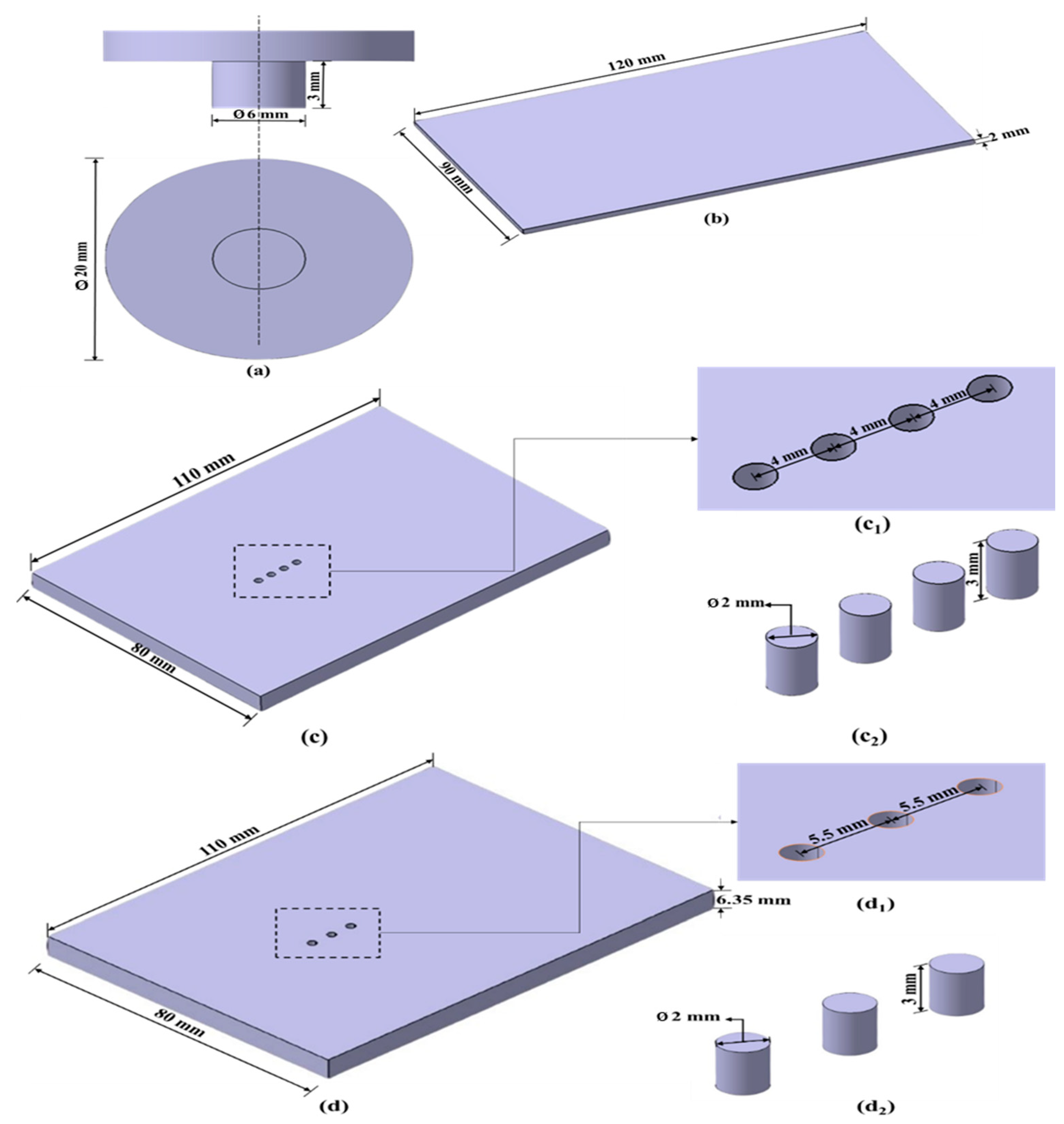

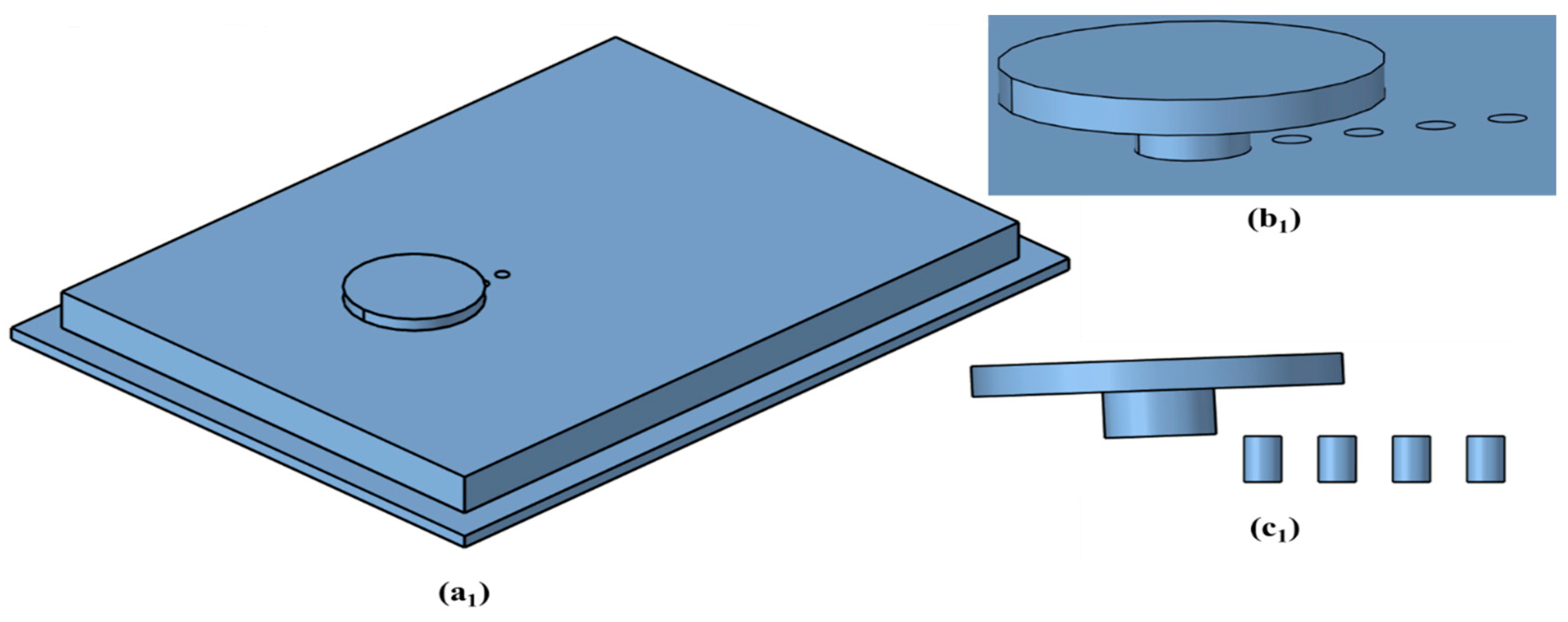

2.1. Experimental Methodology

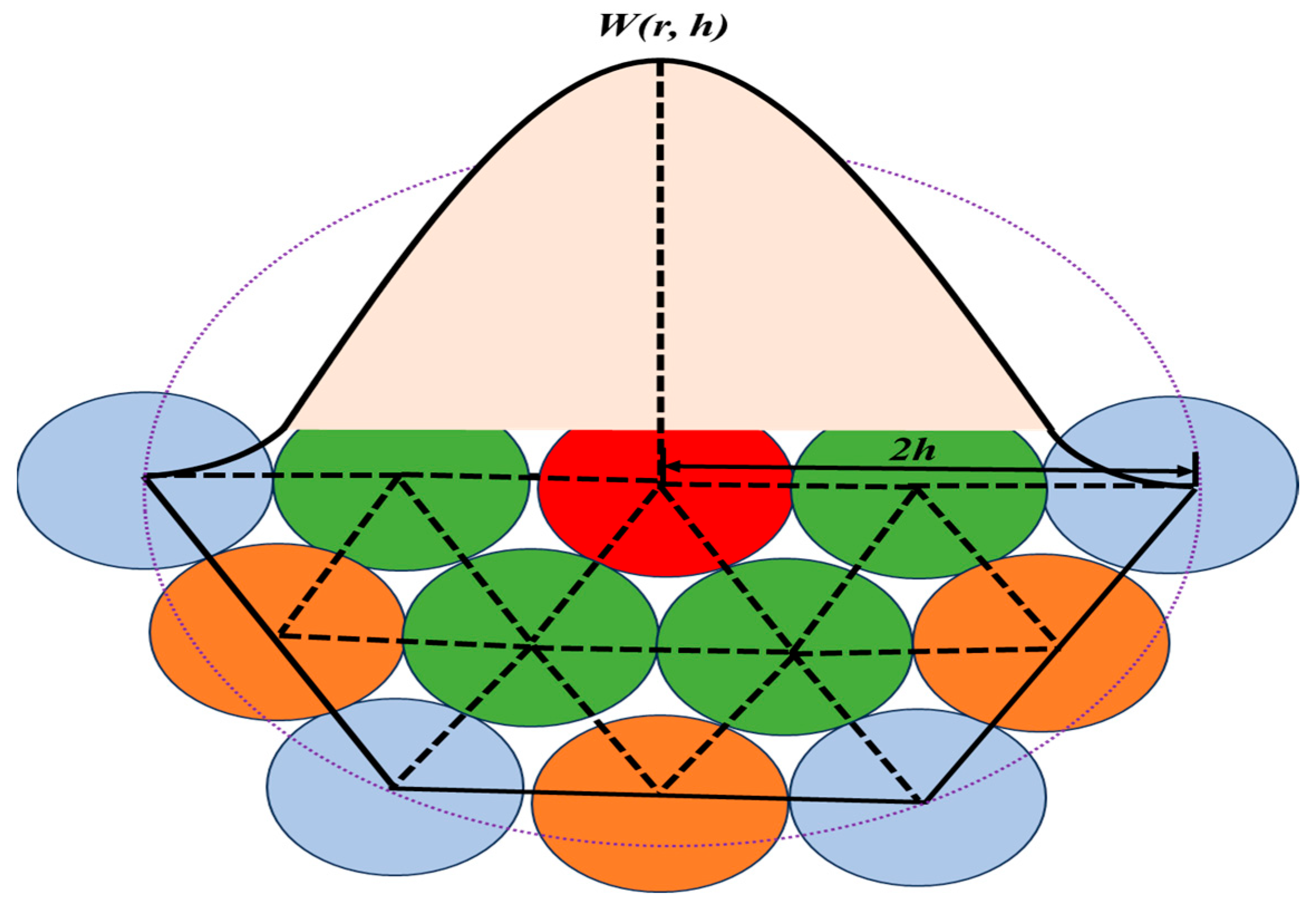

2.2. Meshfree Technique: Smoothed Particle Hydrodynamics (SPH)

2.3. Numerical Model for AZ91 Surface Composites

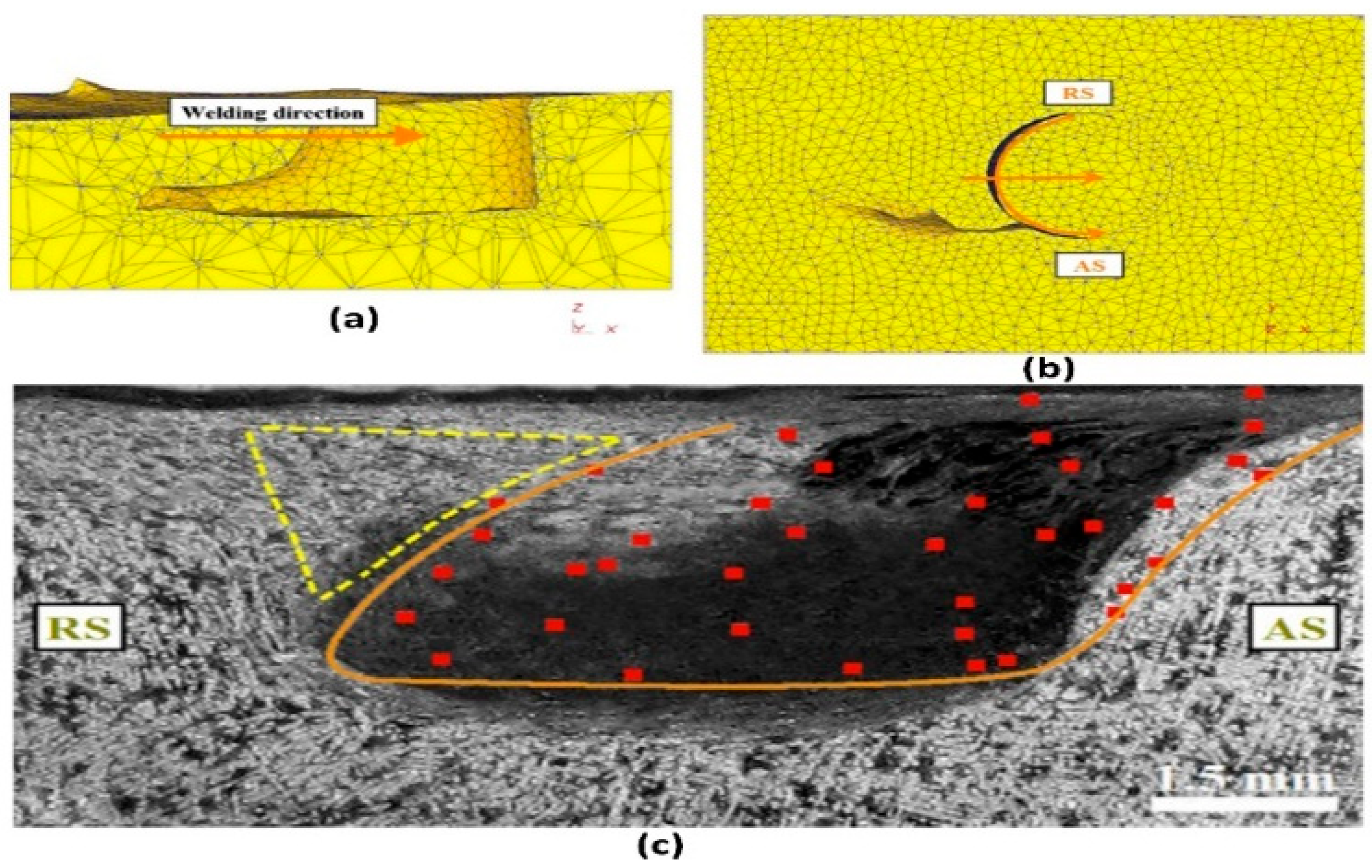

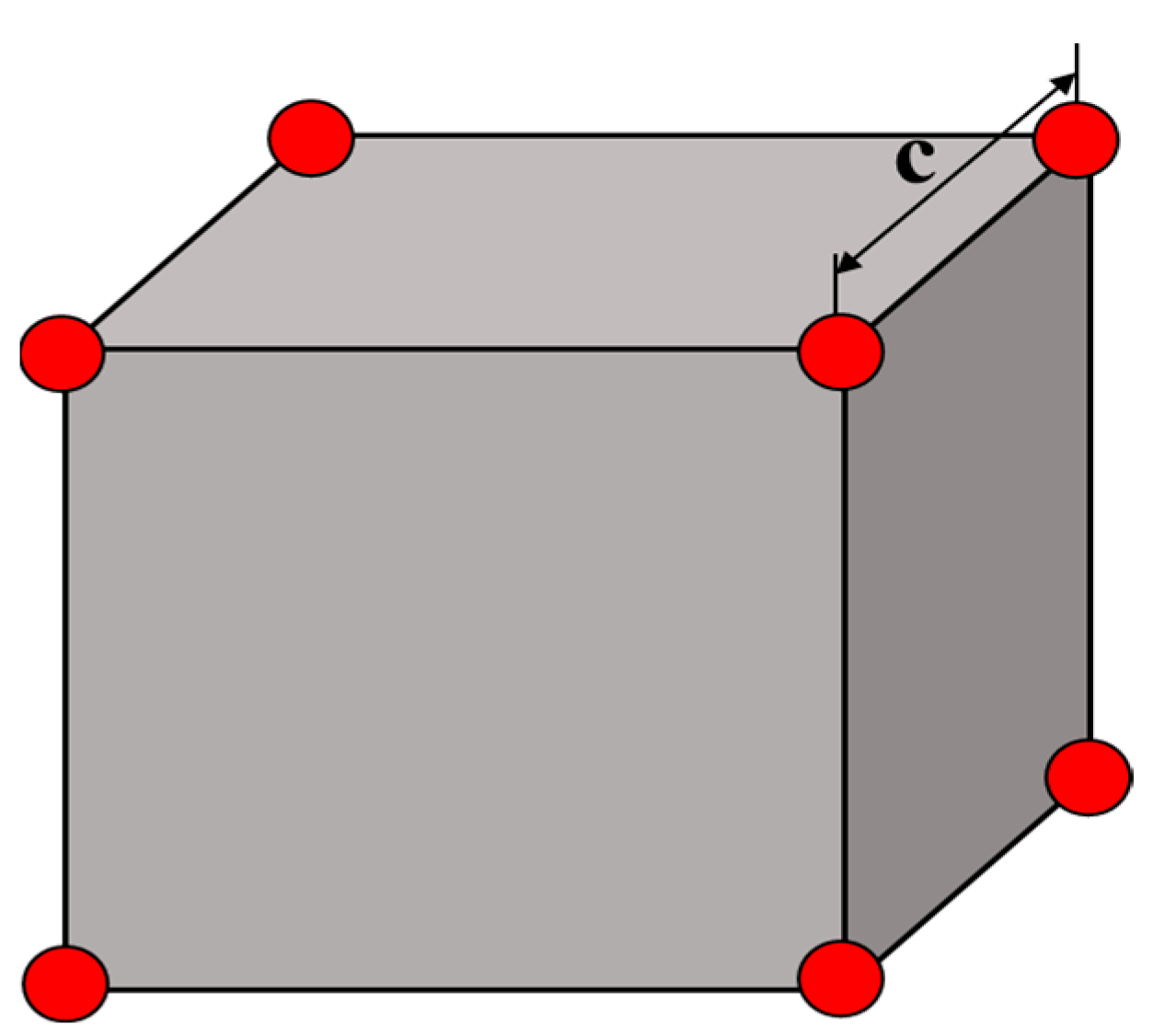

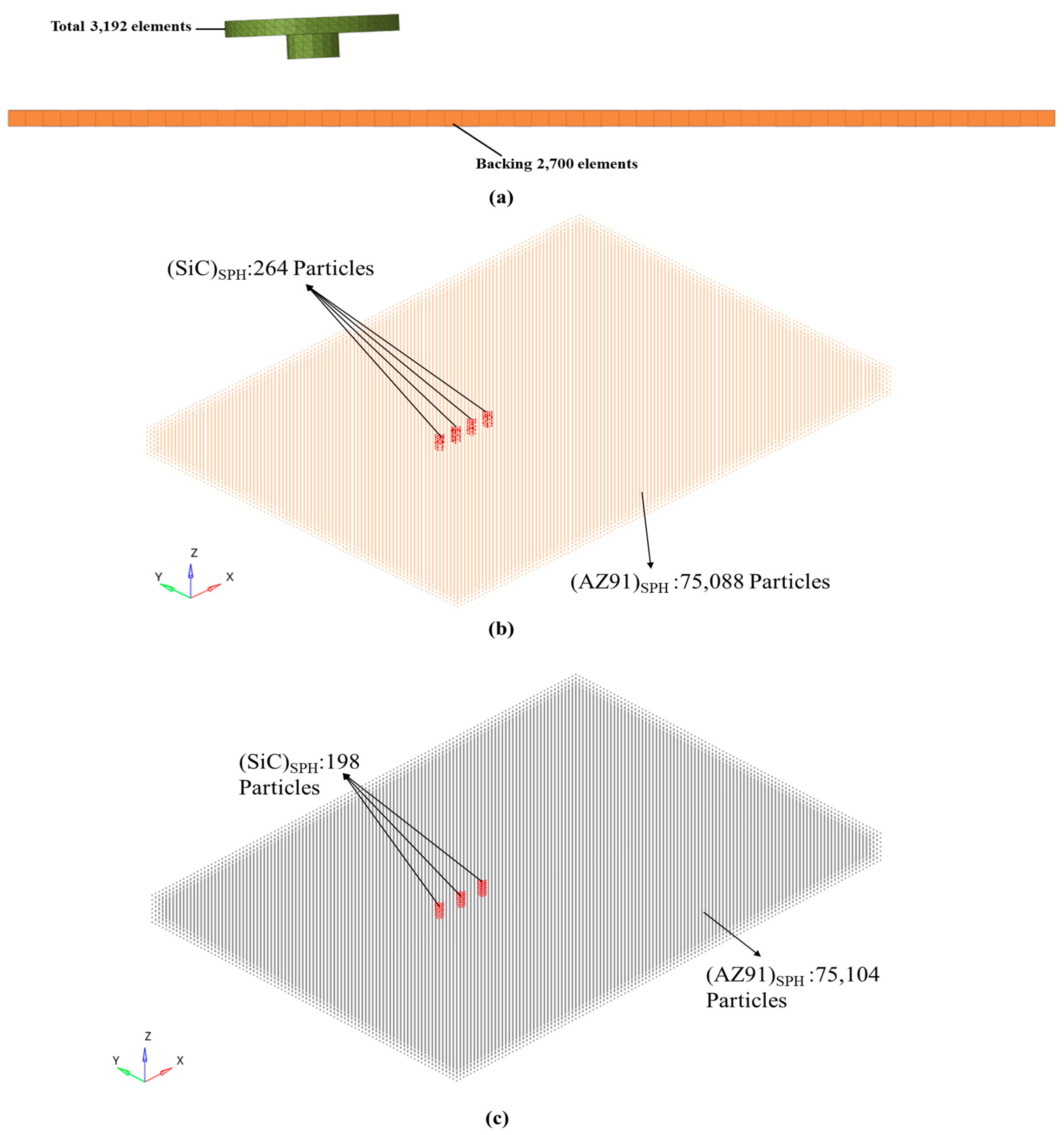

2.3.1. Geometric Model

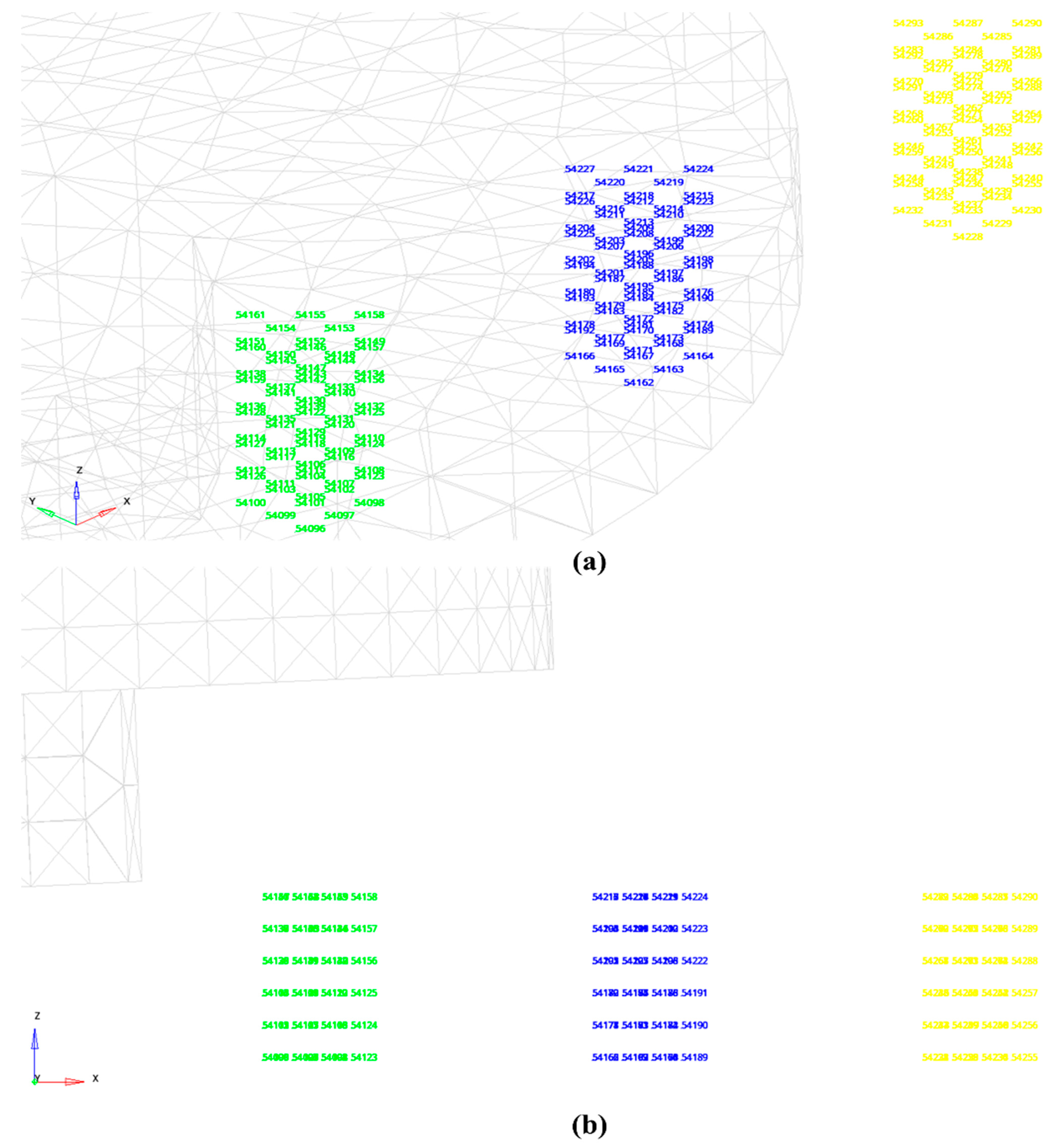

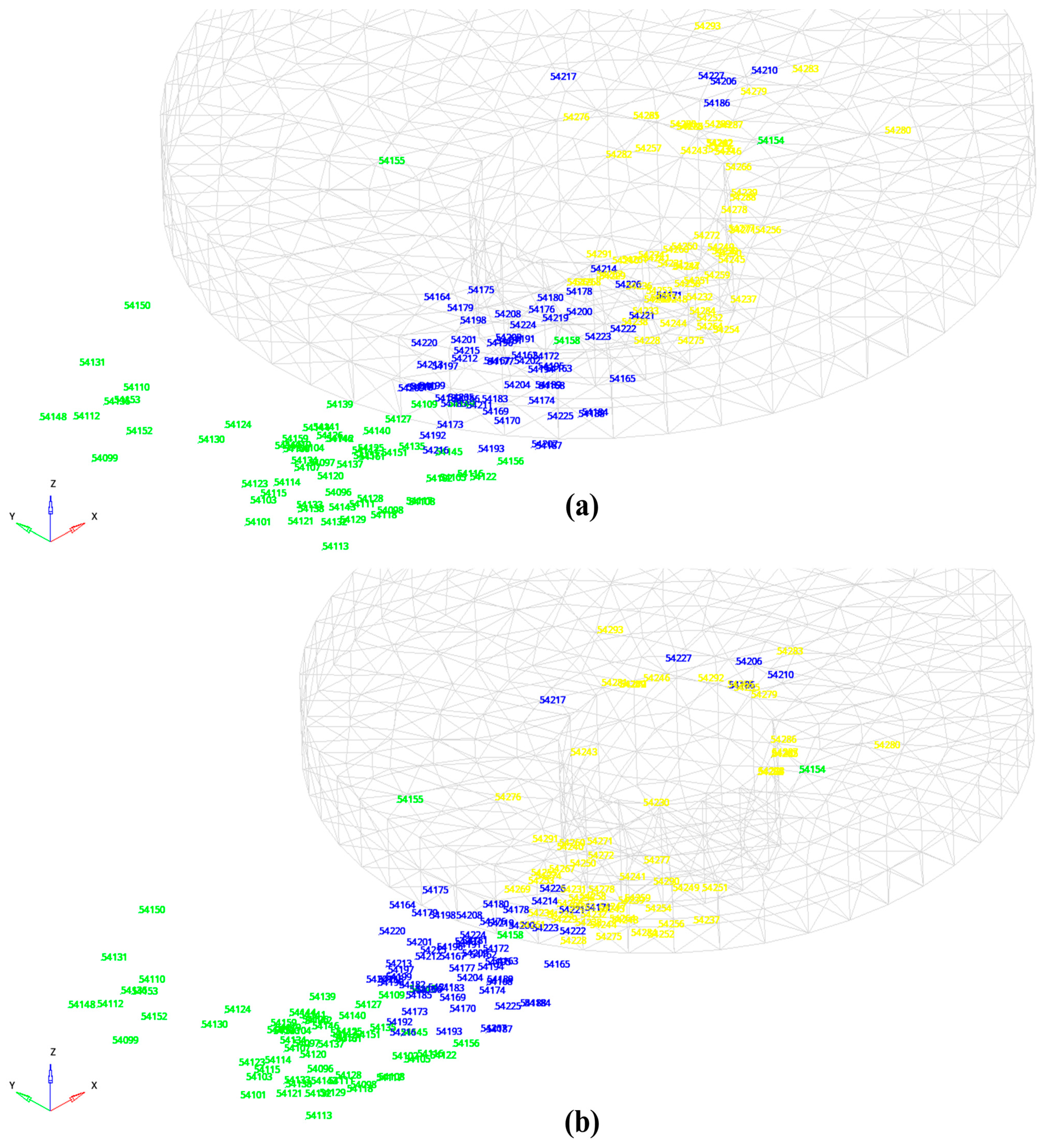

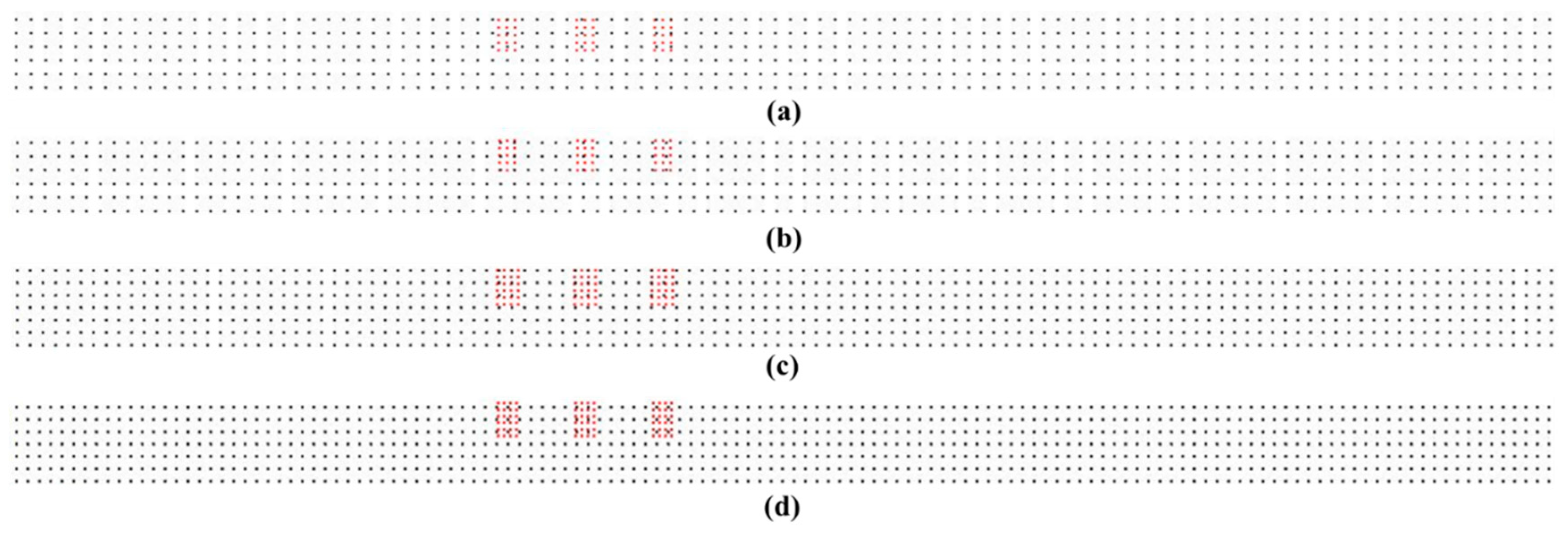

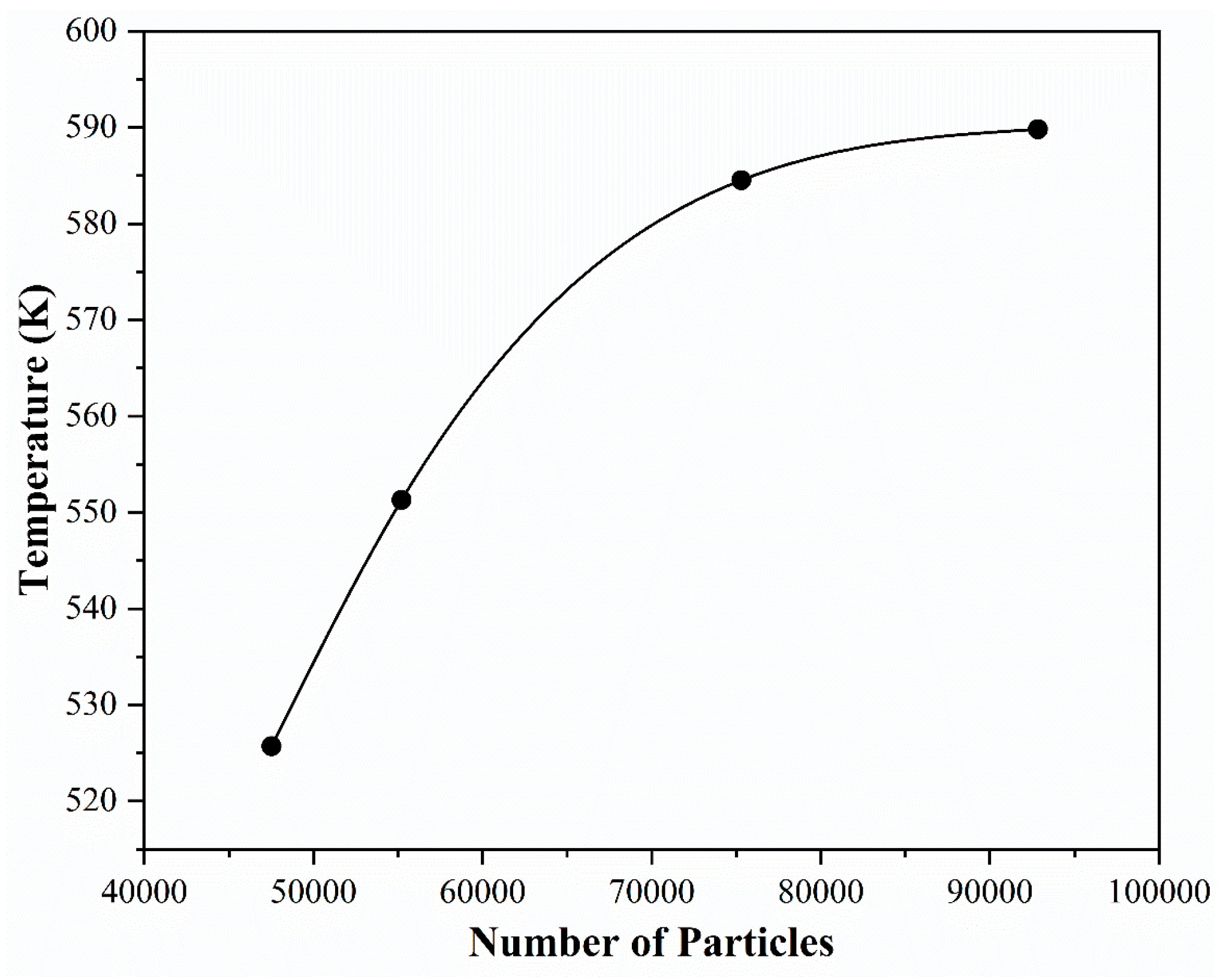

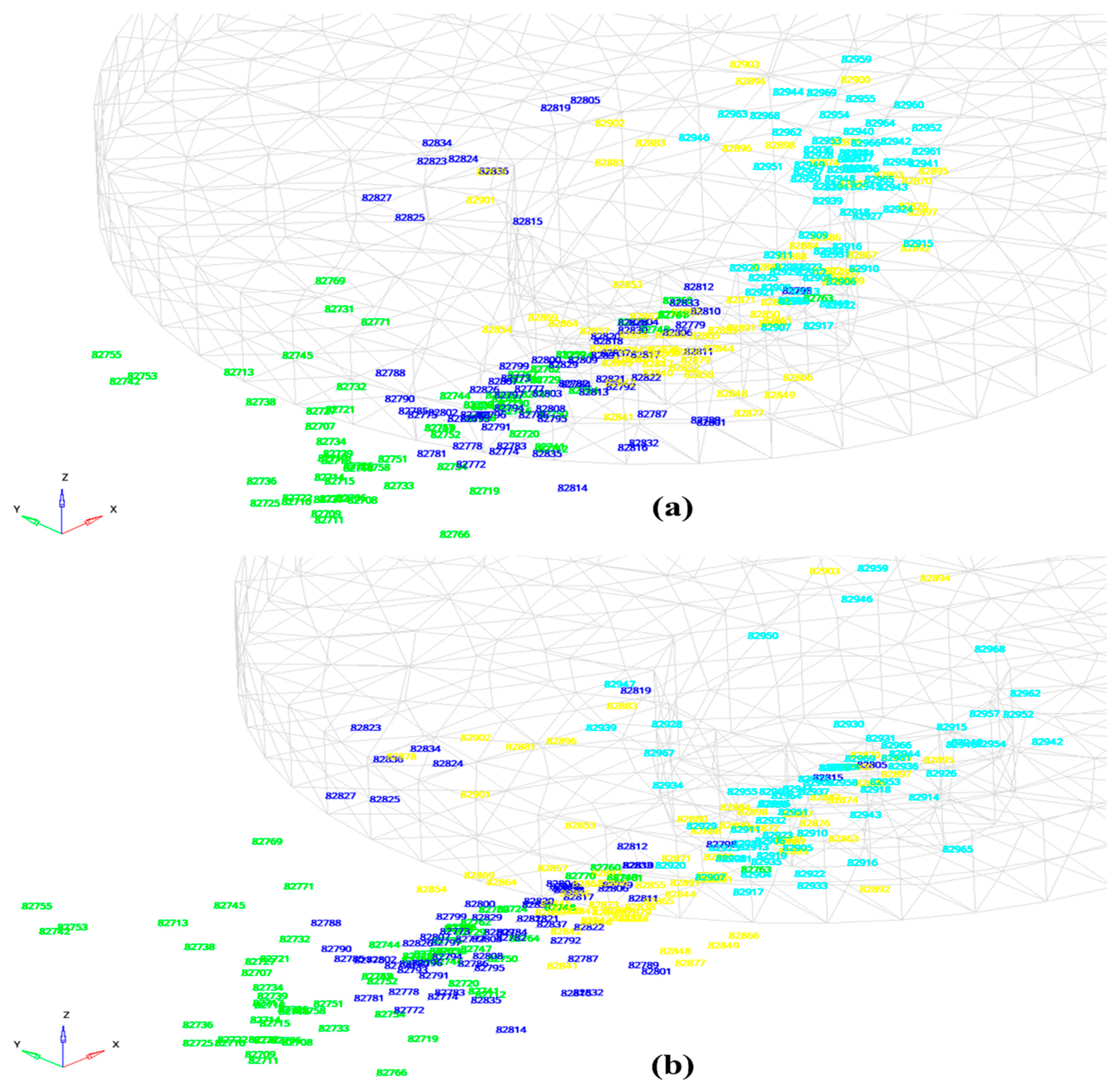

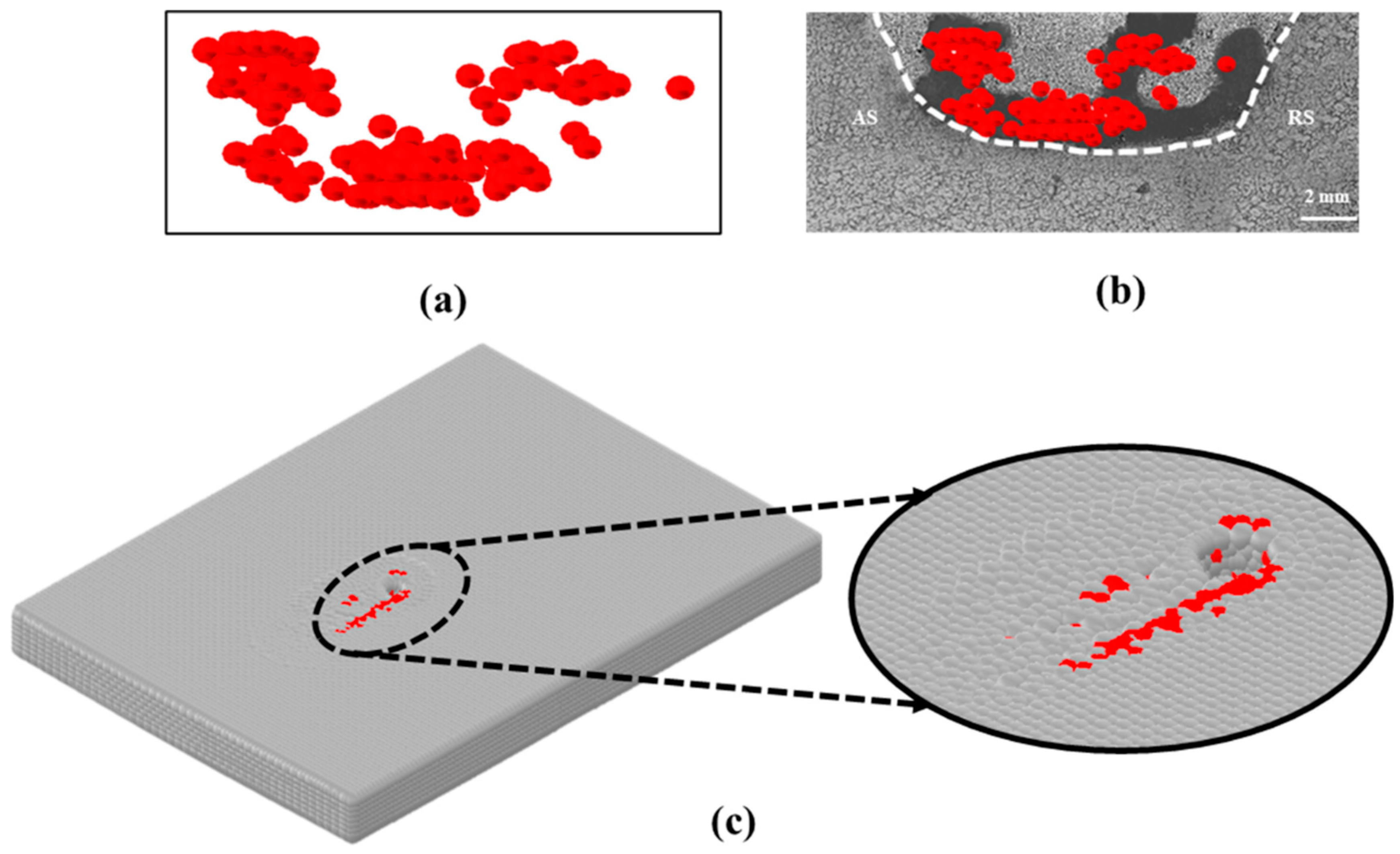

2.3.2. Particle Independence Study

2.3.3. Material Model and Properties

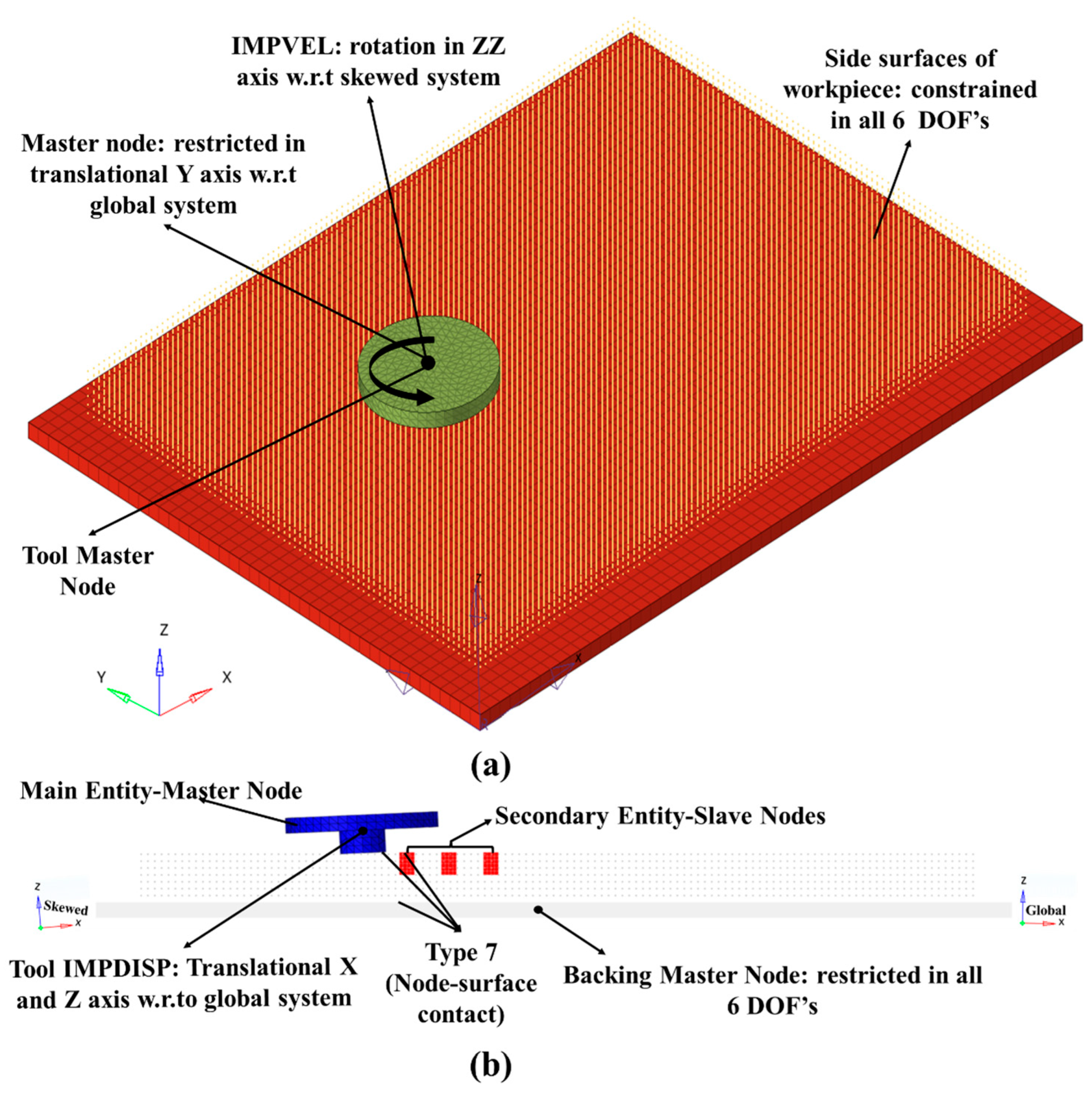

2.3.4. Contact, Boundary Conditions, and Friction Model

2.4. High-Performance Computing (HPC)

2.5. Assumptions

- ➢

- The initial temperatures assumed for the tool, workpiece, backing, and confined reinforcement within the holes are 298K for all simulations.

- ➢

- The tool and backing are assumed to be rigid bodies, while the workpiece and reinforcement are considered homogeneous, isotropic, and elastoplastic.

- ➢

- It is assumed that uniform boundary conditions persist consistently across the processed part in all simulations. No heat is transferred into the workpiece if local temperatures reach the melting point.

- ➢

- Reinforcement particles are assumed to be cylindrical and packed into the hole to maintain a continuum and facilitate the application of SPH particles.

- ➢

- Assuming capping during the experiment, the temperature-dependent COF used for the workpiece is expected to extend to the tool’s interaction with the reinforcement, as it covers the holes with the base material.

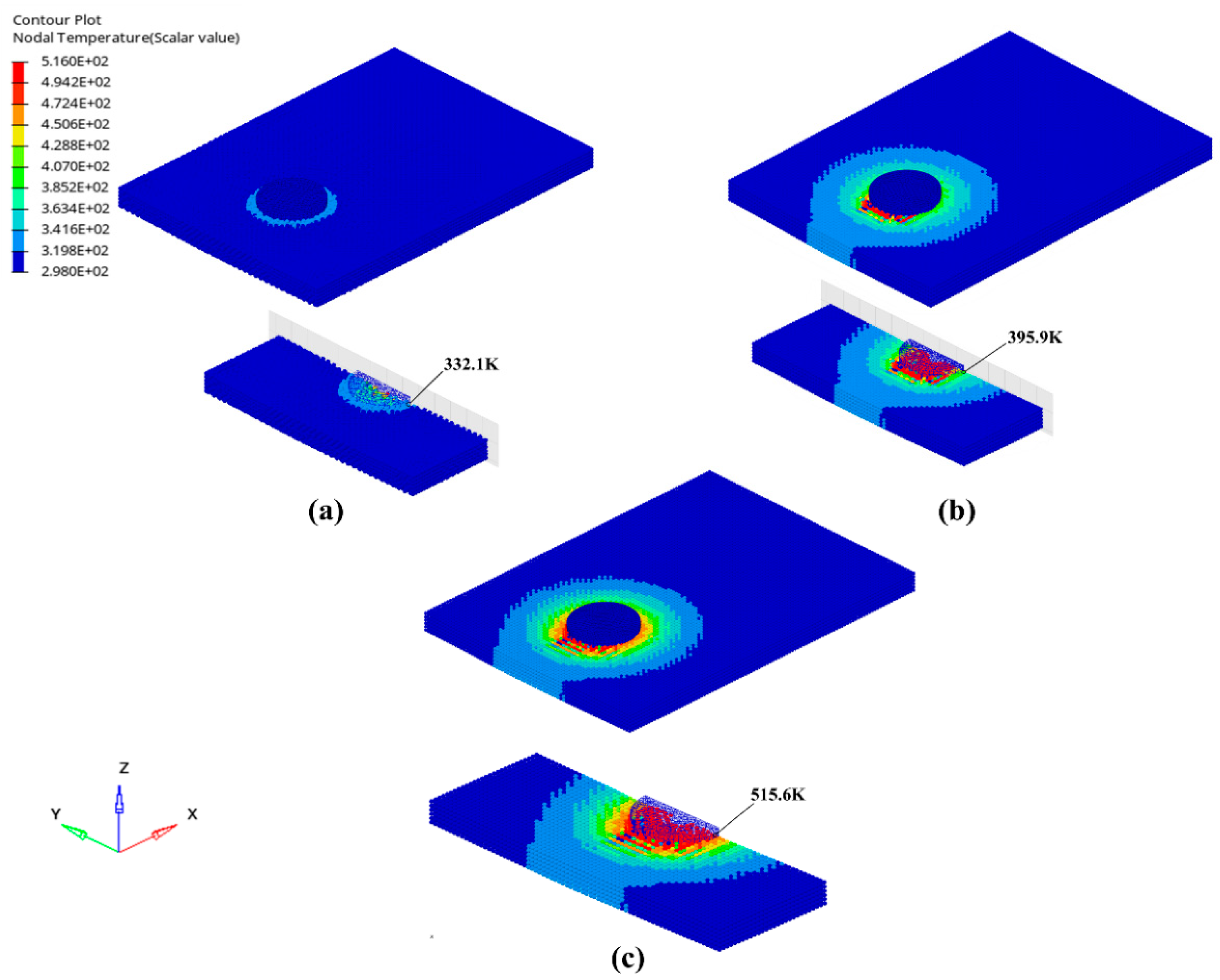

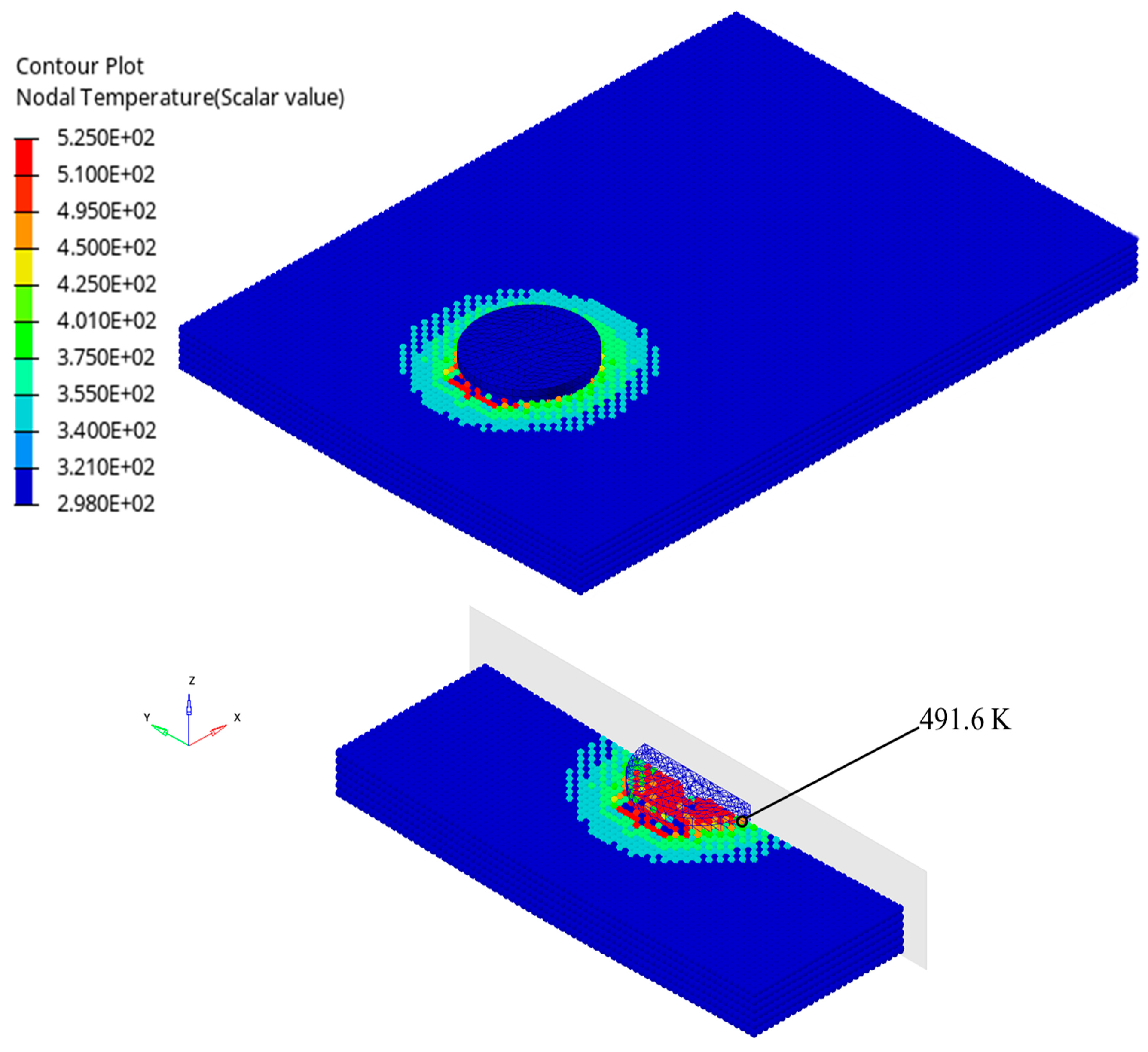

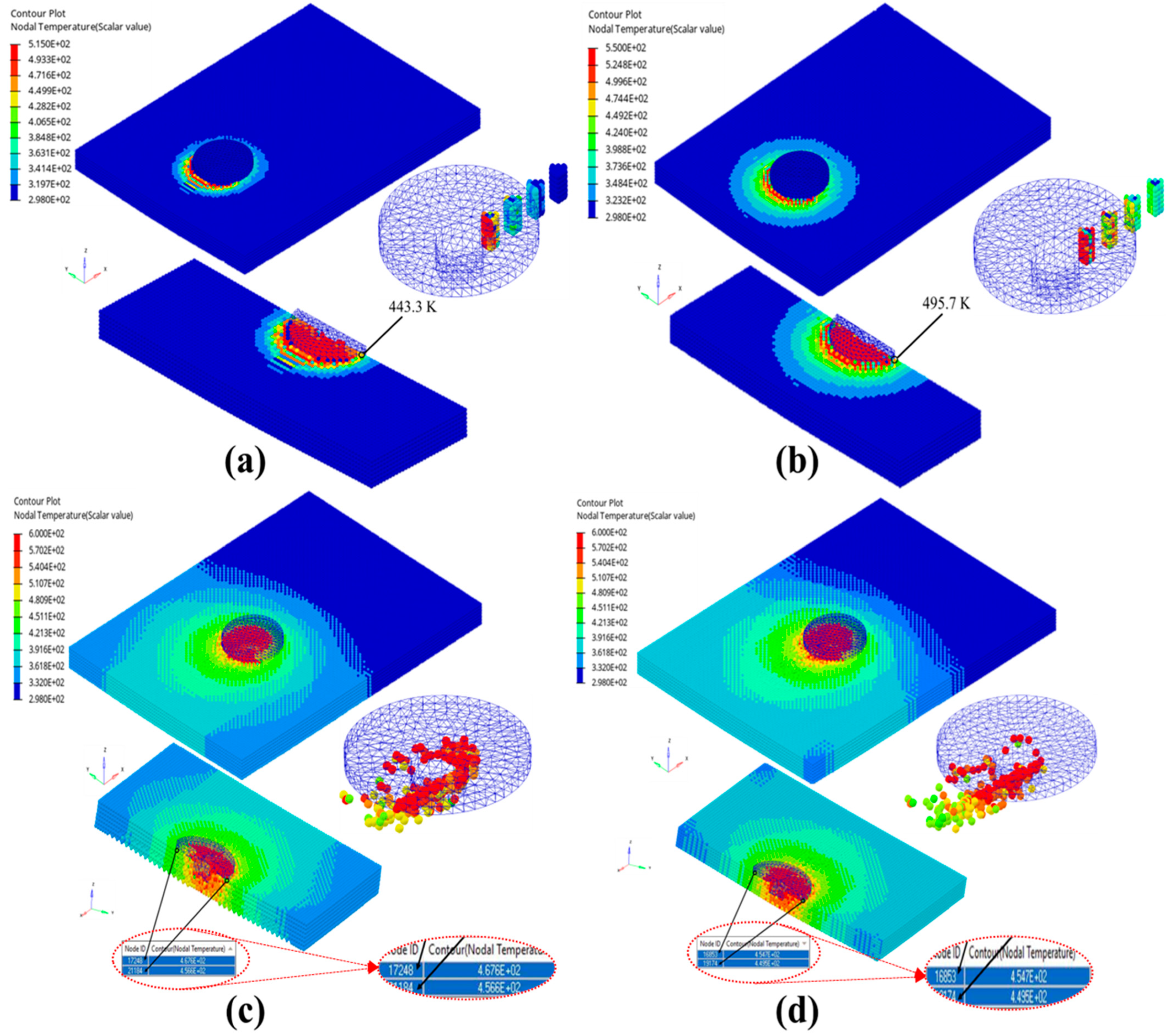

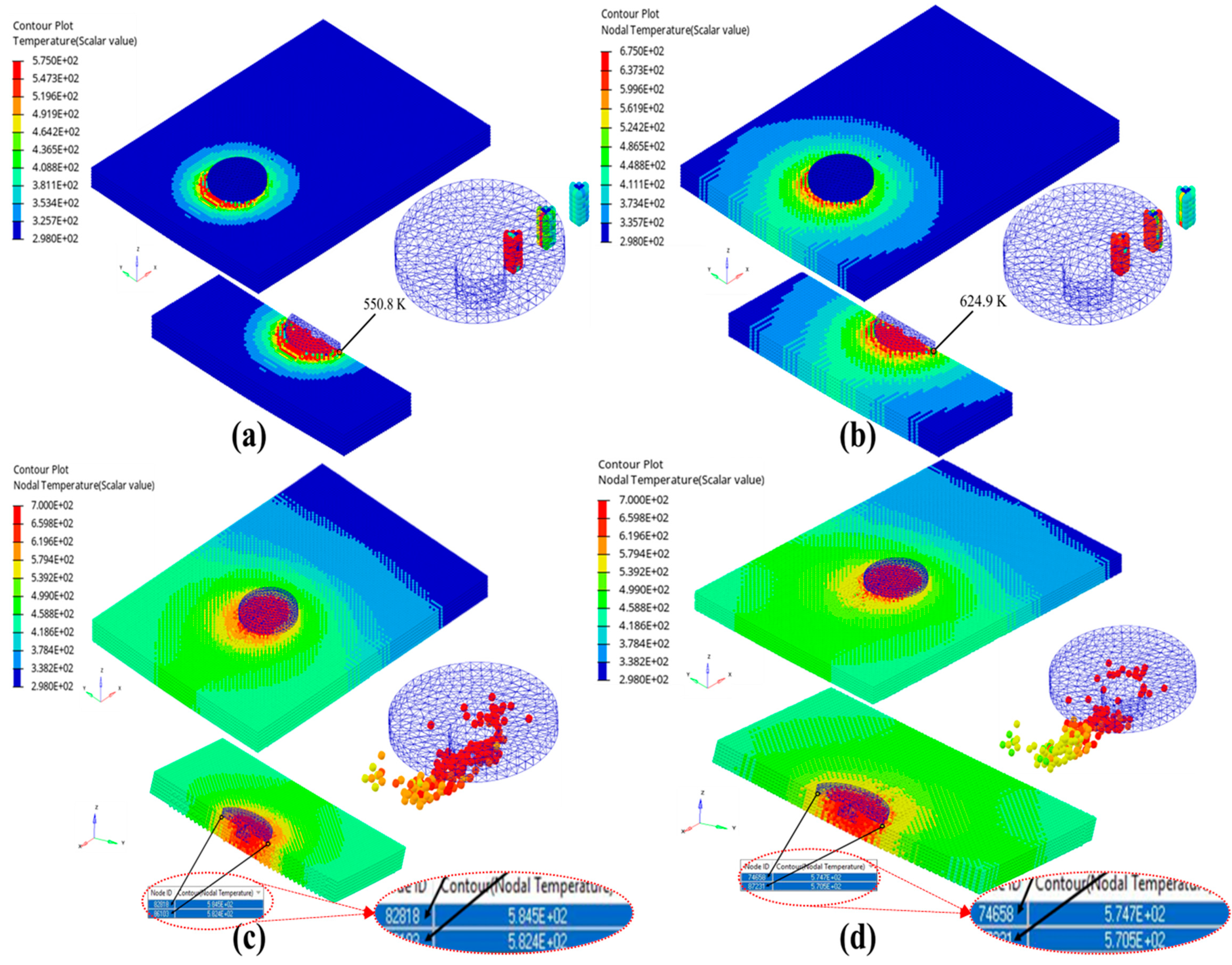

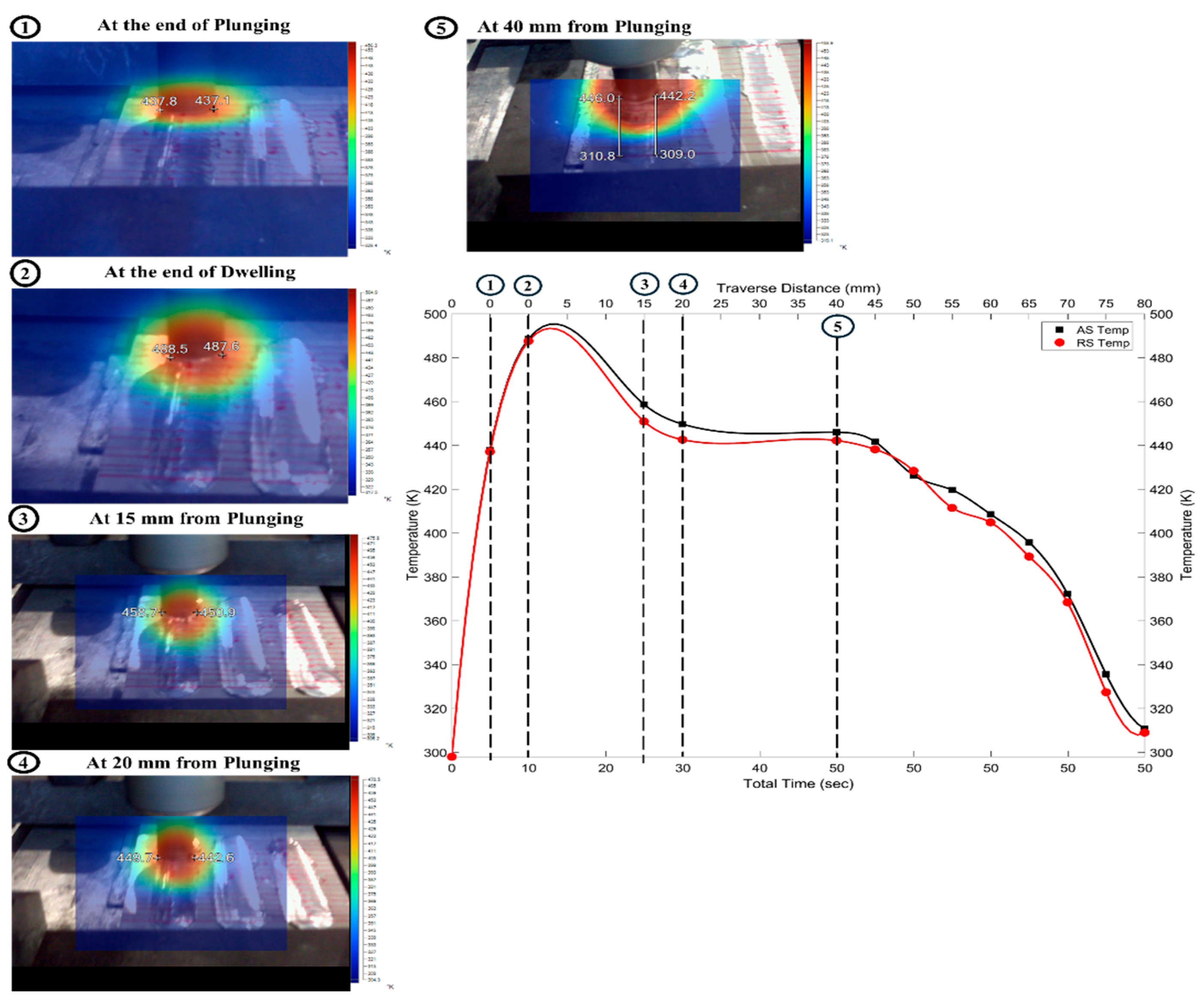

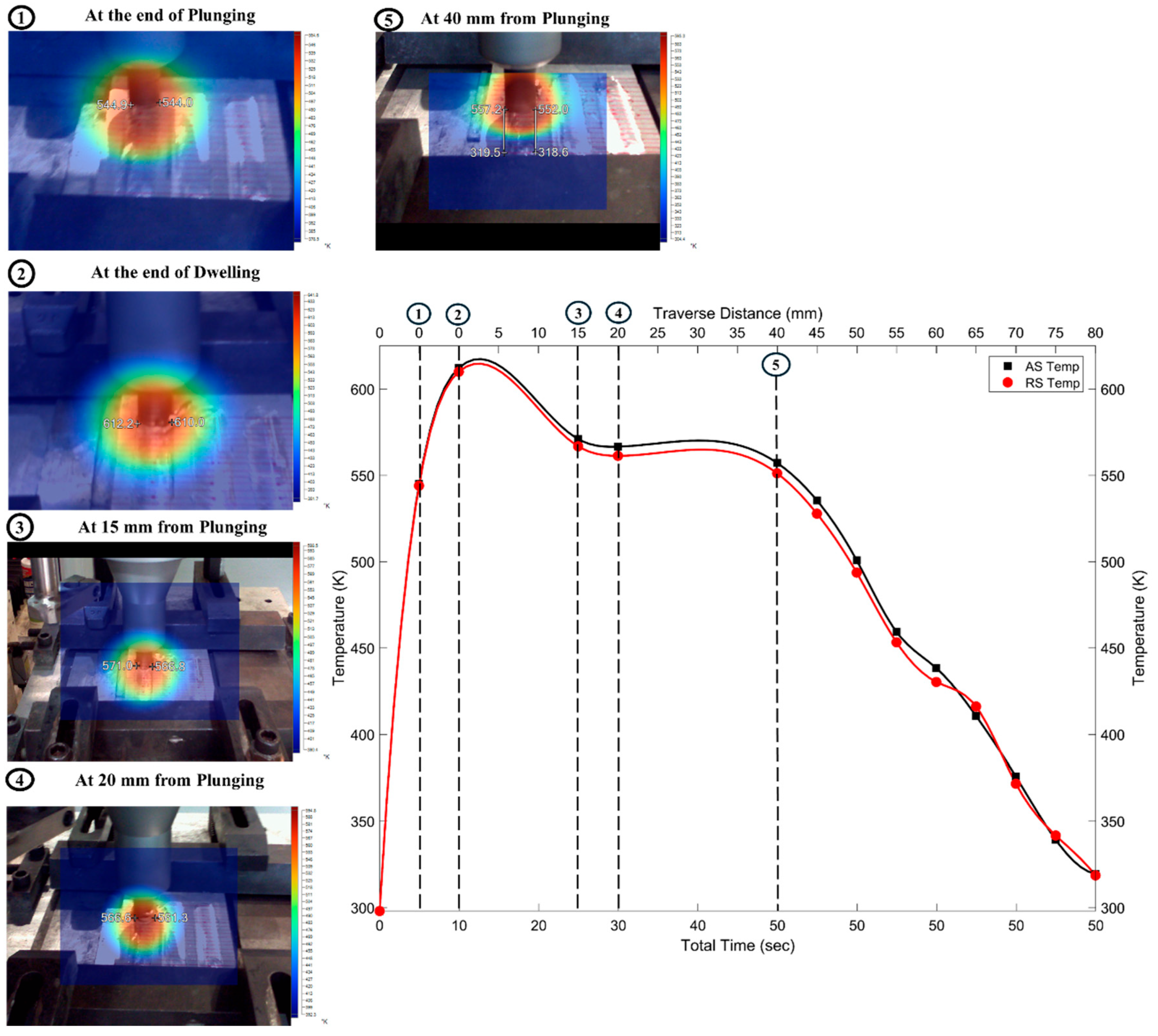

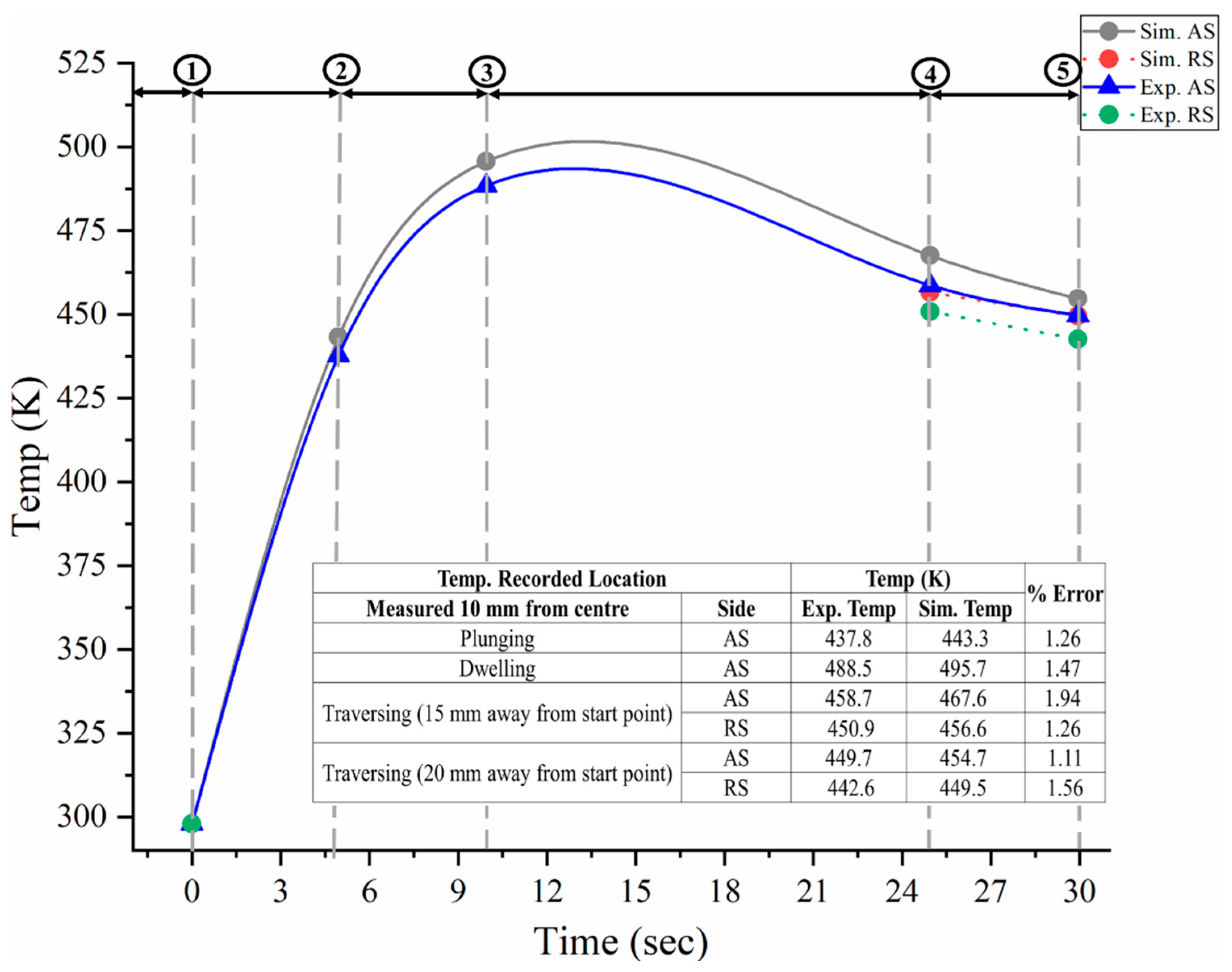

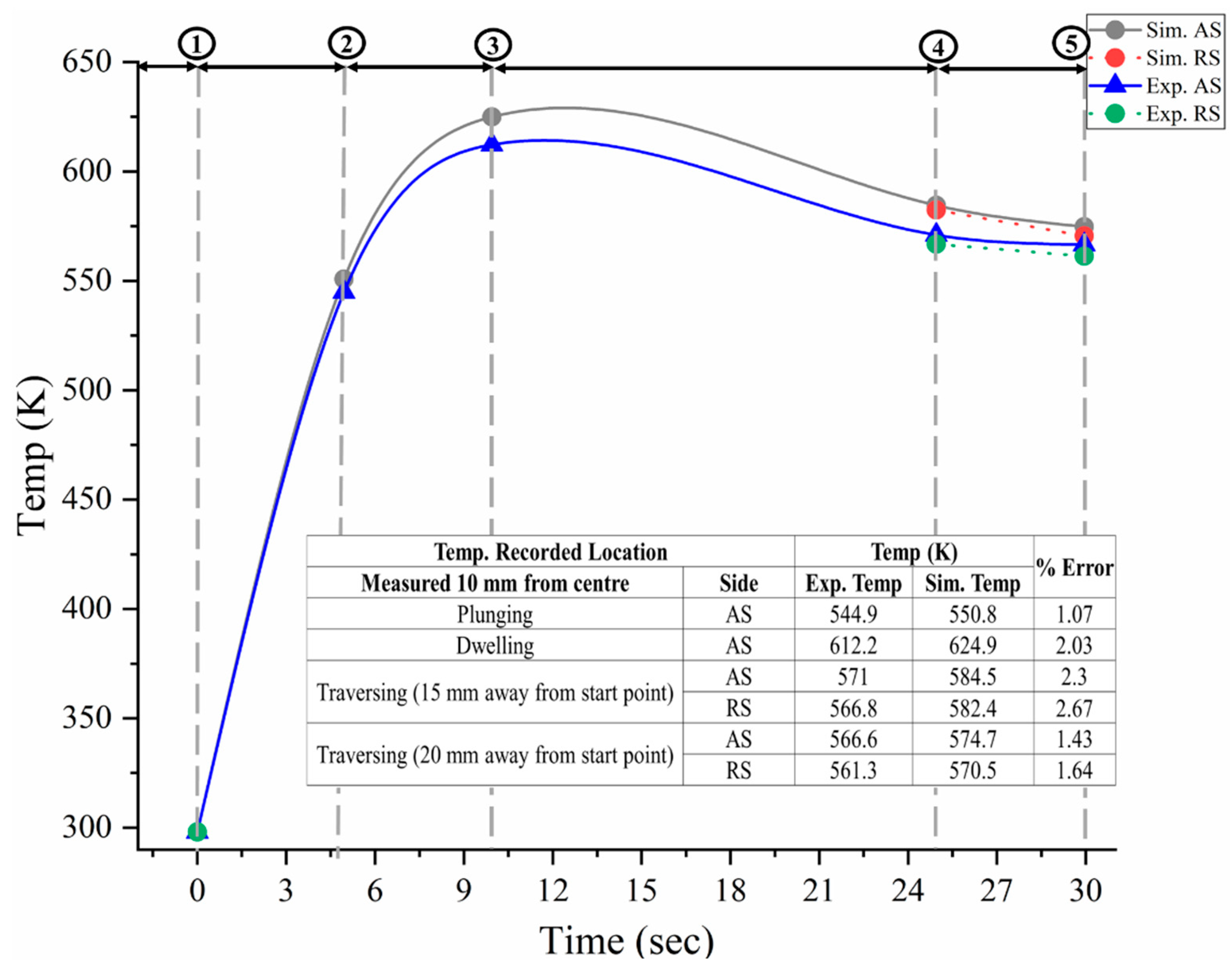

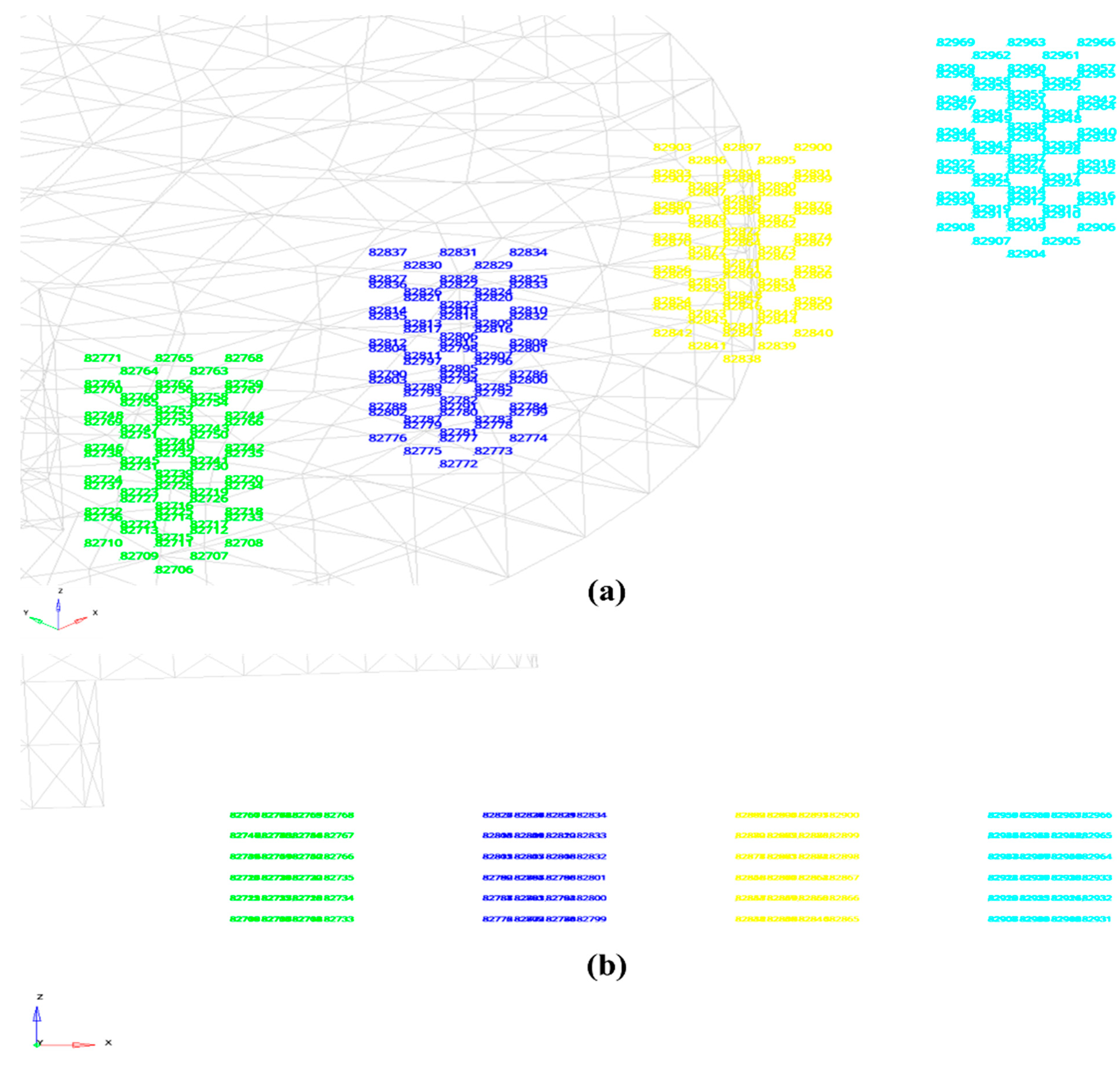

3. Results and Discussion

4. Conclusions

- •

- SPH effectively captured complex FSP interactions, accurately predicting temperature distribution and material flow.

- •

- TRS significantly influenced heat generation and thermal distribution:

- ○

- Higher TRS (S2: 1500 rpm, 10% SiC) produced a wider, more uniform thermal field.

- ○

- Lower TRS (S1: 500 rpm, 13% SiC) caused reinforcement agglomeration and uneven particle distribution.

- •

- Particle distribution varied across the SZ:

- ○

- AS had a higher particle concentration at lower TRS.

- ○

- Higher TRS improved SiC dispersion, reduced defects, and enhanced homogeneity.

- •

- Reinforcement mobility increased with TRS, but excessive SiC content raised matrix viscosity, limiting material flow.

- •

- Optimizing TRS and reinforcement fraction is crucial for achieving uniform composite microstructure and improved properties.

- •

- SPH provides valuable insights for parameter selection and refining FSP strategies for AZ91/SiC composites.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Marode, R.V.; Lemma, T.A.; Sallih, N.; Pedapati, S.R.; Awang, M.; Hassan, A. Research Progress in Friction Stir Processing of Magnesium Alloys and Their Metal Matrix Surface Composites: Evolution in the 21st Century. J. Magnes. Alloy. 2024, 12, 2091–2146. [Google Scholar] [CrossRef]

- Patil, N.A.; Pedapati, S.R.; Marode, R.V. Wear Analysis of Friction Stir Processed AA7075-SiC-Graphite Hybrid Surface Composites. Lubricants 2022, 10, 267. [Google Scholar] [CrossRef]

- Ma, Z.Y.; Mishra, R.S.; Mahoney, M.W. Superplastic Deformation Behaviour of Friction Stir Processed 7075 Al Alloy. Acta Mater. 2002, 50, 4419–4430. [Google Scholar] [CrossRef]

- Marode, R.V.; Awang, M.; Lemma, T.A.; Pedapati, S.R.; Hassan, A.; Janga, V.S.R.; Alam, M.A.; Loyte, A.; Devarajan, Y. Friction Stir Processing of AZ91 Hybrid Composites with Exfoliated Multi-Layered Graphene: A Taguchi-Grey Relational Analysis. J. Alloys Compd. 2023, 972, 172703. [Google Scholar] [CrossRef]

- Akbari, M.; Asadi, P.; Sadowski, T. A Review on Friction Stir Welding/Processing: Numerical Modeling. Materials 2023, 16, 5890. [Google Scholar] [CrossRef]

- Marode, R.V.; Pedapati, S.R.; Lemma, T.A.; Loyte, A.; Devarajan, Y.; Thandavamoorthy, R. Influence of Silicon Carbide on Microhardness and Corrosion Behavior of AZ91/SiC Surface Composites Processed through Friction Stir Processing: Multi-Response Optimization Using Taguchi-Grey Relational Analysis. Silicon 2023, 15, 6921–6943. [Google Scholar] [CrossRef]

- Patil, N.A.; Marode, R.V.; Kusekar, S.K. Friction Stir Welding and Design. In Advanced Welding Techniques: Current Trends and Future Perspectives; CRC Press: Boca Raton, FL, USA, 2024; pp. 153–166. ISBN 9781040112267. [Google Scholar]

- Bellala, S.S.K.; Pedapati, S.R.; Marode, R. V Comparative Study of Thermal Modelling Using Eulerian and SPH Techniques for FSW. ET Conf. Proc. 2023, 2022, 76–82. [Google Scholar] [CrossRef]

- Marode, R.V.; Pedapati, S.R.; Lemma, T.A.; Bellala, S.S.K. Investigation on AA7075 and AA7075/SiC Surface Composites Using Friction Stir Processing: An Experimental and Numerical Approach. Mater. Today Proc. 2024, 109, 12–21. [Google Scholar] [CrossRef]

- He, X.; Gu, F.; Ball, A. A Review of Numerical Analysis of Friction Stir Welding. Prog. Mater. Sci. 2014, 65, 1–66. [Google Scholar] [CrossRef]

- Correia, A.N.; Braga, D.F.O.; Baptista, R.; Infante, V. Experimental and Numerical Investigation on Failure Behaviour of Aluminum-Polymer Friction Stir Composite Joints. Eng. Fail. Anal. 2024, 165, 108805. [Google Scholar] [CrossRef]

- Mishra, R.S.; De, P.S.; Kumar, N. Friction Stir Welding and Processing: Science and Engineering; Springer: Berlin/Heidelberg, Germany, 2014; Volume 9783319070, ISBN 9783319070438. [Google Scholar]

- Akbari, M.; Asadi, P. Effects of Triflute Pin Geometry on Defect Formation and Material Flow in FSW Using CEL Approach. J. Adv. Join. Process. 2024, 10, 100259. [Google Scholar] [CrossRef]

- Hassanamraji, N.; Eivani, A.R.; Aboutalebi, M.R. Finite Element Simulation of Deformation and Heat Transfer during Friction Stir Processing of As-Cast AZ91 Magnesium Alloy. J. Mater. Res. Technol. 2021, 14, 2998–3017. [Google Scholar] [CrossRef]

- Agha Amini Fashami, H.; Bani Mostafa Arab, N.; Hoseinpour Gollo, M.; Nami, B. Numerical and Experimental Investigation of Defects Formation during Friction Stir Processing on AZ91. SN Appl. Sci. 2021, 3, 108. [Google Scholar] [CrossRef]

- Ansari, M.A.; Samanta, A.; Behnagh, R.A.; Ding, H. An Efficient Coupled Eulerian-Lagrangian Finite Element Model for Friction Stir Processing. Int. J. Adv. Manuf. Technol. 2019, 101, 1495–1508. [Google Scholar] [CrossRef]

- Meyghani, B.; Awang, M.B.; Wu, C.S. Thermal Analysis of Friction Stir Processing (FSP) Using Arbitrary Lagrangian-Eulerian (ALE) and Smoothed Particle Hydrodynamics (SPH) Meshing Techniques. Materwiss. Werksttech. 2020, 51, 550–557. [Google Scholar] [CrossRef]

- Shojaeefard, M.H.; Akbari, M.; Khalkhali, A.; Asadi, P. Effect of Tool Pin Profile on Distribution of Reinforcement Particles during Friction Stir Processing of B4C/Aluminum Composites. Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl. 2018, 232, 637–651. [Google Scholar] [CrossRef]

- Tutunchilar, S.; Haghpanahi, M.; Besharati Givi, M.K.; Asadi, P.; Bahemmat, P. Simulation of Material Flow in Friction Stir Processing of a Cast Al-Si Alloy. Mater. Des. 2012, 40, 415–426. [Google Scholar] [CrossRef]

- Hofmann, D.C.; Vecchio, K.S. Thermal History Analysis of Friction Stir Processed and Submerged Friction Stir Processed Aluminum. Mater. Sci. Eng. A 2007, 465, 165–175. [Google Scholar] [CrossRef]

- Khodabakhshi, F.; Derazkola, H.A.; Gerlich, A.P. Monte Carlo Simulation of Grain Refinement during Friction Stir Processing. J. Mater. Sci. 2020, 55, 13438–13456. [Google Scholar] [CrossRef]

- Marode, R.V.; Awang, M.; Janga, V.S.R. Computational Modelling and Comparative Analysis of Friction Stir Welding and Stationary Shoulder Friction Stir Welding on AA6061. Crystals 2023, 13, 1317. [Google Scholar] [CrossRef]

- Cremonesi, M.; Meduri, S.; Perego, U.; Frangi, A. An Explicit Lagrangian Finite Element Method for Free-Surface Weakly Compressible Flows. Comput. Part. Mech. 2017, 4, 357–369. [Google Scholar] [CrossRef]

- Jain, R.; Pal, S.K.; Singh, S.B. Numerical Modeling Methodologies for Friction Stir Welding Process; Elsevier Ltd.: Amsterdam, The Neherlands, 2017; ISBN 9780857094827. [Google Scholar]

- Boscheri, W.; Dumbser, M. High Order Accurate Direct Arbitrary-Lagrangian-Eulerian ADER-WENO Finite Volume Schemes on Moving Curvilinear Unstructured Meshes. Comput. Fluids 2016, 136, 48–66. [Google Scholar] [CrossRef]

- Priyadarshini, A.; Pal, S.K.; Samantaray, A.K. Finite Element Modeling of Chip Formation in Orthogonal Machining. Stat. Comput. Tech. Manuf. 2012, 9783642258, 101–144. [Google Scholar] [CrossRef]

- Altair University. Introduction to Explicit Analysis with Radioss; Altair University: Troy, MI, USA, 2020. [Google Scholar]

- Benson, D.J. Computational Methods in Lagrangian and Eulerian Hydrocodes. Comput. Methods Appl. Mech. Eng. 1992, 99, 235–394. [Google Scholar] [CrossRef]

- Benson, D.J. A Mixture Theory for Contact in Multi-Material Eulerian Formulations. Comput. Methods Appl. Mech. Eng. 1997, 140, 59–86. [Google Scholar] [CrossRef]

- Aval, H.J. Smoothed-Particle Hydrodynamics (SPH) Simulation of AA6061-AA5086 Dissimilar Friction Stir Welding. Metrals 2023, 13, 906. [Google Scholar] [CrossRef]

- Yang, H.G. Numerical Simulation of the Temperature and Stress State on the Additive Friction Stir with the Smoothed Particle Hydrodynamics Method. Strength Mater. 2020, 52, 24–31. [Google Scholar] [CrossRef]

- Bagheri, M.; Mohammadi, M.; Riazi, M. A Review of Smoothed Particle Hydrodynamics. Comput. Part. Mech. 2023, 11, 1163–1219. [Google Scholar] [CrossRef]

- Gingold, R.A.; Monaghan, J.J. Smoothed Particle Hydrodynamics: Theory and Application to Non-Spherical Stars. Mon. Not. R. Astron. Soc. 1977, 181, 375–389. [Google Scholar] [CrossRef]

- Lucy, L.B. A Numerical Approach to the Testing of the Fission Hypothesis. Astron. J. 1977, 82, 1013. [Google Scholar] [CrossRef]

- Benz, W.; Asphaug, E. Simulations of Brittle Solids Using SPH. Comput. Phys. Commun. 1995, 87, 253–265. [Google Scholar] [CrossRef]

- Cleary, P.W.; Ha, J. Three Dimensional Modelling of High Pressure Die Casting. Int. J. Cast Met. Res. 2000, 12, 357–365. [Google Scholar] [CrossRef]

- Vacondio, R.; Altomare, C.; De Leffe, M.; Hu, X.; Le Touzé, D.; Lind, S.; Marongiu, J.C.; Marrone, S.; Rogers, B.D.; Souto-Iglesias, A. Grand Challenges for Smoothed Particle Hydrodynamics Numerical Schemes. Comput. Part. Mech. 2021, 8, 575–588. [Google Scholar] [CrossRef]

- Vijay, R.; Awang, M.; Alemu, T. Numerical Analysis of Temperature and Material Flow Predictions with Defects in the Friction Stir Processing of AZ91 Alloy: An Advanced Meshfree SPH Technique. Eng. Anal. Bound. Elem. 2024, 161, 48–69. [Google Scholar] [CrossRef]

- Zinati, R.F.; Razfar, M.R. Finite Element Simulation and Experimental Investigation of Friction Stir Processing of Polyamide 6. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2015, 229, 2205–2215. [Google Scholar] [CrossRef]

- Asadi, P.; Givi, M.K.B.; Rastgoo, A.; Akbari, M.; Zakeri, V.; Rasouli, S. Predicting the Grain Size and Hardness of AZ91/SiC Nanocomposite by Artificial Neural Networks. Int. J. Adv. Manuf. Technol. 2012, 63, 1095–1107. [Google Scholar] [CrossRef]

- Santos, T.G.; Lopes, N.; MacHado, M.; Vilaça, P.; Miranda, R.M. Surface Reinforcement of AA5083-H111 by Friction Stir Processing Assisted by Electrical Current. J. Mater. Process. Technol. 2015, 216, 375–380. [Google Scholar] [CrossRef]

- Marode, R.V.; Pedapati, S.R.; Lemma, T.A. Effect of Process Parameters on AZ91/SiC Surface Composites for Lightweight E-Vehicles. In Proceedings of the 2022 7th International Conference on Electric Vehicular Technology (ICEVT), Bali, Indonesia, 14–16 September 2022; IEEE: Piscataway, NJ, USA, 2022; pp. 109–115. [Google Scholar]

- Harwani, D.; Badheka, V.; Patel, V.; Li, W.; Andersson, J. Developing Superplasticity in Magnesium Alloys with the Help of Friction Stir Processing and Its Variants—A Review. J. Mater. Res. Technol. 2021, 12, 2055–2075. [Google Scholar] [CrossRef]

- Marode, R.V.; Pedapati, S.R.; Lemma, T.A.; Awang, M. A Review on Numerical Modelling Techniques in Friction Stir Processing: Current and Future Perspective. Arch. Civ. Mech. Eng. 2023, 23, 154. [Google Scholar] [CrossRef]

- Asadi, P.; Mahdavinejad, R.A.; Tutunchilar, S. Simulation and Experimental Investigation of FSP of AZ91 Magnesium Alloy. Mater. Sci. Eng. A 2011, 528, 6469–6477. [Google Scholar] [CrossRef]

- Bagheri, B.; Abdollahzadeh, A.; Abbasi, M.; Kokabi, A.H. Effect of Vibration on Machining and Mechanical Properties of AZ91 Alloy during FSP: Modeling and Experiments. Int. J. Mater. Form. 2020, 14, 623–640. [Google Scholar] [CrossRef]

- Ritti, L.; Bhat, T. Design and Numerical Analysis of Tool for FSP Simulation of Magnesium Alloys. Mater. Today Proc. 2021, 46, 2489–2497. [Google Scholar] [CrossRef]

- Miles, M.P.; Nelson, T.W.; Gunter, C.; Liu, F.C.; Fourment, L.; Mathis, T. Predicting Recrystallized Grain Size in Friction Stir Processed 304L Stainless Steel. J. Mater. Sci. Technol. 2019, 35, 491–498. [Google Scholar] [CrossRef]

- Ren, J.G.; Wang, L.; Xu, D.K.; Xie, L.Y.; Zhang, Z.C. Analysis and Modeling of Friction Stir Processing-Based Crack Repairing in 2024 Aluminum Alloy. Acta Metall. Sin. English Lett. 2017, 30, 228–237. [Google Scholar] [CrossRef]

- Shamanian, M.; Mostaan, H.; Safari, M.; Dezfooli, M.S. Friction-Stir Processing of Al-12%Si Alloys: Grain Refinement, Numerical Simulation, Microstructure Evolution, Dry Sliding Wear Performance and Hardness Measurement. Metall. Res. Technol. 2017, 114, 213. [Google Scholar] [CrossRef]

- Shojaeefard, M.H.; Akbari, M.; Asadi, P.; Khalkhali, A. The Effect of Reinforcement Type on the Microstructure, Mechanical Properties, and Wear Resistance of A356 Matrix Composites Produced by FSP. Int. J. Adv. Manuf. Technol. 2017, 91, 1391–1407. [Google Scholar] [CrossRef]

- Akbari, M.; Ezzati, M.; Asadi, P. Investigation of the Effect of Tool Probe Profile on Reinforced Particles Distribution Using Experimental and CEL Approaches. Int. J. Light. Mater. Manuf. 2022, 5, 213–223. [Google Scholar] [CrossRef]

- Meyghani, B.; Awang, M. Developing a Finite Element Model for Thermal Analysis of Friction Stir Welding (FSW) Using Hyperworks; 2020; ISBN 9789811382963. [Google Scholar]

- Satpute, M.A.; Patil, S.S.; Andhale, S.R.; Gogte, C.L. Thermomechanical Modeling of Friction Stir Welding for Different Material Using Altair’s HyperWeld FSW. Int. J. Eng. Res. 2015, V4, 1–5. [Google Scholar] [CrossRef]

- Altair Radioss Smooth Particle Hydrodynamics. Available online: https://2021.help.altair.com/2021/hwsolvers/rad/topics/solvers/rad/theory_sph_c.htm (accessed on 22 September 2022).

- Jaffarullah, M.S.; Busu, N.; Low, C.Y.; Saedon, J.B.; Armansyah, A.; Shaari, M.S.B.; Jaffar, A. Simulation Analysis of Peak Temperature In Weld Zones During Friction Stir Process. Int. J. 2015, 1, 77–81. [Google Scholar] [CrossRef]

- Dhaliwal, G.S.; Dueck, S.M.; Newaz, G.M. Experimental and Numerical Characterization of Mechanical Properties of Hemp Fiber Reinforced Composites Using Multiscale Analysis Approach. SN Appl. Sci. 2019, 1, 1361. [Google Scholar] [CrossRef]

- Asadi, P.; Faraji, G.; Besharati, M.K. Producing of AZ91/SiC Composite by Friction Stir Processing (FSP). Int. J. Adv. Manuf. Technol. 2010, 51, 247–260. [Google Scholar] [CrossRef]

- Rathee, S.; Maheshwari, S.; Siddiquee, A.N.; Srivastava, M. Effect of Tool Plunge Depth on Reinforcement Particles Distribution in Surface Composite Fabrication via Friction Stir Processing. Def. Technol. 2017, 13, 86–91. [Google Scholar] [CrossRef]

- Rathee, S.; Maheshwari, S.; Siddiquee, A.N.; Srivastava, M. Investigating Effects of Groove Dimensions on Microstructure and Mechanical Properties of AA6063/SiC Surface Composites Produced by Friction Stir Processing. Trans. Indian Inst. Met. 2017, 70, 809–816. [Google Scholar] [CrossRef]

- Saravanan, V.; Rajakumar, S.; Banerjee, N.; Amuthakkannan, R. Effect of Shoulder Diameter to Pin Diameter Ratio on Microstructure and Mechanical Properties of Dissimilar Friction Stir Welded AA2024-T6 and AA7075-T6 Aluminum Alloy Joints. Int. J. Adv. Manuf. Technol. 2016, 87, 3637–3645. [Google Scholar] [CrossRef]

- Silva, A.C.F.; De Backer, J.; Bolmsjö, G. Temperature Measurements during Friction Stir Welding. Int. J. Adv. Manuf. Technol. 2017, 88, 2899–2908. [Google Scholar] [CrossRef]

- Silva-Magalhães, A.; De Backer, J.; Martin, J.; Bolmsjö, G. In-Situ Temperature Measurement in Friction Stir Welding of Thick Section Aluminium Alloys. J. Manuf. Process. 2019, 39, 12–17. [Google Scholar] [CrossRef]

- Senthilkumar, R.; Prakash, M.; Arun, N.; Jeyakumar, A.A. The Effect of the Number of Passes in Friction Stir Processing of Aluminum Alloy (AA6082) and Its Failure Analysis. Appl. Surf. Sci. 2019, 491, 420–431. [Google Scholar] [CrossRef]

- Fraser, K.; Kiss, L.I.; St-Georges, L.; Drolet, D. Optimization of Friction Stir Weld Joint Quality Using a Meshfree Fully-Coupled Thermo-Mechanics Approach. Metals 2018, 8, 101. [Google Scholar] [CrossRef]

- Ti32, TiR32, Ti29, TiR29, Ti27, T. Fluke Manual. Available online: https://www.fluke.com/en/product/thermal-cameras/ti32-eur (accessed on 15 July 2025).

- Benz, W. Smooth Particle Hydrodynamics: A Review. In The Numerical Modelling of Nonlinear Stellar Pulsations; Kluwer Academic Publishers: Berlin, Gernay, 1990; Volume 15, pp. 269–288. [Google Scholar]

- Le Touzé, D.; Colagrossi, A. Smoothed Particle Hydrodynamics for Free-Surface and Multiphase Flows: A Review. Reports Prog. Phys. 2025, 88, 037001. [Google Scholar] [CrossRef]

- Lyu, H.G.; Sun, P.N.; Huang, X.T.; Zhong, S.Y.; Peng, Y.X.; Jiang, T.; Ji, C.N. A Review of SPH Techniques for Hydrodynamic Simulations of Ocean Energy Devices. Energies 2022, 15, 502. [Google Scholar] [CrossRef]

- Altair RADIOSS Help (Manual) SPH Approximation of a Function. Available online: https://2021.help.altair.com/2021/hwsolvers/rad/topics/solvers/rad/theory_sph_c.htm (accessed on 9 November 2023).

- Somi, V.; Janga, R.; Awang, M.; Sallih, N.; Ray, C.; Eng, M.; Wee, B. Computational Analysis of Thermo-Mechanical Characteristics in Refill FSSW of Thin AA7075-T6 Sheets Using Smoothed-Particle Hydrodynamics. Comput. Part. Mech. 2023, 11, 935–949. [Google Scholar] [CrossRef]

- Zhu, Z.; Wang, M.; Zhang, H.; Zhang, X.; Yu, T.; Wu, Z. A Finite Element Model to Simulate Defect Formation during Friction Stir Welding. Metals 2017, 7, 256. [Google Scholar] [CrossRef]

- Türkan, M.; Karakaş, Ö. Numerical Modeling of Defect Formation in Friction Stir Welding. Mater. Today Commun. 2022, 31, 103539. [Google Scholar] [CrossRef]

- Sekhar, R.; Singh, T.P. Determination of Johnson Cook Parameters in Turning of Micro and Nano Reinforced Aluminum Composites Using Trust Region Reflective Algorithm. Int. J. Innov. Technol. Explor. Eng. 2019, 8, 1712–1716. [Google Scholar] [CrossRef]

- Ashby, M.F. Material Property Data for Engineering Materials—ANSYS Granta Edupack 2021; Department of Engineering, University of Cambridge: Cambridge, UK, 2016; pp. 1–27. [Google Scholar]

- Akilu, S.; Baheta, A.T.; Kadirgama, K.; Padmanabhan, E.; Sharma, K.V. Viscosity, Electrical and Thermal Conductivities of Ethylene and Propylene Glycol-Based β-SiC Nanofluids. J. Mol. Liq. 2019, 284, 780–792. [Google Scholar] [CrossRef]

- Zhang, H.F.; Zhou, L.; Li, G.H.; Tang, Y.T.; Li, W.L.; Wang, R. Prediction and Validation of Temperature Distribution and Material Flow during Refill Friction Stir Spot Welding of AZ91D Magnesium Alloy. Sci. Technol. Weld. Join. 2021, 26, 153–160. [Google Scholar] [CrossRef]

- Luo, J.; Wang, H.; Chen, W.; Li, L. Study on Anti-Wear Property of 3D Printed-Tools in Friction Stir Welding by Numerical and Physical Experiments. Int. J. Adv. Manuf. Technol. 2015, 77, 1781–1791. [Google Scholar] [CrossRef]

- Nassar, H.W.; Khraisheh, M.K. Simulation of Material Flow and Heat Evolution in Friction Stir Processing Incorporating Melting. J. Eng. Mater. Technol. 2012, 134, 041006. [Google Scholar] [CrossRef]

- Marode, R.V.; Pedapati, S.R.; Lemma, T.A.; Janga, V.S.R. Thermo-Mechanical Modelling of Friction Stir Processing of AZ91 Alloy: Using Smoothed-Particle Hydrodynamics. Lubricants 2022, 10, 355. [Google Scholar] [CrossRef]

- Marode, R.V.; Lemma, T.A.; Pedapati, S.R.; Sallih, N.; Awang, M.; Hassan, A. Comparative Numerical Analysis Of Tool Tilt Effects In Friction Stir Processing of Az91: Exploring Sph Applications. In Proceedings of the ASME International Mechanical Engineering Congress and Exposition, Proceedings (IMECE), Portland, OR, USA, 17–21 November 2024; American Society of Mechanical Engineers: New York, NY, USA, 2024; Volume 2. [Google Scholar]

- Shackelford, J.F.; Alexander, W. Materials Science and Engineering Handbook, 3rd ed.; CRC Press: New York, NY, USA, 2013; ISBN 9780333227794. [Google Scholar]

- Wu, D.; Huang, C. Thermal Conductivity Study of SiC Nanoparticle Beds for Thermal Insulation Applications. Phys. E Low-Dimens. Syst. Nanostruct. 2020, 118, 113970. [Google Scholar] [CrossRef]

- Salih, O.S.; Ou, H.; Sun, W. Heat Generation, Plastic Deformation and Residual Stresses in Friction Stir Welding of Aluminium Alloy. Int. J. Mech. Sci. 2022, 238, 107827. [Google Scholar] [CrossRef]

- Ragab, M.; Liu, H.; Yang, G.J.; Ahmed, M.M.Z. Friction Stir Welding of 1cr11ni2w2mov Martensitic Stainless Steel: Numerical Simulation Based on Coupled Eulerian Lagrangian Approach Supported with Experimentalwork. Appl. Sci. 2021, 11, 3049. [Google Scholar] [CrossRef]

- Ghiasvand, A.; Suksatan, W.; Tomków, J.; Rogalski, G.; Derazkola, H.A. Investigation of the Effects of Tool Positioning Factors on Peak Temperature in Dissimilar Friction Stir Welding of AA6061-T6 and AA7075-T6 Aluminum Alloys. Materials 2022, 15, 702. [Google Scholar] [CrossRef]

- Hu, Y.; Sun, Y.; He, J.; Fang, D.; Zhu, J.; Meng, X. Effect of Friction Stir Processing Parameters on the Microstructure and Properties of ZK60 Magnesium Alloy. Mater. Res. Express 2022, 9, 016508. [Google Scholar] [CrossRef]

- Gerlich, A.; Yamamoto, M.; North, T.H. Local Melting and Tool Slippage during Friction Stir Spot Welding of Al-Alloys. J. Mater. Sci. 2008, 43, 2–11. [Google Scholar] [CrossRef]

- Kubit, A.; Trzepiecinski, T. A Fully Coupled Thermo-Mechanical Numerical Modelling of the Refill Friction Stir Spot Welding Process in Alclad 7075-T6 Aluminium Alloy Sheets. Arch. Civ. Mech. Eng. 2020, 20, 117. [Google Scholar] [CrossRef]

- Mokhtar, A. Simulation of Friction Stir Spot Welding (FSSW) Process: Study of Friction Phenomena. Ph.D. Thesis, West Wirginia University, Morgantown, WV, USA, 2007. [Google Scholar]

- Kanapady, R.; Tamma, K.K.; Baddourah, M.; Mark, A. High Performance Computing on a Symmetric Multiprocessor (SMP) Environment for RTM Process Modeling of Large Complex Structural Geometries. Adv. Eng. Softw. 1998, 29, 399–408. [Google Scholar] [CrossRef]

- Lee, M.; Park, N.; Ro, W.W.; Li, K.C. Performance Evaluation of Programming Models for SMP-Based Clusters. J. Chin. Inst. Eng. 2008, 31, 1181–1188. [Google Scholar] [CrossRef]

- Cappello, F.; Richard, O.; Etiemble, D. Understanding Performance of SMP Clusters Running MPI Programs. Futur. Gener. Comput. Syst. 2001, 17, 711–720. [Google Scholar] [CrossRef]

- Eliseev, A.A.; Kalashnikova, T.A.; Filippov, A.V.; Kolubaev, E.A. Material Transfer by Friction Stir Processing. In Multiscale Biomechanics and Tribology of Inorganic and Organic Systems; Springer: Berlin/Heidelberg, Germany, 2021; ISBN 9783030601232. [Google Scholar]

- Pan, W.; Li, D.; Tartakovsky, A.M.; Ahzi, S.; Khraisheh, M.; Khaleel, M. A New Smoothed Particle Hydrodynamics Non-Newtonian Model for Friction Stir Welding: Process Modeling and Simulation of Microstructure Evolution in a Magnesium Alloy. Int. J. Plast. 2013, 48, 189–204. [Google Scholar] [CrossRef]

| Configuration Type | Base Material Pitch (mm) | Reinforcement Pitch (mm) | Particle Count (Nos.) |

|---|---|---|---|

| 1 | 1.05 | 0.58 | 47,520 |

| 2 | 0.975 | 0.53 | 55,212 |

| 3 | 0.901 | 0.495 | 75,302 |

| 4 | 0.81 | 0.43 | 92,841 |

| Material Properties | AZ91 | H13 | SiC |

|---|---|---|---|

| Density (Tonne/mm3) | 1.81 × 10−9 | 7.8 × 10−9 | 3.1 × 10−9 |

| Young’s modulus E (MPa) | 46,000 | 210,000 | 438,000 |

| Poisson’s ratio () | 0.33 | 0.3 | 0.15 |

| Specific heat per unit volume (N/mm2. K) | 1.9 | 3.56 | 2.08 |

| Reference temperature (K) | 298 | 298 | 298 |

| Melting temperature (K) | 803 | 1700 | 2970 |

| Thermal Conductivity (W/mK) | 72.7 | 24.5 | 360 |

| Parameters | Initial Yield Stress [MPa] | Hardening Modulus [MPa] | Coefficient Depending on the Strain Rate | Work-Hardening Exponent | Thermal Softening Coefficient |

|---|---|---|---|---|---|

| Symbolized | |||||

| AZ91 | 164 | 343 | 0.021 | 0.283 | 1.768 |

| SiC | 200 | 400 | 0.01 | 0.2 | 0.3 |

| Tint (K) | 273 | 285.5 | 504 | 521 | 530 | >803 |

| () | 0.45 | 0.35 | 0.25 | 0.001 | 0.0001 | 0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Marode, R.V.; Lemma, T.A.; Pedapati, S.R.; Kusekar, S.; Birajdar, V.D.; Hassan, A. Investigation of Thermo-Mechanical Characteristics in Friction Stir Processing of AZ91 Surface Composite: Novel Study Through SPH Analysis. Lubricants 2025, 13, 450. https://doi.org/10.3390/lubricants13100450

Marode RV, Lemma TA, Pedapati SR, Kusekar S, Birajdar VD, Hassan A. Investigation of Thermo-Mechanical Characteristics in Friction Stir Processing of AZ91 Surface Composite: Novel Study Through SPH Analysis. Lubricants. 2025; 13(10):450. https://doi.org/10.3390/lubricants13100450

Chicago/Turabian StyleMarode, Roshan Vijay, Tamiru Alemu Lemma, Srinivasa Rao Pedapati, Sambhaji Kusekar, Vyankatesh Dhanraj Birajdar, and Adeel Hassan. 2025. "Investigation of Thermo-Mechanical Characteristics in Friction Stir Processing of AZ91 Surface Composite: Novel Study Through SPH Analysis" Lubricants 13, no. 10: 450. https://doi.org/10.3390/lubricants13100450

APA StyleMarode, R. V., Lemma, T. A., Pedapati, S. R., Kusekar, S., Birajdar, V. D., & Hassan, A. (2025). Investigation of Thermo-Mechanical Characteristics in Friction Stir Processing of AZ91 Surface Composite: Novel Study Through SPH Analysis. Lubricants, 13(10), 450. https://doi.org/10.3390/lubricants13100450