Thermo-Responsive Wax Millicapsules as Lubricating Agents Carriers

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Methods

2.2.1. Encapsulation of Liquid Lubricants

2.2.2. Encapsulation of Greases

2.2.3. Imaging of Capsules and Studying Their Properties

3. Results and Discussion

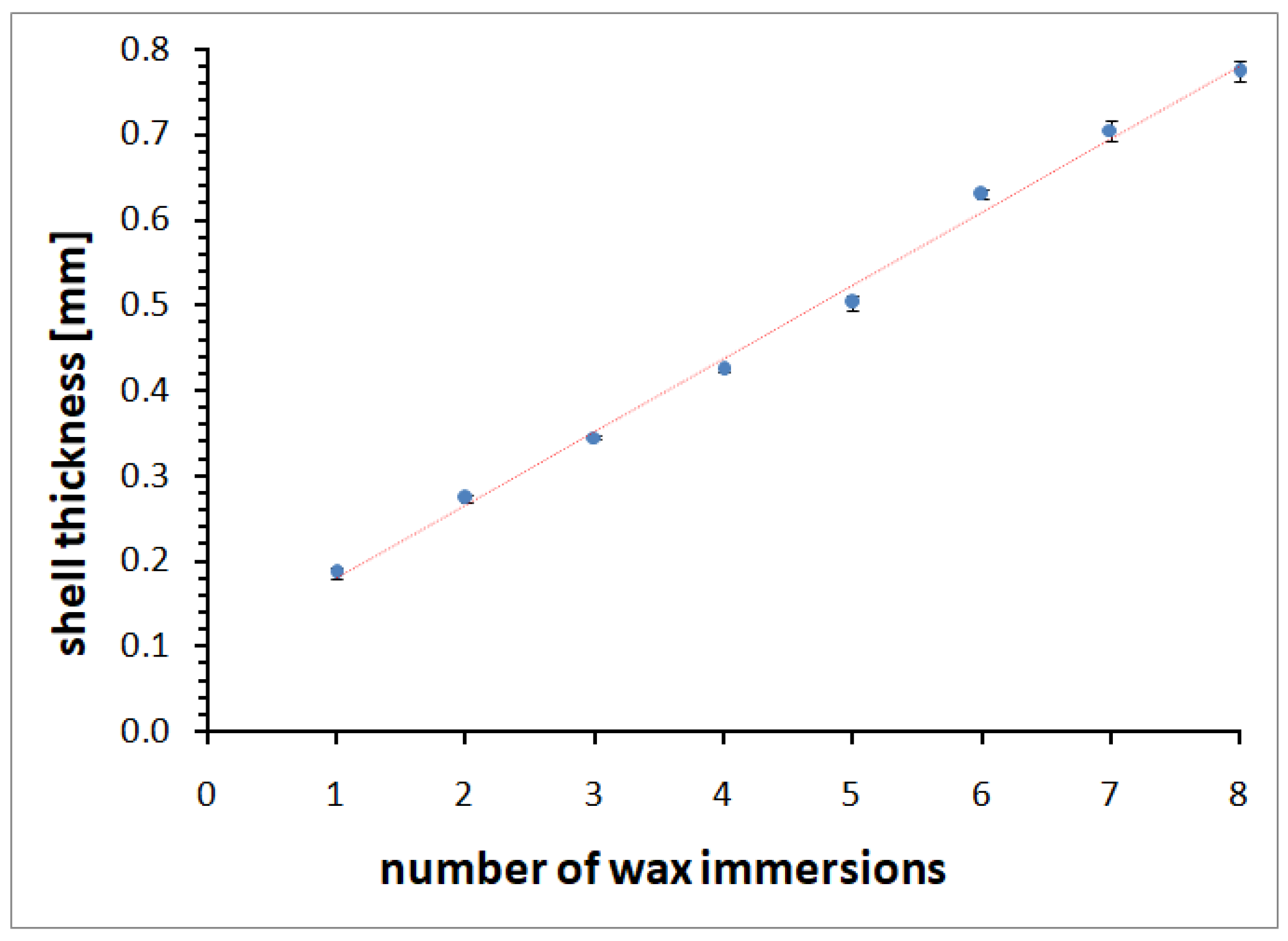

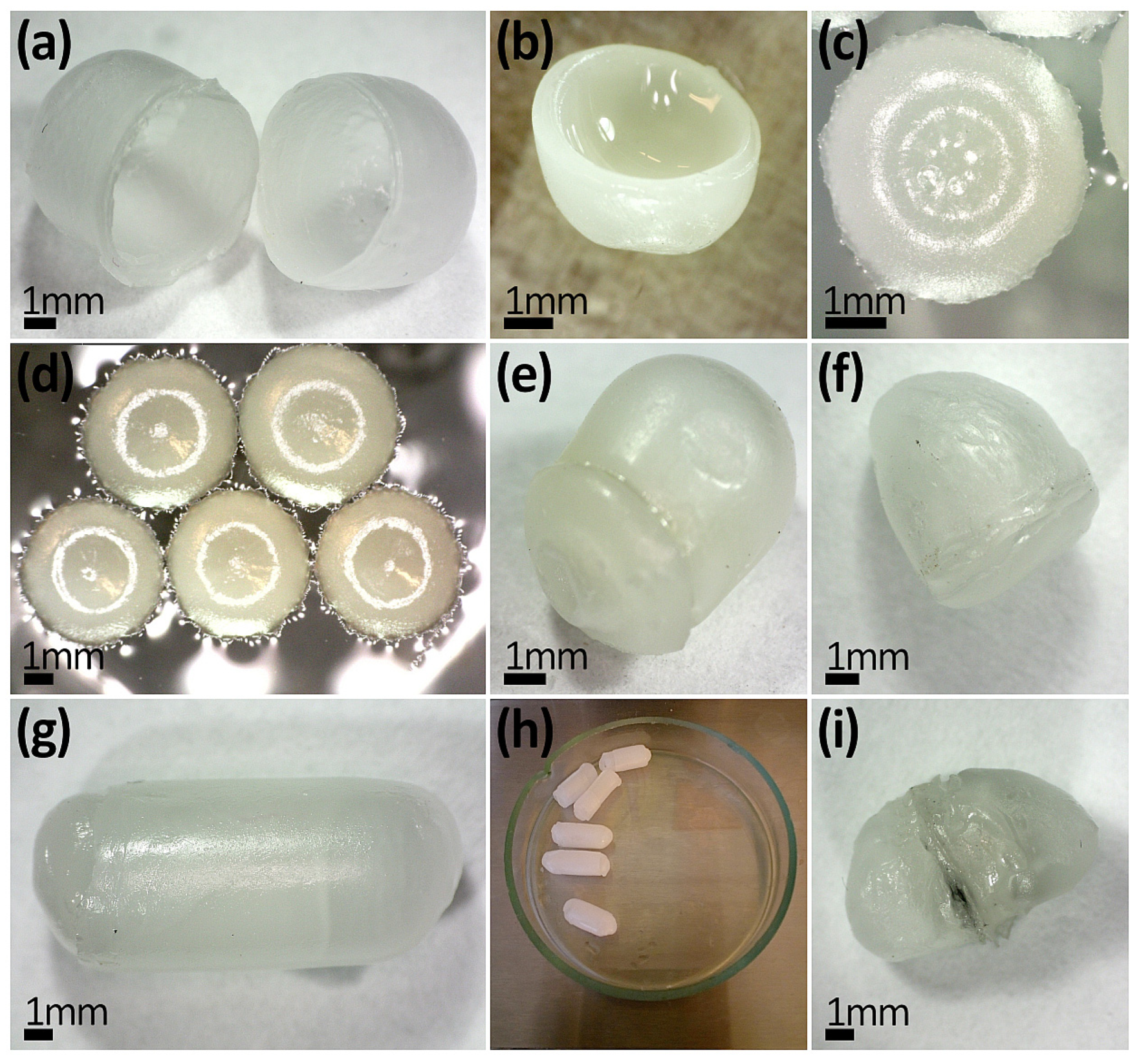

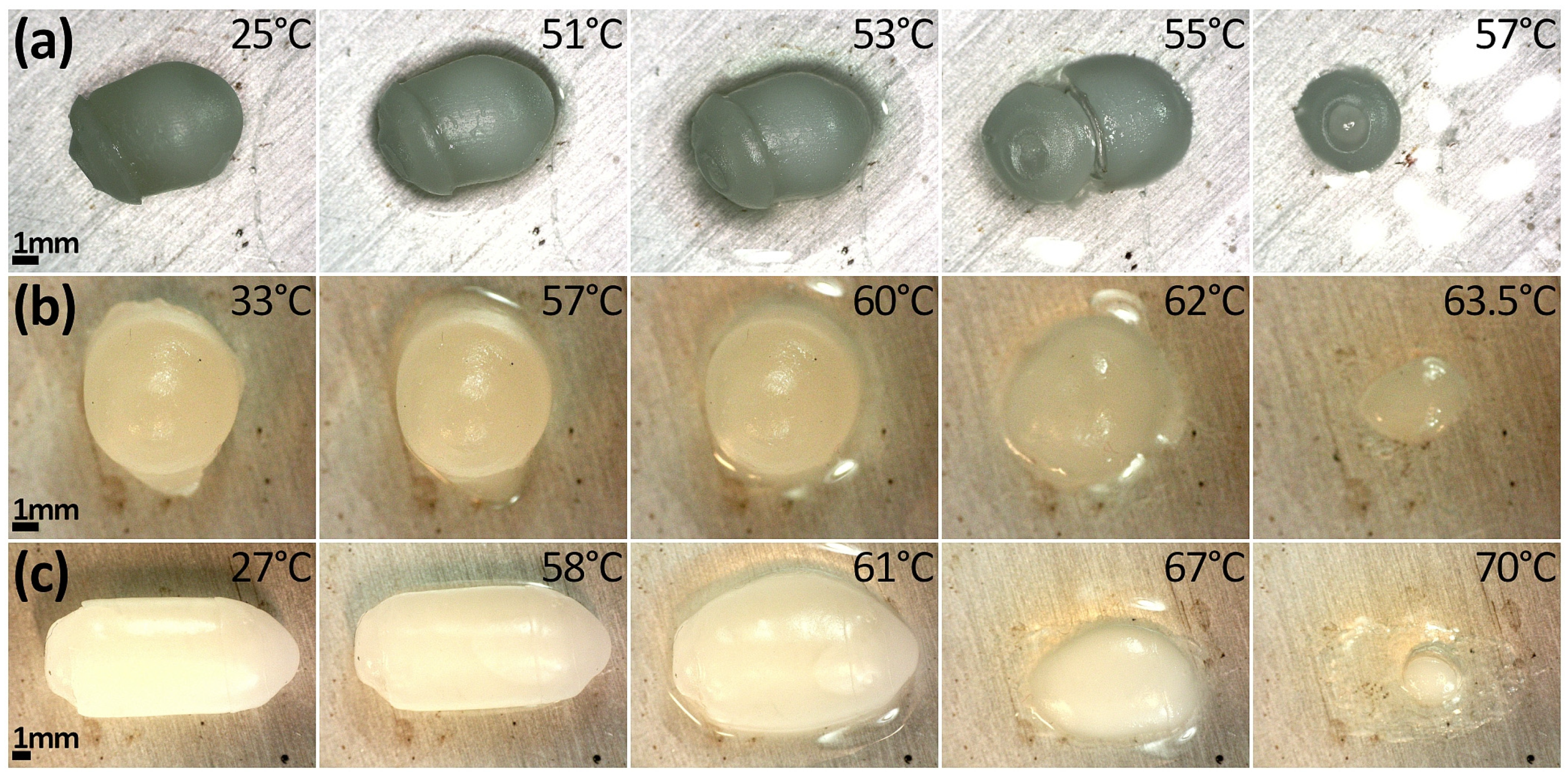

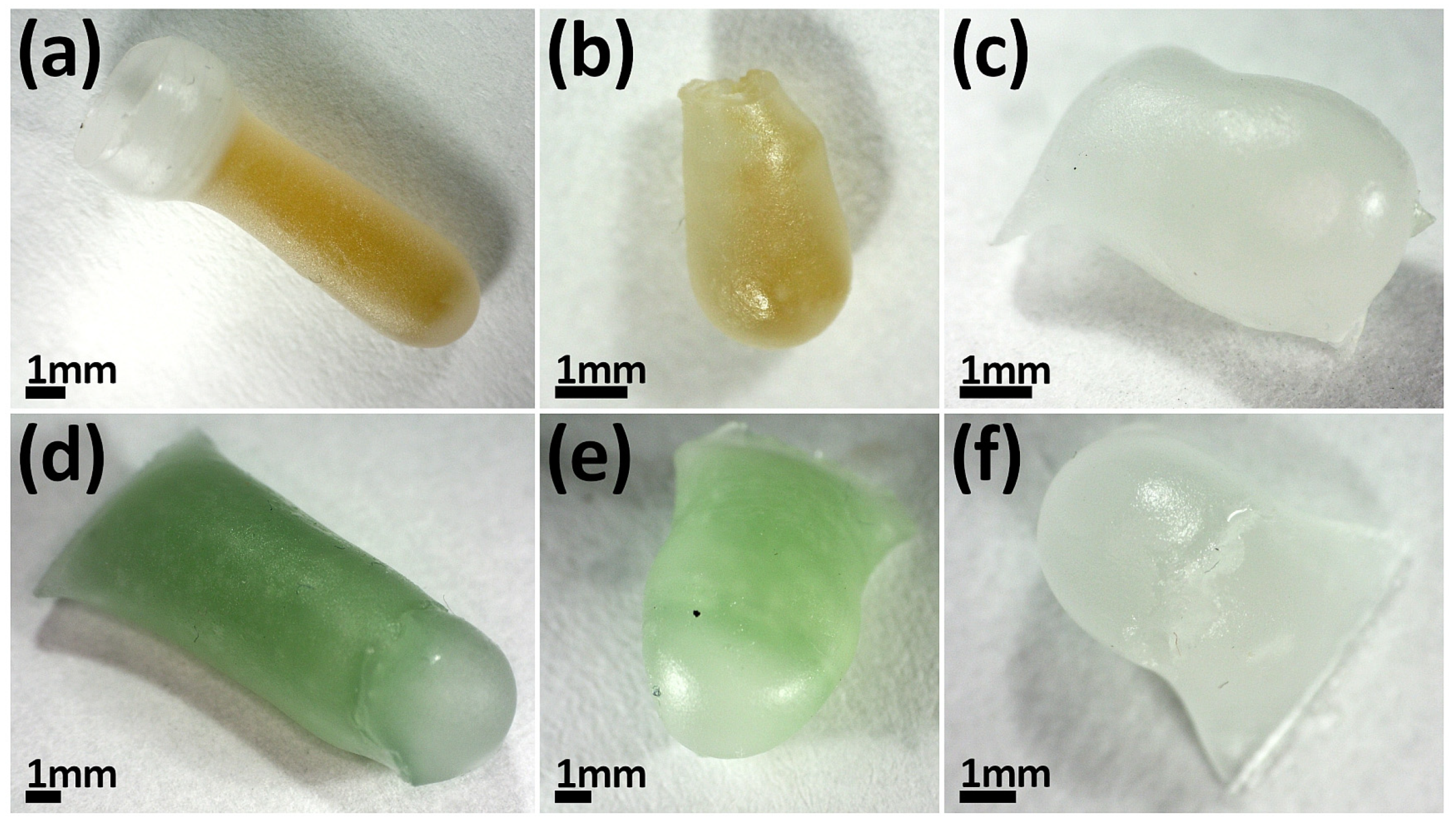

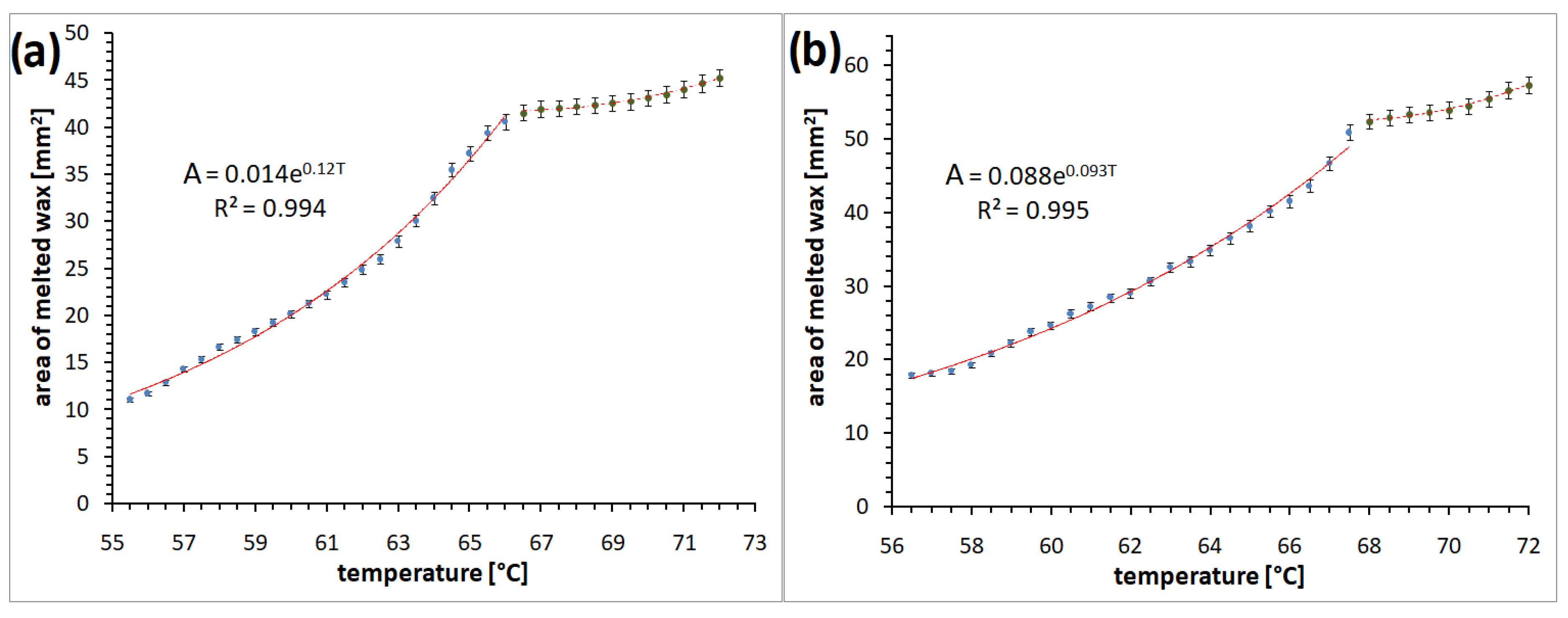

3.1. Capsules Filled with Liquid Lubricants

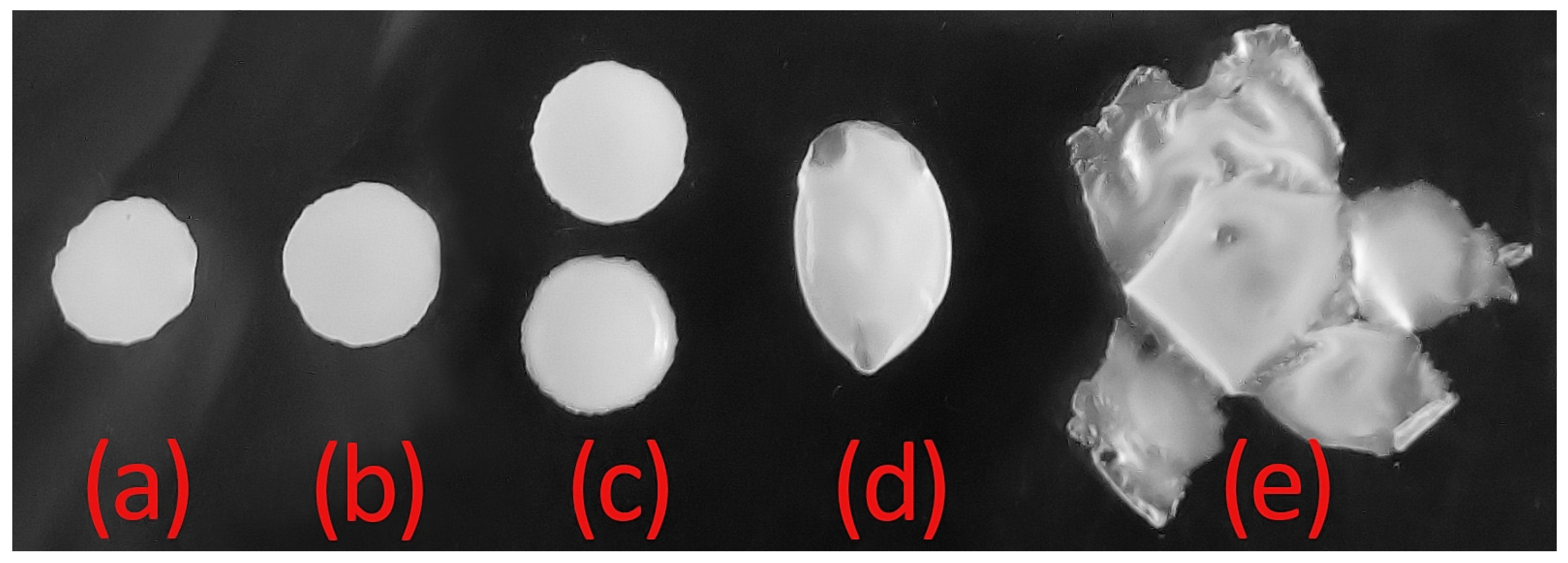

3.2. Capsules with Grease as Payload

3.3. Lubricating Properties and Tribological Mechanisms

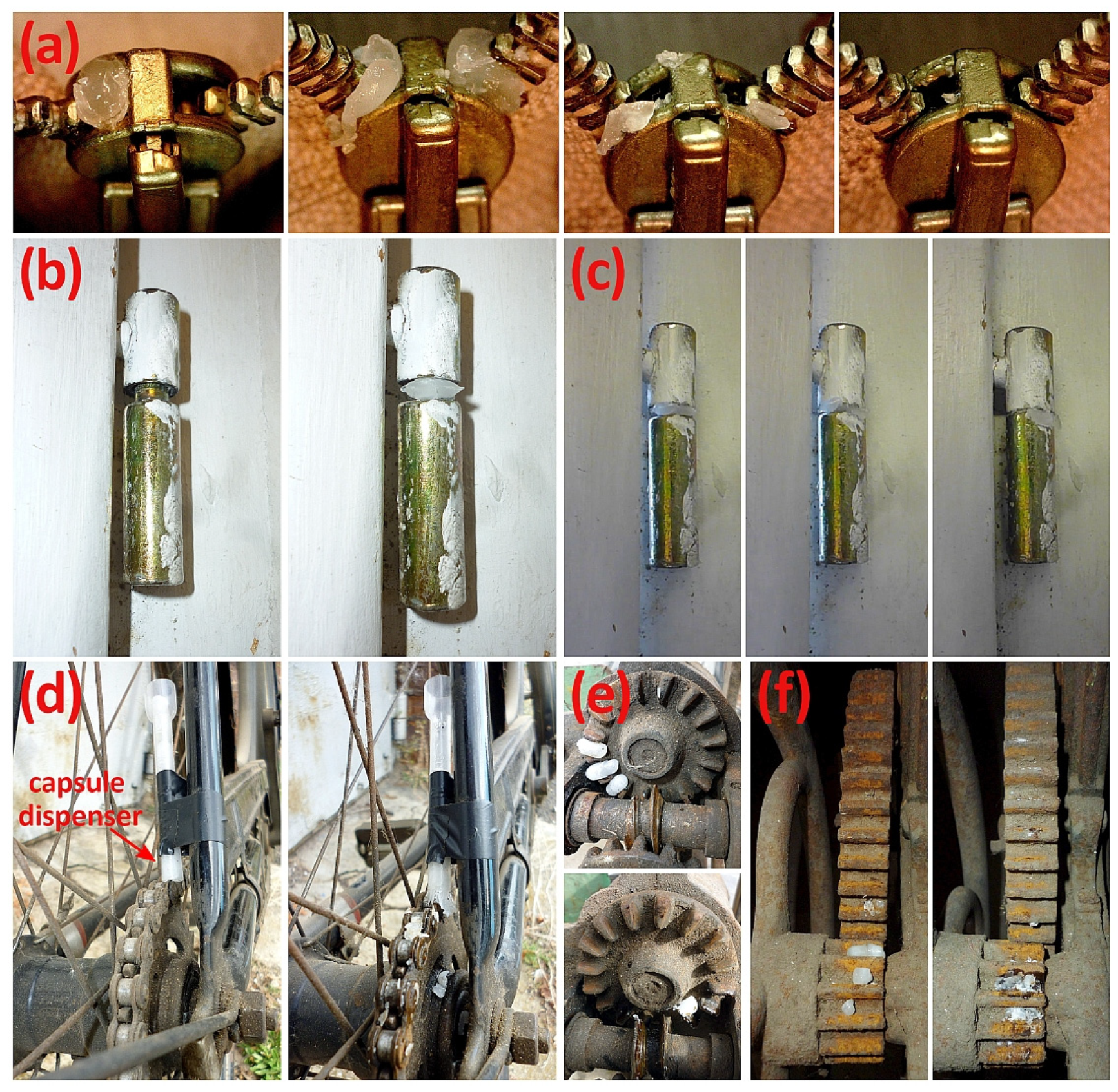

3.4. Applications of Capsules with Wax Shells

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Pichler, J.; Maria Eder, R.; Besser, C.; Pisarova, L.; Dörr, N.; Marchetti-Deschmann, M.; Frauscher, M. A comprehensive review of sustainable approaches for synthetic lubricant components. Green Chem. Lett. Rev. 2023, 16, 2185547. [Google Scholar] [CrossRef]

- Gow, G. Lubricating Grease. In Chemistry and Technology of Lubricants, 3rd ed.; Mortier, R.M., Fox, M.F., Orszulik, S.T., Eds.; Springer Science+Business Media: Dordrecht, The Netherlands, 2010; pp. 411–432. [Google Scholar]

- Lugt, P.M. A Review on Grease Lubrication in Rolling Bearings. Tribol. Trans. 2009, 52, 470–480. [Google Scholar] [CrossRef]

- Gong, H.; Yu, C.; Zhang, L.; Xie, G.; Guo, D.; Luo, J. Intelligent lubricating materials: A review. Compos. B Eng. 2020, 202, 108450. [Google Scholar] [CrossRef]

- Grünewald, M.; Herbig, D.; Heilig, M.; Rudloff, J.; Bastian, M.; Engelmann, G.; Hirsekorn, M.; Latnikova, A. Self-lubricating polyamide 6 and polyamide 6.6 microcapsule-based composites. J. Appl. Polym. Sci. 2024, 141, e55894. [Google Scholar] [CrossRef]

- Kubiak, T.; Zubko, M.; Józefczak, A. The impact of ultrasound on Janus capsules at gel-liquid interface. Curr. Appl. Phys. 2022, 38, 22–29. [Google Scholar] [CrossRef]

- Bielas, R.; Kubiak, T.; Molcan, M.; Dobosz, B.; Rajnak, M.; Józefczak, A. Biocompatible Hydrogel-Based Liquid Marbles with Magnetosomes. Materials 2024, 17, 99. [Google Scholar] [CrossRef]

- Martins, E.; Poncelet, D.; Rodrigues, R.C.; Renard, D. Oil encapsulation techniques using alginate as encapsulating agent: Applications and drawbacks. J.Microencapsul. 2017, 34, 754–771. [Google Scholar] [CrossRef]

- Soleimanian, Y.; Goli, S.A.H.; Shirvani, A.; Elmizadeh, A.; Marangoni, A.G. Wax-based delivery systems: Preparation, characterization, and food applications. Compr. Rev. Food Sci. Food Saf. 2020, 19, 2994–3030. [Google Scholar] [CrossRef]

- Menezes, J.; Athmaselvi, K.A. Report on Edible Films and Coatings. In Handbook of Food Bioengineering: Food Packaging and Preservation; Grumezescu, A.M., Holban, A.M., Eds.; Academic Press: London, UK, 2018; Volume 9, pp. 177–212. [Google Scholar]

- Liew, Y.W.; Matthews, O.; Dao, D.V.; Li, H. Power Transmission Mechanism and Tribological Performance of Modern Bicycle Drivetrains—A Review. Machines 2025, 13, 66. [Google Scholar] [CrossRef]

- Jin, Z.; Wang, Y.; Liu, J.; Yang, Z. Synthesis and properties of paraffin capsules as phase change materials. Polymer 2008, 49, 2903–2910. [Google Scholar] [CrossRef]

- Fortuniak, W.; Slomkowski, S.; Chojnowski, J.; Kurjata, J.; Tracz, A.; Mizerska, U. Synthesis of a paraffin phase change material microencapsulated in a siloxane polimer. Colloid Polym. Sci. 2013, 291, 725–733. [Google Scholar] [CrossRef]

- Shirvani, A.; Goli, S.A.H.; Varshosaz, J.; Sedaghat Doost, A. Cinnamaldehyde encapsulation within new natural wax-based nanoparticles; formation, optimization and characterization. J. Dispers. Sci. Technol. 2022, 44, 1809–1820. [Google Scholar] [CrossRef]

- Mellema, M.; Van Benthum, W.A.; Boer, B.; Von Harras, J.; Visser, A. Wax encapsulation of water-soluble compounds for application in foods. J. Microencapsul. 2006, 23, 729–740. [Google Scholar] [CrossRef]

- Pregent, S.; Adams, S.; Butler, M.F.; Waigh, T.A. The impact and deformation of a viscoelastic drop at the air-liquid interface. J. Colloid Interface Sci. 2009, 331, 163–173. [Google Scholar] [CrossRef] [PubMed]

- Decker, R.J.; Yakimenko, O.A.; Stout, C. Guided Artillery Trajectory Simulation Model for Determination of Required Acquisition Proximity of a Moving Target. In Proceedings of the AIAA Modeling and Simulation Technologies Conference, Minneapolis, MN, USA, 13–16 August 2012; AIAA: Reston, VA, USA, 2012; p. 4944. [Google Scholar]

- Beesabathuni, S.N.; Lindberg, S.E.; Caggioni, M.; Wesner, C.; Shen, A.Q. Getting in shape: Molten wax drop deformation and solidification at an immiscible liquid interface. J. Colloid Interface Sci. 2015, 445, 231–242. [Google Scholar] [CrossRef] [PubMed]

- Stieger, N.; Aucamp, M.; Zhang, S.-W.; De Villiers, M.M. Hot-stage Optical Microscopy as an Analytical Tool to Understand Solid-state Changes in Pharmaceutical Materials. Am. Pharm. Rev. 2012, 15, 1–5. [Google Scholar]

- Franc, A.; Vetchý, D.; Fülöpová, N. Commercially Available Enteric Empty Hard Capsules, Production Technology and Application. Pharmaceuticals 2022, 15, 1398. [Google Scholar] [CrossRef]

- Ryu, S.A.; Hwang, Y.H.; Oh, H.; Jeon, K.; Lee, J.H.; Yoon, J.; Lee, J.B.; Lee, H. Biocompatible wax-based microcapsules with hermetic sealing for thermally triggered release of actives. ACS Appl. Mater. Interfaces 2021, 13, 36380–36387. [Google Scholar] [CrossRef]

- Juaifer, H.J.A.; Ayani, M.B.; Poursadegh,·M. Melting process of paraffin wax inside plate heat exchanger: Experimental and numerical study. J. Therm. Anal. Calorim. 2020, 140, 905–916. [Google Scholar] [CrossRef]

- Li, X.; Liu, R.; Jiang, H.; Yu, P.; Liu, X. Numerical investigation on the melting characteristics of wax for the safe and energy-efficiency transportation of crude oil pipelines. Meas. Sens. 2020, 10, 100022. [Google Scholar] [CrossRef]

- Yang, Y.; Wang, D.; Wei, P.; Pu, W. A mixed EHL model of grease lubrication considering surface roughness and the study of friction behavior. Tribol. Int. 2021, 154, 106710. [Google Scholar] [CrossRef]

- Spikes, H.A.; Olver, A.V. Mixed lubrication—Experiment and theory. Tribol. Ser. 2002, 40, 95–113. [Google Scholar]

- Spies, C.; Parab, Y.; Fatemi, A. Mixed friction: Critical assessment of engineering load sharing equations based on the Lambda-parameter. Tribol. Int. 2025, 211, 110812. [Google Scholar] [CrossRef]

- Bartel, D. Mixed Friction in Fully Lubricated Elastohydrodynamic Contacts—Theory or Reality. Lubricants 2024, 12, 351. [Google Scholar]

- Krawiec, M. Evaluation of the lubrication efficiency of greases according to criterion of wear experimentally determined at variable values of motion parameters. Tribologia 2017, 3, 77–83. [Google Scholar] [CrossRef]

- Lange, K. Metal Forming: Surface Quality of Products. In Encyclopedia of Materials: Science and Technology; Jürgen Buschow, K.H., Cahn, R.W., Flemings, M.C., Ilschner, B., Kramer, E.J., Mahajan, S., Veyssière, P., Eds.; Elsevier: Amsterdam, The Netherlands, 2001; pp. 5433–5436. [Google Scholar]

- Mawatari, T.; Fukuda, R.; Mori, H.; Mia, S.; Ohno, N. High Pressure Rheology of Environmentally Friendly Vegetable Oils. Tribol Lett. 2013, 51, 273–280. [Google Scholar] [CrossRef]

- Diamante, L.M.; Lan, T. Absolute Viscosities of Vegetable Oils at Different Temperatures and Shear Rate Range of 64.5 to 4835 s−1. J. Food Process 2014, 2014, 234583. [Google Scholar]

- Al-Fariss, T.F.; Jang, L.K.; Ozbelge, H.O.; Ghasem, N.M. A new correlation for the viscosity of waxy oils. J. Pet. Sci. Eng. 1993, 9, 139–144. [Google Scholar] [CrossRef]

- Sharma, S.; Mahto, V.; Sharma, V.P.; Saxena, A. An empirical correlation for estimating the viscosity of non-Newtonian waxy crude oils. Pet. Sci. Technol. 2016, 34, 523–530. [Google Scholar] [CrossRef]

- Pandya, M.; Tesini, P.; Bogliacino, F.; Mandrilec, F. A novel numerical analysis method for predicting non-Newtonian lubricant (grease) distribution in ball bearings. Eng. Model. Anal. Simul. 2024, 1, 1–12. [Google Scholar] [CrossRef]

- Sun, Y.; Wang, Y. Study on Rheological Properties of Different Brands of Grease. J. Phys. Conf. Ser. 2019, 1300, 012113. [Google Scholar] [CrossRef]

| Type of Grease | Density at 24 °C [g/cm3] | NLGI | Penetration at 25 °C [mm/10] |

|---|---|---|---|

| ŁT-43 (brown) | 0.96 ± 0.02 | 3 | 237 |

| ŁT-43 (green) | 0.915 ± 0.006 | 3 | 237 |

| silicone | 1.112 ± 0.022 | 2 | 230–270 |

| Type of Oil | Density at 24 °C [g/cm3] | Kinematic Viscosity at 40 °C [mm2/s] | PRESSURE-VISCOSITY Coefficient at 20 °C [GPa−1] |

|---|---|---|---|

| rapeseed oil | 0.9263 ± 0.0003 | 35.1 | 11.0 |

| olive oil | 0.9197 ± 0.0003 | 38.7 | 11.8 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kubiak, T.; Ciesielski, K. Thermo-Responsive Wax Millicapsules as Lubricating Agents Carriers. Lubricants 2025, 13, 439. https://doi.org/10.3390/lubricants13100439

Kubiak T, Ciesielski K. Thermo-Responsive Wax Millicapsules as Lubricating Agents Carriers. Lubricants. 2025; 13(10):439. https://doi.org/10.3390/lubricants13100439

Chicago/Turabian StyleKubiak, Tomasz, and Karol Ciesielski. 2025. "Thermo-Responsive Wax Millicapsules as Lubricating Agents Carriers" Lubricants 13, no. 10: 439. https://doi.org/10.3390/lubricants13100439

APA StyleKubiak, T., & Ciesielski, K. (2025). Thermo-Responsive Wax Millicapsules as Lubricating Agents Carriers. Lubricants, 13(10), 439. https://doi.org/10.3390/lubricants13100439